Abstract

Present-day direct injection (DI) diesel engines with a high power density of displacement are not just promoting an expansion in the utilization of high-temperature resistant alloys in pistons yet, in addition, the expanded cylinder air pressures. When the temperature of the diesel engines piston exceeds a certain limit, it assumes a critical role at the start of sprays. The target of the present investigation was to look at the effects of cylinder air pressures (CAP) (10–25 bar) and high hot surface temperatures (HST) (350–450 °C). The ignition delay (ID) of pure diesel and that of diesel with Iftex clean system D (a cetane enhancer) are investigated experimentally. The experiments are performed by using a constant volume combustion chamber (CVCC) with a single hole pintle-type nozzle mounted on its head. A strong dependence of ID on the CAPs and HSTs was observed. A CAP of 25 bar is much inferior to the precombustion pressure of DI diesel engines; however, it is the case that combustion typical features are the same in spite of an inferior CAP, HST, and injection pressure. The ID tends to decrease to very small values with an increase in either of the two parameters. At a CAP of 25 bar, the measured ID of diesel with fuel additive is 45.8% lower than the pure diesel. Further, the ID of diesel with fuel additive at a 300 bar injection pressure and 25 bar CAP decreases at a rate of close to 0.2 ms/bar.

1. Introduction

Diesel engine can continue running on biodiesel mixed with pure diesel without alteration [1,2,3], and hence, are of interest. Further, their ignition delays (IDs) play a pivotal role in deciding the brisk pressure increase in the underlying burning stage and the resulting ignition stages. The ID is characterized as the time between the beginning of fuel injection and the beginning of combustion. In addition, IDs significantly affect the ignition methodology and can be arranged into physical and chemical ID [4,5].

Huang et al. [6] analytically examined the execution, combustion, and emission attributes of a solitary cylinder direct injection (DI) diesel engine using a balanced diesel–methanol blend with a maximum of 18% methanol. They noticed that ID increased with the amount of methanol in the diesel, causing an increase in the heat discharge rate in the premixed combustion stage and a decrease in the combustion span in the diffusion combustion stage. Ge et al. [7] observed that the ID was diminished when the pilot injection timing approached the main injection timing.

Naber et al. [8] presented the effect of alterations in natural gas contents on the autoignition of natural gas under DI diesel engine conditions in a constant volume combustion chamber (CVCC) experimental setup. It was observed that the minimal temperature appropriate for moderate diesel engine ID for all the examined natural gas mixtures is about 877 °C. At high temperatures, the deliberate IDs are characterized by the rate of fuel infusion. Indistinguishable cutoff points were watched [9] for liquid fuels.

Lapuerta et al. [10] observed that for ethanol–diesel mixture, the pressure rise postponement, and its cycle-to-cycle varieties decline by expanding both the air temperature and pressure and increment by expanding the ethanol percentage in the mixture. Das et al. [11] found that biodiesel is not significantly different from existing combustion characteristics, even when it is mixed with pure diesel. Thus, a higher content of biodiesel results in a shorter ID.

A significant issue in the design of the combustion chamber of the diesel engine is to comprehend the importance of the interaction between the surrounding air and fuel spray before the start of ignition. There are numerous investigations on the fuel–air premixing conditions necessary for igniting diesel spray that is connected to the advancement of outlet emissions [12]. Numerous trial strategies and procedures have been utilized for the assessment of the ignition aspect of fuels, like flow reactors, a rapid compression machine, and CVCCs. CVCCs are much of the time used to consider the autoignition behavior of diesel fuels and diesel fuel blends [13,14,15]. Ishiyama et al. [16] showed that in DI diesel engine combustion, thermal cracking, fuel gasification, and an oxidation process are initiated early in the ID period.

