Abstract

Battery technology is crucial in the transition towards electric mobility. Lithium-ion batteries are conquering the market but are facing fire safety risks that might threaten further applications. In this study, we address the problem and potential solutions for traction batteries in the European Union area. We do so by taking a unique socio-technical system perspective. Therefore, a novel, mixed-method approach is applied, combining literature review; stakeholder interviews; Failure Mode, Mechanisms, and Event Analysis (FMMEA); and rapid prototyping. Our findings confirm that fire safety is an upcoming concern. Still, most stakeholders lack a full understanding of the problem. Improving safety is a shared responsibility among supply chain and societal stakeholders. For automotive applications, voluntary standard-setting on safety risks is an appropriate tool to improve fire safety, whereas for niche applications, a top-down approach setting regulations seems more suited. For both groups, the adaptation of battery pack designs to prevent thermal runaway propagation is shown to be promising from a technological, practical, and organizational perspective. The chosen mixed-method approach allowed for a holistic analysis of the problems and potential solutions. As such, it can serve as an empowerment strategy for stakeholders in the field, stimulating further discussion, agenda building, and action.

1. Introduction

A global shift towards renewable energy sources is required to manage global warming. Electric mobility is seen as a key enabler of this transition, using batteries to drive traction motors [1,2,3]. So far, mainly lithium-ion batteries have been used. This is due to their unique characteristics, including high energy and power densities, long lifetime, low maintenance, and their rapid price decrease as the result of economies of scale and learning curves [2,3,4,5,6]. Following the adoption of battery electric vehicles [2,7], the production of lithium-ion batteries has shown fast growth [8]. Further growth is foreseen: a tenfold increase of the global market between 2020–2030 [9], to an estimated total value of $100 billion annually [10].

However, the increased application of lithium-ion batteries is also resulting in upcoming concerns about battery safety. Although incidents are infrequent, there are increasing reports on short-circuiting, electrocution, and especially fire and explosion of traction batteries (e.g., car batteries, e-bikes) [8,11,12,13,14,15,16,17]. Often, these incidents receive intense media attention in which fire departments, transportation organizations, safety organizations, and insurance companies have expressed their concerns, but in-depth insight into both the problem and possible solutions is typically lacking. These incidents can have severe impacts on the health and property of directly involved stakeholders. They can also have strong repercussions on the manufacturers of batteries, e.g., in the form of a product ban, a required product recall, or reputational damage [15,18,19]. They even have the potential to severely disrupt the further development and diffusion of the technology, and thereby affect the mobility transition at large. This risk is particularly prominent because it is still a relatively new and emerging technology that is not yet fully aligned with policy, practices, and infrastructure [3,15], which makes it more vulnerable [20]. Therefore, in this paper we aim to contribute to the improvement of the safety of lithium-ion batteries by both exploring the problem as well as potential solutions.

We define battery safety in line with product safety. Product safety can be defined as the reduction in the probability that use of a product will result in illness, injury, death, or negative consequences to people, property, or equipment, as well as the reduction of the impact of these events (adapted from [19]). As such, it links to the design, production, and handling of components like battery cells; their application in battery packs; and finally, their integration in final products. It also involves the use of the product, which is possibly up to waste handling. As such, product safety does not only depend on product characteristics but also the result of triggering events and contextual factors that influence the impact. It is partially influenced by and becomes the responsibility of manufacturers. However, as Ralph Nader already argued in his seminal work ‘Unsafe at any speed’ [21], product safety also requires counterforces to industry interest and is a shared responsibility. This also holds for batteries [19,22,23]. There is a role for critical customers—empowered by safety information, product choice, product liability, and media exposure. However, there is also a role for the governmental regulation of product safety, although there are many limitations to governmental control [19,24,25]. To conclude, the effective and efficient governance of product safety requires the application of multiple and diverse policy tools and a strong cooperation between societal stakeholders [26], as product safety is essentially a shared responsibility.

In line with this operationalization of product safety, we will study battery safety as a socio-technical problem [27]. We will study both the social perspectives (stakeholders and their perceptions, roles, agency, regulation, practices) and the technical side, as well as their interaction. This socio-technical systemic viewpoint has so far remained under-explored in the literature on battery safety, which has a strong focus on the technical aspects—i.e., the functioning of the battery. To keep this research consistent and manageable, we focus on fire safety as the dominant concern in battery safety, and our study focuses on the European Union area as a region committed to the transition to electric transport and having consideration for upcoming safety concerns. Our primary research question is: What is the problem with the fire safety of lithium-ion batteries, applied for traction purposes in Europe, and how can this fire safety be improved effectively? To answer this research question, we pose three sub-questions: (1) What are the concerns and roles of stakeholders in the European lithium-ion battery market—explicitly considering their impact on battery safety? (2) What is the safety of current battery technology and how can this be improved? and (3) What role can different stakeholders play in enhancing safety?

We adopt an integrated mixed-method approach that gives due attention to both societal and technical aspects and their interaction and incorporates future-oriented design thinking [28,29] that contributes to exploration of the socio-technical possibility space. It thereby contributes to agenda setting and the generation of governance recommendations. Although it offers a unique approach on battery safety, it builds on well-known concepts of Value Sensitive Design [30,31], Responsible Research and Innovation [32,33], and Soft System Modelling [34,35]. Crucial elements in these concepts are problem exploration, a focus on how values and preferences of societal stakeholder influence the innovation trajectory, and the actions and roles of these stakeholders in the development and application of the technology.

In doing so, we respond to the recent call for more transdisciplinary research and integrative approaches in socio-technical studies on transitions [36,37,38], as well as in systems engineering to address large societal challenges [39,40]. Also, with this approach, we avoid the drawbacks of more traditional socio-technical studies that typically draw on descriptive, qualitative case studies that hardly operationalize technical (im)possibilities and have limited forward orientation.

We first explore the literature on battery safety to introduce key concepts related to battery packs and battery fire safety, and then identify the research gap. Next, we outline the research methodology (Section 2). First, we study the problem setting and stakeholders’ roles through literature review and stakeholder interviews (Section 3.1). We do so in order to better understand the problem and construct a power–interest diagram to identify which stakeholders have the power and interest to influence ongoing developments. This is followed by failure mode analysis, a technical analysis of potential failure events and mechanisms (Section 3.2). Both this analysis and the stakeholder analysis indicate the crucial relevance of battery packs to ensure battery safety, especially for diverse niche applications. Therefore, the approach is complemented by a rapid prototyping approach (Section 3.2). We do this to confront the problem setting and stakeholder preferences with the technological possibility space. It is a quick scan approach to identify the most appropriate and feasible technical solutions. Finally, we combine the insights in an integrative discussion along with our conclusions, in which we address the potential strategies and stakeholder roles that could improve battery safety (Section 4).

2. Materials and Methods

First, we provide an introduction to battery safety issues based on a literature review before addressing the study’s research methodology.

2.1. An introduction to Battery Safety

The increased attention for and development of electric cars has resulted in an enormous increase in publications on battery safety over the past decade, as dedicated searches in Google Scholar and ScienceDirect show. Most publications are of a technical nature and relate to the topics of electrochemistry, energy, heat transfer, material technology, (dis)charging, battery management, safety, testing, fire and fire propagation, failure mechanisms under normal and abnormal operations, and research on improvement strategies. Publications can be found in a wide variety of journals. Some journals are more dedicated to battery development and safety (e.g., Journal of Power Sources, Journal of Energy Storage). These findings are largely in line with recent bibliometric research on battery safety and reliability [41] and on thermal management of electric batteries [42].

Recently, a series of review articles has been published on (thermal) safety, thermal management, and safety strategies for batteries [8,11,41,43,44,45,46,47,48,49,50,51], signaling the urgency and relevance of this study. We will draw on this literature first to conceptually introduce the configuration of a battery system and second to describe the main thermal failure mechanisms, as well as the strategies used to enhance safety. Finally, we will discuss the existing literature that approaches battery safety from a socio-technical perspective to define the research gap.

