A Novel κ-Carrageenase from Marine Bacterium Rhodopirellula sallentina SM41: Heterologous Expression, Biochemical Characterization and Salt-Tolerance Mechanism Investigation

Abstract

1. Introduction

2. Results and Discussion

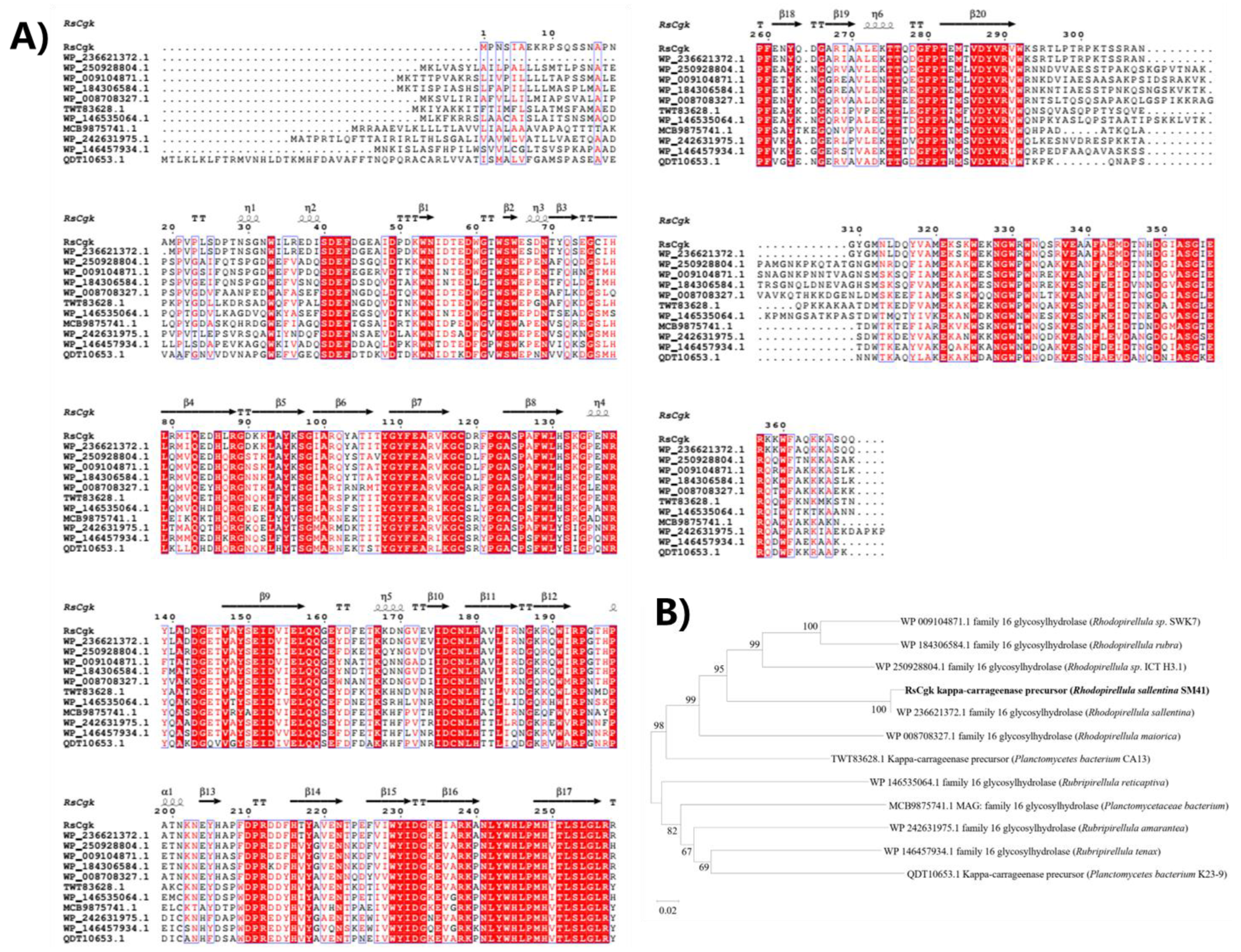

2.1. RsCgk Sequence Information

2.2. Expression and Purification of RsCgk

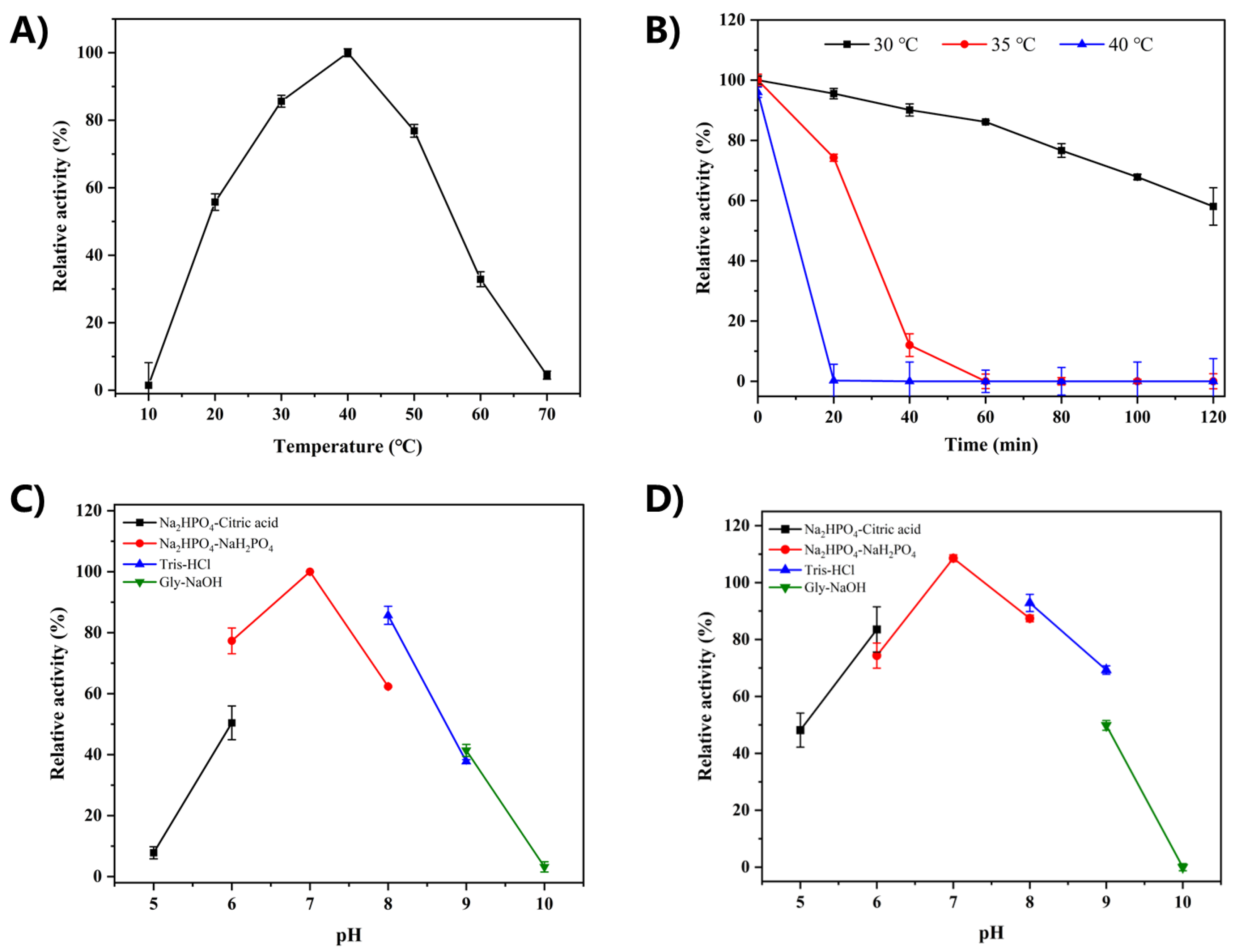

2.3. Biochemical Characterization of RsCgk

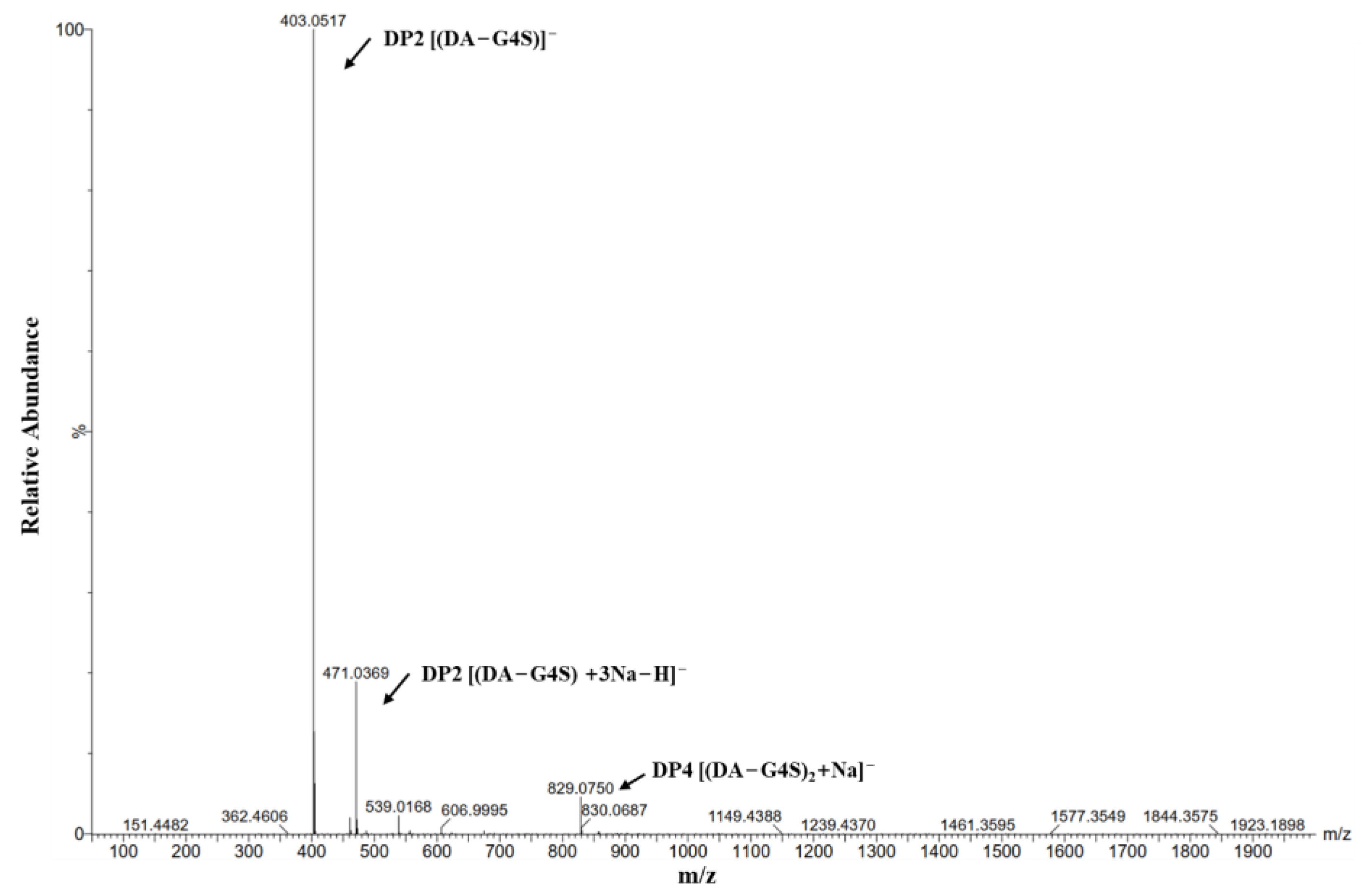

2.4. Degradation Pattern of RsCgk

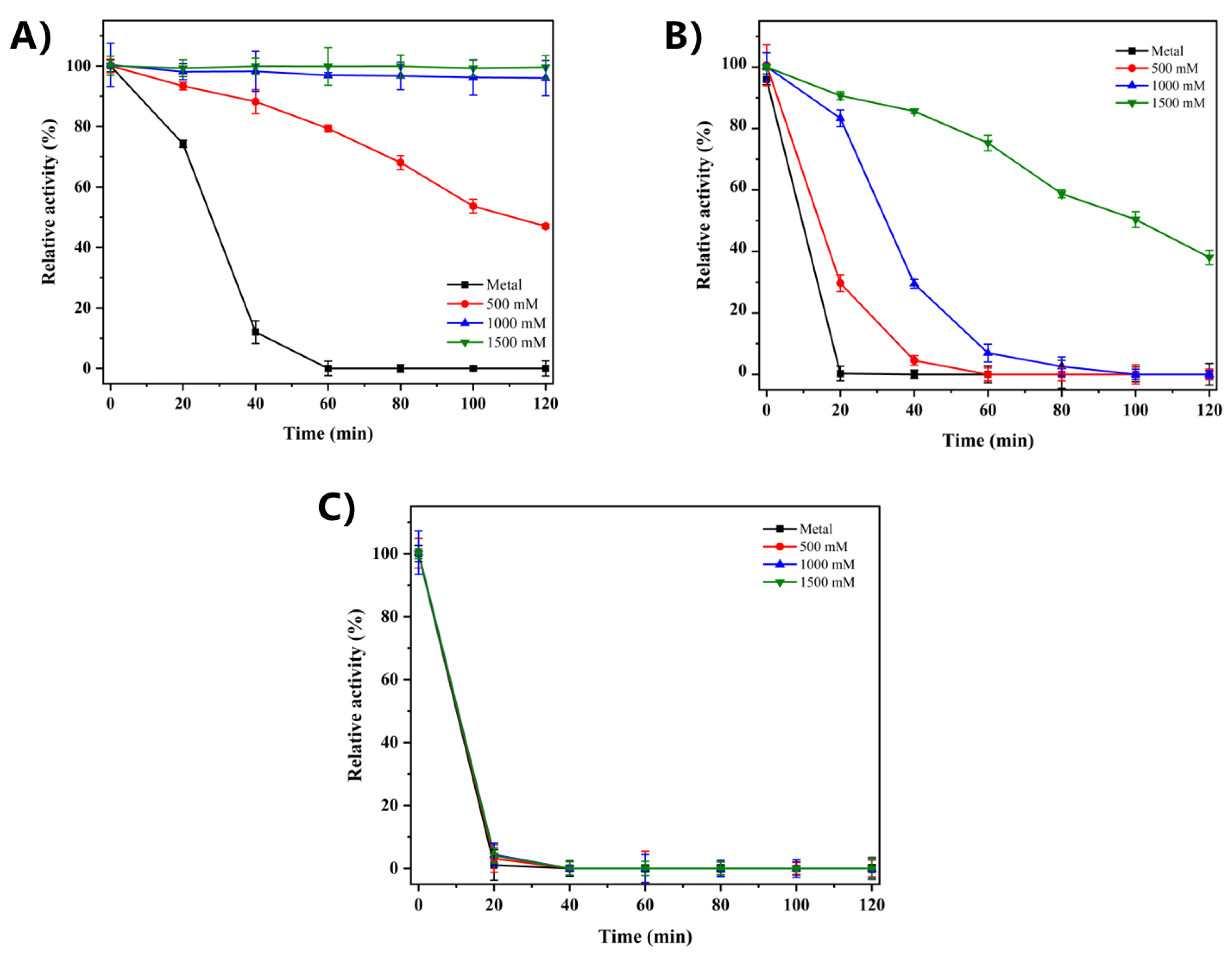

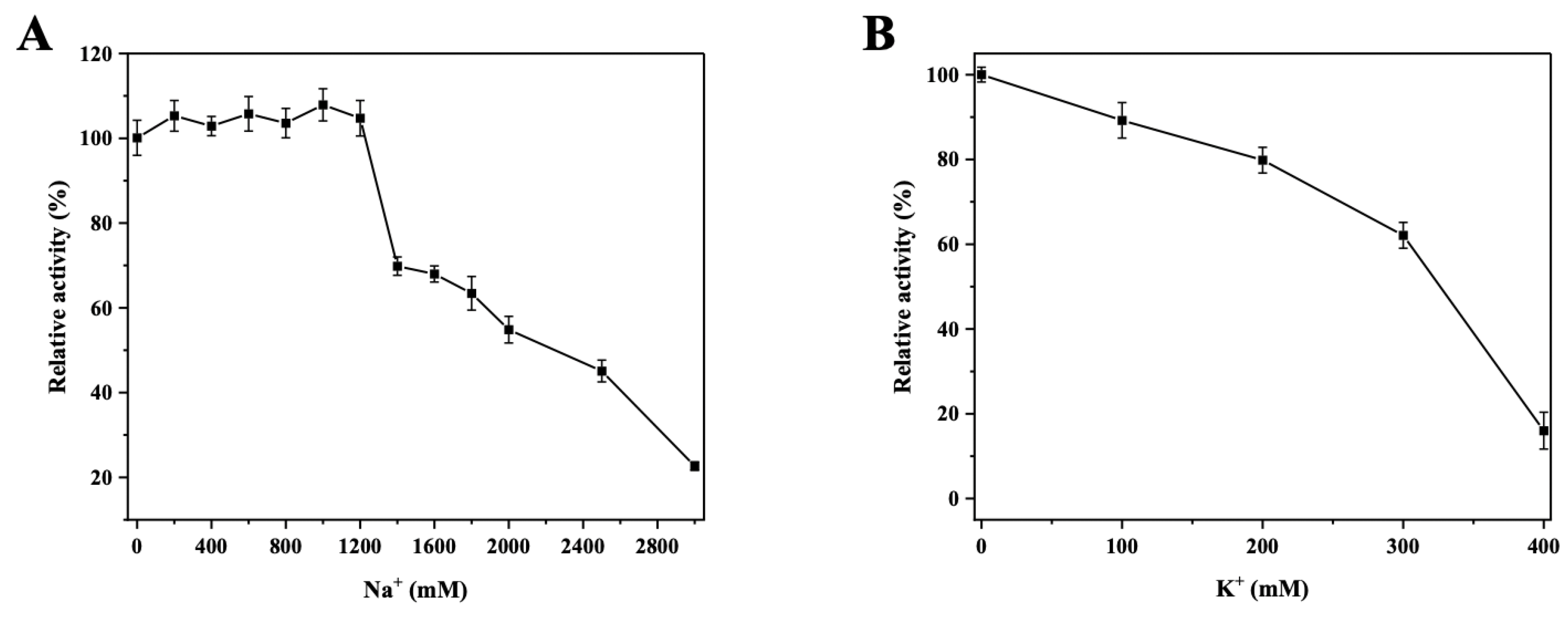

2.5. Salt Stabilization and Salt Tolerance of RsCgk

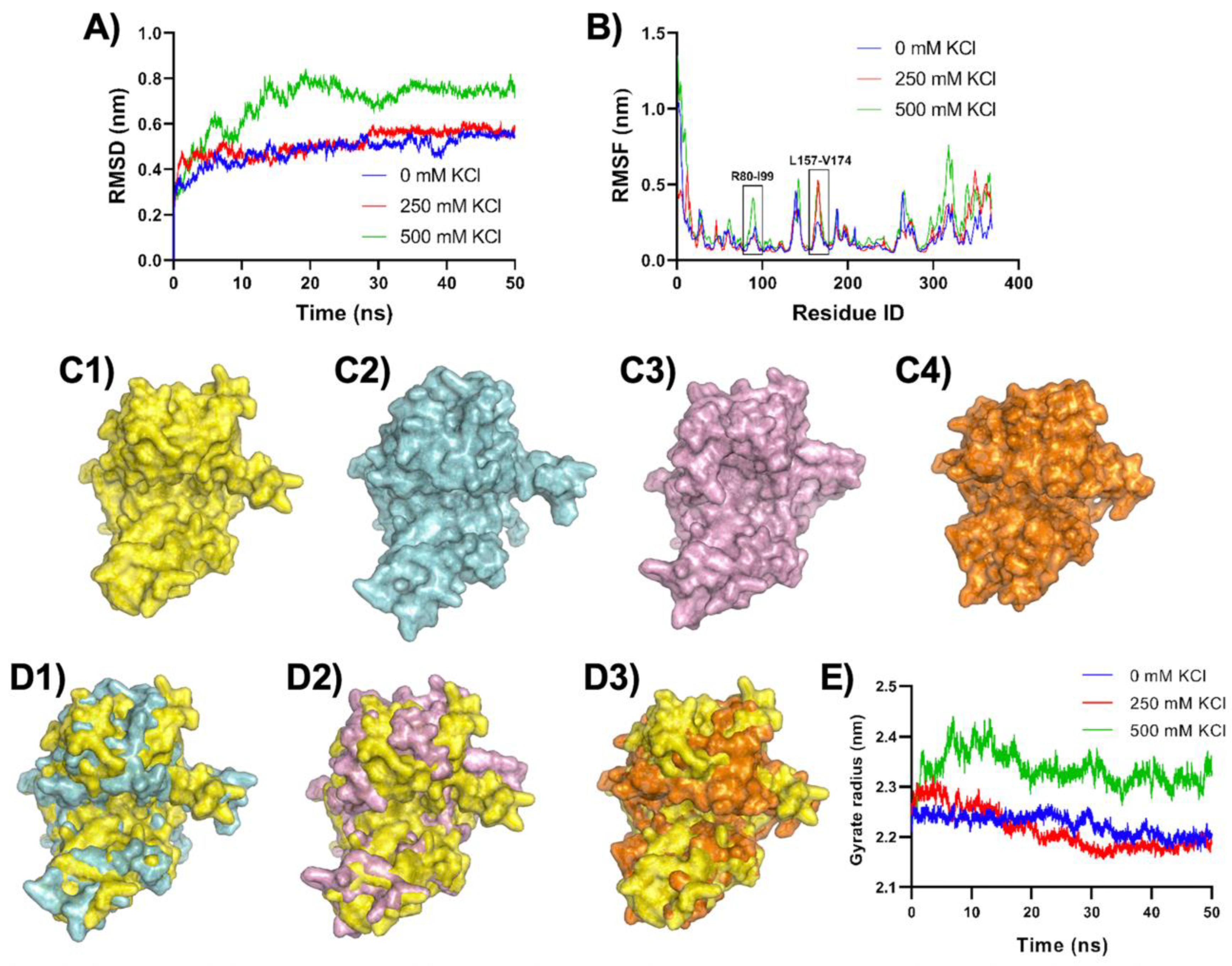

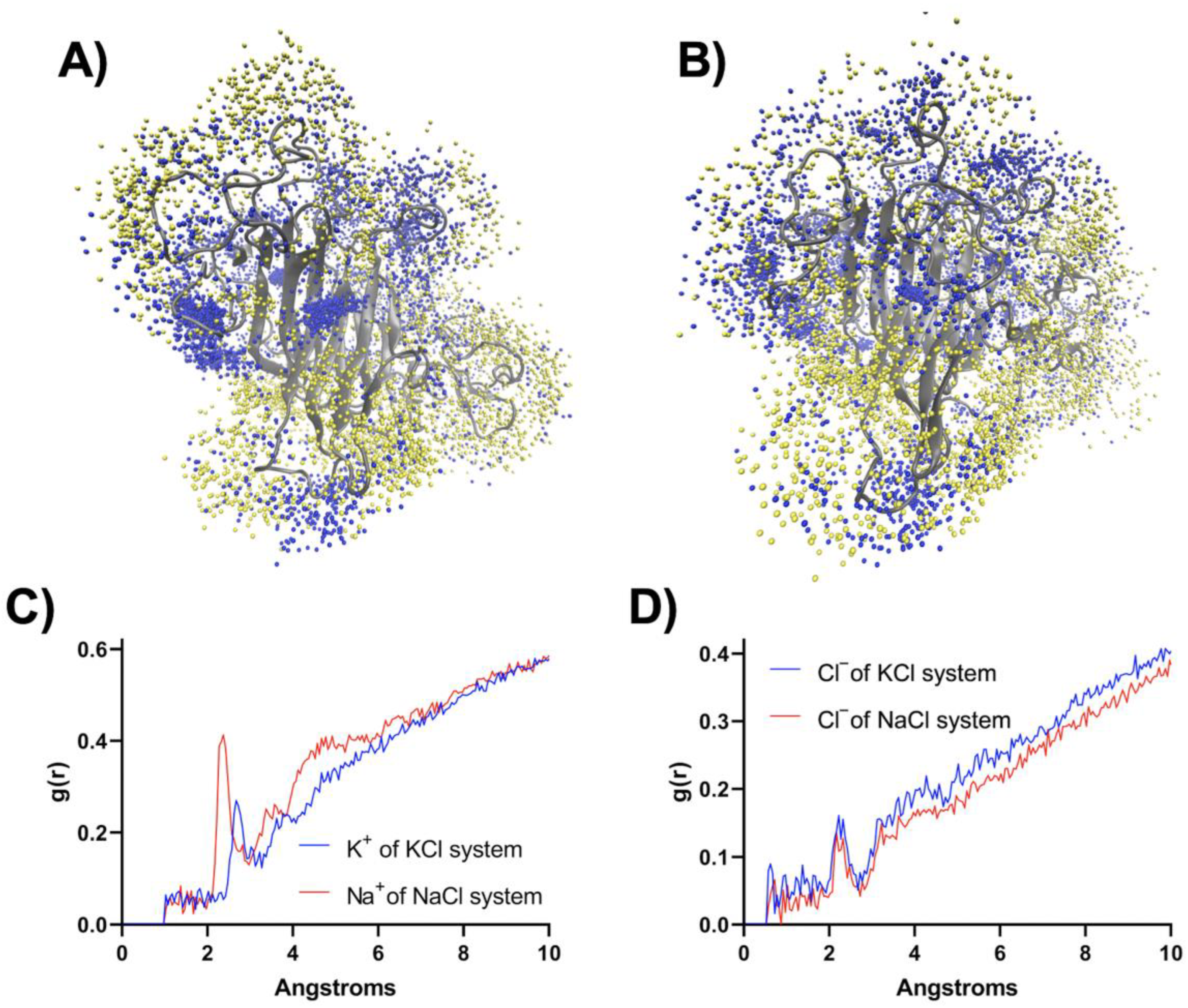

