Abstract

Uranium is one of the strategic minerals used mainly in energetics. The main purpose of uranium mining is to achieve maximum production to meet the rapidly growing demand for energies. It needs to become aware that technological progress in mining processes could significantly reduce the negative impacts associated with environmental, economic, and social risks. Uranium mining is one of the most controversial topics. It is dealt with by many experts and scientists around the world. Various methods and technologies of uranium mining are encountered in professional journals, as well as political or socio-economic decisions based on the impact and importance of the energy potential of uranium deposits, or the environmental impacts of uranium mining. The deposit of Kuriskova is one of the most perspective deposits not only in Slovakia but also in the world. The deposit is located near the town of Kosice (with near 240,000 inhabitants) and near the recreational area of Jahodna in the east of the Slovak Republic. The analysis and determination of the energy potential of the deposit of Kuriskova shows that uranium reserves from this deposit would be able to fully cover the needs for nuclear power plants for the production of nuclear fuel, in the Slovak Republic, even in the longer term. With the above-mentioned energy potential of the deposit of Kuriskova at the level of 600 TWh, nuclear power plants in the Slovak Republic are able to be supplied with raw materials from the deposit of Kuriskova for about 40 years with the current amount of electricity produced (approx. 15 TWh). Therefore, for the purposes of this research, a proposal for the extraction of uranium reserves at the deposit of Kuriskova was made. Based on it, it is possible to determine the amount of recoverable uranium reserves from the deposit. A methodology has been determined with mining this proposal, which takes into account the basic criteria of uranium deposit mining, which was used for the selection of a suitable mining technology for the uranium deposit of Kuriskova.

1. Introduction

Uranium is one of the strategic minerals used mainly in energetics. The main purpose of uranium mining is to achieve maximum production to meet the rapidly growing demand for energies. It needs to become aware that technological progress in mining processes could significantly reduce the negative impacts associated with environmental, economic, and social risks. Since the dawn of our atomic age in the early 20th century, uranium has been a vital resource for the production of nuclear medicine, energy, and defence systems [1]. Before uranium was used for energy production, it was used, for example, in early medical applications, for improved sealing of metal glass in electronic products under vacuum, as an additive in colored glass, and also as part of the pioneering raw material industry and radio discoveries that followed in previous centuries [2]. Uranium plays an important role in the nuclear military industry and the nuclear power industry provides a sufficient guarantee for the sustainable development of nuclear energy [3]. Uranium mining is a very diverse activity, depending on the chosen mining technologies, but it also depends on the conditions of a particular deposit. In addition to the common risks brought by any mining activity, uranium mining brings a threat mainly due to the handling of huge amounts of radioactive material.

Uranium mining is one of the most controversial topics. It is dealt with by many experts and scientists around the world. Various methods and technologies of uranium mining are encountered in professional journals, as well as political or socio-economic decisions based on the impact and importance of the energy potential of uranium deposits, or the impacts of uranium mining on the environment.

Like any other mining and processing of other minerals, uranium mining has destructive effects on the environment [4]. Quite large quantities of material, ranging from raw materials to materials that make up the waste that burdens the environment, are created by mining [5]. The presence of radon gas (Rn-222) and its short-lived progeny (Po-218, Pb-214, Bi-214, and Po-214) represent the risk to workers in uranium mines [6]. Three known methods are used for uranium mining, namely an underground, solution mining (in situ leaching or in situ recovery), and surface (open pit) depending on the geology, location, size, deposit grade, and economic considerations [7]. It is very important to choose the right way to mine uranium, which should be tailored to the company [8]. Within one enterprise, sometimes in mining, it is necessary to combine different extracting technologies [9] and [10] focus on economic efficiency with regard to uranium ore mining technology in their professional work.

To access ores, which occur close to the earth’s surface, open cut mining is used, which is capable of removing infertile or waste rocks (overburden) [11]. If we have a deposit that is economically viable and located relatively deep and open-pit mining would represent a high cost, then underground mining is recommended [12]. In situ recovery (ISR) technique removes the uranium while leaving the associated rocks in place [13]. Conventional mining methods represent the method where the uranium mineral and associated rocks are excavated together and the uranium is recovered on the surface [13]. Uranium is currently being recovered from in situ recovery (ISR), also known as in situ leach (ISL) mining [14].

A relatively common problem in the extraction of raw materials (especially heterogeneous raw materials) is the need to quickly determine the quantities of mined raw materials in operation [15].

After extraction, the uranium ore is processed in a hydrometallurgical processing facility to remove impurities and yellowcake is formed [16]. At present, strict irradiation control is carried out in modern uranium mines. Doses in the range of one year are in almost all cases significantly below the internationally accepted limit of 20 mSv/year (100 mSv in any period of five years without a dose above 50 mSv in any of these monitored years) [17].

Mining activity leads to several environmental impacts. There are often worries about the consequences of uranium mining on human health and the environment including increased levels of radiation and pollution of soil or groundwater and surface water sources. The most common naturally occurring radioactive materials (NORMs) is uranium (U). Uranium (U) shows radioactivity, chemical toxicity, and contamination (U) is becoming more and more pronounced [18]. Uranium (U) is present in low concentrations in almost all rocks, sediments, soils, air, natural waters, humans, animals, plants [19]. Due to changes in the oxidation state and pH of the soil and compositions, the transfer of radionuclides into the environment occurs mainly in the unsaturated soil zone [20]. Therefore, much research has been done around the world to investigate the environmental impacts of uranium ore mining and processing. Only some of them can be mentioned. The ecological risk of the ecosystem and the carcinogenic risk to humans, for the study area contaminated with uranium, was published in [21]. Reference [22] deals with the impact of uranium mining on the environment in Labrador, Canada. Experts [20] created a radiological index based on an assessment of already completed uranium mining in Salamanca, western Spain and they created a radiological index.

The case study [23] focusing on the Pinhal do Souto mine looked at the environmental impacts of uranium mining. They are mainly contaminated in U and as (Arsenicum) and constituted an ecological threat. How much the environment was affected by the old mining activity was described through the computation of significant hot clusters [24]. In [25], soil physicochemical properties and heavy metal concentrations were measured. From Zoige County, Sichuan province, China has collected soils from three differently polluted ditches. So, the influence of heavy metals on bacterial community structure in a uranium mine was investigated. Soil physicochemical properties and heavy metal concentrations were measured. There is a serious problem in the handling of mining tailings, which contain thorium, radium, uranium, and polonium, and radon emission is a water-intensive mining process [26]. The experts [27] have been involved in assessing the risk of heavy metal and uranium sediment mining in the Abiete-Toko area of southern Cameroon. Influence of former uranium mining activities on the floodplains of the river Mulde in Germany was solved in [28].

The aim [29] was to evaluate the chemical quality of soil and water runoff uranium mine Fe (Saelices el Chico, Spain) to determine the diagnosis of the existing environmental problems and potential recovery actions to apply. These research studies have confirmed the need to seek measures to improve environmental protection during uranium ore mining and processing. Important measures to remedy the environment of the affected areas from old uranium deposits were obtained, for example, from research of these problematic areas in Portugal [30]. Extensive research of measures before radioactivity is also realized in Slovakia.

The research deals with testing of materials used for protection against radioactive substances and waste [31]. Findings [32] expand and supplement their possible use in waste and environmental management. The physical properties of these materials are addressed in the article [33]. The degree of sorption and the use of materials in practice in their work are discussed [34] and the advantages and extraction and management of highly radioactive waste in the Slovak Republic are described [35]. For nuclear power generation and nuclear arsenal, using Uranium (U) is an important strategic element, mostly used as enriched U-235 [36]. The demand for uranium is driven by the use of highly capital-intensive nuclear power plants operating continuously in order to achieve economies of scale electricity generation [37]. In the short term, it seems that nuclear energy is the only clean energy [38]. In many parts of the world, uranium deposits are a vital raw material for nuclear fuel [39].