A typical battery system (see Figure 1) consists of multiple battery cells that provide an electric current via a reversible chemical redox reaction. The cells are held in place by a mechanical construction that also protects the cells from external influences. The cells are electrically connected, e.g., via a plate, to provide power at the specified voltage and current, and to allow charging of the cells. A battery management system (BMS) is integrated to make sure cells are not used outside safe operating conditions, e.g., maximum flow of current, minimum and maximum voltages, and specific temperature ranges. Based on measurements, the BMS can calculate the status of the cells, manage (dis)charging, and shut off the battery when dangerous states are reached. The thermal management system, often consisting of a passive heat-conducting plate, regulates the temperature of the cells. Although this configuration is quite typical, a large variety of batteries exist with differences in chemistry, design, shape, power, cells, cooling solutions, and integration in applications [5,44,46,52].

Figure 1.

Archetypical structure of a battery system. Reprinted with permission from Jeroen Bleker-ELEO.

Lithium-ion batteries used for traction, with their typical high energy densities, provide inherent fire risks due to the chemicals used (high chemical energy, highly-flammable) and the release of oxygen by internal chemical reactions. If a battery creates more heat than the system can cool away, it may result in the self-heating of the battery in a process called Thermal Runaway (TR). In this process, the anode and cathode layers in the cell reach a short circuit. This releases heat that further stimulates the process, ultimately resulting in fire. The fire can spread to other cells within the battery pack, a phenomenon called Thermal Runaway Propagation (TRP). This propagation is the result of heat transport from a short circuit triggered by the initiating cell or from cell bursting, either at the top or side, thereby releasing hot and electrically conductive electrolyte.

The initiation of thermal runaway can be the result of mechanical abuse, thermal abuse, or electrical abuse. Mechanical abuse is the deformation of a cell so that the layers inside the cell make contact and short-circuit, e.g., via a penetrating object as the result of a vehicle crash. Thermal abuse is the heating of a cell until internal separators melt, leading to a short circuit. Electrical abuse can be overcharging, under-discharging, or an external short circuit. A fourth option is a ‘spontaneous’ internal short circuit, indicating that thermal runaway cannot always be prevented. A spontaneous short circuit can be the result of overcharging, undercharging, or aging. The material in the cell repositions, resulting in the formation of dendrites and cell-layer-penetrating spikes. The triggers of these risks are flawed design or development, mismatched battery and usage, manufacturing errors, misuse, and abuse (e.g., fire, car crash).

To prevent TR, TRP, and fires, different strategies can be applied, e.g., by applying different cathode and anode materials and electrolyte; separator optimization; adding flame retardant additive; special battery management systems; safety thermal fuses; increased cooling; thermal barriers; adding fire extinguishers; and increased and improved battery testing. However, the only way for battery cells to become inherently safe would be through radical technological innovation, such as the shift towards solid-state cells. The intense dynamics in the electric mobility sector result in the continuous and intensive further exploration of new battery chemistries and designs to increase battery safety and performance, as well as reduce costs [2,5,46].

A significant part of the literature on battery safety focuses on specific cells, mechanisms, or components. Typically, if the scoping is at the system level, the system is defined either as a battery (e.g., in studies on thermal management, battery management, battery pack configuration) or as an electric car (e.g., [46,51,53]. A broader scoping is hardly ever opted for, e.g., looking at the sector, supply chains, or society at large. Stakeholders and their concerns on battery safety or required actions thereby typically remain out of sight. There are a few exceptions to this. Scholars who conduct integral safety evaluations of batteries or electric cars typically take account of the full product and performance under different circumstances [13,45,54] or safety and testing standards [51]. Also, policy studies exist, but these typically focus on the implementation of and transition towards electric cars and do not devote much attention to battery safety [2,7]. An exception is recent publications on the circularity of batteries and battery safety at end-of-life, as these typically consider the supply chain and the roles of policy and stakeholders [55,56,57,58,59]. Further, ref. [60] considers the full battery value chain but lacks a strong focus on safety. Both [44] and [61] approach battery safety and the behavior of batteries from different lenses; especially considering [44], which includes a short mentioning of stakeholders and their roles, and the role of standards and testing, while [62] focuses on global research, development and demonstration (RD&D), and policies for the development of battery cells for automotive applications. However, a more comprehensive outlook on stakeholders involved in the production, use, and waste of batteries is lacking. Yet, it is these stakeholders, by their preferences and actions, who can ensure that battery safety innovations and supporting actions are studied, implemented, and become a success. Therefore, this will be the starting point for this study.

2.2. Research Methodology

2.2.1. General Approach

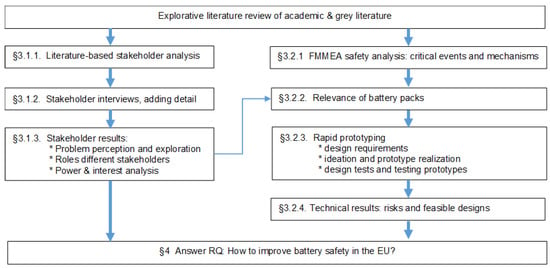

Moving on to our methodology, this is based on a mixed-method approach: an exploration of problems and solutions first from a stakeholder perspective, followed by an engineering perspective—see Figure 2. Below we will discuss the approach of both parts in more detail. Together, these two approaches allow us to analyze the socio-technical system around battery safety: what is the problem, who can take action, and what are possible solutions?

Figure 2.

Structure of research approach.

2.2.2. Stakeholder Analysis

A stakeholder assessment, including a wide variety of relevant stakeholders, can be most helpful in understanding multi-dimensional problems from different perspectives [63,64]. Also, conducting interviews gave us access to first-hand experience and insight, which is highly relevant given the lack of understanding and real-life data on the subject. Finally, it served as an input for the technological exploration of solution directions by revealing design requirements in relation to potential stakeholder roles.

The subsequent technical part of the research relates these stakeholder findings to the technical possibility space. It starts with a technical analysis to create an overview of the failure modes and effects, and to identify critical components, mechanisms, and events. Both this analysis and the stakeholder findings point at the crucial relevance of battery packs to ensure battery safety, especially for diverse niche applications. Therefore, it is followed by a conceptual exploration of the potential solutions at the level of battery packs by a rapid prototyping approach inspired by [29]. It combines thinking in solutions with a quick test of ideas, thereby offering quick checks for viability and possibilities to iterate rapidly. It is especially well suited in circumstances of high uncertainty and multiple design requirements, as it allows for the exploration of several best-guess solutions, and thereby allows us to explore and narrow down the possibility space of design.

Regarding the stakeholder analysis, the most relevant stakeholders and their roles and interests were identified by means of literature review. These initial results guided the purposive sampling process of interviewees. This sampling focused on the most relevant stakeholders (scoring high on power and interest), while ensuring coverage of the diversity of stakeholders. Hard-to-reach stakeholders (e.g., officials of the European Union (EU)) and highly diverse stakeholders (e.g., users) were covered by indirect representation (e.g., norm developers working with EU and a consumer organization). In total, 20 interviews were conducted—see Table 1. The most relevant stakeholder groups were represented by 2–4 interviewees, which enabled the initial triangulation of the results and representation of the diversity within stakeholder groups in support of qualitative exploration [63,64,65]. The interviews were conducted until saturation occurred, i.e., no new key themes or insights were gained [65,66].

Table 1.

Stakeholder interview samples.

The interviews were semi-structured [67]. After general introductory questions, the interviews focused on the issue of battery safety, actor roles, and the specific role of the organization that the interviewee represented. Stakeholders with a more technical background were also asked technical questions regarding battery safety. The interviews were processed by taking notes that were shared afterward with the interviewees for confirmation and consent. The notes were descriptively coded to summarize topics, looking for similarities and differences. In that way, general themes were inductively derived from the data [66,68].

The results of both the literature study and interviews were interpreted and represented in a stakeholder-issue map as well as a stakeholder map based on power and interest [69]—the latter reflecting which stakeholders can have a strong influence and interest in influencing ongoing developments regarding battery safety.

