Abstract

To design a residential or commercial building with high energy performance that would be economical at the same time, an analysis was performed that relates these two aspects of the problem. The first aspect is focused on evaluation of the thermal performance of a multi-layered wall in order to achieve the lowest energy consumption for heating and cooling. The second aspect of the analysis covered the choice of materials (type, thickness and price) so that the building has the lowest possible construction costs, but the best achieved thermal comfort. The three types of external walls with the same structure were analyzed in this paper. The lowest and highest values of the layer thickness offered by the manufacturer were chosen and their dynamic characteristics for the heat transfer were calculated. The following step was to perform optimization of the objective function, which was defined by the unit price of the material per mass of the material, that is, the economical aspect was provided. The genetic algorithm method was used to obtain the optimal thickness of the external wall layers that provided the best dynamic characteristics for the heat transfer in the defined conditions.

1. Introduction

Design of an energy efficient and optimal building is a technique that is increasingly used for designing buildings with better overall performance with the emphasis on energy efficiency.

The international scientific community unequivocally believes that anthropogenic factors affect the climate change and that they are mainly related to the construction sector and disproportionate use of the fossil energy sources, [1,2]. The evidence can be seen in the fact that the floor area in buildings worldwide has increased by 65% since 2000, reaching almost 240,000,000,000 m2 in 2018, while the average energy consumption per m2 has decreased only by 25%, which means that progress has not compensated for the growth of the floor area. Since 2018, only 69 countries, where nearly zero-energy buildings (NZEB) constitute less than 5%, have had a mandatory or voluntary energy code for construction of the commercial and residential buildings. Therefore, the International Organization for Standardization (ISO) published ISO 52000-1 standard for assessing the energy performance of buildings, which established a systematic and comprehensive structure for the assessment of energy performance of buildings.

In order to increase the energy performance of buildings, the European Union established a legislative framework that included Directives on the energy performance of buildings 2010/31/EU and 2012/27/EU (EPBD) [3]. After the introduction of energy performance directives into national building codes, buildings consumed only half the energy compared to typical buildings in 1980s. Buildings in the EU are responsible for about 40% of energy consumption and 36% of carbon dioxide (CO2) emission. Currently, there are 35% of residential buildings older than 50 years and almost 75% of them are not energy efficient. Renovation of the existing buildings could result in significant energy savings as it could reduce the total energy consumption by 5–6% and carbon dioxide emission 5% [4]. Commercial buildings are 40% larger energy consumers than the residential ones (250, KWh/m2 of the former compared to 180, KWh/m2 of the latter). All the new buildings must be nearly zero-energy buildings (NZEB) since 31 December 2020. Starting from 31 December 2018, all the public buildings must be NZEB, all the energy certificates must be issued when the building is sold or rented and a plan for heating and air conditioning systems inspection must be established.

Energy efficiency measures in public buildings reduce the national energy consumption and greenhouse gas emission. However, these measures also reduce indoor air quality and cause productivity losses for building users.

A study on the thermal comfort and energy efficiency, as well as on perception of the construction experts on the market for the low-carbon products, was presented in [5]. The study consisted of four phases. Data obtained in phases 1 and 2 showed that the notion of energy efficiency of a house was largely based on technological aspects, such as energy efficient appliances and/or renewable energy sources that were closely related to economic (i.e., energy saving) or environmental (i.e., carbon emission reduction) aspects.

An analysis of a relationship between the behavioral measures for energy use in a household and household characteristics was performed using a set of data involving about 5000 households in 10 EU countries and Norway, due to the need to balance the common policy framework of the European Union for energy efficiency and flexibility [6]. Households with young children were more likely to adopt energy efficient technologies and save energy for environmental reasons, while households with older members attached greater significance to financial savings and had the lower level of technology adoption, energy saving practice and knowledge on energy use in the household. University education increased the importance of energy savings for reduction of the greenhouse gasses and decreased the importance of financial aspect.

In [7], the measurement system that forms a basis for production of tools necessary for evaluation of energy efficiency in Ghana was developed and an analytic hierarchy process (AHP) model that analyzed the energy performance of a building was presented. The results obtained by the AHP model showed that the design of buildings and energy efficiency of the structures were of the highest priority for buildings in Ghana.

The main aim of research [8] was to study the impact of indoor air quality on total national energy consumption and reduction of the greenhouse gasses emission. A simulation that used a system dynamic model with the two possible scenarios (with and without mechanical ventilation) was performed, results of which showed that when ventilation was done in accordance with national construction standards, the total energy consumption in public buildings increases by 1.3% in 2014 and 2% by 2040 when compared to the situation where there was no mechanical ventilation. When application of energy efficiency measures increased, the difference between the two alternatives was greater.

