Abstract

To investigate the aerodynamic performance of exhaust passage under multi-phase flow, an actual case is conducted in the low-pressure double exhaust passages of 600 MW steam turbine. Then, the flow field is compared and analyzed with and without the built-in extraction pipelines based on the Eulerian–Eulerian homogenous medium multiphase method. Results show that the upstream swirling flow and downstream mixed swirling flow are the main causes to induce the entropy-increase in the exhaust passage. Moreover, the flow loss and static-pressure recovery ability in the exhaust hood are greater than those in the condenser neck. Compared with the flow field without the steam extraction pipelines, the entropy-increase increases, the static pressure recovery coefficient decreases, and the spontaneous condensation rates of wet steam decrease in the downstream area of the pipelines. With the increase of steam turbine loads, an increment in entropy-increase in the exhaust passage is 0.98 J/(kg·K) lower than that without steam extraction pipelines. Moreover, the incrementing range of uniformity coefficient is increased from 14.5% to 40.9% at the condenser neck outlet. It can be concluded that the built-in exhaustion pipeline can improve the aerodynamic performance of exhaust passage and better reflect the real state of the flow field. These research results can serve as a reference for turbine passage design.

1. Introduction

Energy consumption [1,2], energy conversion [3], energy saving [4], and their problem-solving method is getting more and more attention for rotating machinery [5,6,7]. As a key component of power plant, low-pressure (LP) exhaust passage consists of a condenser neck and exhaust hood, where its performance strongly affects the efficiency of LP steam turbine [8,9]. The exhaust passage can decelerate and guide the exhaust steam leaving the last stage blades (LSBs) into the condenser, converting the leaving kinetic energy to pressure energy [10]. Generally, the energy of exhaust steam is approximately equivalent to 1%–2% of the total available isentropic energy, accounting for about 10%–15% of the total loss of steam turbines [11]. However, the efficiency can increase by 0.15% for every 10% decrease in total pressure loss in the exhaust passage [12]. Thus, the research on the performance of LP exhaust passage has great potential to improve the efficiency of steam turbines.

For an understanding of the detailed flow field characteristics of exhaust passage, the numerical simulation and experimental method are employed. Then, the static pressure recovery and total pressure loss coefficients are used to characterize the performance of exhaust passage [13,14]. Lin et al. [15] numerically investigated the three-dimensional flow field of exhaust hood with consideration of various inflow conditions of inlet angle, swirl strength and wetness. They found that the performance is a strong function of inflow conditions. Moreover, the numerical analysis in the exhaust hood can be concluded that the major influences of flow loss result from the rotational flow downstream of last stage blades (LSBs) leading to a non-uniform distribution of flow field, tip leakage jet, asymmetry vortices formed within the diffuser, and flow separation along with the flow guide [16,17,18]. These phenomena can be corroborated by comparison with the experimental investigations [19,20,21]. However, for a theoretical and scale-model experimental study on condenser neck, Cui et al. [22] proposed that the condenser neck’s inner equipment evidently influences on the flow resistance and flow state inside the condenser neck, especially for steam extraction pipelines, inner heater, and desuperheating and reducing device due to their larger size. Simultaneously, the wet steam would affect both efficiency and reliability of LP steam turbine due to the expansion of steam that is a spontaneous and non-equilibrium condensation in the LP cylinder rear stages [23,24]. Lin et al. [25,26] found that the effect of two-phase flow is of importance for the flow field. Then, Han et al. [27,28,29] pointed out that wet steam two-phase flow is particularly important for the improvement of steam turbine efficiency. Although the wetness measurement is restricted by the high expense of experimental studies for wet steam [30], the detailed wetness data can be reliably obtained by the numerical simulation considering the non-equilibrium condensation of wet steam, which is in agreement with a model test rig of LP steam turbine [31,32]. Dykas and Wroblewski [33,34] also presented that the CFD code is successfully applied to the wet steam flow solution. However, there is still little evaluation of the effect of wetness on the whole LP exhaust passage.

As concluded above, it is increasingly clear that the more accurate numerical solutions are achieved when the exhaust passage coupled with both exhaust hood and condenser neck takes into account both the LSBs and an actual working fluid of wet steam. As a continuous work, an accurate representation of the flow field in both double exhaust hood and condenser neck is explored, which takes comprehensively into account the effect of the LSBs, inlet wetness, LP heater, steam extraction pipelines. Then, a numerical simulation of full-scaled LP exhaust passage in a 600 MW supercritical large power steam turbine is conducted. Especially, the effect of the steam extraction pipelines on the flow field is analyzed emphatically due to its large size and built in the condenser neck. In addition, the assessment of the overall performance is compared with and without consideration of the extraction pipelines.