2.2.3. Rapid Prototyping Approach

The second part of the research comprised a technical analysis to specify the origin of the risk and the potential for improvement. First, a Failure Mode, Mechanisms, and Event Analysis (FMMEA) was conducted [70]. FMMEA analysis and the related fault-tree analysis—or similar analysis—have already been applied to battery safety [11,13,45,54,71]. This analysis is typically used to assess the safety of a product and its components by considering the triggers, context, likelihood, and severity of events. It is used to identify critical components, mechanisms, and events. The FMMEA analysis is conducted for a full battery pack, drawing on the literature and expert judgement.

As already indicated before, both this analysis and the stakeholder findings point at the crucial relevance of battery packs to ensure battery safety and prevent thermal runaway propagation. Therefore, in the next phase, a rapid prototyping approach was conducted by following the approach in [29]. It required the design and realization of incomplete products (prototypes); realization of incomplete models of the real environment (test environment); and subsequently performing experiments to explore the problem and learn from the potential solutions.

Promising design directions were identified with reference to designs from the literature [5,18,72]. Within these directions, nine specific and detailed concept designs were created. Keeping in mind the problem setting (safety issues and mechanisms), these general design directions were from the literature, as well as based on practical feasibility (costs, ease of manufacture, etc.). These were confronted with design requirements in a Pugh matrix [73], resulting in a selection of the six most promising designs. For these six concept designs, more specific designs were made and realized as prototypes. Subsequently, these prototypes were subjected to testing in the lab. Five protocols were developed for the rapid effectiveness testing of these designs, building on testing literature [15,17,23,43,74,75,76]. The prototypes were assessed on both practical criteria (e.g., whether they can be produced, costs, assembly) as well as on battery safety (e.g., whether they can help prevent short-circuit between cells, and whether they can prevent cell side rupture and/or thermal runaway propagation).

For the prototypes, standard 18650 Lithium Nickel Cobalt Aluminum Oxides/ Lithium Nickel Manganese Cobalt Oxides (NCA/NCM) cells of 2900 mAh capacity were used, as this chemistry is commonly applied for traction purposes. Some of the tests required the application of trigger cells in thermal runaway mode that would also meet the test requirements (e.g., suited for testing in lab; no interference with design solutions; good representation of use/failures scenarios; reliability) [77]. Special cells, as used by [78,79], are not freely available and are hard to make. Therefore, we adapted regular cells by overcharging [44] while disabling the current interrupting devices that release pressure at the top and interrupt current during the state of overcharging [78]. To initiate cell rupture, normal cells were sanded sideways by following the procedure in [80].

All tests were conducted in an airtight, steel box that contained an overpressure valve, an exhaust, and a window for monitoring the experiment, as well as an action camera to record the cells during the experiment. The prototypes were equipped with heat sensors and with wiring to overcharge the trigger cell. For positioning the cells in the battery pack at 2 mm distance between themselves, a small plastic plate with holes was used either at the top or bottom (see Figure 6).

3. Results

3.1. Stakeholder Analysis

We studied the variety of stakeholders involved in battery safety, including their interests and (potential) roles. We did so to better understand the (perceived) problem and potential solutions. This section documents the results from the literature study (sub-Section 3.1.1), stakeholder interviews (Section 3.1.2), and an analysis of the stakeholder–issue relationships and (potential) roles based on power and interest (Section 3.1.3).

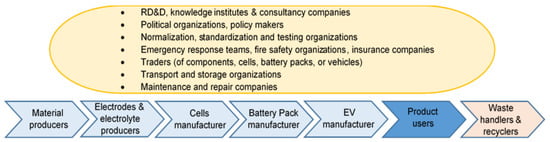

3.1.1. Stakeholder Overview Based on Literature

The safety risks of batteries might be the result of (in)actions, lack of coordination or failing quality assurance in the production value chain, (mis)use or damage of batteries, or how they are handled in the waste processing stage. As such, battery safety is not only a concern for market parties and users, it is also a matter of public concern, regulation, and innovation and, as such, involves stakeholders like the EU and national governments, as well as norm developers and testing centers that affect the different stages of production and use [10,12,19,81]. The most important stakeholders are identified in Figure 3.

Figure 3.

Overview of stakeholders relevant for battery safety.

Most of the required materials are extracted in Asia, some in the USA, and cobalt mining is done mainly in Congo [60]. The chemical industry usually supplies cell materials. These materials are used to create components. The next step is cell production by manufacturers like Panasonic/Sanyo, Contemporary Amperex Technology Co. Ltd. (CATL), BYD Company, LG GEM, Samsung SDI, and Northvolt. Mainly Asian producers serve the global market [82]. Only recently have some Asian companies opened cell facilities in Europe. All the manufacturers are responsible for the safe handling and design and production of cells to meet specifications [83].

Battery pack manufacturers, which are often not the producers of cells, are responsible for creating battery modules from the cells. Examples of these manufacturers are CATL, Panasonic, BMZ, Cleantron, and European producers like Kreisel Electric GmbH (Austria), Johnson Matthey Battery Systems (United Kingdom), and BMZ GmbH (Germany). They often mention battery safety as an important issue on their websites. The battery pack manufacturer must consider cell properties as well as the foreseeable use and misuse of their batteries to ensure safety [84].

The vehicle manufacturers integrate the battery pack into the final product. Vehicle manufacturers have to consider battery pack design as well as product design to safeguard the safe use of the product under all circumstances, including abuse (e.g., vehicle crashing) [83]. There is a large variety of manufacturers, ranging from large automotive companies such as BMW and Tesla to small-sized entrepreneurs such as those making tailored e-bikes. Car manufacturers have implemented numerous measures to ensure safe operation and have taken precautions for events like crashes. However, the required high voltage, the high energy content, the high speeds, and the varying conditions increase the risk in these applications [85]. Some manufacturers have already established strong links with cell or battery pack manufacturers [10]. Car manufacturers in Europe generally control the production of battery packs themselves, partly to compensate for their lack of control over battery cell production [60]. The sector is potentially facing high costs or recall actions, product liability, and brand image damage [19].

Finally, wholesale traders buy battery cells from cell manufacturers and sell these, especially to individuals and small battery pack manufacturers. These clients might not be able to purchase battery cells directly from trusted manufacturers that might put high requirements on sales volumes and safety requirements.

End-users are confronted with the product over most of its lifetime and in a range of user practices, e.g., driving, discharging, maintenance, parking, car washing, towing, and modification. As such, the end-user has a relatively high chance of being exposed to malfunctioning batteries. Surprisingly, not many empirical studies have been published about battery-user interaction. Most safety devices in batteries are designed so that users cannot influence their functionality. Under no circumstances should the user attempt to repair or modify the battery. Also, users are expected to be aware of and follow up on the manufacturer’s instructions for proper use [83,85]. However, typically consumers are not fully informed (e.g., clear performance indicators or tests for battery safety are lacking for products). Also, consumers find it difficult to understand and evaluate the given information on battery safety, and they also might become insensitive when the probabilities of safety events are low [24,86].

The EU has a potentially strong influence on battery safety through financial and legislative instruments. EU policy serves several goals: fast diffusion of electric cars in support of the mobility transition to prevent global warming; economic interest in capturing part of the battery market; and the public concerns of battery safety. High expectations of market growth have resulted in EU interest in securing a role in the cell production of new battery technologies, like solid-state batteries [60]. Policy documents like the EU battery directive [87] mention the aim of ‘safe and reliable batteries,’ but only from the perspective of their environmental impact—suggesting that safety is not a strong concern. EU legislation sets safety rules for products that use batteries. If products fail to meet these requirements, the EU can ban sales or recall products—as happened with electric hoverboards [88]. Furthermore, the EU regulates road vehicles, mostly by norm setting. However, most of the existing standards and regulations impose requirements that are derived from regulatory documents that were initially intended for combustion-engine vehicles. There are no unified standards for battery safety [15,89]. Other traction applications are even less regulated.

National governments can also use financial and legislative instruments and have some freedom to interpret EU regulation. Specific safety issues and incidents are recognized. Still, there does not seem to be a substantial concern regarding lithium-ion batteries in general. Many of the national governments have taken action to benefit from the uptake of battery electric vehicles, with some explicitly focusing on the battery industry.

