Validity of the Favero Assioma Duo Power Pedal System for Measuring Power Output and Cadence

Abstract

1. Introduction

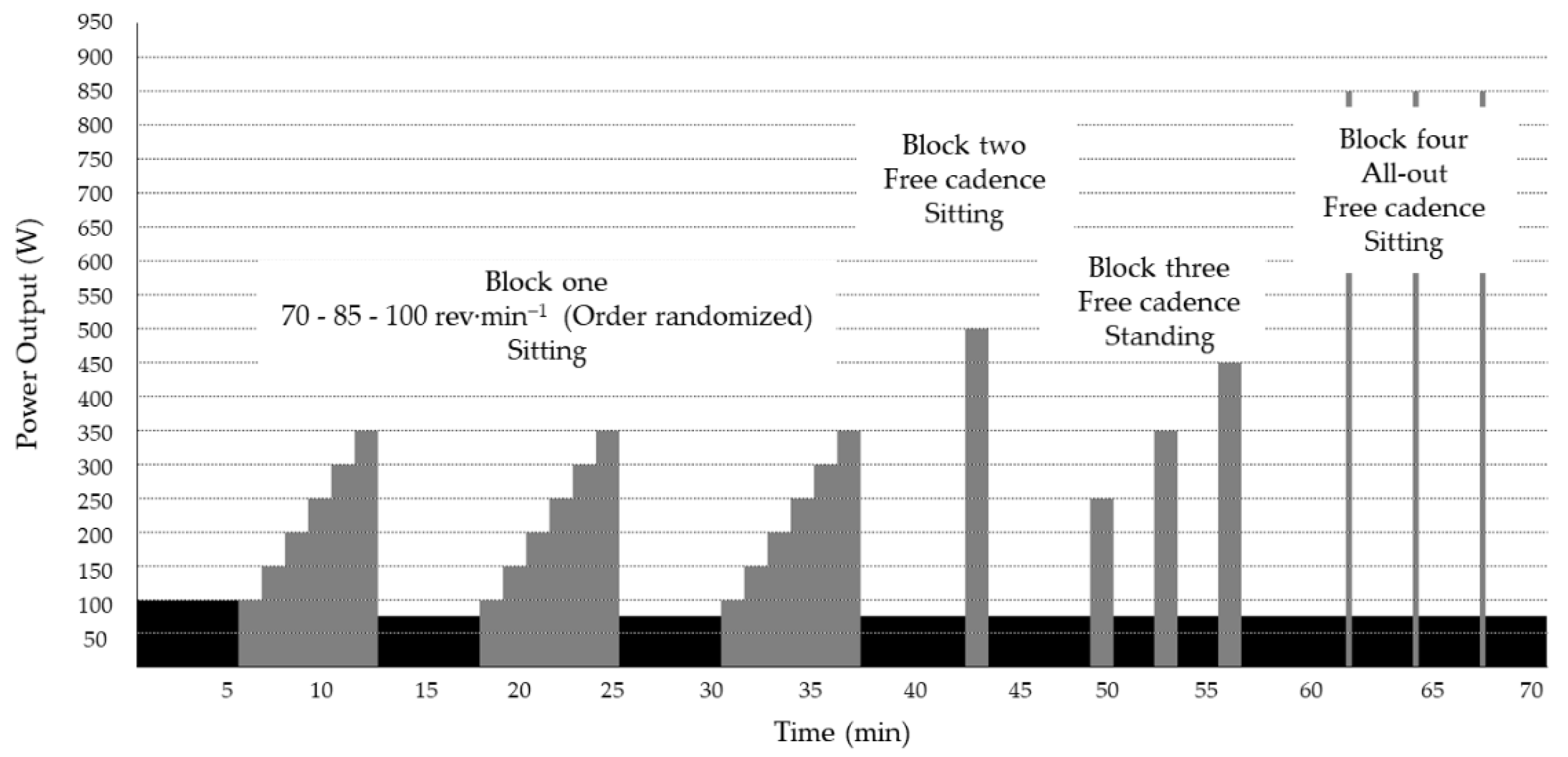

2. Materials and Methods

2.1. Experimental Approach to the Problem

2.2. Participants

2.3. Procedures

2.4. Statistical Analysis

3. Results

3.1. PO

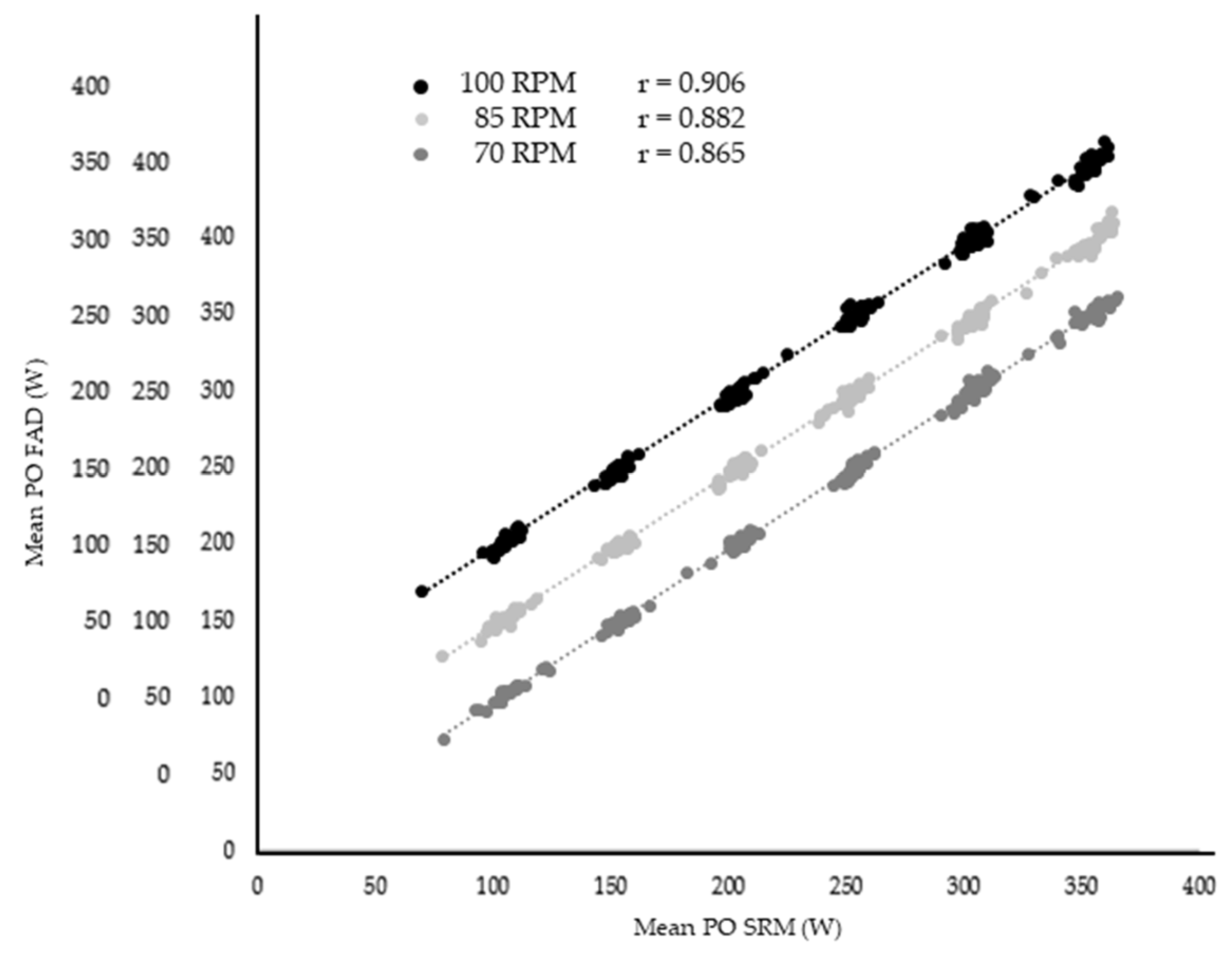

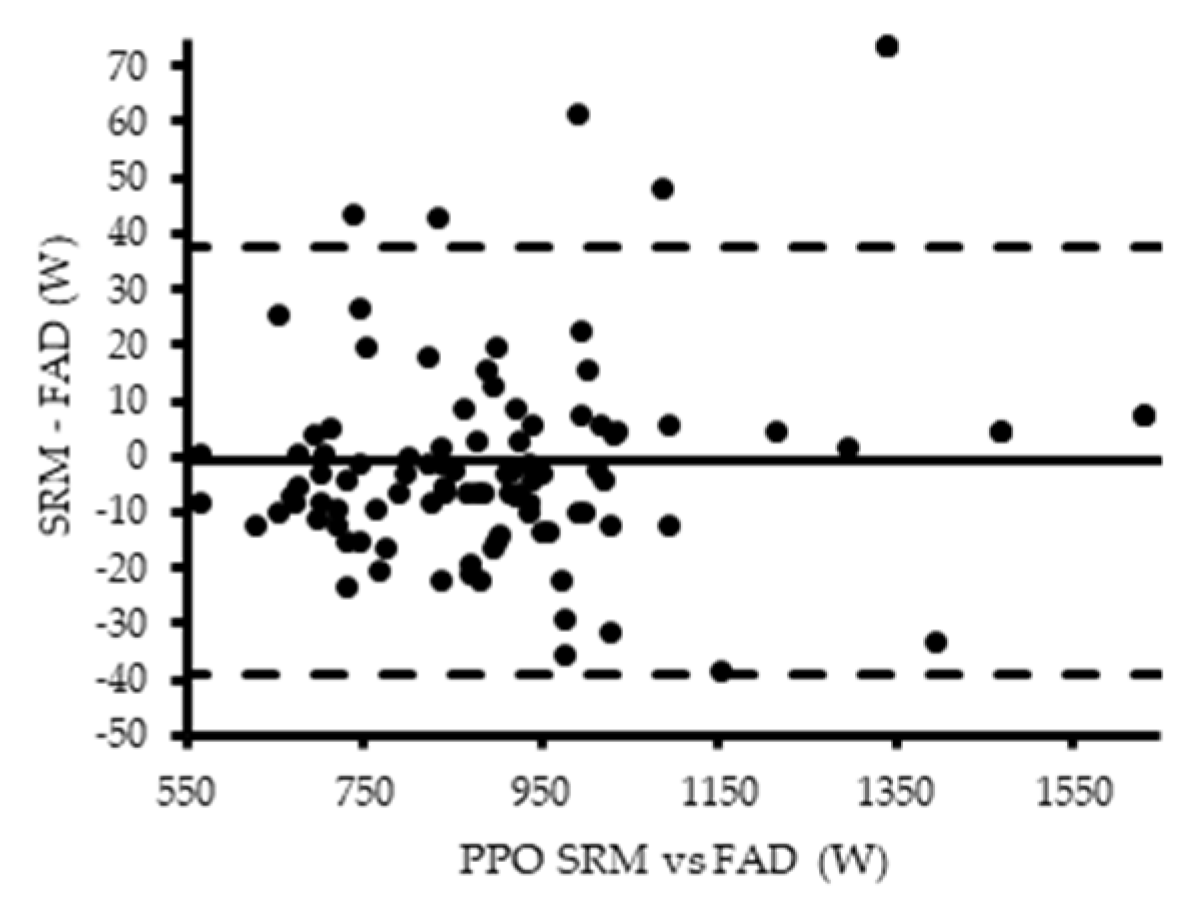

3.1.1. Validity

3.1.2. Reliability

3.2. Cadence

3.2.1. Validity

3.2.2. Reliability

