Abstract

The fundamental circumferential shear horizontal (CSH0) wave is of practical importance in monitoring corrosion defects in large-diameter pipes due to its virtually non-dispersive characteristics. However, so far, there have been limited CSH0 wave transducers which can be used to constitute a structural health monitoring (SHM) system for pipes. Moreover, the CSH0 wave’s capability of sizing the corrosion-like defect has not yet been confirmed by experiments. In this work, firstly, the mechanism of exciting CSH waves was analyzed. A method based on our previously developed bidirectional SH wave piezoelectric transducers was then proposed to excite the pure CSH0 mode and first order circumferential shear horizontal (CSH1) mode. Both finite element simulations and experiments show that the bidirectional transducer is capable of exciting pure CSH0 mode traveling in both circumferential directions of a 1-mm thick steel pipe from 100 to 300 kHz. Moreover, this transducer can also serve a sensor to detect CSH0 mode only by filtering circumferential Lamb waves over a wide frequency range from 100 to 450 kHz. After that, a method of sizing a rectangular notch defect by using CSH0 wave was proposed. Experiments on an 11-mm thick steel pipe show that the depth and circumferential extent of a notch can be accurately determined by using the proposed method. Finally, experiments were performed to investigate the reflection and transmission characteristics of CSH0 and CSH1 waves from notches with different depths. It was found that transmission coefficients of CSH0 mode decrease with the increasing of notch depth, which indicates that it is possible to monitor the depth change of corrosion defects by using CSH0 wave.

1. Introduction

Wall thinning due to corrosion in pipes is a serious problem in the oil and chemical industries. The ultrasonic bulk-wave-based nondestructive testing (NDT) technique and magnetic flux leakage method are available for detecting wall thinning. However, these NDT techniques cannot monitor the growth of damage, since they are usually conducted at regularly scheduled intervals. The limitation of NDT techniques motivates the development of structural health monitoring (SHM) techniques, with the aim of monitoring the overall integrity of structures in a real-time manner [1].

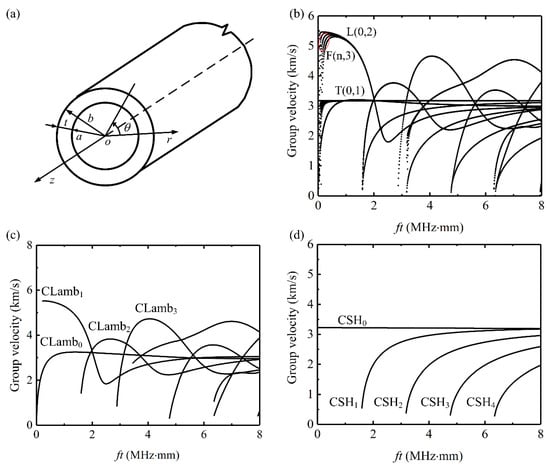

Over the last three decades, the ultrasonic guided-wave-based damage identification approach has demonstrated potential for SHM of pipes [2]. Guided waves can propagate in the axial or circumferential direction of a pipe-like structure [3]. Axial guided waves have attracted the main research interest of this field due to their rapid defect screening capability. Figure 1b shows the group velocity dispersion curves of axial guided waves for a steel pipe (outer diameter 720 mm, wall thicknesses 11 mm). Based on the early works by Gazis [4,5] and Silk and Bainton [6], there are three kinds of axial guided waves in a pipe, namely longitudinal-type modes L(0, m), torsional-type modes T(0, m) and flexural modes F (n, m), where the positive integer ‘n’ represents the circumferential order of a mode and the positive integer ‘m’ denotes the group order of a mode. Since many guided wave modes exist in the axial direction at any given frequency and they are in general dispersive, it is often very difficult to extract relevant information on defects from the complex received wave signals. Therefore, much effort has been made to excite pure longitudinal L(0, 2) mode [7,8,9] and the fundamental torsional wave T(0, 1) mode [10,11], since T(0, 1) wave is nondispersive at all frequencies while L(0, 2) wave is virtually non-dispersive in the selected frequency range [12]. However, the L(0, 2) and T(0, 1) modes are axially symmetric, so they have difficulty to locate the defect circumferential position and size the defect. This problem becomes more serious in large-diameter pipes, which drives researchers to develop circumferential guided-wave-based damage identification method [13,14,15,16,17].

Figure 1.

Group velocity dispersion curves of axial and circumferential guided waves in a steel pipe (outer diameter 720 mm, wall thicknesses 11 mm, Young’s modulus 210 GPa, density 7850 kg/m3 and Poisson’s ratio 0.33): (a) pipe axes configuration; (b) axial guided waves (F modes only shown up to 4th order); (c) circumferential Lamb (CLamb) waves and; (d) circumferential shear horizontal (CSH) waves.

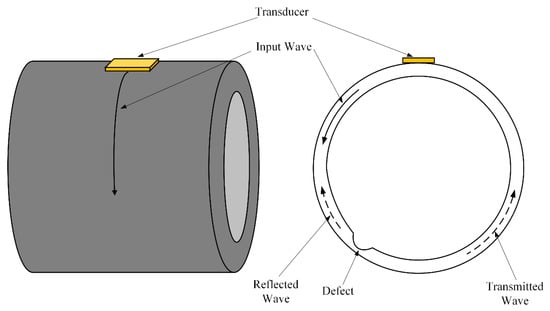

Figure 2 illustrates the basic idea of the circumferential guided-wave-based SHM approach [16]. Transducers are permanently installed on the pipe. The incident guided wave is excited in one direction around the circumference of a pipe and propagates across the defect. By examining the reflected wave and transmitted wave, the defect can be identified. Since the required inspection distance is relatively shorter than that of the axial guided wave, a higher frequency circumferential guided wave can be used to improve the sensitivity to defects. Obviously, circumferential guided-wave-based inspection is an appealing method for monitoring large-diameter pipes such as pressure vessels and oil tanks, in which a transducer array can be used. As for long range pipes, such as oil transporting pipelines, circumferential guided waves can be a good supplement to axial guided wave inspection. Long range pipes can be inspected by using a combination of axial and circumferential guided waves. For example, circumferential guided waves can be used to inspect the welding zones and pipe support regions, which are highly prone to generating defects [18].

Figure 2.

Schematic of circumferential guided-wave-based SHM approach.

