Abstract

In this article, the authors present methods based on hard coal that may ensure energy security for European Union countries. The research was carried out based on the example of Poland. The main reason for which coal is being gradually withdrawn from the energy mixes in EU countries is its negative impact on the natural environment and the health of citizens and economic factors related to domestic fuel production. The authors propose the creation of energy–chemical clusters as a solution to these problems. It is assumed that the clusters would operate following the principles of the circular economy. We also propose methods for the optimization of the production and transport costs within the cluster. Then, we conduct profitability analysis of the proposed waste management methods. At the level of the designated cluster, using network algorithms enabled us to reduce the transport costs by at least 50%. It is possible to obtain rare earth elements (REEs) worth USD 22,970 from 1 Mg of ash. At the level of the analyzed cluster, this leads to an annual profit of USD 3.5 billion. The profit related to algae production at the cluster level is approximately USD 2.5 bn.

1. Introduction

For each country, one of the fundamental aspects of national security is energy security. Access to energy is crucial for a sound economy and to ensure decent living standards for citizens. In the twenty-first century, countries worldwide are facing new challenges related to ensuring energy security for citizens. This security should be considered in terms of the availability of energy in adequate amounts at a given time; the price of energy, which enables every citizen to use it; and the impact of energy production on the natural environment. Each aspect is undoubtedly a challenge; in the European Union, the ecological aspect of energy production is becoming particularly critical. This is reflected in EU policy [1]. This article presents the case of Poland, a country whose energy mix is mainly based on coal (i.e., in approximately 50%). In electricity production, this share is even more significant and amounts to nearly 75% [2]. The use of coal emits 50% more CO2 into the atmosphere than the use of natural gas and 25% more than the use of crude oil. Therefore, EU countries must comply with the provisions of the Climate Change Convention to limit the share of coal in the energy mix.

The situation is similar in Poland. However, Poland is a special case in comparison to other EU countries. Its coal resources are at the level of 5% of the world’s reserves [2]. Therefore, it is not surprising that coal is the main raw material in the Polish energy industry. Accordingly, removing coal from the Polish mix represents an enormous challenge. Firstly, heat and electricity generation infrastructure is tailored to this fossil fuel; secondly, Poland does not have indigenous sources of energy that might replace coal. Even assuming that it would be possible to obtain a stable supply of renewable energy in the future or to store it at a large scale, renewable energy sources will not replace coal for another 30 years [2]. At present, it is not possible to base the energy sector solely on renewable energy sources (RES), crude oil, or natural gas, especially in electricity [3,4]. Therefore, it is impossible to completely and immediately remove coal from the Polish mix. It should be phased out gradually while increasing the energy mix diversification level [5]. The reason for this is that Poland’s energy security level varies depending on the considered energy carrier. The level of security provided by coal is the highest. This is indicated by energy security indicators such as the Stirling indicator, self-sufficiency indicator, or import dependency ratio [6]. Therefore, in the coming years, coal will continue to guarantee energy security. The mix will mainly evolve towards increasing the share of renewable energy sources [7]. These changes are planned by the State. According to the Polish Energy Policy, until 2040, Polish coal will remain the basis of energy security, while the growing demand will be covered thanks to unconventional energy sources. The share of coal will be around 56% by 2030. In turn, renewable energy should obtain a share of 28.5% by 2040 [8]. The National Plan for Energy and Climate for 2021–2030 states that coal will remain the primary fuel in the electricity sector until 2030 [9]. Moreover, the forecasts included in the “Conclusions From Prognostic Analyzes for the Fuel and Energy Sector” indicate that coal will have the largest share in energy production in Poland. Only after 2040, it will be lower than 50% (in the case of electricity generation). The share of renewable energy sources will increase to approximately 30% in 2030. However, the document again emphasizes the importance of coal, which will remain a crucial energy source, among others, thanks to new electricity generation units in Jaworzno and Opole [10]. The main factors influencing this very structure of the energy mix are, apart from energy security, concerns about the increase in energy prices, the ineffectiveness of past restructuring activities in the energy sector, the need to rely on energy resources from Russia, and insufficient funding for innovative research and technologies [11]. The development of renewable energy sources is also slowed down by the lack of adequate power infrastructure [12], high investment costs, low residual operating costs [13], and the lack of financial support from the State. Therefore, the financial responsibility rests with private investors, which indeed inhibits renewable energy development [14]. Additionally, some legal regulations and complicated, extensive administrative procedures, together with significant investment outlays on RES, hold back their development [15,16,17,18].

For the above reasons, the authors have aimed to develop and present methods that would enable the elimination of the negative aspects of the coal combustion process, which will result in its removal from the energy mix in EU countries in the future.

This applies not only to Poland but also to other EU member states, including Germany. Germany uses mainly lignite, the combustion of which emits greater amounts of greenhouse gases into the atmosphere than the combustion of hard coal. The authors identified two main disadvantages of using indigenous coal: the price of fuel, which is not competitive with imported fuel, and the negative impact of the combustion process on the environment. Therefore, the article presents remedial measures to be taken to eliminate these negative features of using hard coal as a fuel.

For this purpose, the authors proposed a combination of two concepts, i.e., creating clusters and the circular economy, enabling the elimination of the identified disadvantages:

- In terms of fuel and energy competitiveness: methods of designing an energy–chemical cluster and optimizing the cluster’s functioning;

- In terms of environmental protection: clean coal technology (CCT).

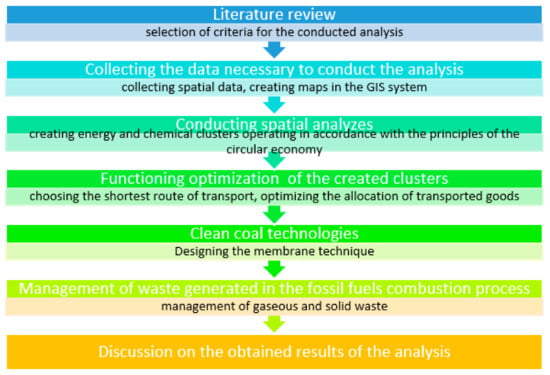

The research began with an analysis of the literature related to the theory of clusters. Then, to create clusters, the tools of the spatial information system were used. The next step was to develop cluster optimization and CCT methods to reduce the emission of pollutants in the coal combustion process. Waste obtained in the incineration process, following the assumptions of the circular economy, was treated as intermediate products, and the methods of their management were proposed. The methodology used in the research is presented in the scheme (Figure 1).

Figure 1.

A scheme showing the methodology used during the research.

The combustion of fossil fuels, in addition to solid waste in the form of fly ash, also produces gases. The most problematic of these gases is CO2, responsible for global warming and climate change [19]. There are many strategies for reducing CO2 emissions, such as sequestration (CCS), including post-combustion, oxyfuel, pre-combustion and carbon capture [20,21]. The separated CO2 can be used in enhanced oil recovery (EOR) operations or to feed algae, phytoplankton, or bacteria, which enables the production of food, nutritional supplements, livestock feed, methane, and lipids that can be converted into biofuel and even an algal plastic called polyethylene furandicarboxylate (PEF) [22]. Because conventional methods used in CO2 separation are energy-consuming and not environmentally friendly [23], membrane technologies are introduced as an alternative. These methods are increasingly used due to their high efficiency, low energy demand, simple design, expandability, and economic and ecological reasons [23,24,25]. Both inorganic and organic membranes are promising in CO2 separation. However, each of the two types of membranes has advantages and disadvantages. Therefore, the best solution is to use hybrid membranes, also known as mixed matrix membranes (MMMs). These membranes are obtained by introducing inorganic additives into a polymer matrix [26,27]. For the production of CO2 selective hybrid membranes, the most common fillers are silica, metal oxides, CNTs, graphene, nanofibers, zeolites, CMS, MOFs, and POFs, which are incorporated into various polymer matrices, such as poly(1-trimethylsilyl-1-propyne) (PTMSP), PEBAX, Matrimid, polydimethylsiloxane (PDMS), poly(vinyl acetate (PVAc), polysulfone (PSF), cellulose acetate (CA), poly(2,6-dimethyl-1,4-phenylene oxide) (PPO), brominated sulfonated poly(2,6-dimethyl-1,4-phenylene oxide) (BSPPO), sulfonated poly(ether ether ketone) (SPEEK), poly(ether-block-amide), Ultrason, polyvinylamine, polymers of intrinsic microporosity (PIM-1), various polyimides, fluorinated polyimides (FPI), and many others [19,20,21,23,24,25,28,29,30,31,32]. This usually leads to the creation of hybrid materials with enhanced gas transport, mechanical, thermal, electric, or magnetic properties, adjusted by control of the composition, content, and morphology of the filler addition, application of different processing techniques, or by applied modification of both phases [33,34].

Considering China’s monopoly, shrinking REE deposits, and their increasing use in modern technologies, there is a need to find alternative sources of these elements. Moreover, conventional REE mining techniques are energy-consuming and generate large amounts of toxic waste [35]. It has been found that fly ash from coal combustion may become an extremely interesting secondary source of REEs. However, even though there are many publications on the disposal of coal fly ash, a small percentage of them treat them as a potential source of REEs [36]. Most of the research focuses on their use in the cement industry, mine reclamation, and agricultural application [36,37], while their use as a potential REE source is a new research area.