Norm and standard-setting organizations guide the process of shaping and formulating different norms, providing information, and ensuring the periodic evaluation of the norm. For specific expertise and support, they depend on other relevant stakeholders, like vehicle producers, battery manufacturers, research institutes (universities, testing centers), advisory institutions, and monitoring institutions.

There are several norms related to batteries and their applications, especially when applied in the automotive sector [15,75]. Some voluntary design guidelines have been constructed specifically for battery pack builders, including IBESA (International Alliance for Battery and Energy Storage), EUROBAT (Association of European Automotive and Industrial Battery Manufacturers), and VDA (Verband der Automobilindustrie) guidelines [89]. Safety risks still exist for batteries that pass these standards [74]. TRP prevention is not yet integrated, but under discussion for inclusion in norms.

Certified testing centers like TUV (Technische Überwachungsverein, Germany) and DEKRA (Deutscher Kraftfahrzeug-Überwachungs-Verein, Netherlands & Germany) test and certify whether products that are offered meet existing norms and regulations. They provide advice to manufacturers on which tests are required. A variety of tests are available [15,75]. As such, they might have a good understanding of the market, norms, and battery safety—but are restricted in disclosing this information. They don’t have the role or power to set standards proactively.

3.1.2. Stakeholder Interview Results

Out of 20 interviewees, almost all acknowledged that battery safety is an upcoming issue in general (19 interviewees), as well as for them or for the company they work for (15). Furthermore, fire safety is especially considered to be a concern (16), besides electric safety, the release of toxic gases, and handling safety. Despite the widely shared concerns, many interviewees had difficulties in defining the issue clearly and mentioned the lack of understanding by stakeholders in the sector. Interviewees indicated being ‘frustrated about not knowing’ (int # 8) and described batteries as ‘a black box’ (int # 15).

The stated safety concerns are diverse and relate to different aspects of safety: lack of data on safety events and causes; (publicly available) data on and judging of the safety of battery design or battery implementation, especially given the variety of batteries and applications; the actual (safety) status of the battery; what measures to take to ensure safety in a battery pack, container, or building; what to do in case batteries catch fire; and the policy, regulatory, and market aspects of safety. Not surprisingly, concerns are often directly related to the role of the interviewee, e.g., a fire department has concerns regarding exposure to fumes from battery fires (int # 18), while a consumer organization has a concern about fires from the batteries used within a household (int # 17).

Several interviewees indicated that safety issues are less of a problem for the large automotive sector (int # 2, # 16, # 17), while situations of particular concern are:

- Storage of large amounts and the large diversity of batteries (e.g., during production, transport, storage, recycling, or in large-scale non-mobile applications like electricity grid balancing), which mainly is a concern for market parties and fire safety organizations (int # 4, # 5, # 6, # 18, # 19).

- Application in other vehicles (e.g., in e-bikes, racing karts, glider planes, boats, other non-road vehicles, or vehicles made in small batches like motorcycles or scooters) (int # 2, # 4, # 8, # 9, # 15, # 17).

- Application or adaptation of batteries by individuals or companies without proper in-depth knowledge (e.g., by resellers, small scale manufacturers, hobbyists, or users of vehicles for the agricultural or building sector, as it is common practice for users in these sectors to fix or adapt their equipment at some point in time) (int # 2, # 3, # 10).

- Selection of batteries by consumers, importers, vehicle manufacturers, and battery producers mainly on price or performance, while neglecting safety (int # 1, # 2, # 4, # 9, # 12, # 13, # 16, # 18, # 19, # 20).

- The functioning of batteries under exceptional circumstances (e.g., after traffic accidents or abuse; aging degraded batteries; after exposure to high temperatures or moisture) (int # 1, # 3, # 5, # 16).

Specific applications that have a strong focus on safety, such as back-up batteries for telecom towers, show that this can influence the choice of the battery system to be applied (int # 3).

As many as 12 interviewees indicated that they contributed to the improvement of battery safety. Most (15) see battery safety as a shared responsibility, something that can only be realized if multiple stakeholders take up their responsibility. Several emphasized a full system perspective (# 1, # 2, # 5, # 11, # 12, # 13, # 19) and confirmed the relevance of already identified stakeholders (Figure 3). If risks are not understood or controlled in all segments of the supply chain, this might affect the performance of the final product and might result in risks of liability in case of personal or economic damage. Good safety performance requires design, safety assessment, proper structuring and controlling of the manufacturing process, supply chain control (testing incoming and outgoing products, sharing information, collaborating with suppliers and customers), and certification and performance guarantees. Vehicle manufacturers (10) and battery producers (14) are frequently mentioned as key responsible actors for safety. Vehicle manufacturers feel accountable for the safety of the batteries that they choose to implement, sometimes making them opt for less energy-dense though slightly safer battery chemistries such as lithium-iron-phosphate batteries.

No less than 15 interviewees see regulation as being the most relevant to ensure and improve battery safety, especially interviewees with a technical background who perceive regulation to be the only way to create incentives for safer but more expensive battery products. Also, it is important to consider the experience that most buyers are strongly cost-driven, which puts them in the position to work with lower quality batteries despite their wishes to do otherwise. Norms are highly valued in the market for their potential contribution: companies that show compliance use this to communicate certain levels of quality to their clients and clients assume that certified products are safe. Overall, norms ease the communication issues around the topic and make it easier to do business.

However, current market regulation and normalization do not function well. Several applications do not require certification, and existing certification falls short in testing battery safety. Other problems with norm-setting are mentioned as well: that regulation has difficulty keeping up with the pace of technological development, and that a strict focus on obligated existing norms reduces the focus on improving beyond the norm—i.e., companies cannot receive certification for these extra efforts and, therefore, cannot communicate this clearly and convincingly to customers.

Some interviewees indicated consumers as key actors for safety, indicating that proper use and storage behavior influences the safety of the batteries (int # 3, # 15). Other interviewees suggested that the user is of less importance as he/she should not be able to influence safety to prevent misuse (int # 10, # 16). The user organization (int # 17) has no strong concerns regarding battery safety. It has been confronted by the issue only recently, mostly due to e-bikes catching fire. It stresses the importance of the safety of products to be safeguarded by legislation and norm-setting, as well as informing the user of proper use.

One interviewee signaled a sign of distrust among stakeholders towards Asian battery manufacturers, due to the lack of proximity and the increase in the number of fire incidents with batteries—and argued for a more regional battery industry (int # 7). Others related these risks to the import of components from low-quality, low-cost manufacturers and unknowledgeable resellers (int # 2, # 3, # 13). Also, the increase in incidents can be attributed, at least partially, to the increased application of batteries, but accurate data are missing. Finally, Asian cell manufacturers have significant knowledge of battery production and battery safety as they also provide high-quality batteries for the large-scale automotive industry, and a significant part of the scientific literature on battery safety finds its origin in Asia. One could argue that the responsibility lies with European manufacturers or importers who ask for the cheapest solutions and do not prioritize, understand, or verify battery safety (int # 13).

Three interviewees answered technical questions on battery safety based on their expertise (int # 1, # 16, # 19). They mentioned that the current chemistry and energy density of lithium-ion batteries is prone to fire risks and that thermal runaway propagation cannot be entirely prevented for competitive batteries with reasonable price and performance. Still, preventing thermal runaway is seen as a critical issue for battery safety. Several interviewees do foresee that new battery chemistries will become available over time, some of which might be inherently fire-resilient (int # 1, # 3, # 13).

3.1.3. Intermediate Results

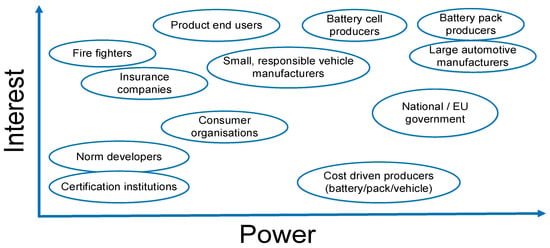

The wide variety of stakeholders involved in the issue of battery safety have different roles and hold different interests, which is reflected in the stakeholder–issue diagram—see Figure 4.

