Application of Biochar Derived from Different Types of Biomass and Treatment Methods as a Fuel Source for Direct Carbon Fuel Cells

Abstract

1. Introduction

2. Materials and Methods

2.1. Pyrolysis of Biomass

2.2. Direct Carbon Fuel Cell Performance

2.3. Chemical Treatment in Biochar Preparation

2.4. Biochar Fuel Characterization

3. Results and Discussion

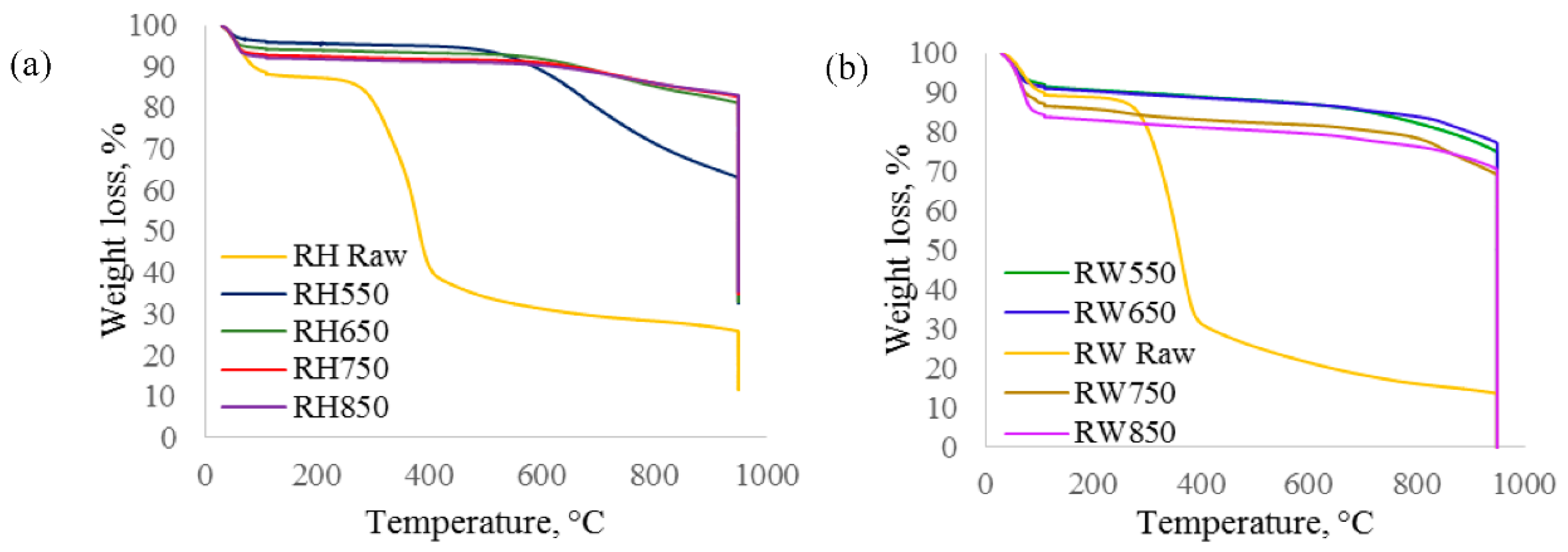

3.1. Effect of Pyrolysis Temperature on the Biochar Characteristics

3.1.1. Biochar Yield at Different Pyrolysis Temperatures

3.1.2. Proximate Analysis for Biochar Characterization

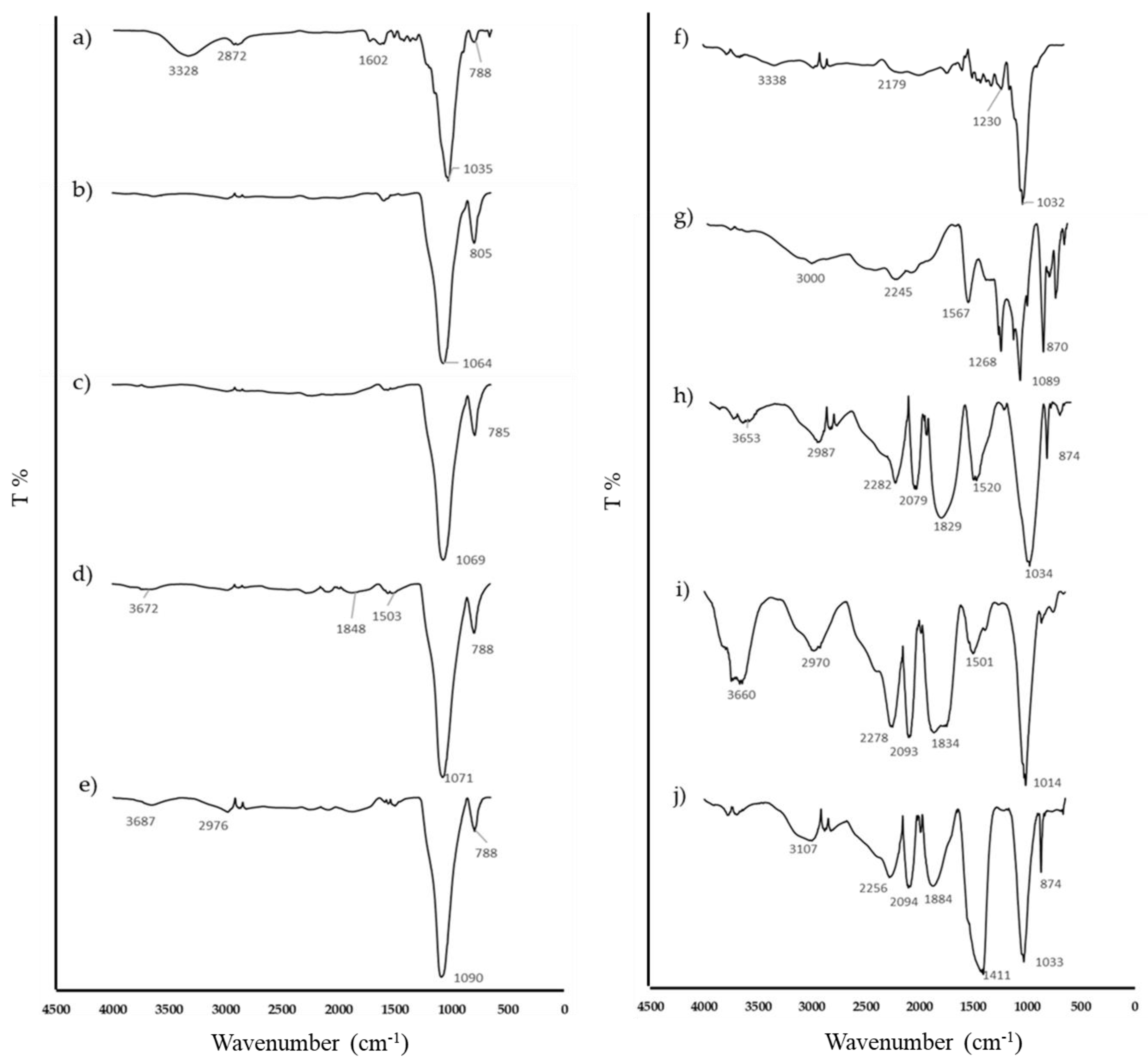

3.1.3. Surface Functional Analysis of Untreated Biochar

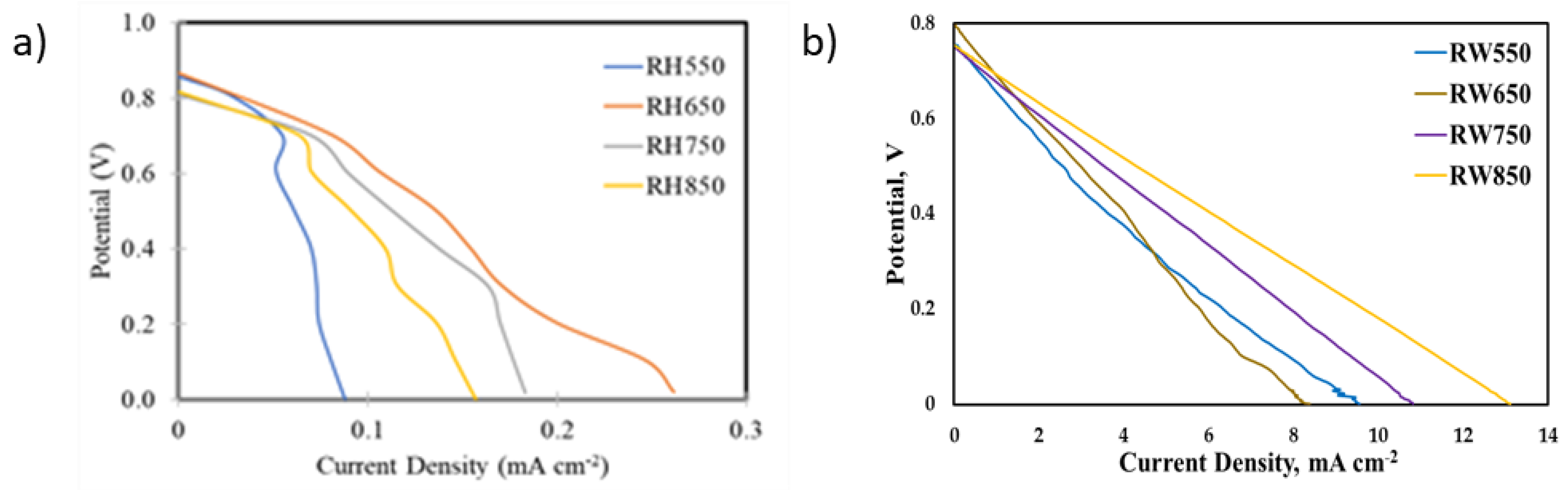