The mining and processing industry of raw materials contributes to a huge share in the national economy and delivers an invaluable resource for modern civilization [40].

Previous mining focused mainly on coal mining, which destroys many mutual and supporting resources such as uranium, gas, and oil [41]. Nuclear fuel as a source of energy production has a number of economic benefits accompanied by environmental benefits. First, it offers a competitive price for fuel, taking into account the capital costs of the power plant for energy production, despite the costly licensing system. Compared to coal or natural gas, nuclear fuel represents only 15% of operating costs. Second, nuclear fuel is a low-carbon energy source [42]. The transition of energy from the current fossil energy system to a carbon-free energy production system is based on an appropriate energy mix combining nuclear energy and renewable energy sources [43].

The economic conditions have a very important position in uranium mining [44]. It is, therefore, necessary to draw up a strategy for investing in uranium resources and then draw attention to this, taking into account the possible difficulties in making overseas investments in uranium resources [45]. The current requirements of industrial enterprises in all industrial fields require a detailed view of the course of events in production systems [46].

To evaluate uranium supply shocks, the sale or purchase of uranium stockpiles or market effects of new uranium mines or enrichment technologies are used for economics analysis and market simulation tools [47]. Another important factor is the impact of the uncertainty of government policy on stock prices, which reflects the tension between the arguments of “private interest” (economic benefits) and “public interest” in connection with mining uranium [48].

The state can also influence the possibilities of uranium mining through its raw materials and energy policy. Raw materials policy is based on respecting the principles of a socially–ecologically oriented market economy [49] as well as the careful use of natural resources in the extraction and processing of minerals [50]. A global assessment of uranium mining resources from a social, environmental, and economic point of view is the basis for policy decisions on the use of uranium deposits [51]. Several works [52,53,54,55] deal with such an evaluation of uranium mining and processing from the above points of view.

There is often met aversion to mining, also higher quality uranium deposits in some countries. But the opposite experience can be met in other countries. The uranium mining industry in India is affected by the fact that most uranium deposits in India still fall into the low-quality category, but provide direct and indirect employment to thousands of people and still bring profit [56].

Uranium mines are often an unwanted source of nuclear energy. It is sometimes appropriate to use an integrative approach to analyze the global–local dynamics of environmental change in relation to the extraction and flow of basic materials that support industrial economies [57]. An important aspect is always the view of the deposit as a mineral wealth that hides potential. At the same time, it should be noted that the value of raw materials reserves in the deposit may change significantly over time due to the development of society and the market. Therefore, even currently unused deposits can be very valuable in the future.

2. Materials and Methods

The Deposit of Kuriskova

The Kosice I. deposit, with the attribute of Kuriskova, is situated 7 km from the outskirt of the city of Kosice and 0.3–0.9 km from the state road going from Kosice to Spisska Nova Ves. The nearest villages are only a few kilometers from the deposit, for example: the village Nizny Klatov—4 km, the village Vysny Klatov—3 km, the recreation center of Jahodna—1.5 km from the subject of the deposit to the surface. The deposit is located below the surface of the mountain ridge, which runs from Kosice (Bankov) to Kosicka Bela. The location of the deposit is shown in Figure 1 [58].

Figure 1.

The location of the deposit of Kuriskova [58].

The deposit of Kuriskova is one of the most perspective deposits not only in Slovakia but also in the world (Table 1) [59].

Table 1.

The comparison of selected significant uranium deposits [59,60].

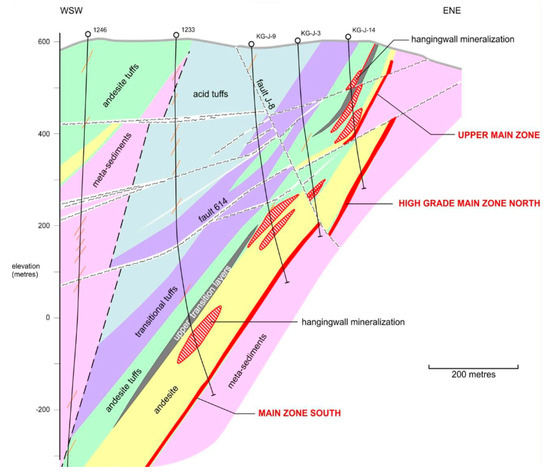

The deposit is geologically located in the North Gemer Permian, in its most eastern part. It has an intricate fold-scaly tectonic style of the structure. In this Permian, the occurrences and deposits of U-Mo (uranium-molybdenum) ores are located in the Petrovohorska complex of strata. The deposit of U-Mo ores is spatially closely related to the bed of basaltoid andesites to basalts with a thickness of max. 120 m and a slope depth of 1 km. Ninety percent of the reserves are located in the main ore position of the deposit. A small amount of reserves, about 10%, is found in tuffs near the volcanic overburden bodies. The primary ore elements are U and Mo. The secondary elements are Cu and S. The main U minerals are uraninite and coffinite (see in Table 2) [61,62].

Table 2.

Mining—geological parameters of the deposit of Kuriskova [62].

The geological section of the deposit of Kuriskova is shown in Figure 2.

Figure 2.

The geological section of the deposit of Kuriskova [58].

The deposit is divided into the following ore locations based on geological exploration, uranium ore quality, and reserves calculation:

- -

- Main ore location (MOL);

- -

- Overlying ore location (OOL);

- -

- Ore location Z-45.

The largest amount of the reserves is in the main ore location, where the quality of reserves corresponds roughly to the average value of the quality of reserves in the deposit. The best reserves are in the ore location Z-45, however, the volume of reserves in this ore location is very low. The reserves level according to the last reserves calculation is in Table 3 [61].

Table 3.

The reserves level of the deposit of Kuriskova [61].

In accordance with the legislation of the Slovak Republic, the reserves of mineral raw materials are classified into 3 basic categories, according to the degree of examination of the exclusive deposit or its part and according to the degree of knowledge of its bed conditions, quality, technological properties, and mining conditions (Table 4):

Table 4.

The reserves of mineral raw materials are classified according to the degree of examination of the exclusive deposit Kuriskova [61].

- -

- Z-1 (verified reserves),

- -

- Z-2 (probable reserves),

- -

- Z-3 (estimated reserves) [61].

