Abstract

Nowadays, biodiesel has become a very promising alternative to fossil diesel fuel, regarding environmental concerns and fuel resource depletion. Biodiesel is usually produced through homogeneous or heterogeneous transesterification of different fatty raw materials. Although main research has been carried out with homogenous catalysts, heterogeneous catalysts may be of interest due to ease of recovery and recycling, as well as readiness for continuous processing. In this work, calcined Mg-Al hydrotalcite (HT) was used for the heterogeneous transesterification of waste cooking oil. Three reaction parameters, namely, reaction time, amount of catalyst, and methanol-to-oil molar ratio, were optimized by means of Response Surface Methodology (RSM) at constant temperature (65 °C), using a Box-Behnken design. Optimal fatty acid methyl ester (FAME) content (86.23% w/w FAME/sample) was predicted by the model with an R-squared value of 98.45%, using 3.39 g of HT (8.5% w/w oil) and an 8:1 methanol-oil molar ratio, for a duration of 3.12 h. It was observed that calcination of HT, while avoiding the previous washing step, allowed the presence of chemical species that enhanced the effect of the catalyst. It can be concluded from this field trial that calcined and nonwashed Mg-Al hydrotalcite may be considered an effective basic catalyst for the production of biodiesel from waste cooking oil. Also, RSM proved to be a useful tool for predicting biodiesel yield.

1. Introduction

Environmental concerns about global warming and climate change have greatly increased the interest in renewable fuels for internal combustion engines. Moreover, as fossil fuels are being depleted day by day, there is a need to find alternative fuels to fulfil the current world energy demand. Hence, biodiesel has become a very attractive alternative fuel for diesel engines, because it produces less harmful effects to environment, reducing the influence over acid rain and greenhouse effects caused by fuel combustion. Due to these factors, its biodegradability, and its essentially sulphur-free and aromatic nature, the use of biodiesel is considered advantageous compared to that of diesel fuel [1].

Biodiesel is the most common biofuel in Europe and is mainly based on the transesterification reaction of vegetable oils with methanol in the presence of a catalyst, to yield the corresponding fatty acid methyl esters (FAME) and glycerol as coproduct [2]. The most popular technology prefers the use of homogeneous basic catalysts (mainly NaOH or KOH) dissolved in methanol [1]. Although a homogeneously catalyzed biodiesel reaction is relatively fast and affords high conversion rates, it presents some serious drawbacks when raw material exhibits high acidity [3]. In this case, the catalyst must be neutralized and separated from the methyl ester phase at the end of the reaction, with the subsequent generation of a large volume of waste water [4]. The use of heterogeneous catalysts may contribute to minimizing the previous problems, including production of soaps and the separation and purification of biodiesel [5,6]. Moreover, the cost of biodiesel could be drastically reduced by the use of heterogeneous catalysts, greatly simplifying product post-treatment. Provided that the higher the raw material acidity, the smaller the conversion efficiency [3], different strategies have been proposed, i.e., the use of solid catalysts for biodiesel production—basic zeolites, alkaline earth metal oxides, and hydrotalcites (HT) among them [7,8,9]. Alkaline earth metal oxides, mainly CaO, are the most studied solid catalysts, as they show high basicity, low miscibility in methanol, and the fact that they can be synthesized from low-cost sources [8,10,11]. With this catalyst activated by ultrasound, Verziu et al. [12] achieved 97% conversion, at 348 K, with a methanol-to-oil molar ratio of 4:1. Considering catalyst thermal activation, the use of 2% catalyst and a 48:1 methanol-oil molar ratio led to 96% FAME conversion when sunflower oil was used [13]. A 2.94 w % quantity of CaO-Al2O3/ZrO2 mixed oxide was used as a heterogeneous catalyst to transesterify waste cooking oil, achieving 93.48% conversion under a reaction temperature of 120 °C, a 15.64:1 methanol-oil molar ratio, and 4 h reaction time [14]. Although zeolites have numerous advantages over other heterogeneous catalysts, another study found that its catalytic activity in transesterification reactions using a pure mix of fatty acids reached 92% conversion, lower than results above [15].

