Abstract

The tire pyrolysis oil is a waste-derived fuel with a lower cetane number and higher den-sity than diesel fuel, but this is a promising waste-based fuel for compression ignition en-gines. In the European Union, it is necessary to increase the bio-share of fuels, and the second-generation waste-derived blend components are essential for achieving the 2030 goals. The injection characteristics of tire pyrolysis oil and diesel oil were investigated on a Bosch solenoid type common rail (CR) injector. Six different premixed ratios were investi-gated, including in a low volume percentage 250 ppm and higher 10%, 20%, and 100% pyrolysis oil and 100% diesel oil. The simulation investigation was done in the AVL Fire software, the experimental investigations were done on a LDX CR injection test bench, and the videos were taken on an Olympus Ispeed 3 camera. The scope of the research was to record the flow pattern of the fuel mixture, flowing out of the high-pressure injector, from which the mixing with air and the quality of the resulting combustion can be deduced, which has a significant effect on the emissions.

1. Introduction

One of the greatest challenges that we face is the increasing amount of power that humankind uses. To maintain the supply of energy on a market where the demand is growing day by day, we need to look for alternative fuels to power our powerplants and machines. Making fuel out of waste is not only a solution for making alternative fuels, but it is also an excellent way to clean the environment from our dangerous byproducts. Over a billion tires are produced each year for the transportation industry. That needed to be recycled after use to protect the environment. The pyrolysis process is a seemingly promising way to recycle waste tires. There are several types of pyrolysis processes and the most used process is vacuum pyrolysis [1]. The pyrolysis oil used for the measurements comes from a pyrolyzer with a vertical structure, inside which a rotating vane mixes the rubber waste [2]. Tire pyrolysis oil has a high gross calorific value (41–44 MJ/kg), and therefore can be used well in internal combustion engines with a suitable mixing ratio [3]. Literature review shows that the tyre pyrolysis oil (TPO) fuel is highly flammable and has a calorific value equivalent to that of commercial diesel fuel [4]. TPO fuel, tested on a modern turbocharged diesel engine without changing its injection strategy, has resulted in higher NOx and CO emissions, according to the literature search [5]. The fuel injection quality (pressure, jet image, and time course) determines the amount of pollutants in the exhaust gas to the greatest extent [6]. According to research, by slightly mixing TPO fuel with commercially available diesel fuel, the emission values do not change or only to a negligible extent. Although it is advisable to use it primarily in industrial engines, road NOx measurements on light-duty modern diesel commercial vehicles did not significantly differ compared to pure diesel fuel [7]. Internal combustion compression ignition engines are now widely used in both the transportation and energy industries. In modern compression ignition (CI) engines, high-pressure injectors used in research are widely used today. As the quality of the tested fuel blend differs from that of standard diesel fuel, it is necessary to test the blend from several aspects. These include the injection jet image, which significantly affects the mixing of the fuel with oxygen and, consequently, the combustion quality and pollutants’ concentration [8]. The research does not cover the service life of injector components as it requires longer-term tests. The scope of the research was thus to investigate the effects of waste-based TPO on injectors, from which the expected service life of the injection system and the expected emissions can be deduced.

Pyrolysis Properties

The pyrolysis reactor has a temperature of about 450 degrees Celsius and no catalysts or other accelerators are used during the process. During the pyrolysis process, the polymer structure of the tire collapses and gases and vapors are released from the solid material (the polymer chains break into smaller ones). These vapors and gases are captured and stored after physical and chemical treatment. Materials formed during the process: gas fraction, gasoline fraction, oil fraction, and water. The resulting gas fraction can heat the pyrolyzer firebox, which is located separately from the reactor. The firebox has a high temperature (950–1050 °C) which provides heating for the reactor. The reactor has a dual-layer wall. Into the outer wall, the hot flue gas is introduced. Within the inner wall, in an isolated environment, pyrolysis takes place so that the structure of the rubber polymer collapses under the influence of external heat transfer without oxygen. [9] The quality of the TPO is greatly influenced by the type of tire waste used. As the processed tire base material comes from several manufacturers, their material composition is also different. Samples taken during processing show different laboratory tests values, so tire-based pyrolysis oil will not have a standard composition like commercially available fuels. The properties of TPO fuel used in this study were analyzed in laboratory with standard methods and presented in Table 1. The diesel fuel used in the tests is a commercially available fuel that meets EN-590 standard [10]. The main parameters of the two fuels are shown in Table 1. The purpose of this study was to test pyrolysis oil using a commercially available diesel–biogas blend.

