Modified Rock Bolt Support for Mining Method with Controlled Roof Bending

Abstract

1. Introduction

2. Characteristics of the Room and Pillar Methods with Mined Roof Bending

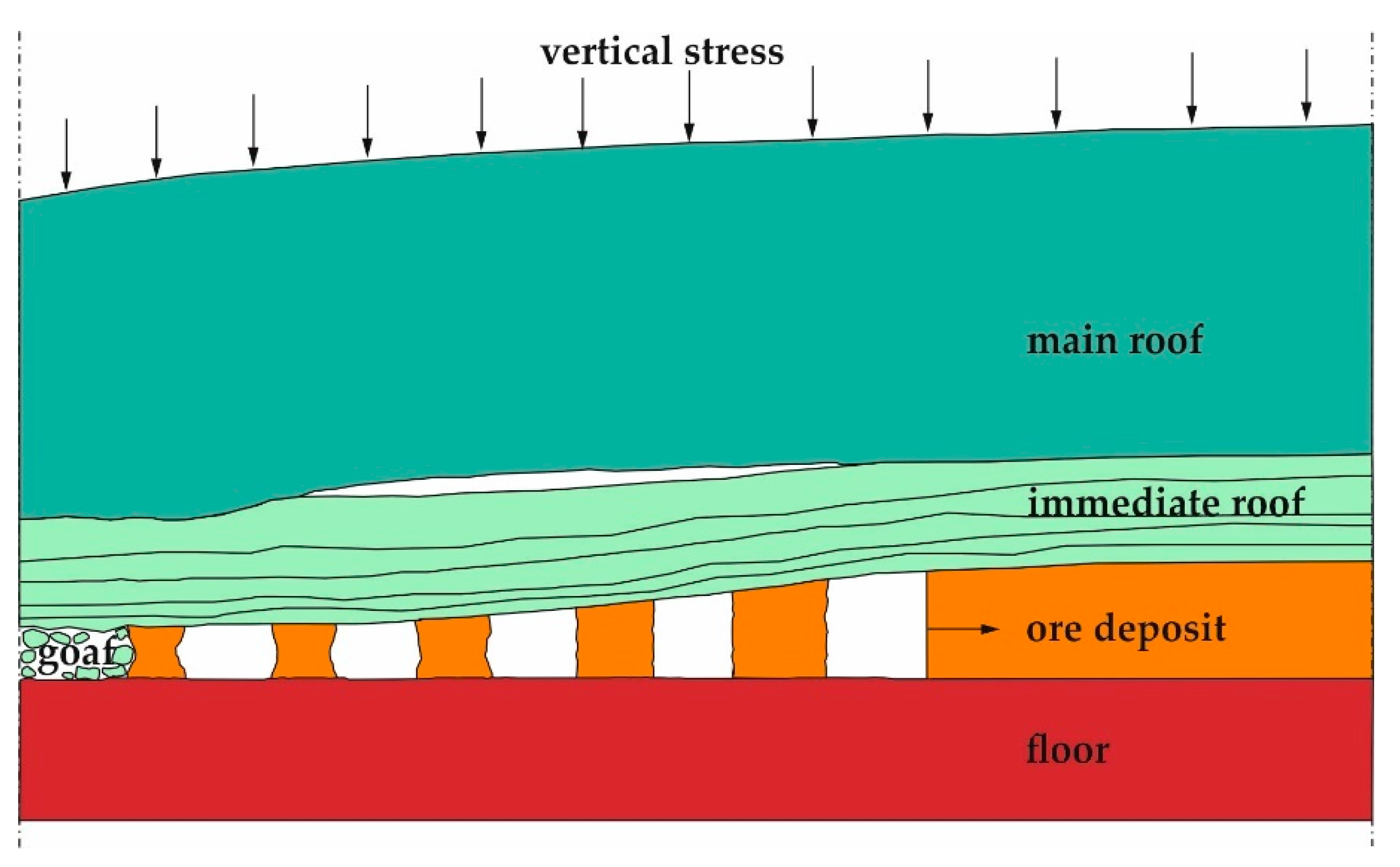

