Abstract

The present study conducts the numerical investigation of flow characteristics and thermal performance of spiral finned-tube heat exchangers. The effects of location of perforations (90°, 120°, and 150°) on heat transfer and pressure drop are analyzed for the air-side. The commercial computational fluid dynamics code ANSYS Fluent (V.17.0) is used for simulations with the RNG k-ε model based on the Reynolds-averaged Navier–Stokes equations. The velocity field, Colburn j-factor, and friction factor are analyzed to evaluate the heat transfer and pressure drop characteristics. Because of the flow through the perforations, the boundary layers on the fin surfaces are interrupted. This results in increased flow disturbances close to the fin, and the heat transfer performance increases compared to the reference case. The pressure drop, which is one of the disadvantages of spiral finned tubes comparing to plate or circular fins, decreases with perforations on the fin. Overall, the cases with perforated fin exhibit greater performance of area goodness factor considering the relationship between the heat transfer and the pressure drop.

1. Introduction

Spiral finned-tube heat exchangers have been used in various industrial fields, such as the automotive, aerospace, air conditioning, waste heat recovery, and refrigeration industries [1,2]. The operating costs and size of the systems can be significantly decreased by improving their thermo-hydraulic performance. The thermal resistance that determines the heat transfer performance of the finned-tube heat exchanger is divided into two parts, the tube-side and the air-side thermal resistance. The air-side thermal resistance is typically dominant regarding the heat transfer performance and can be improved by changing the fin shape, examples being the flat plate fin, the circular fin, and the spiral fin [3,4]. However, a secondary flow is generated that causes the thermal efficiency to decrease, as well as pressure losses when the main flow encounters the finned-tube [5]. Numerical simulations play an important role in analyzing the flow characteristics in the wake region where the secondary flow is generated. It has been recently reported that the secondary flow can be decreased by changing the fin configuration close to the wake region in finned-tube heat exchangers [6].

Numerous studies have been conducted with different arrangements of fins, pitch, and fin size, aimed at improving the heat transfer performance of spiral finned-tube heat exchangers [7,8,9]. Lee et al. [10] conducted experiments to compare the effect of fin pitch and fin alignment on the heat transfer of spiral finned-tube heat exchangers. The thermal performance per surface area decreased with decreasing fin pitch, and the Colburn j-factor of a staggered alignment was greater than that of an inline fin alignment. Mon et al. [11] studied the temperature and velocity distributions considering the fin pitch and alignment of tubes. Ma et al. [12] studied the effects of fin pitch and tube spacing on the heat transfer and pressure drop of finned-tube banks with staggered layouts. The pressure drop increased with the decrease of fin pitch and tube spacing.

Variations in fin configurations influenced the flow characteristics in the wake region significantly. A number of fin configurations were evaluated to improve the thermal performance of finned-tube heat exchangers [13,14]. Nuntaphan et al. [15] conducted experiments at low Reynolds number on the air-side with crimped fins and suggested the correlation for the Colburn j-factor and friction factor. Martinez et al. [16] performed a numerical simulation to examine the flow and pressure drop characteristics of serrated fins. They showed the turbulent kinetic energy to compare the flow interaction through the finned-tube, and the high temperature and pressure gradient appeared at the location of large turbulent kinetic energy. The low turbulent kinetic energy appeared at the recirculation regions with low heat transfer. For the serrated fin, the numerical study was conducted to reduce the fin material [17]. They cut off the fin materials at the rear part of the finned-tube which locations had the lowest heat transfer rate. The cut-off angle less than 60° had similar heat transfer and pressure drop, because the flow separation occurred nearly at the cut-off angle of 60° and the lowest heat transfer appeared at this region. Kumar et al. [18] investigated the thermal-hydraulic performance of plate and annular fins, including plain circular, serrated, crimped, plain plate, and wavy fins, as well as a fin with a delta winglet pair. They reported that the friction factor for crimped and serrated fins was higher than that of the plate fins resulting from the stronger flow disturbance. The perforated circular fin was studied to examine the heat transfer and pressure drop characteristics [19]. The perforation on the circular fin increased the convective heat transfer coefficient due to the disturbance produced by the perforations. Liu et al. [20] conducted the numerical simulations to analyze the effect of perforations at the flat plate fin on the flow characteristics at the rear part of the tube. The heat transfer performance increased with the perforations of the fin, because the fluid flow through the perforation interrupted the boundary layer and reduced the wake region.

The bulk of previous studies investigated the heat transfer and pressure drop characteristics for different fin spacing, fin sizes, and fin configurations in spiral finned-tube heat exchangers. Also, they studied to affect the flow field in the wake region. To the best of our knowledge, no studies have been conducted to investigate the flow characteristics of spiral finned-tube heat exchangers with perforations on the fin. As the spiral fin surfaces partially face the upstream flow, it is expected that the perforations will affect the flow field and heat transfer more significantly than a plate or circular fins where the fin surfaces are parallel to the flow direction. As reported previous studies, the perforations on the fin will cause flow disturbance at the fin surface and affect the flow characteristics at the lowest heat transfer region. In this study, we attempt to quantify the effects of perforated spiral fins on the heat transfer and pressure drop characteristics. Various locations and number of perforations on spiral fins are examined, and flow fields (velocities, turbulent kinetic energies), Colburn j-factor, friction factor, and area goodness factor are analyzed.