The selection of a proper mode is essential to developing a circumferential guided-wave-based SHM system. Two kinds of guided waves can propagate in the circumferential direction of a pipe, namely: circumferential Lamb waves and shear horizontal (SH) waves often abbreviated as CLamb waves and CSH waves [3], respectively, as shown in Figure 1c,d. Early researchers often use plate-wave solutions to model the circumferential guided waves. Liu and Qu [19] and Zhao and Rose [20] developed detailed theoretical models for circumferential guided waves. Their results show that the dispersion curves and wave structures of circumferential guided waves are quite different from that of plate waves especially in thick wall pipes. As shown in Figure 1c, all the circumferential Lamb waves are dispersive and at least two modes coexist at any given frequency. Since CLamb waves have two coupled displacements (radial displacement and circumferential displacement), it is very difficult to excite a pure CLamb mode. Compared with CLamb waves, CSH waves have simpler dispersion equation and less mode conversion when encountering defects. Moreover, CSH waves have simpler wave structures and are less affected by the presence of fluid loads and coatings [21]. In addition, only the fundamental circumferential SH (CSH0) wave can propagate below the cutoff frequency of CSH1 mode and the displacement of CSH waves are decoupled with CLamb waves, which means that theoretically pure CSH0 mode can be excited over a wide frequency range. This characteristic is attractive since CSH0 mode is also practically non-dispersive over a wide frequency range as shown in Figure 1d.

As CSH waves are attractive, especially CSH0 mode has practical importance in developing circumferential guided wave inspection system, much effort has been made to utilize CSH0 wave to detect corrosion-like defects. In laboratory studies, SH modes in plates are often used as an approximation of CSH waves in pipes [22], since numerical model and experiments in the plate are much simpler. The interaction of SH0 wave with wall thinning defects is highly influenced by the thinning geometry and the operating frequency range [23]. When the operating frequency is below the first cutoff frequency, the SH0 wave will not convert to higher order SH modes when encountering defects, so the reflection and transmission behaviors of SH0 wave across thinning defects are relatively simple. Demma et al. [24] investigated the effect of a rectangular notch on the propagation of the SH0 mode, and it was found that the reflection coefficient is strongly influenced by the axial extent (in the propagating direction) of a notch. It has minima when the axial extent is integer multiples of λ/2 and maxima when the axial extent is odd multiples of λ/4, where λ is the wavelength of SH0 wave. This phenomenon was also confirmed by using the principle of reciprocity of elastodynamics [25,26]. Zhao and Rose [27] used boundary element methods to analyze the SH0 wave scattering from a surface half-elliptical shaped defect, which is a better approximation to the corrosion defect than a notch. It was found for a low frequency incident SH0 wave, the reflection and transmission factors change monotonously with the defect depth. Wang et al. [28] investigated the effect of a notch on the propagation of the CSH0 mode in a pipe by using 3D finite element simulations. Their simulations show that the reflection and transmission coefficients of CSH0 waves vary monotonously with an increase in the notch depth. The above results show that CSH0 wave has great potential for corrosion defect sizing when its operating frequency is below the first cutoff frequency. However, there is less experimental evidence to support the CSH0 wave’s defect sizing capability. Even for a simple rectangular notch defect, there is no available guided-wave-based method to determine the depth of a notch. It should be noted that using SH0 wave to model the CSH0 mode in a thin pipe is accurate only for the frequency range below the first cutoff frequency. The simulations conducted by Luo et al. [22] show that, when the operating frequency is above the CSH1 wave cutoff frequency, the CSH0 wave’s reflection and transmission characteristics from a notch in a pipe are quite different from those of SH0 wave from a notch in a plate, even for a thin pipe with a low thickness-to-diameter ratio. Therefore, although there are some investigations which focus on the interaction of SH0 wave with corrosion-like defects in the high frequency-thickness regime [14,23,29,30,31], these conclusions obtained from SH0 wave in the high frequency-thickness regime cannot be extended to CSH0 wave in the pipe straightforwardly.

Undoubtedly, it is necessary to experimentally study the interaction of CSH0 wave with corrosion-like defects in pipes directly. However, currently, there are fewer experimental investigations due to the difficulty of exciting pure CSH0 (or CSH1) mode. To develop a CSH-wave-based SHM system, transducers should be designed to meet the following requirements: (a) The transducer should be light-weight and low-power consumption and hence it can be permanently installed on the pipe. This means that electromagnetic acoustic transducers (EMATs) are not feasible due to their relatively bulk size and high-power consumption, although EMATs can excite pure CSH0 wave [32]. (b) The transducer should be able to excite a pure CSH0 wave in one direction around the circumference of a pipe [16]. This requires that all the axial guided waves, CLamb waves, and high order CSH modes in the pipe must be suppressed by the designed transducer. In recent years, a series of face-shear piezoelectric transducers for SHM have been developed to excite single mode SH0 wave [33,34,35,36]. Since pure SH0 wave excited by the face-shear transducer is along four main directions (0°, 90°, 180° and 270°) [35], it can be inferred that if these face-shear transducers are straightforwardly used to excite CSH0 wave, flexural waves will be excited simultaneously in the axial direction of the pipe [11,37]. Theoretically, our recently developed bidirectional SH wave piezoelectric transducer (BSH-PT) is capable of exciting pure CSH0 wave in the pipe [38], but considering that there are many axial guided waves in the pipe, its capability of suppressing axial guided waves needs to be checked. (c) Besides the above two requirements, it is also expected that this transducer can operate over a wide frequency range, which means that the transducer has tunable detection sensitivity for defects of different sizes. As EMATs are usually able to excite pure CSH0 wave with fixed wavelength, they cannot meet this requirement.

In this work, a piezoelectric transducer system is proposed to excite pure CSH0 wave and single CSH1 mode in large-diameter pipes and the CSH0 wave’s ability of sizing and monitoring corrosion-like defects in a pipe is demonstrated. Firstly, a method based on our previously developed bidirectional SH wave piezoelectric transducers was proposed to excite pure CSH0 wave and single CSH1 mode. Then, experiments were performed to explore the bidirectional transducer’s performance on exciting and receiving CSH0 wave over a wide frequency range. After that, a method of sizing a rectangular notch defect by using CSH0 wave was proposed and then confirmed by experiments. Finally, experiments were conducted to investigate the reflection and transmission characteristics of CSH0 wave and CSH1 wave from notches with different depths. The results show that the depth change of a notch can be monitored by extracting the transmission coefficient of CSH0 wave at different incident frequencies.