2.1. Characteristics of Geological Conditions in the Areas of Ore Deposits in the Polkowice-Sieroszowice Mine

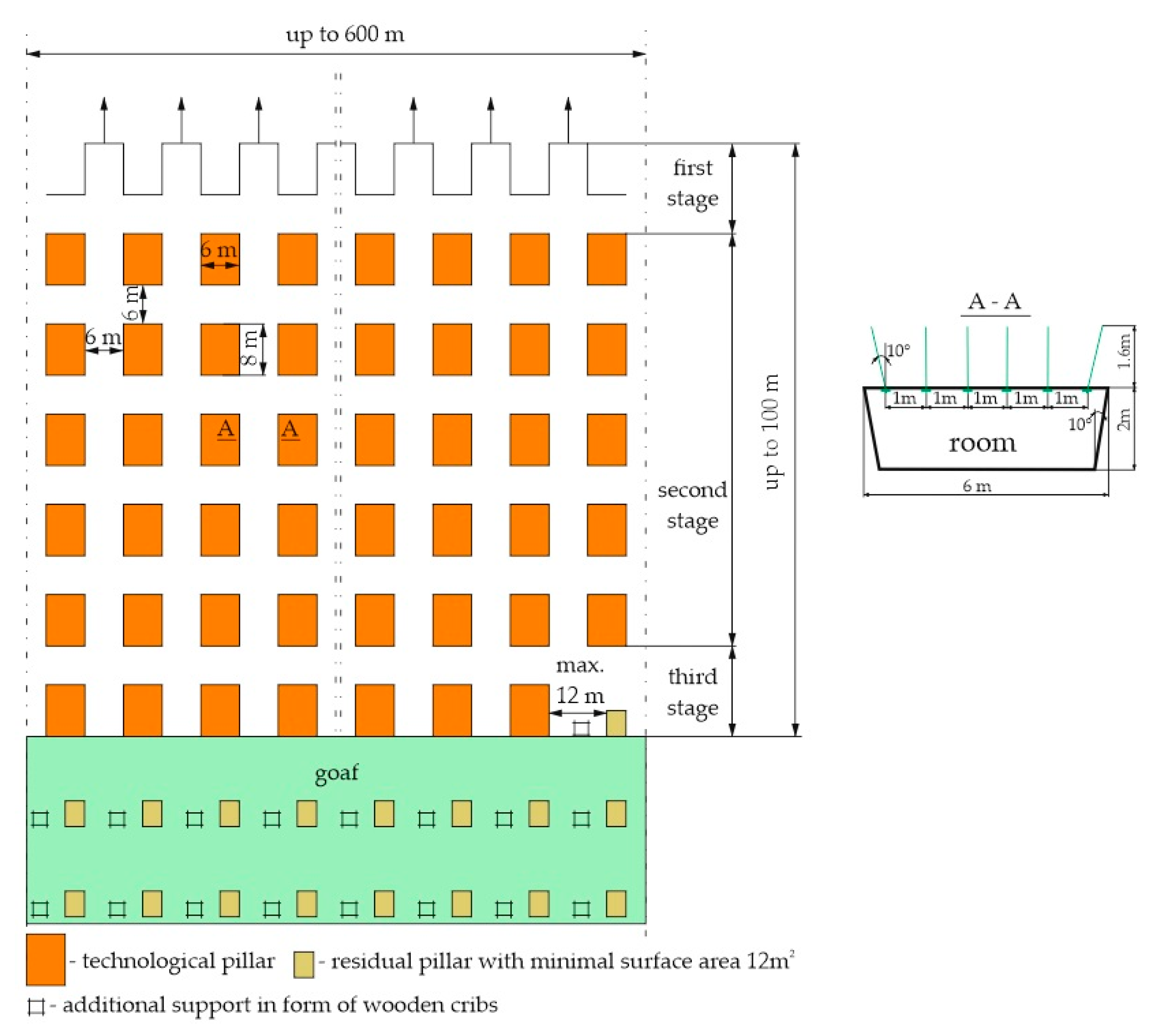

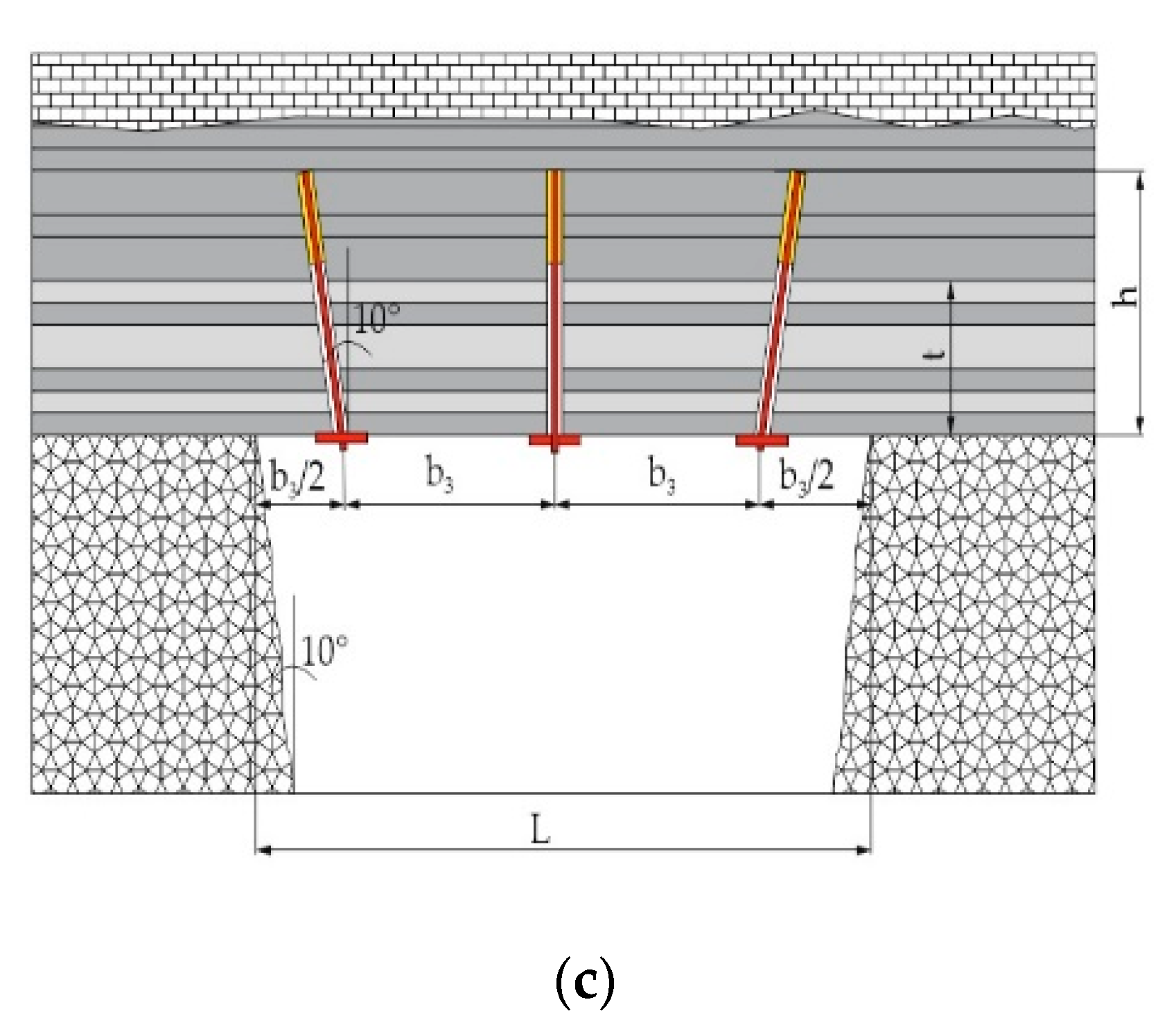

2.2. Room and Pillar Method with Mined Roof Bending

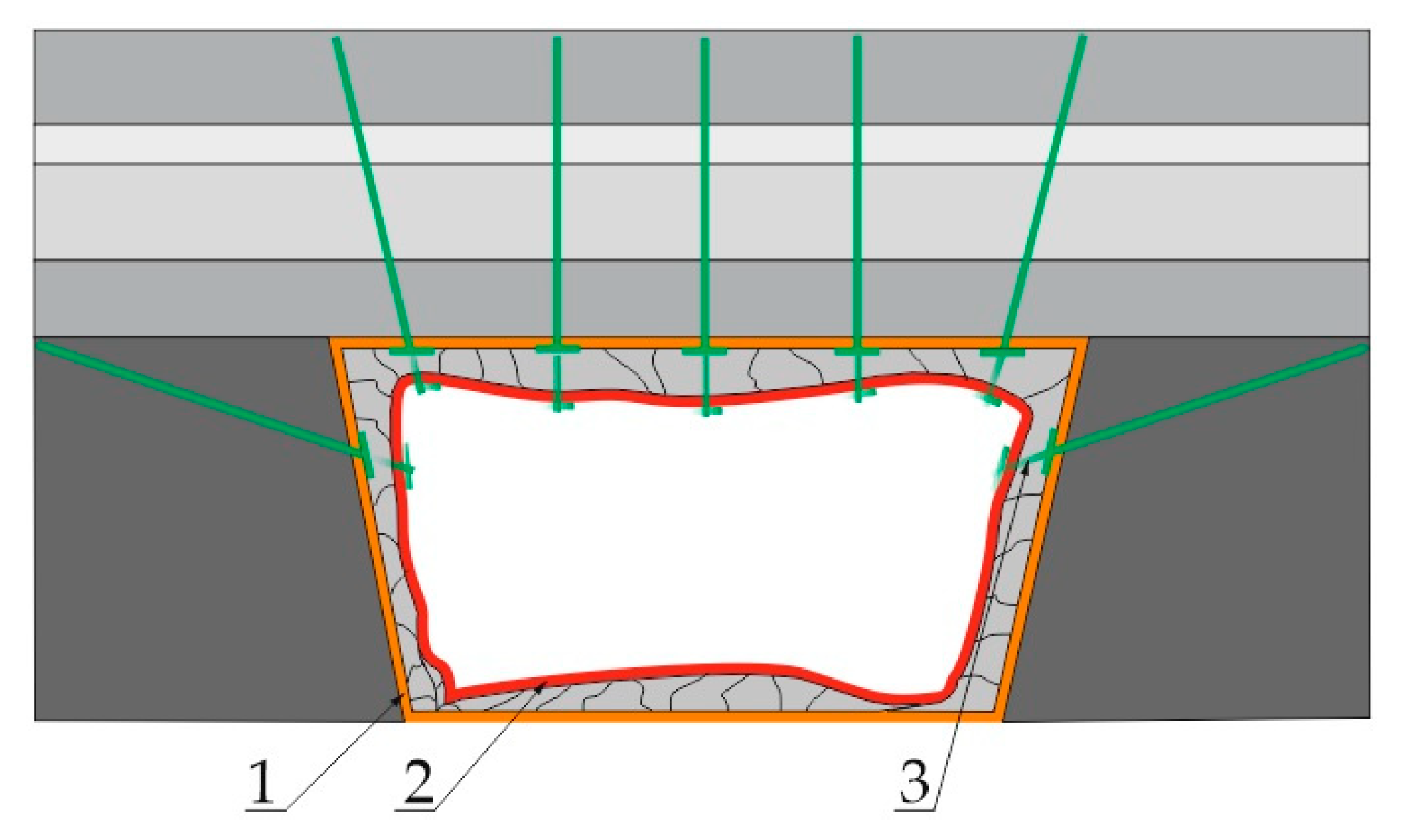