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Bouillod, A.; Pinot, J.; Soto-Romero, G.; Bertucci, W.; Grappe, F. Validity, Sensitivity, Reproducibility, and Robustness of the PowerTap, Stages, and Garmin Vector Power Meters in Comparison with the SRM Device. Int. J. Sports Physiol. Perform. 2017, 12, 1023–1030. [Google Scholar] [CrossRef]

- Maier, T.; Schmid, L.; Müller, B.; Steiner, T.; Wehrlin, J.P. Accuracy of Cycling Power Meters against a Mathematical Model of Treadmill Cycling. Int. J. Sports Med. 2017, 38, 456–461. [Google Scholar] [CrossRef]

- Jobson, S.A.; Passfield, L.; Atkinson, G.; Barton, G.; Scarf, P. The Analysis and Utilization of Cycling Training Data. Sports Med. 2009, 39, 833–844. [Google Scholar] [CrossRef]

- Pinot, J.; Grappe, F. The Record Power Profile to Assess Performance in Elite Cyclists. Int. J. Sports Med. 2011, 32, 839–844. [Google Scholar] [CrossRef] [PubMed]

- Gardner, A.S.; Stephens, S.; Martin, D.T.; Lawton, E.; Lee, H.; Jenkins, D. Accuracy of SRM and Power Tap Power Monitoring Systems for Bicycling. Med. Sci. Sports Exerc. 2004, 36, 1252–1258. [Google Scholar] [CrossRef]