Mg-Al hydrotalcite has been used as catalyst precursor due to its promising performance [13]. To produce homogeneous mixtures of oxides with very small crystallite size, showing high surface area and basic properties, coprecipitation of alkali hydroxides and carbonates is the preferred method for synthesizing hydrotalcite [16]. Coprecipitation is also the most successful method for synthesizing Mg-Al hydrotalcite, at constant pH, between a mixed-metal solution dissolved in deionized water and sodium carbonate solution; the pH is controlled using sodium hydroxide solution. After that, the precipitate is centrifuged, washed with deionized water, and vacuum dried, so that thermal activation is achieved [17]. Conversion of 70% w/w FAME using rapeseed oil has been reported in a fixed-bed reactor working for a duration of 4 h at a catalyst calcination temperature of 450 °C [18]. As calcination temperature is a key factor in conversion efficiency, Zeng et al. studied different calcination temperatures (400–800 °C) with rapeseed oil over a 7 h reaction time, achieving a conversion above 90% [19]. However, to the best of our knowledge, little work concerning the use of hydrotalcite to produce biodiesel from used frying oil has been described. As the authors of one such work, Brito et al. used a Mg-Al layered double hydroxide catalyst (either calcined or not) to produce biodiesel from waste oil [20]. Later, Hernandez et al. introduced up to 10% sodium in calcined hydrotalcite, finding a good response from the catalyst after an 8 h reaction time [21]. Other attempts to use hydrotalcite to produce biodiesel from waste oil proposed the use of lipase immobilized on hydrotalcite, although this increases costs [22]. Up to now, the best result achieved using waste cooking oil and calcined Mg-Al HT as a heterogenous catalyst has been 95.2% w/w, although the reaction temperature needs to be increased over methanol’s boiling point (above 80 °C) [23].

Raw material is the main contributor to biodiesel production costs [24]. The choice of raw material depends mainly on its availability and cost. Waste cooking oil/fat (usually showing high acidity) has been explored as feedstock for biodiesel production, because it is cheap and because the use of edible oil to produce biodiesel could potentially lead to a diminution of the oil available as food for both humans and farm animals [2,25].

In the present study, a heterogeneously Mg-Al hydrotalcite-catalyzed transesterification to produce biodiesel using waste cooking oil has been studied. The basic properties of the HT catalyst were enhanced by avoiding the washing step, previous to catalyst calcination, retaining sodium ions. This is contrary to other authors, who mentioned the need for a washing step to keep the final HT pH equal to 7, and thus removing sodium ions [13]. The influence and further optimization of reaction parameters were carried out by means of Response Surface Methodology (RSM) [1,26]. The aim of the present study was to face the important contemporary problem of using a solid catalyst system to process low-cost raw materials usually characterized as waste (like used oils and animal fats). The search of an efficient catalyst to convert a wide range of raw materials into biofuel may help to develop an economically biodiesel production method.

2. Materials and Methods

2.1. Materials

Waste cooking oil was provided by the campus cafeteria (University of Córdoba, Córdoba, Spain). Frying oil was filtered using a vacuum pump through 27 mm diameter filter paper no. 1305 from ALBET (Filtros Anoia SA, Barcelona, Spain) before further use. Properties of the used frying oil are shown in Table 1. Technical grade reagents, anhydrous methanol (99.9%), NaOH (98%) pellets p.a. CODEX (USP–NF, BP, F. Eur.), Mg(NO3)26H2O (98%), and Al(NO3)39H2O (98%) were purchased from Panreac (Barcelona, Spain). The catalyst was prepared as shown in Section 2.2. Heptadecanoic acid methyl ester from Fluka (Steinheim, Germany) was used as the internal standard for FAME determination, as indicated in the EN 14103 standard.

Table 1.

Used frying oil properties.

2.2. Preparation of Hydrotalcite Catalyst

Hydrotalcite with a Mg/Al ratio of 3:1 was prepared following the coprecipitation method. A solution of Mg(NO3)26H2O (25.4 g) and Al(NO3)39H2O (12.4 g) in distilled water (200 mL) was added cautiously dropwise over 2 h to a stirred solution of NaOH (20 g) in 200 mL of distilled water at room temperature. Next, the mixture was kept for 1 h under vigorous stirring, after which the product was left to settle down overnight. The resulting white precipitate was centrifuged and dried at 80 °C for 24 h. Finally, to obtain the corresponding Mg-Al mixed oxides, the powder was calcined at 600 °C for 3 h. Prior to catalyst calcination, no washing step was included.