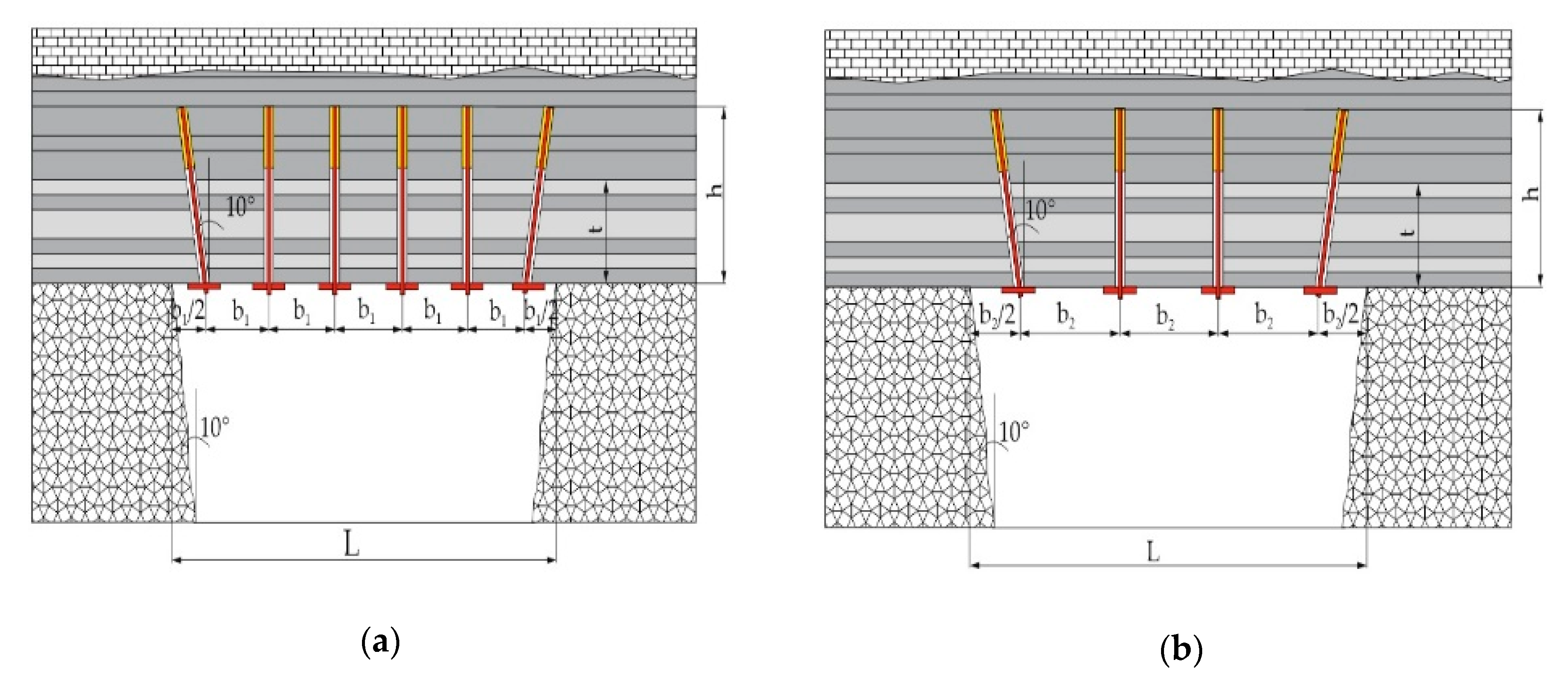

2.3. Roof Reinforcement with Rock Bolt Support

3. Materials and Methods

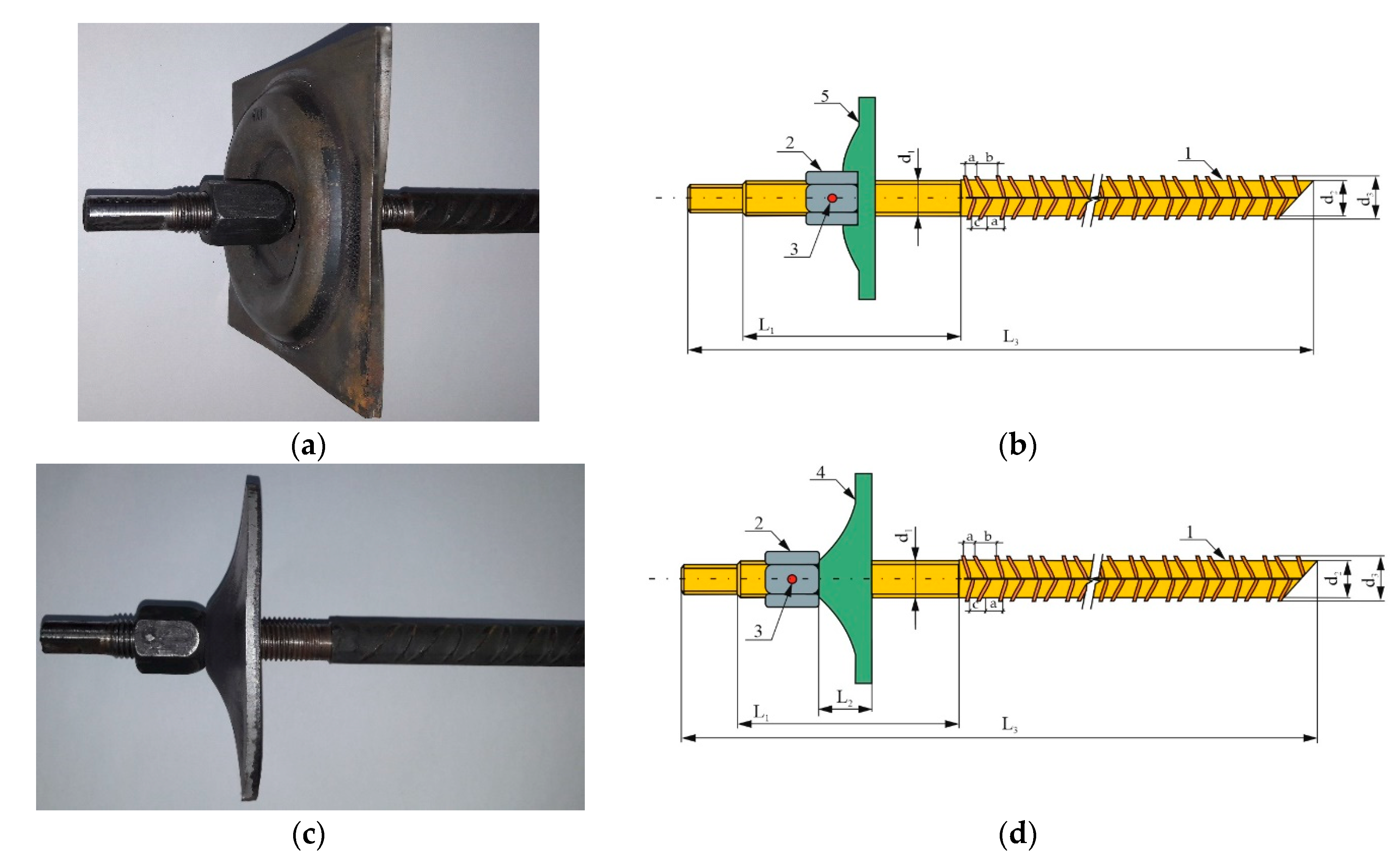

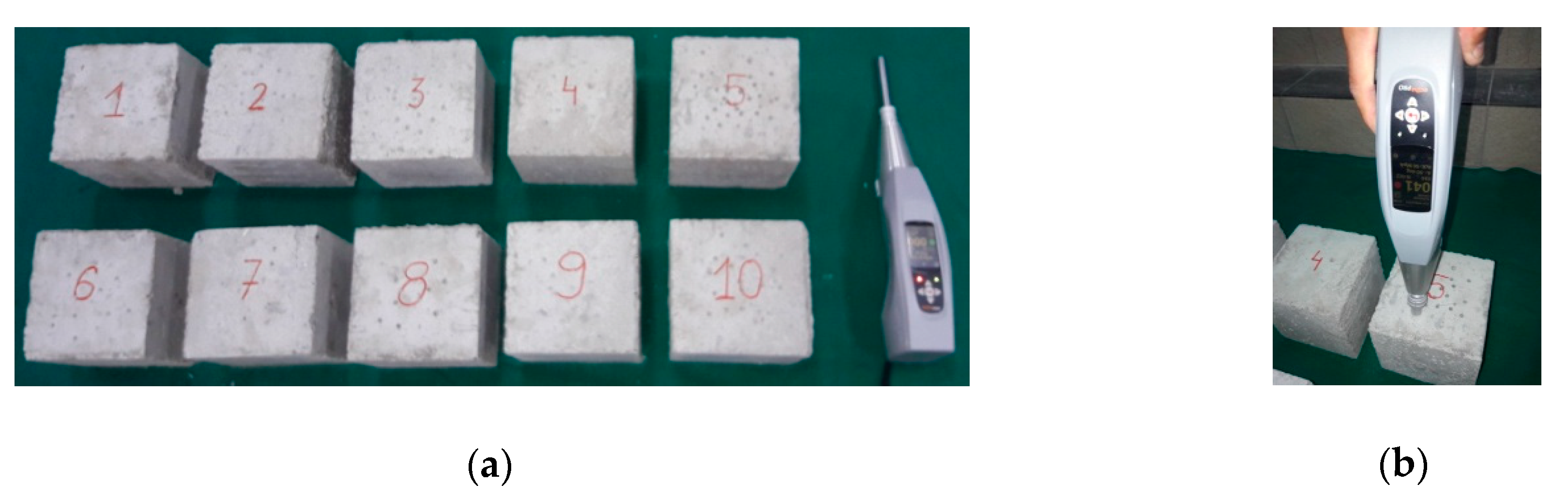

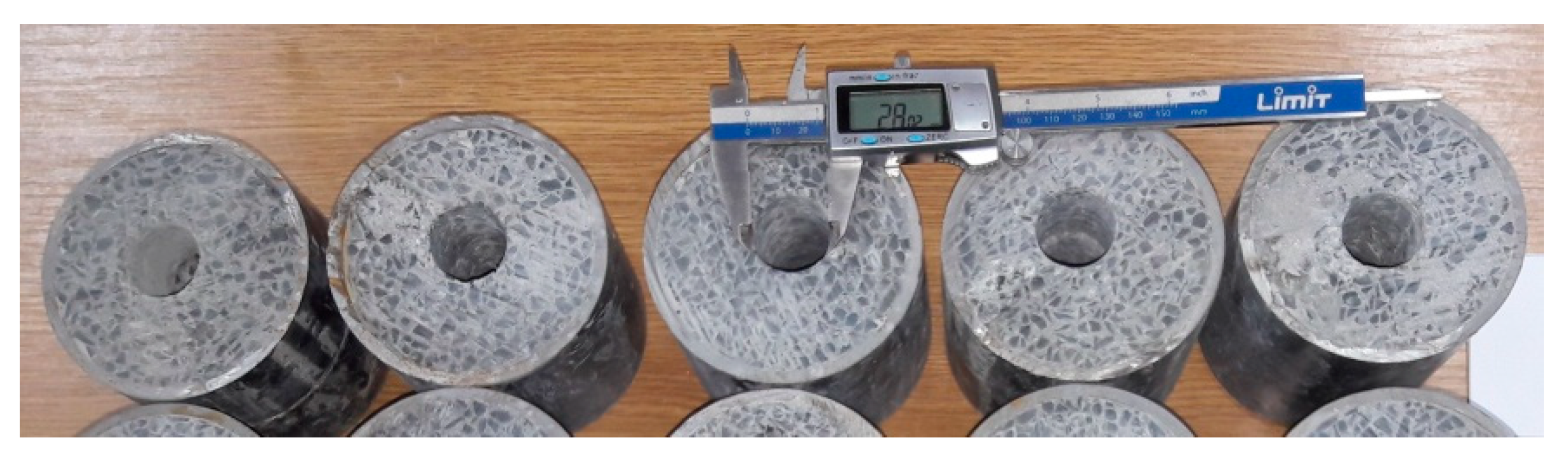

