A Review of the Research Progress of Sensor Monitoring Technology in Harsh Engineering Environments

Abstract

Highlights

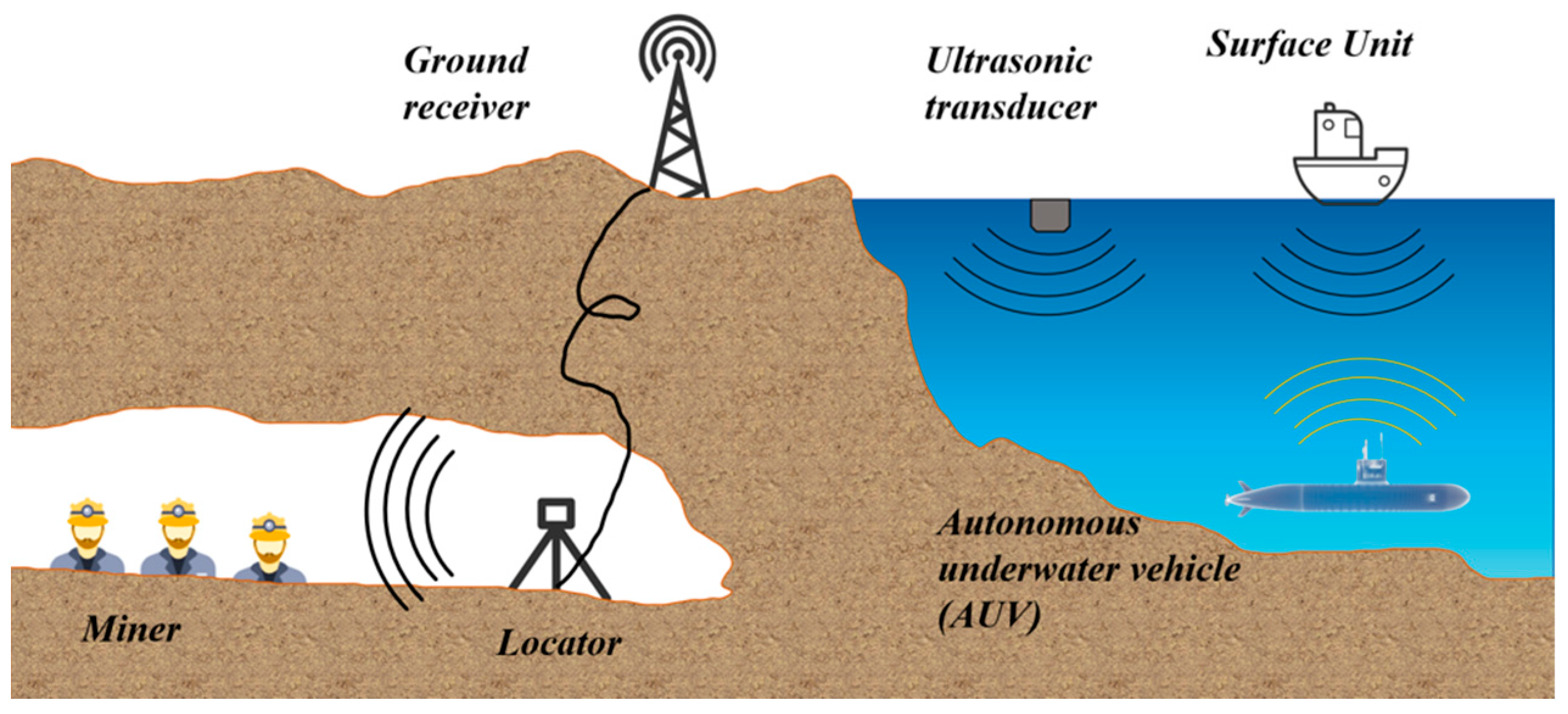

- Sensor monitoring technologies have made significant progress in adapting to harsh engineering environments, including underground, underwater, and high-risk industrial settings.

- Integrated early warning platforms combining sensor networks and communication systems have enhanced real-time monitoring, remote control, and disaster prevention capabilities.

- The application of advanced sensor systems improves safety, operational efficiency, and decision-making accuracy in engineering projects.

Abstract

1. Introduction

- It provides a comprehensive synthesis of the most recent progress on sensor monitoring components tailored to underground high-temperature, high-pressure, and complex liquid environments, which have not been systematically reviewed in prior work.

- It updates previous reviews by providing the latest analysis of mechanical, optical, and acoustic sensors, including their principles, features, limitations, and application scenarios.

- It summarizes the state-of-the-art in communication and transmission methods for monitoring data under harsh subsurface environments, an area that is often underrepresented in the existing literature.

- It expands the discussion to integrated monitoring and early warning platforms, highlighting how sensor technologies and communication systems can be linked for practical engineering applications—an integration rarely addressed in comparable reviews.