- Jones, S.L.P.; Passfield, L. The Dynamic Calibration of Bicycle Power Measuring Cranks. Eng. Sport 1998, 265–274. [Google Scholar]

- Balmer, J.; Bird, S.R.; Davison, R.R.; Doherty, M.; Smith, P.M. Mechanically Braked Wingate Powers: Agreement between SRM, Corrected and Conventional Methods of Measurement. J. Sports Sci. 2004, 22, 661–667. [Google Scholar] [CrossRef]

- Martin, J.C.; Milliken, D.L.; Cobb, J.E.; McFadden, K.L.; Coggan, A.R. Validation of a Mathematical Model for Road Cycling Power. J. Appl. Biomech. 1998, 14, 276–291. [Google Scholar] [CrossRef]

- Bertucci, W.; Duc, S.; Villerius, V.; Pernin, J.N.; Grappe, F. Validity and Reliability of the PowerTap Mobile Cycling Powermeter When Compared with the SRM Device. Int. J. Sports Med. 2005, 26, 868–873. [Google Scholar] [CrossRef]

- Schneeweiss, P.; Haerlen, S.; Ahrend, M.-D.; Niess, A.M.; Krauss, I. Agreement between the Stages Cycling and PowerTap Powermeter. J. Sci. Cycl. 2018, 7, 3–8. [Google Scholar] [CrossRef]

- Granier, C.; Hausswirth, C.; Dorel, S.; Yann, L.M. Validity and Reliability of the Stages Cycling Power Meter. J. Strength Cond. Res. 2017. [Google Scholar] [CrossRef]

- Nimmerichter, A.; Schnitzer, L.; Prinz, B.; Simon, D.; Wirth, K. Validity and Reliability of the Garmin Vector Power Meter in Laboratory and Field Cycling. Int. J. Sports Med. 2017, 38, 439–446. [Google Scholar] [CrossRef]

- Novak, A.R.; Dascombe, B.J. Agreement of Power Measures between Garmin Vector and SRM Cycle Power Meters. Meas. Phys. Educ. Exerc. Sci. 2016, 20, 167–172. [Google Scholar] [CrossRef]

- Pallarés, J.G.; Lillo-Bevia, J.R. Validity and Reliability of the PowerTap P1 Pedals Power Meter. J. Sports Sci. Med. 2018, 17, 305–311. [Google Scholar]

- Whittle, C.; Smith, N.; Jobson, S.A. Validity of PowerTap P1 Pedals during Laboratory-Based Cycling Time Trial Performance. Sports 2018, 6, 92. [Google Scholar] [CrossRef]

- Wright, J.; Walker, T.; Burnet, S.; Jobson, S.A. The Reliability and Validity of the PowerTap P1 Power Pedals Before and after 100 Hours of Use. Int. J. Sports Physiol. Perform. 2019, 14, 855–858. [Google Scholar] [CrossRef]

- Duc, S.; Villerius, V.; Bertucci, W.; Grappe, F. Validity and Reproducibility of the Ergomo®Pro Power Meter Compared with the SRM and Powertap Power Meters. Int. J. Sports Physiol. Perform. 2007, 2, 270–281. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Sparks, S.A.; Dove, B.; Bridge, C.A.; Midgley, A.W.; McNaughton, L.R. Validity and Reliability of the Look Keo Power Pedal System for Measuring Power Output During Incremental and Repeated Sprint Cycling. Int. J. Sports Physiol. Perform. 2015, 10, 39–45. [Google Scholar] [CrossRef]

- Bini, R.R.; Diefenthaeler, F.; Carpes, F.P. Determining Force and Power in Cycling: A Review of Methods and Instruments for Pedal Force and Crank Torque Measurements: Review Article. Int. SportMed J. 2014, 15, 96–112. [Google Scholar]

- Korff, T.; Romer, L.M.; Mayhew, I.; Martin, J.C. Effect of Pedaling Technique on Mechanical Effectiveness and Efficiency in Cyclists. Med. Sci. Sports Exerc. 2007, 39, 991–995. [Google Scholar] [CrossRef] [PubMed]

- Favero Electronics FAQs. Available online: https://cycling.favero.com/faq-assioma (accessed on 14 December 2020).