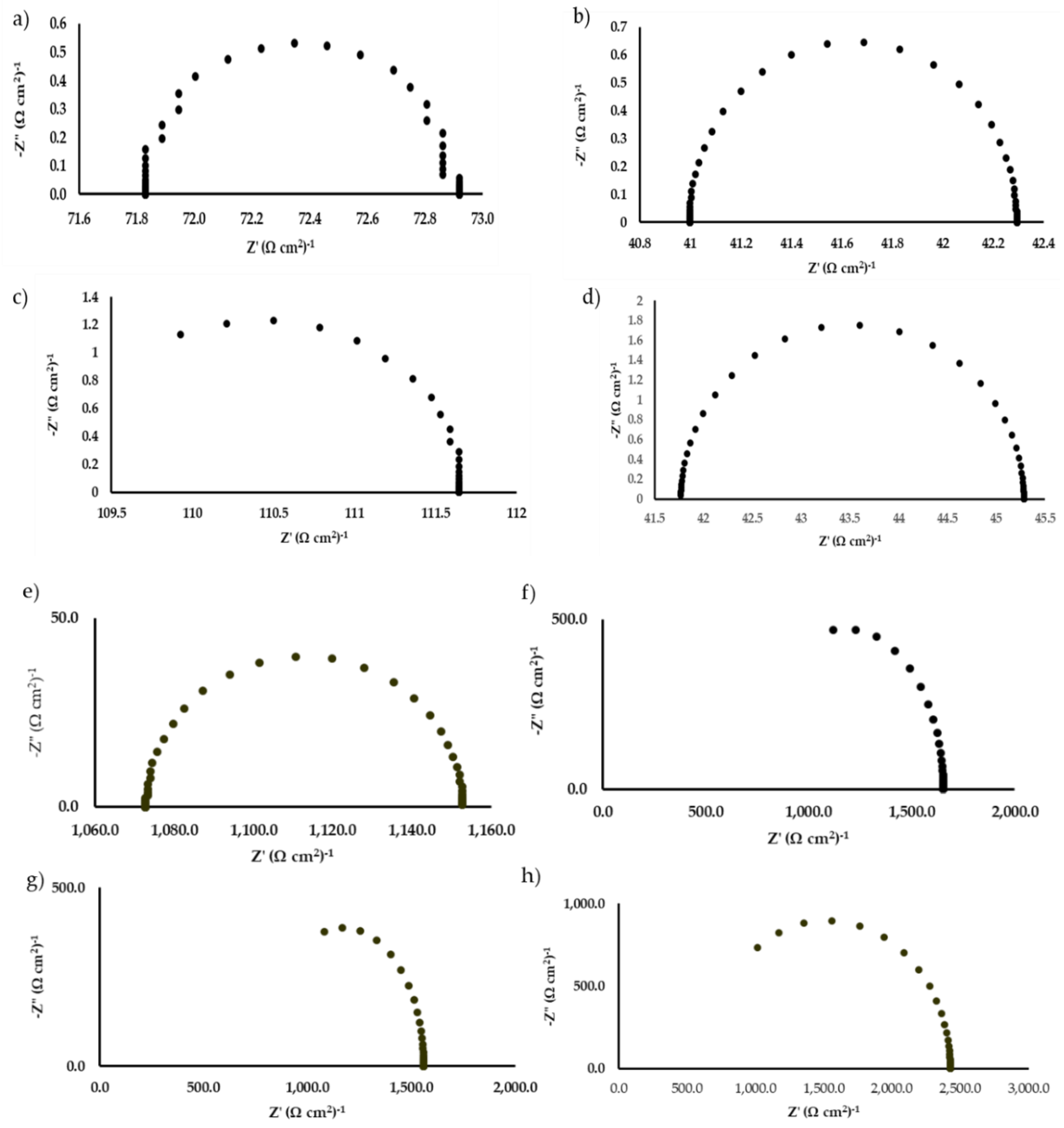

3.2. DCFC Performance Test with Biochar

3.3. Effect of Pre-Treatment and Post-Ttreatment on Rubber Wood Biochar Production

3.3.1. Biochar Yield of Pre-Treated and Post-Treated Woody Biochar

3.3.2. Proximate Analysis of Chemically Modified Rubber Wood Biochar

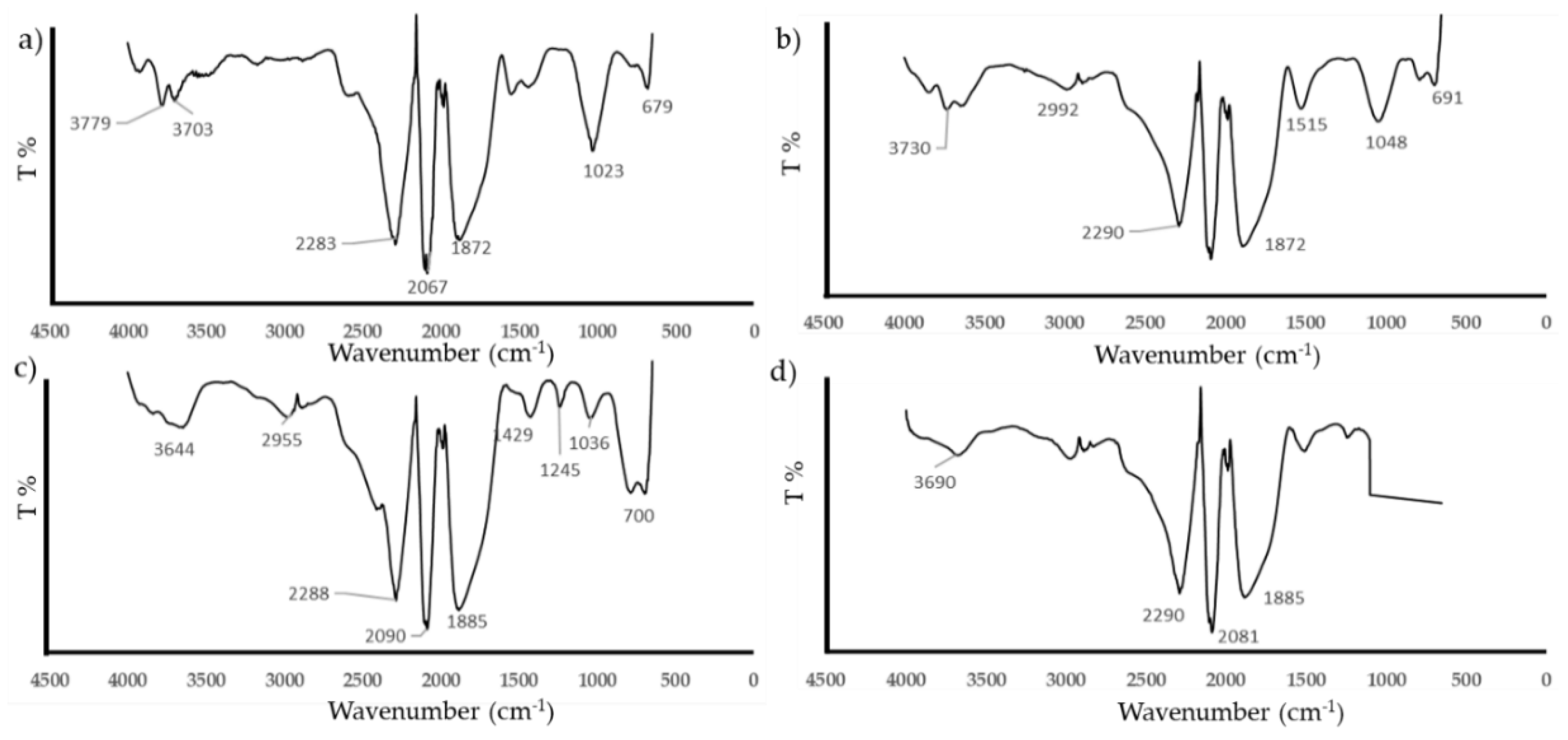

3.3.3. Surface Functional Study of Chemically Modified Rubber Wood Biochar

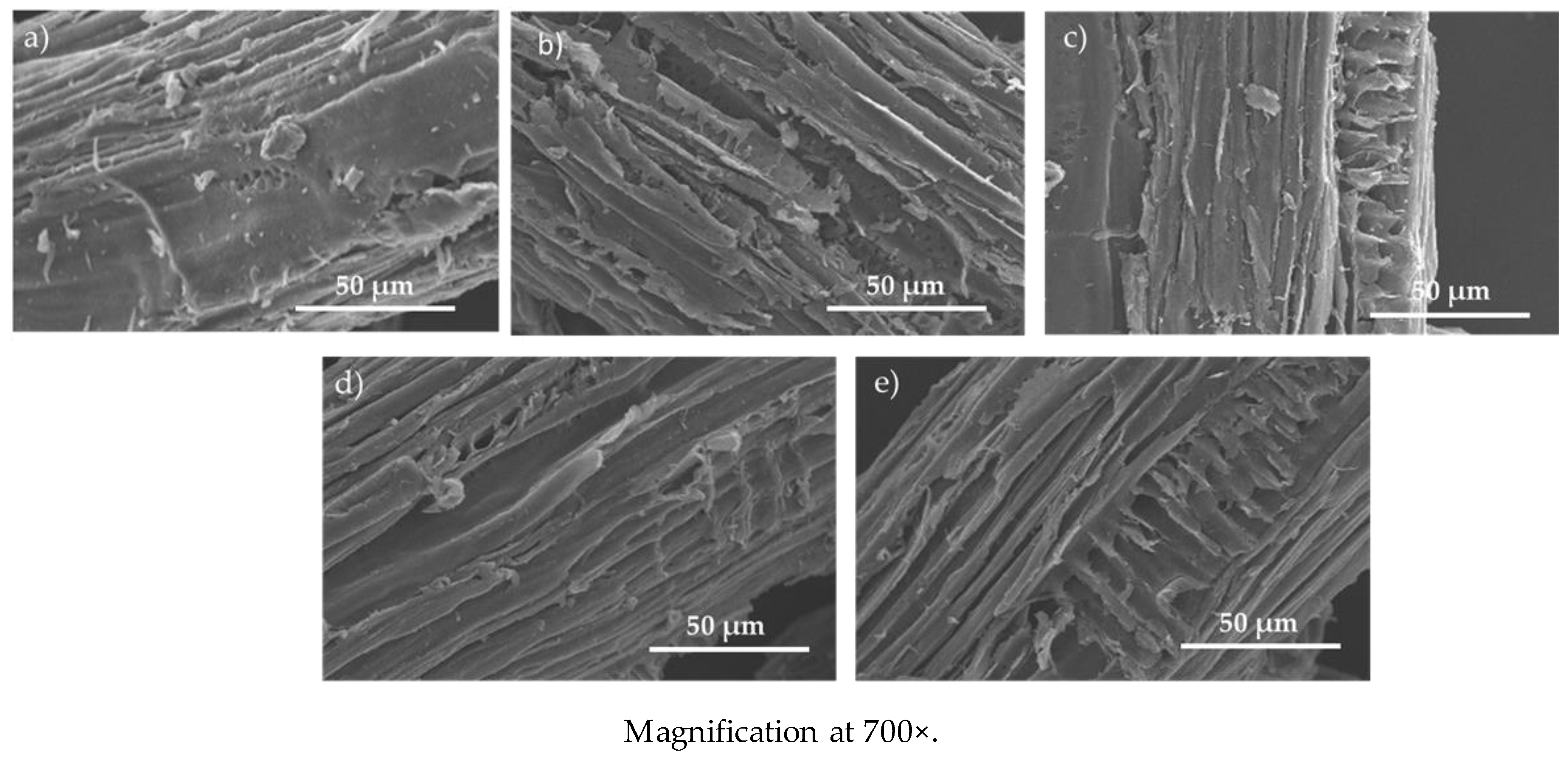

3.3.4. Surface Morphology of Untreated Biochar and Modified Woody Biochar

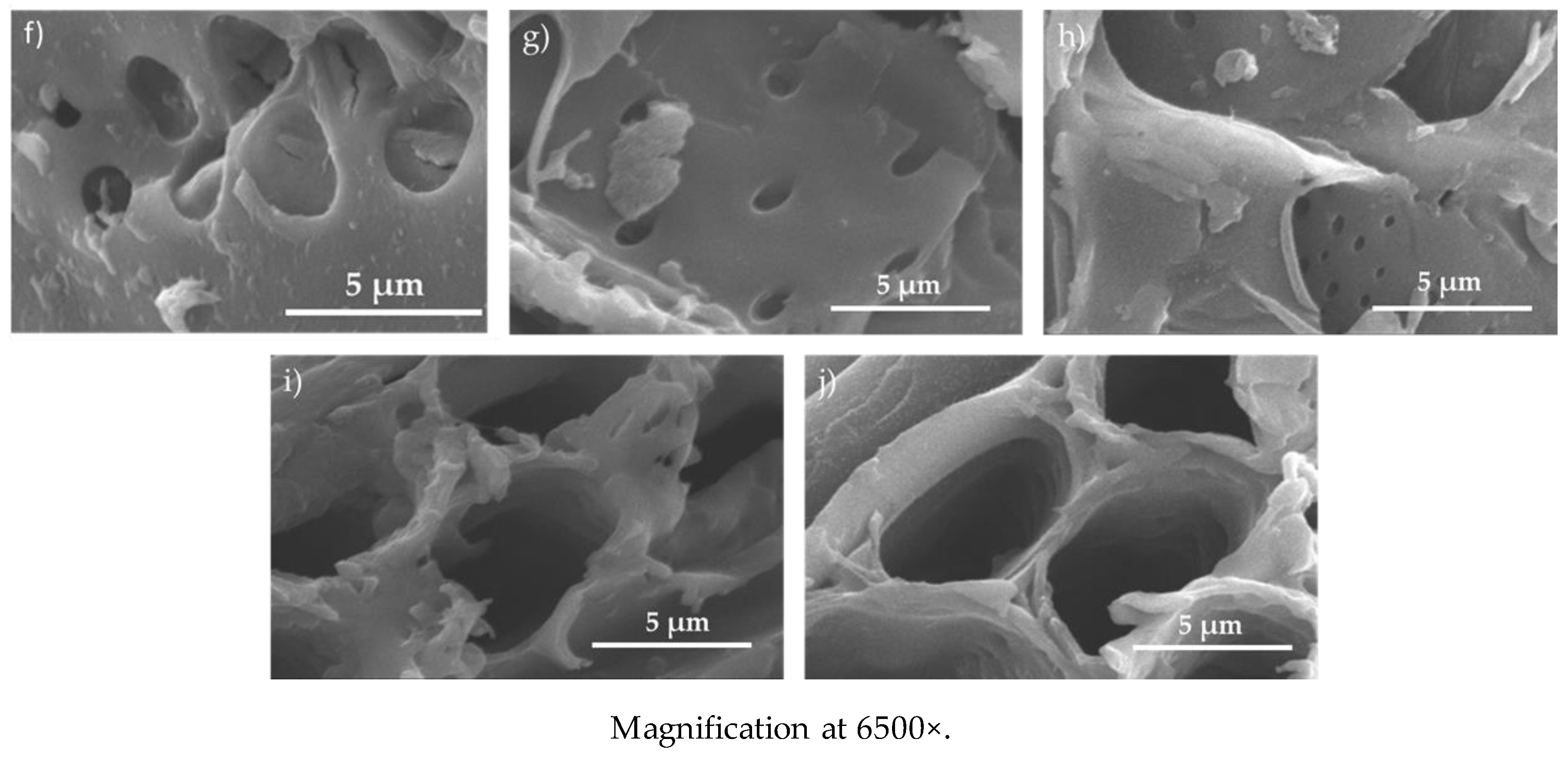

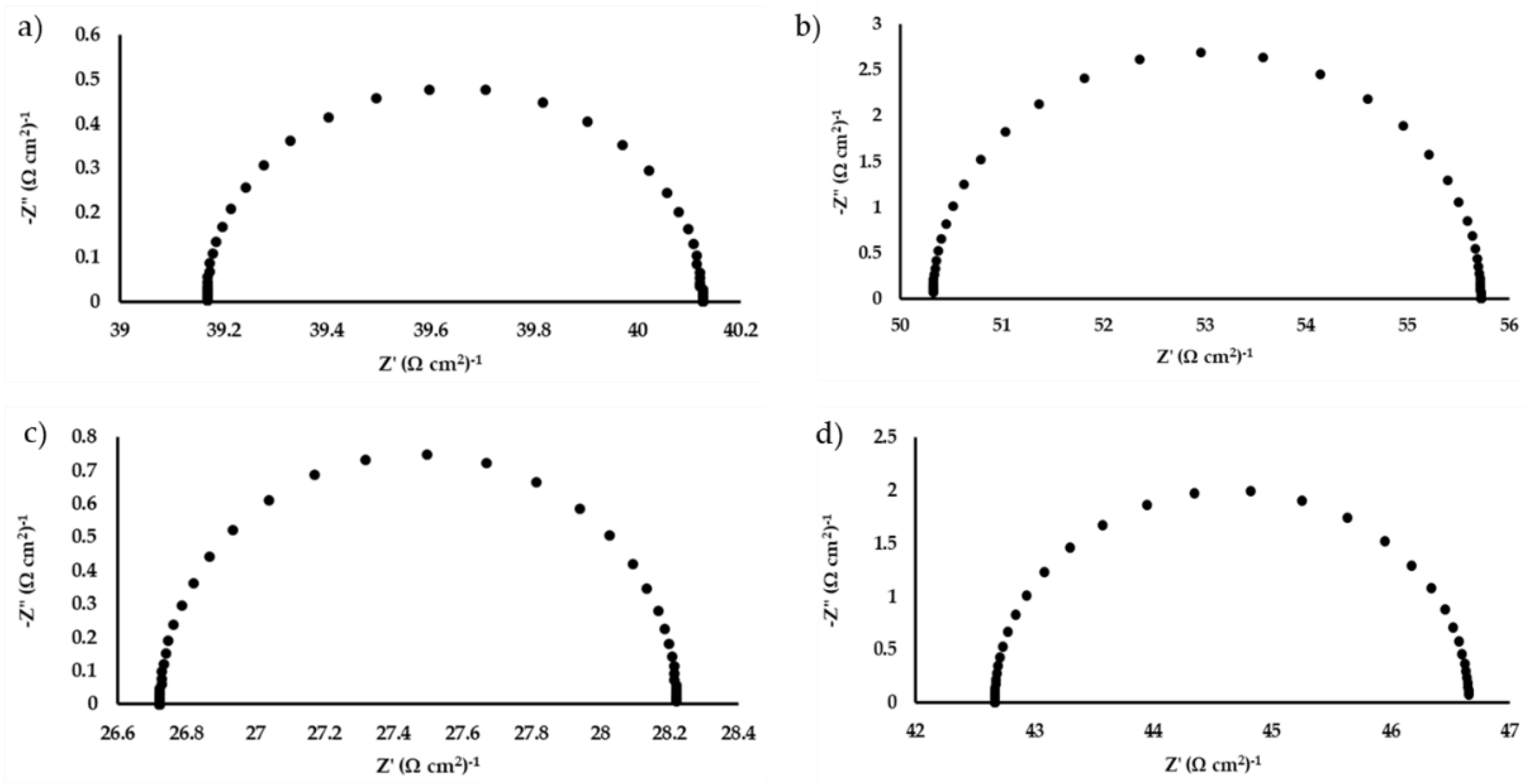

3.3.5. DCFC Performance Test with Direct Solid Fuel of Modified Woody Biochar