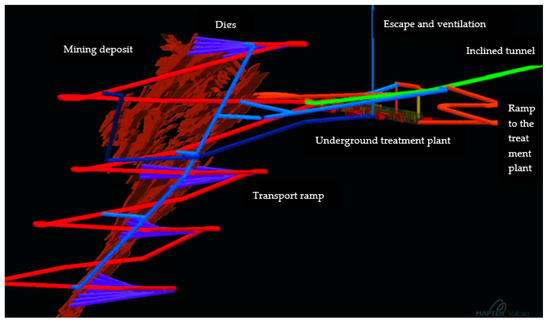

From the hydrogeological point of view, the uranium deposit of Kuriskova is below the local erosive level. The collector complex of rocks (andesite) is characterized by low permissibility, with dominant fracture permeability. Due to this, from the aspect of the future use of the deposit, the limiting factor will be the degree of draining of numerous fracture structures, which are also a source of fractured water springs on the surface in the vicinity of the deposit. The overall hydrogeological attitude is evaluated as simple (2nd degree of difficulty) [63]. The company Tetra Tech, Ltd., Golden, Colorado conducted a partial study that found that the main points of PFS were an initial rate of return of 30.8%, a 1.9-year payback, a net present value of USD 277 million at an 8% discount rate (pre-tax, base case assuming prices of USD 68/lb U3O8 and USD 15/lb Mo). Indicated resources total 28.5 million pounds of U3O8 (10 960 tU) and inferred resources amount to 12.7 million pounds of U3O8 (4 885 tU), using a cut-off of 0.05% U. It is important to note that the lifetime of mining operating costs are USD 22.98/lb U3O8 (USD 59.75/kgU), assuming a net molybdenum credit of about USD 1.27 per pound of U3O8 (USD 3.30/kgU). The project can be developed as an underground mine and a processing facility that would utilize conventional alkaline (non-acid) processing [64]. The method of the deposit opening was proposed by Tetra Tech Ltd. company in the final technical report for Kuriskova (June 2012), where the opening was chosen by a winze and two spiral ramps. The proposal of the deposit opening is shown in Figure 3. According to this proposal, the deposit is opened by the winze 2.6 km long with a cross-section of 6 × 6 m and 9.5% of decrement. The winze is further connected by two spiral ramps with a cross-section of 5 × 5 m and a degree of decrement about 10–12%. The first ramp is an opening work for the construction and access to an underground treatment plant. The second ramp is designed to access the deposit in its foot-wall and along its entire guide length. Transverse ditches will be gradually excavated from the ramp into the mining blocks [63].

Figure 3.

The deposit opening method [58].

3. Results

A valuable mineral is never extracted without losing a certain amount of reserves when mining deposits. Losses can be divided into:

- -

- Losses due to geological and hydrogeological causes;

- -

- Losses in protective pillars;

- -

- Losses caused by a different way of mining;

- -

- Losses caused by loading and transport of a mineral.

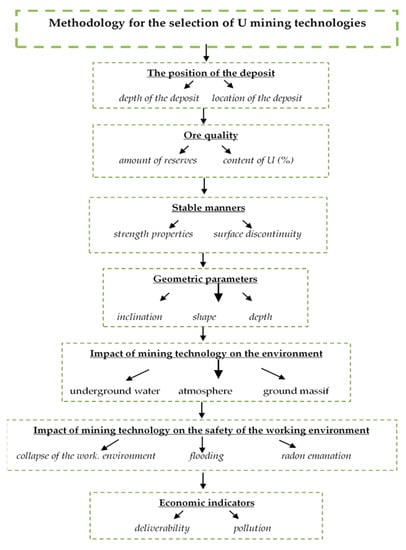

Therefore, a proposal for the extraction of uranium reserves at the deposit of Kuriskova was made for the purposes of this research. Based on it, it is possible to determine the amount of recoverable uranium reserves from the deposit. The methodology (Figure 4) of this mining proposal was determined to take into account the basic criteria of uranium deposit mining, which was used for the selection of suitable mining technology for the Kuriskova uranium deposit.

Figure 4.

Methodology for selecting the technology of uranium mining in the deposit of Kuriskova.

The main limiting factor for the choice of the mining technology but also for the treatment of raw ore is the uranium deposit itself, which is located near the big city and near the areal for recreation. Thus, the impact of mining technology on the environment is extremely significant not only from the point of the protection of landscape but also of the protection of the population. As can be seen from the many experiences of uranium mining in the world, uranium mining has a number of environmental impacts, such as air pollution, contamination of groundwater, soil, the impact of undermining, etc., and this factor is very important when choosing a suitable method of mining [65,66,67]. Because the mining of uranium deposits brings a number of specifics with it, such as air pollution, contamination of groundwater, soil, impact of undermining, etc., this factor is very important for the choice of a suitable mining method. The right technology for deposit mining can ensure the smallest possible or acceptable environmental impact. For the extraction of the deposit, due to the effort to eliminate the impacts of mining on the environment, a system of uranium ore treatment in underground spaces and subsequent loading of waste from the treatment process into the excavated areas in the form of their foundation with a solidifying foundation with control was designed. In this way, surface loads in the form of heaps and sludge are prevented. In addition, the mining water that would be pumped into the mining water treatment plant was also located underground and regular monitoring was proposed [68,69].

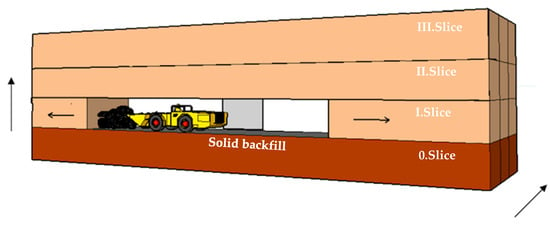

The mining method of cut and fill stopping with a solidifying backfill substance was selected according to the mentioned methodology and with regard to the known characteristics of the main ore position. It is the method which, by its nature, meets the requirements of environmental protection and labor safety. It is also the method that takes into account the variability of mined raw material quality, while this often plays a key role in the efficiency of mining itself.

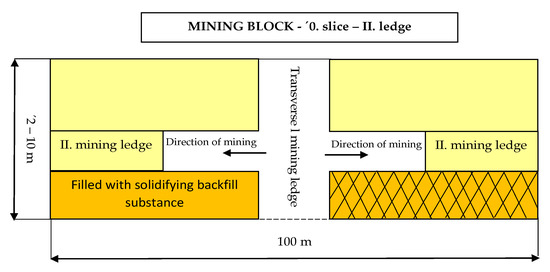

Mining will be carried out in mining blocks whose dimensions have been designed to 4 × 4 × 100 m with this mining method. The mining process in a mining block can be divided into 4 phases (Figure 5). The initial phase is focused on breaking down the transverse central mining ledge, the implementation of which can be obtained the necessary information about the quality and thickness of the ore body in a block. The second phase is mining of the first directional ledge on both sides of the ledge. During the third phase, the extracted spaces are backfilled with a solidifying backfill substance. At the same time, mining in the second directional mining ledge can be prepared. After the backfill has hardened sufficiently, the second mining ledge is mined, which is also filled with the solidifying backfill in the next phase. In the case of a larger thickness of the body in a mining block, it is possible to proceed with the mining and foundation of another mining ledge after the backfill has hardened in the second mining ledge.

Figure 5.

The procedure of excavating of a mining block.

By alternating the mentioned basic phases of the cut and fill mining, all mining blocks will be mined and backfilled at the zero level. Subsequently, it can be progressed with the mining level up to the next slice and the whole ore body is mined by this way (Figure 6).

Figure 6.

The procedure of excavating inside a mining block.

Such mining method was designed to allow, in particular, the highest possible excavation of reserves from the deposit. There are no tied reserves in the protective pillars in a mining block, the entire mining block is mined and then founded with a solidifying backfill. Protective pillars are left only among the individual mining blocks, i.e., level. Due to the fact that each slice is backfilled by a solidifying backfill, only very low losses and contamination are arisen with the chosen mining method.

The basic parameter that affects the mining results is productivity. This includes the losses just mentioned. The productivity is the weight or volume ratio of the amount of ore mined to the ore reserves in a deposit, as defined in the following Formula (1) [68]:

where:

A—is the ore reserves in the deposit in tons or m3,

B—is the real extracted ores in tons or m3.

The total excavation of reserves at the deposit was estimated at 82% when used by the proposed method of mining. This value was also taken into account when calculating the potential amount of electricity produced in a nuclear reactor from extracted uranium of the deposit “E” based on specific energy of natural uranium “e” and amount of natural uranium “m”. This means, according to this mining proposal, it will be possible to obtain approximately 4,613,000 tons of uranium ore from the total amount of geological reserves of uranium ore in the deposit, i.e., 5,427,000 tons listed from the calculation of reserves based on the former geological survey. This mined ore will be a batch to a treatment plant and will be used for the production of so-called yellowcake as an intermediate product for the production of nuclear fuel.