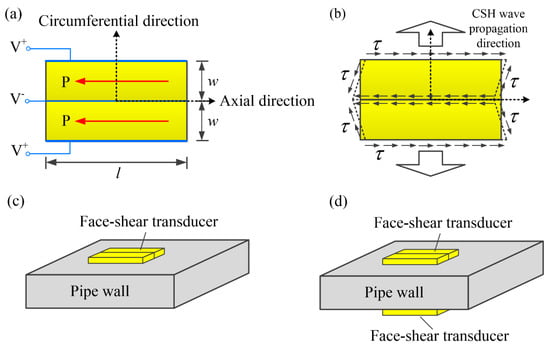

2. Mechanisms of Exciting CSH0 and CSH1 Waves

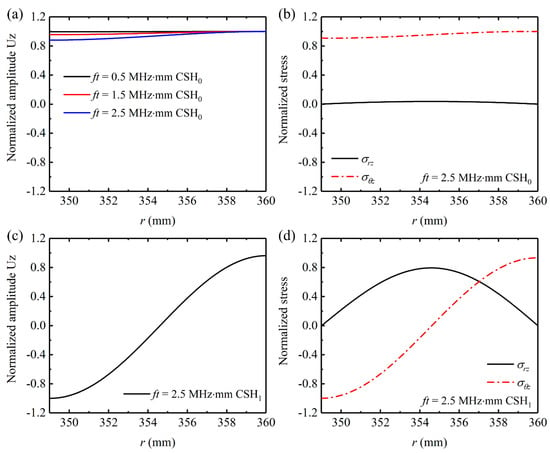

The first step in developing a guided wave transducer is to analyze the wave structures in the waveguide. Figure 3a shows the particle displacement distributions of CSH0 wave in an 11-mm thick steel pipe at different frequencies. For better illustration, the particle displacement distributions are normalized against the maximum displacement of each case. For the CSH0 wave at 0.5 MHz·mm, its particle displacement is uniform across the pipe wall, which is the same as that of a plate-wave solution. Although such a uniform distribution cannot be kept when the frequency increases, the deviation is small and can be neglected especially for the cases below the first cutoff frequency. The quasi-uniform displacement distribution induces that the in-plane shear stress is also almost uniform across the pipe wall as shown in Figure 3b. Moreover, the shear stress of CSH0 wave is negligible. Therefore, the CSH0 wave can be generated by inducing face-shear deformation in the pipe. However, because pure SH0 wave in a plate is generated by the face-shear transducer along four main directions, it can be inferred that a face-shear deformation in the pipe will not only excite CSH wave but also generate axial guided waves. A previously developed bidirectional SH wave piezoelectric transducer [38] may be able to eliminate the possible guided waves propagation in the axial direction of the pipe. As shown in Figure 4a, the bidirectional transducer consists of two identical face-shear d24 PbZr1−xTixO3 (PZT) wafers, which are bonded together via their lateral faces. The two PZT wafers share a same electrode at the bonding interface and their polarization directions (red arrow in Figure 4a) are the same, so the induced face-shear deformations of the two PZT wafers under drive field are opposite. As demonstrated in a recent work [35], the wave field generated by a face-shear transducer is equivalent to that generated by uniform in-plane tractions along its perimeters. Since the induced shear stresses distributed along the PZT wafer edges are symmetric with respect to the axial direction, as shown in Figure 4b, it can be inferred that all the axial guided waves will be suppressed based on the symmetry principle in the theory of elastodynamics. This principle is independent of frequency, so CSH0 wave can be excited over a wide frequency range.

Figure 3.

Wave structures and stresses of CSH waves in a steel pipe (outer diameter 720 mm, wall thicknesses 11 mm, Young’s modulus 210 GPa, density 7850 kg/m3 and Poisson’s ratio 0.33): (a) particle displacement distributions of CSH0 wave at different frequencies, (b) stress components and of CSH0 wave at 2.5 MHz·mm, (c) particle displacement distribution, (d) stress components of CSH1 wave at 2.5 MHz·mm.

Figure 4.

(a) Schematics of the proposed bidirectional CSH wave piezoelectric transducer, (b) bidirectional CSH wave driving mechanism, (c) single transducer configuration for pure CSH0 wave excitation below the first cutoff frequency and (d) dual transducer configuration for selectively exciting CSH0 or CSH1 wave above the first cutoff frequency.

Based on the above analysis, it is known that a single bidirectional transducer configuration, shown in Figure 4c, can be used to generate pure CSH0 wave below the cutoff frequency of CSH1 mode. However, when the drive frequency is above the first cutoff frequency, the CSH1 mode will be also excited simultaneously by the single transducer configuration, since the in-plane shear stress of CSH1 mode is dominant on the surface of the pipe as shown in Figure 3d. Considering that the displacement and shear stress of CSH1 mode are quasi-antisymmetric across the pipe wall, as shown in Figure 3c,d, the symmetrically mounted transducer configuration shown in Figure 4d can be used to selectively excite CSH0 mode and CSH1 mode. With in-phase excitation applied on the two symmetrically-mounted bidirectional transducers, pure CSH0 mode can be generated while pure CSH1 mode can be achieved with an out-of-phase excitation [39,40].

Finite element simulations based on ANSYS software (Version 14.5 by ANSYS, Inc., Canonsburg, PA, USA) were performed to confirm the proposed excitation mechanisms. The bidirectional transducer in the simulations is made up of two rectangular PZT wafers with the dimensions of 25 mm × 6 mm × 1 mm. The material parameters of the PZT (PZT-5H) wafers can be found in the recent work [35]. Firstly, the bidirectional transducer’s performance on suppressing axial guided waves and CLamb waves was investigated. In order to reduce the computational cost, a 300 mm long, 300 mm outer diameter, and 1-mm thick steel pipe was used as the waveguide. The bidirectional transducer was bonded on the outer surface of the pipe as shown in Figure 5a. The transducer was driven at 250 kHz (corresponding to 0.25 MHz·mm in the 1-mm thick steel pipe, below the cutoff frequency of CSH1 mode), so by monitoring the induced displacement time history at point A and point B, the transducer’s performance on exciting pure CSH0 wave can be assessed. Then the thickness of the steel pipe was changed to 11 mm and two bidirectional transducers were symmetrically mounted on the outer and inner surfaces of the pipe to explore the excitation mechanism of CSH1 wave. The two symmetrically mounted bidirectional transducers were energized out-of-phase and the central frequency of the drive signal was 250 kHz (corresponding to 2.75 MHz·mm in the 11-mm thick steel pipe, above the cutoff frequency of CSH1 mode). By monitoring the induced displacement distribution across the pipe wall, the pair of bidirectional transducers’ performance on exciting CSH1 wave can be confirmed. In all cases, the Young’s modulus, Poisson ratio, and density of the steel pipe in the simulations were set to be 210 GPa, 0.33, and 7850 kg/m3, respectively. The steel pipes were modeled by SOLID185 elements, while the PZT wafers were modeled by SOLID5 elements. The largest size of elements was set to be less than 1/20 of the shortest wavelength and the time step was less than 1/(20 fc) to ensure the accuracy of the computational results, where fc was the central frequency of the drive signal. The drive signal was a five cycle Hanning window-modulated sinusoid toneburst and its amplitude was fixed at 40 V.

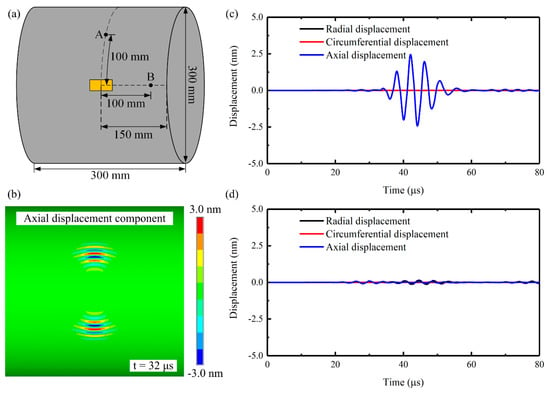

Figure 5.