Commercial high-pressure CVCC systems have become more easily accessible, and a few are particularly designed to quantify the cetane number of diesel fuels. Precise assurance of inferred cetane number is vital for diesel fuel and biodiesel blenders and refineries in order to maintain fuel consistency and quality. Lapuerta et al. [17] analyzed the start and burning attributes of diesel fuel over a scope of beginning conditions with the help of a PAC Herzog cetane ID 510TM [18] system. This system has an exclusive technology to provide high precision and also has other advantages over existing methods.

Kuti et al. [19] researched the combustion qualities and spray of palm oil source and observed that the ID diminished as the cylinder air pressures (CAPs) expanded because of the upgraded blending forms. Rehman [20] contemplated tentatively the ignition and combustion qualities of diesel fuel spray in a CVCC and found that the ID of the diesel fuel sprays diminished with the expansion in CAPs and hot surface temperatures (HSTs).

Our literature survey erects that the impacts of CAPs and HSTs on ID qualities in a DI diesel engine with injection pressures have not been apparently examined. Therefore, in the present study, we examined the ID characteristics of diesel and diesel with fuel additive. This work has its significance in light of the fact that at high CAPs and at a high HSTs, the ID assumes an imperative job in the knocking and fumes outflows of DI diesel engine.

2. Experimental and Analytical Methods

2.1. Problem Formulation

For many years, DI diesel engines have been an important choice as prime movers in heavy-duty applications. The performance attributes of DI diesel engines rely upon different components including injection pressure, fuel amount infused, CAPs, thermal efficiency, and simple mechanism. Because of their greater efficiency, less fuel is consumed for the same distance traveled, which is the main reason for their popularity. To accomplish greater ignition proficiency, the fuel system in a DI diesel engine needs to reach a tremendous level of atomization for improved infiltration of fuel so as to employ the complete air charge.

Experimentally, it is known that ID decreases with an increase in several parameters such as cetane number, temperature, pressure, and optimum injection timing [21]. Physical characteristics that affect the advancement of the air charge and the fuel spray will influence the ID. As the cost of diesel fuel increases and emission standards become more stringent, there is a requirement to decrease emissions and to enhance the efficiency of DI diesel engines. Emissions from diesel engines mainly depend upon the ignition procedure. The study of the combustion characteristics of DI diesel engines is, therefore, an important topic of research.

The intent of the present study was to tentatively examine the impact of high CAPs and high HSTs inside the combustion chamber on IDs of pure diesel and diesel with fuel additives such as Iftex clean system D (a premium multifunctional fuel additive). Iftex, an ISO 9002 company, is one of the leading manufacturers of gasoline additives in India. Other products of Iftex are Iftex clean system G, Iftex clean system Purge, and Iftex clean system 23.

Mixing was performed to analyze the known properties of diesel fuel. A commercially available diesel fuel [22] was picked as a standard fuel. This fuel was tried for variations of ID with changes in the temperatures of hot surfaces and CAPs inside the combustion chamber. A mixture of 195 mL pure diesel and 5 mL of Iftex was also tested. The fuel was set up in a fuel estimating equipment, which ensured the miscibility of the two fuels to a sufficient degree.

2.2. Experimental Setup

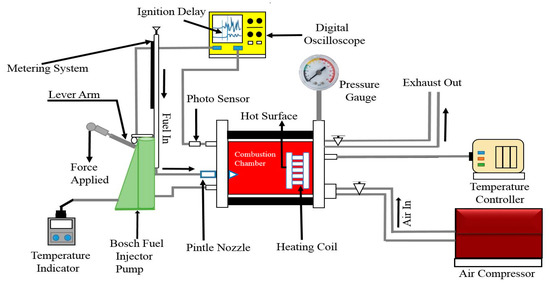

In this investigation, the test arrangement resided of the units appeared in Figure 1. The experimental setup has a combustion chamber with a hot surface plate of stainless steel, and a fuel injector situated on the contrary side of the chamber. The fuel injector has a pintle nozzle to produce a hollow conical spray that impinges on the hot surface.

Figure 1.

Scheme of the experimental setup.