Table 1.

Main dimensions of nozzles [11].

2. Experimental

2.1. The Examined Nozzle Geometries

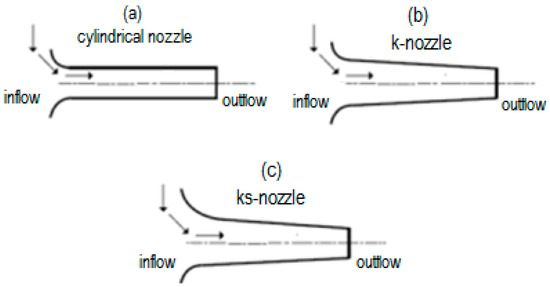

Based on earlier research of Vass and Zöldy [11], three different nozzles were investigated in a BOSCH CRIN1 medium-duty common rail injector. The nozzle’s structure is shown in Figure 1 and its characteristics are presented in Table 1. This shows the simplest nozzle structure. Its design is cylindrical and the radius of the curvature is small at the inflow cross-section. This structure is becoming rarer due to its shape being prone to cavitation. Due to the high velocity and the change of direction, eddies and pressure drop form that causes steam bubbles to form. These bubbles collapse near the exit cross-section. [12]. The only positive aspect of this phenomenon is that the flow rate is significantly increased due to reduced contraction, which favors atomization and evaporation. In this injector type, to further reduce the emissions, the nozzle cone closes onto the nozzle bore. Thus, there is no blind hole-like structure. This is the valve covering orifice (VCO) nozzle. K-nozzles (from the German word konisch) (Figure 1b). The rounding radius is determined by a special process called hydro-grinding (HG) [13]. The nozzle where, in addition to the confusing hole, the HG process is also used called the nozzle (German konisch strömungsoptimiert words) and forms such a type of the second simulation geometry (Figure 1c).

Figure 1.

The types of nozzles.

The taper of the nozzles at the injectors, which are not marked in the usual way in machine design, is called k-factor. The factor k can be determined from the inlet and outlet diameters:

where Di is the inflow’s diameter and D0 is the outflow cross section’s diameter, and k is the k-factor. The geometrical dimensions of the three nozzles tested are shown in Table 1.

The properties of the fuel used in the tests are shown in Table 2.

Table 2.

Main parameters of TPO and Diesel fuels.

The injector used in the tests has a VCO nozzle design. The advantage of the VCO nozzle chamber is that the fuel remaining in the blind hole under the nozzle needle does not enter the combustion chamber, it does not participate in the combustion. If the fuel remained in the blind hole, it would enter the combustion chamber, further increasing hydrocarbon emissions. By reducing emission values, these nozzles are already in use today [14].

2.2. Initial and Boundary Conditions

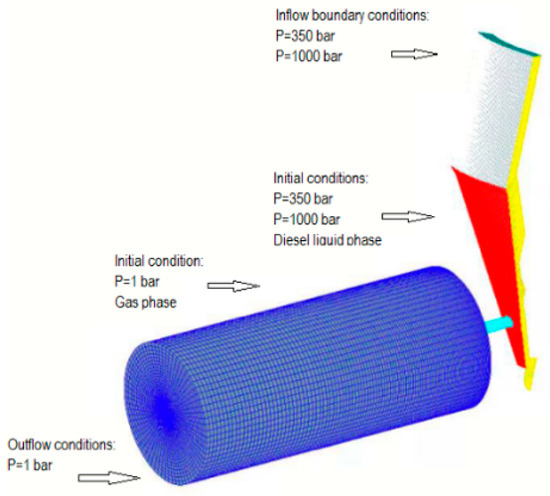

The simulation was defined as a multiphase process with three phases. The first phase is the diesel liquid phase or pyrolysis oil liquid phase, the second phase is the diesel vapor or pyrolysis oil vapor, the third phase in both cases was air-gas phase. The boundary conditions define the physical boundaries of the model and the basic parameters present in them. Boundary conditions were defined in four cases, for four designated surfaces listed earlier. The simulation was designed to run at a rail pressure of 350 bar, with an outflow cross-section boundary condition of 1 bar pressure (Figure 2).

Figure 2.

Initial and boundary conditions.

The k-ε turbulence model was used at the simulations, which is a well-functioning, configurable turbulence model. Basic equations of the k-ε turbulence model:

Turbulent kinetic energy for k:

The relations also have constants: C1ε, C2ε, Cµ, k, ε.