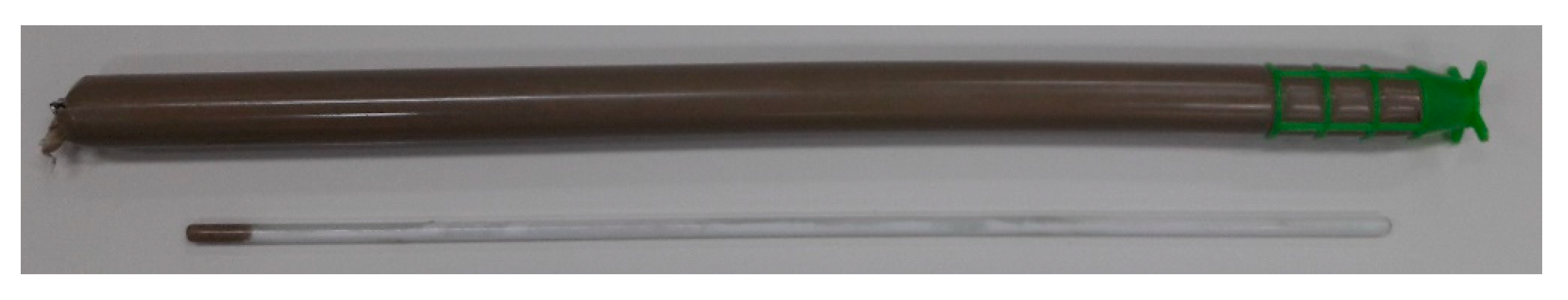

3.1. Segmentally Installed Resin Rock Bolt Support

3.2. The Model of the Rock Mass

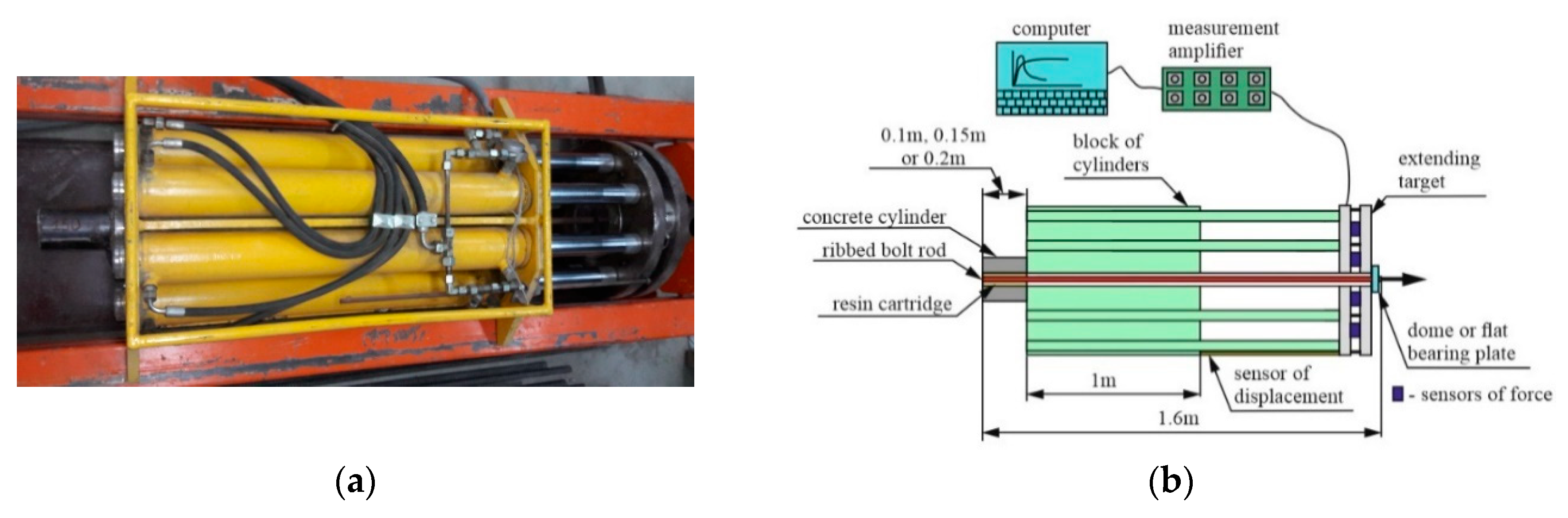

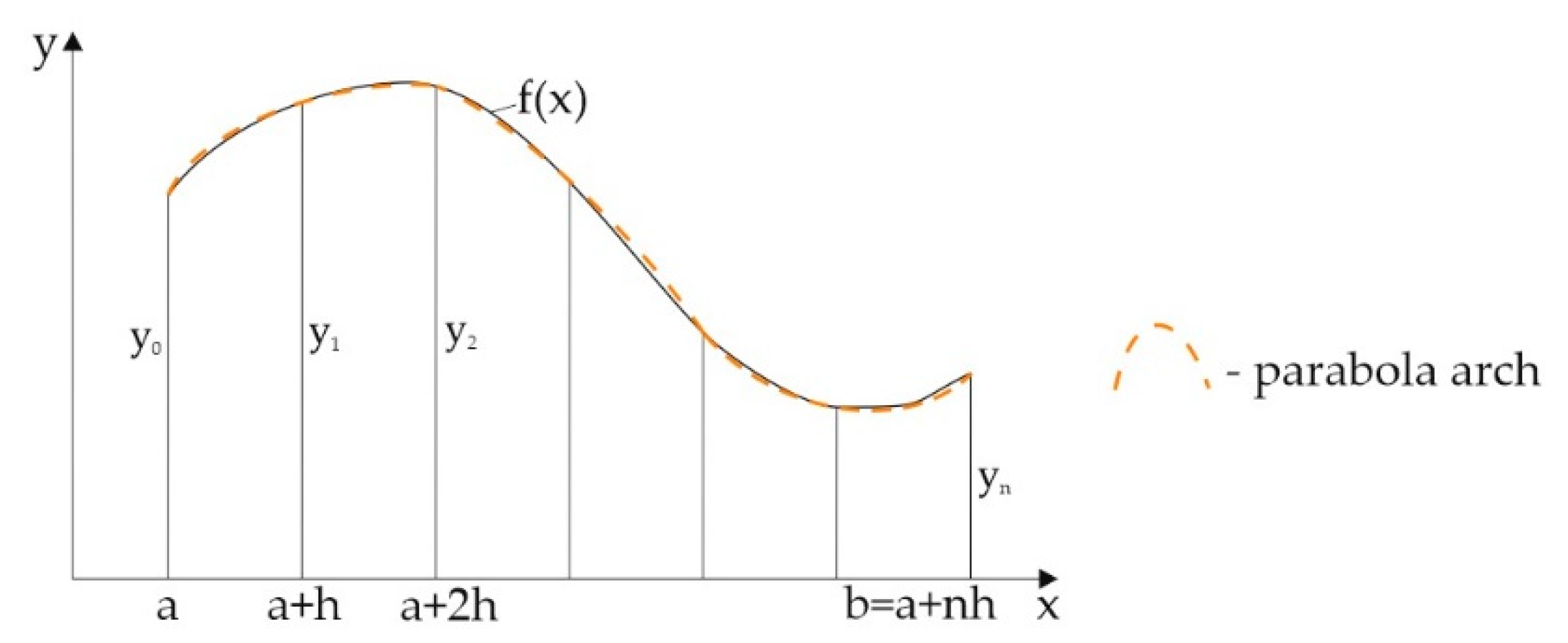

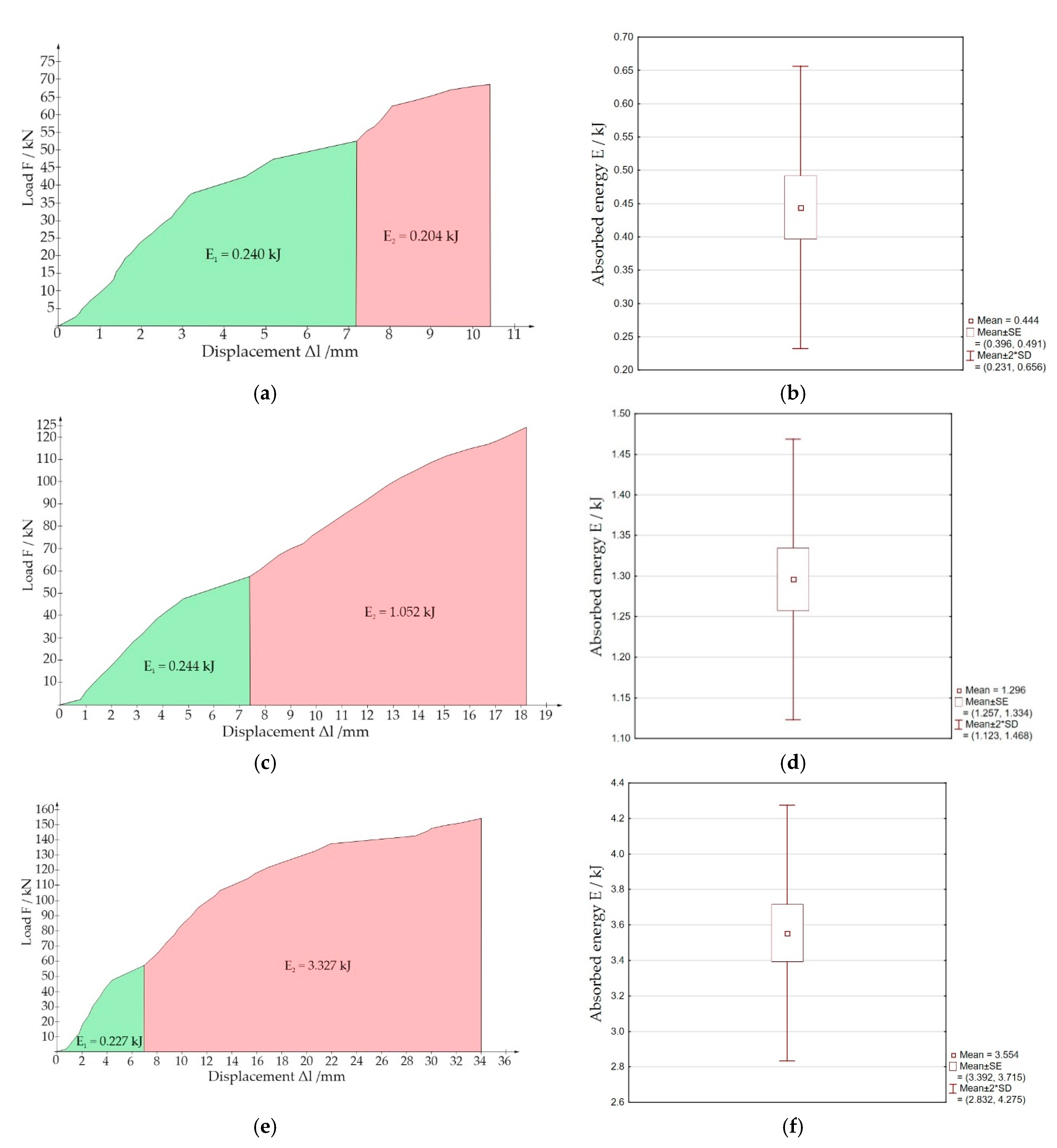