The choice of the building material has an important role in reducing energy consumption especially in the Mediterranean area where the risk of internal overheating is high if the solar radiation was not controlled and if internal heat was poorly managed. Study [9] analyzed the design methodology of a highly efficient ground floor in a warm climate using the optimization code of modeFRONTIER software (ESTECO SpA., Trieste, Italy). The results were characterized by the strong presence of local and environmentally friendly materials and reduced costs, and they showed that the high-performance solutions could be obtained with a small number of layers in the floor construction.

Karatas and Rizaoglu [10] described a new type of environmentally sensitive insulation panels, obtained by applying materials from different lithologies to expanded polystyrene surfaces (EPS). A mortar with 25% acrylic and 75% sand, was applied to the EPS by a stripping method using sand size granite, mica schist, basalt, quartzite and pumice. The new panels are the cost effective, as well, since they reduce paint costs, application time and total building load.

To achieve very low permanent heat transfer, Zero Energy Buildings (ZEBs) in Europe adopt light multilayer wall technology using structural materials with low density, thermal insulation, high thickness, low specific mass and low mass accumulation. Results of study [11] showed that the surface mass of the exterior wall was important for achievement of the best performance in a warm climate. It is possible to achieve high performance in summer with lighter and thinner walls.

In study [12] authors evaluated algorithms used for optimization of energy efficient building design. To index the overall performance of the algorithms, a set of following performance indices was proposed: stability, robustness, validity, speed, coverage and site. Results have shown that none of the algorithms worked best in all the six areas, i.e., the algorithm should be carefully chosen based on the nature of a problem and the most important performance index in order to address the problem of energy efficient design.

Zhelykh et al. [13] presented the classification of energy-efficient houses proposed by international standards and its critical analysis. Emphasis is placed on a problem of improving the solar collectors integrated into the construction of buildings. Authors constructed an experimental solar collector, which was combined with the translucent facade of the building, with the set thermal characteristics, in particular the thermal capacity and thermal efficiency. Since the model of the solar collector was flat and intensity of the solar energy is unstable during the day, authors concluded that the solar collector would be effective for preheating the heat carrier in the energy supply system.

The ITACA Protocol, an assessment system of the environmental sustainability level of buildings, promotes use of the recycled, renewable and local materials. The modeFRONTIER optimization tool (ESTECO SpA., Trieste, Italy) that used computational procedures developed in MATLAB was applied to assess the dynamic performance of building components in [14]. Optimization was performed in terms of continuous heat transfer, periodical heat transfer, time reduction factor, time shift, surface heat capacity, heat transfer, surface mass, thickness and ITACA results. Results showed that the best structure in a warm climate was one with the high surface mass of the first layer (inner side), middle layer made of an insulation material and outer layer made of ecological insulation material.

Research [15] presented a model of energy performance of a residential building, which included heating and cooling systems with an integrated automation system. Three different control scenarios were explored for comparison using different software. The aim was to identify the impact of building’s automation system on energy consumption for heating and cooling by controlling construction system’s scheme of work.

Artificial neural networks (ANN), genetic algorithms (GA), case base reasoning (CBR) and hybrid systems are all the methods of artificial intelligence. Study [16] examined implementation of the artificial intelligence in energy efficient buildings. The CBR compared new and previous problems using previous solution. A previously developed structure design was described in the CBR by defined linguistic variables in a fuzzy set. The designer could make modifications and, after the investor’s approval, new documentation could be entered into a database for further use.

Use of the Energy Efficiency Management System (EEMS) contributes to energy savings and energy conservation. Through the system integration, adjustment and optimization of existing energy consumption, energy conservation can be achieved, i.e., building’s energy efficiency can increase, which is the main objective of using this system. An analysis of the current state of EEMS in China and other countries was presented in study [17]. Use and combination of the CBR and multi-agent system (MAS) methods for solving problems in energy efficiency management was proposed. Artificial intelligence (AI) was applied in design of a building for the smart energy consumption. Feedback between users and the system, where the thermal comfort was vital simulation factor, was introduced to provide users with a chance to present additional information.

Study [18] described an approach that offered advantages provided by multi-agent (MAS) architecture deployed in a cloud environment with a wireless sensor network (WSN) to achieve energy savings. The MAS studied social behavior based on the gathered data and help of the artificial neural network (ANN). The proposed system was designed for a commercial building where average energy savings of 40% could be achieved.

Based on the aforementioned information, it is necessary to identify factors which contribute to increased energy consumption, in order to maintain the desired interior temperature, i.e., the thermal comfort, without increasing the heating of a building in winter or cooling in summer. Some of the factors include building location, condition of a building and climate conditions. The dynamic heat transfer characteristics that depend on construction of the exterior wall were closely analyzed in this paper. The composition and thickness of the wall were optimized for defined conditions by a genetic algorithm.

2. The Problem Formulation

Increasing the energy efficiency of a residential building is reflected in the correct and optimal design of a construction of an external wall with the best dynamic characteristics, which will meet all the requirements for the desired level of thermal comfort.