Formula for turbulent viscosity:

Linear cavitation model set with three phases: The relationships of the linear cavitation model are described in Equations (5) and (6). The mass exchange of the interface was done by introducing Equation (5), this is the mass transfer rate of the interface.

The following relation (6) is the density of the bubbles formed by the cavitation, which represents the number of bubbles per unit volume:

When writing the 3D graphical results, the following parameters were selected: density, pressure, turbulent kinetic energy, velocity, volume ratio. These parameters were examined in all three phases.

2.3. Experimental Setup

The tests were performed on an LDX CR injector test bench, the parameters of the test bench are shown in Table 3 [15]. A special test oil had to be drained and refilled with commercially available diesel fuel, and then with the tested TPO blends. The fuels were heated to 40 degrees Celsius. For the test, an injector was placed in the test tube of the test bench, illuminated by the camera’s frequency-free light source. The test chamber was continuously ventilated with compressed air to prevent fuel-spray fog. Measurements were performed at 350 and 1000 bar rail pressures with pure diesel and pure TPO as well as 10% TPO with 90% diesel, and 20% TPO with 80% diesel fuel. A Bosch CP3 pump provided fuel pressure. For the jet-images pictures, an Olympus Ispeed 3 high-speed camera was used, which was placed in front of the test bench. The parameters of the camera are shown in Table 4.

Table 3.

Main parameters of LDX CR injector test bench.

Table 4.

Main parameters of the Olympus Ispeed 3.

3. Results and Evaluation

3.1. Simulation Results 350 Bar Rail Pressure

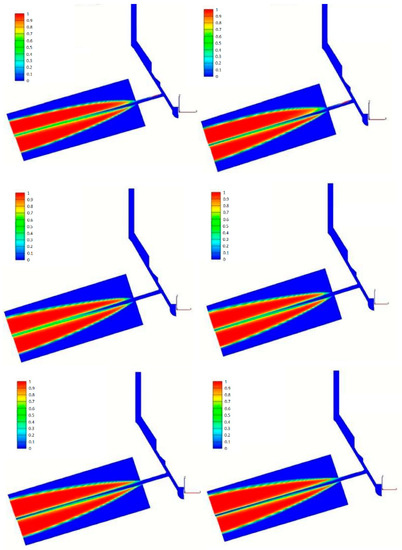

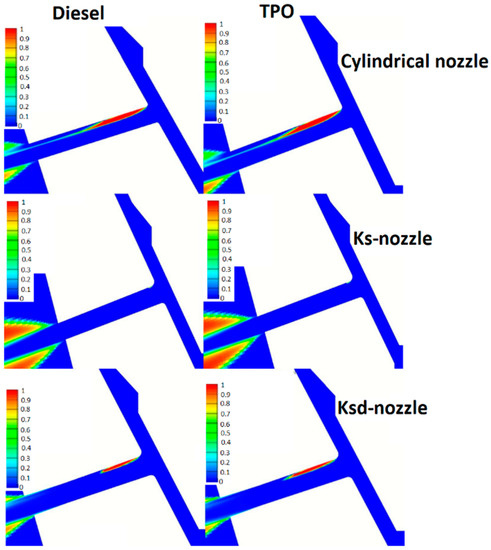

Columns 1 and 2 in Figure 8 show the oil nozzle diagrams of the three nozzle types with pure diesel (left) and pure TPO (right). The figure shows the vapor phase diagrams of the fuels. The nozzle geometries in a row: cylindrical, confusional (ks), confusing-diffusing (ksd). For the diesel test, the literature results show similar results, confirming the functionality of the model. In the case of a cylindrical nozzle, cavitation forms at the inlet edge of the nozzle, the cavitation phenomenon can be seen in the entire extent of the hole. In the case of pyrolysis oil, the rate of cavitation increases. It is clear that its surface is more extensive than in diesel’s case, and this extends completely beyond the nozzle. The design of the ks-nozzle type was guided by the reduction of the amount of cavitation in the nozzle, and this is fully justified; and in contrast to the cylindrical nozzle, the minimum cavitation shown in the figure did not increase in the case of pyrolysis oil simulation. In the vapor phase, there is no change detected at the ks-nozzle. In the ksd nozzle case, cavitation in the diesel oil vapor phase is a bit higher, thanks to the confuser-diffuser design. However, this is a negligible amount of cavitation compared to the cylindrical. Unfortunately, this trend is not the case for the pyrolysis oil’s vapor phase, as it continues to form a much larger cavitation spot here compared to diesel.