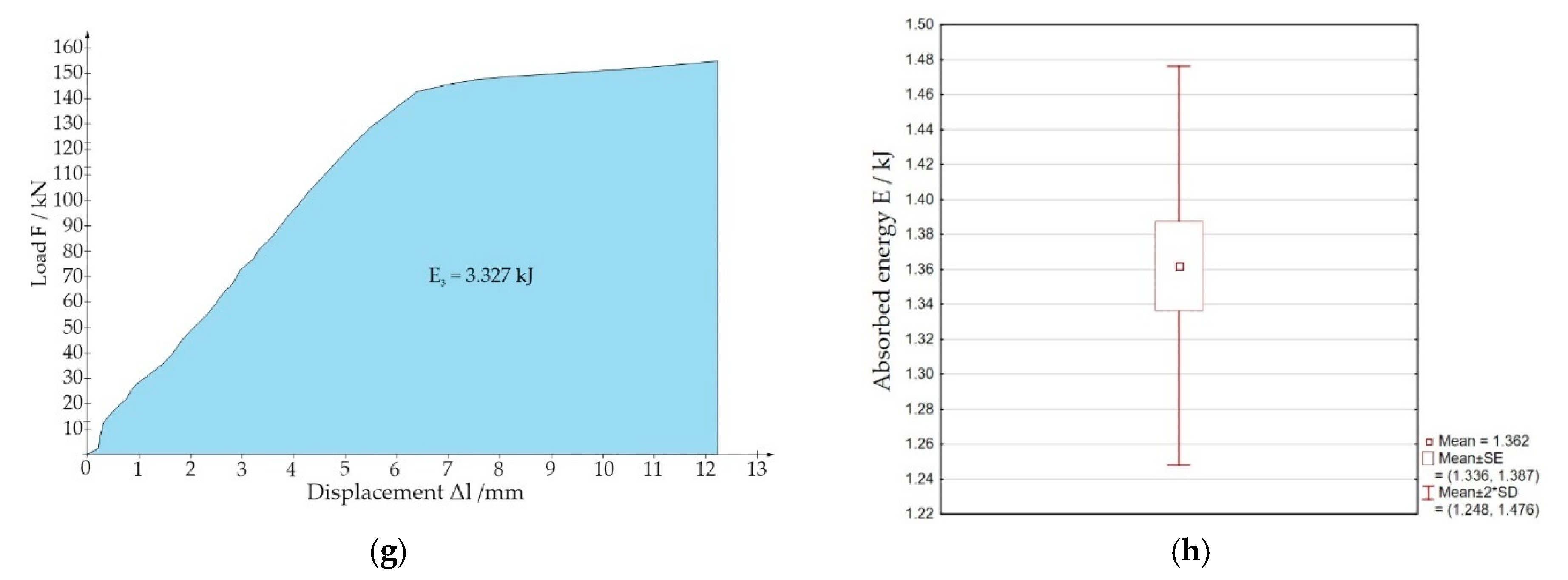

3.3. Load–Displacement Characteristics of a Segmentally Installed Rock Bolt Support

4. Discussion of Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cai, M. Principles of rock support in burst-prone ground. Tunn. Undergr. Space Technol. 2013, 36, 46–56. [Google Scholar] [CrossRef]

- Li, C.C.; Stjern, G.; Myrvang, A. A review on the performance of conventional and energy-absorbing rockbolts. J. Rock Mech. Geotech. Eng. 2014, 6, 315–327. [Google Scholar] [CrossRef]