This paper analyzed the massive external wall of a ventilated façade with a multilayer structure where the energy efficiency increased when an optimization of the external wall construction was performed by genetic algorithms (GA).

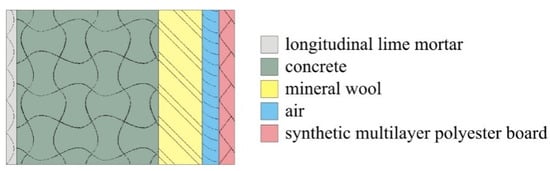

An analysis of the multilayer external wall of the ventilated façade was performed and the results of the dynamic characteristics were obtained. The analyzed wall is shown in Figure 1.

Figure 1.

External wall of a ventilated façade.

Thermo-physical properties of materials used for construction of the external wall of the ventilated façade are presented in Table 1.

Table 1.

Thermo-physical properties of materials used for the external wall of the ventilated façade.

Dynamic characteristics were calculated according to the international standard EN ISO 13786 [19], which was in accordance with the standard SRPS EN ISO 6946 [20] found in the Rulebook on the Energy Efficiency of Buildings of the Republic of Serbia. Dynamic characteristics of the tested ventilated façade walls included internal and external thermal admittance, Y11, W/m2K and Y22, W/m2K, respectively; periodical thermal transmittance Y12, W/m2K, thermal capacity of the heat surface on the internal and external side of the wall, k1, kJ/m2K and k2, kJ/m2K, respectively; the decrement factor f; the temperature variation shift factor τ, h, the heat transfer coefficient U, W/m2K and the heat transfer resistance through the wall R, m2K /W. The formulas and detailed explanation of these variables are given in paper [21] (expressions (9) to (13), pages 217–218) and are not given here for the sake of brevity of the text.

The heat conduction coefficient λ value is obtained by the research done by the material manufacturer, and it depends on the material type and density—so the tabular value is taken from the material manufacturer’s catalogue. The material heat convection coefficient α is adopted for particular designed heat transfer conditions (under the defined and constant outside conditions and designed inside conditions).

The objective function represented the unit price of the material used for construction of layers in the external wall of the ventilated façade, which depended on thickness of individual layers, δi, the density of the materials used for the construction of the layers, ρi and the unit price of the used material per running meter, Bi.

The objective function was defined by equation:

Function Amin is the objective function, which represents the unit price (per unit mass) of the layers’ materials of the outer wall construction.

Optimization of the objective function was performed by the genetic algorithms (GA), which, in this case, meant discovering the minimum price of the material per kilogram, that is Amin.

This was, in addition to satisfying other constraints that would be defined later, the optimal solution Amin obtained and it included the best dynamic characteristics of the external wall of the ventilated façade, and it was economically justified, that is, it was the most inexpensive solution.

In order to perform optimization of the objective function, constraints were needed that could restrict the domain of potential solutions, which would be analyzed by the genetic algorithm.

The first constraint was derived from the standard for the energy efficiency of buildings in Serbia, which stated that all the recently built residential buildings must have the heat transfer coefficient whose value did not exceed 0.3, W/m2K, that is, the value of the heat transfer resistance was greater than 3.3, m2K/W.

This condition was expressed as follows:

i.e.,:

where:

The heat transfer resistance function for the adopted external and internal conditions was defined by equation (i.e., it was based on the known thermo-physical properties of the material):

To increase the energy efficiency of the entire structure, the goal was to optimize the objective function and to obtain the highest value of the heat transfer resistance, Rmax, which could be seen as a good indicator, during the analysis of dynamic characteristics of the heat transfer.

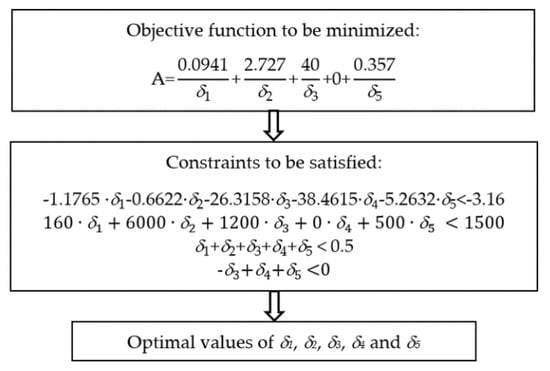

The GA operating scheme is shown in Figure 2. (Values of coefficients follow from material properties of layers and result from the calculations performed).

Figure 2.

The genetic algorithm operating scheme.

The second constraint was a function of the unit price of a material used for the construction of the wall layers per running meter (RSD/m; RSD is Serbian Dinar currency—1 Euro ≈ 117.5 RSD). The function was defined to depend on the unit price of the material per square meter and on thickness of the wall layers and it was expressed in the following way:

Based on the client’s preference, the price of the material per running meter could be limited, that is, it could be set in the desired range. In this paper, the price of a material per running meter C was defined in the range 1000 to 1500, RSD/m (≈8.5 to 12.8 Euro/m).

