1. Introduction

As the world’s energy forms become increasingly tense, green energy and low carbon emissions have become the mainstream. Heat pipe heat exchangers (HPHEXs) are increasingly being applied in all walks of life [

1]. A heat pipe (HP) is a highly efficient heat transfer device mainly made of a hermetically sealed evacuated tube containing a small amount of working medium. The phase change process of the medium is used in the HP to transfer a large amount of heat; a large amount of heat can be transferred with a small temperature difference [

2] and is called a thermal superconductor or thermal “short-circuits” [

3].

A heat exchanger is a device that transfers part of the heat of the hot fluid to the cold fluid. The heat pipe heat exchanger (HPHEX) is composed of HPs, which are inserted into two pipelines to transfer heat from the hot fluid to the cold fluid. Compared with traditional heat exchangers, HPHEXs have the advantages of simple structure, excellent heat transfer performance, low cost, easy processing, etc. [

4]. HPHEXs are applied in various industries, such as waste heat recovery [

5,

6], nuclear power plants [

7,

8], HVAC (heating, ventilation and air conditioning systems) [

9], solar energy systems [

10,

11], the automobile industry [

12], CPU cooling [

13], data center cooling [

14], and many more.

Experimental and theoretical studies on HPHEXs were conducted by many scholars [

5,

15,

16]. For the experimental study of HPHEXs, Ma et al. [

5] investigated a HPHEX used for recovering the waste heat in a slag cooling process in the steel industry, and the influence of the change of waste water mass flow rate on the performance of HPHEX was also studied. For the theoretical calculation of HPHEXs, the mathematical model in the moderate-temperature HPHEX system was established by Han et al. [

15] to study the temperature distribution inside and outside each HP. There were also scholars who combined experiments and theories to analyze HPHEXs. Noie [

16] studied the effects of fluid velocity and heat transfer rate on the outlet temperature and the effectiveness of an air-to-air thermosyphon heat exchanger with the

method and experiments were used to verify the model. It is found that neglecting the thermal resistances in the HPs will lead to overestimation of the effectiveness of the HPHEX and underestimation of the outlet temperature of the fluid. In this paper, the phase change heat transfer resistances are considered to improve the accuracy of the current model.

As we all know, the heat transfer process in HPs is involved in the complex phase changes of condensation and evaporation, including pool boiling, nucleate film boiling, and film condensation. Scholars and engineers carried out various types of HPs experiments, and many empirical correlations for the heat transfer of phase changes in evaporators and condensers were put forward [

3,

17,

18,

19,

20,

21,

22]. The empirical correlation of Imura et al. [

19] was summarized for pool boiling in a thermosyphon, and Shiraishi et al. [

20] improved the correlation of Imura et al. [

19] by changing the exponent of the pressure from 0.3 to 0.23. An empirical correlation on the basis of Nusselt’s theory [

21] of predicting film condensation heat transfer of a thermosyphon at low heat fluxes is presented by Jouhara et al. [

3]. The well-known correlation by Chun et al. [

22] was developed to determine the falling film nucleate boiling heat transfer coefficient. In addition, the structural parameters of the HP, the types of working mediums in the pipe, and the filling rate have an impact on heat transfer analysis in the HP. For instance, an experimental investigation of the performance of thermosyphons charged with water and the dielectric heat transfer liquids FC-84, FC-77, and FC-3283 was carried out by Jouhara et al. [

3], and the condensation heat transfer coefficient was corrected under the condition of a small pipe diameter. The mathematical thermal and hydrodynamic model of an axial swallow-tailed micro-grooved HP was designed by Zhang [

23], and the experimental results were used to verify the correctness of the model. At the same time, the multiphase flow heat transfer model of CFD (Computational Fluid Dynamics) software is increasingly being used to simulate the heat transfer of the two-phase changes [

24] in HPs. The two-phase changes and the simultaneous evaporation and condensation phenomena in a thermosyphon were modeled by Alizadehdakhel et al. [

24], and the simulation in a thermosyphon was carried out at different operating conditions. However, in some models, the saturated vapor temperature in the HP was arbitrarily set, which would reduce the calculation accuracy. In this respect, some work needs to be done to fill this gap. In this paper, the saturated vapor temperature inside the HP is obtained by comparing the predicted saturated temperature with the simulated saturated temperature to improve the accuracy of the simulation.