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mahmud, L.S.; Muchtar, A.; Somalu, M.R. Challenges in fabricating planar solid oxide fuel cells: A review. Renew. Sustain. Energy Rev. 2017, 72, 105–116. [Google Scholar] [CrossRef]

- Shaikh, S.P.S.; Muchtar, A.; Somalu, M.R. A review on the selection of anode materials for solid-oxide fuel cells. Renew. Sustain. Energy Rev. 2015, 51, 1–8. [Google Scholar] [CrossRef]

- O’Hayre, R.; Cha, S.W.; Colella, W.; Prinz, B.F. Fuel Cell Fundamentals, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 3–20. [Google Scholar]

- Li, X.; Zhu, Z.H.; Marco, R.D.; Dicks, A.; Bradley, J.; Liu, S.; Lu, G.Q. Factors that determine the performance of carbon fuels in the direct carbon fuel cell. Ind. Eng. Chem. Res. 2008, 47, 9670–9677. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Z.H.; Chen, J.; Marco, R.D.; Dicks, A.; Bradley, J.; Lu, G.Q. Surface modification of carbon fuels for direct carbon fuel cells. J. Power Sources 2009, 186, 1–9. [Google Scholar] [CrossRef]

- Jafri, N.; Wong, W.Y.; Doshi, V.; Yoon, L.W.; Cheah, K.H. A review on production and characterization of biochars for application in direct carbon fuel cells. Proc. Saf. Environ. Prot. 2018, 118, 152–166. [Google Scholar] [CrossRef]

- Elleuch, A.; Boussetta, A.; Yu, J.; Halouani, K.; Li, Y. Experimental investigation of direct carbon fuel cell fueled by almond shell biochar: Part II. Improvement of cell stability and performance