Numerical verification of pure CSH0 wave excitation by a single surface-bonded piezoelectric transducer at 0.25 MHz·mm in a steel pipe (outer diameter 300 mm, wall thicknesses 1 mm): (a) schematics of the finite element simulation setup, (b) axial displacement wavefield (CSH0 wave), displacements time history extracted from (c) point A and (d) point B.

Figure 5b shows the simulated axial displacement wavefield in the 1-mm thick steel pipe excited by the transducer at 0.25 MHz·mm. Based on the wave structure of CSH0 wave shown in Figure 3a, it is known that the axial displacement shown in Figure 5b can represent the CSH0 wave. As expected, the CSH0 wave was excited in both circumferential directions away from the transducer. To further explore the purity of the excited CSH0 wave, the displacements time history at point A and point B were extracted (shown in Figure 5a) and the results were plotted in Figure 5c,d. Figure 5c shows that the obtained circumferential and radial displacement components at point A are zero, indicating that no CLamb waves are generated. Moreover, Figure 5d shows that all the displacement components at point B are almost zero, which means that no axial guided waves are excited. Thus, it can be concluded that pure CSH0 wave was successfully excited by the bidirectional transducer.

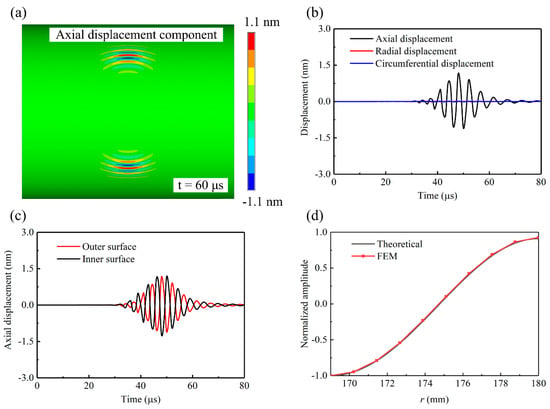

Figure 6a presents the simulated axial displacement wavefield in an 11-mm thick steel pipe excited by a pair of symmetric bonding piezoelectric transducers under out-of-phase excitation at 2.75 MHz·mm. As expected, the wave beam was focused in two circumferential directions. The purity of the excited CSH waves can be confirmed by the displacement time history shown in Figure 6b, which was extracted from the outer surface node at the circumferential distance of 30° from the transducer. Considering that both CSH0 and CSH1 waves can propagate at 2.75 MHz·mm, the displacement time history from the inner surface node was also extracted for comparison and the results are plotted in Figure 6c. It was found that the direction of the particle vibration at the outer surface is opposite to that at the inner surface, indicating that the excited wave is CSH1. This can be further confirmed by the comparison of the simulated and theoretically predicted wave structures of CSH1 mode. Figure 6d shows that the simulated displacement distribution accords well with the theoretical wave structure of CSH1 mode. Obviously, the above simulation results are in good agreement with the proposed excitation mechanisms.

Figure 6.

Numerical verification of pure CSH1 wave excitation by a pair of symmetric bonding piezoelectric transducers under out-of-phase excitation at 2.75 MHz·mm in a steel pipe (outer diameter 360 mm, wall thicknesses 11 mm): (a) axial displacement wavefield (CSH1 wave), (b) displacement time history extracted from the outer surface node at the circumferential distance of 30° from the transducer, (c) axial displacement time history extracted from the outer and inner surface nodes at the circumferential distance of 30° from the transducer and (d) comparison of the simulated and theoretically predicted wave structure of CSH1 mode.

3. Experiments

3.1. Excitation and Reception of CSH0 Wave by the Bidirectional Piezoelectric Transducer

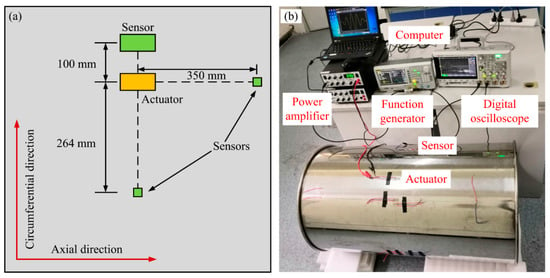

Figure 7 illustrates the experimental setup for exploring the bidirectional piezoelectric transducer’s performance on exciting and receiving CSH0 wave. The bidirectional transducers used in experiments have the same sizes as that used in the finite element simulations in Section 2.

Figure 7.

(a) Schematic of the experimental setup for exploring the bidirectional transducer’s performance on exciting and receiving CSH0 wave. (b) The photo of the experimental setup.

As indicated in Section 2, the proposed bidirectional transducer requires that each d24 PZT element exhibits good face-shear performance within the operating frequency regime. Therefore, we first used a 1-mm thick steel pipe (outer diameter 600 mm, length 1000 mm) to find the frequency regime in which the designed transducer can exhibit good performance. Once the best working frequency range is determined, the transducer’s operating frequency regime in any a given-thickness pipe can be determined based on the corresponding frequency-thickness range. The bidirectional transducer for exciting CSH0 wave was bonded on the outer surface of the pipe using commercial epoxy resins E51 and it located at the center in the axial direction. The transducer was driven by a five-cycle Hanming window-modulated toneburst signal, which was provided by a function generator (DG4062, Rigol, Beijing, China) and amplified to 20 V by a power amplifier (KH7602M, Krohn-Hite Corporation, Brockton, MA, USA) as shown in Figure 7b. A face-shear d36 0.72[Pb(Mg1/3Nb2/3)O3]-0.28[PbTiO3] (PMN-PT) single crystal wafer (d36 = 1600 pC/N and d31 = −360 pC/N, 5 mm × 5 mm × 1 mm) was firstly used as the sensor to check the purity of the excited CSH0 wave in the circumferential direction, since it can detect both CSH0 wave and the possible CLamb waves [33]. As shown in Figure 7a, the distance between the actuator and the PMN-PT sensor was set to be 264 mm. Meanwhile, another d36 PMN-PT sensor was placed in the axial direction to detect the possible axial guided waves. After that, another identical bidirectional piezoelectric transducer was placed in the circumferential direction 100 mm away from the actuator as the sensor to check its ability to receive CSH0 wave. In all cases, the signal received by sensors was collected by an oscilloscope (DSOX3024T, KEYSIGHT, Santa Rosa, CA, USA) with 128 times trace averaging.