In this paper, a novel mathematical model, including the thermal resistances of evaporation and condensation inside HP, is to be proposed for predicting the heat transfer performance of liquid–liquid HPHEX, and the numerical solution results are to be presented. In order to verify the current model, the existing experimental model is to be computed with the mathematical model, and the predicted heat transfer performance is to be compared with the experimental data. With the current model, the temperature profiles of hot side and cold side of HPHEX and the trend of temperature variation of the working fluid inside HPs are to be predicted. The prediction of the outlet temperature of the hot side and cold side and the temperature of the vapor inside HPs can avoid the failure of the HPs and optimize the heat transfer performance of the HPHEX. In addition, heat transfer enhancement is carried out by changing the diameters, the mass flow rates, and the of the HPs, and the effect on the thermal performance is obtained. Because of the coupling relationship between vapor temperature and the working pressure of HPs, which is of great significance to the optimization of the design, it is necessary to systematically study the shape and temperature variation law of HPs.

2. Mathematical model of HPHEX

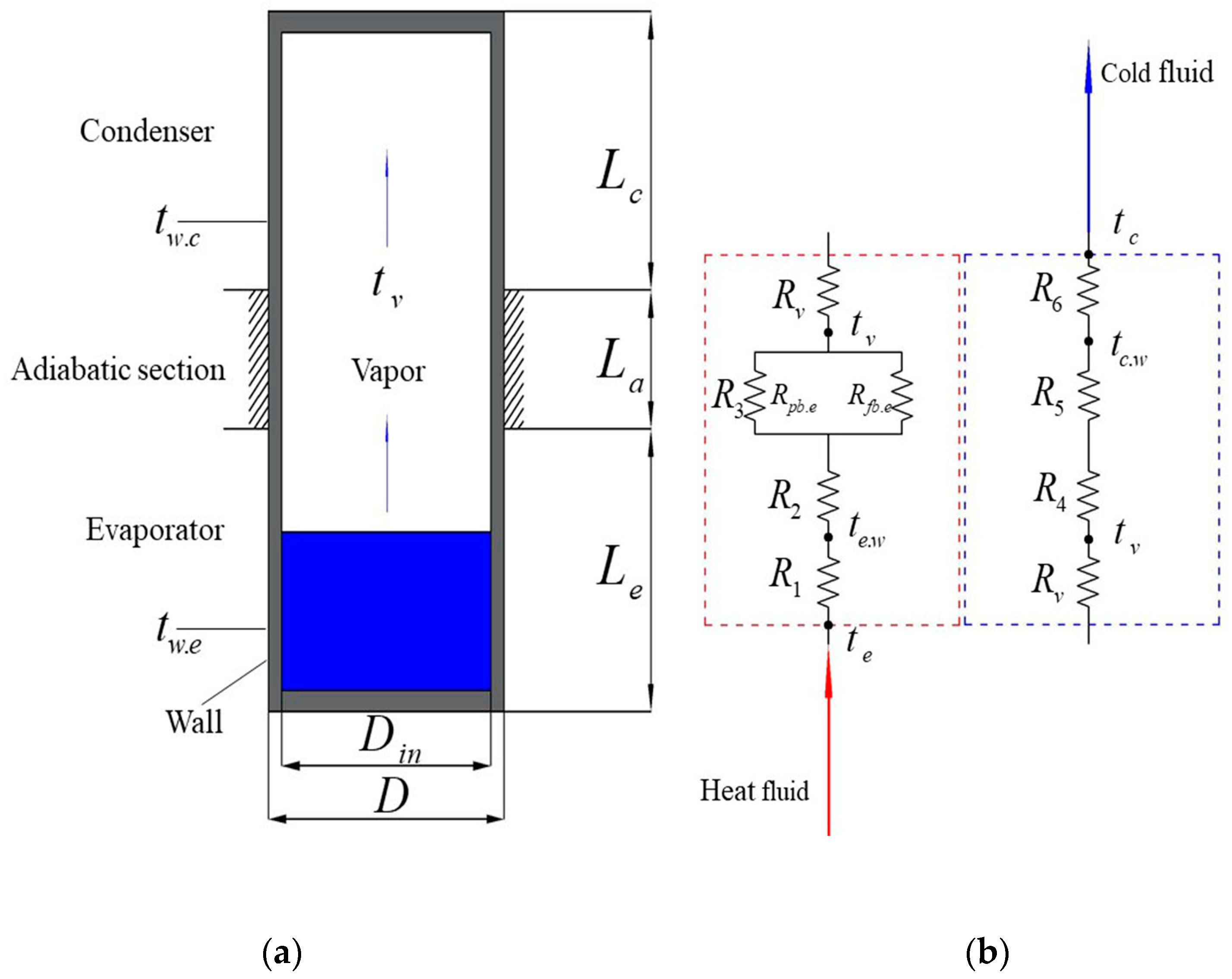

As briefly introduced, the HPs mainly transfer large amounts of heat through the two-phase circulation of the working medium; the specific working principle of the HP can be seen from