The combustion chamber is a stainless-steel round and hollow tank having a volume of 8.906 × 103 mm3. The hot surface plate and pintle-type nozzle’s tip was separated 64 mm approximately. A pintle-type nozzle is straightforwardly toward one side of the combustion chamber. In the interior of the combustion chamber, a heating coil is located between two stainless steel plates so as to expand the temperature of the outside of the plates. The heating coil is associated with the auxiliary coil of a transformer which provides current to the assembly of plates and coil. The stainless steel plate acts as the hot surface inside the combustion chamber and is placed opposite the fuel injection nozzle on the other end of the chamber. Hot surface combustion can, therefore, be realized inside the combustion chamber.

Temperature controller utilized in present work estimates the hot surface temperature of the stainless steel plate within the combustion chamber, and it is a computerized temperature controller. It cuts the supply of current to the heater when the temperature reached beyond a set limit and hence maintains the temperature of the hot plate below a set limit. The temperature controller details, including the range, function, and source voltage, are summarized in Table 1.

Table 1.

Details of temperature controller.

Profoundly compact air brought into the combustion chamber with the assistance of an air compressor. To control the pressure of the combustion chamber, two-stage high pressure reciprocating air compressor was used. The pressure developed in the interior of the combustion chamber can be varied in the extent 1–25 bars with the help of a regulating valve. The primary determinations of the air compressor utilized in this investigation are abridged in Table 2.

Table 2.

Details of air compressor.

Fuel pump consists of a single-acting plunger that reciprocates inside a barrel with a constant stroke. The clearance between the barrel and the plunger is of the request of just 2–3 thousandths of a millimeter which gives an ideal sealing without uncommon pressing, even at exceptionally high pressure and low speeds. The pump barrel has two radically contradicting openings that are the inlet and the control port.

The basic requirement in the experimental setup is to run the fuel pump. This is to be done by imparting reciprocating motion to the plunger of the pump. The entire mechanism consists of three components: pump plate, striking pin, and rocker and lever arm. The details of the fuel pump are summarized in Table 3.

Table 3.

Details of fuel pump.

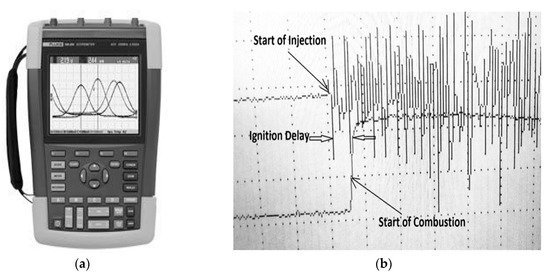

Storage Oscilloscope

The oscilloscope utilized in the present investigation is an advanced two-channel oscilloscope as shown in Figure 2a. The combustion and the fuel injection processes are shown on separate channels as shown in Figure 2b. By adjusting the time scale, the ID can be measured on the screen of the oscilloscope by observing the distinction between the beginning of injection and the beginning of combustion. The details of oscilloscope are summarized in Table 4.

Figure 2.

(a) Digital storage oscilloscope (Injection and Combustion Pulses); (b) Oscilloscope display.

Table 4.

Details of digital storage oscilloscope.

2.3. Test Fuel and Experimental Procedure

Samples were prepared using a measuring cylinder, taking due care for filtration and accurate measurements. The fuels used were pure diesel and diesel with fuel additive. The composition of the mixed fuel was 195 mL diesel with 5 mL fuel additive by volume. The fuel was distinguished by determining its cetane number, specific energy, pour point, and viscosity. The fuel properties of diesel and diesel with fuel additive are represented in Table 5.

Table 5.

Properties of diesel and diesel with fuel additive.

At different CAPs and HSTs, several experiments have been performed in CVCC. Various readings are taken at different arrangements of working conditions. A mean value determined from the five rehashed readings of each set to limit the mistake in the assessment. The experimental requirements are summarized in Table 6.

Table 6.

Experimental conditions.