2.3. Characterization of Hydrotalcite

X-ray diffraction (XRD) patterns were recorded on a Siemens D5000 X-ray diffractometer using non-monochromated Cu K radiation (Siemens, AG, Munich, Germany) and a graphite monochromator for the diffracted beam (Siemens, AG, Munich, Germany). The scanning conditions for structural analysis were 5–55° (2), a 0.03° step size, and 12 s per step.

2.4. Transesterification Reaction

Initially, a methanol-to-oil molar ratio (3:1 to 9:1) was added to an amount of calcined Mg-Al hydrotalcite (5% w/w to 10% w/w) in a 250 mL three-necked glass flask equipped with a reflux condenser and a magnetic stirrer. The mixture was vigorously mixed under atmospheric pressure for a period of 15 min and heated until the temperature reached 50 °C. Then, 40 g of waste cooking oil, previously heated to 50 °C, was added to the reactor and the temperature was increased to 65 °C. The mixture was stirred at 600 rpm during the reaction time (2–4 h). The reaction temperature was kept at 65 °C. At the end of the reaction, methanol was recovered by using a rotary evaporator under vacuum at 50 °C. Subsequently, hydrotalcite, glycerol, and methyl esters were separated by centrifugation.

2.5. Biodiesel Analysis

Biodiesel conversion was calculated by measuring and analyzing methyl ester content (FAME, %) by gas chromatography on a PerkinElmer GC-200 chromatograph with flame ionization detector (FID), according to European biodiesel standard EN 14105. The oven temperature program started at 160 °C (2 min), ramped up at 1.5 °C/min to 215 °C (10 min). A PerkinElmer Elite-5ms 30 m × 0.25 mm capillary column (0.25 μm particle diameter) was used.

2.6. Response Surface Methodology

The Box–Behnken design included in Statgraphics Centurion XVI (StatPoint Technologies, Warrenton, VA, USA) was used to build and analyze the experimental design.