2. Numerical Study

2.1. Computational Model and Boundary Conditions

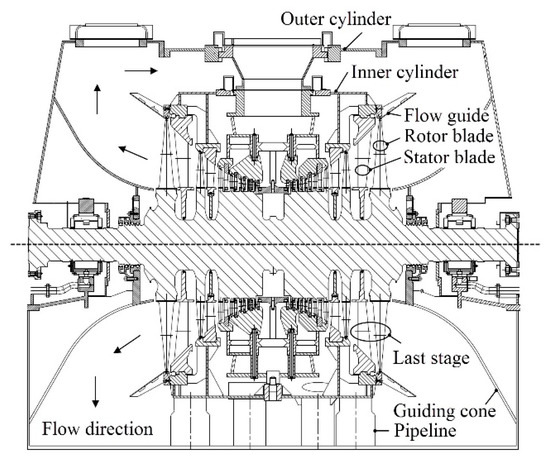

The full-scale geometric structure of the LP cylinder in a 600 MW supercritical condensing steam turbine is illustrated in Figure 1. The LP exhaust hood is a key component connecting the LSBs and condenser. As depicted in the figure, the flow leaving the LSBs decelerates into exhaust hood from the axial direction to the radial direction. All of the exhaust steam will flow through the downstream condenser neck. It is important to emphasize this process where the leaving kinetic energy can turn into the static pressure energy, which can be evaluated by the static pressure recovery coefficient, as follows:

where and are the mass-averaged static pressure and total pressure at the exhaust hood inlet (i.e., at LSB exit), respectively, and ps is the static pressure.

Figure 1.

A full-scale low-pressure (LP) cylinder of a supercritical large power steam turbine [15].

By simplification, the double exhaust passages are taken as a computational domain, as shown in Figure 2. The LSBs are considered in the CFD calculation to estimate the flow parameters at the inlet of the exhaust hood. Hence, the full-scale model is mainly made up of double LSBs, double exhaust hoods, condenser neck, and steam extraction pipelines. Especially for LSBs, each stage row has 52 stator blades and 80 rotor blades with a rotor blade height of 1029 mm, tip clearance of 11.2 mm, and design rotation speed of 3000 r/min. Then, the effect of steam exhaust from both the boiler feed pump turbine (BFPT) and LSBs on flow characteristics is considered.

Figure 2.

Calculational domain of a LP exhaust passage with the addition of LSBs and extraction pipelines [15]. 1. LP inner cylinder; 2. Exhaust hood; 3. Expansion joint; 4. Condenser neck outlet; 5. LP outer cylinder; 6. Flow Guide; 7. Last stage blades; 8. Guiding cone; 9. Steam extraction pipeline; 10. Steam exhaust inlet of BFPT; 11. LP heater.

The effective boundary conditions are given according to experimental validation results in Reference [35]. Hence, the mass flow rate is assigned to the LSBs inlet and steam exhaust inlet of BFPT, and the average static pressure is prescribed at the condenser neck outlet. The working fluid is wet steam (available in the IAPWS-IF97 library), which is taken from actual operation parameters in a 600 MW steam turbine heat acceptance (THA), as shown in Table 1. The heat acceptance of 100%, 75%, 50%, and 40% THA represent the turbine loads of 600, 450, 300, and 240 MW, respectively. Moreover, the exit pressure at each THA load is set to 4900 Pa. The interfaces between static and rotational domains apply the mixing plane model. No-slip and adiabatic are specified on all other walls.

Table 1.

Boundary conditions of LP exhaust passage at 600 MW steam turbine power load from 40% to 100% THA.

2.2. Numerical Method

Since the working fluid in the LSBs and exhaust passage is the wet steam, a feasible technology to simulate the steam-liquid two-phase flow is to conduct a two-way coupling process on alternately solving the governing equations of steam/liquid. The Eulerian–Eulerian homogenous medium multiphase method is applied to pay attention to the effect of wet steam flow on the whole aerodynamic performance. Both the steam and liquid phases are regarded as the continuous phase. Based on time-averaged steady-state conditions, the governing equations can be written as follows.

2.2.1. Homogeneous Medium Multiphase Model

The liquid-phase Steam3l and steam-phase Steam3v are represented as and , respectively. The total number of phases is = 2. Hence, the subscript is a distinguished variable parameter of each phase, such as the volume fraction (), which denotes the ratio of liquid-phase () to the infinitesimal volume V, and the conservation equation of volume for liquid-phase is given by:

The density of phase α and is and , respectively. The density of wet steam can be formulated as below.

The total pressure of wet steam can be obtained from the following equation.

where is the static pressure of wet steam, is the velocity of liquid-phase (i = 1) or steam-phase (i = 2).

There is no slip between liquid-phase and steam-phase according to the assumption above, i.e., the velocity of wet steam is equal to that of each phase. The velocity can be defined by:

The mass conservation equation of the continuous phase (i.e., steam-phase) can be written as the following formula.

where represents the mass source term. The mass source term is the mass flow ratio transferring from the liquid-phase to the steam-phase .