2.6. Structural Insight into the Potassium Tolerance of RsCgk

3. Materials and Methods

3.1. Materials

3.2. Construction of Recombinant E. coli for Expressing RsCgk

3.3. Expression and Purification of RsCgk

3.4. Measurement of RsCgk Activity

3.5. Effects of Temperature and pH on RsCgk Activity and Stability

3.6. Kinetic Parameters of RsCgk

3.7. ESI-MS Analysis

3.8. Effects of Salts on RsCgk

3.9. MD Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- De Ruiter, G.A.; Rudolph, B. Carrageenan biotechnology. Trends Food Sci. Technol. 1997, 8, 389–395. [Google Scholar] [CrossRef]

- Ghanbarzadeh, M.; Golmoradizadeh, A.; Homaei, A. Carrageenans and carrageenases: Versatile polysaccharides and promising marine enzymes. Phytochem. Rev. 2018, 17, 535–571. [Google Scholar] [CrossRef]

- Yu, G.; Guan, H.; Ioanoviciu, A.S.; Sikkander, S.A.; Thanawiroon, C.; Tobacman, J.K.; Toida, T.; Linhardt, R.J. Structural studies on κ-carrageenan derived oligosaccharides. Carbohydr. Res. 2002, 337, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Jayakody, M.M.; Vanniarachchy, M.P.G.; Wijesekara, I. Seaweed derived alginate, agar, and carrageenan based edible coatings and films for the food industry: A review. J. Food Meas. Charact. 2022, 16, 1195–1227. [Google Scholar] [CrossRef]

- Priyan Shanura Fernando, I.; Kim, K.-N.; Kim, D.; Jeon, Y.-J. Algal polysaccharides: Potential bioactive substances for cosmeceutical applications. Crit. Rev. Biotechnol. 