3. Results and Discussion

3.1. Catalyst Characterization

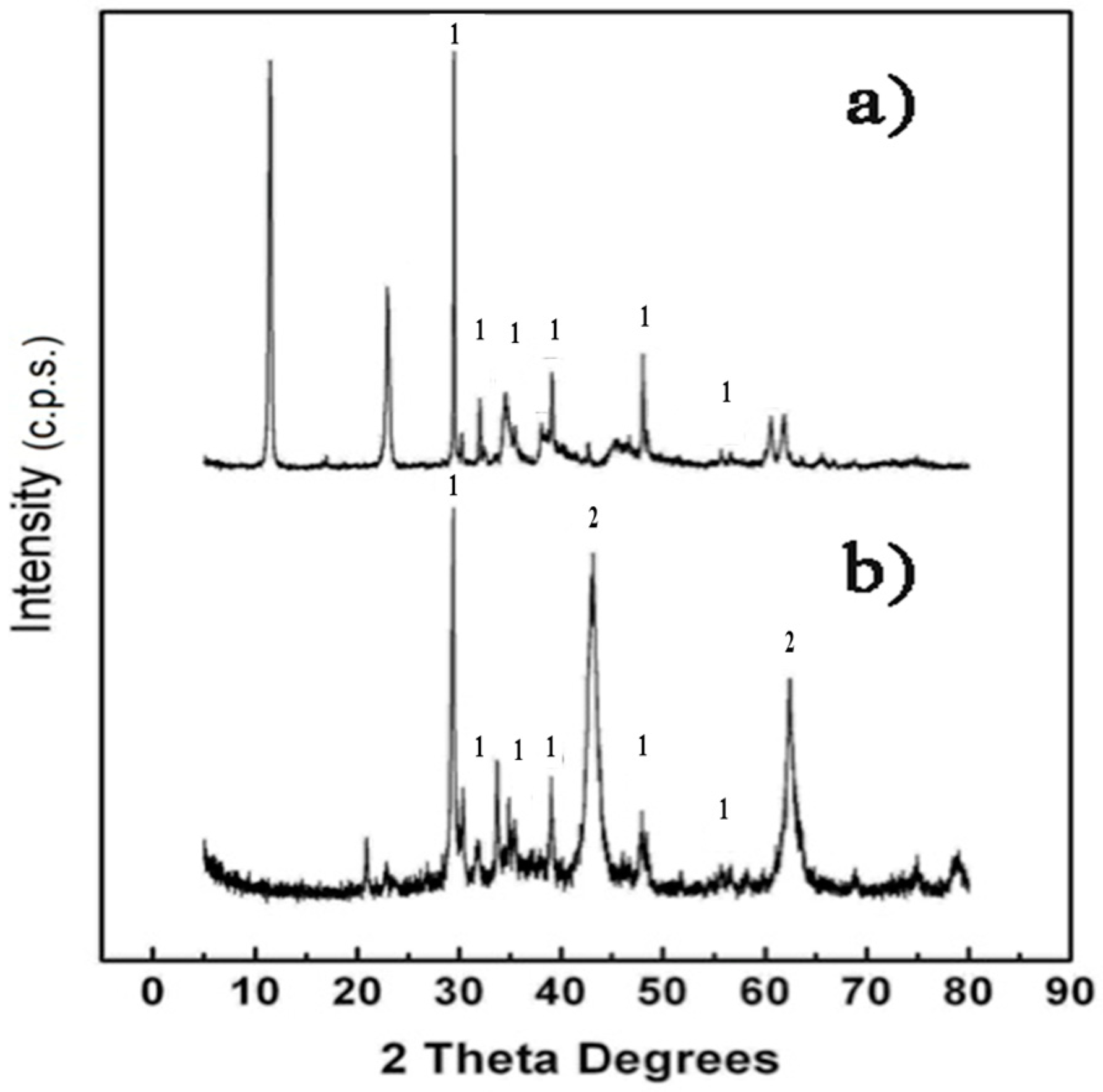

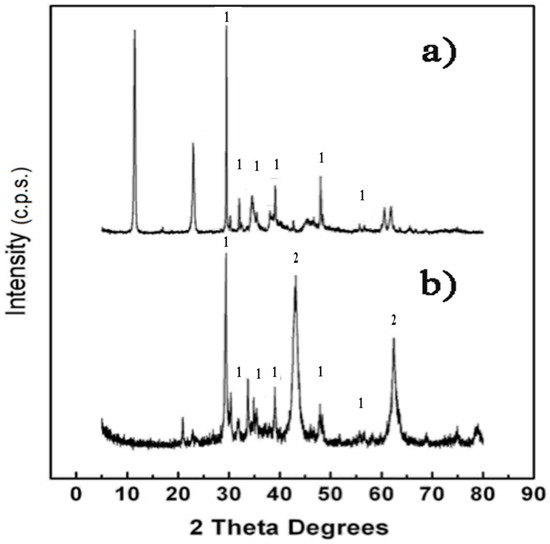

The X-ray diffraction (XRD) pattern of hydrotalcite samples (Figure 1a) shows sharp and symmetric peaks, which indicates that the sample was correctly crystallized. After calcination (Figure 1b), decomposition of hydrotalcite (HT) resulted in the formation of mixed Mg-Al oxide phases. As a result, typical HT peaks (2) and characteristic diffraction at 43° and 63° corresponding to the mixed Mg-Al oxides were clearly observed [27]. This can be explained by the destruction of the hydrotalcite structure and production of mixed oxides during calcination. This fact was confirmed by the XRD pattern of the calcined samples, as shown in Figure 1b. However, either calcined or not, several peaks (1) corresponding to sodium nitrate may be noticed, suggesting the existence of different chemical species in the HT, such as NO3− and Na+, due to the removal of the washing step; this could have significant importance in the catalytic process, as these species add an homogenous contribution to the heterogeneous catalysis, thereby enhancing it [28].

Figure 1.

X-ray diffraction pattern of hydrotalcite samples: (a) before calcination at 600 °C; (b) after calcination at 600 °C. Peaks (1) and (2) correspond to sodium nitrate and Mg-Al oxides (periclase), respectively; c.p.s.: counts per second.