The momentum conservation equation is calculated by:

where is the momentum source term, and is given as:

The energy conservation equation is expressed as:

where the energy source term and H is given by the formula below:

To enclose the equations solved above, the constraint equation given constant pressure is presented in the following formula:

2.2.2. Equilibrium Phase Transition Model

The equilibrium phase transition model is conducted, assuming what wet steam at saturation state is thermodynamic equilibrium. The phase transfer happens quickly so that the mass fraction for each phase of wet steam can be directly determined by the phase diagram. Thus, the mass fraction of Steam3l (i.e., wetness) can be expressed as Equation (12) due to + = 1.

where h is the static enthalpy, and and are the saturation enthalpy with the function of pressure for Steam3l and Steam3v, respectively.

Accordingly, the present numerical solution is arrived by commercial code ANSYS CFX. Then, high Reynolds turbulence model κ-ε coupled with wall function is adapted to simulate the complex flows. The solution accuracy is of a second-order discretization scheme.

2.3. Numerical Procedure Validation of Calculation Accuracy

To improve the solution accuracy to a great extent, the numerical procedure and methodology are qualified by conducting the error analysis and comparing it with the experimental data. Then, an approach to generate fluid domain with high quality is discretized by unstructured and structured grids, respectively, for exhaust passage and LSBs domains. For the computation domain with consideration of steam extraction pipelines, the error analysis and independent study of the calculation grid are conducted by comparison with different mesh cells, as shown in Table 2. Mesh quality is in the range of 0-1, representing a better mesh quality when the number is close to 1. At the design operating condition, the pressure difference of LSB () is 16.9 kPa. Clearly, after case No. 2, the grid cells have little sensitivity to numerical solution results ( and ). Compared with the maximum grid cells (case No. 4), furthermore, the relative error of in case No. 2 is basically the same. For the fluid domain without the consideration of extraction pipelines, however, the results are the similarity at the same operating and other geometrical conditions. Thus, the total computation mesh cells are determined as about 9.90 million.

Table 2.

Error analysis and grid-sensitivity study in the computational domain of last-stage blades (LSBs) and exhaust passage.

A relative error between design value and numerical simulation result can be shown in Table 3 at 100% THA condition. Here, the maximum errors are all less than 3%, revealed that the numerical calculation accuracy is feasible and reliable for the present work.

Table 3.

Comparison of design value and numerical solution result at 100% turbine heat acceptance (THA) load.

3. Results and Discussion

3.1. Flow Field Analysis

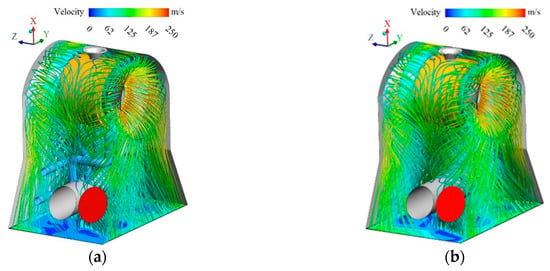

To further investigate the effect of steam extraction pipelines, Figure 3 illustrates a comparative flow structure with and without the addition of steam extraction pipelines at 100% THA load. As depicted in the figure, two strands of exhaust steam from LSBs exit present three-dimensional rotation and complicated flow trajectories in the exhaust passage. It is notable that three different mixing flows occur along the Cartesian coordinates y and z directions, as well as near the steam exhaust inlet of BFPT. The mixing flow is formed by mixing weak swirling flow with strong swirling flow upstream or by two swirling flows with the same tangential component of velocity. Then, the mixed flow region causes significant blockage in the exhaust passage. Hence, the swirling flow will reduce the effective flow area in the exhaust passage, which makes the wet steam velocity and flow state change with a certain loss of kinetic energy, that is, the mixing loss. Particularly, the velocity for wet steam near the wall in the mixture zone is obviously lower, signifying that it is little disturbed by the strong swirl in the main flow zone and has higher potential energy. Simultaneously, the exhaust steam continuously condenses and expands, producing in higher velocity and greater static pressure. In contrast, it can be concluded that the velocity of mixed flow (Figure 3a) around the extraction pipelines is lower than that corresponding to the flow field in the exhaust passage without the extraction pipelines (Figure 3b).

Figure 3.

Three-dimensional velocity streamlines (a) with and (b) without the consideration of steam extraction pipelines in the exhaust passage.

It is necessary to analyze the effect of the mixed flow on uniformity distribution of flow field. Figure 4 gives a comparative velocity contour at the condenser neck outlet. As evidenced in the figure, high-speed zones greater than 90 m/s are concentrated on the surrounding walls and steam exhaust of BFPT. Moreover, five large low-speed zones less than 30 m/s are distributed around the center of the flow field. One of the low-speed zones (i.e., close to the steam exhaust of BFPT) is dispersed by high-speed steam flow from the steam exhaust of BFPT and form two small low-speed zones. This phenomenon can be demonstrated that the kinetic energy decreases gradually in the process of upstream mixed flow to downstream flow. Generally, the upstream flow velocity is uniformly distributed at about 50 m/s; it is beneficial to improve the economy of the condenser vacuum. By comparison, the velocity at condenser neck exit without extraction pipelines (Figure 4b) is larger than that with the consideration of extraction pipelines (Figure 4a), resulting in a better uniform distribution of velocity field with the addition of extraction pipelines.