2018, 39, 113–199. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Wei, Y.; Zhang, Y.; Xu, Y.; Zheng, L.; Zhu, B.; Yao, Z. Carrageenan oligosaccharides: A comprehensive review of preparation, isolation, purification, structure, biological activities and applications. Algal Res. 2022, 61, 102593. [Google Scholar] [CrossRef]

- Wijesekara, I.; Pangestuti, R.; Kim, S.-K. Biological activities and potential health benefits of sulfated polysaccharides derived from marine algae. Carbohydr. Polym. 2011, 84, 14–21. [Google Scholar] [CrossRef]

- Gui, Y.; Gu, X.; Fu, L.; Zhang, Q.; Zhang, P.; Li, J. Expression and characterization of a thermostable carrageenase from an antarctic Polaribacter sp. NJDZO3 strain. Front. Microbiol. 2021, 12, 631039. [Google Scholar] [CrossRef]

- Li, S.; He, N.; Han, Q.; Li, X.; Jung, S.; Suk Lee, B.; Kumar Mongre, R.; Wang, Z.P.; Wang, L.; Lee, M.S. Production of a thermo-tolerant kappa-carrageenase via a food-grade host and anti-oxidant activity of its enzymatic hydrolysate. Food Chem. 2021, 339, 128027. [Google Scholar] [CrossRef]

- Qeshmi, F.I.; Homaei, A.; Khajeh, K.; Kamrani, E.; Fernandes, P. Production of a novel marine Pseudomonas Aeruginosa recombinant L-asparaginase: Insight on the structure and biochemical characterization. Mar. Biotechnol. 2022, 24, 599–613. [Google Scholar] [CrossRef]

- Zeinali, F.; Homaei, A.; Kamrani, E. Identification and kinetic characterization of a novel superoxide dismutase from Avicennia marina: An antioxidant enzyme with unique features. Int. J. Biol. Macromol. 2017, 105, 1556–1562. [Google Scholar] [CrossRef] [PubMed]

- Qeshmi, F.I.; Homaei, A.; Fernandes, P.; Hemmati, R.; Dijkstra, B.W.; Khajeh, K. Xylanases from marine microorganisms: A brief overview on scope, sources, features and potential applications. Biochim. Biophys. Acta Proteins Proteom. 2020, 1868, 140312. [Google Scholar] [CrossRef] [PubMed]

- Sharifian, S.; Homaei, A.; Kim, S.K.; Satari, M. Production of newfound alkaline phosphatases from marine organisms with potential functions and industrial applications. Process Biochem. 2018, 64, 103–115. [Google Scholar] [CrossRef]