3.2. Influence of Reaction Parameters on Conversion

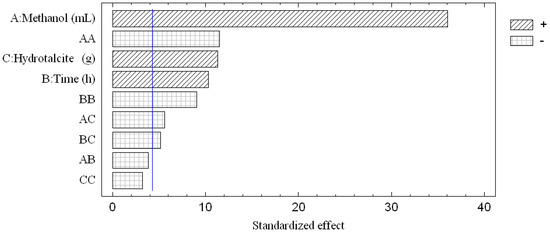

RSM was applied both to evaluate the influence of reaction time, amount of HT, and methanol-to-oil ratio on biodiesel production and to find out the conditions involved in the optimization. Before that, an experimental design comprising 15 trials was carried out (Table 2 and Table 3). The experimental design was used to screen some of the most significant parameters involved in biodiesel transesterification (time, catalyst quantity, and alcohol:oil molar ratio) and to find out the potential correlation between them. Upper and lower limit values of variables were chosen with consideration to the literature [19]. With this in mind, the Pareto chart (Figure 2) shows that all selected variables, separately considered, have a positive effect on FAME content; amount of methanol shows the most significant effect, as opposed to time, which has the lowest positive effect. Interaction between parameters shows a negative effect over the response variable, the highest significance being provided by AA (methanol-to-oil molar ratio). Comparisons between experimental and simulated values (from the quadratic model) are shown in Table 2 and Table 3; the model provides a good fit to the data. The best experimental FAME conversion yield (86.23% w/w) was achieved with the use of 3.4 g of catalyst (8.5% w/w) and 27.5 mL of methanol (8:1 molar ratio of alcohol/oil) during 3.12 h of reaction time. Although the biodiesel yield did not fulfill biodiesel standard specifications (EN 14214), and would therefore need to be blended with diesel fuel to run diesel engines, this result might be considered satisfactory with regards to previous results reported by other researchers: in most of the previous results, mild reaction parameters hardly achieved yields of 70% [29,30]; in others, longer reaction times [21] or higher reaction temperatures [23,31] were needed, thus increasing the final cost.

Table 2.

Experimental design for biodiesel optimization—experiment.

Table 3.

Experimental design for biodiesel optimization—predicted fatty acid methyl ester (FAME) content.

Figure 2.

Pareto chart of the standardized effect of fatty acid methyl ester (FAME) conversion (α = 0.005).