Figure 4.

Velocity contours (a) with and (b) without consideration of extraction pipelines at condenser neck outlet.

Heat dissipation and turbulent flow will cause a loss [36,37]. The irreversible loss of energy in the flow field can be described by the entropy-increase (Δs), as defined in Equation (13). The presented Equation (13) corresponds to an ideal gas with constant specific heat. While for wet steam specific heat depends on real steam and water properties parameters. Here, the entropy-increase (Δs) is a mixture of water and steam entropy.

where cp is the specific heat at constant pressure, κ is the gas adiabatic constant, pt,0 and Tt,0 are corresponding to mass-averaged total pressure and total temperature at LSBs inlet, pt and Tt are total pressure and total temperature, respectively.

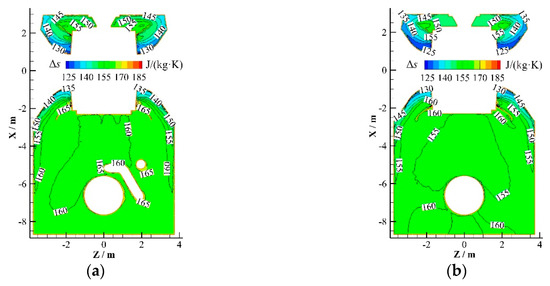

A comparative contour of entropy-increase at the meridional plane of exhaust passage is given in Figure 5. Considering the extraction pipelines, the Δs is relatively high, and then, the low-value area of Δs less than 135 J/(kg·K) is mainly concentrated inside the diffuser, in which the low-value area of Δs in the upper part of the diffuser is larger than that of the lower part. However, the high-value zone of Δs larger than 155 J/(kg·K) is mainly distributed at the top of the exhaust hood and most of the downstream. This phenomenon can be ascribed by the existence of irreversible factors in the wet steam, resulting in the dissipation loss. The dissipation loss is caused by the friction of the single swirl flow and mixed swirl flow, which produce the heat and turbulence dissipation to contribute to entropy-increase. Hence, a higher heat and turbulence dissipation will result in a great and irreversible loss (that is, entropy-increase) in the exhaust passage.

Figure 5.

Entropy-increase at the meridional plane of exhaust passage (a) with and (b) without the consideration of extraction pipelines.

In contrast to Figure 5a,b, it is clear that the steam flow reverses upwards from the diffuser and forms a swirling flow, which continuously affects the whole flow field and makes the exhaust passage full of dissipation loss caused by the vortex structure. Considering the extraction pipelines, the entropy-increase distributions at the top of the exhaust hood are relatively large, indicating that the top swirling flow causes greater dissipation loss. The downstream steam flow is affected by the pipelines, resulting in a relatively larger entropy-increase at the corresponding location. Simultaneously, the exhaust passage with the consideration of extraction pipelines makes more flow losses.

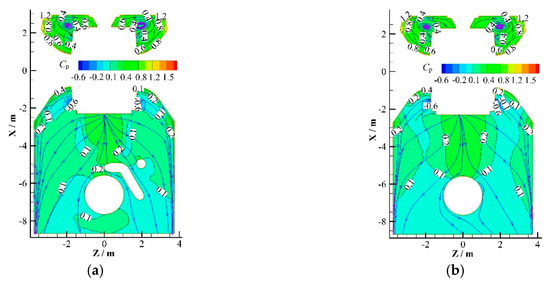

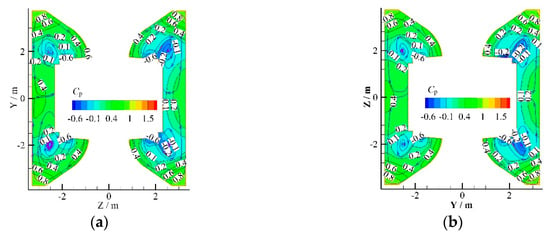

To analyze the ability of static pressure recovery, Figure 6; Figure 7 show the pressure contours between the two cases at different locations. As depicted in Figure 6, the Cp in the middle and upper parts of exhaust hood is in the range of 0.4–1.2 and 0.1–0.2 in the downstream flow area, while the negative value appears in the lower part of the diffuser inlet section. The space in the upstream exhaust hood is smaller than that in the downstream condenser neck, resulting in the flow loss due to the insufficient expansion of the steam flow. In this process, the leaving kinetic energy can turn into the static pressure energy, leading to a higher Cp value upstream than downstream. As evidenced in Figure 7, the separation of the top two vortices into four vortices is the main factor for the formation of downstream mixed flow with a relatively low Cp. By comparison, the low-value area of Cp in the downstream of exhaust passage with the extraction pipelines is smaller, while the area in the upstream exhaust hood is approximately the same, indicating that the Cp in the upstream is less affected by the extraction pipelines, and the scope of influence in the downstream is larger. By comparing the distribution of the entropy-increase and the static pressure recovery coefficient at the same position in the exhaust passage, it can be concluded that there is an inverse relationship between Δs and Cp, that is, the smaller the value of Δs, the larger the value of Cp.