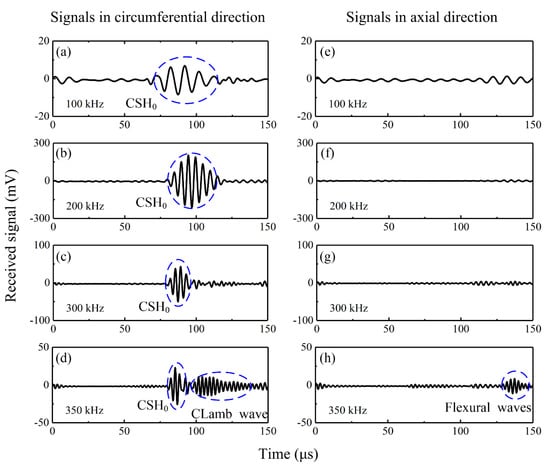

Figure 8 presents the wave signals excited by the bidirectional piezoelectric transducer at different frequencies. Wave signals received by the d36 PMN-PT sensor in the circumferential direction of the pipe are plotted in Figure 8a–d. It was found that pure CSH0 wave was excited over a wide frequency range from 100 kHz to 300 kHz, while CLamb waves were generated at 350 kHz. Correspondingly, Figure 8e–g show that no axial guided waves were generated at the frequency range from 100 kHz to 300 kHz. When the drive frequency increased to 350 kHz, axial guided waves were also excited as shown in Figure 8h. The above phenomenon indicates that the d24 PZT elements used in the bidirectional transducer only exhibit good face-shear performance at the frequency range from 100 kHz to 300 kHz. At this frequency range, the bidirectional transducer can work well as the designed principle introduced in Section 2, so no CLamb waves and axial guided waves are generated. However, when the drive frequency is out of the best working frequency range, the induced deformation of the d24 PZT element is no longer a perfect face-shear deformation, so both CLamb waves and axial guided waves will be excited.

Figure 8.

Wave signals excited by the bidirectional piezoelectric transducer at different frequencies and received by d36 PMN-PT sensors. (a–d) wave signals propagating in the circumferential direction, (e–h) wave signals propagating in the axial direction of the pipe.

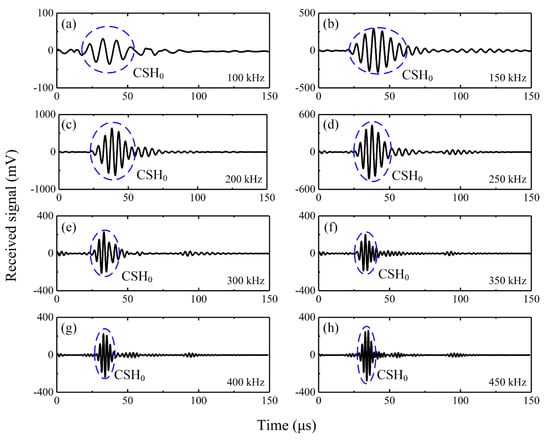

Figure 9 presents the wave signals generated by a bidirectional piezoelectric transducer at different frequencies and measured by another identical bidirectional transducer in the circumferential direction. It seems that pure CSH0 wave was excited over a wide frequency range from 100 kHz to 450 kHz. Bearing in mind that Figure 8 shows that the proposed transducer can only excite pure CSH0 wave from 100 kHz to 300 kHz, so Figure 8 and Figure 9 indicate that the bidirectional piezoelectric transducer can also serve as a sensor, which can receive CSH0 wave only by filtering CLamb waves at the frequency range from 100 kHz to 450 kHz. Obviously, the filtering capability is attractive, since it can reduce the complexity of the received signals.

Figure 9.

Wave signals excited by the bidirectional piezoelectric transducer at different frequencies and received by another bidirectional piezoelectric sensor in the circumferential direction of the pipe.

3.2. Sizing Corrosion-Like Defect with CSH0 Wave

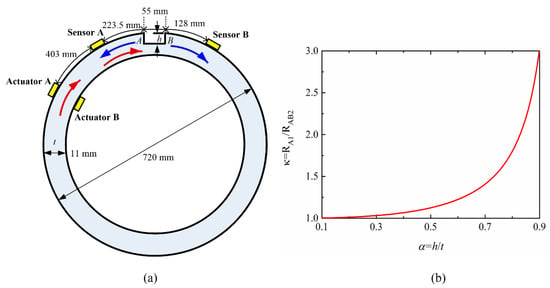

After confirming the proposed bidirectional transducer’s ability to excite and receive CSH waves, a CSH wave piezoelectric transducer system is constituted to monitor corrosion-like defect in thick-wall pipes. As shown in Figure 10a, an 11-mm thick steel pipe (outer diameter 720 mm, length 1000 mm) was used as the waveguide. For simplicity, a rectangular notch was used as an approximation of a corrosion type damage. Note that a real corrosion defect may have rough un-predicted surface conditions, but a rectangular notch could be a first step approximation of a corrosion type defect which is commonly used in the lab tests and theoretical studies [24,26,31]. Four identical bidirectional transducers are used to constitute the monitoring system. The layout of these transducers is shown in Figure 10a. We first consider the simple case where the operating frequency regime is below the CSH1 cutoff frequency. At this case, a single surface-bonded bidirectional transducer (actuator A shown in Figure 10a) is enough to excite pure CSH0 wave. When pure CSH0 wave was incident on the notch, only the CSH0 mode contributes to the reflection and transmission of the wave. Obviously, the CSH0 wave will travel back and forth inside the notch, so there will be a series of consecutive reflections. The first reflection coefficient obtained at a step down (step A shown in Figure 10a) is then given by [24]:

where , where is the depth of the notch and is the original thickness of the pipe as shown in Figure 10a. The corresponding transmission coefficient past the step A would be:

Figure 10.

(a) Schematic of the experimental setup for monitoring the corrosion-like defect. (b) Theoretically predicted the change of the amplitude ratio of the two reflected signals versus the relative depth of the notch defect.

When the transmitted wave travels to the up step (step B shown in Figure 10a), part of wave energy reflects and then passes though step A, so the obtained second reflection is:

Similarly, the amplitude of the third reflection is given by:

For a typical , is only about 3%. Therefore, the third reflection is negligible. Only the first and second reflections have practical importance for detecting the notch defect. The time delay between the first reflection and the second one is , where is the circumferential extent of the notch and is the group velocity of the CSH0 wave. Obviously, if is relatively large, the two reflected signals can be separated in time. This characteristic can be used to measure the circumferential extent of the notch. However, if is too small, the reflected signals will overlap in time domain, which will induce the total reflection signal complex due to the constructive and destructive interference of the two reflected signals. The target of this work is to size the corrosion-like defect larger than in area and deep where is the original thickness of the pipe. Therefore, the circumferential extent of the notch was set to be 55 mm in the experiments as shown in Figure 10a. This extent can separate the two reflected signals in time domain, so it can be measured. The depth of the notch can be determined by using the amplitude ratio of the two reflected signals:

By measuring the amplitude ratio , the relative depth can be obtained. It should be noted that calculation of by using the amplitude ratio is better than using reflection coefficient or directly, since the absolute value of the reflection coefficient is strongly influenced by the beam divergence, roughness of the pipe and the quality of bonding layer between sensor and the pipe. These factors can be minimized by using the amplitude ratio .