Figure 1a. The working medium absorbs heat to evaporate and rises into the condenser, releases heat in the condenser, and condenses down. The mathematical model of HPHEX is mainly formed by coupling the mathematical model of the HPHEX and the mathematical model of the HP. The first model is the evaporation/condensation thermal resistances inside the HP, which is mainly described by the thermal resistance network method. The thermal resistance network can be seen in

Figure 1b. The second model is the convective heat transfer process of the hot/cold fluid outside the HPs flowing through the HPHEX.

Figure 2 shows the working analysis diagram of HPHEX. The HPHEX is divided into the hot side and cold side; the hot side is arranged with hot fluid and the cold side is filled with cold fluid. The cold and hot fluid transfer heat through the thermal coupling of the HPs, and the heat transfer process is completed.

The thermal resistances from hot fluids to cold fluids consist of 7 parts, which can be clearly seen from

Figure 1b. In addition, the total resistance of each HP can be calculated as follows.

where

and

are the evaporator and condenser convection thermal resistances,

and

are the thermal conductivity resistances of evaporator and condenser walls,

and

are evaporation/condensation thermal resistances in the HP, and

is the thermal resistance of vapor pressure drop in HP.

2.1. Thermal Resistance Outside HP

Convection mainly occurs between the evaporator/condenser of the HP and the hot side/cold side external fluids. Convection thermal resistance

and

can be calculated as follows [

25].

where

and

are the average convection heat transfer coefficients. There is a widely applied empirical correlation to calculate the heat transfer coefficient of a fluid flowing around bundle, which was summarized by Zukauskas [

25].

and

are the external heat transfer area of the evaporator and the condenser.

Conduction thermal resistances can be calculated as follows.

where

is outer diameter of HPs and

is inner diameter of the heat pipe.

and

are the length of evaporator and condenser, respectively.

is thermal conductivity of the HP wall material.

2.2. Thermal Resistance Inside HP

Numerical analysis in the HP is based on the internal two-phase heat transfer mechanism. The latent heat of vaporization of the working fluid is used to transfer the heat between the hot and cold fluids. The wall temperature of the evaporator and condenser is considered to be at a uniform temperature. Since the vapor pressure drop along the HP is very small, the vapor temperature in the HP can be considered constant.

Boiling thermal resistance includes pool boiling thermal resistance and falling film thermal resistance; to obtain the boiling resistance, a boiling coefficient must be estimated.

where

and

are the pool boiling heat transfer coefficient and the film boiling heat transfer coefficient, respectively.

stands for the total superficial area of the pool boiling,

.

stands for the total superficial area of the film boiling, and

.

is the filling rate of the HP.

The most well-known correlation for calculating the pool boiling thermal resistance of the HP comes from Shiraish et al. [

20] and can be calculated as follows.

where

and

are liquid and vapor densities,

is the specific heat of the liquid,

is liquid thermal conductivity,

is the dynamic viscosity of the liquid,

is the latent heat of the vaporization,

is gravitational acceleration,

is vapor pressure,

is atmospheric pressure, and

is heat flux to the evaporator.

Film boiling is another important heat transfer method of boiling heat transfer. The film boiling heat transfer is complicated and can be expressed by various correlations [

26].

can be calculated as follows [

26].

where is a dimensionless heat transfer coefficient and

;

is the falling film boiling Reynolds number and

;

is vapor temperature;

is the evaporator wall temperature.

The working medium evaporates from the liquid to the vapor, then rises along the pressure gradient, and its internal pressure will decrease. The thermal resistance due to the decrease in vapor pressure can be calculated as follows.

where

is the specific gas constant,

is the length of the adiabatic section, and

is the dynamic viscosity of the vapor.