Figure 6.

Static pressure recovery coefficient contours and velocity streamlines at the meridional plane of exhaust passage (a) with and (b) without the consideration of extraction pipelines.

Figure 7.

Static pressure recovery coefficient contours and velocity streamlines at the horizontal cross-section of exhaust passage (a) with and (b) without the consideration of extraction pipelines.

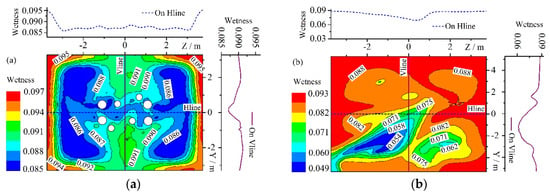

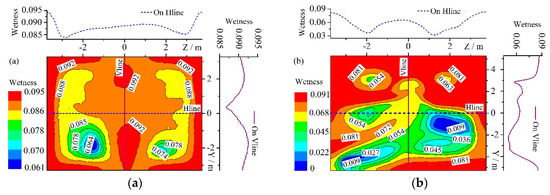

It is essential to comprehend the effect of wet steam two-phase equilibrium condensation flow with the consideration of extraction pipelines. Figure 8; Figure 9 show the wetness distributions in comparison to two cases. As illustrated in Figure 9, owing to the interaction of upstream four swirls and mixed flow, there are four low-wetness areas less than 0.088 with symmetrical distribution at the exhaust hood outlet. From the wetness data on the Hline and Vline curves, it can be found that high-wetness areas greater than 0.09 are near the wall. Considering that the effective area of flow domain decreases after the steam extraction pipelines, the areas corresponding to a low-wetness area are relatively large, while the high-wetness areas are relatively small, which are the same as the distribution trend at condenser neck outlet (Figure 9). Compared with Figure 8; Figure 9, it can be revealed that the steam extraction pipelines not only change the flow state of wet steam but also affect the condensation degree of wet steam. Wet steam temperature decreases from the exhaust hood inlet of 308.85 K and the steam exhaust inlet of BFPT of 309.03 to 305.67 K at the condenser neck outlet. The temperature difference is only about 3 K. Moreover, the temperature of wet steam at the corresponding locations is basically the same. Due to the existence of the pipelines, the effective flow area decreases at the exhaust hood outlet. When the mass flow rate and temperature remain unchanged, the flow velocity increases, and the pressure of the steam phase decreases. The density of the vapor phase gradually deviates from the saturated vapor density under the saturated pressure of the corresponding temperature. This phenomenon results in the relatively slow condensation rate of wet steam. With the downward flow of wet steam, the temperature and humidity decrease gradually. The wetness distribution at the condenser neck outlet is the result of mixing condensation disturbed by upstream inflow and steam exhaust of BFPT.

Figure 8.

Wetness contours with the consideration of extraction pipe at (a) exhaust hood exit and (b) condenser neck exit.

Figure 9.

Wetness contours without the consideration of extraction pipe at (a) exhaust hood exit and (b) condenser neck exit.

3.2. Analysis of Flow Field Characteristics

To quantitatively evaluate the aerodynamic performance of exhaust passage with and without the steam extraction pipelines, the flow loss and static pressure recovery ability are compared and analyzed at different THA loads. Then, the flow loss can be described by entropy-increase increment, as follows:

where the subscript “in” and “out” represent the inlet and outlet of exhaust hood/condenser neck, respectively.

Then, the velocity uniformity coefficient at the condenser neck outlet can be defined as:

where Va and Vm are the area-averaged and mass-averaged velocity, respectively.

Figure 10 shows a comparison for entropy-increase increment (Δs’) and static pressure recovery (Cp) in the exhaust hood and condenser neck. As depicted in the figure, when the given value of pressure at the condenser neck outlet is 4.9 kPa, both Δs’ and Cp show a regular progressive relationship as THA load increases. Clearly, from 40% to 100% THA loads, the flow loss and static pressure recovery ability in the exhaust hood are greater than that in the condenser neck. It can be revealed that the exhaust loss from the LSBs mainly occurs in the exhaust hood, which converts some of the kinetic energy into static-pressure energy to realize the process of static-pressure recovery. However, the kinetic energy of working fluid weakens when the wet steam reaches the downstream condenser neck, which reduces the static pressure recovery ability. This phenomenon can be also indicated that the loss caused by the flow separation in the exhaust hood is greater than that caused by the mixing of the downstream steam flow. With the addition of extraction pipelines, the entropy-increase increment in the exhaust hood and condenser neck is in the ranges of 7.083–13.963 and 1.368–1.662 J/(kg·K), respectively, representing a smaller than the corresponding entropy-increase increment without the extraction pipelines. At 75% THA load, the change of Δs’ in the condenser neck with the extraction pipelines is not significant, but the negative value of Cp exists in the condenser neck without the extraction pipelines. It can be concluded that the flow field with steam extraction pipelines can improve the aerodynamic performance of the downstream condenser neck.

Figure 10.