Figure 4.

Stakeholder–issue diagram.

Next, we summarized the research results in a power–interest diagram—see Figure 5. Power is the extent to which stakeholders can act and influence others, and thereby can change the situation. Interest is the extent to which stakeholders care, whether they feel an urgency, and whether the issue aligns with the interest of the stakeholder. Based on our analysis, we differentiated between stakeholders in the value chain, stakeholders involved in innovation and governance aspects of safety, and broader stakeholder groups that are present in the societal debate with an interest in the topic.

Figure 5.

Stakeholder power–interest diagram.

Battery safety is a widely shared concern among most stakeholders. However, the issue does not seem to be urgent enough for stakeholders to be willing to take decisive immediate action.

The EU and national governments have significant power. They set regulations, influence norms, and provide financial instruments that affect different stakeholders in the diagram. However, their interest is dispersed, as they serve multiple and sometimes competing goals—including the aim to push the electric mobility transition; secure production of new battery technology in the EU; and support RD&D on other battery chemistries with inherent safety properties.

All manufacturers (cell, battery packs, and vehicle manufacturers) have high power as they can directly influence design, production, and battery handling by themselves as well as by influencing value chain partners. Many also show a high interest, as safety issues might affect their business. Battery pack manufacturers are of particular importance. They are in direct contact with both suppliers and vehicle manufacturers, and they can select high-quality cells and can include safety features in the pack design to prevent propagation in case of thermal runaway, which is an inherent risk to the use of lithium batteries. The flip side of the coin is that a faulty implementation of the cells in battery packs can cause safety issues. Due to the smaller size of these companies and their geographic proximity, communication between vehicle manufacturers and the battery manufacturer might be easier in comparison to communication with cell manufacturers.

To understand the market and the safety problem, we differentiate between three groups of vehicle manufacturers. Large automotive industry and suppliers of high-quality products seem to have less of a safety issue—although battery cells can go into thermal runaway spontaneously and firefighters do have concerns regarding how to extinguish fires in electric cars. This large automotive industry has the benefit of extensive knowledge and means to implement supply chain control, set better requirements, ask performance guarantees, and collaborate with suppliers. The next group consists of responsible but smaller manufacturers of a wide variety of applications. They understand the safety issue, but they don’t have the knowledge or the means to act upon that. They ask for regulation and proper norm-setting so that the safety of the products they buy is guaranteed while maintaining a level playing field with competitors. Finally, some producers are cost- and performance-driven, they don’t show an active interest in battery safety. Their power comes from forcing other manufacturers to cut costs, and from the risk that extreme cases of battery fires might backfire on the whole sector. Their role seems to be closely related to some wholesale traders.

Firefighter and insurance companies have a strong interest in battery safety but lack the power to change the batteries or the market. They can proactively contribute to the issue by gathering better data on fire risks, causes, and impacts. By making these data public, they put the issue on the societal agenda; and adapting insurance policies for unsafe batteries or companies might trigger a market response.

End-users who are using the vehicles should have a considerable interest in the topic, as they are exposed to the safety issues. However, they seem to be mostly unaware and uninformed of safety issues in products or product handling; or, for now, they prioritize functionality and cost over safety. If well-organized, end-users would hold significant power in the market, but our analysis does not show a strong sense of urgency or organization.

3.2. Technical Analysis: Exploring Problem and Possibility Space

The technical part of the research relates the stakeholder findings from Section 4 to the technical possibility space. First, we analyze the problem by making an inventory of potential failure modes and effects (Section 3.2.1). Next, we will argue that both this analysis as well as the stakeholder findings from Section 3.1 point at the crucial relevance of battery packs to ensure battery safety, especially for diverse niche applications (Section 3.2.2). Therefore, it is followed by a conceptual exploration of the potential solutions at the level of battery packs (Section 3.2.3). Finally, we will draw intermediate conclusions (Section 3.2.4).

3.2.1. FMMEA: Identifying Critical Events and Mechanisms

As an initial step, the different elements of the battery system are grouped by general function: electrical system, thermal system, information and computing system, structural system, and the external system [52]. Next, 27 potential combinations of failure modes, mechanisms, and observed effects have been identified. For each combination, the Risk Priority Number is qualitatively assessed, based on multiplication of the likelihood, severity, and inverse detectability of events. This was based on expert judgement and literature [6,46,52,71,75,80,90,91]. Based on this analysis, we conclude that priority needs to be given to the following events and mechanisms:

- Internal short circuits, either as the result of manufacturing defects or wear out. This can be both an initiator and a consequence of thermal runaway.

- Extreme heat generation as the result of overstress, including internal short circuits. This can be both an initiator and a consequence of thermal runaway.

- Side rupture of battery cell cans occurring due to a single cell reaching thermal runaway, with the risk of directly propagating to adjacent cells.

- Malfunctioning of thermal systems, potentially resulting in working temperatures that are out of range, or as a factor contributing to thermal runaway propagation.

- Battery management failure, leading to cell abuse or loss of communication of errors.

3.2.2. The Relevance of Battery Packs

The FMMEA analysis identifies the need to prevent thermal runaway. Already significant efforts have been made in improving cells. However, due to the inherent flammability, reactivity, and high-energy density of lithium-ion cells, this can only bring incremental improvement [8]. Even high-quality battery cells can enter thermal runaway by external triggers or by a spontaneous short circuit. The only way to come to inherently safe batteries is to apply other battery chemistries ([91]; int # 1, 3, 13) or to prevent thermal runaway propagation (TRP) [92]. Here, we will focus on the latter, given our research focuses on lithium-ion batteries.

The stakeholder analysis revealed the crucial role of battery pack manufacturers in increasing fire safety. They are in contact with both cell manufacturers as well as vehicle manufacturers, and, as such, can influence safety at the level of cells, battery packs, and vehicle design. Their battery pack designs can potentially contribute to preventing TRP. However, to be applied these measures need to be practical, low cost, and possibly be regulated. At the same time, limited attention has been paid to battery pack configuration in relation to safety [5,12] although [93] took it into account—leaving room for further improvement. Therefore, we will explore the technical possibility space for battery pack improvements to prevent TRP.

3.2.3. Exploring the Technical Possibility Space

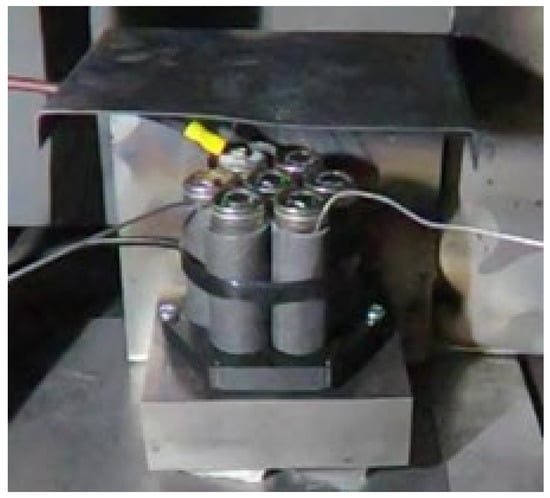

In the next phase, a rapid prototyping approach was conducted by following the approach in [29]. It required the design and realization of incomplete products (prototypes); realization of incomplete models of the real environment (test environment); and subsequently performing the experiment to explore the problem and learn from the potential solutions.

In line with the design goal, we defined nine design requirements. Five requirements were related to preventing thermal runaway propagation (e.g., whether they can help prevent short-circuit between cells, and whether they can prevent cell side rupture and/or thermal runaway propagation), while the others were related to practical considerations (e.g., weight, size, costs). Next, nine conceptual ideas for potential solutions were generated. Each of these ideas was scored on these design requirements in a Pugh matrix. The six best scoring concepts were selected and realized as prototypes. All prototypes were based on standard battery cells with modifications at the battery pack level. The prototypes involved (combinations of) cell level fusing by wire bonding, applying cooling plates, structural support of cells by plastic holders or isolating sleeves, and applying thermal/electrolyte barriers between cells (either foam or powder). Next, a test environment was realized to conduct quick scans on the viability of the prototypes. This included the design of five test experiments (see Table 2 and Figure 6), realization of the test setup, formalizing a test procedure, and conducting the experiments. The experiments involved specially prepared trigger cells in thermal runaway mode or initiating cells showing cell rupture.