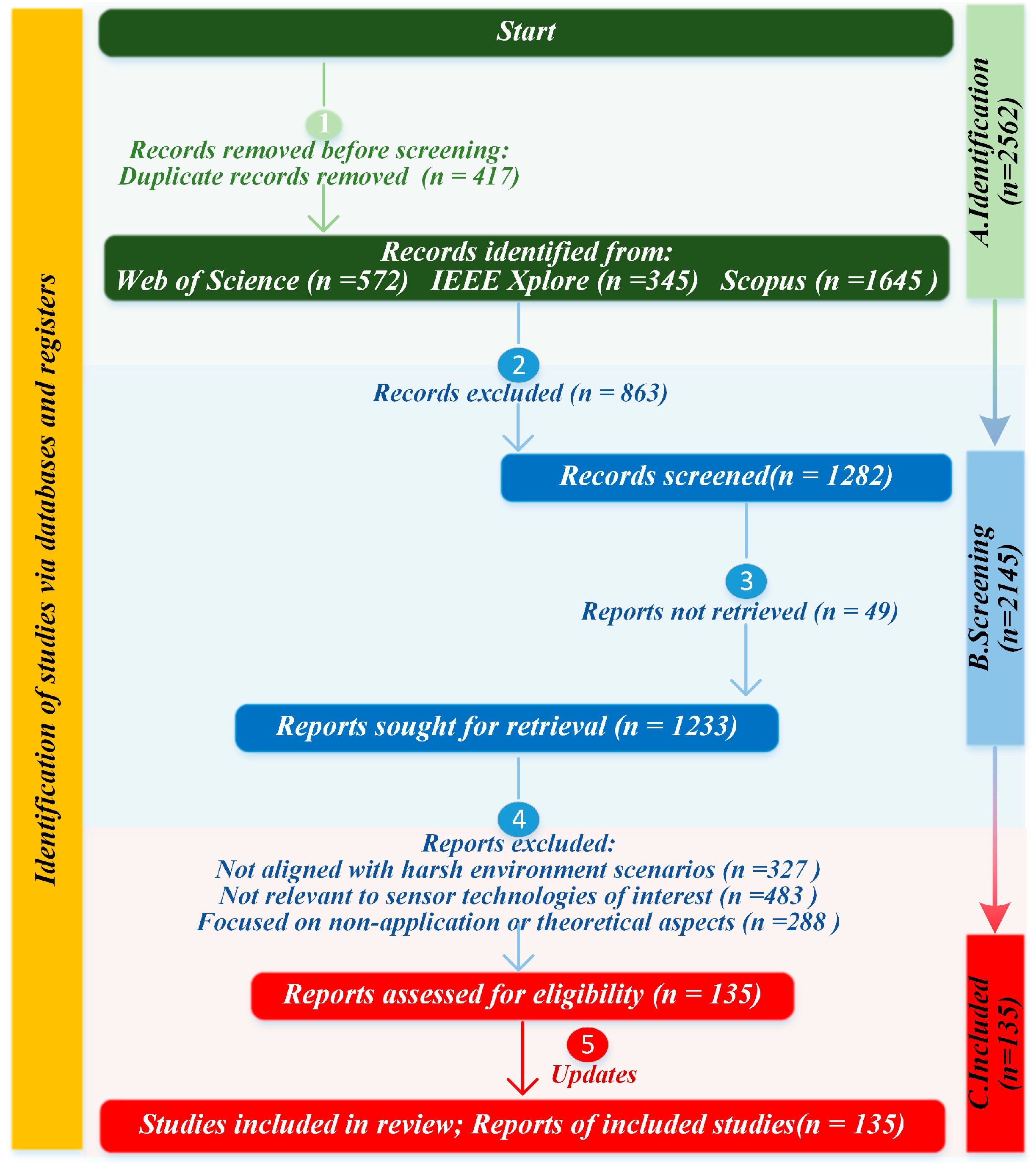

2. Materials and Methods

3. Analysis of the Principles and Applications of Sensors Under Different Mechanisms

3.1. Mechanical Sensors

3.1.1. Mechanical Sensors Based on Different Response Mechanisms

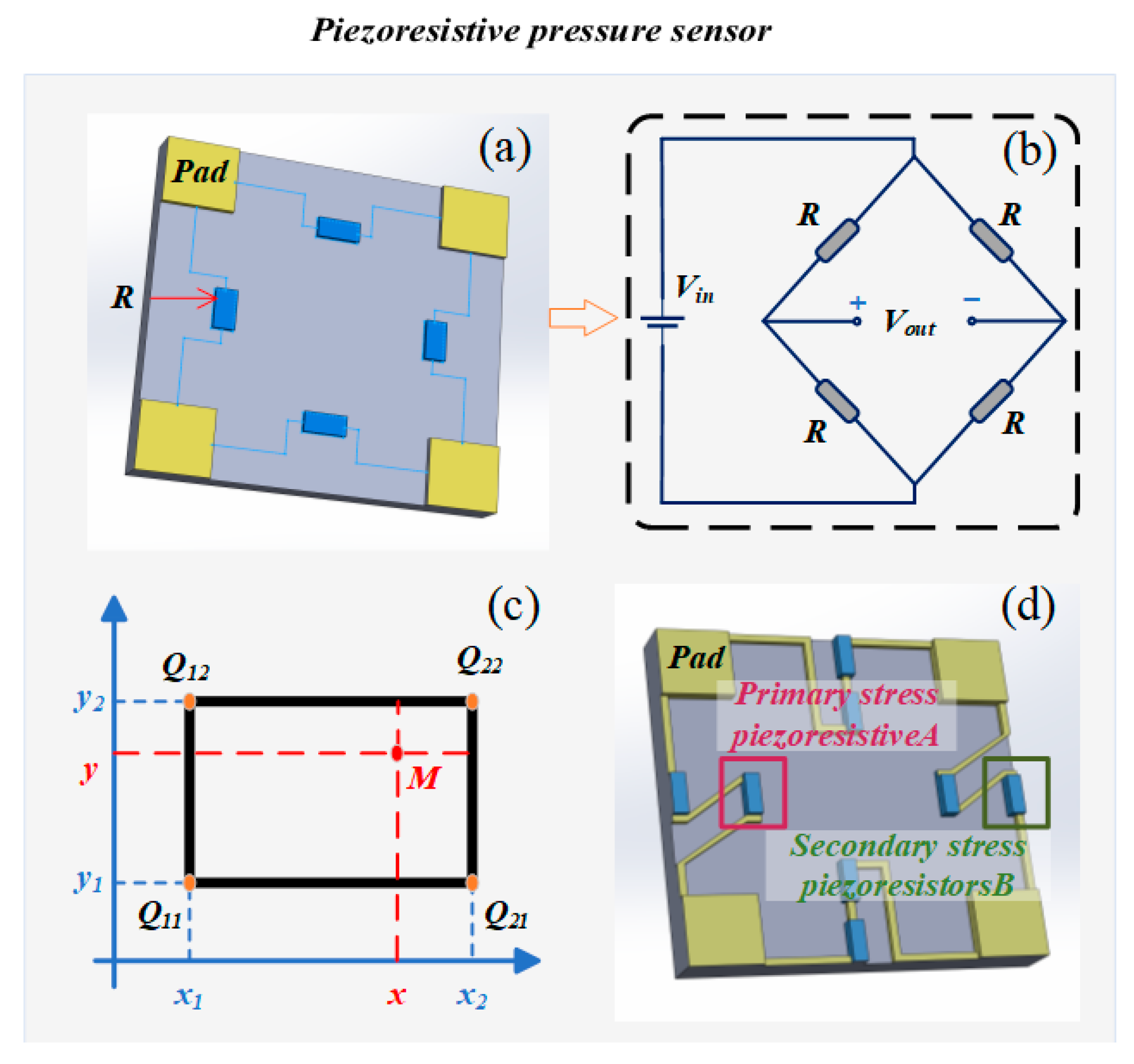

- Piezoresistive Sensors

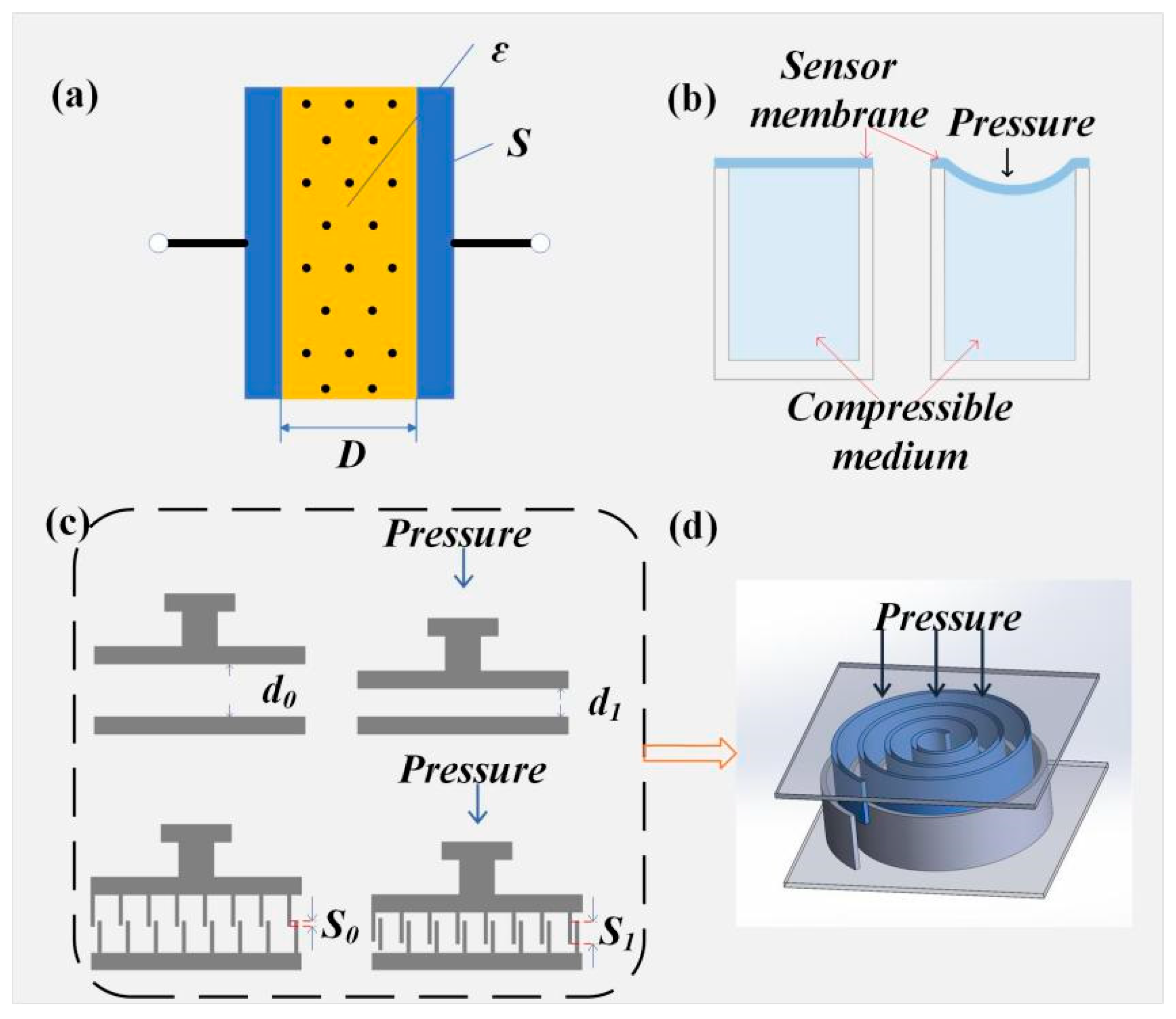

- Capacitive Sensors

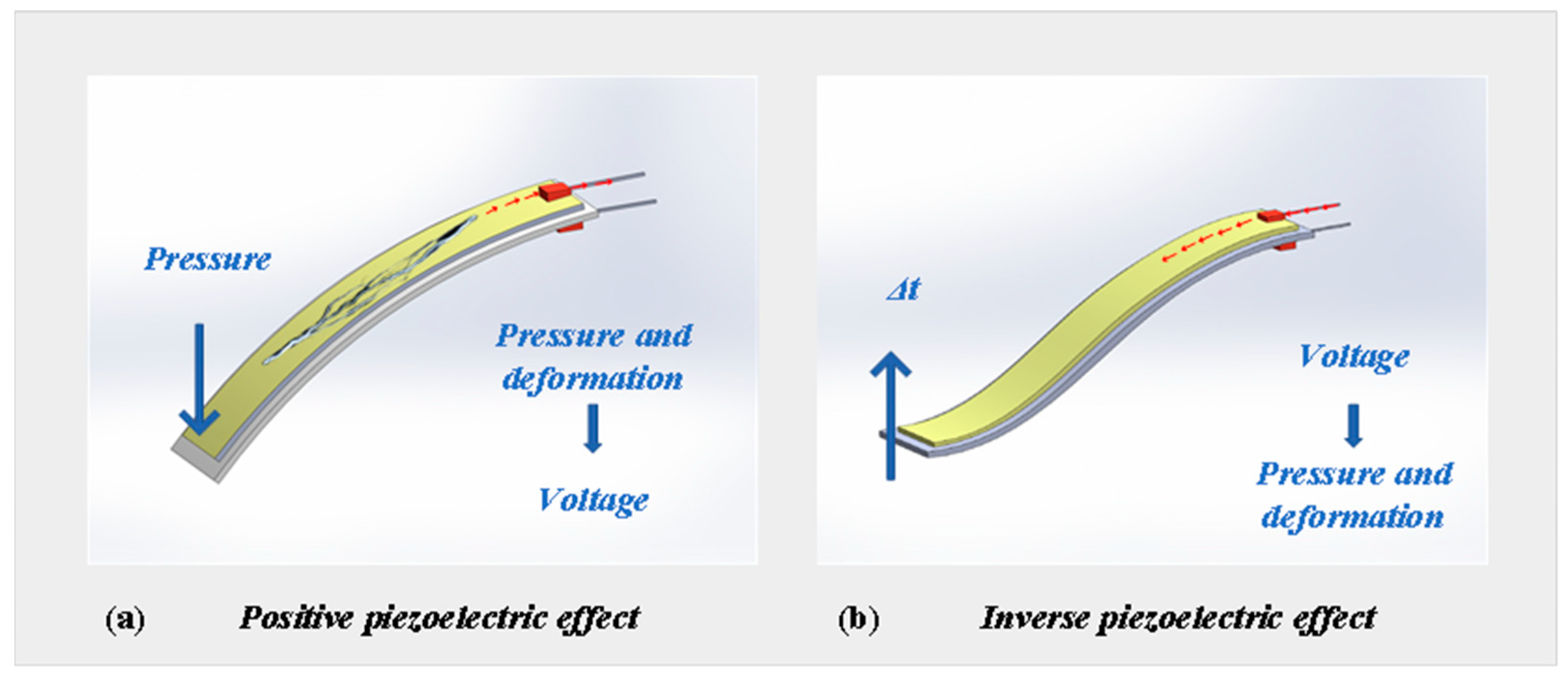

- Piezoelectric Sensors

- Resonant Sensors

3.1.2. Analysis of Mechanical Sensor Applications

- The adoption of temperature compensation algorithms and temperature compensation devices can effectively enhance linearity, sensitivity and reduce errors.

- Based on the characteristics of capacitors, various forms of improvements can be made. In the future, improvements can be made in multiple aspects, such as sensor manufacturing materials and dielectric materials, to meet the monitoring requirements of different scenarios.

- The application of new material coatings can effectively reduce the impact of thermal shock on piezoelectric pressure sensors.

- By adopting a more stable and efficient new pressure conversion structure, the accuracy of the original parameters can be effectively enhanced and the error of the original parameters can be reduced.

- The temperature compensation system based on beat frequency analysis can significantly improve the measurement accuracy of resonant pressure sensors.

3.2. Optical Sensors

3.2.1. Optical Sensors Based on Different Response Mechanisms

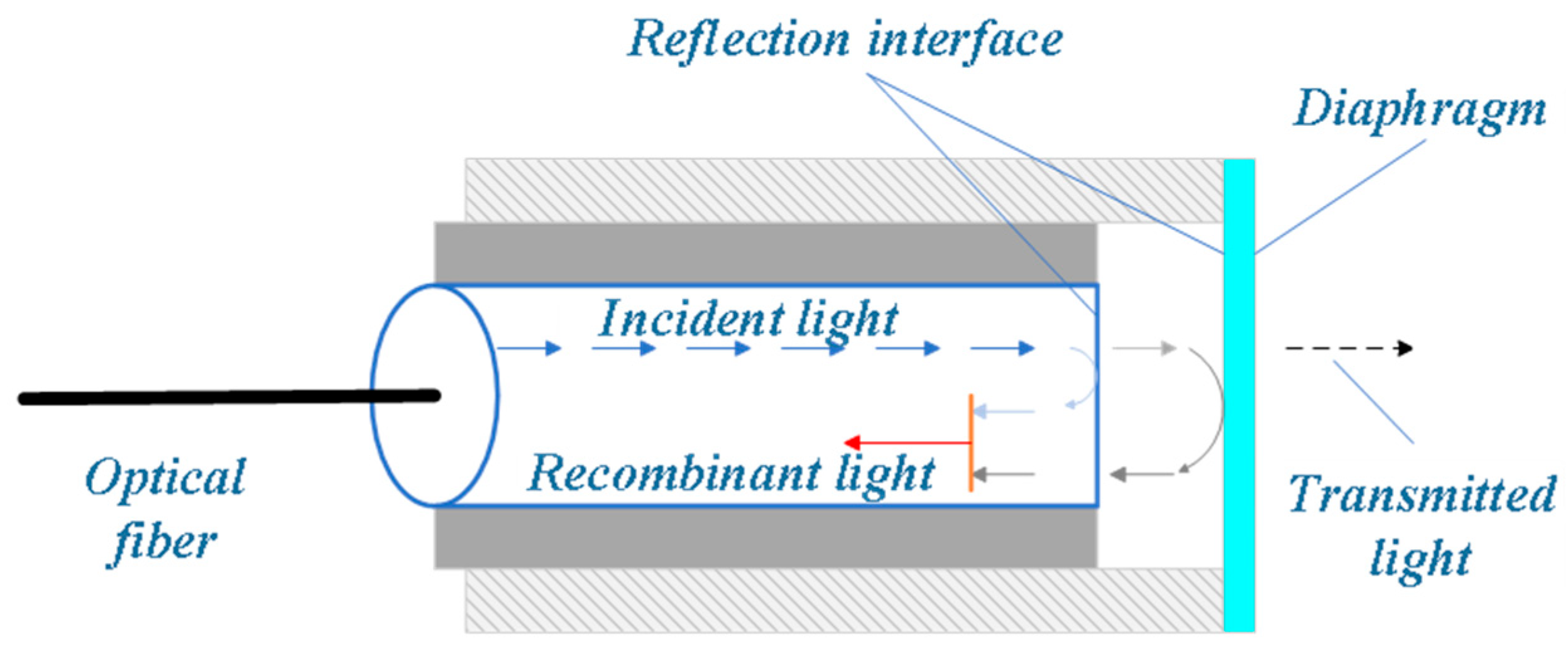

- Fabry–Perot Sensors

- Fiber Bragg Grating Sensors

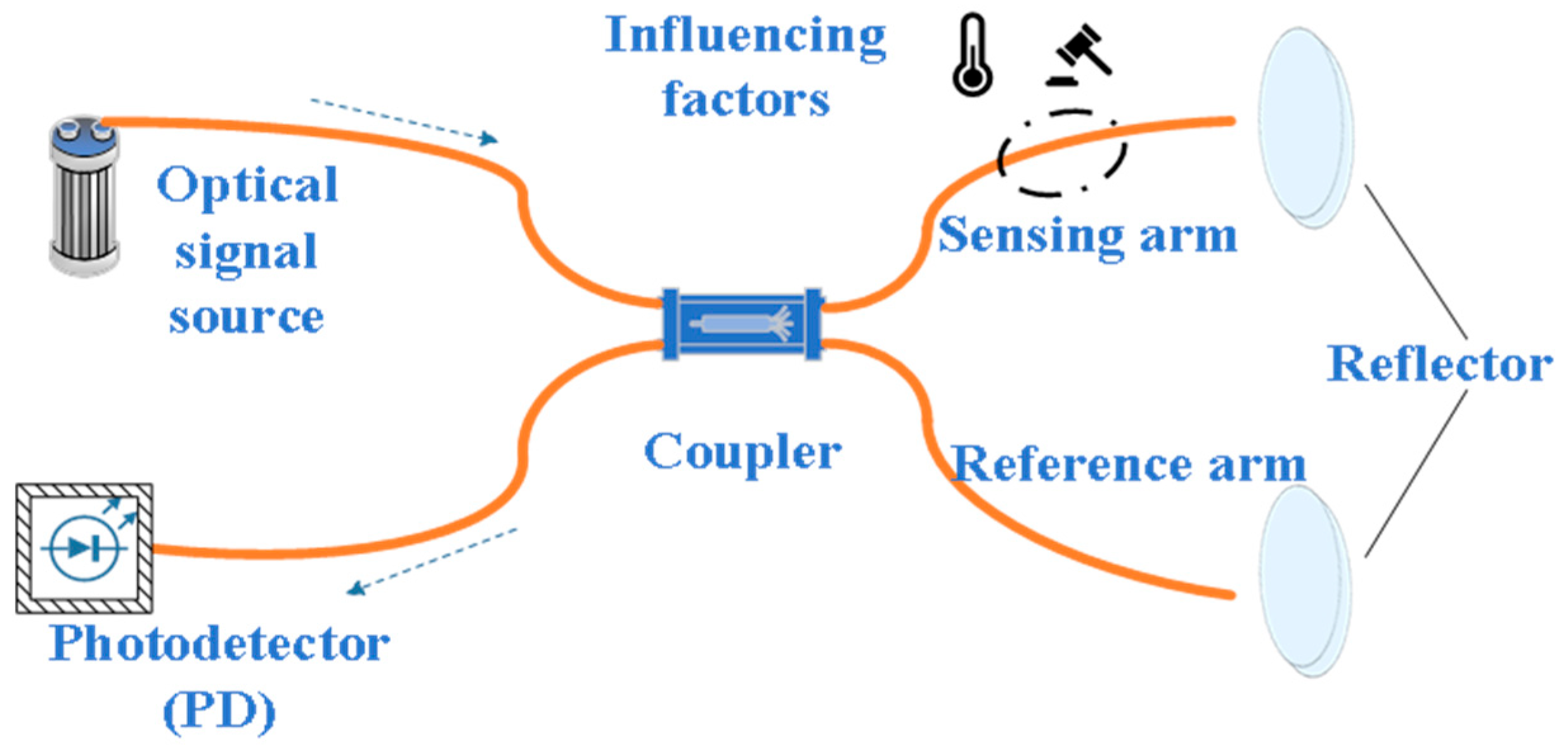

- Michelson Sensors

3.2.2. Analysis of Optical Sensor Applications

- The sensitivity, measurement range and stability of multiple sensors can be improved through various combinations such as cascading and series connection.