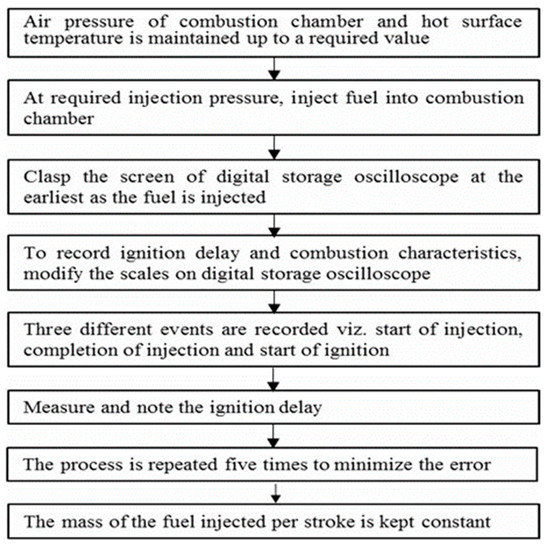

The air pressure of the combustion chamber is initially raised and sustained at the desired CAPs with the help of the compressor and the regulator. The surface temperature inside the combustion chamber is sustained at the desired HSTs via the heating element attached to the hot plate and temperature controller. At the point when there is no longer any combustion taking place inside the chamber, there is no light falling on the photosensor, and consequently, the signal from the oscilloscope is zero. A work approach of the present study is shown by the flowchart in Figure 3.

Figure 3.

Flowchart displaying analysis of the work approach.

3. Results and Discussion

Photosensors are required for further progress in this field because high pressure leads to a short ID; therefore, detailed features of the process can only be analyzed solely a photosensor methodology that is endorsed in the current study. As the operating speed of present-day low-emission high-performance engines is increasing, new techniques based on optical methods are required to observe the traditional concept of ID.

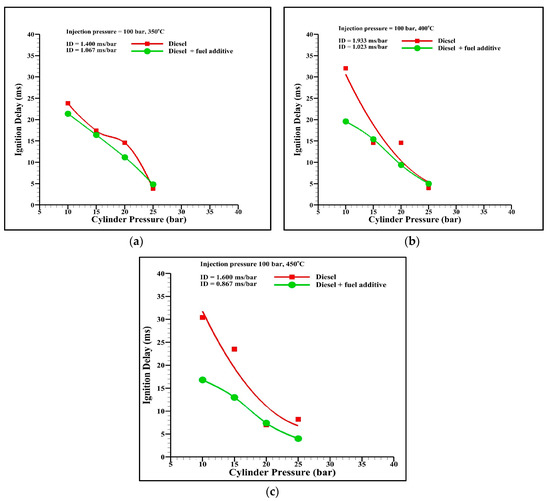

It tends to be seen from Figure 4 that with the increase in the HST, estimated ID decrease ceaselessly. The ID in a DI diesel engine is, for the most part, observed as comprising of two diverse back to back in spite of the fact that covering stages: the physical and the chemical ID. As is usually acknowledged, the physical ID deferral relates to the blend arrangement and the chemical delay to the time important to get a proportional increment in the chemical response rate. Along these lines, chemical ID decreases with an increase in HST.

Figure 4.

Ignition delay (ID) deviation of diesel and diesel with fuel additive at injection pressure 100 bar. (a) CAP 10-25, HST 350; (b) CAP 10-25, HST 400; (c) CAP 10-25, HST 450.

The measured ID is higher for pure diesel as compared with the diesel with fuel additive for lower CAPs; however, it is lower for a CAP of 25 bar as shown in Figure 4. The reason might be that expansion in CAP expands the density of the compacted air achieving closer contact of the particles, subsequently diminishes the season of reaction when fuel is infused consequently lessens the minimal autoignition temperature of the fuel and in this manner, the chemical ID decreases [23].