The production of nuclear fuel from extracted ore can be described in several steps.

Step 1: After mining, the ore is crushed in a mill, where water is added to produce a slurry of fine ore particles and other materials.

Step 2: The slurry is leached with sulfuric acid or alkaline solution to dissolve the uranium, leaving the remaining rock and other minerals undissolved.

Step 3: The uranium solution from the mines is separated, filtered, and dried to form a uranium oxide concentrate, often referred to as a “yellowcake”. The vast majority of nuclear reactors use the isotope U-235 as fuel; however, it accounts for only 0.7% of natural mined uranium and must, therefore, be increased through a process called enrichment. This increases the concentration of U-235 from 0.7% to an interval between 3% and 5%, a level used in most reactors.

Step 4: The enrichment process requires that the uranium is in gaseous form. This is achieved by a process called conversion, in which uranium oxide is converted into another compound (uranium hexafluoride), which is a gas at relatively low temperatures. Uranium hexafluoride is filled into centrifuges with thousands of rapidly rotating vertical tubes that separate uranium 235 from the slightly heavier isotope U 238.

Step 5: The enriched uranium is transported to a fuel fabrication facility where it is converted to uranium dioxide powder.

Step 6: This powder is then compressed into small fuel pellets and heated to the hard ceramic material.

Step 7: The pellets are then inserted into thin tubes known as fuel rods, which are then grouped into fuel assemblies [69].

In utilization of uranium ore, a significant technical and economic indicator is the recovery of ore (leaching) from the processing. According to a study by Tetra Tech Ltd. for the Kuriskova deposit, it is a basic leaching process using sodium hydroxide and hydrogen peroxide. The total recovery of uranium from the processing is estimated at 92% [62].

It was chosen the method of determining the specific energy of natural uranium—“e” for the production of electricity. Then, follow its subsequent recalculation to determine the energy potential of the deposit of Kuriskova (potential amount of electricity produced from extracted uranium) was calculated according to the Formula (2) [70]:

where:

- E—potential amount of electricity produced in a nuclear reactor from extracted uranium (GWh),

- e—specific energy of natural uranium for the production of electricity in a nuclear reactor (kWh/kg),

- m—amount of natural uranium (kg).

It was possible to determine the value of specific energy in 4 ways within the available sources. Due to the fact that these are always general guide values, certain small deviations have been registered, however, which can be accepted due to the fact that it is a question of determining the approximate energy potential of the unmined deposit.

The first method for determining the specific energy of uranium is based on information published by the WNA (World Nuclear Association) [70], which is provided on its website. WNA reports heat values (HV) of various fuels (Table 5, where for natural uranium, in LWR (normal reactor—based on 45,000 MWd/t burn-up of 3.5% enriched U in LWR) is reported as HV value 500 GJ/kg. It is recommended to consider 33% efficiency and then it can be determined according to the following formula to determine the value of specific energy “e” for the production of electricity derived from HV Formula (3) [70]:

where:

Table 5.

The amount of geological and extractable reserves at the deposit of Kuriskova.

- e—specific energy for the production of electricity in a nuclear reactor (kWh/kg),

- HV—heat value of uranium (MJ/kg).

The value of specify energy of natural uranium for the production of electricity in a nuclear reactor was set at 46,300 kWh/kg according to the value mentioned above. The second way of determination is based on information published by Ashby [71]. In his publication (Ashby, 2013), the energy density of uranium “U” is set to value of 470,000 MJ/kg and it considers a conversion efficiency of 38% (ce = 0.38) when converting to electrical power. Subsequently, it is possible to determine the specific energy according to the Formula (4) [71]:

where:

- e—specific energy for the production of electricity in a nuclear reactor (kWh/kg),

- ce—conversion efficiency (−),

- U—energy density of uranium (MJ/kg). The factor 3, 6 converts MJ to kWh.

According to the above, the value of specify energy of natural uranium for the production of electricity in a nuclear reactor can be determined: e = 49,600 kWh/kg.

Many authors [72,73] introduced an indicative value of specific energy for the production of electricity in a nuclear reactor: e = 50,000 kWh/kg.

It is also possible to use the value of specific energy of 0.3% uranium ore (similar quality as the average at the deposit of Kuriskova) to determine the energy potential of the deposit of Kuriskova for electricity production in the nuclear reactor “eo”, which Bartalsky [58] presents in his contribution, citing several sources (eo = 150 kWh/kg). It is possible to determine approximately the value of the energy potential of the deposit of Kuriskova from this value according to the Formula (5) [58]:

where:

- E—potential amount of electricity produced in a nuclear reactor (GWh),

- eo—specific energy of natural uranium for the production of electricity in a nuclear reactor (kWh/kg),

- m0—amount of uranium ore (kt).

The values of geological reserves from Table 5 were used to determine the energy potential of the whole deposit, based on the total amount of uranium contained in known uranium ore reserves according to the year 2012 calculation of reserves and these values were reduced by losses proposed from the method of mining (η = 82%)—Table 5.

The energy potential of the deposit of Kuriskova (potential amount of electricity produced from extracted uranium) was determined according to all the described methods of determining the specific energy—“e”. Due to the fact that reserves of category Z3 are only proposed, and in their case, there is a lower geological examination, the energy potential of the deposit was determined only for reserves of category Z2 (probable) in addition to the total energy potential of the deposit [58]. The determined values of the energy potential of the total amount of extractable reserves (Z2 + Z3) and geological reserves of category Z2 are given in Table 6.

Table 6.

The energy potential of reserves at the deposit of Kuriskova.

Similar values were set at all ways of calculating of the energy potential of the total determined extractable reserves at the deposit. The value of approximately 600,000 GWh of electricity can be taken as an indicative value of the total current energy potential of the deposit of Kuriskova. In the case of assessing the energy potential of only more geologically examined Z2 reserves, the value is also similar for the first three methods. For the 4th method, the data were distorted due to the fact that the quality of reserves in category Z2 is significantly higher (0.471% U) than the value of 0.3% U, which was taken as the standard for determining the value of specific energy of uranium ore. The value of 415,000 GWh of electricity can be taken as an approximate value of the total potential of Z2 reserves at the deposit of Kuriskova [58].

It is also appropriate to determine the energy potential of the mined ore at the planned annual production of 270,000 t from the point of continuous utilization of uranium reserves at the deposit of Kuriskova for the needs of electricity production in nuclear reactors. The quality of uranium ore with an average uranium content of 0.292% U was considered for the calculation of the energy potential, as it is the case for the total uranium ore reserves determined on the basis of the 2012 reserves calculation. It is possible to consider with the amount of 788 t U at this content of uranium ore [58].

The informative energy potential from the annual planned uranium mining at the deposit of Kuriskova according to particular conversion methods is shown in Table 7.

Table 7.

The energy potential at planned annual mining production at the deposit of Kuriskova.

It is possible to calculate the potential of approximately 35,000 GWh of electricity produced from the planned mined ore per year according to the calculated values.

4. Discussion

Electricity production is constantly growing in the world, while up to 13% of the world’s population still lives without electricity. However, global electricity production was at the level of 11,882 TWh in 1990, 15,494 TWh were produced in 2000, 21,539 TWh were produced in 2010 and 26,589 TWh were already produced in 2018. It can be assumed that this trend of growth will continue. The largest share in the increase in electricity production is in Asian countries, where the amount of electricity production in 2018 reached 12,009 TWh, which is more than 5.3 times the amount of electricity produced in 1990. On the contrary, electricity production in Europe is growing much slower and 3883 TWh were produced in 2018, which is only about one third of an increase compared to the amount of electricity produced in 1990 [74].