Flow field characteristics of exhaust passage (a) with the extraction pipe and (b) without the extraction pipelines.

Figure 11 illustrates a comparative error of entropy-increase increment (Δs’) and static pressure recovery coefficient (Cp), relative to that without the consideration of extraction pipelines. From the figure, the relative errors for Δs’ and Cp are within the range of −5~10% and 0~45%, respectively, indicating a larger variation range in the condenser neck. Hence, it can be concluded that the exhaust passage considering the extraction pipelines can better reflect the real flow field, and then the effect of steam extraction pipelines cannot be ignored.

Figure 11.

Relative error analysis for Δs’ and Cp with and without consideration of steam extraction pipelines.

The uniformity of the velocity field in Figure 12 can reflect the influence of upstream inflow on the heat transfer performance of condensers. The larger the uniformity coefficient (λ), the better the heat transfer effect. It can be seen that with the increase of THA loads, an incrementing range in uniformity coefficient with the addition of extraction pipelines is greater than that without the addition of pipelines. Both of them show a monotonic increasing trend. Typically, the λ is relatively low before 75% THA load due to the effect of extraction pipelines. However, the uniformity coefficient with the extraction pipelines is relatively high after 75% THA load. From 40% to 100% THA loads, the uniformity coefficient increases from 67.730% to 77.535% with the extraction pipelines, presenting a 14.5% increase ((77.535% − 67.730%)/67.730 = 14.5%), which is smaller than that without the extraction pipelines of 40.9% increase. Therefore, compared with the LP exhaust passage without the extraction pipelines, the flow field uniformity can be improved with the extraction pipelines, and the aerodynamic performance in the exhaust passage can be also improved.

Figure 12.

Comparison of velocity uniformity distribution at the condenser neck outlet.

4. Conclusions

In this study, an actual case is applied to explore the flow field with consideration of wet steam in a 600 MW supercritical condensing steam turbine. Then, a comparative analysis of the flow field characteristics in the exhaust passage with and without built-in steam extraction pipelines are carried out. The main conclusions are as follows:

The turn-over swirl in the exhaust hood and mixed swirl in the condenser neck are two important factors to cause the entropy-increase in the exhaust passage. Then, the flow loss and static-pressure recovery ability in the exhaust hood are greater than those in the condenser neck. Moreover, the extraction pipelines in the exhaust passage will result in an increment in the entropy-increase and a decrease in the static pressure recovery coefficient. From 40% to 100% THA conditions, an increment in entropy-increase within the condenser neck and exhaust hood varies in the ranges of 1.368–1.662 and 7.083–13.963 J/(kg·K), respectively, which is lower than the flow field without the consideration of built-in extraction pipelines. In addition, the incrementing range of uniformity coefficient enhances from 14.5% to 40.9% for the velocity field at the condenser neck outlet. It is therefore that the effect of steam extraction pipelines cannot be ignored to reflect a more accurate evaluation of the aerodynamic performance of exhaust passage.

Author Contributions

Conceptualization, Q.X., A.L., Y.C., N.A., Y.D. and C.L.; methodology, Q.X., A.L., Y.C., N.A., Y.D. and C.L.; software, Q.X., A.L., Y.C., N.A., Y.D. and C.L.; validation, A.L.; formal analysis, Q.X., A.L., Y.C., N.A., Y.D. and C.L.; investigation, Q.X., A.L., Y.C., N.A., Y.D. and C.L.; writing—original draft preparation, A.L.; writing—review and editing, Q.X. and A.L.; supervision, A.L.; funding acquisition, Q.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Planning Project of Shenzhen City, China, grant number JCYJ20170818111529172. This research was also supported by the Fund of Southern Marine Science and Engineering Guangdong Laboratory (Zhanjiang), China, grant number ZJW-2019-01.

Acknowledgments

For a contribution of this study, Aqiang Lin especially wishes to thank the important help of his master’s supervisor Lihua Cao at Northeast Electricity University of China.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Cp | Static pressure recovery coefficient (-) |

| ps | Static pressure (Pa) |

| pt | Total pressure (Pa) |

| Mass-averaged static pressure (Pa) | |

| Mass-averaged total pressure (Pa) | |

| Tt | Total temperature (K) |

| va | Area-weighted average velocity (m·s−1) |

| vm | Mass-weighted average velocity (m·s−1) |

| α | Steam3l. mass fraction, i.e., wetness (-) |

| β | Steam3v. mass fraction (-) |

| κ | Gas adiabatic constant (-) |

| λ | Velocity uniformity coefficient (-) |

| Entropy-increase (J·kg−1·K−1) | |

| Entropy-increase increment (J·kg−1·K−1) |

Abbreviations

| BFPT | Boiler feed water pump turbine |

| LP | Low pressure |

| LSBs | Last stage blades |

| THA | Steam turbine heat acceptance |

| Steam3l | Liquid-phase fluid |

| Steam3v | Steam-phase fluid |

References

- Lin, A.; Sun, Y.; Zhang, H.; Lin, X.; Yang, L.; Zheng, Q. Fluctuating characteristics of air-mist mixture flow with conjugate wall-film motion in a compressor of gas turbine. Appl. Therm. Eng. 2018, 142, 779–792. [Google Scholar] [CrossRef]