2. Numerical Details

2.1. Mathematical Representation

Numerical simulations are conducted in this study to analyze the heat transfer and flow characteristics of finned-tube heat exchangers using the commercial code ANSYS Fluent (V.17.0, ANSYS, Canonsburg, PA, USA). We assume incompressible flow, Newtonian fluid, and steady state conditions, and neglect the buoyancy. For the numerical simulations, the continuity, momentum, and energy equations are used as follows:

where ui is the velocity vector, E is the total energy, ka is thermal conductivity of air, μt is the turbulent viscosity, Prt is the turbulent Prandtl number, k is the turbulence kinetic energy, and ε is the dissipation rate [21].

The direct numerical simulation (DNS) and large eddy simulation (LES) can be used for the detail flow field of the finned-tube heat exchanger, but it causes higher computational cost [22,23,24]. Reynolds-averaged Navier-Stokes (RANS) based RNG k-ε model, that is the two-equation turbulence model, is used to analyze the complicated flow motion inside the finned-tube heat exchanger [20]. The RNG k-ε model has been used to capture the complex flow and adverse pressure gradients of the finned-tube heat exchanger [16,18].

where μeff = μ + μt is the effective viscosity, S = (2SijSij)0.5 is the modulus of the mean rate of the strain tensor, and Rε is the rate of strain. The αk and αε are the inversed effective Prandtl numbers for k and ε. The C1ε and C2ε are the turbulence model constants which values are 1.42 and 1.68 respectively [21].

2.2. Computational Domain and Boundary Conditions

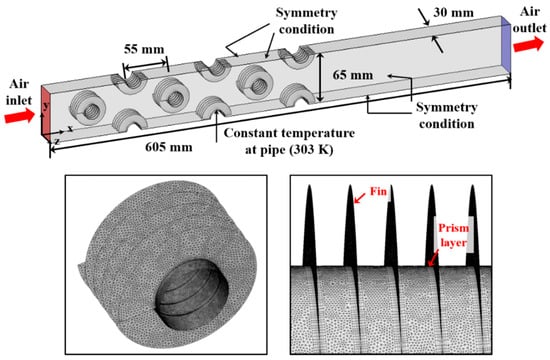

This study focuses on the air-side flows as the heat transfer characteristics are primarily affected by the complex flow physics of the outside flow of the tube. It is difficult to numerically simulate the full configuration of finned-tube heat exchangers, because of their significant computational requirements. Therefore, we analyze the complicated flow and heat transfer characteristics with the use of the repeated section of the finned-tube heat exchanger, as shown in Figure 1.

Figure 1.

Computational domain and grid generation.

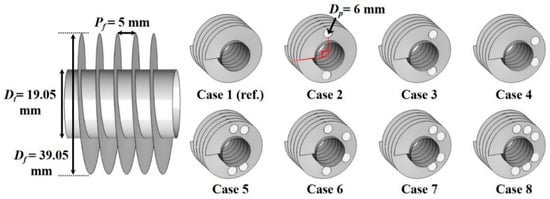

We construct the three-dimensional model and grid system of the spiral finned-tube heat exchanger. A staggered arrangement of tubes with six columns is adopted to analyze the effect of perforation positions on the fins. The distances in the transverse and longitudinal direction of each tube are 65 mm and 55 mm, respectively. The computational domain is extended to remove the backflow effect that is an artificial error at the outlet boundary. The total length of the computational domain is 605 mm, and the width is 30 mm. For the numerical analysis, we construct approximately 11.4 million tetrahedral mesh elements. Five prism layers are constructed on the wall of the fins for a detailed analysis of the flow motions and the heat transfer characteristics close to the fin surfaces. Figure 2 depicts eight fin configurations where the number and location of holes differ. The tube and fin diameters are set at 19.05 mm and 39.05 mm, respectively, the fin pitch is 5 mm, and the size of the hole is 6 mm. Case 1, the spiral fin without perforations, is taken as the reference case. Three locations, at 90°, 120°, and 150° from the leading edge of the tube, are studied. Cases 5, 6, and 7 each have four perforations on the fin per fin pitch, and Case 8 has six perforated holes per fin pitch.

Figure 2.

Fin configuration with different perforation locations. Case 1: Spiral fin (reference case). Location of perforation on fin from leading edge of tube: Case 2 at 90°, Case 3 at 120°, Case 4 at 150°, Case 5 at 90° and 120°, Case 6 at 90° and 150°, Case 7 at 120° and 150°, and Case 8 at 90°, 120°, and 150°.