- Beygmoradi, A.; Homaei, A.; Hemmati, R.; Del Arco, J.; Fernandez-Lucas, J. Identification of a novel tailor-made chitinase from white shrimp Fenneropenaeus merguiensis. Colloid Surf. B 2021, 203, 111747. [Google Scholar] [CrossRef] [PubMed]

- Cui, H.; Peng, Y.; Zhao, B.; Liu, Y.; Chen, F.; Wu, H.; Yao, Z. Cloning, identification and characterization of a novel kappa-carrageenase from marine bacterium Cellulophaga lytica strain N5-2. Int. J. Biol. Macromol. 2017, 105, 509–515. [Google Scholar] [CrossRef]

- Zhu, B.; Ni, F.; Ning, L.; Yao, Z.; Du, Y. Cloning and biochemical characterization of a novel kappa-carrageenase from newly isolated marine bacterium Pedobacter hainanensis NJ-02. Int. J. Biol. Macromol. 2018, 108, 1331–1338. [Google Scholar] [CrossRef]

- Xiao, A.F.; Zeng, J.; Li, J.J.; Zhu, Y.B.; Xiao, Q.; Ni, H. Molecular cloning, characterization, and heterologous expression of a new kappa-carrageenase gene from Pseudoalteromonas carrageenovora ASY5. J. Food Biochem. 2018, 42, e12677. [Google Scholar] [CrossRef]

- Al’Nahdi, Z.; Al-Alawi, A.; Al-Marhubi, I. The effect of extraction conditions on chemical and thermal characteristics of kappa-carrageenan extracted from Hypnea bryoides. J. Mar. Biol. 2019, 2019, 5183261. [Google Scholar] [CrossRef]

- Jiang, F.; Liu, Y.; Xiao, Q.; Chen, F.Q.; Weng, H.F.; Chen, J.; Zhang, Y.H.; Xiao, A.F. Eco-friendly extraction, structure, and gel properties of iota-carrageenan extracted using Ca(OH)2. Mar Drugs 2022, 20, 419. [Google Scholar] [CrossRef]

- Winkelmann, N.; Jaekel, U.; Meyer, C.; Serrano, W.; Rachel, R.; Rossello-Mora, R.; Harder, J. Determination of the diversity of Rhodopirellula isolates from European seas by multilocus sequence analysis. Appl. Environ. Microbiol. 2010, 76, 776–785. [Google Scholar] [CrossRef]

- Yilmaz, P.; Kottmann, R.; Field, D.; Knight, R.; Cole, J.R.; Amaral-Zettler, L.; Gilbert, J.A.; Karsch-Mizrachi, I.; Johnston, A.; Cochrane, G.; et al. Minimum information about a marker gene sequence (MIMARKS) and minimum information about any (x) sequence (MIxS) specifications. Nat. Biotechnol. 2011, 29, 415–420. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.L.; Li, Y.; Chi, Z.; Chi, Z.M. Purification and characterization of kappa-carrageenase from the marine bacterium Pseudoalteromonas porphyrae for hydrolysis of kappa-carrageenan. Process Biochem. 2011, 46, 265–271. [Google Scholar] [CrossRef]

- Liu, Z.M.; Li, G.Y.; Mo, Z.L.; Mou, H.J. Molecular cloning, characterization, and heterologous expression of a new kappa-carrageenase gene from marine bacterium Zobellia sp. ZM-2. Appl. Microbiol. Biot. 2013, 97, 10057–10067. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Wang, F.F.; Gao, Z.; Jin, L.M.; Wu, H.G. Characterization of a kappa-carrageenase from marine Cellulophaga lytica strain N5-2 and analysis of its degradation products. Int. J. Mol. Sci. 2013, 14, 24592–24602. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chi, Z.; Xu, Y.; Shi, N.; Chi, Z.; Liu, G. High-level extracellular expression of κ-carrageenase in Brevibacillus choshinensis for the production of a series of κ-carrageenan oligosaccharides. Process Biochem. 2018, 64, 83–92. [Google Scholar] [CrossRef]

- Genicot, S.M.; Groisillier, A.; Rogniaux, H.; Meslet-Cladiere, L.; Barbeyron, T.; Helbert, W. Discovery of a novel iota carrageenan sulfatase isolated from the marine bacterium Pseudoalteromonas carrageenovora. Front. Chem. 2014, 2, 67. [Google Scholar] [CrossRef]

- Raval, V.H.; Pillai, S.; Rawall, C.M.; Singh, S.P. Biochemical and structural characterization of a detergent-stable serine alkaline protease from seawater haloalkaliphilic bacteria. Process Biochem. 2014, 49, 955–962. [Google Scholar] [CrossRef]

- Li, S.; Jia, P.; Wang, L.; Yu, W.; Han, F. Purification and characterization of a new thermostable kappa-carrageenase from the marine bacterium Pseudoalteromonas sp. QY203. J. Ocean. Univ. China 2013, 12, 155–159. [Google Scholar] [CrossRef]

- Ma, Y.X.; Dong, S.L.; Jiang, X.L.; Li, J.; Mou, H.J. Purification and characterization of kappa-carrageenase from marine bacterium mutant strain Pseudoalteromonas sp. AJ5-13 and its degraded products. J. Food Biochem. 2010, 34, 661–678. [Google Scholar] [CrossRef]