Methods used for REE recovery from coal fly ash could be divided into a few groups, such as physical, acid–alkaline leaching, and biological. All these methods have their advantages and disadvantages. The application of physical methods was ineffective for fly ashes [38,39,40]. In comparison, the biological methods based on bioleaching are less efficient but are environmentally friendly [41,42]. The efficiency of the next group, namely acid–alkaline leaching, depends on many factors, such as ash physicochemical characteristics, leaching of other metals, and the influence of the extract composition. They are characterized by the highest efficiency and high consumption of reagents and energy [43,44,45,46]. To modify them, the roasting of coal fly ashes with various reagents, optimization of process parameters, removal of iron oxides, and combination with physical methods have been proposed [38,43]. Because the conventional methods used to recover REEs from obtained extracts have many limitations, some alternative methods based on ionic liquids and membrane techniques were introduced [47]. It was found that the membrane techniques made it possible to achieve REE recovery of over 90%.

On the other hand, introducing ELM and HFLM membranes and their modification (multistage process, complexation with EDTA or DTPA, and introduction of IIPs) made it possible to achieve 100% recovery of REEs [48,49,50,51]. In turn, the use of appropriately selected ionic liquids and multistage extraction allows for the enrichment of REEs above 95% [52,53]. They could be an alternative for conventionally used organic extractants because of their excellent extractability and safety for the natural environment.

Despite the fact that there are ores more abundant in REEs than fly ash around the world, they often contain a small amount of the most valuable elements, such as neodymium or scandium. In turn, this is a sufficient condition to make the process financially attractive [54,55]. It will be profitable to obtain REEs from Polish ashes because they contain a high concentration of the most valuable elements [55].

This has prompted research on technologies for obtaining REEs from ashes, as was the case with, for example, the US Department of Energy [56], the Battelle Memorial Institute, the University of Wyoming, and the Southern Research Institute’s [56] research on several dozen methods of obtaining REEs in Germany [57], or research conducted in Poland by the Central Mining Institute and the Polish Academy of Sciences [58]. Until now, extraction processes were carried out on the bench or pilot scale [56]. In Poland, no extensive research has yet been carried out on fly ash as an REE source [59]. It has been proven that the best results are achieved by the chemical leaching of ashes, which are additionally subjected to chemical treatment [57]. Apart from economic considerations, an important aspect motivating the interest in fly ash as a source of REEs is the ecological factor. This enables the sustainable management of natural resources and waste disposal [59].

2. Materials and Methods

Polish mining and energy industries have had a stable position so far and they comprise individual plants. The focus of their activity is the creation of only one product, i.e., hard coal or electricity. However, concerns about the natural environment and the need to reduce production costs as well as fuel and energy prices are forcing the introduction of modifications to the production organization of these units. This must be considered taking into account creating “energy factories”. In such a type of factory, both the inputs and outputs of the model are considered. The main focus of energy factories is not only the final product as such, as the boundary between intermediate products and finished products is becoming blurred. Applying a holistic approach to an integrated system of using coal, it should be noted that hard coal is an intermediate product that is further processed through subsequent links in the distribution chain.

Additionally, the generated energy is also not the final product in this supply chain because it is created in conjunction with other products (waste) that maximize the value of intermediates such as coal or electricity. In the current market, and considering the current political conditions, the circular economy is a very effective organizational solution that enables the use of waste [60,61]. This is consistent with the provisions of the European Union and, at the same time, shall enable the adoption of environmentally safe solutions. The basic ideas of the circular economy concept appeared as early as in the 1960s [62]. The European Union emphasizes implementing this type of economy wherever possible. The resolution of the European Parliament draws attention to the advantages of the circular economy and indicates the need for creating appropriate legal regulations and administrative conditions to facilitate its implementation [63]. The resolution also indicates the importance of using all kinds of waste, especially net greenhouse gas emissions for the environment.

The European Green Deal Communication presents an action plan for the efficient use of resources thanks to the circular economy and assumes that, by 2050, the EU economy will be characterized by zero greenhouse gas emissions [64]. The circular economy is a tool for the European Union that will enable the transition towards a competitive and low-emission economy in all Member States. According to the European Commission definition, the circular economy is an economy in which the value of products, materials, and resources is maintained for as long as possible and the generation of waste is kept to a minimum [65]. As a result, the processed resources are used as much as possible, leading to an increase in resource efficiency. The waste is recycled, which brings extra added value. Methods of creating clusters and their optimization, including the principles of the circular economy, are presented below.

2.1. Cluster Design Methods

The authors of the paper have proposed both organizational and technical methods for building and optimizing integrated systems to produce energy and co-products based on fossil fuels. The authors proposed the creation of energy and chemical clusters [66,67]. The idea of creating clusters in the industry was disseminated in the 1990s by Michael Porter [68]. Since then, they have been successfully used in many industries worldwide [69,70,71,72]. In Poland, this idea has evolved slowly since 2004, i.e., when Poland joined the European Union [73]. Regarding the creation of energy clusters, the first serious steps in this direction were taken in 2016. This was related to developing the definition of an energy cluster included in the Law on Renewable Energy Sources [74]. Clusters created in Poland are mainly based on renewable energy sources and on dispersed energy generation [75].

The EU promotes their development, and economic efficiency is not always the main priority. Therefore, it can be concluded that these are clusters created on a top-down basis, i.e., the stimuli to create such structures come from local government units. On the other hand, the clusters proposed by the authors are a bottom-up initiative and their construction should be carried out by enterprises operating in the energy market. The clusters proposed by the authors may enhance competition in the market, reduce the costs of obtaining fuel and energy, and offer added value obtained from the use of waste from the fossil fuel combustion process.

The cluster consists of such facilities as mines, power plants, combined heat and power plants, chemical plants, photovoltaic farms, and biomass-producing units. The clusters were built in the geographical area of the Silesian Voivodeship. It was determined mainly by the concentration of hard coal deposits in this area. Cooperation of the entities included in the cluster should ensure an increase in the effectiveness of their operation.

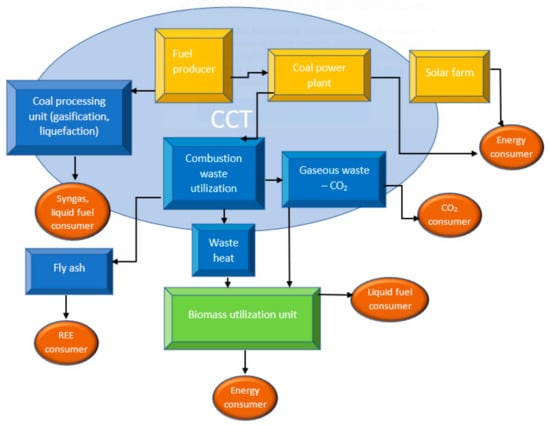

The distribution chain of products and intermediate products within the energy–chemical cluster is presented in Figure 2. It is started by a fuel producer or supplier. The fuel can be converted, for example, into liquid fuels or syngas, electricity, or heat. Finished products are delivered to the recipients. Heat and electricity are generated using clean coal technologies, i.e., the membrane technology proposed by the authors (described later in the paper). Then, the production waste from the process is transferred along the chain to the next stage, where it is reused as raw material for further processing. The gases separated in the membrane modules, such as CO2, are the basis for producing usable chemicals or in biomass production. In the cultivation of biomass (e.g., algae), waste heat from power plants and heating plants is also used, which speeds up the photosynthesis process. Biomass can be delivered to the recipient, used in the co-combustion of fuels, or processed into liquid fuels. On the other hand, combustion solid waste, such as coal fly ash (CFA), can be a source of valuable elements, such as rare earth metals.

Figure 2.

A scheme of operation of the proposed cluster.

Depending on the type of waste, its sale process will vary. CFA recycling scenarios have been developed and described in the literature. They indicate that the waste may be used within the cluster or may be of interest to a third party [76]. The products that will be created thanks to the waste management of the coal combustion process are:

CO2—will be used within the cluster for the production of biomass;

Sulfuric and nitric acids—will be used within the cluster to obtain REEs;

Fly ash—by keeping waste in a closed circuit, the amount of waste will be reduced, and its storage costs will be lowered. The developed CFA recycling scenarios also assume that part of the fly ash may be sold to companies interested in using it, e.g., to produce building materials [76]. The product will be delivered to the recipient, e.g., via the manufacturer’s car transport. This type of sale is carried out by the Tauron Group using an internet service [77]. The remainder of the ashes will be used for the production of REEs, during the sale of which an internet service will also be used. Fly ash for processing within the cluster can be transported in the same way as coal. The use of network algorithms proposed in the article will also make it possible to optimize the route of ash transmission from the power plant to the chemical unit.

The clusters were designed using the Quantum GIS 3.10.2 spatial information system. The input data were partially obtained from the OSM website and geoportal.gov.pl, while the authors created other vector layers that were used during the analysis. For this purpose, spatial information systems tools were used, such as geocoding, heat map creation, attribute-based clustering, and network analysis.

Geocoding is a very useful business analytics tool. It involves assigning geographic coordinates to a postal address. Thanks to this, spatial data, which were subjected to further analysis, were obtained [78,79].

Heat maps are used in many fields of science [80,81,82]. In GIS, a map is created by adding a color gradient to an object with a specified radius. This gradient is determined on the basis of a given attribute, e.g., the frequency of a given phenomenon in a specific area. Therefore, the heat map shows the locations with the highest density of objects presented on the map [83].

For attribute-based clustering, the k-means clustering method was used. It consists in adjusting the classification of objects and determining the cluster centroids. The algorithm selects the clusters in individual iterations so that the position of the centroids remains constant in the following steps. The stability of the centroid position is determined based on the Euclidean distance [84,85,86,87].

Network analysis performed for the conducted research was carried out using the Dijkstra algorithm. This algorithm is based on graph theory. The cost attribute is assigned to the edges of the graph, which, for the analysis performed, was the distance covered on a given path. The input data for the analysis were the road network in the studied area. The algorithm determined the shortest path connecting the indicated starting point and endpoint [88].