- Improving the shape of the diaphragm can enhance the performance of the sensor. An appropriate diaphragm shape can effectively reduce the impact of non-uniform strain.

- Improving the structure at the end of optical fibers can enhance the reflectivity.

- Sensors are made of new high-temperature and high-pressure resistant materials to enhance reliability in high-temperature and high-pressure environments.

3.3. Acoustic Sensors

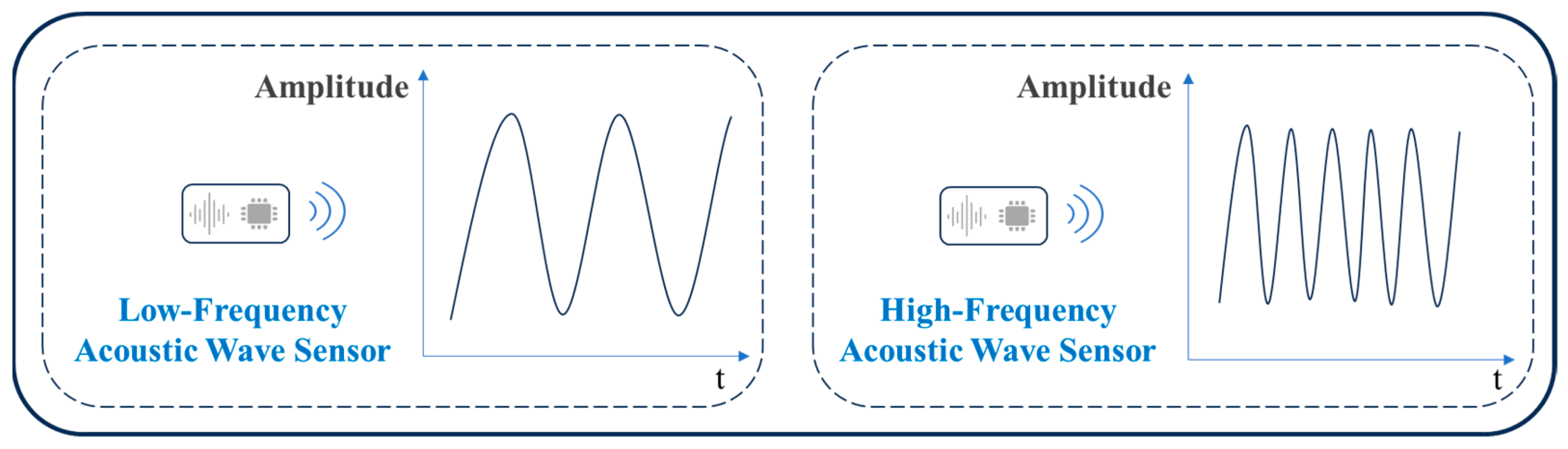

3.3.1. Acoustic Sensors Classified by Frequency Bands

- Low-frequency Acoustic Sensors

- High-frequency Acoustic Sensors

3.3.2. Analysis of Acoustic Sensor Applications

- Hydrogel materials have good application potential in the field of underwater acoustic sensors and can significantly improve sensitivity.

- Low-frequency acoustic wave sensors have broad prospects in environmental detection, such as seismic wave detection, volcanic activity detection and underwater noise measurement.

- By integrating the typical structures of traditional acoustic sensors with mechanical and optical sensors, the detection performance of acoustic sensors can be significantly enhanced.

- Enhance the performance of PMUT during the transmission and reception phases by leveraging the C-shaped slot design. In addition to the C-slot design, various new structural designs can also be developed to enhance the performance during the transceiver stage.

3.4. Cross-Category Sensor Performance

4. Transmission Methods for Monitoring Systems

4.1. Sensor Data Transmission Mode

4.1.1. Wired Transmission

- Power Line Communication

- Optical Fiber Communication

4.1.2. Wireless Transmission

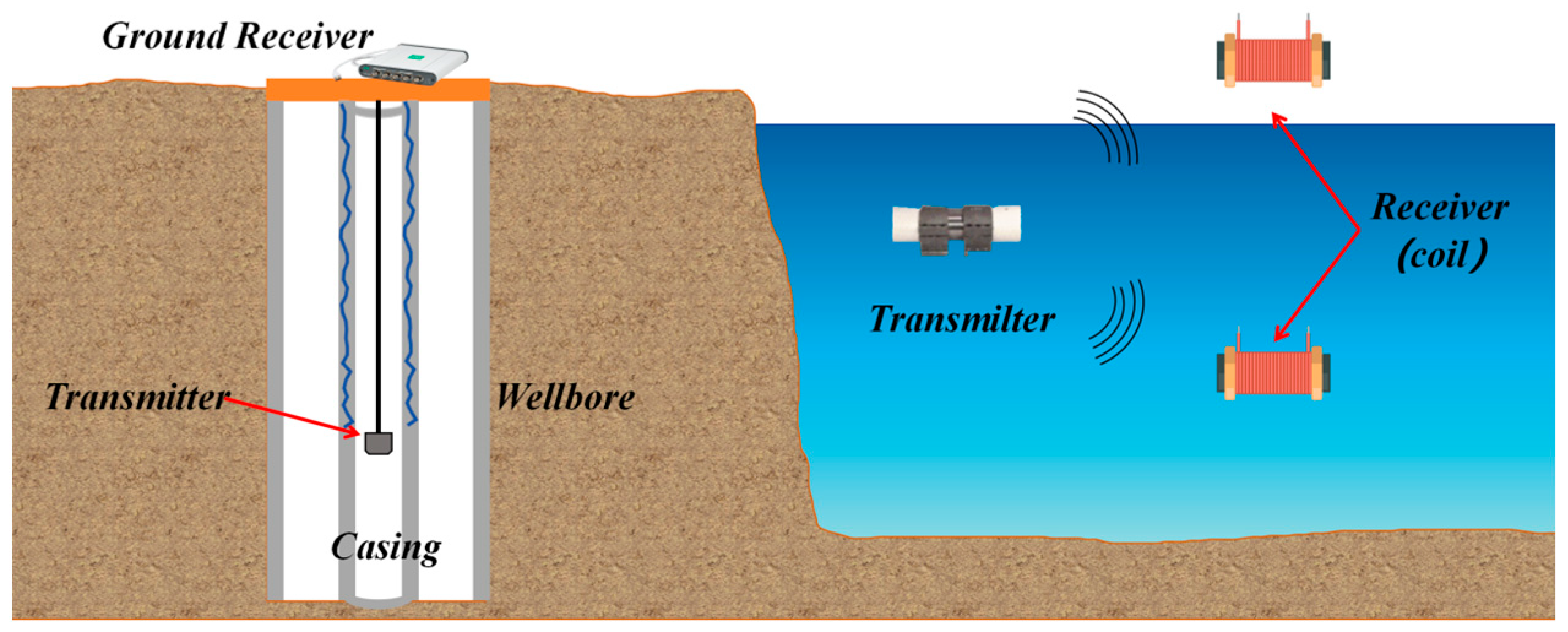

- Electromagnetic Communication

- Acoustic Communication

- Optical Communication

4.2. Engineering Early Warning Platform

5. Discussion

- Sensor device stability and operational lifespan

- 2.

- Biofouling and environmental adaptability of devices

- 3.

- Electromagnetic compatibility (EMC) issues

- 4.

- Packaging and cost

- 5.

- On-site calibration

- 6.

- Lack of standardization and certification

6. Future Perspectives

- At present, mechanical sensors, especially piezoresistive, capacitive, and piezoelectric types, are relatively mature in both fabrication and monitoring applications. Future developments should focus on miniaturization and modularization, enabling integration into underwater robots and autonomous underwater vehicles [214]. For instance, the operational position of an underwater robot can be determined from the pressure and voltage readings of these sensors. Miniaturized and modular sensors will facilitate more convenient deployment in underwater robotics and other equipment.

- Optical sensors generally exhibit high resistance to temperature and pressure, as well as strong immunity to electromagnetic interference, making them particularly suitable for monitoring equipment conditions in the confined spaces of oil and gas wells. In addition, their excellent compatibility with optical fiber communication enables low-loss transmission of monitoring data. Due to their high sensitivity, optical sensors can detect minute changes in strain, temperature, and pressure, making them well-suited for monitoring pipeline leaks, structural corrosion, and fatigue [215]. These characteristics make optical sensors highly valuable for energy security and industrial safety applications.

- Acoustic sensors, particularly high-frequency types, offer unique advantages for underwater structural health monitoring and acoustic detection. By optimizing sensor design, sound wave penetration can be enhanced, enabling the detection of more complex interfaces. These sensors are suitable for monitoring the health of underwater support structures on deep-sea and offshore platforms. With the expansion of offshore wind power, high-frequency acoustic sensors can also be applied to monitor the structural integrity of wind turbine foundations, ensuring safe and long-term operation of underwater components [216]. This provides new technical solutions for the operation, maintenance, and intelligent monitoring of underwater parts of renewable energy equipment.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Technology Type | Included Literature |

|---|---|

| Mechanical sensors | [74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104] |

| Optical sensors | [105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134] |

| Acoustic sensors | [135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156] |

| Wired transmission | [162,163,164,165,166,167,168,169,170,171] |

| Wireless transmission | [172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190] |

| Engineering early warning platform | [191,192,193,194,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210] |

| Application Environment | Included Literature |

|---|---|

| Oil and gas well environment | [32,33,60,72,73,75,76,77,78,80,104,118,121,122,124,125,128,164,168,176,177,178,206,207] |

| Underwater environment | [56,59,74,84,86,87,91,94,99,101,102,114,115,120,129,133,141,143,144,145,146,148,150,151,154,155,165,169,170,171,172,173,174,175,179,180,184,185,186,187,188,189,190,191,192,193,194,197,208,209,210] |

| Underground environments such as mines and tunnels | [26,27,28,29,31,34,35,57,58,61,79,153,166,167,181,182,183,199,200,201,202,203,204,205] |

| Other specialized domains, including high-temperature radiation conditions and aerospace applications | [82,83,88,89,92,96,98,100,117,123,130,131,147,196] |

References

- Prakashan, D.; Kaushik, A.; Gandhi, S. Smart sensors and wound dressings: Artificial intelligence-supported chronic skin monitoring—A review. Chem. Eng. J. 2024, 497, 154371. [Google Scholar]

- Prakash, C.; Singh, L.P.; Gupta, A.; Lohan, S.K. Advancements in smart farming: A comprehensive review of IoT, wireless communication, sensors, and hardware for agricultural automation. Sens. Actuators A Phys. 2023, 362, 114605. [Google Scholar]

- Hong, Q.; Liu, T.; Guo, X.; Yan, Z.; Li, W.; Liu, L.; Wang, D.; Hong, W.; Qian, Z.; Zhang, A.; et al. 3D dual-mode tactile sensor with decoupled temperature and pressure sensing: Toward biological skins for wearable devices and smart robotics. Sens. Actuators B Chem. 2024, 404, 135255. [Google Scholar] [CrossRef]

- Liu, T.; Zhu, C.; Wu, W.; Liao, K.; Gong, X.; Sun, Q.; Li, R.K.Y. Facilely prepared layer-by-layer graphene membrane-based pressure sensor with high sensitivity and stability for smart wearable devices. J. Mater. Sci. Technol. 2020, 45, 241–247. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, Z.; Ruan, H.; Li, Y. High conductivity, low-hysteresis, flexible PVA hydrogel multi-functional sensors: Wireless wearable sensor for health monitoring. Chem. Eng. J. 2025, 505, 158877. [Google Scholar]

- Ion, M.; Dinulescu, S.; Firtat, B.; Savin, M.; Ionescu, O.N.; Moldovan, C. Design and fabrication of a new wearable pressure sensor for blood pressure monitoring. Sensors 2021, 21, 2075. [Google Scholar] [CrossRef]