Figure 3 shows the overall vapor phases. In the case of a cylindrical nozzle, the vapor phases’ distribution is not symmetrical in the outflow volume, especially in the case of the pyrolysis oil vapor phase, where the distortion is visible at the lower parts, which is mainly due to cavitation. In the case of the ks nozzle a complete symmetry is observed, while in the case of the ksd nozzle, the difference is minor in-between the diesel vapor phase and the pyrolysis oil vapor phase.

Figure 3.

Vapor phase of diesel fuel.

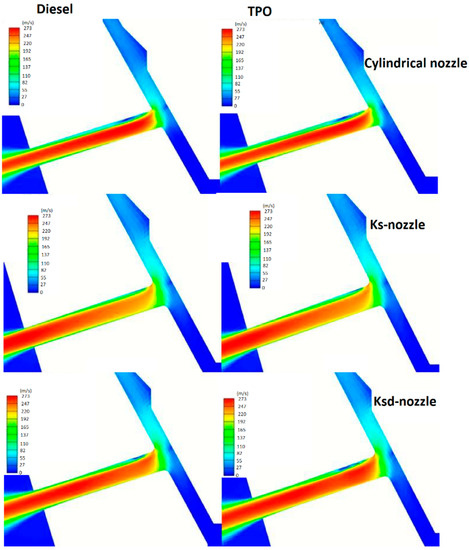

Columns 1 and 2 in Figure 9 present the velocity values in the liquid phases of the fuels. The location of the figures follows the arrangements of the previous figures. For both fuels, it can be observed that the velocity concentrates in the lower range of the cylindrical nozzle due to the small inlet rounding radius. The blue range at the top does not mean that there is no fuel velocity, but that only the vapor phase is present there due to cavitation and in this case, only the velocities of the liquid phase are visible. High velocity values falling further into the nozzle’s bottom region further increase the risk of erosion wear. Based on these observations, we can state that if we use cylindrical nozzles, they will get worn out quickly. The velocity is highly inhomogeneous in the cross section of the exit, and this effect is visible for both fuels. After outflow, pyrolysis is the rate of oil a decrease is seen compared to diesel, and the inhomogeneity is even higher than in the other case. The advantage of inhomogeneity is that, under the influence of the shear forces generated, the fuel’s ability to mix with air gets better. This is a crucial factor for combustion.

The velocity of the lower concentration is also greater for pyrolysis oil. It can be stated that a shorter service life is expected with pure pyrolysis oil, and erosion wear poses a higher risk. At the ks-nozzle, the velocities show a more symmetrical picture, there is no great focus on the nozzle wall, and the diagram also shows a symmetrical picture at the exit for both fuels. Some differences can only be seen around the top edge due to the loss of velocity caused by the vapor phase’s presence. Apart from that, a similar picture was formed for both fuels. Due to the effect of laminar flow at the exit, the droplet decomposition is worse at the ks-nozzle and the outflow rate is also higher. The mixing thus deteriorates compared to the cylindrical nozzle and the quality of the combustion deteriorates because the fuel flare penetrates too deep. The image of the ksd nozzle is more similar to that of the ks nozzle. We can also observe that a vortex is formed by the entrance, causing a drop in velocity. A similar phenomenon is present in the cylindrical nozzle. In the case of pyrolysis oil, this area is slightly larger and it was likely formed during cavitation and the dropout is due to the area of the vapor phase. The outflow is similar to the ks, but the outflow rate is lower, thus ensuring better mixing with the air and less penetration of the fuel flare.