The objective function A is independent on parameter C. This price is introduced as an additional constraint so that the costs would be easier controlled and that one would have better insight.

Based on the previous research, it can be concluded that under the certain conditions walls with the smaller total thickness and specific mass provided the same or even better dynamic characteristics of the heat transfer than significantly bigger and thicker structures of external walls. That is why the third constraint was the total thickness of the external wall, which was calculated based on the following equation:

Based on the construction and thermodynamic recommendations, the constraint for value of the total thickness of the external wall was defined and expressed as:

The fourth constraint, which defined and showed the relationship between the thickness of the thermal insulation layer and the ventilation layer or final outer layer, was introduced to allow the construction of the external wall to have good thermal abilities and possibility to accumulate heat. The relationship between the thicknesses of the layers in the wall was expressed in the following way:

The thermal insulation layer should be thicker than the sum of thicknesses of the air layer (ventilation) and the final layer (synthetics multilayer polyester board).

Due to the thermo-insulating layer influence on the whole construction—it is good as an isolator, but poor as the energy accumulator—the condition in Equation (9) is given. During the investigation of various combinations of thicknesses of layers, the conclusion was drawn that the thickness of this layer plays an especially important role and that it affects the most the materials that are following this layer (air and synthetic multilayer polyester board) and which do not possess the good heat accumulating property, they actually transmit the heat rather fast. The thermo-insulating layer thickness, in a certain moment, can negatively affect the dynamic thermal characteristics of the whole wall construction.

Equation (9) is defined in this way for the construction reasons, as well, so that the final layer structure can be “connected” to the thermo-insulating layer so that it remains steady.

When applying the genetic algorithms, it is important to follow the basic steps to perform the optimization successfully, as described in [22]. The first step in using the genetic algorithm tools was to encode the changeable variables into a finite string of characters. The strings, presenting potential solutions of the problem, were actually the chromosomes, while the corresponding characters were known as genes. The convenience function (the objective function) should be known in advance so that one can assess the convenience of any solution. When the coding was completed and appropriate objective function was defined, evolution of the genetic algorithm (GA) was performed as follows:

Initialization—included the first population of chromosomes, which represented candidates for the solution of the problem. It was chosen from all the possible solutions.

Evaluation—when the population of chromosomes was formed, their fitness scores were calculated. The fitness score defined how “fit” the possible solution was.

Selection—the main objective of the process was to ensure that the next population of chromosomes contained solutions with the higher fitness scores, thus indicating the survival of a solution with the highest fitness scores.

Crossover—enabled the process of combining the two or more parent chromosomes in order to obtain offspring with improved solutions.

Mutation—it was a change in a randomly selected chromosome that took place in one gene, or in a group of randomly selected genes, of the chromosomes.

Replacement—a new population of offsprings, obtained by selection, crossover and mutation, was created from the original parent population. The previous steps should be repeated until the criteria for termination of the algorithm were reached and that was when the best chromosome, the one with the highest fitness score, became the solution for the problem.

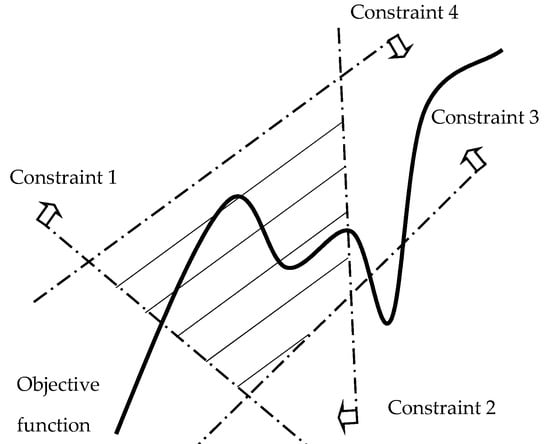

A graphical presentation of the process of obtaining the optimal values for the objective function of the domain limited by the constraints, where the optimal values were in the area of possible solutions, is given in Figure 3 [23].

Figure 3.

Graphical representation of the process of obtaining the optimal values for the objective function of a domain limited by the constraints.

3. Results and Discussion

Calculation of the dynamic characteristics of the ventilated façade was performed for three types of walls:

- (1)

- Calculation of the dynamic characteristics of the external wall, which had the minimum layer thickness from the set of layer thicknesses recommended by the manufacturer.

- (2)

- Calculation of the dynamic characteristics of the external wall, which had the maximum layer thickness from the set of layer thicknesses recommended by the manufacturer.

The next step was to create the objective function, which was related to the price and type of the material used to build the wall layers, so it could be viewed as an important economic aspect.

- (3)

- Calculation of the dynamic characteristics of the external wall of the ventilated façade, with the same wall structure as in the previous cases (1 and 2) but with the optimal wall thickness. The optimal wall thickness for the structure was obtained by the genetic algorithm method.