When the vapor in the HP comes in contact with the wall surface of the HP where the temperature is lower than the saturation temperature of the vapor, condensation occurs. Condensation thermal resistance can be calculated as follows.

where

is the heat transfer coefficient associated with conduction through the liquid film in the condenser, and

is the internal surface area of the liquid film in the condenser that is equivalent to the internal surface area of the condenser.

The Nusselt analysis for condensation on a vertical flat is frequently used to calculate

[

21], and the Nusselt average heat transfer coefficient can be calculated as follows.

where

is the saturated vapor temperature,

is the wall temperature of the condenser, and

is the length of the condenser.

However, the above correlation cannot calculate the condensation heat transfer coefficient well under many conditions. The reason may be that under different heat flow conditions, liquid droplets adhere to the tube wall of the condensing section when the vapor rises. In experimental research under different conditions, many scholars proposed that the correlations can be simply modified to better match the condensation heat transfer coefficient obtained from the experiment, of which the one proposed by Jouhara et al. [

3] is consistent with the requirements of this paper, depicted as follows.

where

means the

number of condensed film and

,

is the heat transfer rate to the condenser.

2.3. Thermodynamic Calculation of HPHEX

The heat transfer rate in the condenser and evaporator could be calculated as follows.

where

and

are the heat transfer rates of the evaporator and condenser.

and

are the thermal resistances of the evaporator and condenser.

and

are the average temperatures of the condenser and the evaporator.

Under steady-state flow conditions on the cold side and hot side, the assumption of heat leakage can be ignored. The heat transfer rate of the evaporator of the heat exchanger is equal to that of the evaporator.

When the fluid flows through the evaporator and condenser, the hot fluid releases heat and causes the temperature to decrease, and the cold fluid absorbs the heat and causes the temperature to rise. The temperature difference between the hot and cold fluid can be calculated by the vapor temperature; the vapor temperature of the HP is an important factor that determines the thermal resistance in the HP. The physical parameters of the vapor in the tube are all determined by

, and

can be obtained by solving the above three correlations.

where

is the temperature difference between the inlet and outlet of the condenser;

is the temperature difference between the inlet and outlet of the evaporator.

and

are the mass flow of the condenser and evaporator.

and

are the densities of the condenser fluid and evaporator fluid.

and

are the heat capacities of the condenser fluid and evaporator fluid.

2.4. Thermodynamic Analysis

Analyzing the performance of the HPHEX can be expressed by its effectiveness. Effectiveness can be defined as the ratio of the actual heat transfer rate of the HPHEX to its maximum possible heat transfer rate [

26], depicted as follows.

where

is the actual heat transfer rate of the HPHEX;

is the maximum possible heat transfer rate of the HPHEX.

Ignoring the external loss of the HPHEX, the actual heat transfer rate for HPHE (

) can be calculated as follows.

where

is the inlet temperature of the evaporator;

is the outlet temperature of the evaporator.

According to the first law of thermodynamics, the actual heat transfer rate for HPHE (

) can be also calculated as follows.

where

is the outlet temperature of the condenser;

is the inlet temperature of the condenser.

In the heat exchange process of the HPHEX, there is the maximum possible heat transfer rate (

), which can be calculated as follows.

where

is the smaller one of the specific evaporator (

) and condenser (

) heat capacities.

and

.

3. Numerical Calculation and Verification

In the design process of the HPHEX model, the thermal resistance inside and outside the HP are two important aspects, which are accurately calculated to improve the HPHEX model to generate predictions with higher accuracy. The thermal resistance outside the HP is dependent on the convection heat transfer coefficient, which is determined by the qualitative temperature and Reynolds number at the cold side and hot side. The qualitative temperature means the average temperature of the fluid at the inlet and outlet section, which is used to determine the physical parameters of the fluid. The thermal resistance inside the HP is based on evaporation and condensation heat transfer coefficients, which are determined by the temperature difference between the vapor and the outside fluid. The HPHEX model is computed iteratively on the basis of the vapor temperature and the qualitative temperature of the outside fluid.

3.1. Numerical Calculation

The liquid–liquid HPHEX model is a countercurrent heat exchanger; fluids of different temperatures are arranged on the hot side and cold side. Each row of HPs is used as an independent heat exchange unit in the HPHEX model. The structural parameters (geometric model) of the entire model and the inlet temperature of the hot side and cold side are determined.