- Chen, L.; Sheng, G.; Chen, G. Investigation of impact dynamics of roof bolting with passive friction control. Int. J. Rock Mech. Min. Sci. 2014, 70, 559–568. [Google Scholar] [CrossRef]

- Małkowski, P. The impact of the physical model selection and rock mass stratification on the results of numerical calculations of the state of rock mass deformation around the roadways. Tunn. Undergr. Space Technol. 2015, 50, 365–375. [Google Scholar] [CrossRef]

- Małkowski, P.; Niedbalski, Z.; Majcherczyk, T. Roadway design efficiency indices for hard coal mines. Acta Geodyn. Geomater. 2016, 13, 201–211. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Evaluation of Rock Bolt Support for Polish Hard Rock Mines. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 35, p. 01006. [Google Scholar] [CrossRef]

- Thenevin, I.; Blanco-Martín, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Pytlik, A.; Prusek, S.; Masny, W. A methodology for laboratory testing of rock bolts used in underground mines under dynamic loading conditions. J. S. Afr. Inst. Min. Metall. 2016, 116, 1101–1110. [Google Scholar] [CrossRef]

- Skrzypkowski, K. The influence of room and pillar method geometry on the deposit utilization rate and rock bolt load. Energies 2019, 12, 4770. [Google Scholar] [CrossRef]

- Bierman, I.R.; Gardner, L.; Piper, P. An evaluation of the bond strength of multiple resin bolt and capsule combinations through laboratory testing and applied methodologies. In Proceedings of the Ninth International Conference on Deep and High Stress Mining, Johannesburg, South Africa, 24–25 June 2019; Joughin, W., Ed.; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2019; pp. 175–190. [Google Scholar] [CrossRef]

- Villaescusa, E.; Varden, R.; Hassell, R. Quantifying the performance of resin anchored rock bolts in the Australian underground hard rock mining industry. Int. J. Rock Mech. Min. Sci. 2008, 45, 94–102. [Google Scholar] [CrossRef]

- Li, C.C.; Kristjansson, G.; Høien, A.H. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, N.; Li, G.; Guo, G. Pullout Test on Fully Grouted Bolt Sheathed by Different Length of Segmented Steel Tubes. Shock Vib. 2017, 2017, 4304190. [Google Scholar] [CrossRef]

- Ma, C.; Wang, P.; Jiang, L.; Wang, C. Deformation and Control Countermeasure of Surrounding Rocks for Water-Dripping Roadway Below a Contiguous Seam Goaf. Processes 2018, 6, 77. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Flexibility and load-bearing capacity of roof bolting as functions of mounting depth and hole diameter. Energies 2019, 12, 3754. [Google Scholar] [CrossRef]

- Aziz, N.; Jalalifar, H. The role of profile configuration on load transfer mechanism of bolt for effective support. J. Mines Met. Fuels 2007, 55, 539–545. [Google Scholar]

- Tao, W.; Chen, C.; Jun, H.; Ting, R. Effect of bolt rib spacing on load transfer mechanism. Int. J. Min. Sci. Technol. 2017, 27, 431–434. [Google Scholar] [CrossRef]

- Ghadimi, M. Effect of profile bolt in bond strength fully grouted rock bolts using analytical and experimental methods. Int. J. Min. Miner. Eng. 2017, 8, 156–167. [Google Scholar] [CrossRef]

- Yokota, Y.; Zhao, Z.; Shanga, J.; Nie, W.; Date, K.; Iwano, K.; Okada, Y. Effect of bolt configuration on the interface behaviour between a rock bolt and bond material: A comprehensive DDA investigation. Comput. Geotech. 2019, 105, 116–128. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Dudek, P. Application of Long Expansion Rock Bolt Support in the Underground Mines of Legnica–Głogów Copper District. Stud. Geotech. Mech. 2017, 39, 47–57. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Laboratory testing of a long expansion rock bolt support for energy-absorbing applications. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 29, p. 00004. [Google Scholar] [CrossRef]

- Skrzypkowski, K. A new design of support for burst-prone rock mass in underground ore mining. In E3S Web Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 71, p. 00006. [Google Scholar] [CrossRef]

- Cai, M.; Champaigne, D.; Coulombe, J.G.; Challagulla, K. Development of two new rockbolts for safe and rapid tunneling in burst-prone ground. Tunn. Undergr. Space Technol. 2019, 91, 103010. [Google Scholar] [CrossRef]

- Ortlepp, W.D.; Human, L.; Erasmus, P.N.; Dawe, S. Static and Dynamic Load Displacement Characteristics of a Yielding Cable Anchor—Determined in a Novel Testing Device. In Proceedings of the Sixth International Symposium on Rockburst and Seismicity in Mines Proceedings, Perth, Australia, 9–11 March 2005; Potvin, Y., Hudyma, M., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2005; pp. 529–534. [Google Scholar]

- St-Pierre, L.; Hassani, F.P.; Radziszewski, P.H.; Oullet, J. Development of a dynamic model for a cone bolt. Int. J. Rock Mech. Min. 2009, 46, 107–114. [Google Scholar] [CrossRef]

- Li, C.C. A new energy-absorbing bolt for rock support in high stress rock masses. Int. J. Rock Mech. Min. Sci. 2010, 47, 396–404. [Google Scholar] [CrossRef]

- Wu, Y.K.; Oldsen, J. Development of a new yielding rock bolt—Yield-Lok bolt. In Proceedings of the 44th US Rock Mechanics Symposium and 5th US-Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010; American Rock Mechanics Association: Alexandria, VA, USA, 2010; pp. 1–6. [Google Scholar]

- Charette, F.; Plouffe, M. Roofex®—Results of Laboratory Testing of a New Concept of Yieldable Tendon. In Proceedings of the 4th International Seminar on Deep and High Stress Mining, Perth, Australia, 7–9 November 2007; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2007; pp. 395–404. [Google Scholar]

- Varden, R.; Lachenicht, R.; Player, J.; Thompson, A.; Villaescusa, E. Development and implementation of the Garford Dynamic Bolt at the Kanowna Belle Mine. In Proceedings of the 10th Underground Operators’ Conference—Boom and Beyond, Tasmania, Australia, 14–16 April 2008; The Australasian Institute of Mining and Metallurgy, Ed.; The Australasian Institute of Mining and Metallurgy Launceston: Tasmania, Australia, 2008; pp. 95–104. [Google Scholar]

- Wang, G.; Wu, X.; Jiang, Y.; Huang, N.; Wang, S. Quasi-static laboratory testing of a new rock bolt for energy-absorbing applications. Tunn. Undergr. Space Technol. 2013, 38, 122–128. [Google Scholar] [CrossRef]

- He, M.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- He, M.; Gao, Y.; Yang, J.; Gong, W. An Innovative Approach for Gob-Side Entry Retaining in Thick Coal Seam Longwall Mining. Energies 2017, 10, 1785. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, Y.; Wang, G.; Gong, B.; Guan, Z.; Deng, T. Performance of a New Yielding Rock Bolt Under Pull and Shear Loading Conditions. Rock Mech. Rock Eng. 2019, 52, 3401–3412. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L.; Zhang, B. An experimental study of a yielding support for roadways constructed in deep broken soft rock under high stress. Min. Sci. Technol. 2011, 21, 839–844. [Google Scholar] [CrossRef]