- Ramírez-Moreno, M.A.; Keshtkar, S.; Padilla-Reyes, D.A.; Ramos-López, E.; García-Martínez, M.; Hernández-Luna, M.C.; Mogro, A.E.; Mahlknecht, J.; Huertas, J.I.; Peimbert-García, R.E.; et al. Sensors for Sustainable Smart Cities: A Review. Appl. Sci. 2021, 11, 8198. [Google Scholar] [CrossRef]

- Chen, S.; Chou, H.; Huang, C.; Chen, C.; Li, L.; Huang, C.; Chen, Y.; Tang, J.; Chang, W.; Huang, J. An Intelligent Water Monitoring IoT System for Ecological Environment and Smart Cities. Sensors 2023, 23, 8540. [Google Scholar] [CrossRef]

- Pascale, A.; Guarnaccia, C.; Macedo, E.; Fernandes, P.; Miranda, A.I.; Sargento, S.; Coelho, M.C. Road traffic noise monitoring in a Smart City: Sensor and Model-Based approach. Transp. Res. D Transp. Environ. 2023, 125, 103979. [Google Scholar]

- Poupry, S.; Medjaher, K.; Béler, C. Data reliability and fault diagnostic for air quality monitoring station based on low cost sensors and active redundancy. Measurement 2023, 223, 113800. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Rashidi, M.; Mashiri, F.; Aslani, F.; Ayubirad, M.S. Application of self-sensing concrete sensors for bridge monitoring—A review of recent developments, challenges, and future prospects. Measurement 2025, 245, 116543. [Google Scholar]

- Wu, J.; Ye, S.; Wang, Z.; Yang, D. Application and Automatic Monitoring and Analysis of Hybrid Support Structure in Ultra-DEEP Foundation Pit Engineering in the Lanzhou Area under Complex Environmental Conditions. Water 2023, 15, 1335. [Google Scholar] [CrossRef]

- Yurovsky, Y.Y.; Dulov, V.A. MEMS-based wave buoy: Towards short wind-wave sensing. Ocean. Eng. 2020, 217, 108043. [Google Scholar] [CrossRef]

- Majumder, A.; Losito, M.; Paramasivam, S.; Kumar, A.; Gatto, G. Buoys for marine weather data monitoring and LoRaWAN communication. Ocean. Eng. 2024, 313, 119521. [Google Scholar] [CrossRef]

- Yin, B.; Jiang, Z.; Liu, S.; Sang, G.; Lv, Y.; Wang, M.; Xiao, S.; Wu, B.; Wang, Q.; Pei, L.; et al. Simultaneous measurement of underwater temperature and pH based on composite F-P fiber interference sensor coated by SCA-PVA/GO hybrid multilayer structure. Measurement 2025, 242, 116237. [Google Scholar] [CrossRef]

- Venkatesan, R.; Ramesh, K.; Arul Muthiah, M.; Thirumurugan, K.; Atmanand, M.A. Analysis of drift characteristic in conductivity and temperature sensors used in Moored buoy system. Ocean. Eng. 2019, 171, 151–156. [Google Scholar] [CrossRef]

- Martínez-Osuna, J.F.; Ocampo-Torres, F.J.; Gutiérrez-Loza, L.; Valenzuela, E.; Castro, A.; Alcaraz, R.; Rodríguez, C.; Ulloa, L.R. Coastal buoy data acquisition and telemetry system for monitoring oceanographic and meteorological variables in the Gulf of Mexico. Measurement 2021, 183, 109841. [Google Scholar] [CrossRef]

- Noufal, K.K.; Sanjana, M.C.; Latha, G.; Raguraman, G.; Arul Muthiah, M. Rainfall estimation through ambient noise measurements in the deep waters of the southeast Arabian Sea. Measurement 2025, 242, 115793. [Google Scholar] [CrossRef]

- McPhaden, M.J.; Connell, K.J.; Foltz, G.R.; Perez, R.C.; Grissom, K. Tropical Ocean Observations for Weather and Climate. Oceanography 2023, 36, 32–43. [Google Scholar]

- Yuan, Y.; Jia, H.; Xu, D.; Wang, J. Novel method in emerging environmental contaminants detection: Fiber optic sensors based on microfluidic chips. Sci. Total Environ. 2023, 857, 159563. [Google Scholar] [CrossRef]

- Hojjati-Najafabadi, A.; Mansoorianfar, M.; Liang, T.; Shahin, K.; Karimi-Maleh, H. A review on magnetic sensors for monitoring of hazardous pollutants in water resources. Sci. Total Environ. 2022, 824, 153844. [Google Scholar] [CrossRef] [PubMed]

- Sandra, M.; Devriese, L.I.; Booth, A.M.; De Witte, B.; Everaert, G.; Gago, J.; Galgani, F.; Langedock, K.; Lusher, A.; Maes, T.; et al. A systematic review of state-of-the-art technologies for monitoring plastic seafloor litter. J. Ocean. Eng. Sci. 2023, in press. [Google Scholar] [CrossRef]

- Yuan, A.; Wang, B.; Li, J.; Lee, J.H.W. A low-cost edge AI-chip-based system for real-time algae species classification and HAB prediction. Water Res. 2023, 233, 119727. [Google Scholar] [CrossRef]

- Vander Woude, A.; Ruberg, S.; Johengen, T.; Miller, R.; Stuart, D. Spatial and temporal scales of variability of cyanobacteria harmful algal blooms from NOAA GLERL airborne hyperspectral imagery. J. Great Lakes Res. 2019, 45, 536–546. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, L.; Yan, X.; Wang, L.; Ma, R.; Qi, X.; Wang, S.; Mao, X. Emerging roles of the aptasensors as superior bioaffinity sensors for monitoring shellfish toxins in marine food chain. J. Hazard. Mater. 2022, 421, 126690. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhu, H.; Jiang, X.; Broere, W. Distributed fiber optic sensors for tunnel monitoring: A state-of-the-art review. J. Rock. Mech. Geotech. 2024, 16, 3841–3863. [Google Scholar] [CrossRef]

- Gómez, J.; Casas, J.R.; Villalba, S. Structural Health Monitoring with Distributed Optical Fiber Sensors of tunnel lining affected by nearby construction activity. Automat Constr. 2020, 117, 103261. [Google Scholar] [CrossRef]

- Liu, S.; Li, Y.; Zhang, Y.; Ma, M.; Qiu, W.; She, L.; Zhou, H.; Li, K.; Sun, K. Monitoring the circumferential cracking of inner concrete core in prestressed concrete cylinder pipe during wire-wrapping using distributed optical fiber sensors. Tunn. Undergr. Sp. Technol. 2025, 157, 106330. [Google Scholar] [CrossRef]

- Johnson Singh, M.; Choudhary, S.; Chen, W.; Wu, P.; Kumar Goyal, M.; Rajput, A.; Borana, L. Applications of fibre Bragg grating sensors for monitoring geotechnical structures: A comprehensive review. Measurement 2023, 218, 113171. [Google Scholar] [CrossRef]

- Acharya, A.; Kogure, T. Advances in fibre-optic-based slope reinforcement monitoring: A review. J. Rock. Mech. Geotech. 2025, 17, 1263–1284. [Google Scholar] [CrossRef]

- Sheikh, M.R.; Nakata, Y.; Shitano, M.; Kaneko, M. Rainfall-induced unstable slope monitoring and early warning through tilt sensors. Soils Found. 2021, 61, 1033–1053. [Google Scholar] [CrossRef]

- Seren, H.R.; Buzi, E.; Al-Maghrabi, L.; Ham, G.; Bernero, G.; Deffenbaugh, M. An Untethered Sensor Platform for Logging Vertical Wells. IEEE T Instrum. Meas. 2018, 67, 798–803. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, Q.; Peng, W. Fiber-optic Fabry–Perot pressure sensor for down-hole application. Opt. Laser Eng. 2019, 121, 289–299. [Google Scholar] [CrossRef]

- Liu, T.; Wei, Y.; Song, G.; Hu, B.; Li, L.; Jin, G.; Wang, J.; Li, Y.; Song, C.; Shi, Z.; et al. Fibre optic sensors for coal mine hazard detection. Measurement 2018, 124, 211–223. [Google Scholar] [CrossRef]

- Sadeghi, S.; Soltanmohammadlou, N.; Nasirzadeh, F. Applications of wireless sensor networks to improve occupational safety and health in underground mines. J. Safety Res. 2022, 83, 8–25. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yang, Y.; Wang, Y.; Huo, J.; Wan, N.; Zhao, Y.; Lyu, Y.; Zhao, Y.; Liu, M. High-Sensitivity 4H-Silicon Carbide MEMS Pressure Sensors for Extreme Temperature Ranges of-75 °C to 600 °C. IEEE Trans. Instrum. Meas. 2025, 74, 9522010. [Google Scholar] [CrossRef]

- Gan, L.; Xu, Y.; Cai, Y.; Zhou, Y. A high sensitivity flexible stretchable fiber optic sensor based on the waveguide loss principle. IEEE Trans. Instrum. Meas. 2024, 74, 7000907. [Google Scholar] [CrossRef]

- Li, H.; Liu, G.; Zhang, G.; Cui, J.; Yang, Y.; He, C.; Jia, L.; Qin, L.; Zhang, W.; Wang, R. A Novel Bionic MEMS Vector Hydrophone based on Ultralow Frequency Detection. IEEE Trans. Instrum. Meas. 2025, 74, 9522716. [Google Scholar] [CrossRef]

- Hassan, A.; Savaria, Y.; Sawan, M. Electronics and Packaging Intended for Emerging Harsh Environment Applications: A Review. IEEE Trans. VLSI Syst. 2018, 26, 2085–2098. [Google Scholar] [CrossRef]

- Moser, M.; Pradhan, M.; Emal, I.U.H.; Bastia, S.; Kaschel, M.; Edelmann, K.; Kallfass, I.; Burghartz, J.N. Low-power AlGaN/GaN pressure sensors for harsh environmental conditions with high sensitivity. Power Electron. Devices Compon. 2025, 10, 100076. [Google Scholar] [CrossRef]

- Wang, X.; Lim, E.G.; Hoettges, K.; Song, P. A Review of Carbon Nanotubes, Graphene and Nanodiamond Based Strain Sensor in Harsh Environments. C 2023, 9, 108. [Google Scholar] [CrossRef]

- Li, Y.; Villada, A.; Lu, S.; Sun, H.; Xiao, J.; Wang, X. Soft, flexible pressure sensors for pressure monitoring under large hydrostatic pressure and harsh ocean environments. Soft Matter 2023, 19, 5772–5780. [Google Scholar] [CrossRef]

- Cui, Y.; Li, X.; Zhang, T.; Ding, W.; Yin, J. Development of High-Temperature Wire-Grid Thin Film Strain Gauges. Sensors 2022, 22, 7595. [Google Scholar] [CrossRef]

- Zhang, C.; Li, A.; Huang, J.; Zhang, J.; Huang, H.; Su, Y.; Wang, L.; Liu, Y.; Chen, D.; Tian, F.; et al. Calibration-free low-drift MEMS piezoelectric accelerometer for high-temperature vibration monitoring. Measurement 2025, 257, 118694. [Google Scholar] [CrossRef]

- Xu, J.; Lu, H.; Cai, L.; Liao, Y.; Lian, J. Surface Protection Technology for Metallic Materials in Marine Environments. Materials 2023, 16, 6822. [Google Scholar] [CrossRef]

- Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R. Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors 2019, 19, 3964. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Zhang, J.; Ye, Z.; Fu, L.; Zhang, B.; Belhora, F. Low frequency vibration monitoring of wind turbine tower based on optical fiber sensor and its potential for internet of things. Sens. Actuators A Phys. 2024, 379, 115891. [Google Scholar] [CrossRef]

- Parida, K.; Bhavanasi, V.; Kumar, V.; Bendi, R.; Lee, P.S. Self-powered pressure sensor for ultra-wide range pressure detection. Nano Res. 2017, 10, 3557–3570. [Google Scholar] [CrossRef]

- Zhou, M.; Zhou, S.; Zhou, Z.; Jiang, S.; Zhang, W. Design, fabrication, and thermal zero drift compensation of a SOI pressure sensor for high temperature applications. Sens. Actuators A Phys. 2025, 382, 116151. [Google Scholar] [CrossRef]

- Jia, Z.; Chen, G.; Zhang, J.; Weng, Y.; Wang, X.; Chen, J.; Dong, A.; Zhang, F.; Xu, H.; Li, L.; et al. A Self-Check Method for Enhancing the Measurement Accuracy of Analog Sensors Under Electromagnetic Interference. IEEE Trans. Instrum. Meas. 2025, 74, 9502913. [Google Scholar] [CrossRef]

- Kim, S.; Lee, E.; Hong, I.; Yook, J. Review of Intentional Electromagnetic Interference on UAV Sensor Modules and Experimental Study. Sensors 2022, 22, 2384. [Google Scholar] [CrossRef]

- Cui, Y.; Jiang, J. Analysis on Anti-Interference Performance of Sensor in Explosive Electromagnetic Environment. IEEE Sens. J. 2024, 24, 2895–2904. [Google Scholar] [CrossRef]

- Anjana, K.; Herath, M.; Epaarachchi, J. Optical fibre sensors for geohazard monitoring—A review. Measurement 2024, 235, 114846. [Google Scholar] [CrossRef]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, technology and applications of piezoresistive sensors: A review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Ali, W.R.; Prasad, M. Piezoelectric MEMS based acoustic sensors: A review. Sens. Actuators A Phys. 2020, 301, 111756. [Google Scholar] [CrossRef]