At the mainstream, the temperature of the injected air is 363 K. The inlet air is injected uniformly with flow velocities of 5.16, 6.19, 7.22, and 8.26 m/s that correspond to Reynolds numbers of 7150, 8580, 10,010, and 11,440, respectively, to evaluate the heat transfer performance according to the mass flow rates. The side walls perpendicular to the flow direction apply symmetric conditions, and it considers a zero gradient to the normal direction of the plane. Also, the turbulence intensity and hydraulic diameter (Dh = 0.0212 m) at the inlet and outlet conditions are set for turbulence. The empirical correlation equation used for turbulence intensity is defined as follows [21]:

The turbulence intensity is 5% for the Re = 11,440. The tube wall is a no-slip condition with a fixed temperature of 303 K. Shell conduction, which can be used to model the thin wall without constructing mesh for the wall thickness, is employed to calculate the heat conduction within the fin. This model can be applied to the thin wall to consider the conjugate heat transfer [21,25]. The fin is made of stainless steel which has a thermal conductivity of 16.27 W/(m⸱K) and specific heat at constant pressure of 502.48 J/(kg⸱K). The fin thickness is set as 0.4 mm. The outlet condition is atmospheric pressure based on the gauge pressure. The density of the air is treated as an incompressible ideal gas. The thermal conductivity and viscosity of the air are set to piecewise-linear functions of temperature.

2.3. Performance of Heat Exchanger

Heat transfer performance and pressure drop characteristics are evaluated using the Colburn j-factor and friction factor that is defined as follows [26]:

where ∆p is the pressure drop, L is the characteristic length of the computational domain (L = 0.11 m), umax is the averaged velocity through the minimum flow cross-sectional area, Dh is the hydraulic diameter of the tube (Dh = 4Ag/Pw), Ag is the minimum flow area, and Pw is the wetted perimeter. The Reynolds number and Nusselt number are defined as:

where ho is the convective heat transfer coefficient of air-side. We calculate the overall heat transfer coefficient to obtain the air-side convective heat transfer coefficient with the following relation [26]:

where Qtot is the total heat transfer rate, Ao is the total surface area of the fin and tube, ∆TLMTD is the log mean temperature difference, is the mass flow rate of air. hi is the convective heat transfer coefficient of water-side, Ai is the surface area of the tube, Rt is the conductive thermal resistance due to the tube wall, and ηo is the overall surface efficiency. The convective heat transfer coefficient of water-side and conductive thermal resistance are neglected since the water-side is not considered in this study. The overall surface efficiency is calculated from the Schmidt approximation that is given as follows [27]:

where, Af is the fin surface area, ηf is the fin efficiency, and Dt is the diameter of the tube. Here, m and φ are defined as follows:

where kf is the thermal conductivity of fin and t is the fin thickness. The range of overall surface efficiency for all cases is 0.791 to 0.794.

3. Results and Discussion

3.1. Grid Independence Test and Validation

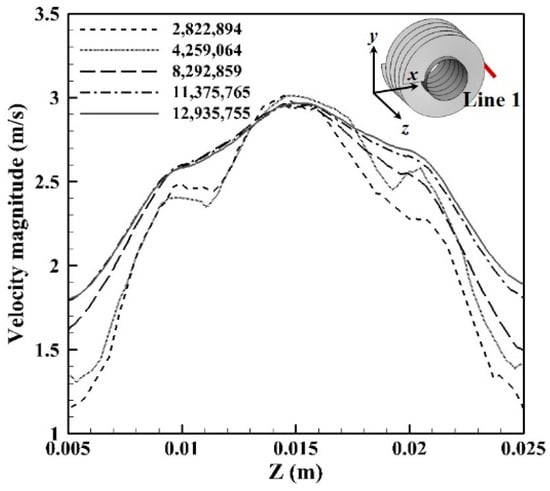

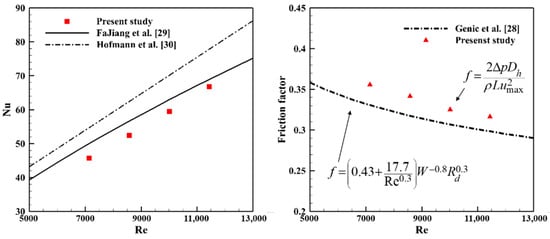

The grid independence test is essential to increase the accuracy of the numerical results and reduce the computational costs. Figure 3 shows the velocity magnitude distribution for the number of grids along Line 1, located 2 mm from the fin tip. The maximum error of the numerical results between the 4th and 5th grids is 5%. Therefore, the grid number of 11,375,765 is chosen for the numerical simulations. The grid independence tests are also conducted for the other cases, and the range of grid number is 11,880,000–12,940,000 with respect to the number of perforations. We compare the experimental correlations with the numerical results using Nusselt number for the heat transfer and friction factor for the pressure drop. The friction factor correlation is proposed by Genic et al. [28], as shown in Equation (20).