- Li, J.; Gu, X.; Zhang, Q.; Fu, L.; Tan, J.; Zhao, L. Biochemical characterization of a carrageenase, Car1383, derived from associated bacteria of antarctic macroalgae. Front. Microbiol. 2022, 13, 851182. [Google Scholar] [CrossRef]

- Sun, F.; Ma, Y.; Wang, Y.; Liu, Q. Purification and characterization of novel kappa-carrageenase from marine Tamlana sp. HC4. Chin. J. Oceanol. Limnol. 2010, 28, 1139–1145. [Google Scholar] [CrossRef]

- Wang, L.; Li, S.; Zhang, S.; Li, J.; Yu, W.; Gong, Q. A new kappa-carrageenase CgkS from marine bacterium Shewanella sp. Kz7. J. Ocean. Univ. China 2015, 14, 759–763. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, Z.; Yang, M.; Chen, M.; Wei, Z.; Shi, L.; Li, L.; Mou, H. Characterization of full-length and truncated recombinant kappa-carrageenase expressed in Pichia pastoris. Front. Microbiol. 2017, 8, 1544. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, Y.; Chen, G.; Shen, J.; Han, J.; Chang, Y.; Xiao, H.; Xue, C. Cloning, heterologous expression, and characterization of a betakappa-carrageenase from marine bacterium Wenyingzhuangia funcanilytica: A specific enzyme for the hybrid carrageenan-furcellaran. Front. Microbiol. 2021, 12, 697218. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, G.; Torres, M.D.; Sousa-Pinto, I.; Hilliou, L. Effect of pre-extraction alkali treatment on the chemical structure and gelling properties of extracted hybrid carrageenan from Chondrus crispus and Ahnfeltiopsis devoniensis. Food Hydrocolloid 2015, 50, 150–158. [Google Scholar] [CrossRef]

- Shen, J.; Chang, Y.; Chen, F.; Dong, S. Expression and characterization of a kappa-carrageenase from marine bacterium Wenyingzhuangia aestuarii OF219: A biotechnological tool for the depolymerization of kappa-carrageenan. Int. J. Biol. Macromol. 2018, 112, 93–100. [Google Scholar] [CrossRef]

- Tang, X.; Jiao, C.; Wei, Y.; Zhuang, X.Y.; Xiao, Q.; Chen, J.; Chen, F.Q.; Yang, Q.M.; Weng, H.F.; Fang, B.S.; et al. Biochemical characterization and cold-adaption mechanism of a PL-17 family alginate lyase Aly23 from marine bacterium Pseudoalteromonas sp. ASY5 and its application for oligosaccharides production. Mar. Drugs 2022, 20, 126. [Google Scholar] [CrossRef]

- Xu, F.; Wang, P.; Zhang, Y.Z.; Chen, X.L. Diversity of three-dimensional structures and catalytic mechanisms of alginate lyases. Appl. Environ. Microbiol. 2018, 84, e02040-17. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Shao, Y.; Jiao, C.; Yang, Q.M.; Weng, H.F.; Xiao, A.F. Characterization and application of an alginate lyase, Aly1281 from marine bacterium Pseudoalteromonas carrageenovora ASY5. Mar. Drugs 2020, 18, 95. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-H.; Chen, Y.-Y.; Zhuang, X.-Y.; Xiao, Q.; Chen, J.; Chen, F.-Q.; Yang, Q.-M.; Weng, H.-F.; Fang, B.-S.; Xiao, A.-F. A Novel κ-Carrageenase from Marine Bacterium Rhodopirellula sallentina SM41: Heterologous Expression, Biochemical Characterization and Salt-Tolerance Mechanism Investigation. Mar. Drugs 2022, 20, 783. https://doi.org/10.3390/md20120783

Zhang Y-H, Chen Y-Y, Zhuang X-Y, Xiao Q, Chen J, Chen F-Q, Yang Q-M, Weng H-F, Fang B-S, Xiao A-F. A Novel κ-Carrageenase from Marine Bacterium Rhodopirellula sallentina SM41: Heterologous Expression, Biochemical Characterization and Salt-Tolerance Mechanism Investigation. Marine Drugs. 2022; 20(12):783. https://doi.org/10.3390/md20120783

Chicago/Turabian StyleZhang, Yong-Hui, Yi-Ying Chen, Xiao-Yan Zhuang, Qiong Xiao, Jun Chen, Fu-Quan Chen, Qiu-Ming Yang, Hui-Fen Weng, Bai-Shan Fang, and An-Feng Xiao. 2022. "A Novel κ-Carrageenase from Marine Bacterium Rhodopirellula sallentina SM41: Heterologous Expression, Biochemical Characterization and Salt-Tolerance Mechanism Investigation" Marine Drugs 20, no. 12: 783. https://doi.org/10.3390/md20120783

APA StyleZhang, Y.-H., Chen, Y.-Y., Zhuang, X.-Y., Xiao, Q., Chen, J., Chen, F.-Q., Yang, Q.-M., Weng, H.-F., Fang, B.-S., & Xiao, A.-F. (2022). A Novel κ-Carrageenase from Marine Bacterium Rhodopirellula sallentina SM41: Heterologous Expression, Biochemical Characterization and Salt-Tolerance Mechanism Investigation. Marine Drugs, 20(12), 783. https://doi.org/10.3390/md20120783