by a three-layer planar configuration. Int. J. Hydrog. Energy 2013, 38, 16605–16614. [Google Scholar] [CrossRef]

- Elleuch, A.; Halouani, K.; Li, Y. Investigation of chemical and electrochemical reactions mechanism in a direct carbon fuel cell using olive wood charcoal as sustainable fuel. J. Power Sources 2015, 281, 350–361. [Google Scholar] [CrossRef]

- Dudek, M.; Socha, R. Direct electrochemical conversion of the chemical energy of raw waste wood to electrical energy in tubular direct carbon solid oxide fuel cell. Int. J. Electrochem. Sci. 2014, 9, 7414–7430. [Google Scholar]

- Tripathi, M.; Sahu, J.N.; Ganesan, P. Effect of process parameters on production of biochar from biomass waste through pyrolysis: A review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Ghani, W.A.W.A.K.; Mohd, A.; Silva, G.D.; Bachmann, R.T.; Taufiq, Y.; Yun, H.; Raashid, U.; Al-Muhtaseb, A. Biochar production from waste rubber-wood-sawdust and its potential use in C sequestration: Chemical and physical characterization. Ind. Crops Prod. 2013, 44, 18–24. [Google Scholar] [CrossRef]

- Srinivasaakannan, C.; Bakar, M.Z.A. Production of activated carbon from rubber wood sawdust. Biomass Bioenergy 2004, 27, 89–96. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Z.; Marco, R.D.; Bradley, J.; Dicks, A. Modification of coal as a fuel for the direct carbon fuel cell. J. Phys. Chem. A 2010, 114, 3855–3862. [Google Scholar] [CrossRef] [PubMed]