where W is the ratio of heat transfer area of a row of tubes to frontal free flow area, Pf, is the fin pitch, Pt is the transverse tube pitch, Pl is the longitudinal tube pitch, Rd is the ratio of diagonal free cross-sectional area to frontal free cross-sectional area, and Pd is diagonal tube pitch. The friction factor correlation is valid for 550 < Re < 130,000, Pt/Dt ≤ 3.5, Pl/Dt ≤ 3.5, and Rd ≥ 1. Figure 4 depicts the comparison of Nu and the friction factor correlation equations for different Reynolds number. The Nu of present results shows good agreement with experimental correlations proposed by FaJiang et al. [29] and Hofmann et al. [30]. A decreasing trend of the friction factor is observed with increasing Reynolds numbers. The maximum error is estimated at approximately 7.5% that is within the 8.3% of uncertainty range of correlation equation.

Figure 3.

Grid independence test based on velocity magnitude along Line 1, located 2 mm from fin tip in the x-direction.

Figure 4.

Comparison of Nu and friction factor between numerical predictions and correlations. (Left): Nusselt number; (Right): Friction factor.

3.2. Flow Characteristics of Finned-Tube Heat Exchanger

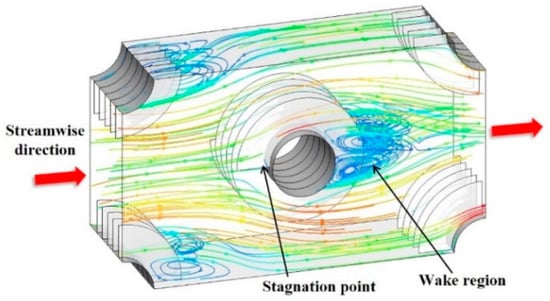

Figure 5 shows the flow characteristics of the finned-tube heat exchanger using streamlines. The stagnation point appears when the main flow encounters the leading edge of the tube. The flow velocity increases on both sides of the central tube with a decreasing cross-sectional area and reaches a maximum value at the smallest cross-sectional area. Also, flow separation is generated that causes a decrease in the heat transfer performance in the rear part of the tube. A wake region with the recirculation flow is observed behind the tube in the streamwise direction. In the wake region, heat transfer occurs owing to the recirculating flow that interacts with the mainstream and finned-tube surface [18].

Figure 5.

Flow characteristics of the spiral finned-tube heat exchanger.

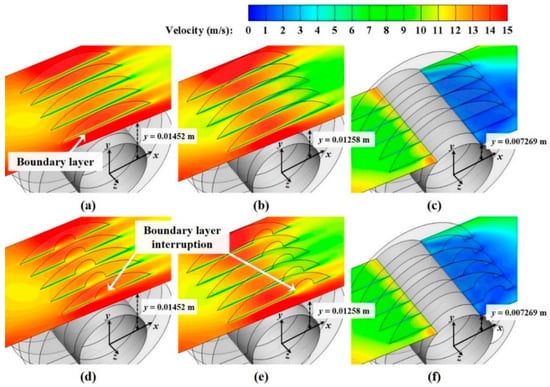

In Figure 6, the velocity distribution at a Reynolds number of 11,440 is shown in the plane perpendicular to the y-axis that is located at the center of each hole. For all cases, the boundary layers are developed in the streamwise direction close to the fin surfaces. These grow at the leading edge of the fins and attain their maximum thickness close to the junction of the fin and tube [11]. In Cases 2 and 3, boundary layer interruption occurs due to the perforations, increasing the flow disturbance at the location of the holes. The redevelopment of the boundary layer also occurs after the perforations. In Figure 6f, the flow velocity slightly increases in the rear part of the tube due to the perforations. In addition, the velocity vector is compared between Cases 1 and 4 in the wake region, as shown in Figure 7. The fin configurations in the wake region resist the air flow resulting in a greater pressure drop, but the perforations on the fins at 150° reduce the resistance of the air flow and decrease the pressure drop. In this study, a finite gap between the end of the spiral fin and the side wall of the computational domain is applied to generate a well-defined grid system (see Figure 1). This causes numerical artifacts especially with respect to the flow directions, as shown in Figure 7b. However, this does not significantly affect the overall tendency of heat transfer and pressure drop with different locations and the number of perforations.

Figure 6.

Velocity magnitude distributions with different hole locations at Re = 11,440. (a) Case 1(ref.) at y = 0.01452 m; (b) Case 1(ref.) at y = 0.01258 m; (c) Case 1(ref.) at y = 0.007269 m; (d) Case 2 at y = 0.01452 m; (e) Case 3 at y = 0.01258 m; and (f) Case 4 at y = 0.007269 m.