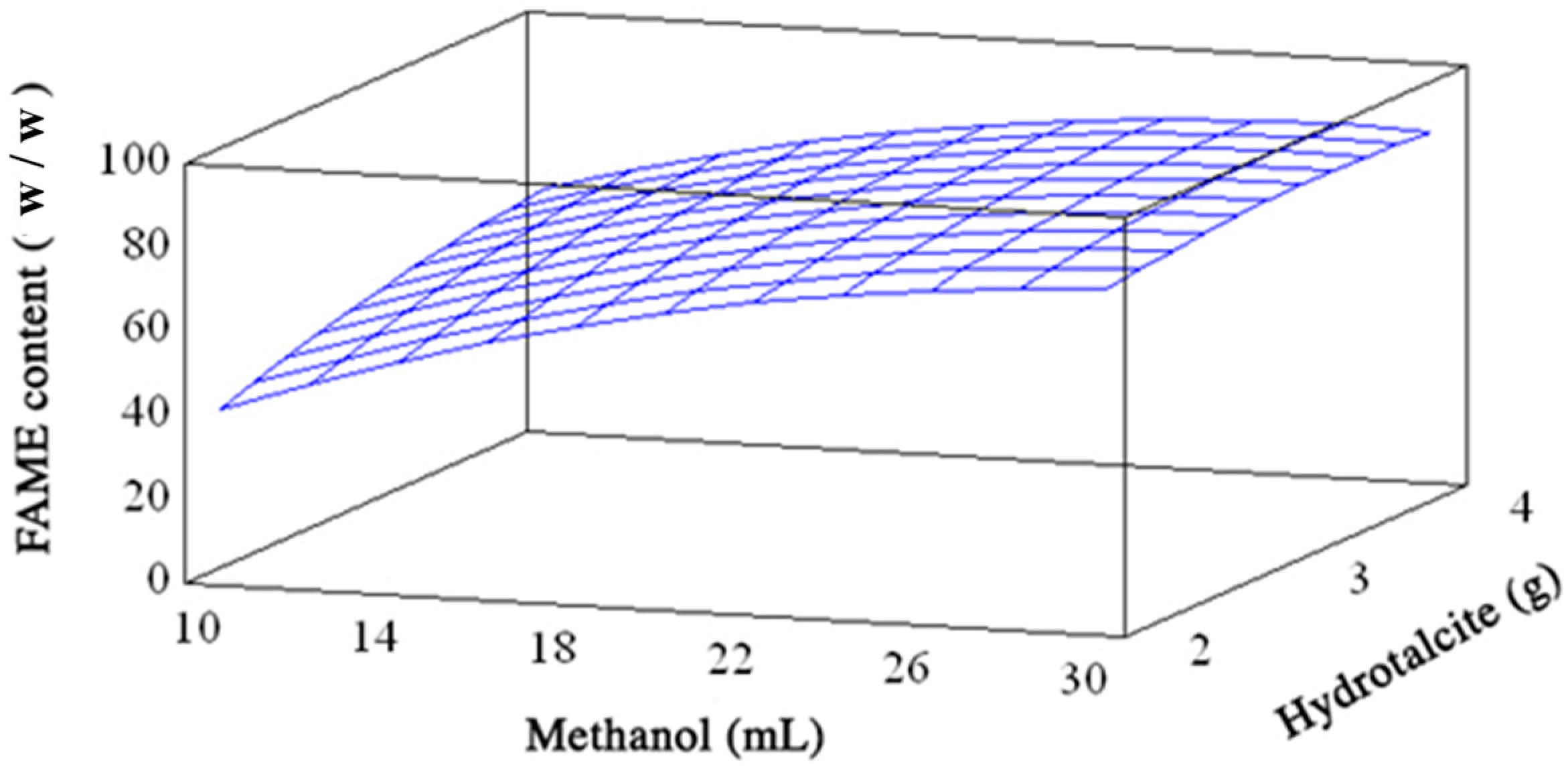

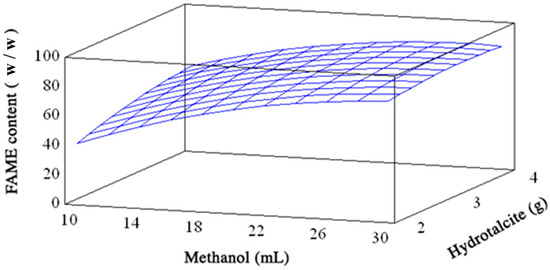

Regression coefficients of the quadratic model are shown in Table 4. The lack of fit value (above 0.05) indicates that the model fits selected values with an R2 value of 98.45%, which is very good. Considering a reaction time of 3.12 h (provided by the design of experiments), the influence of the amounts of both catalyst and methanol was studied. The optimum concentration of reagents is shown in Figure 3. It can be observed from Figure 3 that the conversion rate predicted by RSM increases with the alcohol-to-oil molar ratio and catalyst amount when the theoretical maximum reaction time is used. In fact, higher parameter values provide lower FAME content. Finally, an analysis of variance (ANOVA) test indicates that a high catalyst concentration (with sodium nitrate contribution) suffices to achieve the maximum response variable. This finding will lead future research to focus on the calcination time needed to keep the sodium nitrate contribution, which is important in terms of catalyst reutilization.

Table 4.

Analysis of variance (ANOVA) test for response surface quadratic model and regression coefficients to describe the variability of the effects on FAME content (R-squared = 98.45%; R-squared adjusted for the degree of freedom = 95.65%; estimation standard error = 1.34).

Figure 3.

Surface response for FAME content under optimal reaction time (3.12 h).

4. Conclusions

For the production of biodiesel from waste cooking oil, calcined Mg-Al hydrotalcite (HT) may be considered an effective heterogenous catalyst. It was observed that HT calcination allowed the presence of chemical species that worked as basic catalysts during transesterification, thus enhancing the effect of HT. Methanol-to-oil molar ratio, HT amount, and reaction time appear to show positive impacts on the ester yield. However, values above the optimum interfered with glycerol separation (in the case of methanol) or increased viscosity, thus reducing matter transfer (in the case of the catalyst). Finally, Response Surface Methodology (RSM) was proved to be a useful methodology for predicting biodiesel yield in the present conditions. Despite not fulfilling the EN 14214 biodiesel standard in terms of ester yield, it is reasonable to assume that higher conversions would be reached if catalyst production conditions were optimized. This way, catalyst activity could be substantially improved. Therefore, further research to enhance Mg-Al hydrotalcite yield as a basic catalyst is proposed. In any case, this is the first time that a significantly high ester yield, achieved under mild reaction parameters, has been reported.

Acknowledgments

This research was supported by the Spanish Ministry of Economy and Competitiveness (ENE2013-47769-R) and the Andalusian Research, Innovation, and Enterprise Council, Spain (TEP-4994). Authors are also grateful to the Spanish Ministry of Science and Education for the provision of research leave to L. Costarrosa to carry out this work.