The authors created a point layer containing the coordinates of all analyzed objects. Based on this, the thermal map and clusters were determined in further steps.

2.2. Cluster Functioning Optimization Methods

The transportation problem (TP) is one of the problems falling within the scope of integer programming. The transport algorithm makes it possible to optimize the transport of goods from the producer to the recipient. Thanks to this, it is possible to reduce the costs of transport. The mathematical model of the classical TP can be described by the following formulas [89,90]:

where:

xij—the volume of coal transported from the i-mine to the j-power plant;

cij—the unit cost of coal transported from the i-mine to the j-th power plant;

ai—the supply limit of the i-th mine;

bj—the demand of the j-th power plant;

m—the number of mines;

n—the number of recipients.

The transport issue can occur in two varieties:

and

If the demand and the supply are the same, it is a balanced problem. Otherwise, it is an unbalanced transport problem.

2.3. Clean Coal Technologies (CCT)

The authors conduct research on clean coal technology that would enable the separation of the mixture of gases generated during the combustion of fossil fuels [91]. This especially applies to the separation of gases such as SOX, CO2, or NOX. Thanks to this, the problem of the emission of harmful substances would be eliminated. Additionally, the technology proposed by the authors enables the capture and management of gaseous waste generated during the fossil fuel combustion process.

Clean coal technologies (CCT) are all technological solutions designed to increase the efficiency of the combustion, processing, and extraction of hard coal. As the level of greenhouse gas emissions is constantly increasing worldwide, it is necessary to use technologies that will reduce the negative impact on the natural environment. The authors used membrane techniques for this purpose. These were chosen due to their numerous advantages—first of all, their high energy efficiency and mechanical, thermal, and chemical resistance. Membrane techniques are also much more financially attractive than competing methods [92,93].

The fundamental problem related to the research on finding effective membranes is identifying their proper composition, which would guarantee optimization of their parameters, mainly selectivity and permeability. Additionally, the membranes must be stable and adapted to the conditions of the fuel combustion process. Therefore, the authors proposed using hybrid membranes, also called mixed matrix membranes (MMMs) [94,95,96]. Hybrid membranes allow us to take advantage of a polymer matrix and inorganic additives. The conducted research made it possible to design a membrane module. A module consists of membranes whose type will be selected depending on the composition of the separated gas mixture.

The module may consist of several types of membranes. Additionally, a dust separator will be installed in it, whose purpose will be the protection of the membranes from structural damage caused by solid particles, which are emitted from the furnace during fuel combustion. The feed will first be led through the separator. After pre-cleaning, it will be directed to the membrane module, where the individual gases are separated. Carbon dioxide constitutes 80% of these gases. The rest are, among others, sulfur and nitrogen oxides. The separated gases can be stored as retentate, while the cleaned air can be discharged back into the atmosphere.

The green chemistry concept can be implemented while producing the proposed membranes for flue gas treatment and REE recovery. During the production of membranes, it is also possible to use, for example, biodegradable biopolymers and ionic liquids, which have pro-ecological properties [47,97,98,99,100,101,102,103,104,105].

2.4. Conventional Fuel Combustion Waste Management

The waste generated during the combustion of fossil fuels can be separated into solid and gaseous waste. In line with the principles of the circular economy, these wastes should be used to produce value-added products for the energy generation process. Therefore, the authors proposed methods that allow, firstly, the generation of financial benefits resulting from their utilization and, secondly, the elimination of the waste storage problem. It should be noted that the necessity to store waste clearly creates a cost and has a negative impact on the natural environment.

The obtained gases, which are waste from the combustion process, can be utilized. However, in line with the circular economy principles, it has been assumed that they can be reused. For example, carbon dioxide is used during gas or oil production [106,107,108,109]. It is a factor that stimulates the bed to displace volumes of fuel. After the crude oil has been exploited, CO2 will be stored in depleted deposits.

Carbon dioxide is also used in phytoplankton or algae production, as it is an indispensable component of the photosynthesis process. Algae biomass is a raw material used to produce biofuels. It can also be used during co-combustion with conventional fuels. Algae are used in agriculture as fodder and fertilizers rich in calcium, magnesium, and phosphorus [22]. A biomass-producing and burning unit has been installed near the Jaworzno III Power Plant as a part of the designed cluster. It was assumed that it would produce biomass in the form of algae. To ensure algae’s rapid growth, their cultivation must take place under appropriate conditions. These could be provided by CO2 delivered via a pipeline directly from the power plant and waste heat generated during electricity production.

Solid waste from the combustion process is currently used in the construction industry, in cement production, for filling voids in the rock mass, etc. Fly ash is also successfully used all over the world in many industries, inter alia, in the cement industry [110,111], in the production of synthetic zeolites [112,113,114], in agricultural applications, and in mine reclamation [37,38]. These methods of fly ash usage eliminate the need for waste storage and thus prevent the migration of harmful substances into soil and water [115]. The use of fly ash in the construction industry is common. In Poland, it can be used in construction if it complies with the developed standards, e.g., PN-EN 450-1: 2012, PN-EN 206: 2014.

As mentioned, the most significant problem is that fly ash is produced in huge quantities and must be stored. The authors also proposed the application of these wastes in the production of rare earth elements (REEs) [112,116].

Fly ash can therefore be a source of obtaining REEs. This kind of extraction process is considered to be less intensive than mining raw products. Additionally, the composition of fly ash contains many REEs, while most mines deliver only several elements. As a result, obtaining REEs from fly ash may be less harmful to the natural environment [117,118,119]. Therefore, obtaining REEs from fly ash has attracted interest among many researchers and companies. For example, the Neumann Systems Group announced that their method made it possible to obtain 60% of REEs from the tested samples [112].

3. Results and Discussion

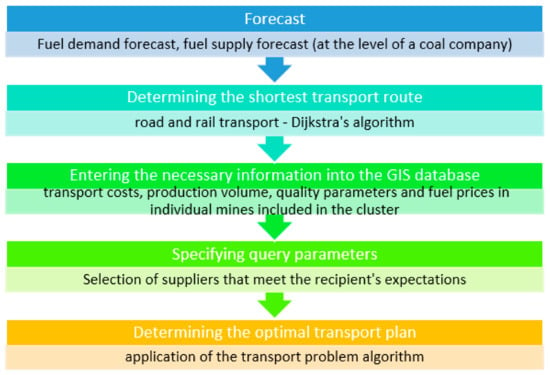

It was assumed that the functioning of the proposed clusters would be based on the principles of the circular economy. For this reason, the clusters could produce fuel, generate energy, but also recycle the waste generated in the combustion process to produce additional products. The analysis was limited to the geographical area of the Silesian Province. The province was chosen as energy infrastructure, chemical plants, and hard coal producers are located in the described area and are connected by a well-developed transportation network. The high level of industrialization of the Silesian Voivodeship enables access to expertise, a qualified workforce, and specialists. There are also universities and research centers in the Silesian Province. These are the primary conditions for building clusters. The production and transport plan within the cluster is presented in

Figure 3.

Figure 3.

Planning of fuel production and its transport in the area of clusters.

The following two sections of the chapter present the clusters’ creation and the optimization methodology as well as the financial analysis of the proposed waste management solutions.

3.1. Creating Energy–Chemical Clusters

Planning of fuel production should begin with preparing forecasts of customer demand and the level of production of coal companies. In their numerous papers, the authors have proposed reliable mathematical models that can be used for this purpose [120,121,122].

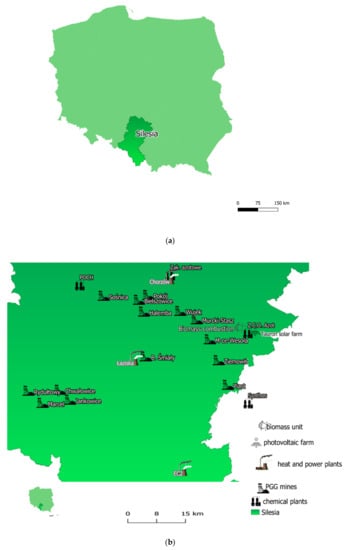

The first step in the analysis was to collect the data necessary to build the energy and chemical clusters. For this purpose, the administrative map of the provinces in Poland was obtained [123]. It was also necessary to obtain maps of roads and railway routes in Poland from the Open Street Map website [124]. Data that did not fall within the analyzed area were eliminated with the geoprocessing tools of the QGIS system. Thanks to this, it was possible to speed up the performed analysis. The geocoding process was carried out on the basis of the created maps. This made it possible to build a vector layer, as presented in Figure 4. The layer was called “Objects” and was used in further stages of the analysis. The map contains all the objects that are to be included in the created clusters. In addition, to facilitate visual analysis, individual objects were assigned Scalable Vector Graphics that characterized them.

Figure 4.

Vector map of Poland with the analyzed area (a), vector layer containing the objects to be clustered (b).

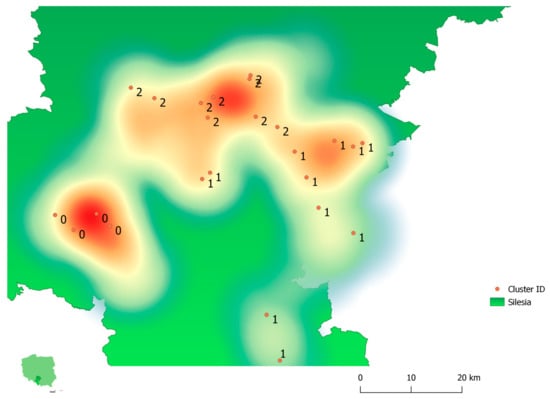

In the next step, the cluster map was constructed on the basis of the vector layer. This helped to identify hotspots and a group of points was obtained during geocoding. The QGIS plug-in uses Kernel Density Estimation for this purpose. The Kernel shows how the influence of a point decreases as the distance from it increases. Thanks to the conducted analysis, three clusters of points were initially identified (Figure 5).