Figure 10b presents the theoretically predicted change of the amplitude ratio versus the relative depth of the notch defect. It can be seen that the amplitude ratio always increases with the increase of relative depth. When the relative depth is smaller than 0.5, the ratio almost keeps constant, indicating that this method is insensitive to shallow defects. However, when the relative depth becomes larger than 0.6, the increase rate of the ratio becomes larger and larger. Therefore, the ratio is a good damage index for deep defects. In order to explore the effectiveness of the proposed method, the shallowest depth of the notch in the experiments is set to be 7 mm. Then the depth of the same notch was machined in 1 mm steps to 8 mm and then to 9 mm. For each case, machining started in the shallowest depth, the measurement experiment was conducted, and then the same notch was remachined to the next depth. In all cases, the incident CSH0 wave was excited by the actuator A at 135 kHz and the reflected signals from the notch were received by the sensor A shown in Figure 10a. For an 11-mm thick steel pipe, 135 kHz is corresponding to 1.485 MHz·mm, which is below the cut off frequency of CSH1 mode, so only CSH0 wave can propagate.

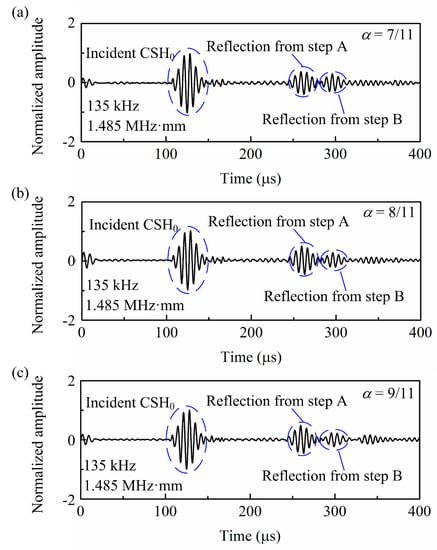

Figure 11 presents the wave signals excited by actuator A at 135 kHz and received by the sensor A shown in Figure 10a. As expected, pure CSH0 wave was successfully generated in the 11-mm thick steel pipe. After the incident CSH0 wave travels across the notches, the two reflected signals can be totally separated in the time domain. By extracting the time interval of 136.15 μs between the incident signal and the reflected signal from step A, the CSH0 wave’s group velocity of 3283 m/s can be obtained based on the propagation distance of 447 mm shown in Figure 10a. Combining the time interval of 35.47 μs between the reflection from step A and that from step B, the circumferential extent of the notch is estimated as 58.1 mm, which agrees with the real value of 55 mm. Moreover, by extracting the amplitudes of the two reflected signals from notches with different depths, the amplitude ratio was calculated and then the depth of notches can be obtained from Equation (5). Table 1 presents the notch depth sizing results for the rectangular notches with different depths. As shown, the estimated depths by using the amplitude ratio accord very well with the true values of the notches. The estimation errors for the cases of 7 mm and 9 mm are within 2%. However, larger error is observed in the case of 8 mm, which is attributed to the machining error of the notch.

Figure 11.

Experimental CSH0 wave signals showing the reflections from the rectangular notches with different depths.

Table 1.

Notch depth sizing results for the rectangular notches with different depths.

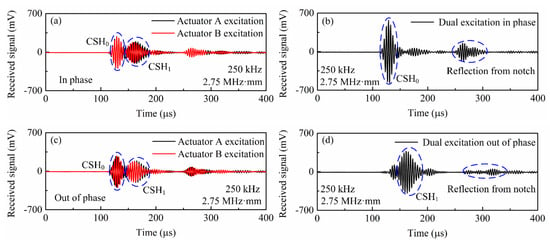

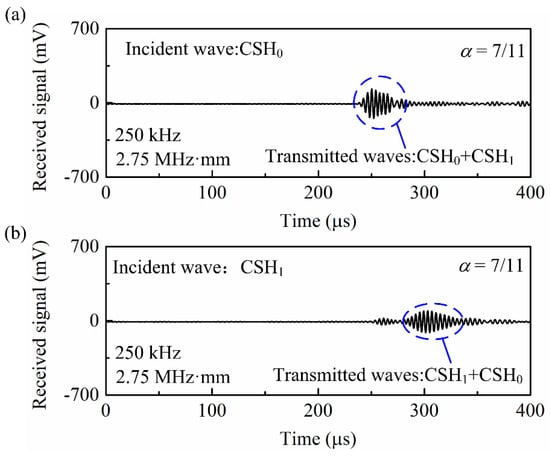

Subsequently, the case where the operating frequency regime is above the CSH1 cutoff frequency is investigated. Note that this discussion is limited to that the pipe thickness only supports CSH0 and CSH1 modes. Figure 12a presents the wave signals generated by a single outer-surface-bonded bidirectional transducer (actuator A shown in Figure 10a) at 250 kHz and received by the sensor A. The corresponding frequency-thickness of 2.75 MHz·mm is above the cutoff frequency of CSH1 mode, so both CSH0 and CSH1 modes are simultaneously excited in the pipe. For comparison, the inter-surface-bonded bidirectional transducer (actuator B shown in Figure 10a) was then energized with the same drive signal used in actuator A. The obtained wave signals are also plotted in Figure 12a. As shown, the CSH0 wave excited by actuator A is almost the same as that generated by actuator B, while the two excited CSH1 modes are out-of-phase. Analogously, if the drive signal for actuator B is antiphase relative to that for actuator A, Figure 12c shows that the CSH0 wave excited by actuator B is also antiphase relative to that generated by actuator A, while the obtained two CSH1 modes are in-phase. This phenomenon is attributed that the wave structure of CSH0 mode is uniform across the thickness of the pipe, while the corresponding distribution of CSH1 mode is antisymmetric across the pipe wall as shown in Figure 3. Therefore, when actuators A and B are energized in-phase, Figure 12b shows that the excited CSH0 wave is significantly enhanced, while the CSH1 wave decreases significantly. By contrast, when actuators A and B are energized out-of-phase, Figure 12d presents that almost pure CSH1 mode is obtained, since the weak CSH0 mode can be neglected. Obviously, these results are in good agreement with the excitation mechanisms proposed in Section 2.

Figure 12.

Selective generation of CSH0 and CSH1 modes by using dual excitation. (a) Actuator A and actuator B are driven one by one in phase, (b) the two transducers are simultaneously energized in phase, (c) the two transducers are driven one by one out-of-phase and (d) the two transducers are simultaneously energized out-of-phase.

Although pure incident CSH0 wave is generated by using dual excitation, Figure 12b shows that the reflected signals from the notch (depth: 7 mm) are still more complex than that shown in Figure 11a. The reflections contain not only the two reflected CSH0 waves but also the CSH1 mode due to mode conversion. These wave modes overlap in time domain, so the above methods to determine the depth and circumferential extents of the notch become invalid. Therefore, we move to explore the transmission signals. After the incident CSH0 wave passes through a 7-mm deep notch, its transmitted signals are measured by sensor B (shown in Figure 10a) and the results are plotted in Figure 13a. Obviously, both CSH0 and CSH1 modes are generated in the transmitted signals and their waveforms also overlap in the time domain. Similarly, when pure CSH1 mode is excited as the incident wave, the transmitted wave measured by sensor B also contains CSH0 and CSH1 modes as shown in Figure 13b.