- Cai, Y.; Li, X.; Zaidi, A.; Shi, Y.; Zhang, K.; Feng, R.; Lin, A.; Liu, C. Effect of hydraulic retention time on pollutants removal from real ship sewage treatment via a pilot-scale air-lift multilevel circulation membrane bioreactor. Chemosphere 2019, 236, 124338. [Google Scholar] [CrossRef]

- Lin, A.; Zheng, Q.; Fawzy, H.; Luo, M.; Zhou, J.; Zhang, H. Effect of water injection cooling on flow field characteristics in the cooling section of precooled turbine-based combined cycle engine. Int. J. Heat Mass Transf. 2019, 141, 615–626. [Google Scholar] [CrossRef]

- Jiang, X.; Lin, A.; Ma, H.; Li, X.; Li, Y. Minimizing the thermal bridge through the columns in a refrigeration room. Appl. Therm. Eng. 2020, 165, 114565. [Google Scholar] [CrossRef]

- Jia, X.; He, L.; Zhang, H. Effect of turbine rotor disc vibration on hot gas ingestion and rotor-stator cavity flow. Aerosp. Sci. Technol. 2020, 98, 105719. [Google Scholar] [CrossRef]

- Han, X.; Zeng, W.; Han, Z. Investigating the dehumidification characteristics of the low-pressure stage with blade surface heating. Appl. Therm. Eng. 2020, 164, 114538. [Google Scholar] [CrossRef]

- Jia, X.; Zheng, Q.; Jiang, Y.; Zhang, H. Leakage and rotordynamic performance of T type labyrinth seal. Aerosp. Sci. Technol. 2019, 88, 22–31. [Google Scholar] [CrossRef]

- Beevers, A.; Congiu, F.; Pengue, F.; Mokulys, T. An analysis of the merits of CFD for the performances prediction of a low pressure steam turbine radial diffuser. In Proceedings of the ASME Turbo Expo, Glasgow, UK, 14–18 June 2010. ASME Paper No. GT2010-22107. [Google Scholar]

- Zoe, B.; Grant, L.I.; Simon, H. A literature review of low pressure steam turbine exhaust hood and diffuser studies. J. Eng. Gas Turbines Power 2013, 135, 062001. [Google Scholar]

- Jiang, X.; Lin, A.; Malik, A.; Chang, X.; Xu, Y. Numerical investigation on aerodynamic characteristics of exhaust passage with consideration of multi-factor components in a supercritical steam turbine. Appl. Therm. Eng. 2019, 162, 114085. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, X.; Du, Z.; Yang, H. Aerodynamic optimization system development for low pressure exhaust hood of steam turbine. In Proceedings of the ASME Turbo Expo, Glasgow, UK, 14–18 June 2010. ASME Paper No. GT2010-22280. [Google Scholar]

- Zaryankin, A.E.; Simonov, B.P.; Paramonov, A.N.; Chusov, S.A. Advancements in the aerodynamics of exhaust hoods of turbines. Therm. Eng. 1998, 45, 23–27. [Google Scholar]

- Cao, L.; Si, H.; Lin, A.; Li, P.; Li, Y. Multi-factor optimization study on aerodynamic performance of low-pressure exhaust passage in steam turbines. Appl. Therm. Eng. 2017, 124, 224–231. [Google Scholar] [CrossRef]

- Mizumi, S.; Ishibashi, K.; Sawamura, Y. Steam turbine exhaust hood with swirl flow separtion ducts. In Proceedings of the ASME Turbo Expo, Copenhagen, Denmark, 11–15 June 2012. ASME Paper No. GT2012-68315. [Google Scholar]

- Lin, A.; Chang, X.; Cao, L.; Zhang, H.; Sun, L. Effect of wet steam on aerodynamic performance of low-pressure exhaust passage with last stage blade. J. Appl. Fluid Mech. 2019, 12, 1837–1845. [Google Scholar] [CrossRef]

- Štastný, M.; Ladislav, T.; Kolár, P.; Tucek, A. Effect of inlet swirl on the flow in a steam turbine exhaust hood. J. Therm. Sci. 2000, 9, 327–333. [Google Scholar] [CrossRef]

- Musch, C.; Stuer, H.; Hermle, G. Optimization strategy for a coupled design of the last stage and the successive diffuser in a low pressure steam turbine. ASME J. Turbomach. 2013, 135, 011013. [Google Scholar] [CrossRef]

- Zhang, L.; Congiu, F.; Gan, X.; Karunakara, D. Performance prediction and optimisation of LP steam turbine radial diffuser at design and off-design conditions using streamline curvature method. In Proceedings of the ASME Turbo Expo, Seoul, Korea, 13–17 June 2016. ASME Paper No. GT2016-56974. [Google Scholar]