- Lillo-Bevia, J.R.; Pallarés, J.G. Validity and Reliability of the Cycleops Hammer Cycle Ergometer. Int. J. Sports Physiol. Perform. 2018, 13, 853–859. [Google Scholar] [CrossRef]

- Millet, G.P.; Tronche, C.; Fuster, N.; Candau, R. Level Ground and Uphill Cycling Efficiency in Seated and Standing Positions. Med. Sci. Sports Exerc. 2002, 34, 1645–1652. [Google Scholar] [CrossRef] [PubMed]

- Ozkaya, O.; Balci, G.A.; As, H.; Vardarli, E. The Test-Retest Reliability of New Generation Power Indices of Wingate All-Out Test. Sports 2018, 6, 31. [Google Scholar] [CrossRef]

- Hopkins, W. Spreadsheets for Analysis of Validity and Reliability. Sportscience 2015, 36–42. [Google Scholar]

- Hopkins, W.G.; Marshall, S.W.; Batterham, A.M.; Hanin, J. Progressive Statistics for Studies in Sports Medicine and Exercise Science. Med. Sci. Sports Exerc. 2009, 41, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Koo, T.K.; Li, M.Y. A Guideline of Selecting and Reporting Intraclass Correlation Coefficients for Reliability Research. J. Chiropr. Med. 2016, 15, 155–163. [Google Scholar] [CrossRef]

- Hopkins, W.G. Measures of Reliability in Sports Medicine and Science. Sports Med. 2000, 30, 1–15. [Google Scholar] [CrossRef]

- Hurst, H.T.; Atkins, S.; Sinclair, J.; Metcalfe, J. Agreement Between the Stages Cycling and SRM Powermeter Systems during Field-Based Off-Road Climbing. J. Sci. Cycl. 2015, 4, 21–27. [Google Scholar]

- Hopkins, W.G.; Schabort, E.J.; Hawley, J.A. Reliability of Power in Physical Performance Tests. Sports Med. 2001, 31, 211–234. [Google Scholar] [CrossRef] [PubMed]

- A New View of Statistics: Home Page. Available online: https://www.sportsci.org/resource/stats/newview.html (accessed on 23 December 2020).

- Paton, C.D.; Hopkins, W.G. Tests of Cycling Performance. Sports Med. 2001, 31, 489–496. [Google Scholar] [CrossRef]

- Czajkowski, M.; Bouillod, A.; Dauriannes, A.; Soto-Romero, G.; Grappe, F. Validity and Reproducibility of the Powertap P1 Power Meter When Compared with SRM Device. J. Sci. Cycl. 2016, 5, 2. [Google Scholar]

- Hayes, M.; Smith, D.; Castle, P.C.; Watt, P.W.; Ross, E.Z.; Maxwell, N.S. Peak Power Output Provides the Most Reliable Measure of Performance in Prolonged Intermittent-Sprint Cycling. J. Sports Sci. 2013, 31, 565–572. [Google Scholar] [CrossRef] [PubMed]

- Hutchison, R.; Klapthor, G.; Edwards, K.; Bruneau, K.; Mocko, G.; Vahidi, A. Validity and Reproducibility of the Garmin Vector Power Meter When Compared to the SRM. J. Sports Sci. 2017, 5, 235–241. [Google Scholar] [CrossRef]

| SRM (W) | FAD (W) | TEM (W) | CV% | ICC | Pearson r-Value | PO × Measurement System p-Value | Effect Size (ηp2) | Bland-Altman | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean ± SD | CV | Mean ± SD | CV | Bias (W) | SD Bias (W) | ||||||||||

| 70 rev·min−1 | Sitting | 100 W | 104.5 ± 11.3 | 10.84% | 106.0 ± 11.6 *** | 10.91% | 1.34 | 1.27% | 0.89% | 0.99 | 0.99 | 0.006 | 0.121 | −2.29 | 2.86 LoA (−7.89 to 3.31) |

| 150 W | 151.5 ± 4.1 | 2.71% | 152.6 ± 3.7 ** | 2.44% | 1.35 | 0.89% | 0.89 | 0.90 | |||||||

| 200 W | 200.2 ± 5.5 | 2.73% | 202.8 ± 5.5 *** | 2.71% | 1.65 | 0.82% | 0.91 | 0.93 | |||||||

| 250 W | 249.1 ± 3.6 | 1.45% | 251.1 ± 5.2 *** | 2.06% | 1.90 | 0.76% | 0.83 | 0.88 | |||||||

| 300 W | 298.9 ± 5.4 | 1.81% | 301.9 ± 7.3 *** | 2.41% | 2.68 | 0.89% | 0.83 | 0.84 | |||||||

| 350 W | 346.9 ± 7.6 | 2.19% | 350.5 ± 7.8 *** | 2.24% | 2.38 | 0.68% | 0.91 | 0.89 | |||||||

| 85 rev·min−1 | Sitting | 100 W | 102.2 ± 6.8 | 6.67% | 103.2 ± 6.8 * | 6.61% | 1.63 | 1.59% | 1.01% | 0.95 | 0.94 | 0.020 | 0.091 | −1.78 | 3.05 LoA (−7.76 to 4.20) |

