Optimization of Chemical Extraction Conditions of Dietary Fiber from Cistanche deserticola Residues and Its Structural Characteristics and Physicochemical and Functional Properties

Abstract

:1. Introduction

2. Results

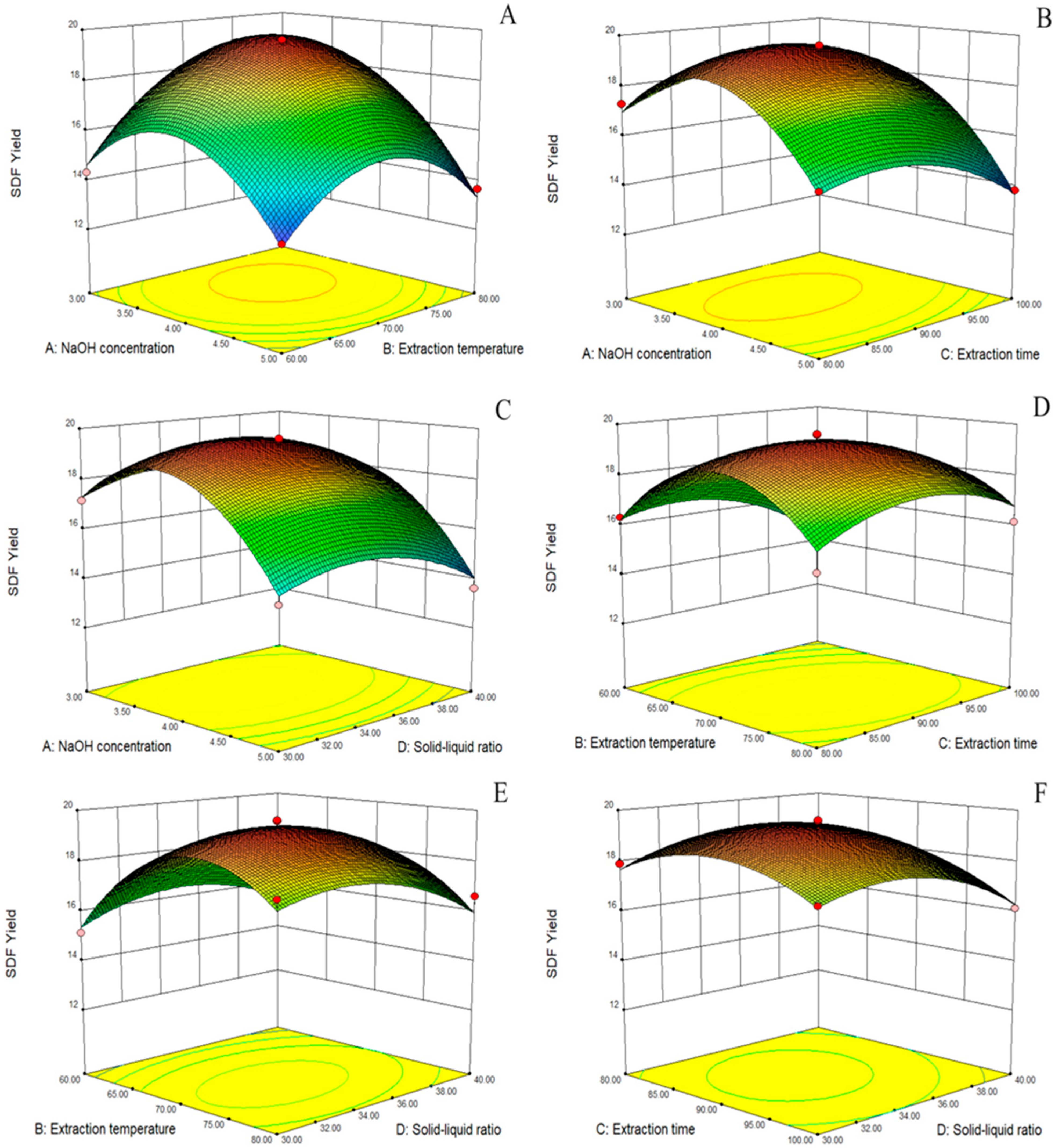

2.1. Response Surface Optimization Results

2.1.1. Optimization of SDF Extraction