Author Contributions

M. Pilar Dorado and Juan José Ruiz conceived and designed the experiments; Laureano Costarrosa and Laureano Costarrosa performed the experiments; all authors analyzed the data; Juan José Ruiz contributed reagents/materials/analysis tools; Laureano Costarrosa and David Eduardo Leiva-Candia wrote the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Corral Bobadilla, M.; Lostado Lorza, R.; Garcia, R.E.; Somovilla Gomez, F.; Vergara Gonzalez, E.P. An improvement in biodiesel production from waste cooking oil by applying thought multi-response surface methodology using desirability functions. Energies 2017, 10, 130. [Google Scholar] [CrossRef]

- Pinzi, S.; Lopez Garcia, I.; Lopez-Gimenez, F.J.; Luque de Castro, M.D.; Dorado, G.; Dorado, M.P. The ideal vegetable oil-based biodiesel composition: A review of social, economical and technical implications. Energy Fuels 2009, 23, 2325–2341. [Google Scholar] [CrossRef]

- Dorado, M.P.; Ballesteros, E.; de Almeida, J.A.; Schellert, C.; Lohrlein, H.P.; Krause, R. An alkali-catalyzed transesterification process for high free fatty acid waste oils. Trans. ASAE 2002, 45, 525–529. [Google Scholar] [CrossRef]

- Dorado, M.P.; Ballesteros, E.; Lopez, F.J.; Mittelbach, M. Optimization of alkali-catalyzed transesterification of Brassica carinata oil for biodiesel production. Energy Fuels 2004, 18, 77–83. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Korstad, J. Latest developments on application of heterogenous basic catalysts for an efficient and eco friendly synthesis of biodiesel: A review. Fuel 2011, 90, 1309–1324. [Google Scholar] [CrossRef]

- Lee, H.V.; Juan, J.C.; Hin, T.Y.Y.; Ong, H.C. Environment-friendly heterogeneous alkaline-based mixed metal oxide catalysts for biodiesel production. Energies 2016, 9, 611. [Google Scholar] [CrossRef]

- Arzamendi, G.; Campo, I.; Arguinarena, E.; Sanchez, M.; Montes, M.; Gandia, L.M. Synthesis of biodiesel with heterogeneous NaOH/alumina catalysts: Comparison with homogeneous NaOH. Chem. Eng. J. 2007, 134, 123–130. [Google Scholar] [CrossRef]

- Reyero, I.; Arzamendi, G.; Gandia, L.M. Heterogenization of the biodiesel synthesis catalysis: CaO and novel calcium compounds as transesterification catalysts. Chem. Eng. Res. Des. 2014, 92, 1519–1530. [Google Scholar] [CrossRef]

- Santacesaria, E.; Vicente, G.M.; Di Serio, M.; Tesser, R. Main technologies in biodiesel production: State of the art and future challenges. Catal. Today 2012, 195, 2–13. [Google Scholar] [CrossRef]

- Kouzu, M.; Kasuno, T.; Tajika, M.; Yamanaka, S.; Hidaka, J. Active phase of calcium oxide used as solid base catalyst for transesterification of soybean oil with refluxing methanol. Appl. Catal. A Gen. 2008, 334, 357–365. [Google Scholar] [CrossRef]

- Granados, M.L.; Poves, M.D.Z.; Alonso, D.M.; Mariscal, R.; Galisteo, F.C.; Moreno-Tost, R.; Santamaría, J.; Fierro, J.L.G. Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 2007, 73, 317–326. [Google Scholar] [CrossRef]

- Verziu, M.; Coman, S.M.; Richards, R.; Parvulescu, V.I. Transesterification of vegetable oils over CaO catalysts. Catal. Today 2011, 167, 64–70. [Google Scholar] [CrossRef]

- Navajas, A.; Campo, I.; Moral, A.; Echave, J.; Sanz, O.; Montes, M.; Odriozola, J.A.; Arzamendi, G.; Gandía, L.M. Outstanding performance of rehydrated Mg-Al hydrotalcites as heterogeneous methanolysis catalysts for the synthesis of biodiesel. Fuel 2018, 211, 173–181. [Google Scholar] [CrossRef]

- Hojjat, M.; Nayebzadeh, H.; Khadangi-Mahrood, M.; Rahmani-Vahid, B. Optimization of process conditions for biodiesel production over CaO-Al2O3/ZrO2 catalyst using response surface methodology. Chem. Pap. 2017, 71, 689–698. [Google Scholar] [CrossRef]