In the countercurrent HPHEX model, the outlet temperature at the cold side and hot side is unknown. The inlet temperature at the cold side can be calculated by assuming the outlet temperature at the cold side for comparison with the determined inlet temperature at the cold side, and the numerical calculation iterative process of the HPHEX is accomplished. The specific flow chart applied to the calculation is shown in

Figure 3. Then, the temperature change trend of the HPHEX is accurately obtained by assuming the saturated vapor temperature, the outlet temperature at the hot side of the first row, and the inlet temperature at the cold side of the first row. When the HP is working, the working medium vapor and the working fluid in the HP are saturated, and the saturated vapor temperature is the same as the saturated liquid temperature. The results of the comparison calculation and the assumed value are consistent with the predefined difference value, and the first row of HP iteration ends. If not, we re-estimate the vapor saturation temperature, outlet temperature at the hot side, and inlet temperature at the cold side of the first row, and then restart the iterative calculation to obtain a new calculation result. The iterative calculation model of the first row HPs is completed, and the heat transfer calculation model of the second row HPs starts. The outlet temperature of the first row HPs at the hot side is taken as the inlet temperature of the second row HPs at the hot side, and the inlet temperature of the first row HPs at the cold side is taken as the outlet temperature of the second row of HPs at the cold side. After the iterative calculation of the n-th row HPs, the inlet temperature of the n-th row at the cold side is obtained and compared with the determined inlet temperature at the cold side of the HPHEX model. If they are consistent with the predefined difference, the calculation process ends; otherwise, the cold side outlet temperature of the HPs is re-estimated.

The specific flow chart mainly includes 4 loop iterations: the vapor saturation temperature cycle, the temperature distribution cycle at the cold side and hot side, the number of HPs in the HPHEX cycle and the cold side inlet temperature cycle.

is the outlet temperature of the i-th row HPs of the evaporator and is the inlet temperature of the i-th row HPs of the condenser. is the average convection heat transfer coefficient of the i-th row HPs of the condenser and is the average convection heat transfer coefficient of the i-th row HPs of the evaporator. is the saturated vapor temperature of the i-th row HPs and is the calculated saturated vapor temperature of the i-th row HPs. is the relaxation factor. is the calculated inlet temperature of the i-th row HPs of the condenser and is the calculated outlet temperature of the i-th row HPs of the evaporator. is the outlet temperature of the i + 1-th row HPs of the condenser and is the inlet temperature of the i + 1-th row HPs of the evaporator. is the number of rows of HPs and is the inlet temperature of the n-th row HPs of the condenser.

3.2. Model Verification

In order to verify the current model, the liquid–liquid HPHEX established by Ma et al. [

5] is used to validate the current model. Selected experimental data and numerical results are compared to verify the correctness of the model. As shown in

Figure 4a,b, the HPHEX mainly includes 31 HPs with a length of 1 m; the specific structural parameters are shown in

Table 1. The same structure as the experimental model is selected to verify the numerical model, such as the wall thickness and diameter of the HPs, so as to improve the accuracy of the numerical model.

Figure 5a,b summarize the comparison between the heat transfer rate predicted by the current model and the selected experimental data in Ref. [

5] at the cold side inlet mass flow as 2.6 and 2.9 m

3/h, respectively. Whereas the inlet mass flow of the hot side varies from 0.83 to 1.87 m

3/h in the experiment, the inlet mass flow of the hot side varies from 0.83 to 1.9 m

3/h in the simulation. It can be clearly seen from

Figure 5a,b that the results of the current model simulation and the experimental results have a high degree of fit. The maximum deviations are equal to 0.32 and 0.34 kW for the cases with cold fluid inlet mass flow of 2.6 and 2.9 m

3/h, respectively, and the error is within 5%.

In summary, the HPHEX model for iterative calculation of the thermal resistance in the HP has high accuracy, which is consistent with the experimental data. Under the condition of lower mass flow rate at the hot side, the error between the simulation results and the experimental results is large because part of the heat is transferred by radial conduction during the start-up stage of the HPs. However, when the mass flow rate at the hot side increases, the start-up time of the HPs is shortened, the heat transfer in the radial guide decreases, and the error between the simulation results and the experimental results decreases. The accuracy of the HPHEX model is higher under the condition of higher hot side mass flow rate. The novel model can reasonably predict the working performance of the heat exchanger and can be used in the following research.