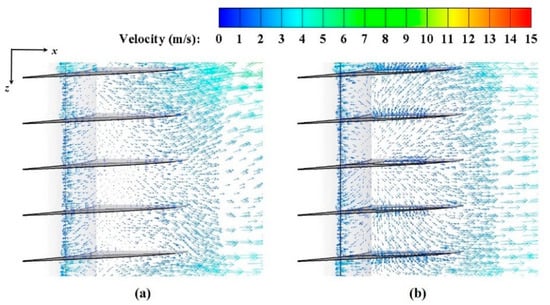

Figure 7.

Comparison of velocity vectors at Re = 11,440. (a) Case 1(ref.) at y = 0.007269 m; (b) Case 4 at y = 0.007269 m located in wake region.

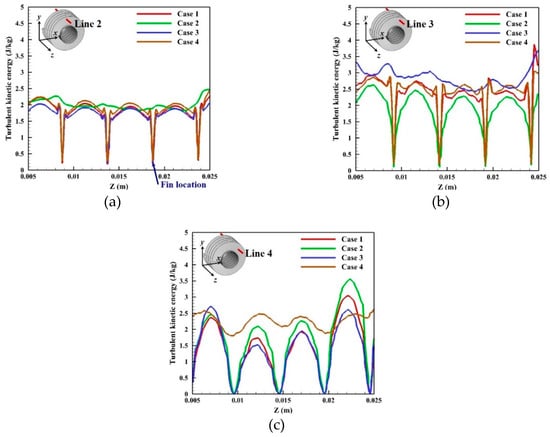

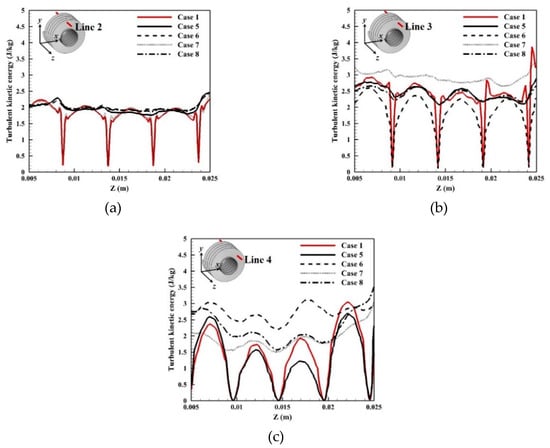

Figure 8 and Figure 9 show the local turbulent kinetic energy distributions reflecting the flow disturbance. Lines 2, 3, and 4 correspond to the center lines of the upper holes at 90°, 120°, and 150°, respectively. The peak points of each figure are due to the walls of the fins. In Figure 8a, the turbulent kinetic energy increases slightly for Case 2 as the perforations are in the minimum cross-sectional area region where the flow velocity is a maximum, resulting in the decrease of the flow disturbance due to the stronger momentum in the streamwise direction. However, Case 3 exhibits increasing turbulent kinetic energy at the location of holes, as shown in Figure 8b, as the perforations on the fin interrupt the growth of the boundary layer. In addition, the turbulent kinetic energy decreases for Case 2 at Line 3 as the boundary layer growth is disturbed by the perforation on the fin and redeveloped in this region. As discussed, the fin configuration restricts the air flow in the wake region, resulting in decreased turbulent kinetic energy. This tendency is observed for the cases without perforations at 150° (Figure 8c and Figure 9c). Greater turbulent kinetic energy in the wake region means that the fluid flows well through the perforations. The perforations locate at 120° and 150° marginally affect the turbulent kinetic energy at Line 2, as shown in Figure 9a. The greatest turbulent kinetic energy is observed for Case 7, as shown in Figure 9b, with the resulting in significant pressure losses.

Figure 8.

Comparison of turbulent kinetic energy at fixed locations in z-direction at Re = 11,440. Case 1(ref.) is compared with Cases 2, 3, and 4, (a) at Line 2 (y = 0.01452 m), (b) at Line 3 (y = 0.01258 m), and (c) at Line 4 (y = 0.007269 m).

Figure 9.

Comparison of turbulent kinetic energy at fixed locations along z-direction at Re = 11,440. Case 1(ref.) is compared with Cases 5, 6, 7, and 8, (a) at Line 2 (y = 0.01452 m), (b) at Line 3 (y = 0.01258 m), and (c) at Line 4 (y = 0.007269 m).

3.3. Heat Transfer and Pressure Drop Characteristics

The heat transfer and pressure drop characteristics are examined in the fifth tube row region where the flow is fully developed [31]. The total heat transfer rate across the heat exchanger, calculated by , is significantly affected by the heat transfer area and the convective heat transfer coefficient of the air-side. Each perforation per fin pitch reduces the heat transfer area by 2.2%, that in turn decreases the surface area by 4.4% (Cases 2, 3, and 4), 8.8% (Cases 5, 6, and 7), and 13.2% (Case 8), compared to the reference case. However, the maximum difference of the total heat transfer rate between Case 1 and the perforation cases is only approximately 3% (82.9–85.8 W for the lowest Re = 7150, and 115.7–119.5 W for the highest Re = 11,440). This indicates that the heat transfer performance can be improved significantly by perforations on the fin that enhance the flow disturbances close to the fin surfaces.