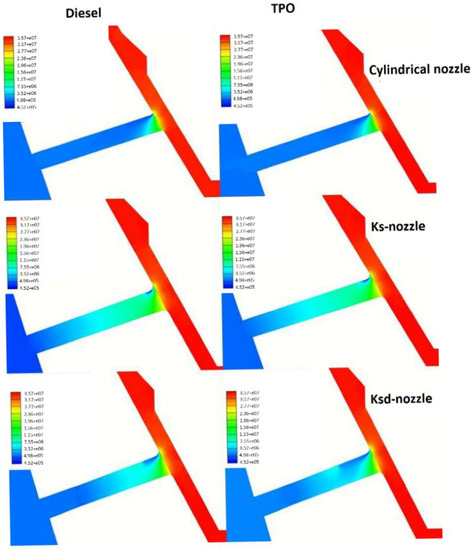

Figure 4 shows the pressure values around the nozzles. It is well observed that the pressure value drops drastically in the vicinity of the nozzle, falling towards to a pressure of 1 bar in the outflow volume. The most significant pressure drop is observed on the cylindrical nozzle, which is due to the small rounding radius and the cylindrical nozzle design. No pressure difference can be detected between the two fuels. The pressure drop is more even at the ks-nozzle. The pressure decreases continuously until the end of the nozzle, of course at a larger inlet cross-section. Due to the higher pressure, cavitation cannot form in the ks-nozzles. The difference in pressure formation was not observable between the two fuels. The image of the ksd nozzle is shown between the previous two, here the pressure drop lasts about to the middle of the nozzle bore, and then the ambient pressure is already visible. Diesel shows an orderly picture, but this is no longer the case for pyrolysis oil. A cylindrical pressure drop occurs at the inlet cross-section and then the pressure increases slightly again. This is a good indication of the cavitation of pyrolysis oil why it developed, the pressure is lower after the inlet cross-section. Thus, pyrolysis oil is less responsive to diffuser design than diesel. By reshaping the nozzle, the degree of cavitation could be reduced. The problem could be solved by changing the length of the switch to a diffuser design, which would increase the confuser’s length, thereby stabilizing the pressure drop of the pyrolysis oil, thus reducing cavitation.

Figure 4.

The pressure values around the nozzles.

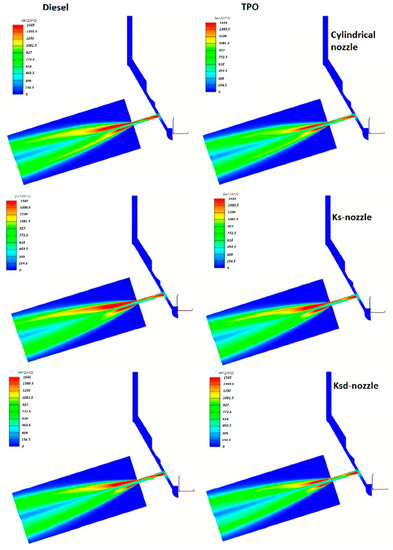

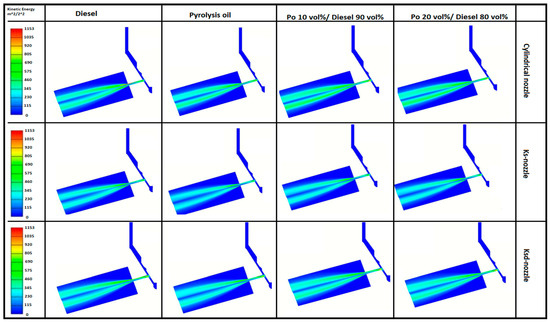

Figure 10 shows the evolution of the turbulent kinetic energy (TKE) associated with the nozzles. “TKE is defined as the average kinetic energy per unit mass for swirling flows”. The higher the value of TKE, the higher the specific kinetic energy of the fluid. It has the highest value in the zones with high pressure change, clearly seen in Figure 10. The highest TKE values are mainly found in the boreholes. In the cylindrical and ksd nozzles, the pyrolysis oil shows lower values than the diesel oil. The minimal difference can also be observed at the ks nozzle. The lower specific kinetic energy caused by pyrolysis oil suggests that more imperfect mixing with air occurs, with a lower shear force in the jet, which impairs droplet decomposition processes and combustion.

3.2. Simulation Results at 1000 Bar Rail Pressure

Figure 5 shows the liquid phases of the fuels. In the cylindrical nozzle case, the degree of cavitation is increased with the diesel fuel, as expected. It can be seen that the increase in the degree of cavitation with pyrolysis oil is much higher than with diesel. Cavitation is already significant in two-thirds of the nozzle’s boreholes and extends enormously into the effluent volume, thus degrading the parameters. Since the cylindrical nozzle is still standard and being used regularly, it does not worth experimenting with this nozzle combined with pure pyrolysis oil in real tests, due to the reasons mentioned above.

Figure 5.

Fuel liquid phases around the nozzle at a pressure of 1000 bar.

On the other hand, the ks-nozzle did not bring any change; despite the triple pressure, the cavitation still only appears in a nuanced area. The ksd nozzle shows a cylindrical nozzle, like cavitation increase, but not to the same extent. Although cavitation is present only in half of the borehole and does not reach the outflow volume, an improvement in the geometry would be required to achieve a lower cavitation degree.

Figure 6 shows the velocities of the liquid phases of the two fuels in the form of a diagram. At a pressure of 1000 bar, the speeds were approximately doubled compared to a pressure of 350 bar.

Figure 6.

Fuel liquid phase velocities at 1000 bar in the nozzle.