Figure 5.

Thermal map based on the “Objects” layer.

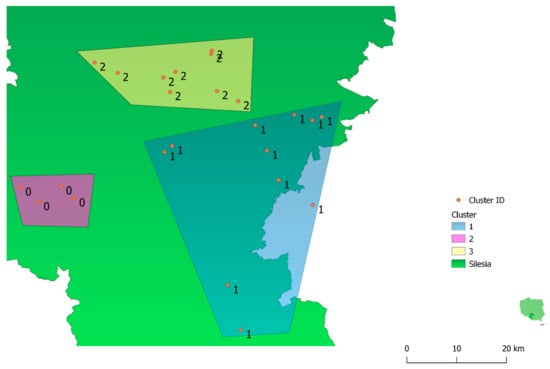

Clusters were selected using attribute-based clustering. The coordinates of the analyzed objects were input as attributes for the analysis. It was assumed that the phenomenon of spatial autocorrelation occurs between the individual n elements. This means that geographically close objects are more similar to each other than those that are spatially distant. The similarity of individual objects was determined based on the distance between them. For this purpose, the Euclidean measure was used, which is the distance between two points in the x-space. The determined clusters are shown in

Figure 6.

Figure 6.

Designated clusters.

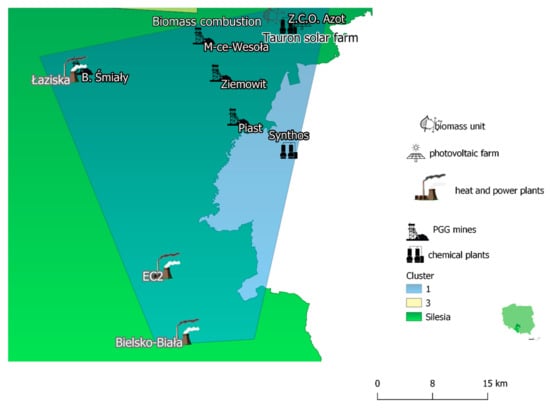

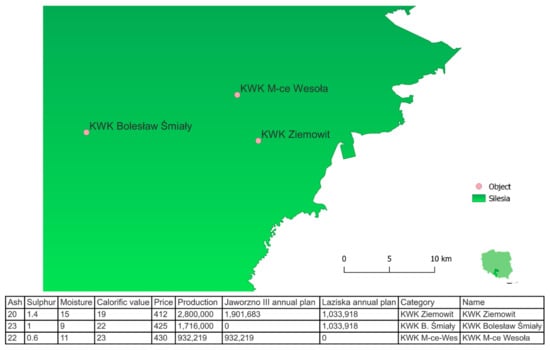

Cluster 1 was selected for further analysis. The operation of the proposed methods was presented based on this example (Figure 7). The analyzed cluster included the following facilities: Jaworzno III and Łaziska Power Plants, Ziemowit, Mysłowice-Wesoła, Piast and Bolesław Śmiały mines, EC2 and Bielsko-Biała Power Plants, Synthos chemical plant, and Tauron Solar Farm. In addition to these existing facilities, a biomass production and combustion unit was introduced.

Figure 7.

Objects included in cluster 1.

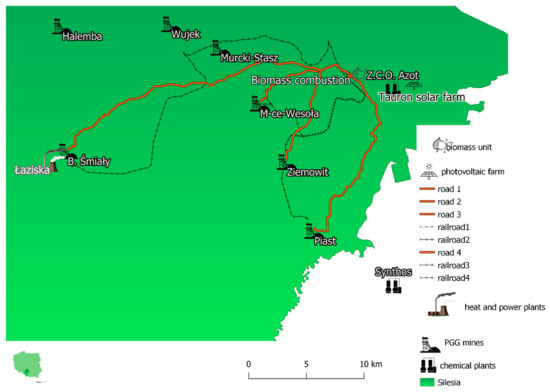

After creating the cluster, a network analysis was performed. This made it possible to determine the shortest routes connecting individual cluster objects. Maps of the road network in the Upper Silesia area were used as input data. The authors applied the Dijkstra algorithm. The shortest paths were determined using the length of the road in km as the selection criterion. There was also the option to select the travel time on a given path as a decision parameter. The algorithm could choose optimal routes and thus the network of connections between the mines and power plants was determined. Two networks were created separately for rail and car connections. The results of the analysis are presented in Figure 8.

Figure 8.

The network of railway and car connections within cluster 1.

Table 1.

Designated distances between objects—rail transport.

Table 2.

Designated distances between objects—road transport.

The created database stored in the QGIS program contains data on the chemical composition of the fuel, its price, and the volume of production for each of the mines included in cluster 1. This enables the preliminary selection of mines following the criteria provided by fuel recipients. An exemplary selection was made by imposing restrictions on calorific value and fuel moisture on the records stored in the database. The database was a reference database. Therefore, its search and filtering were performed in SQL. The entire structure of the used query sent to the database was as follows:

- SELECT Mine

- FROM Tab_atryb_21

- WHERE “Moisture” < 19 AND “Calorific value” ≥ 19

The inquiry made it possible to reject those producers whose fuel did not meet the recipient’s expectations.

The next step in the analysis was to build a mathematical model of the transport issue. On the basis of data from the websites of the fuel producers (PGG) and the electricity producer (Tauron), it was determined that the constructed transport issue would be unbalanced. The volume of fuel producers’ supply included in the cluster exceeded the volume of power plants’ demand. Therefore, the surplus fuel had to be sent to other recipients, e.g., heat and power plants, authorized sellers, or be exported. Since the transport issue is a linear programming algorithm, the simplex method was used to solve it.

The limiting conditions were adjusted to the relationship between the volume of demand and supply. It was assumed that the demand would be fully covered while the supply would be greater than or equal to the demand. The objective function is the sum of the products of transport costs and transport amount on a given route. The function aims at a minimum. Based on the length of the routes and DB Cargo price lists [125], the cost of rail transport on the designated routes was determined. In the case of road transport, the lowest rate was assumed for the coal delivery service of Katowicki Węgiel [126]. The results of the analysis are presented in Table 3 and Table 4. We determined the amount of coal to be transferred from the producer to the recipient, thus reducing the transport costs.

Table 3.

Optimization results for road transport.

Table 4.

Optimization results for rail transport.

Table 5 presents the analysis results considering limitations regarding customers’ requirements of fuel quality following the SELECT query presented above. As a result of sending the query to the database, one of the mines that did not meet the selection criteria was eliminated. Therefore, an additional restriction was introduced to the transport issue, eliminating this mine from the transport plan. The presented example concerns rail transport.

Table 5.

Optimization results for rail transport with additional constraints.

The information obtained with respect to the optimal fuel transport plan within the cluster was entered into the database in order to create an annual transport plan (Figure 9).

Figure 9.

The database of the analyzed layer subjected to filtering.

According to the data of the Polish Central Statistical Office, 95 million Mg of coal was transported by rail transport in 2018, while approximately 28 million Mg of coal was transported by road. The average lengths of the transport routes were 158 km and 132 km, respectively. Therefore, if the rate per ton-kilometer of coal was set at a minimum level of PLN 1, the annual costs of coal transport would amount to approximately PLN 15 billion for rail transport and almost PLN 4 billion for road transport. Due to such considerable costs, their reduction, even to a minimal extent, will bring significant financial benefits (Table 6).

Table 6.

Comparison of the costs of road and rail transport.

3.2. CO2 and REE Management

Annually, approximately 320 million Mg of CO2 is produced in Poland [2], almost half of which (138 million Mg) is emitted during the combustion of hard coal [127]. The production of 1 Mg of algae needs 1.78 Mg CO2 [128]. If the CO2 generated during the combustion of hard coal was used to produce biomass, 77 million tons of algae could be obtained annually.

Such management of CO2 brings a dual benefit. First, there is no need to purchase CO2 for algae production. The cost of Mg of CO2 is approximately USD 25/Mg [129], which translates into savings of USD 3 billion. In addition, this procedure allows us to avoid CO2 emission payments. The cost of emission is USD 67/Mg CO2 [130]. Considering the rates for the emission of one Mg, this gives savings of USD 9 billion. The cost of producing 1 kg of algae is USD 0.67 [131]. The total production volume adopted in the analysis amounts to USD 51.5 billion, while the total savings amount to USD 12.7 billion. The average market price per Mg of algae was assumed to be USD 1300 [132]. The revenue from the sale of algae is USD 104.74 billion. Profit after savings is USD 65.8 billion nationwide per year. A similar analysis was performed for the Jaworzno III Power Plant, a part of cluster 1, proposed in this paper. The results of the financial analysis are presented in Table 7 and Table 8.

Table 7.

Economic analysis of the profitability of algae cultivation on a national scale.

Table 8.

Economic analysis of the profitability of algae cultivation within cluster 1.