In the first case, the external wall of the ventilated façade with the minimum layer thickness (which were taken into consideration) was analyzed. The structure of the wall is presented in Table 2.

Table 2.

External wall of the ventilated façade with the minimum layer thickness.

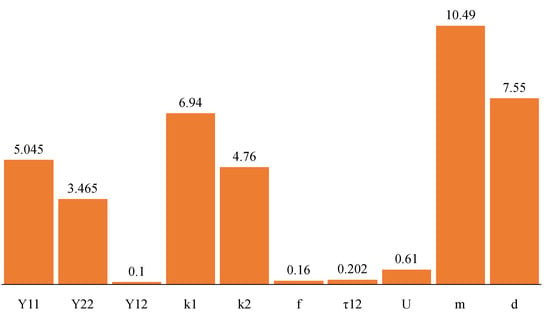

The obtained dynamic characteristics of the external wall of the ventilated façade according to the standard EN ISO 13786 are shown in Figure 4.

Figure 4.

Dynamic characteristics of the external wall of the ventilated façade with the minimum layer thickness.

Figure 4 shows that the construction of the external wall of the ventilated façade had good thermal characteristics. The decrement factor did not have the low value, which implied that the structure did not have a massive layer, i.e., because it was not massive it could not accumulate large amount of heat, which was received through the solar radiation during the day.

Periodical thermal transmittance is a measure for the thermal insulation of a wall and it represents the heat loss through the provided thickness of the wall. A higher value of the thermal transmittance indicates the lower thermal performance. Therefore, a wall with good thermal mass has the lower values of the thermal transmittance and higher values of the thermal admittance.

Based on values for the thermal absorption on the inner side of the wall Y11 and thermal absorption on the outer side of the wall Y22, which were the highest in the performed analysis, it could be assumed that the external wall 1 would have the greatest possibility for the thermal admittance and accumulation on both sides (internal and external). Moreover, due to the highest values for the thermal admittance and accumulation on the surface of both sides of the final layers, this construction possessed good thermal characteristics.

However, as the value for the periodical thermal transmittance factor Y12 was the highest compared to all the analyzed cases, it meant that this structure of the external wall had the high heat conduction, i.e., transfer of heat through the wall occurred with low resistance.

The consequence of the high thermal transmittance, i.e., high values of the periodical thermal transmittance factor Y12 and decrement factor f, which indicated that the external wall was built out of the light materials (specific mass was low, m = 350, kg/m2), would be the lower temperature variation shift factor than it was expected (τ = 12.64, h).

The maximum thickness of material layers that were considered and recommended by the manufacturer were used in calculation of dynamic properties of the external wall of the ventilated façade for the wall 2. As it was expected, this wall construction had the highest specific mass, total thickness and maximum layer thickness, as well. The layer thickness of this wall is shown in Table 3.

Table 3.

External wall of the ventilated façade with the maximum layer thickness.

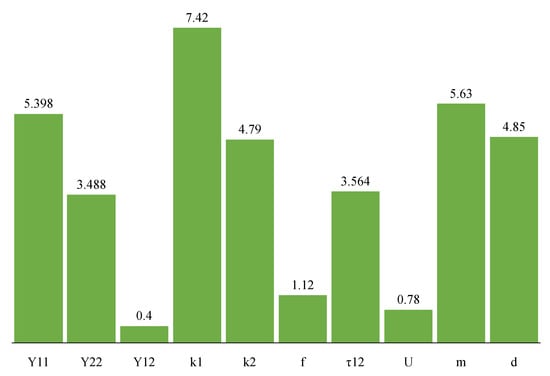

The dynamic characteristics of the heat transfer for this type of the external wall construction, obtained by the analysis, are shown in Figure 5.

Figure 5.

Dynamic characteristics of the external wall of the ventilated façade with the maximum layer thickness.

The structure of the external wall with the maximum layer thickness offered by the manufacturer was analyzed in the second case. As expected, this construction had the best insulation properties, i.e., the periodical thermal transmittance factor had the lowest value, Y12 = 0.001, W/m2K.

The thermal absorption on the inner side of the wall Y11 and thermal absorption on the outer side of the wall Y22 factors had values, which were for 12.8% and 4%, respectively, lower than in the previously analyzed case. This fact suggested that this construction did not have the poor heat accumulation capacity and thermal admittance on both sides of the wall, as well.

The wall construction with the maximum layer thickness had the highest specific mass and the value of the decrement factor was the lowest, f = 0.004, which was a feature of massive structures.

As the thermal capacity of the heat on surface on both sides of the wall (internal and external) was the lowest in the overall analysis, the consequence was seen in the fact that this external wall construction represented the solution with the best insulation and the weakest thermal characteristics since the temperature variation shift was τ = 1.01, h.

Analysis of the external wall 2 showed that, due to increase of the thickness of thermal insulation layers outside the optimal values, good insulation was achieved; however, the ability to accumulate and delay the heat transfer through the wall construction was lost.