- Palniandy, L.K.; Wong, W.Y.; Yap, J.J.; Doshi, V.; Daud, W.R.W. Effect of alkaline pre-treatment on rice husk-derived biochar for direct carbon fuel cell. J. Eng. Sci. Technol. 2017, 84–100. [Google Scholar]

- Chien, A.C.; Arenillas, A.; Jiang, C.; Irvine, J.T.S. Performance of direct carbon fuel cells operated on coal and effect of operation mode. J. Electrochem. Soc. 2014, 161, F588–F593. [Google Scholar] [CrossRef][Green Version]

- Zhang, J.; Zhong, Z.; Zhao, J.; Yang, M.; Li, W.; Zhang, H. Study on the preparation of activated carbon for direct carbon fuel cell with oak sawdust. Can. J. Chem. Eng. 2012, 90, 762–768. [Google Scholar] [CrossRef]

- Cao, D.; Wang, G.; Wang, C.; Wang, J.; Lu, T. Enhancement of electrooxidation activity of activated carbon for direct carbon fuel cell. Int. J. Hydrog. Energy 2010, 35, 1778–1782. [Google Scholar] [CrossRef]

- Lim, S.H.; Yong, S.T.; Ooi, C.W.; Doshi, V.; Daud, W.R.W. Pyrolysis of palm waste for the application of direct carbon fuel cell. Energy Proc. 2014, 61, 878–881. [Google Scholar] [CrossRef]

- Ghani, W.A.W.A.K. Sawdust-derived biochar: Characterization and CO2 adsorption/desorption study. J. Appl. Sci. 2014, 14, 1450–1454. [Google Scholar] [CrossRef]

- Adam, C.R.; Giddey, S.; Kulkarni, A.; Badwal, S.P.S.; Bhattacharya, S.; Ladewig, B. Direct carbon fuel cell operation on brown coal. Appl. Energy 2014, 120, 56–64. [Google Scholar]

- Park, J.; Hung, I.; Gan, Z.; Rojas, O.J.; Lim, K.H.; Park, S. Activated carbon from biochar: Influence of its physicochemical properties on the sorption characteristics of phenanthrene. Bioresour. Technol. 2013, 149, 383–389. [Google Scholar] [CrossRef]

- Zhao, S.X.; Ta, N.; Wang, X. Effect of temperature on structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.; Yang, J.E.; Ok, Y.S. Effects of pyrolysis temperature on soybean stover- and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Worasuwannarak, N.; Sonobe, T.; Taanthapanichakoon, W. Pyrolysis behaviors of rice straw, rice husk, and corncob by TG-MS technique. J. Anal. Appl. Pyrolysis 2007, 78, 265–271. [Google Scholar] [CrossRef]

- Leng, L.; Yuan, X.; Zheng, G.; Shao, J.; Chen, X.; Wu, Z.; Wang, H.; Peng, X. Surface characterization of rice husk bio-char produced by liquefaction and application for cationic dye (Malachite green) adsorption. Fuel 2015, 155, 77–85. [Google Scholar] [CrossRef]

- Claoston, N.; Samsuri, A.W.; Ahmad Husni, M.H.; Mohd Amran, M.S. Effects of pyrolysis temperature on the physicochemical properties of empty fruit bunch and rice husk biochars. Waste Manag. Res. 2014, 32, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Xiong, S.; Zhuo, J.; Zhang, B.; Yao, Q. Effect of moisture content on the characterization of products from the pyrolysis of sewage sludge. J. Anal. Appl. Pyrolysis 2013, 104, 632–639. [Google Scholar] [CrossRef]

- Wei, L.; Huang, Y.; Li, Y.; Huang, L.; Mar, N.N.; Huang, Q.; Liu, Z. Biochar characteristics produced from rice husks and their sorption properties for the acetanilide herbicide metolachlor. Environ. Sci. Pollut. Res. 2017, 24, 4552–4561. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Seong, Y.E.; Young, H.R.; Yon, M.S.; Cheor, E.M.; Gyung, M.C.; Duck, J.K. Utilization of wood biomass char in a direct carbon fuel cell (DCFC) system. App. Energy 2013, 105, 207–216. [Google Scholar] [CrossRef]

- Nabae, Y.; Pointon, K.D.; Irvine, J.T.S. Electrochemical oxidation of solid carbon in hybrid DCFC with solid oxide and molten carbonate binary electrolyte. Energy Environ. Sci. 2008, 1, 148–155. [Google Scholar] [CrossRef]

- Angin, D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Bioresour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef]

- Dudek, M. On the utilization of coal samples in direct carbon solid oxide fuel cell technology. Solid State Ion. 2015, 271, 121–127. [Google Scholar] [CrossRef]

| Pyrolysis Condition | Rice Husk (%) | Rubber Wood (%) |

|---|---|---|

| 550 °C | 33.9 ± 0.26 | 28.0 ± 0.35 |

| 650 °C | 33.6 ± 0.05 | 25.4 ± 0.10 |

| 750 °C | 33.1 ± 0.05 | 24.6 ± 0.34 |

| 850 °C | 31.4 ± 0.01 | 21.3 ± 1.40 |

| Type of Biochar | Moisture (%) | Volatile Matter (%) | Fixed Carbon (%) | Ash (%) |