Therefore, it should be noted that this type of industrial undertaking brings enormous financial benefits, both on a national scale and within the analyzed cluster. In the initial phase, the production of algae will require investments. However, the authors indicated a potential source of funding. Funds can be obtained based on the shown savings, i.e., the lack of necessity to pay fees for CO2 emission payments. In addition, power plants such as Jaworzno will not have to allocate funds to the purchase of CO2. In the case of REE production, an analysis of the project profitability was also carried out based on a literature study. It was established that 12 million Mg of fly ash is produced annually in Poland. Based on the analyses of ash composition [113] and the prices of elements from the end of 2020 [133], it was determined that from 1 Mg of ash, it is possible to obtain REEs worth USD 22,970. The purchase cost of Mg of fly ash is approximately USD 13 [133]. Therefore, it is possible to obtain revenues of USD 275 billion. The calculations were based on the average operating costs of obtaining REEs from various sources [134]. This cost is USD 15/kg. Including these, the profit is USD 94.6 billion nationwide. A similar analysis was performed for cluster 1.

Additionally, in this case, the necessity to purchase ashes was eliminated. It was calculated that the profit is USD 3.5 billion. The necessary investments will also be inevitable in the construction process of an REE recovery facility. However, the storage of ashes also involves fees that must be paid throughout the entire storage period. Therefore, energy companies could allocate these funds to make the necessary investments. The results are presented in Table 9 and Table 10.

Table 9.

Economic analysis of the profitability of REE recovery in Poland.

Table 10.

Economic analysis of the profitability of REE recovery within a cluster 1.

Currently, the demand for energy resources is growing worldwide. Their availability is varied, and the resources are limited. Therefore, it is necessary to search for solutions enabling their most effective use and, secondly, the use of waste generated during raw materials processing. Here, the solution is to apply a circular economy model to the mining and energy industries. To meet this challenge and the European Union requirements, it is necessary to develop appropriate technologies and organizational methods. They will allow for:

- A reduction in raw material consumption;

- A reduction in the emissions level;

- Use of the waste’s potential and, on the basis, the generation of added value;

- Optimization of cooperation between objects included in the cluster.

The emission of gases and dust in Poland has a negative impact on the life and health of citizens and on the flora and fauna of the country. Therefore, importantly, the presented technologies will also reduce the negative impact of the energy industry on the natural environment. Since energy security is of crucial importance for the development and security of countries and their citizens, it is necessary to ensure it at an appropriate level. Poland’s energy security is based on coal. The combustion of this fuel is becoming increasingly controversial. The reason for this is the emission of pollutants in the combustion process and the price of Polish fuel. For the next several dozen years, Poland will not be able to build an energy potential that meets the needs of consumers based on a different energy source. Therefore, the authors proposed methods to eliminate emissions and allow coal and energy companies to survive in a competitive market.

4. Conclusions

The article presents methods for ensuring the energy security of EU countries based on coal. The research was conducted and presented based on the example of Poland. The authors made such a choice due to the composition of the country’s energy mix. The methods were classified into two categories: organizational and technological. The organizational methods presented in the article are, above all, combining the units of the fuel and energy industry into clusters. Such a solution will make it possible to reduce the operating costs of individual cluster facilities in many respects. The authors presented some of them, such as optimization of transport in the cluster area. This solution alone would result in savings of PLN 15 million per cluster.

The annual costs of rail coal transport in Poland reach PLN 15 billion, and PLN 4 billion in the case of road transport. Therefore, reducing them even by 1% brings savings of PLN 200 million. Additionally, and importantly, the organizational methods proposed by the authors do not require any investments. They can be applied within a few months directly to cluster objects in their present form. This only requires the implementation of appropriate regulations and organizational procedures. The second category, i.e., technological solutions, will, of course, require financial outlays. However, the proposed Clean Coal Technology can eliminate the negative features of the solutions used so far. Firstly, it does not require interference with the combustion process itself and does not burden it with additional energy consumption. Moreover, it can be used in the case of already existing energy infrastructure.

Additionally, it is suitable for both industrial and household power engineering. The obtained by-products are no longer treated as waste but are processed as an intermediate product. This applies to both solid waste in the form of fly ashes and gaseous waste. The authors proposed using ashes to obtain REEs and gaseous waste to produce biomass used within the cluster for co-combustion. The financial analysis showed that the investments made to produce the goods mentioned above, i.e., biomass and REEs, will be economically viable. Savings associated with such waste management may constitute a source of financing the necessary investments.

It has been estimated that the solutions proposed by the authors will bring substantial financial benefits. At the level of the designated cluster, the use of network algorithms will allow for a reduction in transport costs by at least 50%. From 1 Mg of ash, it is possible to obtain REEs worth USD 22,970. At the level of the analyzed cluster, this would provide an annual profit of USD 3.5 bn. The profit generated in connection with algae production at the cluster level would be approximately USD 2.5 bn.

Author Contributions

Conceptualization, A.R. (Aleksandra Rybak) and A.R. (Aurelia Rybak); Methodology, A.R. (Aleksandra Rybak) and A.R. (Aurelia Rybak); Software, A.R. (Aleksandra Rybak) and A.R. (Aurelia Rybak); Writing—Original Draft Preparation, A.R. (Aleksandra Rybak) and A.R. (Aurelia Rybak). Both authors have read and agreed to the published version of the manuscript.

Funding

The work was elaborated in the frames of the statutory research of Silesian University of Technology number 06/010/BK_21/0046.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the extremely large size.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Communication from The Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions Next Steps for a Sustainable European Future European action for sustainability. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2016%3A739%3AFIN (accessed on 5 May 2021).

- BP Statistical Review of World Energy. Available online: http://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 10 May 2021).

- Kruyt, B.; van Vuuren, D.P.; de Vries, H.J.M.; Groenenberg, H. Indicators for energy security. Energy Policy 2009, 37, 2166–2181. [Google Scholar] [CrossRef]

- Nyga-Łukaszewska, H.; Aruga, K.; Stala-Szlugaj, K. Energy Security of Poland and Coal Supply: Price Analysis. Sustainability 2020, 12, 2541. [Google Scholar] [CrossRef] [Green Version]

- Samson, Z. Poland’s Energy Security Strategy. Pol. Political Sci. Yearb. 2019, 48, 489–499. [Google Scholar] [CrossRef]

- Rybak, A. Poland’s Energy Mix and Energy Security of the Country. World Sci. News 2019, 128, 402–415. [Google Scholar]

- Szczerbowski, R.; Kornobis, D. The proposal of an energy mix in the context of changes in Poland’s energy policy. Polityka Energetyczna Energy Policy J. 2019, 22, 5–18. [Google Scholar] [CrossRef]

- Ministry of Energy (ME). Energy Policy of Poland until 2040 v. 1.2. 2018. (In Polish). Available online: https://www.gov.pl/documents/33372/436746/PEP2040_projekt_v12_2018-11-23.pdf/ee3374f4-10c3-5ad8-1843-f58dae119936 (accessed on 26 August 2021).

- Ministry of Energy (ME). National Plan for Energy and Climate for 2021–2030. Annex 2–Impact Assessment of Planned Policies and Measures; 2019. (In Polish). Available online: https://www.gov.pl/web/klimat/krajowy-plan-na-rzecz-energii-i-klimatu (accessed on 26 August 2021).

- Ministry of Energy (ME). Conclusions from Prognostic Analyzes for the Fuel and Energy Sector. 2019; (In Polish). Available online: https://www.gov.pl/web/aktywa-panstwowe/zaktualizowany-projekt-polityki-energetycznej-polski-do-2040-r (accessed on 26 August 2021).

- Brauers, H.; Oei, P. The political economy of coal in Poland: Drivers and barriers for a shift away from fossil fuels. Energy Policy 2020, 144, 111621. [Google Scholar] [CrossRef]

- Szabo, J.; Fabok, M. Infrastructures and state-building: Comparing the energy politics of the European Commission with the governments of Hungary and Poland. Energy Policy 2020, 138, 111253. [Google Scholar] [CrossRef]

- Hirt, L.; Steckel, J.C. The role of capital costs in decarbonizing the electricity sector. Environ. Res. Lett. 2016, 11, 114010. [Google Scholar] [CrossRef]

- EC. Communication from the Commission to the European Parliament EC the European Council, the Council. 2019. Available online: https://ec.europa.eu/info/sites/info/files/european-green-deal-communication_en.pdf (accessed on 26 August 2021).

- Ogarek, P. Przyszłość odnawialnych źródeł energii w Polsce w oparciu o Politykę energetyczną Polski do 2040 roku (The future of renewable energy sources in Poland based on Poland’s Energy Policy until 2040). In Bezpieczeństwo Energetyczne Polski i Europy Uwarunkowania—Wyzwania—Innowacje; Instytut Polityki Energetycznej im. I. Łukasiewicza: Rzeszów, Poland, 2019; pp. 98–119. [Google Scholar]

- Hajto, M.; Cichocki, Z.; Bidłasik, M.; Borzyszkowski, J.; Kuśmierz, A. Constraints on Development of Wind Energy in Poland due to Environmental Objectives. Is There Space in Poland for Wind Farm Siting? Environ. Manag. 2019, 59, 204–217. [Google Scholar] [CrossRef] [Green Version]

- Gnatowska, R.; Moryń-Kucharczyk, E. Current status of wind energy policy in Poland. Renew. Energy 2020, 135, 232–237. [Google Scholar] [CrossRef]

- Przybylska-Czastkiewicz, M. Prawne uwarunkowania rozwoju energetyki odnawialnej w Polsce po 2015 r. (Legal conditions for the development of renewable energy in Poland after 2015). Polityka Energetyczna Energy Policy J. 2017, 20, 103–116. [Google Scholar]