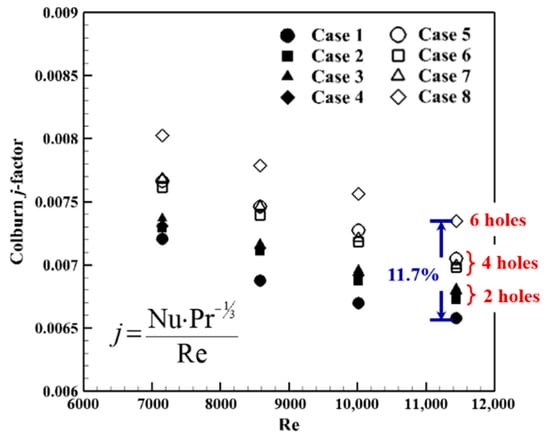

The heat transfer performance in the finned-tube heat exchanger can be quantitatively examined using the Colburn j-factor. An increasing Colburn j-factor points to the heat transfer performance per unit surface area of the fin and tube is increasing. In general, the Colburn j-factor decreases with the increase of the Reynolds numbers [26]. In Figure 10, the heat transfer performance increases in the perforated fin cases compared to the reference case, because the flow disturbance increases at the location of the perforations, resulting in stronger flow mixing between the main flow and the flow near the fin surfaces. The boundary layer redevelopment also increases the heat transfer performance [32]. The cases of two perforated fins per fin pitch (Cases 2, 3, and 4) exhibit similar heat transfer performances with differences smaller than 1%. Case 8 shows the greatest Colburn j-factor, which is 11.7% larger than that of reference case.

Figure 10.

Colburn j-factor with the Reynolds number.

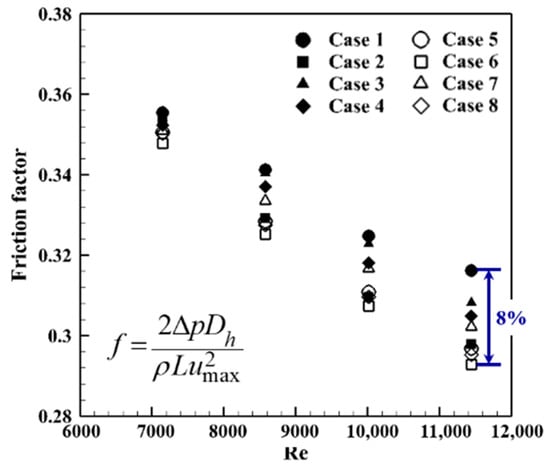

The friction factor is a critical parameter in the design of finned-tube heat exchangers as the pumping power is proportional to the pressure drop [26]. It is associated with the flow disturbance and the surface area of the fins and tubes. The perforations on the fin enhance the flow disturbance, but reduce the surface area. Figure 11 compares the friction factor of the eight cases for various Reynolds numbers. Cases 2, 5, 6, and 8 show almost identical pressure drops, with a difference less than 2%. However, Case 7, showing the greatest turbulent kinetic energy, exhibits a larger pressure drop than the cases with four perforations per fin pitch. The smallest pressure drop is observed for Case 6, showing a maximum difference of friction factor approximately 8% compared to the reference case. It indicates that the skin friction drag of the perforation cases is decreased, because of the smaller surface area, and the flow resistance decreases in the wake region, because the fluid flows well through the perforations that cause the decrease in the pressure drop.

Figure 11.

Friction factor concerning the Reynolds number.

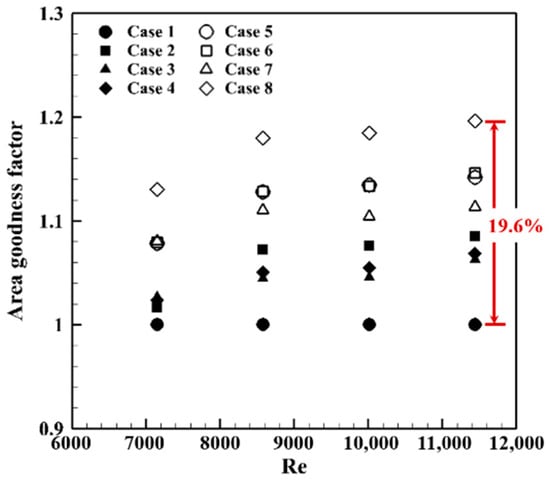

It is essential to analyze the heat transfer performance considering the pressure drop in the finned-tube heat exchanger. Numerous parameters have elucidated the relationship between heat transfer and pressure drop characteristics. Among them, the area goodness factor, the ratio of the Colburn j-factor to friction factor, is used as defined below [33]:

where jr and fr are the Colburn j-factor and friction factor of reference case, respectively. A higher value of area goodness factor means that the finned-tube heat exchanger requires a lower surface area. Figure 12 provides the area goodness factor for the eight cases for various Reynolds numbers. The perforated fin cases exhibit greater area goodness factors with increasing Reynolds numbers. The highest area goodness factor is observed for Case 8, because it shows better heat transfer performance with similar pressure drops compared to other perforated fin cases. This indicates that the surface area of the finned-tube heat exchanger can be reduced by using perforated fins.