- Qin, L.; Lu, Y.; Xu, Y.; He, W. The calibration methods of hydrophones for underwater environmental sound measurements or biomedical ultrasound measurements: A review. Measurement 2025, 242, 115700. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, M.; Wang, K.; Fu, G. A dynamic information platform for underground coal mine safety based on internet of things. Safety Sci. 2019, 113, 9–18. [Google Scholar] [CrossRef]

- Ikeda, H.; Kolade, O.; Cheng, L.; Cawood, F.; Kawamura, Y. Development of underground communication system for data transmission using Wi-Fi direct and power line communication. Tunn. Undergr. Sp. Technol. 2024, 153, 106047. [Google Scholar] [CrossRef]

- Esmaiel, H.; Sun, H. Underwater Wireless Communications. Sensors 2024, 24, 7075. [Google Scholar] [CrossRef]

- Lakal, N.; Shehri, A.H.; Brashler, K.W.; Wankhede, S.P.; Morse, J.; Du, X. Sensing technologies for condition monitoring of oil pump in harsh environment. Sens. Actuators A Phys. 2022, 346, 113864. [Google Scholar] [CrossRef]

- Li, J.; Zhan, K. Intelligent Mining Technology for an Underground Metal Mine Based on Unmanned Equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Yao, F.; Ji, Y.; Tong, W.; Li, H.X.; Liu, G. Sensing technology based quality control and warning systems for sleeve grouting of prefabricated buildings. Autom. Constr. 2021, 123, 103537. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, Q.; Zhang, X.; Kuang, M. Materials and sensing mechanisms for high-temperature pressure sensors: A review. IEEE Sens. J. 2023, 23, 26910–26924. [Google Scholar] [CrossRef]

- Shi, Y.; Li, X.; Wang, P.; Zhang, Y.; Shi, B.; Li, Y. A review: Salinity and temperature measurement based on optical fiber sensors. Sens. Actuators A Phys. 2024, 380, 116040. [Google Scholar] [CrossRef]

- Mujahid, A.; Afzal, A.; Dickert, F.L. An overview of high frequency acoustic sensors—QCMs, SAWs and FBARs—Chemical and biochemical applications. Sensors 2019, 19, 4395. [Google Scholar] [CrossRef]

- Zhao, Y.; Miao, L.; Xiao, Y.; Sun, P. Research progress of flexible piezoresistive pressure sensor: A review. IEEE Sens. J. 2024, 24, 31624–31644. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, H.; Liang, J.; Zhang, Q.; Li, Y.; Song, T.; Li, Z.; Li, B.; Zang, J.; Zhang, Z. Wearable capacitive sensor based on ionic gels and a multi-channel sensor array for space mapping of pressure. IEEE Sens. J. 2025, 25, 21134–21140. [Google Scholar] [CrossRef]

- Li, Y.; Lin, H.; Lin, J.; Zhou, C.; Luo, A.; Yang, J.; Zhang, J.; Hong, Z.; Hou, X.; Xiao, P.; et al. Thermally stable piezoelectric sensors for quantitative pressure sensing based on linear piezoelectric zinc oxide thin films. Mater. Design 2023, 235, 112466. [Google Scholar] [CrossRef]

- Alcheikh, N.; Hajjaj, A.Z.; Younis, M.I. Highly sensitive and wide-range resonant pressure sensor based on the veering phenomenon. Sens. Actuators A Phys. 2019, 300, 111652. [Google Scholar] [CrossRef]

- Yao, W.; Zhan, L.; Rooke, S.S.; Vizas, C.; Kaybulkin, V.; King, T.J.; Xiao, B.; Li, Z.; Liu, Y.; Yin, H. Intensity-modulated fiber-optic sensor: A novel grid measurement unit. IEEE Trans. Ind. Inform. 2022, 19, 5566–5575. [Google Scholar] [CrossRef]

- Ren, Z.; Cui, K.; Li, J.; Zhu, R.; Peng, W.; Qian, J. A high-quality phase modulation scheme with strong noise-suppressing capability for interferometric fiber-optic sensor applications. Opt. Laser Eng. 2019, 118, 34–41. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Zhao, Q.; Che, C. Real-time monitoring of pressure and temperature of oil well using a carbon-coated and bellow-packaged optical fiber sensor. Opt. Fiber Technol. 2021, 67, 102703. [Google Scholar] [CrossRef]

- Yang, Y.; Fan, J.; Wu, S.; Liu, D.; Ma, F. Multi-acoustic-wave-feature-based method for detection and quantification of downhole tubing leakage. J. Nat. Gas. Sci. Eng. 2022, 102, 104582. [Google Scholar] [CrossRef]

- Lata, A.; Maurya, P.; Sarkar, R.; Mandal, N. Design of a Hydrostatic Liquid Level Wireless Transmitter for Efficient Level Measurement. IEEE Sens. J. 2024, 24, 8105–8113. [Google Scholar] [CrossRef]

- Wu, C.; Fang, X.; Kang, Q.; Fang, Z.; Wu, J.; He, H.; Zhang, D.; Zhao, L.; Tian, B.; Maeda, R.; et al. Exploring the nonlinear piezoresistive effect of 4H-SiC and developing MEMS pressure sensors for extreme environments. Microsyst. Nanoeng. 2023, 9, 41. [Google Scholar] [CrossRef]

- Shu, Y.; Hua, C.; Zhao, Z.; Wang, P.; Zhang, H.; Yu, W.; Yu, H. Temperature Compensation Method Based on Bilinear Interpolation for Downhole High-Temperature Pressure Sensors. Sensors 2024, 24, 5123. [Google Scholar] [CrossRef] [PubMed]

- Su, W.; Ren, W.; Han, X.; Hua, Y.; Mu, X.; Huang, M.; Chen, S.; Wang, S.; Cui, Z.; Zhao, L. Thermal Compensation System for Silicon Piezoresistive Pressure Sensors Based on Surface Fitting and Wild Horse Algorithm. IEEE Sens. J. 2024, 24, 10347–10354. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Y.; Wei, G.; Pang, L.; Xu, C. A comprehensive compensation method for piezoresistive pressure sensor based on surface fitting and improved grey wolf algorithm. Measurement 2023, 207, 112387. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, F.; Wang, X.; Liang, X.; Guo, Z.; Luo, X.; Deng, J.; Zhang, X.; Luo, J.; Ma, B. A diaphragm secondary stress utilization method for increasing the sensitivity of piezoresistive pressure sensors without sacrificing linearity. Measurement 2025, 242, 116271. [Google Scholar] [CrossRef]

- Guo, Z.; Song, Z.; Guo, Z.; Zhou, F. Design and implementation of a kind of high precision temperature compensating system for silicon-on-sapphire pressure sensor. Measurement 2024, 226, 114119. [Google Scholar] [CrossRef]

- Aryafar, M.; Hamedi, M.; Ganjeh, M.M. A novel temperature compensated piezoresistive pressure sensor. Measurement 2015, 63, 25–29. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Li, H.; Wang, J.; Wang, Y.; Cheng, F.; Han, H.; Zhang, P. A Review of SiC Sensor Applications in High-Temperature and Radiation Extreme Environments. Sensors 2024, 24, 7731. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Liu, X.; Luo, S.; Jiang, X.; Yang, D.; Yuan, W. Design and Numerical Simulation of Capacitive Pressure Sensor Based on Silicon Carbide. IEEE Sens. J. 2023, 23, 30535–30545. [Google Scholar] [CrossRef]

- Wang, H.; Ruan, D.; Gan, L.; Shen, Z.; Zhuo, J.; Chen, X.; Zhou, F.; Jia, Z.; Li, T.; Hu, H. A Capacitive Pressure Sensor with Adjustable Working Range for Deep Sea. IEEE Sens. J. 2024, 24, 37005–37014. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Q.; Liu, Q.; Zhang, Y.; He, L.; Xia, Y.; Wang, Z.; Xia, C.; Huang, Y. Study of a novel capacitive pressure sensor using spiral comb electrodes. Meas. Sci. Technol. 2024, 35, 125111. [Google Scholar] [CrossRef]

- Wang, D.; Tang, E.; Li, L.; Peng, H.; Han, Y.; Chen, C.; Chang, M.; Guo, K.; He, L. Temperature and pressure propagation characteristics in multi-media interfaces of PVDF pressure sensor near underwater explosion source. Ocean. Eng. 2023, 287, 115810. [Google Scholar] [CrossRef]

- Krause, T.; Meier, M.; Brunzendorf, J. Influence of thermal shock of piezoelectric pressure sensors on the measurement of explosion pressures. J. Loss Prev. Proc. 2021, 71, 104523. [Google Scholar] [CrossRef]

- Kim, N.; Chang, Y.; Chen, J.; Barbee, T.; Wang, W.; Kim, J.; Kwon, M.; Shervin, S.; Moradnia, M.; Pouladi, S.; et al. Piezoelectric pressure sensor based on flexible gallium nitride thin film for harsh-environment and high-temperature applications. Sens. Actuators A Phys. 2020, 305, 111940. [Google Scholar] [CrossRef]

- Du, S.; Zhou, J.; Li, F. Dynamic deformation monitoring of cantilever beams using piezoelectric sensors: Theory and experiment. Measurement 2024, 227, 114305. [Google Scholar] [CrossRef]

- Liu, Z.; Cai, G.; Wang, J.; Liu, L.; Zhuang, H. Evaluation of mechanical and electrical properties of a new sensor-enabled piezoelectric geocable for landslide monitoring. Measurement 2023, 211, 112667. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, C.; Zhao, Y.; Zhang, Z. A Quartz Resonant Ultra-High Pressure Sensor With High Precision and High Stability. IEEE Sens. J. 2021, 21, 22553–22561. [Google Scholar] [CrossRef]

- Cheng, C.; Lu, Y.; Yao, J.; Chen, J.; Chen, D.; Wang, J. Development of a new MEMS resonant differential pressure sensor with high accuracy and high stability. Measurement 2024, 226, 114080. [Google Scholar] [CrossRef]

- Pham, T.T.; Zhang, H.; Yenuganti, S.; Kaluvan, S.; Kosinski, J.A. Design, Modeling, and Experiment of a Piezoelectric Pressure Sensor Based on a Thickness-Shear-Mode Crystal Resonator. IEEE Trans. Ind. Electron. 2017, 64, 8484–8491. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y.; Zhang, Z.; Jing, J.; Yao, B.; Gao, L.; Xue, C.; Tian, Z. Dual-mode AT-cut quartz resonant pressure sensor for wide pressure and temperature measurement ranges. Sens. Actuators A Phys. 2025, 382, 116103. [Google Scholar] [CrossRef]

- ASTM E1742; Standard Practice for Radiographic Examination of Weldments. ASTM International: West Conshohocken, PA, USA, 2020.

- Yenuganti, S.; Zhang, H.; Zhang, C. Langasite crystal based pressure sensor with temperature compensation. Sens. Actuators A Phys. 2018, 281, 108–116. [Google Scholar] [CrossRef]

- Han, D.; Yuan, S.; Feng, C.; Yang, T. A self-temperature compensation barometer based on all-quartz resonant pressure sensor. Sensors 2024, 24, 2460. [Google Scholar] [CrossRef]

- Wu, C.; Pan, X.; Lin, F.; Cui, Z.; He, Y.; Chen, G.; Zeng, Y.; Liu, X.; Chen, Q.; Sun, D.; et al. TiB2/SiCN Thin-Film Strain Gauges Fabricated by Direct Writing for High-Temperature Application. IEEE Sens. J. 2022, 22, 11517–11525. [Google Scholar] [CrossRef]

- Yang, N.; Yin, X.; Liu, H.; Zhou, X.; Yan, X.; Zhao, Y.; Cheng, T. A Multifunctional and Waterproof Wearable Microneedle Piezoresistive Sensor Based on CNT/CB/PDMS With Wide Temperature Range. IEEE Trans. Instrum. Meas. 2024, 73, 9519209. [Google Scholar] [CrossRef]

- Li, C.; Sun, B.; Jia, P.; Xue, Y.; Jia, M.; Xiong, J. Capacitive Pressure Sensor With Integrated Signal-Conversion Circuit for High-Temperature Applications. IEEE Access 2020, 8, 212787–212793. [Google Scholar] [CrossRef]

- Hosseini, E.S.; Chakraborty, M.; Roe, J.; Petillot, Y.; Dahiya, R.S. Porous elastomer based wide range flexible pressure sensor for autonomous underwater vehicles. IEEE Sens. J. 2022, 22, 9914–9921. [Google Scholar] [CrossRef]

- Riccioli, F.; Huijer, A.; Grasso, N.; Rizzo, C.M.; Pahlavan, L. Development of a retrofit layer with an embedded array of piezoelectric sensors for transient pressure measurement in maritime applications. Mar. Struct. 2023, 89, 103395. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Cheng, Z.; Du, X.; Wang, L. Low Temperature Coefficient and Large Range Pressure Sensor Based on Single End Fixed-Support U-Beam Resonator. IEEE Sens. J. 2024, 24, 35413–35422. [Google Scholar] [CrossRef]

- Ye, P.; Yu, Z.; Tan, Z.; Xie, B.; Lu, Y.; Chen, D.; Wang, J. Extreme Environment-Compatible silicon resonant pressure sensors with high precision and reliability. Measurement 2025, 256, 118275. [Google Scholar] [CrossRef]