There was no significant change in the cylindrical nozzle’s diesel speed. Only the speed values increased. Pyrolysis oil was entirely concentrated in the lower range, with a particularly high erosive effect on the lower part. In addition to this result, it can be concluded that the cylindrical nozzle is not very suitable for pyrolysis oil usage and does not have a long service life in practice. In the ks-nozzle’s case, it can be repeated that the velocity distribution is the same for both fuels. A uniform laminar flow is seen at the exit, impairs the formation of good mixing, since the fuel flare penetrates too deep. No particular change can be detected with the ksd nozzle.

Figure 7 shows the TKE at 1000 bar. In the case of diesel fuel, similarly to 350 bar, a large TKE is formed in the nozzle, but since the Rail pressure is also higher, the higher kinetic energy can be observed even in the jet image. The vortex is more significant by higher pressure in all three designs. Kinetic energy was generated to a lesser, narrower extent than the cylindrical nozzle version of pyrolysis oil. In the case of pyrolysis oil, slightly worse droplet decomposition can be expected. The cylindrical version is not suitable for pyrolysis oil. The ks-nozzle shows almost the same kinetic energy for both fuels with a slightly lower value for pyrolysis oil. The same situation is seen for the ksd nozzle. The pyrolysis in the oil phase has a similar picture for both fuels, slightly smaller than pyrolysis oil. Based on the simulations, it can be stated that if we want to run a diesel compression-ignition engine with pure pyrolysis oil, the nozzle with a confuser-diffuser design gives the best results if all aspects are taken into account. The cavitation of the cylindrical nozzle showed only an upward trend, the ks-nozzle produced similar results with diesel, but the ksd-nozzle brought better mixing and lower flow rates for both fuels.

Figure 7.

TKE at 1000 bar Rail pressure.

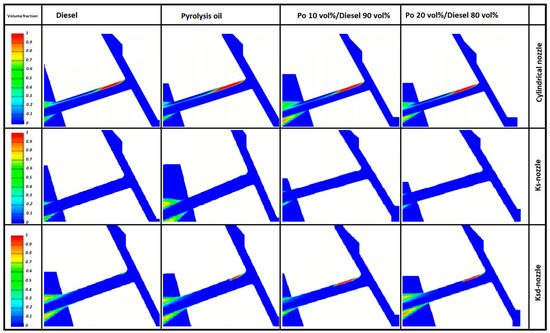

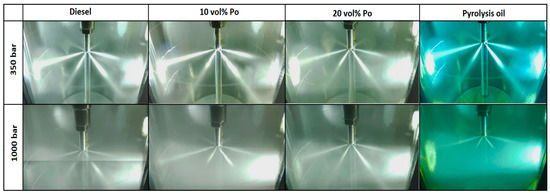

The simulations were validated on an injector test bench. For injector tests, the test bench is filled with test oil which does not contain bio-additives. For the measurements, instead of the test oil, commercially available diesel fuel was first loaded, and the injection jet image was photographed at 350 and 1000 bar rail pressure. After that, 10% TPO and then 20% TPO were mixed with diesel, and finally, the beam image was photographed with 100% TPO fuel. Injection jet images of fuels taken on a test bench with a camera at a rail pressure of 350 and 1000 bar are shown in Figure 11.

The vapor phase diagram, the liquid phase velocity diagram, and the TKE diagram are examined.

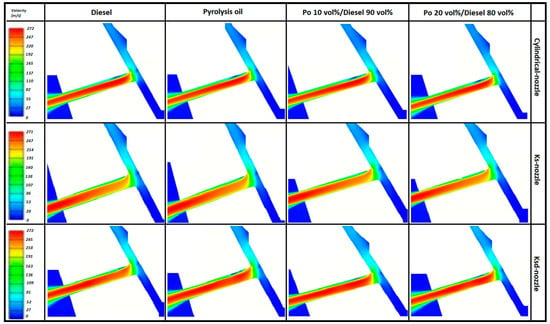

Figure 8, column 3 and 4 shows the fuel vapor phase diagrams of the blends. The original 350 bar Rail pressure diesel and pyrolysis oil results for all three nozzles have now been attached to make the results more illustrative.

Figure 8.

Liquid phase diagrams of different fuel mixtures.

At the cylindrical nozzle we start from the cavitation state and unfortunately, as in the case of 100 vol% pyrolysis oil, the cavitation degree increased. The case of 10 vol% and 20 vol% mixtures shows a similar picture to the pure pyrolysis oil test. Moreover, in the pure pyrolysis oil test, it was found that it is not worthwhile to start tests with a cylindrical nozzle because it either provides worse mixing for combustion or creates a robust erosive effect in the nozzle, leading to rapid failure. As shown in the previous study, the ks-nozzle did not produce substantial cavitation here either, as was to be expected. The ksd nozzle does not provide excellent results. Cavitation is formed in a larger area than the 10% by volume and 20% by volume mixture.