This happened because there was the maximum thickness of a layer made of a solid material (concrete) that could accumulate heat steadily on one hand, however, on the other hand, there was the maximum thickness of a thermal insulation layer (air) that was good insulation material, but it could not accumulate heat.

In the third case, the external wall of the ventilated façade was with the same structure as the two previously analyzed walls, only this time the layers’ thickness was analyzed by the genetic algorithm (GA).

The optimal thicknesses of the layers in the external wall, obtained by the genetic algorithm method, are presented in Table 4.

Table 4.

External wall of the ventilated façade with the optimal layer thickness.

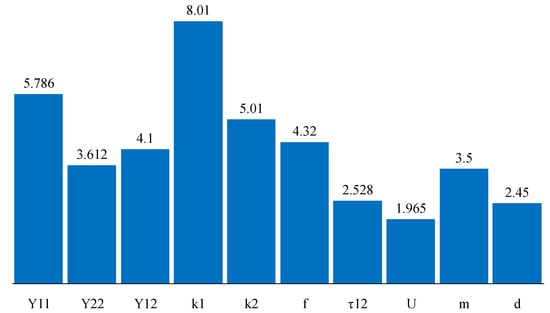

The next step was to perform analysis of the dynamic characteristics of the heat transfer of this wall type. Results of the analysis are shown in Figure 6.

Figure 6.

Dynamic characteristics of the external wall of the ventilated façade with the optimal layer thickness.

Based on results presented in Figure 6, it can be concluded that the observed structure of the external wall had good thermal characteristics and insulation properties (periodical thermal transmittance factor, Y12 = 0.004, W/m2K, had low value).

Values of the thermal absorption on the inner side of the wall Y11 and thermal absorption on the outer side of the wall Y22 factors were relatively high (by 6.7% and 3.4% lower, respectively, compared to the structure of the analyzed external wall in the first case). However, the decrement factor had a low value (f = 0.028) due to the lower heat transfer coefficient U, compared to wall 1 and lower specific mass m for 486, kg/m2 compared to wall 2.

A large phase delay can be seen as a consequence of all the above mentioned, where the temperature variation shift factor was τ = 17.82, h, the highest in all the analyzed cases.

Due to importance of economic factors to the client (buyer or investor), such as the value of investment, payback period and energy savings, when a new residential building is built, the optimization was performed by the genetic algorithm in order to reduce the price of the material to a minimum and to keep the external wall with the best dynamic characteristics.

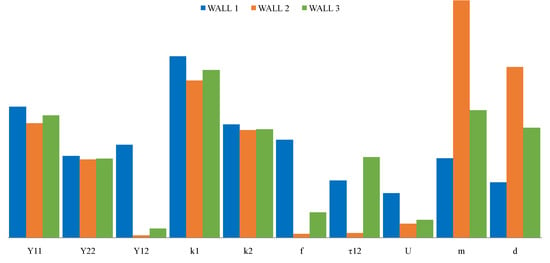

Figure 7 shows a comparative diagram of the dynamic characteristics of the heat transfer of all the analyzed walls.

Figure 7.

Comparative diagram of dynamic characteristics of all the external walls of the ventilated façade.

Figure 7 shows that the optimization performed by a genetic algorithm offered the structure of the external wall with the best dynamic characteristics of the heat transfer, i.e., the structure that would be the most energy efficient.

The genetic algorithm (GA) provided values of thickness for the layers in the external wall of the ventilated façade that met the manufacturer and investor’s predefined conditions (requirements).

Figure 7 shows that the wall 3 represents the structure with the highest temperature variation shift factor (τ = 17.82, h, for 29% and 94.3% higher than for walls 1 and 2, respectively).

Since the specific mass of the external wall 3 (m = 563, kg/m2) was 37.8% higher than for the wall 1 and 86.3% lower than the specific mass of the wall 2, it can be concluded that the wall 3 had the most compact structure with the best dynamic characteristics of the heat transfer.

The optimization was performed by finding the minimum value of a function in the form:

where, for the given limit conditions, the value of the function was:

As mentioned earlier, the optimization of the objective function was performed by the genetic algorithm that provided optimum values for the solution of the objective function. This method determined the optimum values of the layer thickness for the external wall so the unit price of the material per material mass was minimal, since the objective function depended on the layer thickness of the materials used to construct the external wall.

4. Conclusions

Residential and commercial buildings are the greatest consumers of all types of energy. They particularly consume a huge amount of energy for the heating and cooling processes for which the fossil fuels are used. One of the solutions to reduce the energy consumption in buildings is either the use of renewable energy sources or the optimization of the heating and cooling processes in order to increase building’s energy efficiency and decrease energy consumption of the building in general.

The solution for reducing the energy consumption of a building, needed for heating and cooling processes, is presented in this paper. It represents optimization of the building’s construction costs with the highest energy efficiency, i.e., a construction of a building with the best dynamic characteristics for heat transfer through the external wall.