- De Paiva, E.J.M.; Sterchele, S.; Corazza, M.L.; Murzin, D.Y.; Wypych, F.; Salmi, T. Esterification of fatty acids with ethanol over layered zinc laurate and zinc stearate—Kinetic modeling. Fuel 2015, 153, 445–454. [Google Scholar] [CrossRef]

- Stošić, D.; Hosoglu, F.; Bennici, S.; Travert, A.; Capron, M.; Dumeignil, F.; Couturier, J.L.; Dubois, J.L.; Auroux, A. Methanol and ethanol reactivity in the presence of hydrotalcites with Mg/Al ratios varying from 2 to 7. Catal. Commun. 2017, 89, 14–18. [Google Scholar] [CrossRef]

- Theiss, F.L.; Ayoko, G.A.; Frost, R.L. Synthesis of layered double hydroxides containing Mg2+, Zn2+, Ca2+ and Al3+ layer cations by co-precipitation methods—A review. Appl. Surf. Sci. 2016, 383, 200–213. [Google Scholar] [CrossRef]

- Kutalek, P.; Capek, L.; Smolakova, L.; Kubicka, D. Aspects of Mg-Al mixed oxide activity in transesterification of rapeseed oil in a fixed-bed reactor. Fuel Proc. Technol. 2014, 122, 176–181. [Google Scholar] [CrossRef]

- Zeng, H.-Y.; Feng, Z.; Deng, X.; Li, Y.-Q. Activation of Mg-Al hydrotalcite catalysts for transesterification of rape oil. Fuel 2008, 87, 3071–3076. [Google Scholar] [CrossRef]

- Brito, A.; Borges, M.E.; Garin, M.; Hernandez, A. Biodiesel production from waste oil using Mg-Al layered double hydroxide catalysts. Energy Fuels 2009, 23, 2952–2958. [Google Scholar] [CrossRef]

- Del Remedio Hernández, M.; Reyes-Labarta, J.A.; Valdés, F.J. New heterogeneous catalytic transesterification of vegetable and used frying oil. Ind. Eng. Chem. Res. 2010, 49, 9068–9076. [Google Scholar] [CrossRef]

- Yagiz, F.; Kazan, D.; Akin, A.N. Biodiesel production from waste oils by using lipase immobilized on hydrotalcite and zeolites. Chem. Eng. J. 2007, 134, 262–267. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Zheng, L.; Gao, Z.; Wang, Q.; Ma, Y. Mixed methanol/ethanol on transesterification of waste cooking oil using Mg/Al hydrotalcite catalyst. Energy 2016, 107, 523–531. [Google Scholar] [CrossRef]

- Dorado, M.P.; Cruz, F.; Palomar, J.M.; Lopez, F.J. An approach to the economics of two vegetable oil-based biofuels in Spain. Renew. Energy 2006, 31, 1231–1237. [Google Scholar] [CrossRef]

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste cooking oil as an alternate feedstock for biodiesel production. Energies 2008, 1, 3–18. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Koh, W.; Brown, R.J.; Senadeera, W.; O’Hara, I.; Moghaddam, L. Biodiesel production from non-edible beauty leaf (Calophyllum inophyllum) oil: Process optimization using response surface methodology (RSM). Energies 2014, 7, 5317–5331. [Google Scholar] [CrossRef]

- Kustrowski, P.; Chmielarz, L.; Bozek, E.; Sawalha, M.; Roessner, F. Acidity and basicity of hydrotalcite derived mixed Mg-Al oxides studied by test reaction of MBOH conversion and temperature programmed desorption of NH3 and CO2. Mater. Res. Bull. 2004, 39, 263–281. [Google Scholar] [CrossRef]

- Fraile, J.M.; García, N.; Mayoral, J.A.; Pires, E.; Roldán, L. The basicity of mixed oxides and the influence of alkaline metals: The case of transesterification reactions. Appl. Catal. A Gen. 2010, 387, 67–74. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, M.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef] [PubMed]

- Qasim, M.; Ansari, T.M.; A Hussain, M. Combustion, performance, and emission evaluation of a diesel engine with biodiesel like fuel blends derived from a mixture of Pakistani waste canola and waste transformer oils. Energies 2017, 10, 1023. [Google Scholar] [CrossRef]

- Di Serio, M.; Ledda, M.; Cozzolino, M.; Minutillo, G.; Tesser, R.; Santacesaria, E. Transesterification of soybean oil to biodiesel by using heterogeneous basic catalysts. Ind. Eng. Chem. Res. 2006, 45, 3009–3014. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).