Table 2.

Test experiments for initial validation of prototypes.

Figure 6.

Testing the structural support by isolating sleeves.

In prototype 1, cell level fusing is applied by ultrasonic wire bonding, similar to what Tesla uses. This can be applied to different designs, is cost-effective, and can connect cylindrical cells at the top (both anode and cathode), leaving the bottom side available for cooling [94]. Tests showed that design and production are challenging, especially to accurately blow up the fuse. A direct short circuit did result in a disconnection.

In prototype 2, cooling is applied at the anode side by a heat-conducting plate. Under normal working conditions, this setup enables uniform temperatures between and within cells and, as such, optimizes lifetime [95,96]. The computer simulation showed that heat is spread sufficiently, so that heat transfer over the conducting plate of a cell in TR does not cause TRP. However, experiments with cell-side rupture show heat transfer to the plate is not sufficient to prevent TRP under these extreme conditions.

Prototypes 3 and 4 focus on mechanical support to prevent cell-side rupture. Prototype 3 is a plastic holder to provide structural support and prevent side rupture, as well as act as spacer for the cells. The plastic holder is made from ABS-PC by 3D printing. One of the advantages would be that such a holder comes with low weight and cost. However, the cells could not be fitted in the housing correctly. Subsequently, an injection molding expert came with design suggestions that would meet the assembly requirements. However, these designs could no longer provide integral cell support to the cells, and as such could not prevent side burst.

In prototype 4, sleeves are applied around each cell (see Figure 6). This should provide structural support to prevent cell-side rupture, while also improving cell insulation and allowing for bottom-end cooling. In the test, the sleeve prevented the cell from bursting. However, after the build-up of pressure, the cell exploded, shooting out its contents via the top end. In a second experiment, a battery pack was used of all cells equipped with a sleeve and one trigger cell without a sleeve. The trigger cell erupted, and the adjacent cells were exposed to the heat and flames. However, all cells stayed cool (~25oC) and there was no TRP.

In prototypes 5 and 6, barriers were applied between cells, which should block flames, heat, and the electrolytes of a ruptured cell—and thereby prevent TRP. Initially, multiple options were considered, but had low scores on design requirements. These included sheets between cells, fluid cooling, and the application of phase-changing materials. In prototype 5, polyurethane foam insulation was applied. In the test, the foam did not catch fire but lost its structure, which allowed the flames to spread, thereby resulting in an almost immediate TRP. In prototype 6, Perlite isolating powder is applied and contained in a house. The test showed that at TR, the flames immediately spread throughout the battery pack, resulting in fast TRP.

3.2.4. Intermediate Results

We applied FMMEA to get a detailed overview of the failures and risks of batteries. Internal short circuits, extreme heat generation, side rupture, and malfunctioning of thermal systems or battery management systems are critical risks. They often can contribute to both thermal runaway initiation as well as propagation.

For the exploratory design, we focused on preventing thermal runaway propagation in battery packs by low-cost measures. Isolating sleeves and bottom-end cooling plates showed to be effective in reducing thermal runaway propagation. Cell level fusing based on wire bonds and plastic holders for structural support were shown to be promising, but it requires more knowledge and testing to become a successful application. Barriers to block flames and electrolytes, like foam insulation and isolating powder, were shown to be ineffective.

The combination of FMMEA and rapid prototyping was found to be very valuable for arriving at a better understanding of the risks and mechanisms triggering battery safety events, as well as for exploring multiple solution directions in the design space.

4. Discussion and Conclusions

Lithium-ion batteries have become increasingly applied and play a crucial role in the transition towards sustainable transport. Battery safety, and more specifically fire safety, is an upcoming concern in society. There is upcoming literature on battery safety, but so far this issue has been mainly addressed as a technical issue. The key contribution of this paper is to fill the gap by operationalizing battery fire safety as a shared responsibility among stakeholders. The knowledge, actions, and responsibilities are shared among the stakeholders involved. The characteristics of and the interaction between components, between manufacturing steps, and with handling influences overall safety performance. We approach battery fire safety as a socio-technical problem by addressing the questions about what the concerns and roles of stakeholders are; what the technical safety of batteries is; and how to improve fire safety by technical measures and stakeholders’ actions.

The stakeholder analysis showed that there are multiple different issues with battery safety. First, there is a lack of understanding among stakeholders. Furthermore, several factors contribute to this: the diversity in battery chemistries, design, and application; the lack of (safety) data on batteries, failure events, and the battery status; the variety of potential failure mechanisms; and the lack of appropriate, reliable, and understandable safety tests for batteries. For most stakeholders, battery fire safety is an upcoming issue, although of modest concern. Our study of power–interest showed pivotal stakeholders: cell and pack producers, large automotive manufacturers, and national and EU governments with their regulatory power. Some stakeholders, like the fire brigade and insurance company in our study, showed a high interest in the topic combined with an increased sense of urgency, but they lacked the power to influence developments directly. They can attempt to put the subject on the agenda by collecting data on events, taking concerns to the media, and by actively cooperating (e.g., in the norm-setting process). The systemic nature of the safety issues is widely recognized among stakeholders, and most stakeholders expect further improvements to be realized by introducing higher standards and shared responsibility.

Many stakeholders explicitly differentiate between the market segments. Large automotive manufacturers are committed to electric vehicles and take a high interest in battery safety for that reason, as they face the risk of expensive call back actions and reputational risk. It is a challenging market, as cars can crash at high speed and batteries are becoming more widely applied, while reducing the costs of batteries is seen as crucial. Manufacturers face the safety challenges by harnessing their knowledge on the topic, by actively cooperating across the value chain to secure quality and safety aspects, by cell acceptance screening, and by trying to control battery pack manufacturing.

Other applications include a variety of niche products such as e-bikes, agricultural apparatus, and a wide range of vehicles for recreational use. These markets are being supplied by small vehicle manufacturers and cell/pack manufacturers that focus on cost reduction. Most stakeholders flag these applications as having the highest safety concerns. These manufacturers do not invest in RD&D or value chain cooperation due to a lack of knowledge, human resources, or strategic (cost-reduction) reasons. It is questionable whether progressive voluntary norm-setting based on deliberation among market stakeholders can be an appropriate tool in this setting.

Our technical analysis focused on the exploration of the problem of battery safety as well as the exploration of the solution space by a rapid prototyping approach. FMMEA analysis revealed the broad scope of the components, mechanisms, and events that can trigger a fire in batteries. The essential events and mechanisms include internal short circuits, extreme heat generation, side rupture of batteries, malfunctioning of thermal systems, and failing battery management systems. Often these can be a cause as well as consequence of thermal runaway, and thereby contribute to thermal runaway propagation. Individual lithium-ion battery cells can never be made entirely safe. Therefore, options to prevent thermal runaway propagation at the battery pack level become relevant, especially as the literature states that these options are not yet fully explored. This aligns with the conclusions of the stakeholder analysis that identified battery pack designers and manufacturers as having the utmost relevance for safety. Different designs were explored, and the prototypes were tested by rapid prototyping. This part of the study showed that it is possible to reduce the risk of thermal runaway propagation through adaptation of battery pack designs, especially when combinations of isolating sleeves, bottom-end cooling plates, and cell level fusing seem promising.

Linking these results back to the stakeholder perspectives, we see three logical paths forward. The first one involves the large automotive industry. Progressive norm-setting on safety aspects is foreseen and supported by more specific safety tests and RD&D. Norms will likely focus on required safety levels rather than on specific system designs or configurations, giving room to battery pack manufacturers and car manufacturers to apply appropriate packs. The second path relates to other applications in diverse niche markets. The diversity of actors, battery designs, and applications make it hard to set universal safety standards, come to successful voluntary regulation, or provide adequate safety information to end-users. Therefore, top-down regulatory standard setting might be required. The standard can focus on reducing the risks of thermal runaway propagation in battery packs. The geographic proximity of several battery pack manufacturers might help to explore possibilities and come to a set standard. Such a regulatory approach will only work if it is supported by appropriate tests and sufficient control. The third path relates to funding of RD&D to further explore the most promising options in order to learn and disclose safety data by conducting specific RD&D, as well as by supporting research and test infrastructure. This should more prominently include solutions to battery pack design.