Figure 12.

Area goodness factor with Reynolds number.

4. Conclusions

Numerical simulations were conducted to predict the flow and thermal characteristics of spiral finned-tube heat exchangers. We investigated the effects of perforated fins on the heat transfer and pressure drop characteristics of finned-tube heat exchangers. The conclusions are as follows.

The flow through the perforations on the fins influences the flow field of the boundary layers near the fin surfaces. The turbulent kinetic energy increases locally close to the locations of the holes indicating the stronger mixing flow. It is found that the Colburn j-factor increases by 11.7 % for Case 8 compared to the reference case. The pressure drop for the perforation cases decreases, because of the increased flow in the wake region behind the tubes. Similar pressure drops are observed for cases 2, 5, 6, and 8, with differences of less than 2%. Case 6 exhibits the smallest friction factor with a maximum difference of 8% compared to the reference case. The area goodness factor considers the relationship between heat transfer and the pressure drop. Case 8, with the smallest surface area, showed the highest value of area goodness factor. In general, the spiral finned-tube heat exchanger has a larger pressure drop and higher heat transfer performance compared to flat plate finned-tube heat exchangers. In this study, we have shown that the pressure drop can be reduced by perforations on the spiral fin while maintaining the total heat transfer rate.

Author Contributions

H.J.L. established the numerical model and conducted simulations of the current manuscript with all figures under the supervision of J.R. and S.H.L. (co-corresponding authors). Above all, J.R. and S.H.L., as the co-corresponding authors (equally contributed), have provided useful suggestions for data analysis and have discussed research progress.

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF-2017R1C1B2012068).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kakaç, S.; Liu, H.; Pramuanjaroenkij, A. Heat Exchangers: Selection, Rating, and Thermal Design, 3rd ed.; Taylor & Francis: Abingdon, UK, 2012. [Google Scholar]

- Wang, C.C.; Lo, J.; Lin, Y.T.; Wei, C.S. Flow visualization of annular and delta winglet vortex generators in fin-and-tube heat exchanger application. Int. J. Heat Mass Transf. 2002, 45, 3803–3815. [Google Scholar] [CrossRef]

- Pongsoi, P.; Pikulkajorn, S.; Wang, C.C.; Wongwises, S. Effect of fin pitches on the air-side performance of crimped spiral fin-and-tube heat exchangers with a multipass parallel and counter cross-flow configuration. Int. J. Heat Mass Transf. 2011, 54, 2234–2240. [Google Scholar] [CrossRef]

- Kakaç, S.; Bergles, A.E.; Mayinger, F.; Yüncü, H. Heat Transfer Enhancement of Heat Exchangers; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Lee, J.; Lee, H.J.; Ryu, J.; Lee, S.H. Three-dimensional turbulent flow and heat transfer characteristics of longitudinal vortices embedded in turbulent boundary layer in bent channels. Int. J. Heat Mass Transf. 2016, 117, 958–965. [Google Scholar] [CrossRef]

- Pongsoi, P.; Pikulkajorn, S.; Wongwises, S. Heat transfer and flow characteristics of spiral fin-and-tube heat exchangers: A review. Int. J. Heat Mass Transf. 2016, 79, 417–431. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, M.; Yoon, W.J.; Kim, Y. Frost growth characteristics of spirally-coiled circular fin-tube heat exchangers under frosting conditions. Int. J. Heat Mass Transf. 2016, 64, 1–9. [Google Scholar] [CrossRef]

- Kawaguchi, K.; Okui, K.; Kashi, T. The heat transfer and pressure drop characteristics of finned tube banks in forced convection (comparison of the pressure drop characteristics of spiral fins and serrated fins). Heat Transfer Asian Res. 2004, 33, 431–444. [Google Scholar] [CrossRef]

- Pongsoi, P.; Promoppatum, P.; Pikulkajorn, S.; Wongwises, S. Effect of fin pitches on the air-side performance of L-footed spiral fin-and-tube heat exchangers. Int. J. Heat Mass Transf. 2013, 59, 75–82. [Google Scholar] [CrossRef]

- Lee, M.; Kang, T.; Kim, Y. Air-side heat transfer characteristics of spiral-type circular fin-tube heat exchangers. Int. J. Refrig. Rev. Int. Froid 2010, 33, 313–320. [Google Scholar] [CrossRef]

- Mon, M.S.; Gross, U. Numerical study of fin-spacing effects in annular-finned tube heat exchangers. Int. J. Heat Mass Transf. 2004, 47, 1953–1964. [Google Scholar] [CrossRef]