As the HST increases, the decrease in ID for the diesel with fuel additive is greater compared with that of pure diesel. The amount of vaporized fuel and the chemical response rate in the combustion chamber increments as the HST increments. The diesel with fuel additive displays a shorter ID as the temperature of the hot surface increases because of the improved cetane number. Yusop et al. [24] concluded that the dispersion combustion stage for pure diesel was longer than the mixed fuels due to the higher cetane number for biodiesel caused a decrease in ID and higher fuel utilization during combustion.

A fuel additive is a cetane enhancer which contains alkyl nitrates and therefore the addition to diesel improves ignition quality of the mixture. Cetane quality of pure diesel is characterized as far as the simplicity with which the fuel ignites. Actuating a DI diesel engine on competent cetane quality fuel results in great beginning attributes, particularly in chilly climate, lower clamor levels, and diminished fuel utilization.

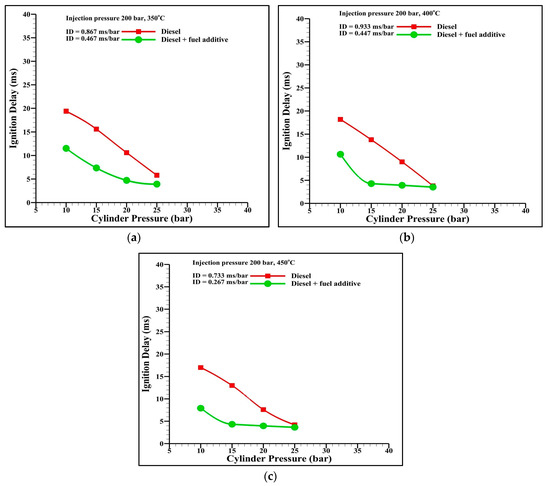

The pour point of diesel with fuel additive is higher than the pure diesel as appeared in Table 4. Therefore, diesel with fuel additive sprays vaporizes quickly in the low temperature and structures a combustible mixture with cylinder air and ignition happens quickly because of high pour point temperature of diesel with fuel additive sprays as soon as it reaches the hot surface. Accordingly, during the low-temperature operation (less than 400 °C), IDs of diesel are longer than diesel with fuel additive. In any case, during the high-temperature operation (more than 400 °C), pure diesel sprays likewise vaporize in the high temperature like that of diesel with fuel additive as shown in Figure 5, and ignition to happen when it achieves the hot surface. Accordingly, IDs of pure diesel and diesel with fuel additive are about equivalent at high HST.

Figure 5.

ID deviation of diesel and diesel with fuel additive at injection pressure 200 bar. (a) HST 350; (b) HST 400; (c) HST 450.

The observations as shown in Figure 5 are similar to the results of Khan and Hussain [25]. They showed that ID was higher for pure diesel as compared with diesel with vegetable oil, at any CAP. In addition, as the CAP was increased, the ID value was decreased for both the fuels, i.e., pure diesel and diesel with vegetable oil. The impingement of fuel spray on the hot surface affected the fuel dissipation and chemical blending processes. Alireza Varipour [26] reported a similar effect—with an increase in HST, ID decreased. Hence, the shortest IDs were obtained at higher HSTs, while the longest at lower HSTs.