| 150 W | 150.4 ± 3.5 | 2.31% | 151.5 ± 3.6 ** | 2.39% | 1.51 | 1.00% | 0.83 | 0.81 | |||||||

| 200 W | 199.8 ± 4.4 | 2.19% | 201.8 ± 5.8 *** | 2.89% | 2.11 | 1.05% | 0.84 | 0.88 | |||||||

| 250 W | 247.3 ± 5.6 | 2.26% | 249.4 ± 6.7 *** | 2.69% | 2.11 | 0.85% | 0.89 | 0.90 | |||||||

| 300 W | 298.0 ± 4.4 | 1.47% | 299.6 ± 5.6 ** | 1.88% | 2.08 | 0.70% | 0.84 | 0.85 | |||||||

| 350 W | 347.1 ± 8.2 | 2.35% | 345.0 ± 10.3 *** | 2.94% | 3.02 | 0.87% | 0.90 | 0.92 | |||||||

| 100 rev·min−1 | Sitting | 100 W | 101.9 ± 7.1 | 6.98% | 104.0 ± 7.8 *** | 7.50% | 1.89 | 1.84% | 1.15% | 0.94 | 0.92 | 0.020 | 0.088 | −2.41 | 3.37 LoA (−9.02 to 4.20) |

| 150 W | 149.9 ± 3.7 | 2.47% | 151.8 ± 5.2 *** | 3.46% | 1.99 | 1.32% | 0.82 | 0.86 | |||||||

| 200 W | 99.8 ± 3.9 | 1.95% | 201.3 ± 5.2 ** | 2.56% | 2.07 | 1.03% | 0.81 | 0.87 | |||||||

| 250 W | 248.6 ± 6.1 | 2.44% | 251.6 ± 6.4 *** | 2.53% | 2.39 | 0.96% | 0.86 | 0.86 | |||||||

| 300 W | 298.8 ± 3.8 | 1.28% | 301.5 ± 5.4 *** | 1.78% | 2.78 | 0.93% | 0.66 | 0.69 | |||||||

| 350 W | 338.5 ± 44.7 | 13.19% | 341.9 ± 44.5 *** | 13.03% | 2.88 | 0.85% | 0.99 | 0.99 | |||||||

| FCC | Sitting | 500 W | 494.0 ± 22.5 | 4.56% | 501.4 ± 23.6 *** | 4.72% | 5.51 | 1.11% | 1.11% | 0.95 | 0.94 | <0.001 | 0.481 | −7.33 | 7.80 LoA (−22.62 to 3.27) |

| FCC | Standing | 250 W | 250.2 ± 7.8 | 3.11% | 255.1 ± 8.9 *** | 3.48% | 3.18 | 1.26% | 1.06% | 0.86 | 0.86 | <0.001 | 0.803 | −7.86 | 5.68 LoA (−18.99 to 3.27) |

| 350 W | 345.8 ± 17.1 | 4.95% | 353.4 ± 18.2 *** | 5.27% | 3.42 | 0.98% | 0.97 | 0.97 | |||||||

| 450 W | 442.2 ± 27.8 | 6.30% | 453.2 ± 28.0 *** | 6.31% | 4.23 | 0.94% | 0.98 | 0.97 | |||||||

| FCC | Sitting | ALL-OUT | 756.3 ± 143.0 | 18.90% | 755.0 ± 155.4 | 20.60% | 21.87 | 2.89% | 2.82% | 0.98 | 0.94 | 0.167 | 0.057 | 6.26 | 29.39 LoA (−51.34 to 63.86) |