- Ma, Y.F.; Yuan, Y.C.; Liu, Y.Z.; Hu, X.H.; Huang, Y. Experimental investigation of heat transfer and pressure drop in serrated finned tube banks with staggered layouts. Appl. Therm. Eng. 2012, 37, 314–323. [Google Scholar] [CrossRef]

- Lindqvis, K.; Wilson, Z.T.; Naess, E.; Sahinidis, N.V. A machine learning approach to correlation development applied to fin-tube bundle heat exchanger. Energies 2018, 11, 3450. [Google Scholar] [CrossRef]

- Lemouedda, A.; Schmid, A.; Franz, E.; Breuer, M.; Delgado, A. Numerical investigations for the optimization of serrated finned-tube heat exchangers. Appl. Therm. Eng. 2011, 31, 1393–1401. [Google Scholar] [CrossRef]

- Nuntaphan, A.; Kiatsiriroat, T.; Wang, C.C. Air side performance at low Reynolds number of cross-flow heat exchanger using crimped spiral fins. Int. Commun. Heat Mass Transf. 2005, 32, 151–165. [Google Scholar] [CrossRef]

- Martinez, E.; Vicente, W.; Salinas-Vazquez, M.; Carvajal, I.; Alvarez, M. Numerical simulation of turbulent air flow on a single isolated finned tube module with periodic boundary conditions. Int. J. Therm. Sci. 2015, 92, 58–71. [Google Scholar] [CrossRef]

- Martinez, E.; Vicente, W.; Salinas-Vazquez, M. Numerical analysis for saving fin material in helical segmented-tubes. Appl. Therm. Eng. 2017, 110, 306–317. [Google Scholar] [CrossRef]

- Kumar, A.; Joshi, J.B.; Nayak, A.K. A comparison of thermal-hydraulic performance of various fin patterns using 3D CFD simulations. Int. J. Heat Mass Transf. 2017, 109, 336–356. [Google Scholar] [CrossRef]

- Lee, D.H.; Jung, J.M.; Ha, J.H.; Cho, Y.I. Improvement of heat transfer with perforated circular holes in finned tubes of air-cooled heat exchanger. Int. Commun. Heat Mass Transf. 2012, 39, 161–166. [Google Scholar] [CrossRef]

- Liu, X.Q.; Yu, J.L.; Yan, G. A numerical study on the air-side heat transfer of perforated finned-tube heat exchangers with large fin pitches. Int. J. Heat Mass Transf. 2016, 100, 199–207. [Google Scholar] [CrossRef]

- Fluent Inc. Fluent 17.0 User’s Manual; Fluent Inc.: Canonsburg, PA, USA, 2016. [Google Scholar]

- Ryu, J.; Lele, S.K.; Viswanathan, K. Study of supersonic wave components in high-speed turbulent jets using an LES database. J. Sound Vib. 2014, 333, 6900–6923. [Google Scholar] [CrossRef]

- Ryu, J.; Livescu, D. Turbulence structure behind the shock in canonical shock–vortical turbulence interaction. J. Fluid Mech. 2014, 756, R1. [Google Scholar] [CrossRef]

- Jin, W. Numerical investigation of icing effects on dynamic inlet distortion. Int. J. Aeronaut. Space Sci. 2018, 19, 354–362. [Google Scholar] [CrossRef]

- Zhang, J.F.; He, Y.L.; Tao, W.Q. 3D numerical simulation on shell-and-tube heat exchangers with middle-overlapped helical baffles and continuous baffles—Part Ⅱ: Simulation results of periodic model and comparison between continuous and noncontinuous helical baffles. Int. J. Heat Mass Transf. 2009, 52, 5381–5389. [Google Scholar] [CrossRef]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar]

- Schmidt, T.E. Heat transfer calculations for extended surfaces. Refrig. Eng. 1949, 57, 351–357. [Google Scholar]

- Genic, S.B.; Jacimovic, B.M.; Latinovic, B.R. Research on air pressure drop in helically-finned tube heat exchangers. Appl. Therm. Eng. 2006, 26, 478–485. [Google Scholar] [CrossRef]

- FaJiang, H.; WeiWu, C.; Ping, Y. Experimental investigation of heat transfer and flowing resistance for air flow cross over spiral finned tube heat exchanger. Energy Procedia 2012, 17, 741–749. [Google Scholar] [CrossRef]

- Hofmann, R.; Ponweise, K. Heat transfer and pressure drop performance comparison of finned-tube bundles in forced convection. WSEAS Trans. Heat Mass Transf. 2007, 2, 72–88. [Google Scholar]

- Papa, F. Local Velocities and Heat Transfer Coefficients over Fin Tubes. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1997. [Google Scholar]

- Sadeghianjahromi, A.; Kheradmand, S.; Nemati, H.; Liaw, J.S.; Wang, C.C. Compound heat transfer enhancement of wavy fin-and-tube heat exchangers through boundary layer restarting and swirled flow. Energies 2018, 11, 1959. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data; Academic Press: Cambridge, MA, USA, 1978. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).