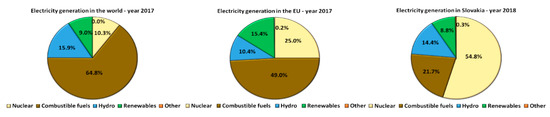

Within the total electricity production, which represented 25,691 TWh in 2017, the share of nuclear energy is 10.3% (see Eurostat, Scheme 1) [75]. According to the forecasts of the international agencies dealing with this issue, this share could rise to 15% over the next 20 years. This assumption is based mainly on the probable impact of environmental policy and the “sustainable development scenario”, where there will be pressure to increase the share of use of so-called low-carbon energy sources at this time [76].

Scheme 1.

The share of particular sources in the production of electricity in the world, EU, and the Slovak Republic, source: [74,75,78].

The prediction from the Redbook [70] says that there will be an increase in uranium capacity requirements. From this, it can be stated that there will be an increase from about 391 GWe net at the beginning of 2017 to between about 331 GWe (low case) and 568 GWe (high case) by the year 2035. In case of a decrease, we are talking about a decrease of 15% from 2016 nuclear-generating capacity, while in the case of an increase, it represents an increase of about 45%. In the case of the next forecast, an increase of 10% is expected, meaning that some countries have already started to prepare for this in their work in this area [77].

In order to meet the demand by 2025 (secondary supplies will not be taken into account), all existing mines and mines that plan to mine must operate and mine at the required production capacity. Even so, it is assumed that these required capacities will be met by 2035 for normal operations and to 60% for high case requirements. Very important is the fact that, in general, real production of mining is more than 85% of the required mining capacity. It is necessary to think about this in the future and consider a secondary complementarity strategy [77]. Within the European Union (EU), 3100 TWh of electricity were produced in 2017, while approximately 25% of this amount (Scheme 1) involved the amount of nuclear energy [74]. There are still different opinions about production electricity in nuclear power plants in the EU. While some countries are preparing and building new nuclear reactors (including Slovakia, which is completing and preparing to start new units of the nuclear power plant of Mochovce), other EU countries have accepted and are implementing plans for the decommissioning of nuclear power plants as a result of the Fukushima incident in 2011 (e.g., Germany plans to shut down the last active nuclear reactor by the end of 2022).

In 2018, 27,149 GWh of electricity were produced in the Slovak Republic, while the share of nuclear energy in this production was 57.4%. For comparison, there was an increase of about 12.8% of electricity production in the Slovak Republic during the period 1990–2018 (Scheme 1). However, during this period, there was also a decrease in electricity production caused by the shutdown of the V1 nuclear reactor in Jaslovske Bohunice as well as several units in thermal power plants [78].

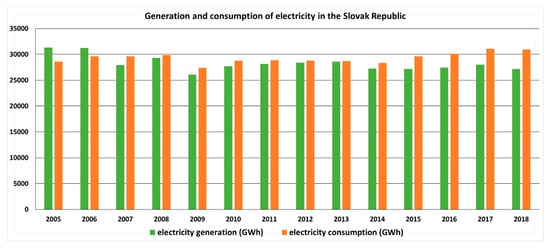

Electricity consumption in 2018 was at the level of 30,947 GWh and similarly to 2016 and 2017, it exceeded the level of 30 TWh. Thus, the trend of slightly higher consumption than electricity production continues, which can be observed since 2007 (Scheme 2), when there was a decrease in electricity production for the reasons mentioned above [78].

Scheme 2.

Generation and consumption of electricity in the Slovak Republic, source: [78].

In terms of natural conditions and current technological possibilities, the Slovak Republic can only use a small extent of its own primary energy sources and is very dependent on imports. Almost 90% of primary energy resources (PER), including nuclear fuel, are imported. In 2017, the dependency reached the level of 64.7%, which is the highest value in the last six years. The use of domestic energy resources in the Slovak Republic is mainly involved in the production of electricity through water, renewable energy sources and fossil fuels. In 2017, 4677 GWh of electricity were produced by hydroelectric power plants in Slovakia, 2445 GWh from renewable energy sources and 1484 GWh from brown coal (mined in the Slovak Republic) by the Novaky power plant. In 2018, there was a further decrease in the amount produced electricity, when 3920 GWh were produced in hydroelectric power plants, 2399 GWh from renewable energy sources and 1271 GWh from brown coal (mined in SR). It is assumed that the share of currently used own energy sources will continue to decline during the next years. There is even no expectation of significant increase in use of hydropower for electricity production. Higher use of renewable energy sources for electricity production can only be considered with the introduction of more massive support. Without it, the amount of energy produced from these sources will stagnate [79].

There will also be a decrease and later total decommissioning in the production of energy from brown coal mined in the Slovak Republic during the next years, which will further increase dependence on foreign primary energy sources for electricity production in Slovakia. As part of the Slovak Republic’s commitments in connection with reducing carbon emissions, brown coal mining is to be terminated. The extraction of brown coal has decreased in recent years from 1834 kt mined in 2017 to 1465 kt mined in 2019 [80]. The amount of electricity produced by the power plant of Novaky, which produces on the basis of mined brown coal in the Slovak Republic, is also declining, where it produced 1908 GWh in 2012, there was a gradual decline in production to 1271 GWh produced in 2018. From the perspective of the further development of electricity production in the Slovak Republic, the share of energy produced from nuclear reactors is expected to increase. After the completion and putting to the operation of units 3 and 4 of the nuclear power plant in Mochovce, the production of electricity will increase significantly and the Slovak Republic will become again self-sufficient in the production of electricity [79].

As it was mentioned above, due to natural conditions and known reserves of energy raw materials in the Slovak Republic, the most promising option for reducing the dependence on supplies of primary energy sources from abroad, especially from Russia, is the use of own uranium reserve. When using its own uranium deposits, in addition to the deposit of Kuriskova, it is also possible to consider the deposit of Novoveska Huta (where, however, the quality of uranium ore is significantly lower—approx. 0.1%). The analysis and determination of the energy potential of the deposit of Kuriskova shows that uranium reserves from this deposit would be able to fully cover the needs for nuclear power plants for the production of nuclear fuel, in the Slovak Republic even in the longer term. With the above-mentioned energy potential of the deposit of Kuriskova at the level of 600 TWh, nuclear power plants in the Slovak Republic are able to be supplied with the raw materials from the deposit of Kuriskova for about 40 years with the current amount of electricity produced (approx. 15 TWh). The increase of electricity production is expected after the completion of new units of the nuclear power plant in Mochovce (approx. up to 19 TWh) and the reserves of the deposit are still enough for 32 years of supply. Of course, these values are very approximate and it is very problematic to predict the development of the energy politics for such a long period [80].

5. Conclusions

It is necessary to mention several obstacles that significantly complicate the use of the uranium deposit of Kuriskova in this proposed solution of the elimination of dependence of the Slovak Republic on the supply of primary energy sources from abroad. The first problematic factor is the technology of our nuclear reactors VVER-440 in Slovak nuclear power plants, which require precise requirements for nuclear fuel. The only supplier of this fuel is the Russian company TVEL, which supplies it to reactors in the total of 15 countries and also has a 45% share on the world market in terms of uranium enrichment. That is why there would not be complete acquittal from dependence on foreign countries, even in the case of using the deposit of Kuriskova [81].