- Liu, J.; Cui, Y.; Jiang, H. Investigation of flow in a steam turbine exhaust hood with/without turbine exit conditions simulated. J. Eng. Gas Turbine Power 2003, 125, 292–299. [Google Scholar] [CrossRef]

- Zhang, W.; Paik, B.G.; Jang, Y.G.; Lee, S.J.; Lee, S.E.; Kim, J.H. Particle image velocimetry measurements of the three-dimensional flow in an exhaust hood model of a low-pressure steam turbine. J. Eng. Gas Turbine Power 2007, 129, 411–419. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Zhou, S. Experimental and numerical investigation of interaction between turbine stage and exhaust hood. Proc. Inst. Mech. Eng. Part A J. Power Energy 2007, 221, 991–999. [Google Scholar] [CrossRef]

- Cui, G.; Zhang, L.; Wang, F. Theoretical and model-experimental study on structure optimization of condenser-throat. J. Eng. Thermophys. 2007, 28, 131–133. [Google Scholar]

- Kasilov, V.F.; Sharkov, A.V. Evaluating the effect of steam wetness on the efficiency of the exhaust hoods of the low-pressure cylinders of steam turbines. Therm. Eng. 2004, 51, 378–383. [Google Scholar]

- Tanuma, T.; Sasao, Y.; Yamamoto, S.; Niizeki, Y.; Shibukawa, N.; Saeki, H. Numerical investigation of three-dimensional wet steam flow in an exhaust diffuser with non-uniform inket flows from the turbine stages in a steam turbine. In Proceedings of the ASME Turbo Expo, Copenhagen, Denmark, 11–15 June 2012. ASME Paper No. GT2012-69496. [Google Scholar]

- Lin, A.; Zheng, Q.; Jiang, Y.; Lin, X.; Zhang, H. Sensitivity of air/mist non-equilibrium phase transition cooling to transient characteristics in a compressor of gas turbine. Int. J. Heat Mass Transf. 2019, 137, 882–894. [Google Scholar] [CrossRef]

- Lin, A.; Zhou, J.; Fawzy, H.; Zhang, H.; Zheng, Q. Evaluation of mass injection cooling on flow and heat transfer characteristics for high-temperature inlet air in a MIPCC engine. Int. J. Heat Mass Transf. 2019, 135, 620–630. [Google Scholar] [CrossRef]

- Han, X.; Zeng, W.; Han, Z. Numerical investigation of the condensation flow characteristics and modification optimization of a condensing steam turbine cascade. Int. J. Numer. Method H 2019, 29, 4531–4548. [Google Scholar] [CrossRef]

- Han, X.; Zeng, W.; Han, Z. Investigation of the comprehensive performance of turbine stator cascades with heating endwall fences. Energy 2019, 174, 1188–1199. [Google Scholar] [CrossRef]

- Han, X.; Zeng, W.; Han, Z.; Li, P.; Qian, J. Effect of the nonaxisymmetric endwall on wet steam condensation flow in a stator cascade. Energy Sci. Eng. 2019, 7, 557–572. [Google Scholar] [CrossRef]

- Wróblewski, W.; Dykas, S.; Gepert, A. Steam condensing flow modeling in turbine channels. Int. J. Multiph. Flow 2009, 35, 498–506. [Google Scholar] [CrossRef]

- Grübel, M.; Starzmann, J.; Schatz, M.; Eberle, T.; Vogt, D.M.; Sieverding, F. Two-phase flow modeling and measurements in low-pressure turbines–Part I: Numerical validation of wet steam models and turbine modeling. J. Eng. Gas Turbine Power 2014, 137, 042602. [Google Scholar] [CrossRef]

- Schatz, M.; Eberle, T.; Grübel, M.; Starzmann, J.; Vogt, D.M.; Suerken, N. Two-phase flow modeling and measurements in low-pressure turbines–Part II: Turbine wetness measurement and comparison to computational fluid dynamics-predictions. J. Eng. Gas Turbine Power 2014, 137, 042603. [Google Scholar] [CrossRef]

- Dykas, S.; Wroblewski, W. Single- and two-fluid models for steam condensing flow modeling. Int. J. Multiph. Flow 2011, 37, 1245–1253. [Google Scholar] [CrossRef]

- Dykas, S.; Wroblewski, W.; Lukowicz, H. Prediction of losses in the flow through the last stage of low-pressure steam turbine. Int. J. Numer. Methods Fluids 2007, 53, 933–945. [Google Scholar] [CrossRef]

- Veerabathraswamy, K.; Kumar, A. Effective boundary conditions and turbulence modeling for the analysis of steam turbine exhaust hood. Appl. Therm. Eng. 2016, 103, 773–780. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, H.; Zheng, Q. Numerical investigation on the effect of hot running rim seal clearance on hot gas ingestion into rotor-stator system. Appl. Therm. Eng. 2019, 152, 79–91. [Google Scholar] [CrossRef]

- Jia, X.; Zheng, Q.; Tian, Z.; Jiang, Y.; Zhang, H. Numerical investigations on lifting and flow performance of finger seal with grooved pad. Aerosp. Sci. Technol. 2018, 81, 225–236. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).