- Ahmadi, M.; Janakiram, S.; Dai, Z.; Ansaloni, L.; Deng, L. Performance of Mixed Matrix Membranes Containing Porous Two-Dimensional (2D) and Three-Dimensional (3D) Fillers for CO2 Separation. Membranes 2018, 8, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bryan, N.; Lasseuguette, E.; van Dalen, M.; Permogorov, N.; Amieiro, A.; Brandani, S.; Ferrari, M.C. Development of mixed matrix membranes containing zeolites for post-combustion carbon capture. Energy Procedia 2014, 63, 160–166. [Google Scholar] [CrossRef] [Green Version]

- Sarfraz, M.; Ba-Shammakh, M. Water-stable ZIF-300/Ultrason® mixed-matrix membranes for selective CO2 capture from humid postcombustion flue gas. Chin. J. Chem. Eng. 2018, 26, 1012. [Google Scholar] [CrossRef]

- Kokkoli, A.; Zhan, Y.; Angelidaki, I. Microbial electrochemical separation of CO2 for biogas upgrading. Bioresour. Technol. 2018, 247, 380–386. [Google Scholar] [CrossRef] [Green Version]

- Kusworo, T.D.; Budiyono, A.F.; Ismail, A.; Mustafa, A. Fabrication and Characterization of Polyimide-CNTs hybrid membrane to enhance high performance CO2 separation. Int. J. Sci. Eng. 2015, 8, 115–119. [Google Scholar] [CrossRef]

- Hasebe, S.; Aoyama, S.; Tanaka, M.; Kawakami, H. CO2 separation of polymer membranes containing silica nanoparticles with gas permeable nano-space. J. Membr. Sci. 2017, 536, 148–155. [Google Scholar] [CrossRef]

- Sarfraz, M.; Ba-Shammakh, M. A novel zeolitic imidazolate framework based mixed-matrix membrane for efficient CO2 separation under wet conditions. J. Taiwan Inst. Chem. Engin. 2016, 65, 427–436. [Google Scholar] [CrossRef]

- Sridhar, S.; Smith, B.; Ramakrishna, M.; Aminabhavi, T.M. Modified poly(phenylene oxide) membranes for the separation of carbon dioxide from methane. J. Membrane Sci. 2006, 280, 202–209. [Google Scholar] [CrossRef]

- Bershtein, V.A.; Egorova, L.M.; Yakushev, P.N.; Georgoussis, G.; Kyritsis, A.; Pissis, P.; Sysel, P.; Brozova, L. Molecular dynamics in nanostructured polyimide-silica hybrid materials and their thermal stability. J. Polym. Sci. B 2002, 40, 1056. [Google Scholar] [CrossRef]

- Luebke, D.; Myers, C.; Pennline, H. Hybrid Membranes for Selective Carbon Dioxide Separation from Fuel Gas. Energy Fuels 2006, 20, 1906–1913. [Google Scholar] [CrossRef]

- Vu, D.Q.; Koros, W.J.; Miller, S.J. Mixed matrix membranes using carbon molecular sieves: I. Preparation and experimental results. J. Membr. Sci. 2003, 211, 311–334. [Google Scholar] [CrossRef]

- Yu, B.; Cong, H.; Zhao, X. Hybrid brominated sulfonated poly(2,6-diphenyl-1,4-phenyleneoxide) and SiO2 nanocomposite membranes for CO2/N2 separation. Prog. Nat. Sci. Mater. 2012, 22, 661–667. [Google Scholar] [CrossRef] [Green Version]

- Xin, Q.; Liu, T.; Li, Z.; Wang, S.; Li, Y.; Li, Z.; Ouyang, J.; Jiang, Z.; Wu, H. Mixed matrix membranes composed of sulfonated poly(ether ether ketone)and a sulfonated metal–organic framework for gas separation. J. Membrane Sci. 2015, 488, 67–78. [Google Scholar] [CrossRef]

- Xiang, L.; Pan, Y.; Jiang, J.; Chen, Y.; Chen, J.; Zhang, L.; Wang, C. Thin poly(ether-block-amide)/attapulgite composite membranes with improved CO2 permeance and selectivity for CO2/N2 and CO2/CH4. Chem. Eng. Sci. 2017, 160, 236–244. [Google Scholar] [CrossRef]

- Yang, L.; Tian, Z.; Zhang, X.; Wu, X.; Wu, Y.; Wang, Y.; Peng, D.; Wang, S.; Wu, H.; Jiang, Z. Enhanced CO2 selectivities by incorporating CO2-philic PEG-POSS into polymers of intrinsic microporosity membrane. J. Membr. Sci. 2017, 543, 69–78. [Google Scholar] [CrossRef]

- Ionita, M.; Vasile, E.; Crica, L.E.; Voicu, S.I.; Pandele, A.M.; Dinescu, S.; Predoiu, L.; Galateanu, B.; Hermenean, A.; Costache, M. Synthesis, characterization and in vitro studies of polysulfone/graphene oxide composite membranes. Compos. B 2015, 72, 108–115. [Google Scholar] [CrossRef]

- Liu, P.; Huang, R.; Tang, Y. Comprehensive Understandings of Rare Earth Element (REE) Speciation in Coal Fly Ashes and Implication for REE Extractability. Environ. Sci. Technol. 2019, 53, 5369–5377. [Google Scholar] [CrossRef]

- Kogarko, L.N.; Kononova, V.A.; Orlova, M.P.; Woolley, A.R. Alkaline Rocks of the World, Part 2: Former Soviet Union; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Baba, A.; Usmen, M.A. Effects of Fly Ash from Coal-Burning Electrical Utilities on Ecosystem and Utilization of Fly Ash, Groundwater Ecosys; Springer: Berlin/Heidelberg, Germany, 2006; pp. 15–31. [Google Scholar]

- Korcak, R. Agricultural uses of coal combustion byproducts. In: Agricultural uses of municipal, animal and industrial byproducts. USDA-ARS Conserv. Res. Rep. 1998, 44, 103–119. [Google Scholar]

- Kolker, A.; Scott, C.; Hower, J.C.; Vazquez, J.A.; Lopano, C.L.; Dai, S. Distribution of rare earth elements in coal combustion fly ash, determined by SHRIMP-RG ion microprobe. Int. J. Coal Geol. 2017, 184, 1–10. [Google Scholar] [CrossRef]

- Lin, R.; Howard, B.H.; Roth, E.A.; Bank, T.L.; Granite, E.J.; Soong, Y. Enrichment of rare earth elements from coal and coal by-products by physical separations. Fuel 2017, 200, 506–520. [Google Scholar] [CrossRef] [Green Version]

- Blissett, R.S.; Smalley, N.; Rowson, N.A. An investigation into six coal fly ashes from the United Kingdom and Poland to evaluate rare earth element content. Fuel 2014, 119, 236–239. [Google Scholar] [CrossRef] [Green Version]

- Meier, A.L.; Slowik, T. Rare earth elements by inductively coupled plasma-mass spectrometry (Version 5.0 Ed.). In Analytical Methods for Chemical Analysis of Geologic and Other Materials; Taggart, J.E., Jr., Ed.; U.S. Geological Survey: Reston, VA, USA, 2002. [Google Scholar]

- Nugroho, N.D.; Rosita, W.; Perdana, I.; Bendiyasa, I.M.; Mufakhir, F.R.; Astuti, W. Iron bearing oxide minerals separation from rare earth elements (REE) rich coal fly ash. Mater. Sci. Engin. 2019, 478, 012026. [Google Scholar] [CrossRef]

- Frugier, P.; Gin, S.; Minet, Y.; Chave, T.; Bonin, B.; Godon, N.; Lartigue, J.-E.; Jollivet, P.; Ayral, A.; De Windt, L.; et al. SON 68 nuclear glass dissolution kinetics: Current state of knowledge and basis of the new GRAAL model. J. Nucl. Mater. 2008, 380, 8–21. [Google Scholar] [CrossRef]

- Konishi, Y.; Shimaoka, J.; Asai, S. Sorption of rare-earth ions on biopolymer gel beads of alginic acid. React. Funct. Polym. 1998, 36, 197–206. [Google Scholar] [CrossRef]

- Murty, D.S.R.; Chakrapani, G. Preconcentration of rare earth elements on activated carbon and its application to groundwater and sea-water analysis. J. Anal. At. Spectrom. 1996, 11, 815. [Google Scholar] [CrossRef]

- Davoodi-Nasab, P.; Rahbar-Kelishami, A.; Safdari, J.; Abolghasemi, H. Application of emulsion nanofluids membrane for the extraction of gadolinium using response surface methodology. J. Mol. Liq. 2017, 244, 368–373. [Google Scholar] [CrossRef]

- Park, S.; Liang, Y. Bioleaching of trace elements and rare earth elements from coal fly ash. Int. J. Coal Sci. Technol. 2019, 6, 74–83. [Google Scholar] [CrossRef] [Green Version]

- Sutar, A.S.; Awasare, S.D. Bioleaching of ore using chemolithotrophic microorganisms (Acidithiobacillus ferrooxidans). Int. J. Res. Environ. Sci. Technol. 2015, 5, 14–21. [Google Scholar]

- Karwowska, E.; Andrzejewska-Morzuch, D.; Łebkowska, M.; Tabernacka, A.; Wojtkowska, M.; Telepko, A.; Konarzewska, A. Bioleaching of metals from printed circuit boards supported with surfactant-producing bacteria. J. Hazard. Mater. 2014, 264, 203–210. [Google Scholar] [CrossRef]

- Desouky, O.A.; El-Mougith, A.A.; Hassanien, W.A.; Awadalla, G.S.; Hussien, S.S. Extraction of some strategic elements from thorium–uranium concentrate using bioproducts of Aspergillus ficuum and Pseudomonas aeruginosa. Arab. J. Chem. 2011, 9, 795–805. [Google Scholar] [CrossRef] [Green Version]

- Dong, Y.M.; Sun, X.Q.; Wang, Y.L.; Huang, C.; Zhao, Z.Y. The sustainable and efficient ionic liquid type saponification strategy for rare earth separation processing. ACS Sustain. Chem. Eng. 2016, 4, 1573–1580. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Y.; Huang, B.; Dong, Y.; Sun, X. The recovery of rare earth elements from coal combustion products by ionic liquids. Miner. Eng. 2019, 130, 142–147. [Google Scholar] [CrossRef]

- Peiro, L.T.; Mendez, G.V. Material and Energy Requirement for Rare Earth Production. J. Metullargy 2013, 65, 1327–1340. [Google Scholar]

- Das, S.; Gaustad, G.; Sekar, A.; Williams, E. Techno-economic analysis of supercritical extraction of rare earth elements from coal ash. J. Clean. Prod. 2018, 189, 539–551. [Google Scholar] [CrossRef]

- Duke Energy—EPRI Re-Use Technologies Report. 2016. Available online: https://www.energy.gov/articles/department-energy-duke-energy-and-epri-partner-test-advanced-energy-technologies-utilities (accessed on 26 August 2021).