| ALL-OUT | 736.3 ± 114.5 | 15.56% | 723.1 ± 100.3 | 13.96% | 21.03 | 2.88% | 0.96 | 0.97 | |||||||

| ALL-OUT | 715.1 ± 102.0 | 14.26% | 710.7 ± 103.3 | 14.53% | 19.03 | 2.67% | 0.97 | 0.97 | |||||||

| SRM (W) | FAD (W) | TEM (W) | CV% | ICC | Pearson r-Value | PO × Measurement System p-Value | Effect Size (ηp2) | Bland-Altman Analysis | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean ± SD | CV | Mean ± SD | CV | Bias (W) | SD Bias (W) | ||||||||||

| FCC | Sitting | ALL-OUT | 947.2 ± 233.6 | 24.67% | 943.6 ± 233.1 | 24.71% | 14.65 | 1.55% | 1.49% | 0.99 | 0.99 | 0.282 | 0.039 | −0.60 | 19.63 LoA (−39.08 to 37.89) |

| ALL-OUT | 898.4 ± 204.4 | 22.75% | 900.9 ± 203.9 | 22.64% | 9.10 | 1.01% | 0.99 | 0.99 | |||||||

| ALL-OUT | 877.0 ± 189.0 | 21.56% | 879.8 ± 178.4 | 20.28% | 16.71 | 1.90% | 0.99 | 0.99 | |||||||

| SRM (rev·min−1) | FAD (rev·min−1) | TEM (rev·min−1) | CV% | ICC | Pearson r-Value | Cadence × Measurement System p-Value | Effect Size (ηp2) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean ± SD | CV | Mean ± SD | CV | ||||||||||

| 70 rev·min−1 | Sitting | 100 W | 70.7 ± 2.0 | 2.77% | 70.9 ± 1.9 | 2.73% | 0.31 | 0.44% | 0.42% | 0.88 | 0.98 | 0.164 | 0.048 |

| 150 W | 70.0 ± 1.4 | 2.05% | 70.1 ± 1.4 | 1.96% | 0.26 | 0.37% | 0.97 | 0.97 | |||||

| 200 W | 70.4 ± 1.4 | 2.04% | 70.8 ± 1.3 | 1.90% | 0.35 | 0.50% | 0.94 | 0.94 | |||||

| 250 W | 70.2 ± 1.4 | 2.01% | 70.5 ± 1.4 | 2.04% | 0.32 | 0.45% | 0.95 | 0.95 | |||||

| 300 W | 70.2 ± 1.4 | 2.05% | 70.4 ± 1.4 | 2.01% | 0.26 | 0.37% | 0.97 | 0.97 | |||||

| 350 W | 70.6 ± 1.6 | 2.29% | 70.8 ± 1.7 | 2.41% | 0.26 | 0.37% | 0.98 | 0.98 | |||||

| 85 rev·min−1 | Sitting | 100 W | 84.0 ± 1.8 | 2.11% | 84.4 ± 1.9 | 2.20% | 0.35 | 0.42% | 0.38% | 0.96 | 0.96 | 0.190 | 0.046 |

| 150 W | 84.4 ± 1.0 | 1.15% | 84.7 ± 1.0 | 1.13% | 0.31 | 0.37% | 0.90 | 0.90 | |||||

| 200 W | 84.4 ± 0.9 | 1.10% | 84.6 ± 0.9 | 1.10% | 0.32 | 0.38% | 0.89 | 0.88 | |||||

| 250 W | 84.4 ± 0.9 | 1.11% | 84.7 ± 0.9 | 1.07% | 0.34 | 0.40% | 0.87 | 0.87 | |||||

| 300 W | 84.5 ± 1.5 | 1.78% | 84.8 ± 1.5 | 1.81% | 0.35 | 0.41% | 0.95 | 0.95 | |||||

| 350 W | 85.0 ± 2.0 | 2.33% | 85.1 ± 2.0 | 2.41% | 0.26 | 0.31% | 0.98 | 0.98 | |||||

| 100 rev·min−1 | Sitting | 100 W | 98.8 ± 1.9 | 1.94% | 99.2 ± 2.0 | 2.02% | 0.35 | 0.35% | 0.36% | 0.97 | 0.97 | 0.900 | 0.009 |