The preference for specific paths and the pace of progress will be highly dependent on future safety events and the media exposure given to these events. So far, the literature suggests that governments recognize the considerable potential of electric mobility, both to reduce environmental impacts as well as to support socio-economic development goals. We did not find signals—either in the literature or in stakeholder interviews—that governments feel the need for strict control or to push for stringent norms. A sense of urgency is lacking, applications are diverse, and the dynamic field of batteries is still developing. The EU might benefit from changes—like new applications, improved safety, or also new battery chemistries—and is therefore not likely to stabilize the status and lock in the current practice. However, besides norm-setting, governments can influence developments in other ways, e.g., by supporting the creation of specific (testing) infrastructure, by RD&D, and by supporting data collection and the sharing and providing of information.

We argued for a novel mixed-method approach to study the socio-technical system of battery safety and came up with suggestions for improvement. Thereby, we aimed to improve the standard approaches of descriptive case studies in transition studies and the technology-focused approach in systems engineering. The applied mixed-method approach allowed for the reconstruction of the problem and exploration of solutions in a holistic manner, actively contributing to realistic societal agenda setting. It ensures an in-depth and balanced exploration of the social and technical aspects, as well as their (potential) interaction. The rapid prototyping approach offers a quick exploration of the solution space. As such, it offers a technical reality check that is typically absent in most of the transition literature. However, such an approach is only indicative. It does not allow for risk assessment or for broader parametrized testing (e.g., using different materials, different conditions), and, as such, cannot be considered definitive proof.

With our approach, we were able to identify three realistic paths forward. However, the true value of the approach does not lie in identifying or prescribing development paths, but in triggering further deliberation by relevant stakeholders and empowering them with insight in the problem, potential solutions, and stakeholder roles. As such, it can stimulate further agenda building and action.

Author Contributions

A.F.K.: Conceptualization; Validation; Formal analysis; Investigation; Data curation; Writing–original draft; Writing–review and editing; Supervision. J.B.: Conceptualization; Methodology; Software; Formal analysis; Validation; Investigation; Resources; Data Curation; Writing–original draft; Visualization; Supervision. H.A.R.: Conceptualization; Formal analysis; Writing–review and editing; Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Informed Consent Statement

All subjects who participated in the interviews gave their informed consent (orally) for inclusion before they participated. They were informed on the goal of the research, and the anonymous storage, analyzing and reporting of the data. All subjects provided consent on notes of the interviews. At the time that these interviews were conducted (2019–2020), Eindhoven University of Technology did not have a standard policy regarding interviews for research. Since then, the policy has been updated to be in line with the Declaration of Helsinki, including the requirement of written consent and approval by the Ethics Committee, see https://www.tue.nl/en/our-university/about-the-university/integrity/tue-ethical-review-board/.

Data Availability Statement

Anonymized transcripts of the interviews can be obtained from the authors upon request.

Acknowledgments

The authors would like to thank the anonymous reviewers for their useful comments and suggestions that helped to improve the paper.

Conflicts of Interest

The authors declare not to have any conflict of interest.

References

- ERTRAC, EPoSS, & ETIP SNET. European Roadmap Electrification of Road Transport, 3rd ed.; ERTRAC: Brussels, Belgium, 2007; Available online: https://www.2zeroemission.eu/wp-content/uploads/2018/01/ertrac_electrificationroadmap2017.pdf (accessed on 25 March 2022).

- IEA. Global EV Outlook 2020 Entering the Decade of Electric Drive? 2020. Available online: https://www.iea.org/reports/global-ev-outlook-2020 (accessed on 25 March 2022).

- Mahmoudzadeh Andwari, A.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Bordes, A.; Danilov, D.L.; Desprez, P.; Lecocq, A.; Marlair, G.; Truchot, B.; Dahmani, M.; Siret, C.; Laurent, S.; Herreyre, S.; et al. A holistic contribution to fast innovation in electric vehicles: An overview of the DEMOBASE research project. ETransportation 2021, 11, 100144. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O. Integration issues of lithium-ion battery into electric vehicles battery pack. J. Clean. Prod. 2016, 113, 1032–1045. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J.; Tillmetz, W. (Eds.) Advances in Battery Technologies for Electric Vehicles; Woodhead Publishing Series in Energy; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Lebrouhi, B.E.; Khattari, Y.; Lamrani, B.; Maaroufi, M.; Zeraouli, Y.; Kousksou, T. Key challenges for a large-scale development of battery electric vehicles: A comprehensive review. J. Energy Storage 2021, 44, 103273. [Google Scholar] [CrossRef]

- Ould Ely, T.; Kamzabek, D.; Chakraborty, D. Batteries Safety: Recent Progress and Current Challenges. Front. Energy Res. 2019, 7, 71. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Tarvydas, D.; Lebedeva, N. Li-Ion Batteries for Mobility and Stationary Storage Applications. Scenarios for Costs and Market Growth. JRC Science for Policy Report, European Commission 2018. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC113360 (accessed on 25 March 2022).

- Dinger, A.; Martin, R.; Mosquet, X.; Rabl, M.; Rizoulis, D.; Russo, M.; Sticher, G. Batteries for Electric Cars. Challenges, Opportunities, and the Outlook to 2020. The Boston Consulting Group 2010. Available online: https://gerpisa.org/en/system/files/file36615.pdf (accessed on 25 March 2022).

- Chombo, P.V.; Laoonual, Y. A review of safety strategies of a Li-ion battery. J. Power Sources 2020, 478, 228649. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Lu, L. Overview about accidents: Selected lessons learned from prior safety-related failures of Li-ion batteries. In Electrochemical Power Sources: Fundamentals, Systems, and Applications. Li-Battery Safety; Garche, J., Brandt, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 12D; pp. 571–602. [Google Scholar] [CrossRef]

- Hu, G.; Huang, P.; Bai, Z.; Wang, Q.; Qi, K. Comprehensively analysis the failure evolution and safety evaluation of automotive lithium ion battery. ETransportation 2021, 10, 100140. [Google Scholar] [CrossRef]

- Lisbona, D.; Snee, T. A review of hazards associated with primary lithium and lithium-ion batteries. Process Saf. Environ. Prot. 2011, 89, 434–442. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Sun, P.; Huang, X. A review of battery fires in electric vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A review of lithium ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Marucheck, A.; Greis, N.; Mena, C.; Cai, L. Product safety and security in the global supply chain: Issues, challenges and research opportunities. J. Oper. Manag. 2011, 29, 707–720. [Google Scholar] [CrossRef] [Green Version]

- Geels, F.W. Technological transitions as evolutionary reconfiguration processes: A multi-level perspective and a case-study. Res. Policy 2002, 31, 1257–1274. [Google Scholar] [CrossRef] [Green Version]

- Nader, R. Unsafe at Any Speed: The Designed-in Dangers of the American Automobile; Grossman: New York, NY, USA, 1965. [Google Scholar]

- Brandt, K.; Garche, J. General battery safety considerations. In Electrochemical Power Sources: Fundamentals, Systems, and Applications Li-Battery Safety; Garche, J., Brandt, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–19. [Google Scholar] [CrossRef]

- Niu, X.; Garg, A.; Goyal, A.; Simeone, A.; Bao, N.; Zhang, J.; Peng, X. A coupled electrochemical-mechanical performance evaluation for safety design of lithium-ion batteries in electric vehicles: An integrated cell and system level approach. J. Clean. Prod. 2019, 222, 633–645. [Google Scholar] [CrossRef]

- Armstrong, A.G. Consumer Safety and the Regulation of Industry. Manag. Decis. Econ. 1981, 2, 67–73. [Google Scholar] [CrossRef]