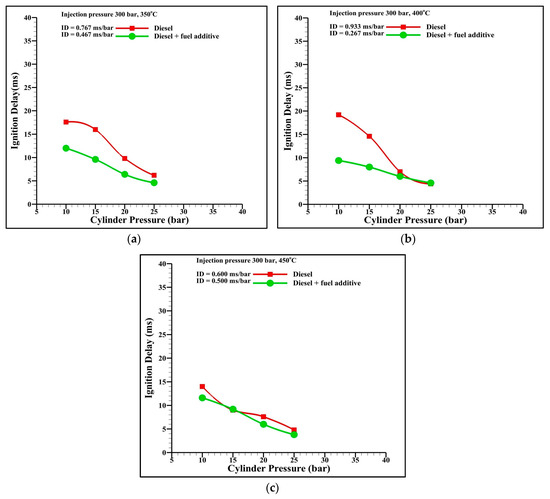

The diffusion of fuel spray toward the hot surface plate is quicker for pure diesel than the vaporousness of fuel spray of the diesel with fuel additive, in light of its higher viscosity as appeared in Table 4. Diesel with fuel additive, therefore, has an ID comparable to that of pure diesel. Additionally, diesel with a fuel additive is having a lower viscosity than pure diesel which advances great atomization of diesel with fuel additive at lower CAPs. As observed from graphs of Figure 6, that at lower CAPs, viscosity plays an important role for IDs. At 10 bar of CAP, diesel with fuel additive shows a lower ID as compared to pure diesel but when we increase the CAP from 10 bar to 25 bar the pure diesel and diesel with fuel additive shows nearly the same IDs.

Figure 6.

ID deviation of diesel and diesel with fuel additive at injection pressure 300 bar. (a) HST 350, Injection pressure 300; (b) HST 400, injection pressure 300; (c) HST 450, injection pressure 300.

The fuel evaporation and fuel–air mixing process are affected by the contact of the spray with the hot surface. An important point to note from Figure 6b is that with an increase in CAP, the ID decreases by approximately 0.2 ms/bar. NOx emissions are reduced to an optimum value by the proper mixing of fuel and air at higher CAP values [27]. On the whole, however, the graphs show that, as expected, the ID is reduced as the CAP is increased. Nursal et al. [28] found that the higher injection pressure emerged in a larger amount of fuel-air premixing, and thus an improvement in atomization of the combustible mixture.

The results obtained showed similarities with the work of Rehman and Zaidi [29]. They showed that the ID of both diesel fuel and n-pentane blends decreased with an increase in HST. Further, n-pentane blends of diesel had a longer ID than n-hexane blends of diesel, for all concentrations. With an increase in HST, the reduction in ID was nonlinear, irrespective of the injection pressure values. This implies that the decrease in the ID is relatively less as the HST is increased to higher values. This behavior of ID was investigated by Lapuerta et al. [30]. As shown in the graphs, it was experimentally observed that ID decreases with the increase of HST for constant CAPs, and also with an increase in CAP at constant HST. This is because at high temperatures, the fuel–air mixing is faster, and a homogenous mixture of fuel and air occurs more quickly.

4. Conclusions

The reason for the present work is to experimentally investigate the effects of HST (350–450 °C) and CAPs (10–25 bar) on the ID of diesel and diesel with fuel added substance. The ends drawn from the present examination are as per the following:

- (1)

- The ID of diesel sprays strongly depends on the HST and CAP inside the combustion chamber. The explanation behind the decrease in IDs is that with the expansion in HST, the blending rate of fuel vapor and air become abrupt because of the quick fuel vanishing on the high hot surface of the plate and quicker rate of burning. When the surface temperature surpasses 450 °C, the impact of mixing of fuel on ID on the hot surface diminishes.

- (2)

- It is found that the abatement in ID lessens at higher HST. At an HST of greater than 400 °C, the decrease in ID is generally limited with an expansion in surface temperatures. This is due to the impinging fuel sprays on the hot surface providing swift fuel evaporation at high HST.

- (3)

- The results also indicate that at high HST above 400 °C, the effect of CAP is less significant on ID at constant injection pressures.

- (4)

- Cylinder air density increases with the increase in intake air pressure. With an increase in the CAP, the ID decreases at a rate of approximately 0.2 ms/bar, and it can be conjectured that with further increase in the CAP, the value of the ID will decrease further.

- (5)

- The ID of diesel decreases when the CAP increases, but at 25 bar, the ID decreases significantly for a given HST.

A large portion of the nitric oxide frames during premixed consuming after the culmination of the ID. Any decrease in ID also causes a decrease in premixed combustion. It is logical to assume that a decrease in the premixed combustion after the end of ID will likewise result in a corresponding decrease in the amount of nitric oxide. The IDs in real DI diesel engines are shorter at typical ordinary engine working conditions as compared to the present study. In this study, HST was studied; however, in DI diesel engines, hot air ignition can occur. The magnitude of ID is in good agreement with that for stationary diesel engines and large-bore marine engines.