- Kermer, R.; Hedrich, S.; Bellenberg, S.; Brett, B.; Schrader, D.; Schönherr, P.; Köpcke, M.; Siewert, K.; Günther, N.; Gehrke, T.; et al. Lignite ash: Waste material or potential resource—Investigation of metal recovery 838 and utilization options. Hydrometallurgy 2017, 168, 141–152. [Google Scholar] [CrossRef]

- Jarosiński, A. Możliwości pozyskiwania metali ziem rzadkich w Polsce. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią Pol. Akad. Nauk. 2016, 92, 75–88. [Google Scholar]

- Świnder, H.; Żelazny, S.; Jarosiński, A.; Białecka, B. The recovery of rare-earth metals from fly ash using alkali pre-treatment with sodium hydroxide. Gospod. Surowcami Miner. Miner. Resour. Manag. 2020, 36, 127–144. [Google Scholar] [CrossRef]

- Geissdoerferab, M.; Savageta, P.; Bockenab, N.M.P.; Hultinkb, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- McDowall, W.; Geng, Y.; Huang, B.; Barteková, E.; Bleischwitz, R.; Türkeli, S.; Kemp, R.; Doménech, T. Circular economy policies in China and Europe. J. Ind. Ecol. 2017, 21, 651–661. [Google Scholar] [CrossRef] [Green Version]

- Boulding, K. The Economics of the Coming Spaceship Earth. In Resources for the Future; Johns Hopkins University Press: Baltimore, MD, USA, 1966; pp. 1–14. [Google Scholar]

- European Parliament. European Parliament resolution of 10 February 2021 on the New Circular Economy Action Plan (2020/2077(INI)). Available online: https://www.europarl.europa.eu/doceo/document/TA-9-2021-0040_EN.html (accessed on 1 May 2021).

- Communication From The Commission To The European Parliament, The European Council, The Council, The European Economic And Social Committee And The Committee Of The Regions Of 11 December 2019 The European Green Deal, Com/2019/640. Available online: https://eur-lex.europa.eu/legal-content/EN/LSU/?uri=COM:2019:640:FIN (accessed on 1 May 2021).

- Communication From The Commission To The European Parliament, The Council, The European Economic And Social Committee And The Committee Of The Regions Closing The Loop - An EU Action Plan For The Circular Economy, COM/2015/0614. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 1 May 2021).

- Murray, A.T.; Estivill-Castro, V. Cluster discovery techniques for exploratory spatial data analysis. Int. J. Geogr. Inf. Sci. 1998, 12, 431–443. [Google Scholar] [CrossRef]

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Porter, M.E. Location, Competition, and Economic Development: Local Clusters in a Global Economy. Econ. Dev. Q. 2000, 14, 15–34. [Google Scholar] [CrossRef]

- Das, K. Collective dynamism and firm strategy: Study of an Indian industrial cluster. Entrep. Reg. Dev. 1998, 10, 33–49. [Google Scholar] [CrossRef]

- van Dijk, M.P.; Rabellotti, R. Enterprise Clusters and Networks in Developing Countries; Frank Cass: London, UK, 1997. [Google Scholar]

- Taddeo, R.; Simboli, A.; Ioppolo, G.; Morgante, A. Industrial Symbiosis, Networking and Innovation the Potential Role of Innovation Poles. Sustainability 2017, 9, 169. [Google Scholar] [CrossRef] [Green Version]

- Ramirez Camargo, L.; Gruber, K.; Nitsch, F.; Dorner, W. Hybrid renewable energy systems to supply electricity self-sufficient residential buildings in Central Europe. Energy Procedia 2019, 158, 321–326. [Google Scholar] [CrossRef]

- Knop, L. Development of Clusters in Poland. Int. J. Innov. Econ. Dev. 2019, 5, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Grantham Research Institute on Climate Change and the Environment. Act of 22.06.2016 on Amending the Act on Renewable Energy Sources and Certain Other Acts (Dz.U. 2016, poz. 925, Journal of Laws 2016, item 925S). Available online: https://climate-laws.org/geographies/poland/laws/act-on-renewable-energy-sources-res-act-dz-u-2015-poz-478 (accessed on 1 May 2021).

- Szewrański, S.; Bochenkiewicz, M.; Kachniarz, M.; Kazak, J.K.; Sylla, M.; Świąder, M.; Tokarczyk-Dorociak, K. Location support system for energy clusters management at regional level. IOP Conf. Ser. Earth Environ. Sci 2019, 354, 1–11. [Google Scholar] [CrossRef]

- Marinina, O.; Nevskaya, M.; Jonek-Kowalska, I.; Wolniak, R.; Marinin, M. Recycling of Coal Fly Ash as an Example of an Efficient Circular Economy: A Stakeholder Approach. Energies 2021, 14, 3597. [Google Scholar] [CrossRef]

- Available online: https://bioeko.tauron.pl/sprzedaz-detaliczna/sprzedaz-popiolow-lotnych (accessed on 26 August 2021).

- Longley, P.A.; Goodchild, M.F.; Maguire, D.J.; Rhind, D.W. GIS, Teoria I praktyka; PWN: Warsaw, Poland, 2008. [Google Scholar]

- Davis, C.A.; Fonseca, F. Assessing the Certainty of Locations Produced by an Address Geocoding System. Geoinformatica 2007, 11, 103–129. [Google Scholar] [CrossRef]

- Moon, J.Y.; Jung, H.J.; Moon, M.; Chung, B.C.; Choi, M.H. Heat-Map Visualization of Gas Chromatography-Mass Spectrometry Based Quantitative Signatures on Steroid Metabolism. J. Am. Soc. Mass Spectrom. 2009, 20, 1626–1637. [Google Scholar] [CrossRef] [Green Version]

- Raschke, M.; Blascheck, T.; Burch, M.; Kurzhals, K.; Pflueger, H. Visualization of eye tracking data. Cogn. Process. 2014, 15, S25. [Google Scholar]

- Morstatter, F.; Kumar, S.; Liu, H.; Maciejewski, R. Understanding Twitter data with TweetXplorer. In Proceedings of the 19th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Chicago, IL USA, 11–14 August 2013; pp. 1482–1485. [Google Scholar]

- Longley, P.; Goodchild, M.F.; Maguire, D.J.; Rhind, D.W. Geographic Information Systems and Science; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Yun, H.J.; Kang, D.J.; Kim, D.-K.; Kang, Y. A GIS-Assisted Assessment and Attribute-Based Clustering of Forest Wetland Utility in South Korea. Sustainability 2019, 11, 4632. [Google Scholar] [CrossRef] [Green Version]

- MacQueen, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 21 June–18 July 1965 and 27 December 1965–7 January 1966; Volume 1, pp. 281–297. [Google Scholar]

- Anderson, T.K. Kernel density estimation and K-means clustering to profile road accident hotspots. Accid. Anal. Prev. 2009, 41, 359–364. [Google Scholar] [CrossRef]

- Bluszcz, A.; Manowska, A. The Use of Hierarchical Agglomeration Methods in Assessing the Polish Energy Market. Energies 2021, 14, 3958. [Google Scholar] [CrossRef]

- Dijkstra, E.W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef] [Green Version]

- Bazaraa, M.; Jarvis, J. Linear Programming and Network Flows; Wiley: New York, NY, USA, 1990. [Google Scholar]

- Kasana, H.S.; Kumar, K.D. Introductory Operations Research Theory and Applications; Springer International Edition: New Delhi, India, 2005. [Google Scholar]

- Rybak, A.; Rybak, A.; Sysel, P. Modeling of Gas Permeation through Mixed-Matrix Membranes Using Novel Computer Application MOT. Appl. Sci. 2018, 8, 1166. [Google Scholar] [CrossRef] [Green Version]

- Minko, E.; Sysel, P.; Hauf, M.; Brus, J.; Kobera, L. Synthesis and properties of hyperbranched polyimides combined with silica. Macromol. Symp. 2010, 295, 88–93. [Google Scholar] [CrossRef]

- Fang, J.; Hidetoshi, K.; Okamoto, K. Hyperbranched Polyimides for Gas Separation Applications. 1. Synthesis and Characterization. Macromolecules 2000, 33, 4639–4646. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, A.; Kaszuwara, W. Characterization of selected parameters of organic-inorganic hybrid membranes based on various polymers and Nd-Fe-B fillers. Arch. Metall. Mater. 2016, 61, 1825–1832. [Google Scholar] [CrossRef] [Green Version]