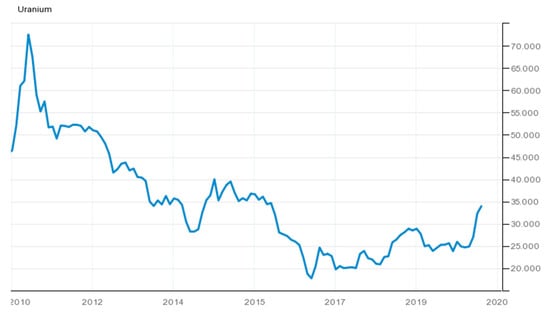

The second problematic factor in the use of the deposit of Kuriskova is the development of uranium (U3O8) prices. The price of uranium is changing significantly, which can be seen in the Scheme 3 of the development of uranium price since 2010. The price of uranium is approximately 34 USD/LB and it is currently about half of the price in comparison with year 2010. Even more significant is the difference compared to the maximum price of uranium in the last 25 years, which reached the highest value in 2007, above 140 USD/LB. Such dynamic changes in the price of the commodity can have very negative impact on the mining of the deposit during the implementation phase and therefore, they make it very difficult to plan the extraction of the deposit. Such price fluctuations can be caused, for example, by releasing uranium reserves from non-natural sources (e.g., military arsenal, etc.) [80].

Scheme 3.

The development of uranium prices, source: [75].

The location of the deposit of Kuriskova itself is another problematic factor. The deposit is located near the town of Kosice (near 240,000 inhabitants) and near the recreational area of Jahodna. Therefore, the use of uranium obtained from the deposit of Kuriskova is most hinder8/ed by a public acceptance and public concern about the negative effects of mining and subsequent technological processing of uranium ore to a tradable commodity. Despite the fact that all procedures, proposed for the deposit of Kuriskova, have been designed to prevent environmental contamination, there is still strong resistance to the mining plans. Any activities at the deposit of Kuriskova are also strongly limited by the legislation of the Slovak Republic nowadays. According to it, uranium mining is possible in Slovakia only if it is agreed in a referendum by the inhabitants of all affected municipalities, which is currently the most serious obstacle to exploiting the energy potential of the deposit, due to the prevailing opinion against uranium mining [80].

The reserves of the Kuriskova uranium deposit (Kosice I.) represent an interesting potential for their use for the production of electricity. Although these problems make their current use difficult, uranium reserves must be considered in the future as a potential source of large amounts of energy that could cover the energy needs of the Slovak Republic for several years. Especially in a situation where the gradual cessation of coal-fired power generation is planned within the EU. The basis for their use, however, remains the environmental safety of their use while maintaining acceptable economic efficiency, which is the key to a possible change in the current opinion of the population and government on uranium mining in the Slovak Republic.

Author Contributions

Each author (M.S., S.K., O.V., P.K., T.M., M.K., M.T., Z.S.) has equally contributed to this publication. A short paragraph specifying authors individual contributions on article preparing: Conceptualization, M.S. and S.K.; methodology, M.S. and O.V.; validation, T.M. and P.K.; formal analysis, M.K.; resources, M.K. and T.M.; data curation, M.S.; writing—original draft preparation, M.S. and S.K.; writing—review and editing, P.K. and O.V.; visualization, M.S., Z.S. and O.V.; supervision, M.S., M.T.; project administration, T.M.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the projects of the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences project No. VEGA 1/0317/19, project No. VEGA 1/0797/20 and was supported by the projects of the Cultural and Educational Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences project No. KEGA 006TUKE-4/2019, project No. KEGA 016TUKE-4/2020.

Acknowledgments

Authors would like to thank anonymous reviewers for their helpful and constructive comments and suggestions that greatly contributed to improving the final version of this paper.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Malin, S.A.; Alexis-Martin, B. Assessing the state of uranium research: Environmental justice, health, and extraction. Extr. Ind. Soc. 2020, 7, 512–516. [Google Scholar] [CrossRef]

- Degueldre, C.; Joyce, M.J. Evidence and uncertainty for uranium and thorium abundance: A review. Prog. Nucl. Energy 2020, 124, 103299. [Google Scholar] [CrossRef]

- Wang, R.; Mai, J.; Guan, Y.; Liu, Z. Radionuclides in the environment around the uranium mines in Guangxi, China. Appl. Radiat. Isot. 2020, 159, 109098. [Google Scholar] [CrossRef]

- Matshusa, K.; Makgae, M. Prevention of future legacy sites in uranium mining and processing: The South African perspective. Ore Geol. Rev. 2017, 86, 70–78. [Google Scholar] [CrossRef]

- Straka, M.; Bindzar, P.; Kadukova, A. Utilization of the multicriteria decision-making methods for the needs of mining industry. Acta Montan. Slovaca 2014, 19, 199–206. [Google Scholar]

- Linsley, G. Radiological protection and the nuclear fuel cycle. Nucl. Fuel Cycle Sci. Eng. 2012, 24–51. [Google Scholar] [CrossRef]

- Campbell, K.M.; Gallegos, T.J.; Landa, E.R. Biogeochemical aspects of uranium mineralization, mining, milling, and remediation. Appl. Geochem. 2015, 57, 206–235. [Google Scholar] [CrossRef]

- Trebuna, P.; Popovic, R.; Kłos, S. Methodology of the Creation of Human and Robot Operation in the Tecnomatix Process Simulate. Procedia Eng. 2014, 96, 483–488. [Google Scholar] [CrossRef]

- Gallo, P.; Balogova, B.; Tomcikova, L.; Nemec, J. The Impact of the Innovative Total Quality Management Tool in Small and Medium-Sized Enterprises. Mark. Manag. Innov. 2019, 4, 22–30. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Vladyko, O.; Maltsev, D.; Cabana, E.C. Some aspects of the compatibility of mineral mining technologies. Rud. Geol. Naft. Zb. 2018, 33, 73–83. [Google Scholar] [CrossRef]

- Woods, P.H. Uranium mining (open cut and underground) and milling. Uranium Nucl. Power 2016, 125–156. [Google Scholar]

- King, B.; Goycoolea, M.; Newman, A. Optimizing the open pit-to-underground mining transition. European, J. Oper. Res. 2017, 257, 297–309. [Google Scholar] [CrossRef]

- Pelizza, M.S.; Bartels, C.S. Introduction to uranium in situ recovery technology. Uranium Nucl. Power 2016, 157–213. [Google Scholar]

- Ruiz, O.; Thomson, B.; Cerrato, J.M.; Rodriguez-Freire, L. Groundwater restoration following in-situ recovery (ISR) mining of uranium. Appl. Geochem. 2019, 109, 104418. [Google Scholar] [CrossRef]

- Blistan, P.; Jacko, S.; Kovanic, L.; Kondela, J.; Pukanska, K.; Bartos, K. TLS and SfM Approach for Bulk Density Determination of Excavated Heterogeneous Raw Materials. Minerals 2020, 10, 174. [Google Scholar] [CrossRef]

- Kenzhaliev, B.K.; Surkova, T.Y.; Berkinbayeva, A.N.; Dosymbayeva, Z.D.; Chukmanova, M.T. To the question of recovery of uranium from raw materials. Ser. Geol. Tech. Sci. 2019, 1, 112–119. [Google Scholar] [CrossRef]

- Harris, F. Management for health, safety, environment, and community in uranium mining and processing. Uranium Nucl. Power 2016, 385–404. [Google Scholar] [CrossRef]

- Yin, M.; Tsang, D.C.W.; Sun, J.; Wang, J.; Shang, J.; Fang, F.; Wu, Y.; Liu, J.; Song, G.; Xiao, T.; et al. Critical insight and indication on particle size effects towards uranium release from uranium mill tailings: Geochemical and mineralogical aspects. Chemosphere 2020, 250, 126315. [Google Scholar] [CrossRef]