- Ashford, N.A.; Hall, R.P. The Importance of Regulation-Induced Innovation for Sustainable Development. Sustainability 2011, 3, 270–292. [Google Scholar] [CrossRef] [Green Version]

- Jänicke, M.; Blazejczak, J.; Edler, D.; Hemmelskamp, J. Environmental policy and innovation: An international comparison of policy frameworks and innovation effects. In Innovation-Oriented Environmental Regulation; Hemmelskamp, J., Rennings, K., Leone, F., Eds.; ZEW Economic Studies; Physica: Heidelberg, Germany, 2000; Volume 10, pp. 125–152. [Google Scholar] [CrossRef]

- Schot, J.; Kanger, L.; Verbong, G. The roles of users in shaping transitions to new energy systems. Nat. Energy 2016, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Mootee, I. Design Thinking for Strategic Innovation; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Tronvoll, S.A.; Elverum, C.W.; Welo, T. Prototype experiments: Strategies and trade-offs. Procedia CIRP 2017, 60, 554–559. [Google Scholar] [CrossRef]

- Friedman, B.; Hendry, D.G. Value Sensitive Design: Shaping Technology with Moral Imagination; MIT Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Friedman, B. Value-sensitive design. Interactions 1996, 3, 16–23. [Google Scholar] [CrossRef]

- Owen, R.; Macnaghten, P.; Stilgoe, J. Responsible research and innovation: From science in society to science for society, with society. Sci. Public Policy 2012, 39, 751–760. [Google Scholar] [CrossRef] [Green Version]

- Stilgoe, J.; Owen, R.; Macnaghten, P. Developing a framework for responsible innovation. Res. Policy 2013, 42, 1568–1580. [Google Scholar] [CrossRef] [Green Version]

- Checkland, P. Soft Systems Methodology: A Thirty Year Retrospective. Syst. Res. Behav. Sci. 2000, 17, 11–58. [Google Scholar] [CrossRef]

- Mingers, J.; Brocklesby, J. Multimethodology: Towards a framework for mixing methodologies. Omega 1997, 25, 489–509. [Google Scholar] [CrossRef]

- Köhler, J.; Geels, F.W.; Kern, F.; Markard, J.; Onsongo, E.; Wieczorek, A.; Alkemade, F.; Avelino, F.; Bergek, A.; Boons, F.; et al. An agenda for sustainability transitions research: State of the art and future directions. Environ. Innov. Soc. Transit. 2019, 31, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Sovacool, B.K.; Hess, D.J.; Amir, S.; Geels, F.W.; Hirsh, R.; Medina, L.R.; Miller, C.; Palavicino, C.A.; Phadke, R.; Ryghaug, M.; et al. Sociotechnical Agendas: Reviewing Future Directions for Energy and Climate research. Energy Res. Soc. Sci. 2020, 70, 101617. [Google Scholar] [CrossRef]

- Turnheim, B.; Berkhout, F.; Geels, F.W.; Hof, A.; Mcmeekin, A.; Nykvist, B.; Van Vuuren, D.P. Evaluating sustainability transitions pathways: Bridging analytical approaches to address governance challenges. Glob. Environ. Change 2015, 35, 239–253. [Google Scholar] [CrossRef] [Green Version]

- INCOSE. A World in Motion. Systems Engineering Vision 2025; INCOSE: San Diego, CA, USA, 2014; Available online: https://www.researchgate.net/publication/277019221_A_World_in_Motion_-_Systems_Engineering_Vision_2025?msclkid=f0eadd54ad2b11ecbe558c208688c3a9#fullTextFileContent (accessed on 26 March 2022).

- Kirkels, A.; Evers, V.; Muller, G. Systems engineering for the energy transition: Potential contributions and limitations. Sustainability 2021, 13, 5423. [Google Scholar] [CrossRef]

- Gandoman, F.H.; Jaguemont, J.; Goutam, S.; Gopalakrishnan, R.; Firouz, Y.; Kalogiannis, T.; Omar, N.; Van Mierlo, J. Concept of reliability and safety assessment of lithium-ion batteries in electric vehicles: Basics, progress, and challenges. Appl. Energy 2019, 251, 113343. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Frazzica, A.; Chàfer, M.; Vérez, D.; Palomba, V. Research trends and perspectives of thermal management of electric batteries: Bibliometric analysis. J. Energy Storage 2020, 32, 101976. [Google Scholar] [CrossRef]

- Chen, M.; Dongxu, O.; Liu, J.; Wang, J. Investigation on thermal and fire propagation behaviors of multiple lithium-ion batteries within the package. Appl. Therm. Eng. 2019, 157, 113750. [Google Scholar] [CrossRef]

- Garche, J.; Brandt, K. (Eds.) Electrochemical Power Sources: Fundamentals, Systems, and Applications. Li-Battery Safety; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Qiu, Y.; Jiang, F. A review on passive and active strategies of enhancing the safety of lithium-ion batteries. Int. J. Heat Mass Transf. 2021, 184, 122288. [Google Scholar] [CrossRef]

- Stephens, D.; Shawcross, P.; Stout, G.; Sullivan, E.; Saunders, J.; Risser, S.; Sayre, J. Lithium-ion Battery Safety Issues for Electric and Plug-in Hybrid Vehicles; Report No. DOT HS 812 418; USA National Highway Traffic Safety Administration: Washington, DC, USA, 2017.

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in battery thermal management systems for electric vehicles: A technical review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Q.; Wang, G.; Lu, P.; Zhao, M.; Bao, W. A review on research status and key technologies of battery thermal management and its enhanced safety. Int. J. Energy Res. 2018, 42, 4008–4033. [Google Scholar] [CrossRef]

- Wu, X.; Song, K.; Zhang, X.; Hu, N.; Li, L.; Li, W.; Zhang, L.; Zhang, H. Safety issues in lithium ion batteries: Materials and cell design. Front. Energy Res. 2019, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, L.; Sun, F.; Wang, Z. An Overview on Thermal Safety Issues of Lithium-ion Batteries for Electric Vehicle Application. IEEE Access 2018, 6, 23848–23863. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Warner, J. The Handbook of Lithium-Ion Battery Pack Design: Chemistry, Components, Types and Terminology; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Zhu, J.; Wierzbicki, T.; Li, W. A review of safety-focused mechanical modeling of commercial lithium-ion batteries. J. Power Sources 2018, 378, 153–168. [Google Scholar] [CrossRef]

- Held, M.; Brönnimann, R. Safe cell, safe battery? Battery fire investigation using FMEA, FTA and practical experiments. Microelectron. Reliab. 2016, 64, 705–710. [Google Scholar] [CrossRef]

- Berkeley, N.; Bailey, D.; Jones, A.; Jarvis, D. Assessing the transition towards Battery Electric Vehicles: A Multi-Level Perspective on drivers of, and barriers to, take up. Transp. Res. Part A Policy Pract. 2017, 106, 320–332. [Google Scholar] [CrossRef] [Green Version]

- Christensen, P.A.; Anderson, P.A.; Harper GD, J.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240. [Google Scholar] [CrossRef]

- Li, J.; Qiao, Z.; Simeone, A.; Bao, J.; Zhang, Y. An activity theory-based analysis approach for end-of-life management of electric vehicle batteries. Resour. Conserv. Recycl. 2020, 162, 105040. [Google Scholar] [CrossRef]

- Melin, H.E.; Rajaeifar, M.A.; Ku, A.Y.; Kendall, A.; Harper, G.; Heidrich, O. Global implications of the EU battery regulation. Science 2021, 373, 384–387. [Google Scholar] [CrossRef] [PubMed]

- Wrålsen, B.; Prieto-Sandoval, V.; Mejia-Villa, A.; O’Born, R.; Hellström, M.; Faessler, B. Circular business models for lithium-ion batteries—Stakeholders, barriers, and drivers. J. Clean. Prod. 2021, 317, 128393. [Google Scholar] [CrossRef]

- Lebedeva, N.; Di Persio, F.; Boon-Brett, L. Lithium Ion Battery Value Chain and Related Opportunities for Europe; EUR 28534 EN; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar] [CrossRef]