The liquid phase velocity diagrams are presented Figure 9. It is proven that, for the cylindrical nozzle, neither the 10% by volume nor the 20% by volume mixture is suitable for proper operation. The erosion effect is increased by the high-velocity fluid’s impact in the lower half of the borehole.

Figure 9.

Liquid phase velocity diagrams of different fuel mixtures.

The mixing is well ensured by the cylindrical nozzle, but due to the high cavitation and erosion effect, it proves to be not a very durable construction. The ks problem does not occur with the ks nozzle, the speed is slightly skewed in the lower range, but this is still acceptable. The problem lies in the high-velocity outflow mentioned several times, in accordance with the confusing design. The trend continues at the ksd nozzle. The presence of pyrolysis oil determines the velocity diagrams, the velocity is decreasing shifts, which should have an erosive effect for the hole, but not to the same extent as for the cylindrical one. In terms of combustion, as shown in previous studies, the ksd nozzle is the most suitable type. The degree of cavitation is still adequate and the velocity is sufficient, the fuel flare penetration is reduced compared to the ks-nozzle and the mixing with air is adequate, but this is also backed up by the TKE values shown in Figure 10.

Figure 10.

TKE values in different nozzles with different fuel mixtures.

The development of the kinetic energy in the jet image of the cylindrical nozzle shows an exciting result. The jet is asymmetric, but pyrolysis oil concentrates develop a higher TKE in the lower half of the jet than pure pyrolysis oil.

A higher value indicates that higher shear forces are generated in the jet when the fuel and air are mixed, and droplet decomposition dictates a good value, which is essential for combustion and emissions. Based on the higher percentage by volume of diesel, the development of the results is not surprising—mainly, the 10 vol% pyrolysis oil mixture shows a higher energy level.

In the ks-nozzle case, the former case is reversed, and higher kinetic energy is generated in the jet image with conventional diesel, and the symmetry is the same in all four cases. In the ksd nozzle case, similar to the cylindrical one, pyrolysis oil concentrates entail lower energy compared to diesel. However, the jet image also becomes more asymmetric due to greater cavitation from the borehole. Overall, diesel fuel containing 10 vol% and 20 vol% pyrolysis oil are almost identical based on these simulations. Cavitation values deteriorated somewhat at both the cylindrical and ksd nozzles, with the ks nozzle stagnating in this case. The speeds were similar to conventional diesel. The kinetic energy was almost the same for the cylindrical and ksd nozzles under the mixtures’ effect, while it showed a more decreasing trend for the ks nozzle.

Injection jet images of mixed fuels taken on a test bench with a camera at a rail pressure of 350 and 1000 bar are also shown in Figure 11.

Figure 11.

Injector jet images with different fuel mixture with the pressure of 350 and 1000 bars.

4. Conclusions

The research aimed to perform a numerical simulation of the combustion influencing the use of waste-based fuel and examine the injection beam image. Given the possibilities, three diesel common rail injector nozzle types were also tested, and the literature also obtained different results for diesel tests for different types. Based on the models, computational fluid dynamics (CFD) grids were created that gave the model functionality. The research dealt with recycled pyrolysis oil from tires within waste-based fuels. During the cylindrical nozzle tests, it was proved that the amount of cavitation formed in the nozzle, with the addition of pyrolysis oil, and during the pure pyrolysis oil tests, enormously increased. The stable fuel flare was not formed, it took on an asymmetrical shape, but the mixing showed a good ratio due to the cavitation. However, due to the high erosion effect, the cylindrical nozzle is not recommended for more extended use, as a lower service life is expected. During the ks nozzle simulations, no significant change occurred when the parameters of the fuel were changed. Cavitation was negligible, but the velocity of the liquid was too high to provide poor quality mixing. Fuels penetrate deep at high speeds, leading to wetting of the combustion chamber walls, and evaporation is also lower. In pyrolysis oil, TKE also represented lower energy levels, which further impairs mixing and evaporation. Worse values were also obtained for the ks-nozzle for the pyrolysis oil. The confuser-diffuser (ksd) nozzle provided perhaps the most perfect picture. The cavitation was not very large, and the liquid phase’s velocity was also lower than that of the ks-no, so better mixing is obtained by using the nozzle. Pyrolysis oil produced worse values there, but compared to the previous two nozzles, this was the most ideal considering most aspects. Studies have shown that pyrolysis oil can be used in CR injectors, even without changing geometric dimensions. However, the formation of a fuel-air mixture produced worse values in most cases, and harmful cavitation increased. With the elaboration of other geometries and the further refining of pyrolysis oil, there are plenty of development opportunities.