- Lakaniemi, A.-M.; Douglas, G.; Kaksonen, A.H. Engineering and kinetic aspects of bacterial uranium reduction for the remediation of uranium contaminated environments. J. Hazard. Mater. 2019, 371, 198–212. [Google Scholar] [CrossRef] [PubMed]

- Gil-Pacheco, E.; Suárez-Navarro, J.A.; Sánchez-González, S.M.; Suarez-Navarro, M.J.; Hernáiz, G.; García-Sánchez, A. A radiological index for evaluating the impact of an abandoned uranium mining area in Salamanca, Western Spain. Environ. Pollut. 2020, 258, 113825. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.K.; Yang, Z.H.; Sun, Z.X.; Liao, Q.; Guo, Y.D.; Chen, J.Y. Multidimensional pollution and potential ecological and health risk assessments of radionuclides and metals in the surface soils of a uranium mine in East China. J. Soils Sediments 2020, 20, 775–791. [Google Scholar] [CrossRef]

- Sarkar, A.; Wilton, D.H.C.; Fitzgerald, E.; Sharma, A.; Sharma, A.; Sathya, A.J. Environmental impact assessment of uranium exploration and development on indigenous land in Labrador (Canada): A community-driven initiative. Environ. Geochem. Health 2019, 41, 939–949. [Google Scholar] [CrossRef]

- Neiva, A.M.R.; Carvalho, P.C.S.; Antunes, I.M.H.R.; Silva, M.M.V.G.; Santos, A.C.T.; Pinto, M.M.S.C.; Cunha, P.P. Contaminated water, stream sediments and soils close to the abandoned Pinhal do Souto uranium mine, central Portugal. J. Geochem. Explor. 2014, 136, 102–117. [Google Scholar] [CrossRef]

- Neiva, A.M.R.; Albuquerque, M.T.D.; Antunes, I.M.H.R.; Carvalho, P.C.S.; Santos, A.C.T.; Boente, C.; Cunha, P.P.; Henriques, S.B.A.; Pato, R.L. Assessment of metal and metalloid contamination in soils trough compositional data: The old Mortorios uranium mine area, central Portugal. Environ. Geochem. Health 2019, 41, 2875–2892. [Google Scholar] [CrossRef]

- Xiao, S.Q.; Zhang, Q.; Chen, X.M.; Dong, F.Q.; Chen, H.; Liu, M.X.; Ali, I. Speciation Distribution of Heavy Metals in Uranium Mining Impacted Soils and Impact on Bacterial Community Revealed by High-Throughput Sequencing. Front. Microbiol. 2019, 10, 1867. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Pathak, P.; Perween, M. Environmental and Health Impact Due to Uranium Mining. In Uranium in Plants and the Environment. Radionuclides and Heavy Metals in the Environment; Gupta, D., Walther, C., Eds.; Springer: Cham, Switzerland, 2020; Volume 1, pp. 69–89. [Google Scholar]

- Mandeng, E.P.B.; Bidjeck, L.M.B.; Bessa, A.Z.E.; Ntomb, Y.D.; Wadjou, J.W.; Doumo, E.P.E.; Dieudonne, L.B. Contamination and risk assessment of heavy metals, and uranium of sediments in two watersheds in Abiete-Toko gold district, Southern Cameroon. Heliyon 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Bister, S.; Birkhan, J.; Lullau, T.; Bunka, M.; Solle, A.; Stieghorst, C.; Riebe, B.; Michel, R.; Walther, C. Impact of former uranium mining activities on the floodplains of the Mulde River, Saxony, Germany. J. Environ. Radioact. 2015, 144, 21–31. [Google Scholar] [CrossRef]

- Aran, D.; Verde, J.R.; Antelo, J.; Macias, F. Environmental quality of soils and waters in Fe Mine: Initial situation and remediation alternatives. Span. J. Soil Sci. 2020, 10, 81–100. [Google Scholar]

- Carvalho, F.P. Environmental health risk from past uranium mining and milling activities. Environ. Health Risk IV 2007, 11, 107–114. [Google Scholar]

- Krajnak, A.; Viglasova, E.; Galambos, M.; Krivosudsky, L. Kinetics, thermodynamics and isotherm parameters of uranium (VI) adsorption on natural and HDTMA-intercalated bentonite and zeolite. Desalin. Water Treat. 2018, 127, 272–281. [Google Scholar] [CrossRef]

- Viglasova, E.; Dano, M.; Galambos, M.; Krajnak, A.; Rosskopfova, O.; Rajec, P. Investigation of Cu(II) adsorption on Slovak bentonites and illite/smectite for agricultural applications. J. Radioanal. Nucl. Chem. 2017, 314, 2425–2435. [Google Scholar] [CrossRef]

- Adamcova, R.; Suraba, V.; Krajnak, A.; Rosskopfova, O.; Galambos, M. First shrinkage parameters of Slovak bentonites considered for engineered barriers in the deep geological repository of high-level radioactive waste and spent nuclear fuel. J. Radioanal. Nucl. Chem. 2014, 302, 737–743. [Google Scholar] [CrossRef]

- Galambos, M.; Suchanek, P.; Rosskopfova, O. Sorption of anthropogenic radionuclides on natural and synthetic inorganic sorbents. J. Radioanal. Nucl. Chem. 2012, 293, 613–633. [Google Scholar] [CrossRef]

- Galambos, M.; Rosskopfova, O.; Kufcakova, J.; Rajec, P. Utilization of Slovak bentonites in deposition of high-level radioactive waste and spent nuclear fuel. J. Radioanal. Nucl. Chem. 2011, 288, 765–777. [Google Scholar] [CrossRef]

- Kaksonen, A.H.; Lakaniemi, A.-M.; Tuovinen, O.H. Acid and ferric sulfate bioleaching of uranium ores: A review. J. Clean. Prod. 2020, 264, 121586. [Google Scholar] [CrossRef]

- Considine, T.J. The market impacts of US uranium import quotas. Resour. Policy 2019, 63, 101445. [Google Scholar] [CrossRef]

- Fang, J.; Lau, C.K.M.; Lu, Z.; Wu, W. Estimating Peak uranium production in China—Based on a Stella model. Energy Policy 2018, 120, 250–258. [Google Scholar] [CrossRef]

- Cui, G.; Wei, J.; Feng, X.T.; Liu, J.; Elsworth, D.; Chen, T.; Xiong, W. Preliminary study on the feasibility of co-exploitation of coal and uranium. Mech. Min. Sci. 2019, 123, 104098. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Saidur, R. A review on the impact of mining and mineral processing industries through life cycle assessment. J. Clean. Prod. 2019, 231, 1200–1217. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, N.; Chen, X.; Gong, L.; Lv, C.; Guo, Y. Exploitation Contradictions Concerning Multi-Energy Resources among Coal, Gas, Oil, and Uranium: A Case Study in the Ordos Basin (Western North China Craton and Southern Side of Yinshan Mountains). Energies 2016, 9, 119. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Lang, C. Comparative life-cycle assessment of uranium extraction processes. J. Clean. Prod. 2018, 202, 666–683. [Google Scholar] [CrossRef]

- Serp, J.; Poinssot, C.; Bourg, S. Assessment of the Anticipated Environmental Footprint of Future Nuclear Energy Systems. Evidence of the Beneficial Effect of Extensive Recycling. Energies 2017, 10, 1445. [Google Scholar] [CrossRef]

- Glova, J.; Dancakova, D.; Suleimenova, S. Managerial Aspect of Intangibles: Own Development or External Purchased Intangible Assets—What Does Really Count? Pol. J. Manag. Stud. 2018, 18, 84–93. [Google Scholar] [CrossRef]