- Wang, B.; Niu, Y.; Qin, X.; Yin, Y.; Ding, M. Review of high temperature measurement technology based on sapphire optical fiber. Measurement 2021, 184, 109868. [Google Scholar] [CrossRef]

- Chen, K.; Yang, B.; Deng, H.; Guo, M.; Zhang, B.; Yang, Y.; Liu, S.; Zhao, Y.; Peng, W.; Yu, Q. Simultaneous measurement of acoustic pressure and temperature using a Fabry-Perot interferometric fiber-optic cantilever sensor. Opt. Express 2020, 28, 15050–15061. [Google Scholar] [CrossRef]

- Jayawickrema, U.M.N.; Herath, H.M.C.M.; Hettiarachchi, N.K.; Sooriyaarachchi, H.P.; Epaarachchi, J.A. Fibre-optic sensor and deep learning-based structural health monitoring systems for civil structures: A review. Measurement 2022, 199, 111543. [Google Scholar] [CrossRef]

- He, X.; Pan, Y.; You, H.; Lu, Z.; Gu, L.; Liu, F.; Yi, D.; Zhang, M. Fibre optic seismic sensor for down-well monitoring in the oil industry. Measurement 2018, 123, 145–149. [Google Scholar] [CrossRef]

- Reja, M.I.; Nguyen, L.V.; Ebendorff-Heidepriem, H.; Warren-Smith, S.C. Multipoint pressure sensing at up to 900 °C using a fiber optic multimode interferometer. Opt. Fiber Technol. 2023, 75, 103157. [Google Scholar] [CrossRef]

- Yi, X.; Li, Y.; Zhao, K.; Wu, Z.; Wang, Q.; Liu, B.; Buric, M.; Wright, R.; Chen, K.P. CO2Laser Tapering of Intrinsic Fabry–Perot Interferometers for Sensing. IEEE Sens. J. 2023, 23, 5824–5830. [Google Scholar] [CrossRef]

- Wang, M.; Yang, Y.; Huang, S.; Wu, J.; Zhao, K.; Li, Y.; Peng, Z.; Zou, R.; Lan, H.; Ohodnicki, P.R.; et al. Multiplexable high-temperature stable and low-loss intrinsic Fabry-Perot in-fiber sensors through nanograting engineering. Opt. Express 2020, 28, 20225–20235. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.; Chen, Z.; Lin, X.; Yang, H.; Zhang, X. A breathing rate sensor with diaphragm-based Fabry-Perot interferometer. Opt. Fiber Technol. 2025, 90, 104098. [Google Scholar] [CrossRef]

- Zhu, X.; Li, K.; Qu, H.; Hu, X. Advancements in fiber optic tactile sensors: A comprehensive review on principles, fabrication, and applications. Opt. Laser Eng. 2025, 186, 108777. [Google Scholar] [CrossRef]

- Li, G.; Yang, S.; Wu, C. Seeing more clearly: Improving the resolution of ocean salinity measurements using a Fabry-Perot resonant cavity. Opt. Laser Eng. 2024, 181, 108356. [Google Scholar] [CrossRef]

- Wang, W.; Duan, S.; Xiong, L.; Liu, B.; Yao, Y.; Lin, W.; Zhang, H.; Liu, H.; Wu, J. Hybrid structured fiber-optic Fabry–Pérot interferometer for simultaneous bicarbonate and temperature measurements. Opt. Laser Technol. 2024, 175, 110752. [Google Scholar] [CrossRef]

- Ma, C.; Chen, Y.; Qu, W.; Peng, D.; Bai, X.; Liu, S.; Luo, L. High-sensitivity fiber temperature and pressure sensor based on fabry-perot interferometry and Vernier effect. Opt. Laser Technol. 2025, 181, 111999. [Google Scholar] [CrossRef]

- Li, J.; Jia, P.; Fang, G.; Wang, J.; Qian, J.; Ren, Q.; Xiong, J. Batch-producible all-silica fiber-optic Fabry–Perot pressure sensor for high-temperature applications up to 800 °C. Sens. Actuators A Phys. 2022, 334, 113363. [Google Scholar] [CrossRef]

- Hu, Y.; Cao, L.; Nie, S.; Liu, Q.; Xie, F.; Peng, X.; Zhu, Y.; Han, J.; Chen, X.; Wang, L.; et al. MEMS Fabry-Perot sensor for accurate high pressure measurement up to 10 MPa. Opt. Express 2024, 32, 37059–37072. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L. Fiber Optic Fabry-Perot Sensor with Stabilization Technology for Acoustic Emission Detection of Partial Discharge. In Proceedings of the 2018 International Conference on High Voltage Engineering and Application, ICHVE, Athens, Greece, 10–13 September 2018; IEEE: New York, NY, USA, 2018; pp. 1–4. [Google Scholar]

- Min, R.; Liu, Z.; Pereira, L.; Yang, C.; Sui, Q.; Marques, C. Optical fiber sensing for marine environment and marine structural health monitoring: A review. Opt. Laser Technol. 2021, 140, 107082. [Google Scholar] [CrossRef]

- Qiao, X.; Shao, Z.; Bao, W.; Rong, Q. Fiber Bragg Grating Sensors for the Oil Industry. Sensors 2017, 17, 429. [Google Scholar] [CrossRef]

- Xu, D.; Feng, D.; Chen, Q.; Liu, G.; Qiao, X. Small-sized temperature and pressure sensors based on fiber bragg grating for oil and gas wells. Sens. Actuators A Phys. 2023, 357, 114397. [Google Scholar] [CrossRef]

- Hegde, G.; Prasad, M.V.N.; Asokan, S. Temperature compensated diaphragm based Fiber Bragg Grating (FBG) sensor for high pressure measurement for space applications. Microelectron. Eng. 2021, 248, 111615. [Google Scholar] [CrossRef]

- Feng, D.; Xu, D.; Chen, F.; Chen, Q.; Qiao, X. An FBG Temperature–Pressure Sensor Based on Diaphragm and Special-Shaped Bracket Structure. IEEE Sens. J. 2023, 23, 3589–3596. [Google Scholar] [CrossRef]

- Liu, X.; Liang, L.; Jiang, K.; Xu, G. Sensitivity-Enhanced Fiber Bragg Grating Pressure Sensor Based on a Diaphragm and Hinge-Lever Structure. IEEE Sens. J. 2021, 21, 9155–9164. [Google Scholar] [CrossRef]

- American, P.I. API RP 19B: Evaluation of Well Perforators, 3rd ed.; Addendum 1; American Petroleum Institute: Washington, DC, USA, 2021. [Google Scholar]

- Fan, Q.; Jia, Z.A.; Feng, D.; Yong, Z. Highly sensitive FBG pressure sensor based on square diaphragm. Optik 2021, 225, 165559. [Google Scholar] [CrossRef]

- Liu, M.; Cai, Q.; Song, H. Regional strain homogenized diaphragm based FBG high pressure sensor. Sens. Actuators A Phys. 2023, 355, 114298. [Google Scholar] [CrossRef]

- Liu, M.; Wu, Y.; Du, C.; Jiang, D.; Wang, Z. FBG-Based Liquid Pressure Sensor for Distributed Measurement With a Single Channel in Liquid Environment. IEEE Sens. J. 2020, 20, 9155–9161. [Google Scholar] [CrossRef]

- Egorova, O.N.; Semjonov, S.L.; Zhuravlev, S.G.; Salganskii, M.Y.; Yashkov, M.V.; Ferraro, M. Michelson interferometer based on a fiber with a germanium-doped core and inner cladding for high-temperature sensing. Opt. Fiber Technol. 2024, 88, 104016. [Google Scholar] [CrossRef]

- Guo, J.; Lian, S.; Zhang, Y.; Zhang, Y.; Liang, D.; Yu, Y.; Chen, R.; Du, C.; Ruan, S. High-Temperature Measurement of a Fiber Probe Sensor Based on the Michelson Interferometer. Sensors 2022, 22, 289. [Google Scholar] [CrossRef]

- Wang, P.; Ni, K.; Wang, B.; Ma, Q.; Tian, W. Methylcellulose coated humidity sensor based on Michelson interferometer with thin-core fiber. Sens. Actuators A Phys. 2019, 288, 75–78. [Google Scholar] [CrossRef]

- Wang, X.; Bai, X.; Zhang, M.; Wang, M.; Yang, B.; Wu, C. Optical salinity sensing based on Michaelson interferometer under water pressure up to 11,500 meters. Ocean. Eng. 2024, 299, 117307. [Google Scholar] [CrossRef]

- Bai, X.; Wang, X.; Zhang, M.; Zhao, S.; Wang, M.; Chen, S.; Su, J.; Wu, C. High-Resolution Seawater Density Sensor Based on Michelson Interferometer. IEEE Sens. J. 2024, 24, 40400–40408. [Google Scholar] [CrossRef]

- Moradi, H.; Parvin, P.; Ojaghloo, A.; Shahi, F. Ultrasensitive fiber optic Fabry Pérot acoustic sensor using phase detection. Measurement 2021, 172, 108953. [Google Scholar] [CrossRef]

- Yi-Wu, Z.; Jing, T.; Qing, Y.; Xiao, H.; Yang, J. A low-frequency acoustic sensing scheme based on cladding mode of large-angle tilted fiber Bragg grating. Acta Phys. Sin. 2023, 72, 124304. [Google Scholar] [CrossRef]

- Janneh, M.; Bruno, F.A.; Guardato, S.; Donnarumma, G.P.; Iannaccone, G.; Gruca, G.; Werzinger, S.; Gunda, A.; Rijnveld, N.; Cutolo, A.; et al. Field demonstration of an optical fiber hydrophone for seismic monitoring at Campi-Flegrei caldera. Opt. Laser Technol. 2023, 158, 108920. [Google Scholar] [CrossRef]

- Qu, Z.; Lu, P.; Li, Y.; Fu, X.; Zhang, W.; Liu, D.; Zhang, J. Low-frequency acoustic Fabry–Pérot fiber sensor based on a micromachined silicon nitride membrane. Chin. Opt. Lett. 2020, 18, 101201. [Google Scholar] [CrossRef]

- Gao, Y.; Song, J.; Li, S.; Elowsky, C.; Zhou, Y.; Ducharme, S.; Chen, Y.M.; Zhou, Q.; Tan, L. Hydrogel microphones for stealthy underwater listening. Nat. Commun. 2016, 7, 12316. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, Q.; Fu, T.; Liu, H.; Yao, Y.; Zhou, W.; Zhu, Z. Capacitive Low-Frequency Hydrophone Based on Micronanostructured Iontronic Hydrogel for Underwater Monitoring. Acs Nano 2024, 18, 22010–22020. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, G.J.; Geng, Y.N.; Bai, Z.Y.; Zhang, F.Z.; Zhao, H.; Chen, J.Y.; Hao, J.S.; Wang, R.X.; Jia, L.C.; et al. A novel integrated scalar-vector hydrophone for enhanced low-frequency acoustic detection in marine environments. Measurement 2025, 256, 118216. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Liu, Z.; Sun, M.Z.; Xu, P.; Hu, Z.L.; Zou, Y.C. Bionic cilium-based fiber-optic underwater acoustic sensor enhanced by resonance. Sens. Actuators A Phys. 2025, 393, 118216. [Google Scholar] [CrossRef]

- Wei, H.; Wei, Y.; Zhuang, C.; He, G.; Yang, T.; Zhang, X.; Pang, F.; Wang, T.; Krishnaswamy, S.; Caucheteur, C.; et al. Sensitivity-Enhanced Fiber-Optic Fabry–Perot Ultrasonic Sensor Based on Direct Laser Writing of Dual-Resonant Cavity. IEEE Trans. Instrum. Meas. 2025, 74, 7000706. [Google Scholar] [CrossRef]

- Fu, Y.; Sun, S.; Wang, Z.; Niu, P.; Zhang, M.; Chen, S.; Pang, W. Piezoelectric Micromachined Ultrasonic Transducer With Superior Acoustic Outputs for Pulse-Echo Imaging Application. IEEE Electron Device Lett. 2020, 41, 1572–1575. [Google Scholar] [CrossRef]

- Yao, Y.; Jia, L.; Liu, C.; Wang, X.; Sun, C.; Liu, S.; Wu, G. A transceiver integrated piezoelectric micromachined ultrasound transducer array for underwater imaging. Sens. Actuators A Phys. 2023, 359, 114476. [Google Scholar] [CrossRef]

- Mansouri, S.; Ganji , B.A. Enhancing the Performance of Piezoelectric Micromachined Ultrasonic Transducers Using C Slots. IEEE Sens. J. 2023, 23, 19037–19043. [Google Scholar] [CrossRef]

- Hu, L.; Fu, L.; Ren, X.; Zheng, S.; Wang, S.; Xu, Z.; Yan, Y. High-temperature piezoelectric ultrasonic transducer based on BiScO3-PbTiO3 ceramics. Sens. Actuators A Phys. 2023, 362, 114657. [Google Scholar] [CrossRef]

- Huang, H.M.; Cui, J.G.; Zhang, W.D.; Zhang, G.J.; Wang, R.X.; Yang, Y.H.; Wang, Y.H. A microfiber knot resonator for ultrasonic underwater detection. Opt. Fiber Technol. 2025, 91, 104152. [Google Scholar] [CrossRef]