Figure 13.

Experimental wave signals showing the transmission from a 7-mm deep rectangular notch.

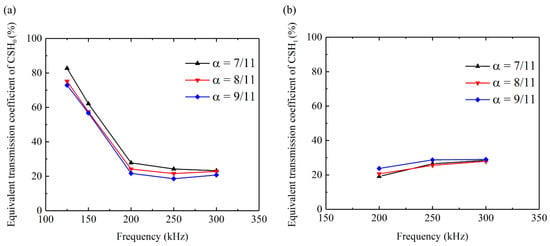

By analyzing the group velocity, it is found that when the incident wave is CSH0 mode, most of the transmitted wave’s energy comes from the CSH0 mode. Analogously, when CSH1 mode is used as incident wave, CSH1 wave is the dominant mode in the transmitted signals. Therefore, by extracting the amplitude of the transmitted signal and combining the incident wave measured by sensor A, the equivalent transmission coefficient can be calculated. By sending pure CSH0 wave at different frequencies, the equivalent transmission coefficients for notches with different depths can be obtained as shown in Figure 14a. It can be seen that the transmission coefficients for all the notches first decrease monotonically with frequency and then keep almost constant after 200 kHz. This phenomenon accords very well with the simulations conducted by Luo, Zhao and Rose [22].

Figure 14.

Equivalent transmission coefficients for notches with different depths by sending pure (a) CSH0 and (b) CSH1 wave at different frequencies.

The transmission coefficient of CSH0 wave first decreases monotonically with frequency when the frequency range is approximately below the first cutoff frequency and then keep almost constant when the frequency range exceeds the cutoff frequency of CSH1 mode. This is the first experimental evidence for the simulated transmission characteristics of CSH0 wave across a notch at different frequencies. Moreover, Figure 14a shows that the transmission coefficients at all the frequencies decrease with increasing the notch depth. This phenomenon is valuable because it makes possible the depth monitoring through transmission coefficients. Analogously, by sending pure CSH1 wave at different frequencies, the corresponding equivalent transmission coefficients can also be obtained as shown in Figure 14b. It can be seen that the transmission coefficients for all the notch depths are almost independent of the frequency of the incident CSH1 wave. Moreover, no obvious change is observed when changing the notch’s depth. Therefore, CSH0 mode is more useful than CSH1 mode to monitor the change of the defect depth by using the transmission coefficient.

4. Summary and Conclusions

In summary, a circumferential SH wave piezoelectric transducer system was developed to monitor corrosion-like defect in large-diameter pipes. Firstly, a previously proposed bidirectional SH wave piezoelectric transducer’s performance on exciting CSH waves was investigated by using both finite element simulations and experiments. Results show that the bidirectional piezoelectric transducer is capable of exciting pure CSH0 mode traveling in both circumferential directions of a 1-mm thick steel pipe from 100 to 300 kHz. All the axial guided waves and circumferential Lamb waves are suppressed within this frequency range. Moreover, the bidirectional transducer can also serve as a sensor to detect CSH0 mode only by filtering CLamb waves over a wide frequency range from 100 kHz to 450 kHz. After that, a method of sizing a rectangular notch defect by using CSH0 wave was proposed and then confirmed by experiments. Experiments on an 11-mm thick steel pipe show that the depth and circumferential extent of a notch can be accurately determined by using the reflection signals from the notch. This inversion method is valid only below the cutoff frequency of CSH1 mode. When the operating frequency is above the first cutoff frequency, dual excitation with symmetrically mounted bidirectional transducers was validated as a useful method for selectively exciting CSH0 or CSH1 mode. When pure CSH0 mode above the first cutoff frequency passed through notch defects, it was found that the equivalent transmission coefficients at all the frequencies decreased with the increasing of notch depth. This phenomenon was not observed when pure CSH1 mode was used as the incident wave. Therefore, CSH0 mode is more useful than CSH1 mode to monitor the change of the defect depth by using the transmission coefficient. This work indicates that for a simple rectangular notch, defect sizing is possible by using CSH0 mode. Future investigations will focus on studying the reflection and transmission characteristics of CSH waves encountering half-elliptical shaped defects, which are more approximate to corrosion defects than notches.

Author Contributions

Conceptualization, H.M.; Methodology, H.M. and H.Z.; Software, H.Z.; Validation, H.Z., Y.D. and J.T; Formal Analysis, H.Z., Y.D. and H.M.; Investigation, H.Z., Y.D. and J.T.; Resources, H.Z., Y.D. and J.T.; Data Curation, H.Z.; Writing-Original Draft Preparation, H.Z.; Writing-Review & Editing, H.M and G.K.; Visualization, H.Z., Y.D. and J.T.; Supervision, H.M. and G.K.; Project Administration, H.M.; Funding Acquisition, H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the National Natural Science Foundation of China (11802249) and the Fundamental Research Funds for the Central Universities of China (2682019CX41 and 2682019LXCGKY002).

Conflicts of Interest

Authors declare no conflict of interest.

References

- Su, Z.Q.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer Science & Business Media: Heidelberg, Germany, 2009; Volume 48. [Google Scholar]

- Guan, R.; Lu, Y.; Duan, W.; Wang, X. Guided waves for damage identification in pipeline structures: A review. Struct. Control Health Monit. 2017, 24, e2007. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- Gazis, D.C. Three-Dimensional Investigation of the Propagation of Waves in Hollow Circular Cylinders. I. Analytical Foundation. J. Acoust. Soc. Am. 1959, 31, 568–573. [Google Scholar] [CrossRef]

- Gazis, D.C. Three-Dimensional Investigation of the Propagation of Waves in Hollow Circular Cylinders. II. Numerical Results. J. Acoust. Soc. Am. 1959, 31, 573–578. [Google Scholar] [CrossRef]

- Silk, M.G.; Bainton, K.F. The propagation in metal tubing of ultrasonic wave modes equivalent to Lamb waves. Ultrasonics 1979, 17, 11–19. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Lowe, M.J.S.; Cawley, P. The Reflection of Guided Waves from Circumferential Notches in Pipes. J. Appl. Mech. 1998, 65, 635–641. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Cawley, P. The excitation of Lamb waves in pipes using dry-coupled piezoelectric transducers. J. Nondestruct. Eval. 1996, 15, 11–20. [Google Scholar] [CrossRef]

- Liu, Z.H.; He, C.F.; Wu, B.; Wang, X.M.; Yang, S.M. Circumferential and longitudinal defect detection using T (0, 1) mode excited by thickness shear mode piezoelectric elements. Ultrasonics 2006, 44, e1135–e1138. [Google Scholar] [CrossRef]