| 150 W | 99.0 ± 1.9 | 1.97% | 99.3 ± 1.8 | 1.86% | 0.34 | 0.34% | 0.97 | 0.97 | |||||

| 200 W | 98.9 ± 2.5 | 2.49% | 99.3 ± 2.3 | 2.36% | 0.35 | 0.35% | 0.98 | 0.98 | |||||

| 250 W | 99.3 ± 1.8 | 1.86% | 99.7 ± 1.8 | 1.83% | 0.37 | 0.37% | 0.96 | 0.96 | |||||

| 300 W | 99.2 ± 2.0 | 1.98% | 99.7 ± 2.1 | 2.09% | 0.36 | 0.36% | 0.97 | 0.97 | |||||

| 350 W | 99.7 ± 3.5 | 3.50% | 100.1 ± 3.4 | 3.45% | 0.36 | 0.36% | 0.99 | 0.99 | |||||

| FCC | Sitting | 500 W | 91.3 ± 7.3 | 8.03% | 91.7 ± 7.2 | 7.91% | 0.35 | 0.38% | 0.38% | 0.99 | 0.99 | ||

| FCC | Standing | 250 W | 77.1 ± 8.2 | 10.69% | 77.4 ± 8.3 | 10.76% | 0.33 | 0.43% | 0.45% | 0.99 | 0.99 | 0.580 | 0.017 |

| 350 W | 77.9 ± 6.4 | 8.26% | 78.3 ± 6.6 | 8.44% | 0.39 | 0.50% | 0.99 | 0.99 | |||||

| 450 W | 82.2 ± 4.6 | 5.58% | 82.6 ± 4.5 | 5.48% | 0.35 | 0.42% | 0.99 | 0.99 | |||||

| FCC | Sitting | ALL-OUT | 115.8 ± 11.4 | 9.88% | 115.0 ± 11.4 | 9.95% | 1.43 | 1.24% | 1.10% | 0.99 | 0.98 | 0.512 | 0.020 |

| ALL-OUT | 116.7 ± 9.8 | 8.44% | 116.0 ± 9.5 | 8.20% | 1.20 | 1.03% | 0.99 | 0.99 | |||||

| ALL-OUT | 115.8 ± 9.8 | 8.49% | 115.4 ± 9.7 | 8.44% | 1.20 | 1.04% | 0.99 | 0.99 | |||||

| PEAK CADENCE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SRM (rev·min−1) | FAD (rev·min−1) | TEM (rev·min−1) | CV% | ICC | Pearson r-Value | Cadence × Measurement System p-Value | Effect Size (ηp2) | ||||||

| Mean ± SD | CV | Mean ± SD | CV | ||||||||||

| FCC | Sitting | ALL-OUT | 129.8 ± 17.9 | 13.79% | 129.9 ± 17.7 | 13.61% | 0.79 | 0.61% | 0.83% | 0.99 | 0.99 | 0.299 | 0.036 |

| ALL-OUT | 130.5 ± 13.8 | 10.55% | 130.8 ± 13.8 | 10.54% | 0.84 | 0.64% | 0.99 | 0.99 | |||||

| ALL-OUT | 128.4 ± 12.2 | 9.51% | 129.1 ± 11.8 | 9.12% | 1.61 | 1.25% | 0.98 | 0.98 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montalvo-Pérez, A.; Alejo, L.B.; Valenzuela, P.L.; Castellanos, M.; Gil-Cabrera, J.; Talavera, E.; Lucia, A.; Barranco-Gil, D. Validity of the Favero Assioma Duo Power Pedal System for Measuring Power Output and Cadence. Sensors 2021, 21, 2277. https://doi.org/10.3390/s21072277

Montalvo-Pérez A, Alejo LB, Valenzuela PL, Castellanos M, Gil-Cabrera J, Talavera E, Lucia A, Barranco-Gil D. Validity of the Favero Assioma Duo Power Pedal System for Measuring Power Output and Cadence. Sensors. 2021; 21(7):2277. https://doi.org/10.3390/s21072277

Chicago/Turabian StyleMontalvo-Pérez, Almudena, Lidia B. Alejo, Pedro L. Valenzuela, Mario Castellanos, Jaime Gil-Cabrera, Eduardo Talavera, Alejandro Lucia, and David Barranco-Gil. 2021. "Validity of the Favero Assioma Duo Power Pedal System for Measuring Power Output and Cadence" Sensors 21, no. 7: 2277. https://doi.org/10.3390/s21072277

APA StyleMontalvo-Pérez, A., Alejo, L. B., Valenzuela, P. L., Castellanos, M., Gil-Cabrera, J., Talavera, E., Lucia, A., & Barranco-Gil, D. (2021). Validity of the Favero Assioma Duo Power Pedal System for Measuring Power Output and Cadence. Sensors, 21(7), 2277. https://doi.org/10.3390/s21072277