Author Contributions

I.P.K. conducted the tests on the injector testbench and wrote the publication. M.Z. made the computer simulations. Both authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The research reported in this paper and carried out at BME has been supported by the KTI_KVIG_8-1_2021 fund based on the charter of bolster issued by the KTI.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| CAD | Computer Aided Design |

| CI | Compression Ignition |

| CFD | Computational Fluid Dynamics |

| CFPP | Cold Filter Plugging Point |

| CR | Common Rail |

| HG | Hydro Grinding |

| HP | High pressure |

| LP | Low pressure |

| MSZ | Hungarian Standard |

| TKE | Turbulent Kinetic Energy |

| TPO | Tyre Pyrolysis Oil |

| VCO | Valve Covering Orifice |

References

- Zöldy, M. Investigation of Correlation Between Diesel Fuel Cold Operability and Standardised Cold Flow Properties. Period. Polytech. Transp. Eng. 2021, 49, 120–125. [Google Scholar] [CrossRef]

- Zöldy, M. Improving heavy duty vehicles fuel consumption with density and friction modifier. Int. J. Automot. Technol. 2019, 20, 971–978. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Shahir, V.K.; Jawahar, C.P.; Vinod, V.; Suresh, P.R. Experimental investigations on the performance and emissions characteristics of a common rail direct injection engine using tyre pyrolitic biofuel. J. King Saud Univ. Eng. Sci. 2020, 32, 78–84. [Google Scholar] [CrossRef]

- Baškovič, U.Ž.; Seljak, T.; Katrašnik, T. Feasibility analysis of 100% tire pyrolysis oil in a common rail Diesel engine. Energy 2017, 137, 980–990. [Google Scholar] [CrossRef]

- Wongkhorsub, C.; Chindaprasert, N. A Comparison of the Use of Pyro lysis Oils in Diesel Engine. Energy Power Eng. 2013, 5, 350–355. [Google Scholar] [CrossRef]

- Bodisco, T.A.; Rahman, S.A.; Hossain, F.M.; Brown, R.J. On-road NOx emissions of a modern commercial light-duty diesel vehicle using a blend of tyre oil and Diesel. Energy Rep. 2019, 5, 349–356. [Google Scholar] [CrossRef]

- Barabás, I. Liquid densities and excess molar volumes of ethanol + biodiesel binary system between the temperatures 273.15 K and 333.15 K. J. Mol. Liq. 2015, 204, 95–99. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Januszewicz, K.; Kosakowski, W. Efficiency and proportions of waste tyre pyrolysis products depending on the reactor type—A review. J. Anal. Appl. Pyrolysis 2019, 140, 25–53. [Google Scholar] [CrossRef]

- Available online: https://mol.hu/hu/autozzon-velunk/uzemanyagok/evo-diesel-garantalt-teljesitmeny/mol_dizel_termeklap.pdf (accessed on 8 June 2020).

- Vass, S.; Zöldy, M. A model based new method for injection rate determination. Therm. Sci. 2020, 159. Available online: http://thermalscience.vinca.rs/pdfs/papers-2020/TSCI190417159V.pdf (accessed on 8 June 2020). [CrossRef]

- Payri, F.; Payri, R.; Salvador, F.J.; Martínez-López, J. A contribution to the understanding of cavitation effects in Diesel injector nozzles through a combined experimental and computational investigation. Comput. Fluids 2012, 58, 88–101. [Google Scholar] [CrossRef]

- He, Z.; Zhong, W.; Wang, Q.; Jiang, Z.; Shao, Z. Effect of nozzle geometrical and dynamic factors on cavitating and turbulent flowin a diesel multi-hole injector nozzle. Int. J. Therm. Sci. 2013, 70, 132–143. [Google Scholar] [CrossRef]

- Vass, S.; Zöldy, M. Detailed Model of a Common Rail Injector. Acta Univ. Sapientiae Electr. Mech. Eng. 2019, 11, 22–33. [Google Scholar] [CrossRef]

- Available online: http://www.lito-technik.hu/en/ldx-4_cr_injector_and_pump_test_bench.html (accessed on 8 June 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).