- Huang, S.L.; Li, W.Y.; Li, Y.; Yu, Y.J.; Liu, Q.; Chen, S.; Liao, J.B. High-Temperature Pipeline Wall Thickness Monitoring Using a Waveguide Sensor Structure Based on Wave Mode Conversion. IEEE Sens. J. 2025, 25, 33579–33586. [Google Scholar] [CrossRef]

- Wang, R.X.; Shen, W.; Zhang, W.J.; Song, J.L.; Li, N.S.; Liu, M.R.; Zhang, G.J.; Xue, C.Y.; Zhang, W.D. Design and implementation of a jellyfish otolith-inspired MEMS vector hydrophone for low-frequency detection. Microsyst. Nanoeng. 2021, 7, 1. [Google Scholar] [CrossRef]

- Yuan, G.Z.; Rong, J.M.; Zhang, D.W.; Xing, E.B.; Liu, W.Y.; Li, L.; Tang, J.; Liu, J. Underwater Low-Frequency Acoustic Wave Detection Based on a High-Q CaF2 Resonator. Machines 2024, 12, 234. [Google Scholar] [CrossRef]

- Ul Reyaz, S.; Beniwal, S. Geometry measurement of subsurface cracks in concrete from ultrasonic images. Measurement 2025, 240, 115624. [Google Scholar] [CrossRef]

- Yin, J.; Wong, V.K.; Xu, Q.W.; Subhodayam, P.; Yousry, Y.M.; Shashidhara, A.; Zhou, J.; Luo, P.; Lim, P.C.; Wei, F.X.; et al. Conformable Shear Mode Transducers from Lead-Free Piezoelectric Ceramic Coatings: An Innovative Ultrasonic Solution for Submerged Structural Health Monitoring. Adv. Funct. Mater. 2024, 34, 2401544. [Google Scholar] [CrossRef]

- Choi, W.Y.; Park, K.K. Array type miniaturized ultrasonic sensors to detect urban sinkholes. Measurement 2019, 141, 371–379. [Google Scholar] [CrossRef]

- Chen, H.; Shao, Z.H.; Hao, Y.X.; Rong, Q.Z. A high-frequency hydrophone using an optical fiber microknot resonator. Opt. Commun. 2019, 446, 77–83. [Google Scholar] [CrossRef]

- Song, J.H.; Guo, D.H.; Jia, J.H.; Tu, S.D. A new on-line ultrasonic thickness monitoring system for high temperature pipes. Int. J. Press. Vessels Pip. 2022, 199, 104691. [Google Scholar] [CrossRef]

- Dao, N.; Tu, N.H.; Thanh, T.T.; Bao, V.N.Q.; Na, W.; Cho, S. Neglected infrastructures for 6G—Underwater communications: How mature are they? J. Netw. Comput. Appl. 2023, 213, 103595. [Google Scholar] [CrossRef]

- Che, X.; Wells, I.; Dickers, G.; Kear, P.; Gong, X. Re-evaluation of RF electromagnetic communication in underwater sensor networks. IEEE Commun. Mag. 2010, 48, 143–151. [Google Scholar] [CrossRef]

- Flores, H.; Motlagh, N.H.; Zuniga, A.; Liyanage, M.; Passananti, M.; Tarkoma, S.; Youssef, M.; Nurmi, P. Toward Large-Scale Autonomous Marine Pollution Monitoring. IEEE Internet Things Mag. 2021, 4, 40–45. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Jin, C.; Zhang, Y.; Jiang, T. A Survey of Underwater Magnetic Induction Communications: Fundamental Issues, Recent Advances, and Challenges. IEEE Commun. Surv. Tut 2019, 21, 2466–2487. [Google Scholar] [CrossRef]

- Shao, C.; Zheng, S.; Xu, Y.; Gu, H.; Qin, X.; Hu, Y. A visualization system for dam safety monitoring with application of digital twin platform. Expert. Syst. Appl. 2025, 271, 126740. [Google Scholar] [CrossRef]

- Zimmermann, M.; Dostert, K. A multipath model for the powerline channel. IEEE Trans. Commun. 2002, 50, 553–559. [Google Scholar] [CrossRef]

- Huiyun, M.; Chenggang, Y.; Liangliang, D.; Yukun, F.; Chungang, S.; Hanwen, S.; Xiaohua, Z. Review of intelligent well technology. Petroleum 2020, 6, 226–233. [Google Scholar] [CrossRef]

- Xu, L.; Liu, C.; Yang, L.; Zhao, Y.; Ming, K.; Zhang, C.; Ren, B.; Dang, B. Long-term downhole monitoring and controlling production from wells based on high-temperature DC power line communication. Energy Rep. 2022, 8, 175–186. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, F.; Zhuang, Y.; Zhang, Y.; Lei, Y.; Diao, X. An Mbps High-Bitrate Power Line Communication Based on Power-Signal Direct Superposition Method for AUVs. IEEE Trans. Ind. Inform. 2024, 20, 11587–11595. [Google Scholar] [CrossRef]

- Stoicuta, O.; Riurean, S.; Burian, S.; Leba, M.; Ionica, A. Application of Optical Communication for an Enhanced Health and Safety System in Underground Mine. Sensors 2023, 23, 692. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, D.; Hötzel, J. IoT Based information and communication system for enhancing underground mines safety and productivity: Genesis, taxonomy and open issues. Ad Hoc Netw. 2018, 78, 115–129. [Google Scholar] [CrossRef]

- He, H.; Jiang, L.; Pan, Y.; Yi, A.; Zou, X.; Pan, W.; Willner, A.E.; Fan, X.; He, Z.; Yan, L. Integrated sensing and communication in an optical fibre. Light Sci. Appl. 2023, 12, 25. [Google Scholar] [CrossRef]

- Cao, S.; Guo, C.; Zhang, X.; Jiang, X.; Xu, H.; Liu, Z.; Wang, Z.; Wei, W. Design and experimental verification of a novel optical fiber for the full ocean depth communication. Opt. Commun. 2021, 478, 126398. [Google Scholar] [CrossRef]

- Li, R.; Deng, C.; Huang, Y.; Chen, Z.; Zhang, X.; Wang, T. A Novel Trench-Assisted Optical Fiber With Ultra-Low Microbending Loss for the Full Ocean Depth Communication. IEEE Photonics J. 2023, 15, 7202409. [Google Scholar] [CrossRef]

- Glover, H.E.; Wengrove, M.E.; Holman, R. Measuring hydrodynamics and exploring nearshore processes using distributed sensing of fiber-optic cable strain. Coast. Eng. 2024, 190, 104487. [Google Scholar] [CrossRef]

- Qu, Z.; Lai, M. A Review on Electromagnetic, Acoustic, and New Emerging Technologies for Submarine Communication. IEEE Access 2024, 12, 12110–12125. [Google Scholar] [CrossRef]

- Smolyaninov, I.I.; Balzano, Q.; Kozyrev, A.B. Surface Electromagnetic Waves at Seawater-Air and Seawater-Seafloor Interfaces. IEEE Open J. Antennas Propag. 2023, 4, 51–59. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, H.; Yang, K. Modeling of Medium- and Long-Range Electromagnetic Communication Channel for Underwater Wireless Sensor Networks. IEEE Sens. J. 2024, 24, 24865–24879. [Google Scholar] [CrossRef]

- Yang, S.; Geng, J.; Zhou, H.; Wang, K.; Zhao, X.; Lu, J.; Zhao, R.; Tang, X.; Zhang, Y.; Su, D. Long-range EM communication underwater with ultracompact ELF magneto-mechanical antenna. IEEE Trans. Antenn Propag. 2022, 71, 2082–2097. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, D.; Sun, F.; Chen, Q.; Zhu, S.; Wang, Q. Research on extremely low frequency electromagnetic wave model and simulation in wellbore communication. Sci. Rep. 2024, 14, 20093. [Google Scholar] [CrossRef]

- Salem, J.M.; Lohrabi Pour, F.; Ha, D.S. High temperature RF transceiver design for high-speed downhole communications. Microelectron. J. 2022, 129, 105609. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, D.; Sun, F.; Hao, Z.; Chen, Q. Network model and application in wellbore wireless communication of extremely low-frequency electromagnetic waves. J. Geophys. Eng. 2025, 22, 672–681. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, X.; Liu, C.; Yang, S.; Xiang, X.; Chen, H. Acoustic communication and imaging sonar guided AUV docking: System infrastructure, docking methodology and lake trials. Control Eng. Pract. 2023, 136, 105529. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, J.; Chen, G.; Yao, Q.; Huang, L.; Hou, X.; Li, Z.; Duan, F. Bio-inspired secure underwater acoustic communication by quasi-orthogonal keying. Appl. Acoust. 2024, 218, 109907. [Google Scholar] [CrossRef]

- Gabbrielli, A.; Bordoy, J.; Xiong, W.; Fischer, G.K.J.; Schaechtle, T.; Wendeberg, J.; Höflinger, F.; Schindelhauer, C.; Rupitsch, S.J. RAILS: 3-D Real-Time Angle of Arrival Ultrasonic Indoor Localization System. IEEE Trans. Instrum. Meas. 2023, 72, 9600215. [Google Scholar] [CrossRef]

- Hammer, F.; Pichler, M.; Fenzl, H.; Gebhard, A.; Hesch, C. An acoustic position estimation prototype system for underground mining safety. Appl. Acoust. 2015, 92, 61–74. [Google Scholar] [CrossRef]

- Zeeshan, M.; Chavda, M.; Ehshan, K.M.; Nayek, R.; Malik, S. A Review on Non-RF Underground Positioning Techniques for Mining Applications. IEEE Trans. Instrum. Meas. 2023, 72, 9510217. [Google Scholar] [CrossRef]

- Saeed, N.; Celik, A.; Al-Naffouri, T.Y.; Alouini, M.S. Underwater optical wireless communications, networking, and localization: A survey. Ad Hoc Netw. 2019, 94, 101935. [Google Scholar] [CrossRef]

- Spagnolo, G.S.; Cozzella, L.; Leccese, F. Underwater Optical Wireless Communications: Overview. Sensors 2020, 20, 2261. [Google Scholar] [CrossRef]

- Chen, L.K.; Shao, Y.J.; Di, Y.J. Underwater and Water-Air Optical Wireless Communication. J. Lightw. Technol. 2022, 40, 1440–1452. [Google Scholar] [CrossRef]

- Baykal, Y.; Ata, Y.; Gökçe, M.C. Underwater turbulence, its effects on optical wireless communication and imaging: A review. Opt. Laser Technol. 2022, 156, 108624. [Google Scholar] [CrossRef]

- Jamali, M.V.; Mirani, A.; Parsay, A.; Aboihassani, B.; Nabavi, P.; Chizari, A.; Khorramshahi, P.; Abdollahramezani, S.; Salehi, J.A. Statistical Studies of Fading in Underwater Wireless Optical Channels in the Presence of Air Bubble, Temperature, and Salinity Random Variations. IEEE Trans. Commun. 2018, 66, 4706–4723. [Google Scholar] [CrossRef]

- Dong, Y.H.; Tang, S.J.; Zhang, X.D. Effect of Random Sea Surface on Downlink Underwater Wireless Optical Communications. IEEE Commun. Lett. 2013, 17, 2164–2167. [Google Scholar] [CrossRef]

- Rao Angara, B.; Shanmugam, P.; Ramachandran, H. Influence of sea surface waves and bubbles on the performance of underwater-to-air optical wireless communication system. Opt. Laser Technol. 2024, 174, 110652. [Google Scholar] [CrossRef]

- Sun, N.; Wang, X.J.; Han, G.J.; Peng, Y.; Jiang, J.F. Collision-free and low delay MAC protocol based on multi-level quorum system in underwater wireless sensor networks. Comput. Commun. 2021, 173, 56–69. [Google Scholar] [CrossRef]

- Wang, B.; Ben, K.R.; Lin, H.T.; Zuo, M.J.; Zhang, F.C. EP-ADTA: Edge Prediction-Based Adaptive Data Transfer Algorithm for Underwater Wireless Sensor Networks (UWSNs). Sensors 2022, 22, 5490. [Google Scholar] [CrossRef] [PubMed]

- Stewart, C.; Ayaz, B.; Fough, N.; Prabhu, R. Towards the underwater internet of things for subsea oil and gas monitoring. Internet Things 2025, 30, 101510. [Google Scholar] [CrossRef]

- Elgharbi, S.E.; Iturralde, M.; Dupuis, Y.; Gaugue, A. Maritime monitoring through LoRaWAN: Resilient decentralised mesh networks for enhanced data transmission. Comput. Commun. 2025, 241, 108276. [Google Scholar] [CrossRef]

- Ghafoor, H.; Noh, Y.; Koo, I. OFDM-based spectrum-aware routing in underwater cognitive acoustic networks. Iet Commun. 2017, 11, 2613–2620. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Busacca, F.; Galluccio, L.; Palazzo, S.; Panebianco, A.; Qi, Z.; Pompili, D. Adaptive versus predictive techniques in underwater acoustic communication networks. Comput. Netw. 2024, 252, 110679. [Google Scholar] [CrossRef]

- Deng, L.N.; Lai, S.J.; Ma, J.C.; Lei, L.Z.; Zhong, M.J.; Liao, L.; Zhou, Z. Visualization and monitoring information management of bridge structure health and safety early warning based on BIM. J. Asian Archit. Build. 2022, 21, 427–438. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, G.; Huang, J.; Bai, D. Development of tunnel intelligent monitoring and early warning system based on micro-service architecture: The case of AnPing tunnel. Geomat. Nat. Hazards Risk 2020, 11, 1404–1425. [Google Scholar] [CrossRef]