Author Contributions

M.S. performed the experimental analysis and drafted the manuscript. S.C.K. organized the overall evaluation and reviewed the manuscript.

Funding

This research received no external funding.

Acknowledgments

This work was supported by the 2019 Yeungnam University Research Grant.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| CAP | Cylinder air pressure (bar) |

| CVCC | Constant volume combustion chamber |

| cm3 | Cubic centimeter |

| DI | Direct injection |

| HST | Hot surface temperature (°C) |

| ID | Ignition delay (ms) |

| mm | Millimeter |

References

- Ziejewski, M.; Goettler, H.; Pratt, G.L. Comparative analysis of the long-term performance of a diesel engine on vegetable oil based alternate fuels. SAE Tech. Paper 1986. [Google Scholar] [CrossRef]

- Montagne, X. Introduction of rapeseed methyl ester in diesel fuel-the French national program. SAE Tech. Paper 1996. [Google Scholar] [CrossRef]

- İlkılıç, C.; Çılğın, E.; Aydın, H. Terebinth oil for biodiesel production and its diesel engine application. J. Energy Inst. 2015, 88, 292–303. [Google Scholar] [CrossRef]

- Rosseel, E.; Sierens, R. The physical and the chemical part of the ignition delay in diesel engines. SAE 1996. [Google Scholar] [CrossRef]

- Toni, A.R.D.E.; Werler, M.; Hartmann, R.M.; Cancino, L.R.; Schießl, R.; Ikri, M.; Schulz, C.; Oliveira, A.A.M.; Oliveira, E.J.; Rocha, M.I. Ignition Delay Times of Jet A-1 Fuel: Measurements in a High-Pressure Shock Tube and a Rapid Compression Machine. Proc. Combust. Inst. 2017, 36, 3695–3703. [Google Scholar] [CrossRef]

- Huang, Z.H.; Lu, H.B.; Jiang, D.M.; Zeng, K.; Liu, K.; Zhang, J.Q.; Wang, X.B. Combustion characteristics and heat release analysis of a compression ignition engine operating on a diesel/methanol blend. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2004, 218, 1011–1024. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, M.S.; Yoon, S.K.; Choi, N.J. Effects of pilot injection timing and EGR on combustion, performance and exhaust emissions in a common rail diesel engine fueled with a canola oil biodiesel-diesel blend. Energies 2015, 8, 7312–7325. [Google Scholar] [CrossRef]

- Naber, J.D.; Siebers, D.L. Effect of natural gas composition on ignition delay under diesel condition. In Proceedings of the 25th International Symposium on Combustion, Irvine, CA, USA, 31 July–5 August 1994. [Google Scholar]

- Siebers, D.L. Ignition delay characteristics of alternative diesel fuels: implications on cetane number. Trans. SAE 1985, 94, 673–686. [Google Scholar]

- Lapuerta, M.; Hernandez, J.J.; Rodríguez, D.F.; Bonillo, A.C. Auto ignition of blends of n-butanol and ethanol with diesel or biodiesel fuels in a constant volume combustion chamber. Energy 2016. [Google Scholar] [CrossRef]

- Das, S.K.; Jo, H.; Jwa, K.H.; Lin, O.; Woo, Y. Combustion chamber of biodiesel blended gasoline fuel in engine like conditions using constant volume chamber. Energy Procedia 2018, 145, 187–197. [Google Scholar] [CrossRef]

- Ogawa, H.; Li, T.; Miyamoto, N.; Kido, S. Dependence of ultra-high EGR and low temperature diesel combustion on fuel injection conditions and compression ratio. SAE Tech. Paper 2006. [Google Scholar] [CrossRef]