|---|---|---|---|---|

| Raw RH | 11.5 | 58.5 | 10.3 | 19.7 |

| RH550 | 3.5 | 40.9 | 19.5 | 36.1 |

| RH650 | 5.2 | 18.2 | 41.6 | 35.1 |

| RH750 | 6.7 | 12.9 | 42.7 | 37.7 |

| RH850 | 7.3 | 11.9 | 43.4 | 37.4 |

| Raw RW | 10.4 | 59.9 | 11.1 | 18.6 |

| RW550 | 7.5 | 23.8 | 62.0 | 6.7 |

| RW650 | 8.1 | 22.4 | 67.0 | 2.5 |

| RW750 | 10.8 | 24.0 | 62.7 | 2.4 |

| RW850 | 14.2 | 21.8 | 62.0 | 2.0 |

| Parameter | RW550 | RW650 | RW750 | RW850 | RH550 | RH650 | RH750 | RH850 |

|---|---|---|---|---|---|---|---|---|

| OCP (V) | 0.77 ± 0.03 | 0.78 ± 0.02 | 0.75 ± 0.01 | 0.76 ± 0.01 | 0.86 ± 0.01 | 0.86 ± 0.01 | 0.80 ± 0.02 | 0.82 ± 0.01 |

| i at 0.7 V (mA cm −2) | 0.69 ± 0.19 | 0.79 ± 0.17 | 0.54 ± 0.16 | 0.75 ± 0.13 | 0.04 ± 0.01 | 0.09 ± 0.01 | 0.07 ± 0.01 | 0.07 ± 0.01 |

| i at 0.4 V (mA cm −2) | 3.64 ± 0.01 | 3.95 ± 0.13 | 4.19 ± 1.16 | 5.44 ± 0.86 | 0.09 ± 0.02 | 0.19 ± 0.04 | 0.17 ± 0.04 | 0.13 ± 0.03 |

| i at 0.1 V (mA cm −2) | 7.60 ± 0.41 | 7.31 ± 0.75 | 8.57 ± 1.09 | 10.65 ± 1.03 | 0.11 ± 0.04 | 0.26 ± 0.01 | 0.21 ± 0.04 | 0.18 ± 0.05 |

| Pmax (mW cm −2) | 1.49 ± 0.03 | 1.59 ± 0.05 | 1.74 ± 0.42 | 2.21 ± 0.33 | 0.05 ± 0.01 | 0.08 ± 0.01 | 0.07 ± 0.01 | 0.06 ± 0.01 |

| Pyrolysis Condition | Biochar Yield, % |

|---|---|

| Post acid RW | 22.0 ± 0.85 |

| Post alkali RW | 24.9 ± 0.49 |

| Pre-treated acid RW | 25.5 ± 4.44 |

| Pre-treated alkali RW | 31.8 ± 0.32 |

| Type of Biochar | Moisture (%) | Volatile Matter (%) | Fixed Carbon (%) | Ash (%) |

|---|---|---|---|---|

| Post acid RW | 9.4 | 32.9 | 56.2 | 1.5 |

| Post alkali RW | 16.4 | 31.3 | 63.4 | - |

| Pre-treated acid RW | 10.4 | 11.3 | 76.5 | 0.8 |

| Pre-treated alkali RW | 11.9 | 25.3 | 55.1 | 2.3 |

| Parameter | Post Acid RW | Post Alkali RW | Pre-Treated Acid RW | Pre-Treated Alkali RW |

|---|---|---|---|---|

| OCP (V) | 0.74 ± 0.00 | 0.76 ± 0.00 | 0.74 ± 0.03 | 0.77 ± 0.02 |

| i at 0.7 V (mA cm−2) | 0.51 ± 0.04 | 0.79 ± 0.06 | 0.41 ± 0.20 | 1.15 ± 0.01 |

| i at 0.4 V (mA cm−2) | 3.54 ± 0.43 | 5.27 ± 0.50 | 3.36 ± 0.36 | 7.23 ± 1.18 |

| i at 0.1 V mA cm−2) | 6.81 ± 0.65 | 9.75 ± 0.73 | 6.66 ± 0.48 | 14.36 ± 1.75 |

| Pmax (mW cm−2) | 1.44 ± 0.18 | 2.13 ± 0.19 | 1.36 ± 0.15 | 2.94 ± 0.47 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palniandy, L.K.; Yoon, L.W.; Wong, W.Y.; Yong, S.-T.; Pang, M.M. Application of Biochar Derived from Different Types of Biomass and Treatment Methods as a Fuel Source for Direct Carbon Fuel Cells. Energies 2019, 12, 2477. https://doi.org/10.3390/en12132477

Palniandy LK, Yoon LW, Wong WY, Yong S-T, Pang MM. Application of Biochar Derived from Different Types of Biomass and Treatment Methods as a Fuel Source for Direct Carbon Fuel Cells. Energies. 2019; 12(13):2477. https://doi.org/10.3390/en12132477

Chicago/Turabian StylePalniandy, Lithnes Kalaivani, Li Wan Yoon, Wai Yin Wong, Siek-Ting Yong, and Ming Meng Pang. 2019. "Application of Biochar Derived from Different Types of Biomass and Treatment Methods as a Fuel Source for Direct Carbon Fuel Cells" Energies 12, no. 13: 2477. https://doi.org/10.3390/en12132477

APA StylePalniandy, L. K., Yoon, L. W., Wong, W. Y., Yong, S.-T., & Pang, M. M. (2019). Application of Biochar Derived from Different Types of Biomass and Treatment Methods as a Fuel Source for Direct Carbon Fuel Cells. Energies, 12(13), 2477. https://doi.org/10.3390/en12132477