- Moridi, M.A.; Sharifzadeh, M.; Kawamura, Y.; Jang, H.D. Development of wireless sensor networks for underground communication and monitoring systems (the cases of underground mine environments). Tunn. Undergr. Sp. Technol. 2018, 73, 127–138. [Google Scholar] [CrossRef]

- Ali, M.H.; Al-Azzawi, W.K.; Jaber, M.; Abd, S.K.; Alkhayyat, A.; Rasool, Z.I. Improving coal mine safety with internet of things (IoT) based Dynamic Sensor Information Control System. Phys. Chem. Earth 2022, 128, 103225. [Google Scholar]

- Ullo, S.L.; Sinha, G.R. Advances in Smart Environment Monitoring Systems Using IoT and Sensors. Sensors 2020, 20, 3113. [Google Scholar] [CrossRef]

- Yugay, V.; Mekhtiyev, A.; Madi, P.; Neshina, Y.; Alkina, A.; Gazizov, F.; Afanaseva, O.; Ilyashenko, S. Fiber-Optic System for Monitoring Pressure Changes on Mine Support Elements. Sensors 2022, 22, 1735. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Bi, L.; Li, J.; Wu, Z.; Zhao, Z. Development Status and Trend of Mine Intelligent Mining Technology. Mathematics 2025, 13, 2217. [Google Scholar] [CrossRef]

- Zhang, K.; Kang, L.; Chen, X.; He, M.; Zhu, C.; Li, D. A Review of Intelligent Unmanned Mining Current Situation and Development Trend. Energies 2022, 15, 513. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, Q.; Liu, J.; Zhou, L.; Zhang, Z. Robust Intelligent Monitoring and Measurement System toward Downhole Dynamic Liquid Level. Sensors 2024, 24, 3607. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wei, Y.; Wang, Y.; Chen, Q.; Liu, P.; Chai, X. Research on comprehensive and effective acoustic signal processing methods for caculating downhole liquid level depth. Measurement 2022, 199, 111452. [Google Scholar] [CrossRef]

- Li, X.; Cheng, X.; Gong, P.; Yan, K. Design and Implementation of a Wireless Sensor Network-Based Remote Water-Level Monitoring System. Sensors 2011, 11, 1706–1720. [Google Scholar] [CrossRef] [PubMed]

- Trucco, A.; Palmese, M.; Repetto, S. Devising an Affordable Sonar System for Underwater 3-D Vision. IEEE Trans. Instrum. Meas. 2008, 57, 2348–2354. [Google Scholar] [CrossRef]

- Ludvigsen, M.; Sørensen, A.J. Towards integrated autonomous underwater operations for ocean mapping and monitoring. Annu. Rev. Control 2016, 42, 145–157. [Google Scholar] [CrossRef]

- IEEE 1451; Standard for a Smart Transducer Interface for Sensors and Actuators. Institute of Electrical and Electronics Engineers: New York, NY, USA, 2010.

- ISO 5725-1:2023; Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 1: General Principles and Definitions. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- IEC 61709:2017; Electric Components—Reliability—Reference Conditions for Failure Rates and Stress Models for Conversion. IEC: Geneva, Switzerland, 2017.

- Kuo, C.; Pu, Y.; Chen, Q. Position tracking of an underwater robot based on floating-downing PI control. Processes 2022, 10, 2346. [Google Scholar] [CrossRef]

- Zhou, R.; Xiao, A.; Zhang, X.; Wang, Y.; Lu, Y.; Ling, Q.; Tao, C.; Zhang, Y.; Yu, Z.; Chen, D. Early pipeline leak detection: Hydraulic pressure sensor based on all-fiber Fabry–Perot interferometer. Eng. Fail. Anal. 2025, 181, 109927. [Google Scholar] [CrossRef]

- Iliopoulos, A.N.; Van Hemelrijck, D.; Vlassenbroeck, J.; Aggelis, D.G. Assessment of grouted samples from monopile wind turbine foundations using combined non-destructive techniques. Constr. Build. Mater. 2016, 122, 855–862. [Google Scholar] [CrossRef]

| Mechanism | Temp Range (°C) | Pressure Range | Oil and Gas Wells | Underwater Environments | Function | References |

|---|---|---|---|---|---|---|

| Piezoresistive | RT–150 | 0–60 MPa | √ | - | Pressure | [76] |

| 25–700 | - | - | - | Pressure | [98] | |

| - | - | - | √ | Pressure | [99] | |

| −75–600 | - | - | - | Pressure | [36] | |

| Capacitive | - | 100 MPa | - | √ | Pressure | [84] |

| RT–350 | - | - | - | Pressure | [100] | |

| - | - | - | √ | Pressure, liquid level | [74] | |

| - | - | - | √ | Pressure | [101] | |

| Piezoelectric | - | 1790 MPa | - | √ | Dynamic pressure | [86] |

| - | 0–0.739 MPa | - | √ | Dynamic pressure | [87] | |

| 100–350 | - | √ | - | Dynamic pressure | [88] | |

| - | - | - | √ | Dynamic pressure | [102] | |

| Resonant | - | 120 MPa | - | √ | Pressure | [91] |

| −40–150 | 0–120 MPa | √ | - | Pressure, temperature | [94] | |

| - | 120 MPa | - | - | Pressure | [103] | |

| 50–175 | 2–72 MPa | √ | √ | Pressure | [104] |

| Mechanism | Temp Range (°C) | Pressure Range | Oil and Gas Wells | Underwater Environments | Function | References |

|---|---|---|---|---|---|---|

| Fabry–Perot | - | - | - | √ | Salinity | [114] |

| RT–800 | - | - | - | Pressure | [117] | |

| - | 0–10 MPa | √ | √ | Pressure | [118] | |

| Fiber Bragg Grating | 50–200 | 0–40 MPa | √ | - | Pressure, temperature | [124] |

| - | - | √ | - | Pressure | [125] | |

| - | 0–30 MPa | √ | - | Pressure | [128] | |

| Michelson | 20–600 | - | - | - | Temperature | [130] |

| 100–900 | - | - | - | Temperature | [131] | |

| - | 115 MPa | - | √ | Pressure, Salinity | [133] |

| Mechanism | Frequency Range | Sensitivity/ Accuracy | Subsurface/ High-Temperature Infrastructure | Underwater Environments | Function | References |

|---|---|---|---|---|---|---|

| Low-frequency | 1–80 Hz | −300 nm/Pa | - | √ | Earthquake monitoring | [137] |

| 20–800 Hz | −159.7 dB | - | √ | Communication | [140] | |

| 20–200 Hz | −173.8 dB | - | √ | Underwater acoustic detection | [150] | |

| 20–500 Hz | −168.5 dB | - | √ | Underwater acoustic detection | [141] | |

| 30–80 Hz | −118 dB re 1 rad/μPa | - | √ | Underwater acoustic detection | [142] | |

| 100–1000 Hz | −176.3 dB re 1 rad/μPa | √ | Underwater acoustic detection | [151] | ||

| High-frequency | 150 kHz | −173.70 dB | - | √ | Ultrasound imaging | [145] |

| 50 Hz–150 kHz | - | √ | - | Damage detection | [152] | |

| 100 Hz–200 kHz | - | √ | √ | Damage detection | [153] | |

| 40 kHz | - | √ | - | Damage detection | [154] | |

| 180 kHz–1 MHz | −177 dB | - | √ | Underwater acoustic detection | [148] | |

| 3 MHz–6 MHz | - | - | √ | Underwater acoustic detection | [155] | |

| 2.5 MHz | 0.05 mm | √ | - | High-temperature pipeline health monitoring | [149] | |

| >20 kHz | −0.01 mm | √ | - | High-temperature pipeline health monitoring | [156] |

| Mechanism | Sensitivity Level | Operating Temperature/ Frequency Range | Anti-Electromagnetic Interference | Stability | Cost/Packaging Difficulty | |

|---|---|---|---|---|---|---|

| Mechanical | Piezoresistive | Several mV/kPa to tens of mV/kPa | −75~700 °C | Medium | Medium (Drift influence) | Low, Mature packaging |

| Capacitive | Several fF/MPa | RT–350 °C | Medium | Medium | Medium | |

| Piezoelectric | ~1 mV/psi | 100–350 °C | Medium | Medium | Medium | |

| Resonant | 27.3–365 Hz/MPa | −40–175 °C | Medium | High (Long-term stability) | High, Complex packaging | |

| Optical | Fabry–Perot | Several μm/MPa to tens of μm/MPa | RT–800 °C | High | High | High |

| Fiber Bragg Grating | ~50 pm/MPa | 50–200 °C | High | High | Medium to high | |

| Michelson | ~100 pm/°C 10−4~10−5 PSU | 20–900 °C | High | High | High | |

| Acoustic | Low-frequency | −159.7 to −173.8 dB(Scalar Channel) −118 to−176.3 dB re 1 rad/μPa(Vector Channel) | <1000 Hz | Medium | Medium | Medium |

| High-frequency | −173.70 to −177 dB | >20 kHz | Medium | Low to Medium (Affected by material aging) | Medium to high | |

| Environmental Conditions | Applicable Sensor Types M: Mechanical O: Optical A: Acoustic | Applicable Transmission Method T1: Wired T2: Wireless | Collaborative Characteristics | ||||

|---|---|---|---|---|---|---|---|

| High-temperature environment (such as downhole high-temperature zones, industrial high-temperature chambers) | M | m1 | Piezoresistive | T1 | t11 | Power line communication (suitable for short-distance communication and power delivery) | Optical sensors are highly coupled with optical fiber communication and exhibit good stability under high-temperature conditions. Mechanical sensors require integration with temperature compensation algorithms and rely on optical fiber or power line communication for data transmission. |

| m3 | Piezoelectric | ||||||

| m4 | Resonant | ||||||

| O | o2 | FBG | t12 | Optical fiber communication (EMI-resistant, high-temperature tolerant) | |||

| o3 | Michelson | ||||||

| High-pressure environment (such as deep-sea, high-pressure test chamber) | M | m2 | Capacitive | T1 | t12 | Optical fiber communication (long-distance, low-loss) | Capacitive and resonant sensors acquire high-pressure signals, and optical fiber communication ensures accurate and high-speed data transmission. Acoustic sensors, combined with acoustic communication, form a natural transmission link. |

| m4 | Resonant | ||||||

| O | o1 | Fabry–Perot | T2 | t21 | Acoustic communication (suitable for long-range transmission) | ||

| o2 | FBG | ||||||

| o3 | Michelson | ||||||

| A | a1 | Low-frequency | |||||

| Downhole oil and gas environment (high temperature and high pressure, EMI, confined space) | M | m1 | Piezoresistive | T1 | t11 | Power line communication (simultaneous power delivery and data transmission) | Piezoresistive and capacitive sensors are compact, suitable for deployment in confined spaces, and can achieve low-cost installation using power line communication. Optical sensors are highly coupled with optical fiber communication, enabling accurate and stable data transmission in downhole environments with strong electromagnetic interference. |

| m2 | Capacitive | ||||||

| m4 | Resonant | ||||||

| O | o1 | Fabry–Perot | t12 | Optical fiber communication | |||

| o2 | FBG | ||||||

| o3 | Michelson | ||||||

| Underwater environment (such as deep-sea monitoring, marine corrosion monitoring) | M | m2 | Capacitive | T1 | t12 | Optical fiber communication (long-distance transmission, corrosion-resistant) | Capacitive and piezoelectric sensors are suitable for dynamic pressure monitoring. Optical sensors are highly coupled with optical fiber communication and exhibit corrosion resistance, enabling long-term monitoring and data transmission in submerged environments. The combination of acoustic sensors and acoustic communication provides stable and efficient operation for large-scale underwater environmental sensing. |

| m3 | Piezoelectric | ||||||

| O | o1 | Fabry–Perot | T2 | t21 | Acoustic communication (long-range) | ||

| o2 | FBG | ||||||

| o3 | Michelson | ||||||

| A | a1 | Low-frequency | t22 | Optical communication (high-speed transmission in underwater environment) | |||

| a2 | High-frequency | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Wang, Y.; Zhao, F.; Zheng, C.; Xie, J. A Review of the Research Progress of Sensor Monitoring Technology in Harsh Engineering Environments. Sensors 2025, 25, 6308. https://doi.org/10.3390/s25206308

Liu Q, Wang Y, Zhao F, Zheng C, Xie J. A Review of the Research Progress of Sensor Monitoring Technology in Harsh Engineering Environments. Sensors. 2025; 25(20):6308. https://doi.org/10.3390/s25206308

Chicago/Turabian StyleLiu, Qiang, Yang Wang, Fengjiao Zhao, Chuanxing Zheng, and Jinping Xie. 2025. "A Review of the Research Progress of Sensor Monitoring Technology in Harsh Engineering Environments" Sensors 25, no. 20: 6308. https://doi.org/10.3390/s25206308

APA StyleLiu, Q., Wang, Y., Zhao, F., Zheng, C., & Xie, J. (2025). A Review of the Research Progress of Sensor Monitoring Technology in Harsh Engineering Environments. Sensors, 25(20), 6308. https://doi.org/10.3390/s25206308