- Ma, J.; Wang, L.L. Study on Overseas Investment of Uranium Resources in China. Environ. Technol. Resour. Util. II 2014, 675–677, 1328–1331. [Google Scholar] [CrossRef]

- Straka, M.; Khouri, S.; Lenort, R.; Besta, P. Improvement of logistics in manufacturing system by the use of simulation modelling: A real industrial case study. Adv. Prod. Eng. Manag. 2020, 15, 18–30. [Google Scholar] [CrossRef]

- Auzans, A.; Schneider, E.A.; Flanagan, R.; Tkaczyk, A.H. A Mine-Based Uranium Market Clearing Model. Energies 2014, 7, 7673–7693. [Google Scholar] [CrossRef]

- Ferguson, A.; Lam, P. Government policy uncertainty and stock prices: The case of Australia’s uranium industry. Energy Econ. 2016, 60, 97–111. [Google Scholar] [CrossRef]

- Glova, J.; Mrazkova, S.; Dancakova, D. Measurement of Intangibles and Knowledge: An Empirical Evidence. Ad Alta 2018, 8, 76–80. [Google Scholar]

- Benkova, E.; Gallo, P.; Balogova, B.; Mihalcova, B. Effects of using strategic planning as a managerial tool: A case of industrial companies. Pol. J. Manag. Stud. 2019, 20, 145–160. [Google Scholar]

- Mudd, G.M. The future of Yellowcake: A global assessment of uranium resources and mining. Sci. Total Environ. 2014, 472, 590–607. [Google Scholar] [CrossRef]

- Bretesche, S.; Gherardi, A. A cultural approach to environmental risk—The example of uranium mines. Dev. Durable Territ. 2018, 9, 3. [Google Scholar]

- Bjorst, L.R. Uranium: The road to “economic self-sustainability for greenland”? Changing uranium-positions in greenlandic politics. In Northern Sustainabilities: Understanding and Addressing Change in the Circumpolar World; Springer: Cham, Switzerland, 2017; pp. 25–34. [Google Scholar]

- Tosovic, R.; Jelenkovic, R. Uranium mineral resources of Serbia and their potential economic importance. Acta Montan. Slovaca 2016, 21, 9–18. [Google Scholar]

- Galas, S.; Galas, A. The qualification process of mining projects in environmental impact assessment: Criteria and thresholds. Resour. Policy 2016, 49, 204–212. [Google Scholar] [CrossRef]

- Chaki, A.; Purohit, R.K.; Mamallan, R. Low grade uranium deposits of India—A bane or boon. Asian Nucl. Prospect. 2010, 7, 153–157. [Google Scholar] [CrossRef]

- Conde, M.; Kallis, G. The global uranium rush and its Africa frontier. Effects, reactions and social movements in Namibia. Glob. Environ. Chang. Hum. Policy Dimens. 2012, 22, 596–610. [Google Scholar] [CrossRef]

- Survey Report. Cermel-Jahodna Exploration Area; Ludovika Energy, Ltd.: Spisska Nova Ves, Slovakia, 2008. [Google Scholar]

- Uranium, an Important Slovak Energy Source. Available online: http://archive.ceec.sk/wp-content/uploads/2013/10/Boris-Bartalsky.pdf (accessed on 7 April 2020).

- Cameco: Mineral Reserves and Resources. Available online: https://s3-us-west-2.amazonaws.com/assets-us-west-2/annual/mineral-reserves-and-resources-2019.pdf (accessed on 25 July 2020).

- Partial Final Report with Calculation of Reserves Kosice, I. Deposit, Spisska Nova Ves; Ludovika Energy, Ltd.: Spisska Nova Ves, Slovakia, 2012.

- New Edition of “Red Book” Uranium Report. Available online: https://www.iaea.org/newscenter/pressreleases/new-edition-of-red-book-uranium-report-is-published (accessed on 17 July 2020).

- Technical Report Kuriskova Uranium Project Tetratech: NI 43—101; Tetra Tech: Golden, CO, USA, 2012.

- Merkel, B.J.; Hasche-Berger, A. Uranium, Mining and Hydrogeology; Springer Science & Business Media: Berlin, Germany, 2008; pp. 59–85. [Google Scholar]

- Mudd, G.M. Uranium mining in Australia: Environmental impact, radiation releases and rehabilitation. In Protection of the Environment from Ionising Radiation: The Development and Application of a System of Radiation Protection for the Environment; IAEA: Vienna, Austria, 2003; pp. 184–189. [Google Scholar]

- Cech, J.; Sofranko, M. Economic Projection and Evaluation of Mining Venture. Econ. Manag. 2018, 21, 38–52. [Google Scholar]

- How is Uranium Made into Nuclear Fuel? Available online: https://www.world-nuclear.org/nuclear-essentials/how-is-uranium-made-into-nuclear-fuel.aspx (accessed on 25 July 2020).

- Nero, M.J.; Dias, M.A.; Pereira, J.; Neves, L.J.; Torrinha, J.A. Environmental evaluation and remediation methodologies of abandoned radioactive mines in Portugal. Environmental Contamination from Uranium Production Facilities and their Remediation. In Proceedings of the International Workshop, Lisbon, Portugal, 11–13 February 2004; pp. 145–158. [Google Scholar]

- Kornilovych, B.; Wireman, M.; Ubaldini, S.; Guglietta, D.; Koshik, Y.; Caruso, B.; Kovalchuk, I. Uranium Removal from Groundwater by Permeable Reactive Barrier with Zero-Valent Iron and Organic Carbon Mixtures: Laboratory and Field Studies. Metals 2018, 8, 408. [Google Scholar] [CrossRef]

- Heat Values of Various Fuels. Available online: https://www.world-nuclear.org/information-library/facts-and-figures/heat-values-of-various-fuels.aspx (accessed on 8 April 2020).

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Elsevier: Amsterdam, The Netherlands, 2012; Available online: https://www.sciencedirect.com/book/9780123859716/materials-and-the-environment (accessed on 9 April 2020).

- Valkovic, V. Radioactivity in the Environment. (Physicochemical Aspects and Applications). 2000. Available online: https://www.elsevier.com/books/radioactivity-in-the-environment/valkovic/978-0-444-82954-2 (accessed on 9 April 2020).

- Jachymov–Joachimsthal. Available online: https://www.jachymov-joachimsthal.cz/informace-o-knize/ (accessed on 10 April 2020).

- Electricity Production, Consumption and Market Overview. Available online: https://ec.europa.eu/eurostat/statisticsexplained/index.php/Electricity_production,_consumption_and_market_overview#Electricity_generation (accessed on 14 April 2020).

- Electricity Production. Available online: https://yearbook.enerdata.net/electricity/world-electricity-production-statistics.html (accessed on 10 April 2020).

- Uranium prices. Available online: https://tradingeconomics.com/commodity/uranium. (accessed on 10 April 2020).

- Uranium 2018: Resources, Production and Demand. Available online: https://www.oecd-nea.org/ndd/pubs/2018/7413-uranium-2018.pdf (accessed on 17 July 2020).

- Energy (Electricity Generation and Consumption). Available online: https://www.enviroportal.sk/indicator/detail?id=762 (accessed on 16 April 2020).

- Annual Reports of Slovak Power Plants, Years 2010–2018. Bratislava, Slovakia, 2011–2019.

- Annual Reports of Main Mining Office, Years 2010–2018. Banska Stiavnica, Slovakia, 2011–2019.

- Markets/Uranium. Available online: https://tradingeconomics.com/commodity/uranium (accessed on 24 April 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).