- Sun, X.; Wang, L.; Lu, Y.; Jiang, B.; Li, Z.; Zhang, J. A yielding bolt—Grouting support design for a soft-rock roadway under high stress; a case study of the Yuandian No. 2 coal mine in China. J. S. Afr. Inst. Min. Metall. 2018, 118, 71–82. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Skrzypkowski, K.; Zagórski, K. Reinforcement of Underground Excavation with Expansion Shell Rock Bolt Equipped with Deformable Component. Stud. Geotech. Mech. 2017, 39, 39–52. [Google Scholar] [CrossRef]

- Chen, L.; Li, Q.; Yang, J.; Qiao, L. Laboratory Testing on Energy Absorption of High-Damping Rubber in a New Bolt for Preventing Rockburst in Deep Hard Rock Mass. Shock Vib. 2018, 2018, 7214821. [Google Scholar] [CrossRef]

- Dai, L.; Pan, Y.; Wang, A. Study of the energy absorption performance of an axial splitting component for anchor bolts under static loading. Tunn. Undergr. Space Technol. 2018, 81, 176–186. [Google Scholar] [CrossRef]

- Sepehri, M.; Apel, D.; Szymanski, J. Full three-dimensional finite element analysis of the stress redistribution in mine structural pillar. J. Powder Metall. Min. 2013, 3, 1–7. [Google Scholar] [CrossRef]

- Niedbalski, Z.; Małkowski, P.; Majcherczyk, T. Monitoring of stand-and-roof-bolting support: Design optimization. Acta Geodyn. Geomater. 2013, 10, 215–226. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Dominik, K.; Lalik, K. Fast, non-destructive measurement of roof-bolt loads. Stud. Geotech. Mech. 2019, 41, 93–101. [Google Scholar] [CrossRef]

- KGHM POLSKA MIEDŹ S.A. Available online: https://kghm.com (accessed on 24 November 2019).

- Panek, L.A. Principles of Reinforcing Bedded Mine Roof with Bolts; Report of Investigations 5156; US Dept. of the Interior, Bureau of Mines: Washington, DC, USA, 1956.

- Pytel, W. Geomechanical Problems of Selecting the Rock Bolt Support for Mining Excavations; KGHM CUPRUM Sp. z o.o.—Research & Development Centre: Wrocław, Poland, 2012; p. 222. [Google Scholar]

- Epstal. Available online: http://epstal.pl/en/reinforcing-steel/properties (accessed on 30 November 2019).

- PRIG. Available online: https://prig-kleje.pl (accessed on 29 October 2019).

- Korzeniowski, W.; Skrzypkowski, K.; Herezy, Ł. Laboratory Method for Evaluating the Characteristics of Expansion Rock Bolts Subjected to Axial Tension. Arch. Min. Sci. 2015, 60, 210–224. [Google Scholar] [CrossRef]

- Karman, T.V.; Biot, M.A. Mathematical Methods in Engineering, 3rd ed.; State Scientific Publisher: Warszawa, Poland, 1958; p. 20. [Google Scholar]

| Parameter | Excavation without Support | Rock Bolt Pattern | ||

|---|---|---|---|---|

| 1 m × 1 m | 1.5 m × 1.5 m | 2 m × 2 m | ||

| relative reduction of roof deflection (D) | - | 0.584 | 0.416 | 0.327 |

| reinforcement factor (RF) | 1 | 2.404 | 1.713 | 1.487 |

| load per individual rock bolt support (in kN) | - | 43.12 | 97.65 | 174.70 |

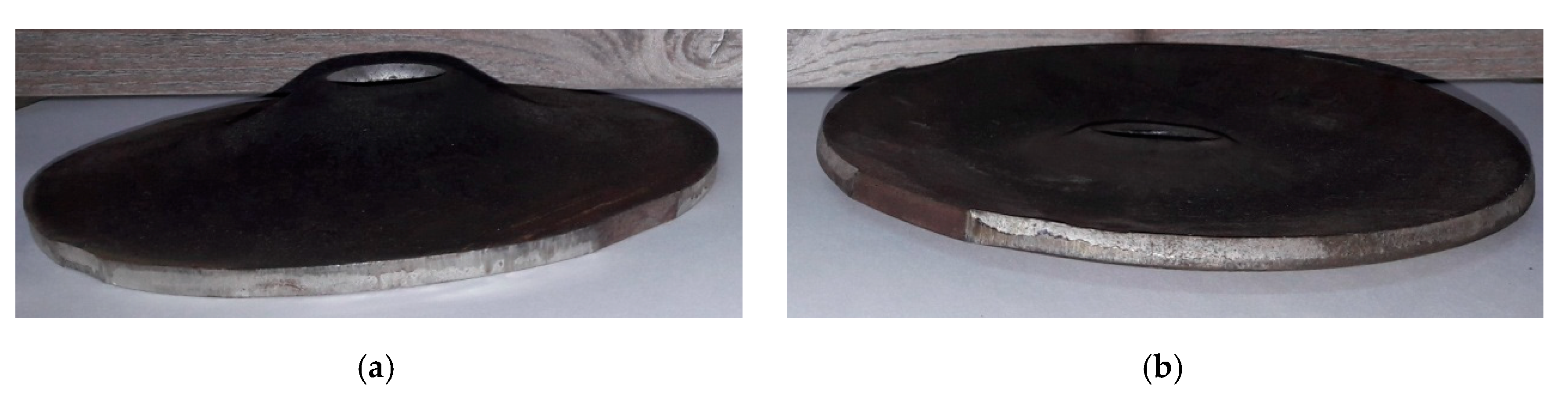

| Embedded Length (mm) | Bolt Hole Diameter (mm) | Shape of the Bearing Plate | Average Load-Bearing Capacity of the Bolt F (kN) | Average Displacement Δl (mm) | Comments |

|---|---|---|---|---|---|

| 100 | 28 | dome | 66.45 | 9.0 | extension from the hole |

| 150 | dome | 123.49 | 17.91 | extension from the hole | |

| 200 | dome | 153.97 | 32.67 | breakage at the thread | |

| 200 | flat | 153.29 | 10.30 | breakage at the thread |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K.; Zagórska, A. Modified Rock Bolt Support for Mining Method with Controlled Roof Bending. Energies 2020, 13, 1868. https://doi.org/10.3390/en13081868

Skrzypkowski K, Korzeniowski W, Zagórski K, Zagórska A. Modified Rock Bolt Support for Mining Method with Controlled Roof Bending. Energies. 2020; 13(8):1868. https://doi.org/10.3390/en13081868

Chicago/Turabian StyleSkrzypkowski, Krzysztof, Waldemar Korzeniowski, Krzysztof Zagórski, and Anna Zagórska. 2020. "Modified Rock Bolt Support for Mining Method with Controlled Roof Bending" Energies 13, no. 8: 1868. https://doi.org/10.3390/en13081868

APA StyleSkrzypkowski, K., Korzeniowski, W., Zagórski, K., & Zagórska, A. (2020). Modified Rock Bolt Support for Mining Method with Controlled Roof Bending. Energies, 13(8), 1868. https://doi.org/10.3390/en13081868