- Miao, H.C.; Huan, Q.; Wang, Q.Z.; Li, F.X. Excitation and reception of single torsional wave T (0,1) mode in pipes using face-shear d24 piezoelectric ring array. Smart Mater. Struct. 2017, 26, 025021. [Google Scholar] [CrossRef]

- Alleyne, D.N.; Vogt, T.; Cawley, P. The choice of torsional or longitudinal excitation in guided wave pipe inspection. Insight Non-Destr. Test. Cond. Monit. 2009, 51, 373–377. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, X.; Wu, B.; Song, G.; He, C. Thick Wall Pipes Inspection by Using Circumferential Shear Horizontal Waves and Continuous Wavelet Transform Approach Tions. In Proceedings of the 2013 International Congress on Ultrasonics, Singapore, 2–5 May 2013; pp. 81–86. [Google Scholar]

- Clough, M.; Fleming, M.; Dixon, S. Circumferential guided wave EMAT system for pipeline screening using shear horizontal ultrasound. NDT E Int. 2017, 86, 20–27. [Google Scholar] [CrossRef]

- Howard, R.; Cegla, F. On the probability of detecting wall thinning defects with dispersive circumferential guided waves. NDT E Int. 2017, 86, 73–82. [Google Scholar] [CrossRef]

- Howard, R.; Cegla, F. Detectability of corrosion damage with circumferential guided waves in reflection and transmission. NDT E Int. 2017, 91, 108–119. [Google Scholar] [CrossRef]

- Luo, W.; Rose, J.L.; Van Velsor, J.K.; Avioli, M.; Spanner, J. Circumferential guided waves for defect detection in coated pipe. AIP Conf. Proc. 2006, 820, 165–172. [Google Scholar]

- Chua, C.A.; Alleyne, D.N.; Calva, M. Crack growth monitoring using low-frequency guided waves. Insight 2017, 59, 64–71. [Google Scholar] [CrossRef]

- Liu, G.L.; Qu, J.M. Guided circumferential waves in a circular annulus. J. Appl. Mech. Trans. ASME 1998, 65, 424–430. [Google Scholar] [CrossRef]

- Zhao, X.L.; Rose, J.L. Guided circumferential shear horizontal waves in an isotropic hollow cylinder. J. Acoust. Soc. Am. 2004, 115, 1912–1916. [Google Scholar] [CrossRef]

- Zhao, X.L.; Varma, V.K.; Mei, G.; Ayhan, B.; Kwan, C. In-line nondestructive inspection of mechanical dents on pipelines with guided shear horizontal wave electromagnetic acoustic transducers. J. Press. Vessel Technol. ASME 2005, 127, 304–309. [Google Scholar] [CrossRef]

- Luo, W.; Zhao, X.L.; Rose, J.L. A guided wave plate experiment for a pipe. J. Press. Vessel Technol. ASME 2005, 127, 345–350. [Google Scholar] [CrossRef]

- Kubrusly, A.C.; Freitas, M.A.; von der Weid, J.P.; Dixon, S. Interaction of SH guided waves with wall thinning. NDT E Int. 2019, 101, 94–103. [Google Scholar] [CrossRef]

- Demma, A.; Cawley, P.; Lowe, M. Scattering of the fundamental shear horizontal mode from steps and notches in plates. J. Acoust. Soc. Am. 2003, 113, 1880–1891. [Google Scholar] [CrossRef]

- Pau, A.; Capecchi, D.; Vestroni, F. Reciprocity principle for scattered fields from discontinuities in waveguides. Ultrasonics 2015, 55, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Pau, A.; Achillopoulou, D.V. Interaction of Shear and Rayleigh-Lamb Waves with Notches and Voids in Plate Waveguides. Materials 2017, 10, 841. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.G.; Rose, J.L. Boundary element modeling for defect characterization potential in a wave guide. Int. J. Solids Struct. 2003, 40, 2645–2658. [Google Scholar] [CrossRef]

- Wang, S.; Huang, S.; Zhao, W.; Wei, Z. 3D modeling of circumferential SH guided waves in pipeline for axial cracking detection in ILI tools. Ultrasonics 2015, 56, 325–331. [Google Scholar] [CrossRef]

- Nakamura, N.; Ogi, H.; Hirao, M.; Nakahata, K. Mode conversion behavior of SH guided wave in a tapered plate. NDT E Int. 2012, 45, 156–161. [Google Scholar]

- Nurmalia, N.; Nakamura, N.; Ogi, H.; Hirao, M. Detection of Shear Horizontal Guided Waves Propagating in Aluminum Plate with Thinning Region. Jpn. J. Appl. Phys. 2011, 50, 07HC17. [Google Scholar] [CrossRef]

- Kubrusly, A.C.; von der Weid, J.P.; Dixon, S. Experimental and numerical investigation of the interaction of the first four SH guided wave modes with symmetric and non-symmetric discontinuities in plates. NDT E Int. 2019, 108, 102175. [Google Scholar] [CrossRef]

- Hirao, M.; Ogi, H. An SH-wave EMAT technique for gas pipeline inspection. NDT E Int. 1999, 32, 127–132. [Google Scholar] [CrossRef]

- Miao, H.C.; Dong, S.X.; Li, F.X. Excitation of fundamental shear horizontal wave by using face-shear (d36) piezoelectric ceramics. J. Appl. Phys. 2016, 119, 174101. [Google Scholar] [CrossRef]

- Miao, H.C.; Huan, Q.; Li, F.X. Excitation and reception of pure shear horizontal waves by using face-shear d (24) mode piezoelectric wafers. Smart Mater. Struct. 2016, 25, 11LT01. [Google Scholar] [CrossRef]

- Miao, H.C.; Xu, L.; Zhang, H. SH guided wave excitation by an apparent face-shear mode (d36) piezocomposite transducer: Experiments and theory. Smart Mater. Struct. 2019, 28, 115045. [Google Scholar] [CrossRef]

- Huan, Q.; Chen, M.; Li, F. A Comparative Study of Three Types Shear Mode Piezoelectric Wafers in Shear Horizontal Wave Generation and Reception. Sensors 2018, 18, 2681. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Yuan, F.G.; Shi, T. Guided torsional wave generation of a linear in-plane shear piezoelectric array in metallic pipes. Ultrasonics 2016, 65, 69–77. [Google Scholar] [CrossRef] [PubMed]

- Miao, H.C.; Huan, Q.; Li, F.X.; Kang, G.Z. A variable-frequency bidirectional shear horizontal (SH) wave transducer based on dual face-shear (d24) piezoelectric wafers. Ultrasonics 2018, 89, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.Q.; Ye, L. Selective generation of Lamb wave modes and their propagation characteristics in defective composite laminates. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2004, 218, 95–110. [Google Scholar] [CrossRef]

- Kubrusly, A.C.; Freitas, M.A.; von der Weid, J.P.; Dixon, S. Mode Selectivity of SH Guided Waves by Dual Excitation and Reception Applied to Mode Conversion Analysis. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2018, 65, 1239–1249. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).