Analysis of the dynamic characteristics of the heat transfer of the external wall with minimum and maximum layer thickness of the ventilated façade was performed. The obtained values were related to the economic profitability of the investment, as well. The following step was to use the genetic algorithm (GA) to optimize the objective function to reduce the investment costs by providing optimal values of the layer thickness used in construction of the external wall for defined limit conditions.

By determining the optimal values of the layer thickness, the objective function offered the lowest unit price of the material per mass of material, which could further reflect on the value of the entire investment. Afterwards, the analysis of the dynamic characteristics for the heat transfer of the external wall of the ventilated façade, with obtained values for layer thickness for the wall, was performed and all the three walls were evaluated from the energy and economic aspects.

Based on analysis of the dynamic characteristics of the external wall of the ventilated façade, the structure of the external wall 3 was found to be the most energy efficient. It meant that this structure had good insulation (the periodical thermal transmittance factor Y12 was lower for 0.037, W/m2K than for wall 1 and it was higher for 0.003, W/m2K than value obtained for wall 2). This wall (3) had a façade with the great ability to accumulate heat, which suggested that the temperature variation shift factor τ would have the highest value compared to other analyzed walls. This fact guaranteed that the thermal comfort inside the building would be at the desired level.

The advantage of this optimization can be seen in the fact that the structure of the external wall with the best thermal characteristics is obtained for conditions defined by the client and that this structure is economically viable, as well. A disadvantage of this method is that the client is offered the opportunity to choose only three parameters, namely the price of a material per unit mass, total thickness of a wall and the heat transfer coefficient.

Analysis of this façade system and external wall, defined in this way, proved that optimization of a façade by the genetic algorithm provided an acceptable result and that use of the GA was possible for the further process of energy efficiency increase or, in other words, reduction of energy consumption in buildings. The genetic algorithm was used for optimization of the façade objective function for one specific structure of the external wall and façade. The further research direction would be to analyze different façade systems with different external wall structures, to expend and integrate the database and to perform optimization of one or more objective functions using the genetic algorithm.

Author Contributions

Conceptualization, S.M.K. and D.I.T.; methodology, J.M.D. and R.R.N.; software, S.M.K., D.I.T. and J.M.D.; validation, R.R.N. and B.H.; formal analysis, R.U.; resources, B.H.; data curation, S.M.K. and D.I.T.; writing—original draft preparation, S.M.K. and D.I.T.; writing—review and editing, J.M.D. and R.R.N.; supervision, B.H. and R.U.; funding acquisition, B.H. and R.U. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially financially supported by the “Innovative Solutions for Propulsion, Power and Safety Components of Transport Vehicles” ITMS 313011V334 of the Operational Program Integrated Infrastructure 2014–2020 and co-funded by the European Regional Development Fund and by the Ministry of Education, Science and Technological Development of Republic of Serbia through the funding of the scientific research work at the University of Belgrade, Technical Faculty in Bor, according to contract 451-03-9/2021-14/200131. Publication co-financed from the statutory research fund of Czestochowa University of Technology SPB-600/3016/2021.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Thermal absorption on the inner side of the wall | Y11 | W/m2K |

| Thermal absorption on the outer side of the wall | Y22 | W/m2K |

| Periodical thermal transmittance | Y12 | W/m2K |

| Thermal capacity of the heat surface at the internal side | k1 | kJ/m2K |

| Thermal capacity of the heat surface at the external side | k2 | kJ/m2K |

| Decrement factor | f | - |

| Temperature variation shift factor | τ12 | h |

| Material density | ρ | kg/m3 |

| Specific heat capacity | c | J/kgK |

| Thermal conduction coefficient | λ | W/mK |

| Specific mass | m | kg/m2 |

| Layer thickness | δ | m |

| Total thickness of the external wall | d | m |

| Heat transfer coefficient | U | W/m2K |

| Heat transfer resistance through the wall | R | m2K/W |

| Price of a material per unit mass | A | RSD/kg |

| Unit price of a material per m2 | B | RSD/m2 |

| Unit price of a material per running meter | C | RSD/m |

| Heat convection coefficient | α | W/m2K |

References

- Abergel, T.; Delmastro, C. IEA Tracking Buildings. Building Envelopes, Tracking Report—June 2020. Available online: https://www.iea.org/reports/tracking-buildings-2020 (accessed on 5 October 2020).

- Kucęba, R.; Pabian, A.; Bylok, F. Energy security intensification determinants in the chains of final energy value creation. Pol. J. Manag. Stud. 2010, 2, 68–80. [Google Scholar]

- European Commission. Energy, Energy Efficient Buildings, Energy Performance of Buildings Directive 2010/31/EU of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-conent/EN/TXT/PDF/?uri= CELEX:32010L0031&from=EN (accessed on 12 October 2020).