- Rybak, A.; Rybak, A.; Kaszuwara, W.; Awietjan, S.; Jaroszewicz, J. The rheological and mechanical properties of magnetic hybrid membranes for gas mixtures separation. Mater. Lett. 2016, 183, 170–174. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, A.; Kaszuwara, W.; Boncel, S. Poly(2,6-dimethyl-1,4-phenylene oxide) hybrid membranes filled with magnetically aligned iron-encapsulated carbon nanotubes (Fe@MWCNTs) for enhanced air separation. Diam. Relat. Mater. 2018, 83, 21–29. [Google Scholar] [CrossRef]

- Mutlu, B.K.; Cantoni, B.; Turolla, A.; Antonelli, M.; Hsu-Kim, H.; Wiesner, M.R. Application of nanofiltration for Rare Earth Elements recovery from coal fly ash leachate: Performance and cost evaluation. Chem. Eng. J. 2018, 349, 309–317. [Google Scholar]

- Shimizu, H.; Ikeda, K.; Kamiyama, Y. Refining of a Rare Earth Including a Process for Separation by a Reverse Osmosis Membrane. U.S. Patent No. 5,104,544, 14 April 1992. [Google Scholar]

- Wen, B.; Shan, X.; Xu, S. Preconcentration of ultratrace rare earth elements in seawater with 8-hydroxyquinoline immobilized polyacrylonitrile hollow fiber membrane for determination by inductively coupled plasma mass spectrometry. Analyst 1999, 124, 621–626. [Google Scholar] [CrossRef]

- Murthy, Z.V.P.; Gaikwad, M.S. Separation of praseodymium (III) from aqueous solutions by nanofiltration. Can. Metall. Q. 2013, 52, 18–22. [Google Scholar] [CrossRef]

- Qin, Q.W.; Zhao, H.Q.; Lai, Y.Q.; Li, J.; Liu, Y.X.; Deng, Z.G. Extraction of rare earth metals by liquid surfactant membranes containing Cyanex272 as a carrier. Miner. Metallurg. Eng. 2002, 22, 74–78. [Google Scholar]

- Wannachod, P.; Chaturabul, S.; Pancharoen, U.; Lothongkum, A.W.; Patthaveekongka, W. The effective recovery of praseodymium from mixed rare earths via a hollow fiber supported liquid membrane and its mass transfer related. J. Alloy. Compd. 2011, 509, 354–361. [Google Scholar] [CrossRef]

- Liu, E.; Xu, X.; Zheng, X.; Zhang, F.; Liu, E.; Li, C. An ion imprinted macroporous chitosan membrane for efficiently selective adsorption of dysprosium. Sep. Purif. Technol. 2017, 189, 288–295. [Google Scholar] [CrossRef]

- Ambare, D.N.; Ansari, S.A.; Anitha, M.; Kandwal, P.; Singh, D.K.; Singh, H.; Mohapatra, P.K. Non-dispersive solvent extraction of neodymium using a hollow fiber contactor: Mass transfer and modeling studies. J. Membr. Sci. 2013, 446, 106–112. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, F.; Liu, E.; Xu, X.; Yan, Y. Efficient recovery of neodymium in acidic system by free-standing dual-template docking oriented ionic imprinted mesoporous films. ACS Appl. Mater. Inter. 2017, 9, 730–739. [Google Scholar] [CrossRef] [PubMed]

- Wojnarowski, P. Potential for increasing oil recovery from Polish oilfields by applying EOR methods. Miner. Resour. Manag. 2012, 28, 47–58. [Google Scholar]

- Pruess, K. Enhanced geothermal systems (EGS) using CO2 as working fluid—A novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef] [Green Version]

- Aresta, M.; Schloss, J.V. Enzymatic and Model Carboxylation and Reduction Reactions for Carbon Dioxide Utilization; Kluwer Academic Publisher: Dordrecht, The Netherlands, 1990. [Google Scholar]

- Zapart, L.; Sciążko, M.; Dreszer, K. Estymacja kosztów wytwarzania produktów konwersji węgla. Energy Policy J. 2009, 12, 645–657. [Google Scholar]

- Całus Moszko, J.; Białecka, B. Analiza możliwości pozyskania pierwiastków ziem rzadkich z węgli kamiennych i popiołów lotnych z elektrowni. Gospod. Surowcami Miner-Miner. Resour. Manag. 2013, 29, 67–80. [Google Scholar]

- King, J.F.; Taggart, R.K.; Smith, R.C.; Hower, J.C.; Hsu-Kim, H. Aqueous acid and alkaline extraction of rare earth elements from coal combustion ash. Int. J. Coal Geol. 2018, 195, 75–83. [Google Scholar] [CrossRef]

- Franus, W.; Wiatros-Motyka, M.M.; Wdowin, M. Coal fly ash as a resource for rare earth elements. Environ. Sci. Pollut. Res. 2015, 22, 9464–9474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wdowin, M.; Franus, W. Analiza popiołów lotnych pod kątem uzyskania z nich pierwiastków ziem rzadkich. Energy Policy J. 2014, 17, 369–380. [Google Scholar]

- Querol, X.; Moreno, N.; Umaña, J.C.; Alastuey, A.; Hernández, E.; López-Soler, A. Synthesis of zeolites from coal fly ash: An overview. Int. J. Coal. Geol. 2002, 50, 413–423. [Google Scholar] [CrossRef]

- Kucowski, J.; Laudyn, D.; Przekwas, M. Energetyka a Ochrona Środowiska; WNT: Warszawa, Poland, 1997; p. 395. [Google Scholar]

- Rybak, A.; Rybak, A. Characteristics of Some Selected Methods of Rare Earth Elements Recovery from Coal Fly Ashes. Metals 2021, 11, 142. [Google Scholar] [CrossRef]

- Mayfield, D.B.; Lewis, A.S. Environmental review of coal ash as a resource for rare earth and strategic elements. In Proceedings of the World of Coal Ash (WOCA) Conference, Lexington, KY, USA, 22–25 April 2013. [Google Scholar]

- Couto, N.; Ferreira, A.R.; Lopes, V.; Peters, S.C.; Mateus, E.P.; Ribeiro, A.B.; Pamukcu, S. Electrodialytic recovery of rare earth elements from coal ashes. Electrochim. Acta 2020, 359, 136934. [Google Scholar]

- Pan, J.; Nie, T.; Hassas, B.V.; Rezaee, M.; Wen, Z.; Zhou, C. Recovery of rare earth elements from coal fly ash by integrated physical separation and acid leaching. Chemosphere 2020, 248, 126112. [Google Scholar]

- Rybak, A. Application of the Cobb-Douglas production function to study the results of the production process and planning under turbulent environment conditions. Miner. Resour. Manag. 2019, 35, 99–118. [Google Scholar]

- Rybak, A.; Manowska, A. The forecast of coal sales taking the factors influencing the demand for hard coal into account. Miner. Resour. Manag. 2019, 35, 129–140. [Google Scholar]

- Rybak, A.; Rybak, A. Possible strategies for hard coal mining in Poland as a result of production function analysis. Resour. Policy 2016, 50, 27–33. [Google Scholar] [CrossRef]

- GIS Support. Available online: https://gis-support.pl/dane-do-pobrania/ (accessed on 10 May 2021).

- Open Street Map. Available online: openstreetmap.org/#map=5/55.015/13.997 (accessed on 10 May 2021).

- DB Cargo. Available online: https://pl.dbcargo.com/rail-pl-pl/strefa-klienta/taryfy-towarowe (accessed on 20 May 2021).

- Katowicki Węgiel. Available online: https://wegiel.katowice.pl/ (accessed on 27 May 2021).

- Kobize. Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/monitorowanie_raportowanie_weryfikacja_emisji_w_eu_ets/WO_i_WE_do_stosowania_w_SHE_2017.pdf (accessed on 10 May 2021).

- Sundaramurthy, S.; Premalatha, M. An overview of CO2 mitigation using algae cultivation technology. Int. J. Chem. Res. 2011, 3, 110–117. [Google Scholar] [CrossRef] [Green Version]

- Wallace, M.; Goudarzi, L.; Callahan, K.; Wallace, R. A Review of the CO2 Pipeline Infrastructure in the US; National Energy Technology Laboratory, US Department of Energy: Washington, DC, USA, 2015. [Google Scholar]

- Available online: https://handel-emisjami-co2.cire.pl/st,34,514,me,0,0,0,0,0,ceny-uprawnien-do-emisji-co2.html (accessed on 10 May 2021).

- Valdovinos-García, E.M.; Barajas-Fernández, J.; Olán-Acosta, M.d.l.Á.; Petriz-Prieto, M.A.; Guzmán-López, A.; Bravo-Sánchez, M.G. Techno-Economic Study of CO2 Capture of a Thermoelectric Plant Using Microalgae (Chlorella vulgaris) for Production of Feedstock for Bioenergy. Energies 2020, 13, 413. [Google Scholar] [CrossRef] [Green Version]

- Davis, R.; Markham, J.; Kinchin, C.; Grundl, N.; Tan, E.C.D. Process Design and Economics for the Production of Algal Biomass: Algal Biomass Production in Open Pond Systems and Processing Through Dewatering for Downstream Conversion. Technical Report NREL/TP-5100-64772; National Renewable Energy Laboratory: Golden, CO, USA, 2016.

- ISE. Available online: https://en.institut-seltene-erden.de/our-service-2/Metal-prices/high-purity-metals-prices/ (accessed on 30 June 2021).

- Chalmers, I.; MacDonald, A. Economics of Rare Earth Projects (Alkane Resources LTD). In Proceedings of the Materials Science & Technology (MS&T) Conference, Pittsburgh, PA, USA, 8–12 October 2017. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).