- Lee, S.W.; Baik, D.S. Experimental study on spray and combustion characteristics of biodiesel blends. Int. J. Bio Sci. Bio Technol. 2014, 6, 91–98. [Google Scholar] [CrossRef]

- Emberger, P.; Hebecker, D.; Pickel, P.; Remmele, E.; Thuneke, K. Ignition and combustion behavior of vegetable oils after injection in a constant volume combustion chamber. Biomass Bioenergy 2015, 78, 48–61. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A.; Lejda, K.; Balawender, K.; Wos, P. Use of the constant volume combustion chamber to examine the properties of auto ignition and derived cetane number of mixtures of diesel fuel and ethanol. Fuel 2017, 200, 564–575. [Google Scholar] [CrossRef]

- Ishiyama, T.; Miwa, K.; Horikoshi, O. A study on ignition process of diesel spray. Comodia 1994, 38, 337–342. [Google Scholar] [CrossRef][Green Version]

- Lapuerta, M.; Sanz, A.J.; Raine, R.R. Ignition characteristics of diesel fuel in a constant volume bomb under diesel-like conditions. effect of the operation parameters. Energy Fuels 2014, 28, 5445–5454. [Google Scholar]

- PAC Cetane ID 510TM Derived Cetane Number Analyzer, PAC Houston, TX, USA. Available online: http://www.paclp.com (accessed on 23 January 2019).

- Kuti, O.A.; Zhu, J.; Nishida, K.; Wang, X.; Huang, Z. Characterization of spray and combustion processes of biodiesel fuel injected by diesel engine common rail system. Fuel 2013, 104, 838–846. [Google Scholar] [CrossRef]

- Rehman, S. Hot surface ignition and combustion characteristics of sprays in constant volume combustion chamber using various sensors. Cogent Eng. 2018. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engines, 2nd ed.; McGraw Hill International: New York, NY, USA, 1988. [Google Scholar]

- Rehman, S. Fuel Property Testing Lab; Petroleum Engineering Department, AMU: Aligarh, India, 2018. [Google Scholar]

- Ganesan, V. Internal Combustion Engines, 4th ed.; Tata McGraw Hill: New Delhi, India, 2012. [Google Scholar]

- Yusop, A.F.; Mamat, R.; Yusaf, T.; Najafi, G.; Yasin, M.H.M.; Khathri, A.M. Analysis of particulate matter (pm) emissions in diesel engines using palm oil biodiesel blended with diesel fuel. Energies 2018, 11, 1039. [Google Scholar] [CrossRef]

- Khan, M.N.; Hussain, I. An experimental measurement of ignition delay for diesel fuel blends at different cylinder pressures. J. Mater. Sci. Mech. Eng. 2015, 2, 20–23. [Google Scholar]

- Valipour, A. Experimental combustion analysis of biodiesel fuel spray with hot surface ignition. IPASJ Int. J. Mech. Eng. 2014, 2, 1–14. [Google Scholar]

- Kiplimo, R.; Tomita, E.; Kawahara, N.; Yokobe, S. Effects of spray impingement, injection parameters, and egr on the combustion and emission characteristics of a PCCI diesel engine. Appl. Therm. Eng. 2012, 37, 165–175. [Google Scholar] [CrossRef]

- Nusral, R.S.; Khalid, A.; Tajuddin, A.; Syukri, A. Performance and emissions of alternative biodiesel fuel on small diesel engine. ARPN J. Eng. Appl. Sci. 2016, 11, 7424–7430. [Google Scholar]

- Rehman, S.; Zaidi, K. Study of ignition delay of certain blended petroleum fuel sprays in a cylindrical combustion chamber. Int. J. Sci. Technol. 2012, 1, 65–76. [Google Scholar]

- Lapuerta, M.; Sanz, A.J.; Raine, R.R. Heat release determination in a constant volume combustion chamber from the instantaneous cylinder pressure. Appl. Thermal Eng. 2014, 63, 520–527. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).