- European Commission. Energy, Energy Efficient Buildings, Energy Performance of Buildings Directive. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-uildings/energy-performance-buildings-directive_en (accessed on 7 October 2020).

- European Commission. Energy, Content Energy Consumption by End-Use. Available online: https://ec.europa.eu/energy/content/energy-consumption-end-use_en (accessed on 12 October 2020).

- Romanach, L.; Leviston, Z.; Jeanneret, T.; Gardner, J. Low-carbon homes, thermal comfort and household practices: Uplifting the energy efficiency discourse. Energy Procedia 2017, 121, 238–245. [Google Scholar] [CrossRef]

- Mills, B.; Schleich, J. Residential energy-efficient technology adoption, energy conservation, knowledge and attitudes: An analysis of European countries. Energy Policy 2012, 49, 616–628. [Google Scholar] [CrossRef]

- Addy, M.N.; Adinyira, E.; Ayarkwa, J. Identifying and weighting indicators of building energy efficiency assessment in Ghana. Energy Procedia 2017, 134, 161–170. [Google Scholar] [CrossRef]

- Asere, L.; Blumberga, A. Energy efficiency-indoor air quality dilemma in public buildings. Energy Procedia 2018, 147, 445–451. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M. Optimization of high efficiency slab-on-ground floor by multi-objective analysis for zero energy buildings in Mediterranean climate. J. Build. Eng. 2019, 24, 100733. [Google Scholar] [CrossRef]

- Karataş, M.Z.; Rizaoğlu, T. Thermo-physical characteristics of acrylic-based building external isolation panels produced from different geological materials. Prod. Eng. Arch. 2018, 21, 12–19. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M.; Fazio, A.; Laforgia, D. Multi-objective optimization analysis for high efficiency external walls of zero energy buildings (ZEB) in the Mediterranean climate. Energy Build. 2014, 84, 483–492. [Google Scholar] [CrossRef]

- Si, B.; Tian, Z.; Jin, X.; Zhou, X.; Tang, P.; Shi, X. Performance indices and evaluation of algorithms in building energy efficient design optimization. Energy 2016, 114, 100–112. [Google Scholar] [CrossRef]

- Zhelykh, V.; Venhryn, I.; Kozak, K.; Shapoval, S. Solar collectors integrated into transparent facades. Prod. Eng. Arch. 2020, 26, 84–87. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.M.; Fazio, A. Multi-criteria optimization analysis of external walls according to ITACA protocol for zero energy buildings (ZEB) in the Mediterranean climate. Build. Environ. 2014, 82, 467–480. [Google Scholar] [CrossRef]

- Sozer, H.; Tuysuz, F. Dynamic evaluation method to increase the effect of the automation system on the building energy performance. J. Clean. Prod. 2020, 253, 119811. [Google Scholar] [CrossRef]

- Węglarz, A. Using Artificial Intelligence in energy efficient construction. In Proceedings of the SOLINA 2018—VII Conference SOLINA Sustainable Development: Architecture—Building Construction—Environmental Engineering and Protection Innovative Energy-Efficient Technologies—Utilization of Renewable Energy Sources, Polańczyk, Poland, 19–23 June 2018. [Google Scholar]

- Xu, K.Y.; Zhou, D.W.; Chen, Y.Q.; Lu, W.B. Research on Intelligent Energy Efficiency Management System Based on CBR/MAS. In Proceedings of the International Conference on Computer Information Systems and Industrial Applications (CISIA 2015), Bangkok, Thailand, 28–29 June 2015. Advances in Computer Science Research Series; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 520-523. [Google Scholar]

- González-Briones, A.; Prieto, J.; De La Prieta, F.; Herrera-Viedma, E.; Corchado, J.M. Energy Optimization Using a Case-Based Reasoning Strategy. Sensors 2018, 18, 865. [Google Scholar] [CrossRef] [PubMed]

- The International Organization for Standardization. Thermal Performance of Building Components. Dynamic Thermal Characteristics—Calculation Methods. Available online: https://www.iso.org/standard/65711.html (accessed on 12 October 2020).

- The International Organization for Standardization. Building Components and Building Elements. Thermal Resistance and Thermal Transmittance—Calculation Methods. Available online: https://www.iso.org/standard/65708.html (accessed on 11 October 2020).

- Kalinović, S.M.; Djoković, J.M.; Nikolić, R.R.; Hadzima, B. Calculation of the thermal dynamic performance of the residential buildings’ walls. In Quality Production Improvement 2019; Ulewicz, R., Ed.; Sciendo De Gruyter: Warsaw, Poland, 2019; Volume 1, pp. 212–221. [Google Scholar]

- Tanikić, D.; Manić, M.; Djoković, J.; Kalinović, S. Machining Parameters Optimization with Genetic Algorithm. In Proceedings of the 19th International Conference on Industrial Automation Systems and Engineering, World Academy of Science, Engineering and Technology, Rome, Italy, 11–12 December 2017; pp. 687–690. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).