2.1.2. Response Surface Analysis

2.1.3. Optimization of Parameters and Verification of the Model

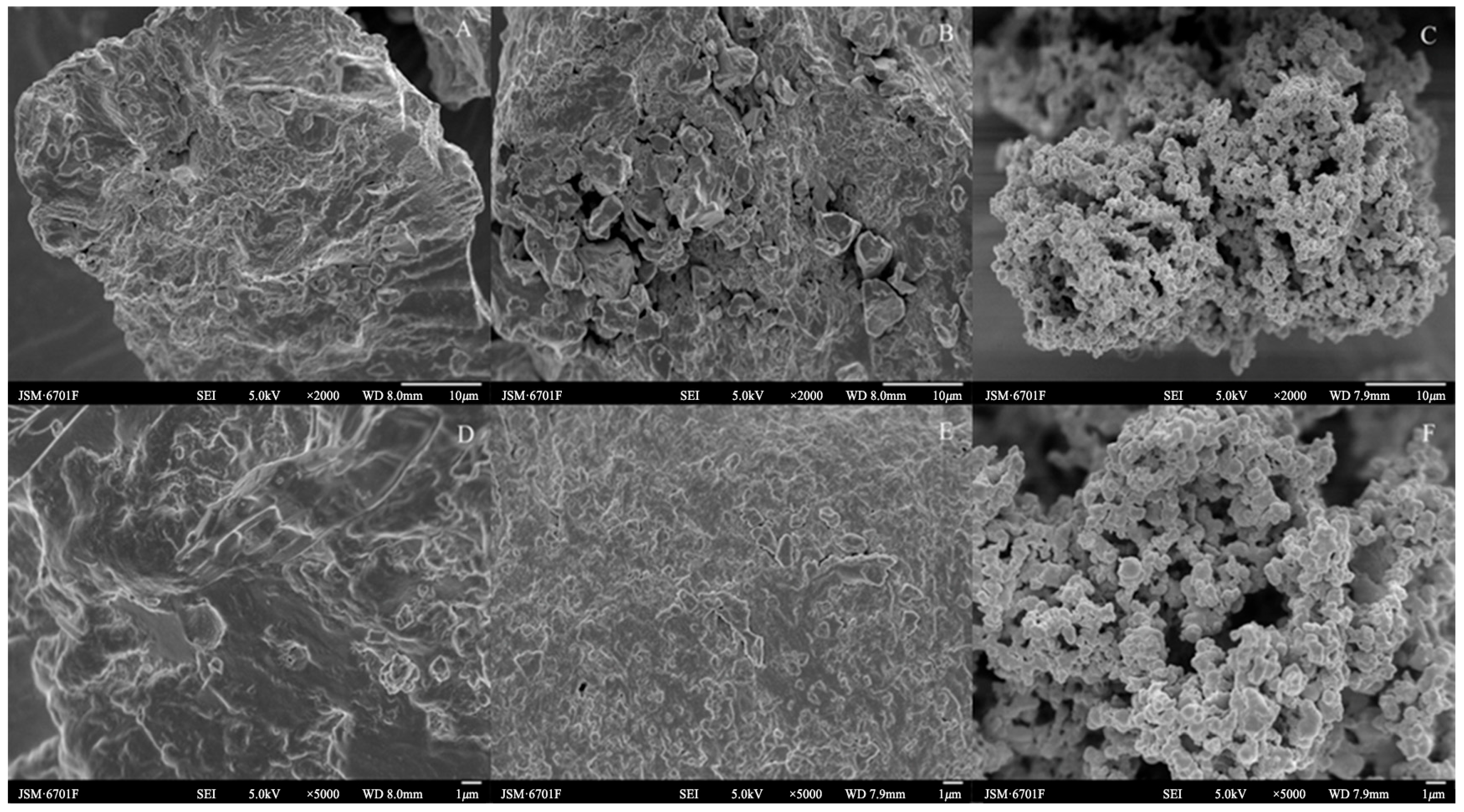

2.2. SEM

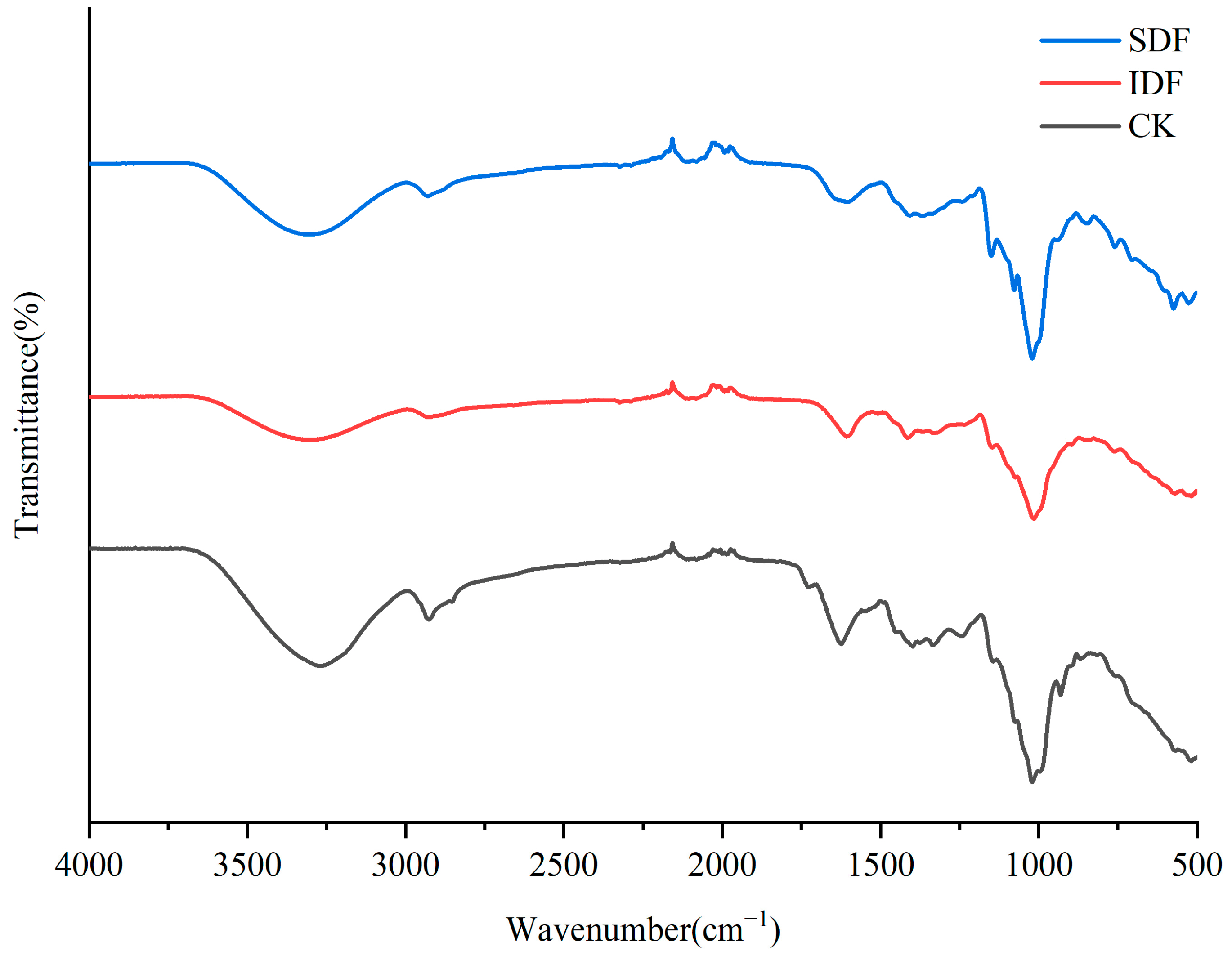

2.3. FTIR

2.4. XRD

2.5. Composition of Monosaccharides

2.6. Physicochemical Properties

WHC and OHC

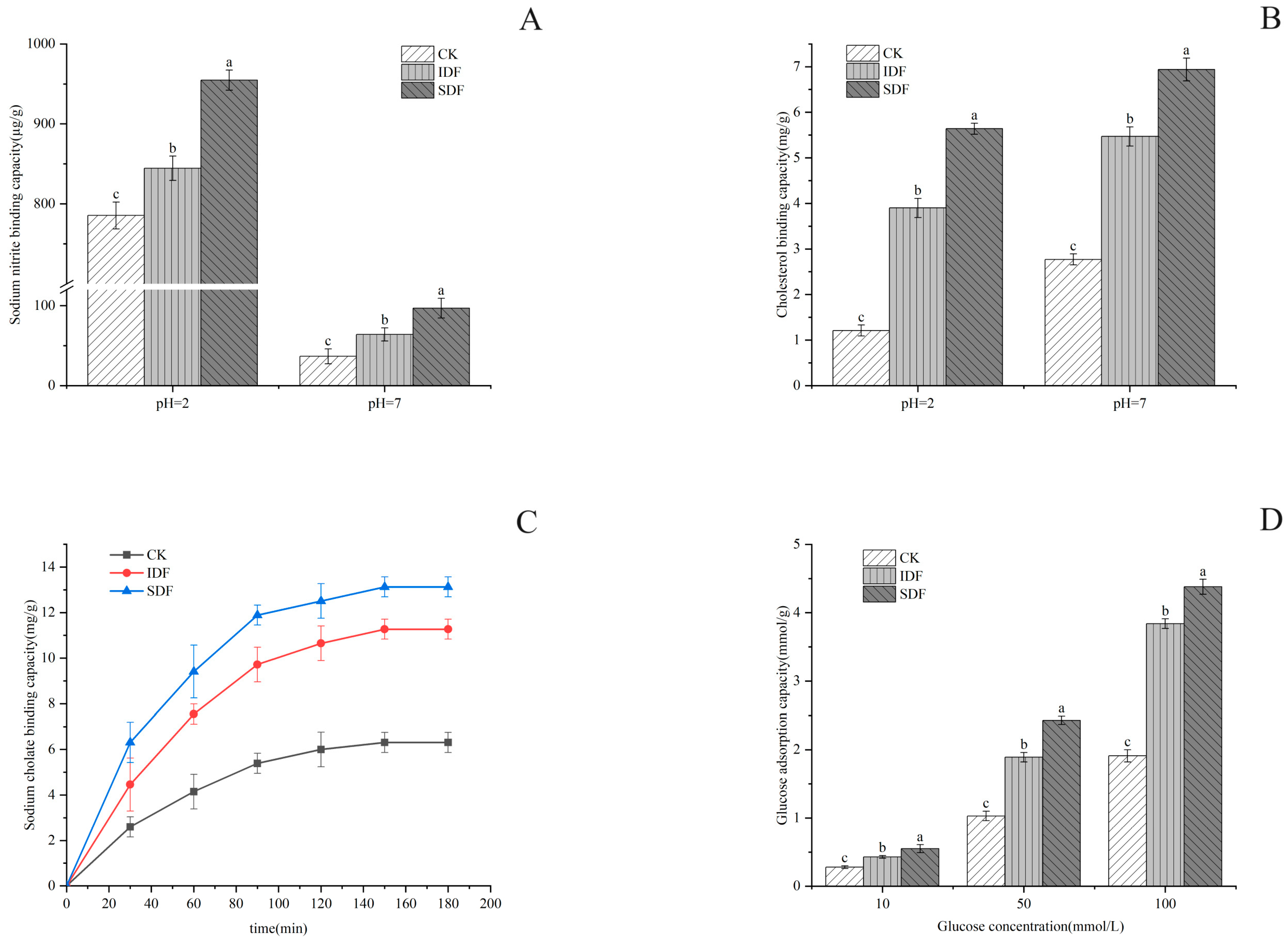

2.7. Functional Properties

2.7.1. NIAC

2.7.2. CAC

2.7.3. SAC

2.7.4. GAC

3. Materials and Methods

3.1. Reagents and Chemicals

3.2. Extraction of SDF and IDF

3.2.1. Extraction of Dietary Fiber

3.2.2. Optimization of Extraction Conditions

3.3. Scanning Electron Microscopy (SEM)

3.4. Fourier Transform Infrared Spectrometry (FTIR)

3.5. X-ray Diffraction (XRD)

3.6. Composition of Monosaccharides

3.7. Physicochemical Properties

3.7.1. Water-Holding Capacity (WHC)

3.7.2. Oil-Holding Capacity (OHC)

3.8. Functional Properties

3.8.1. Nitrite Ion Adsorption Capacity (NIAC)

3.8.2. Cholesterol Adsorption Capacity (CAC)

3.8.3. Sodium Cholate Adsorption Capacity (SAC)

3.8.4. Glucose Adsorption Capacity (GAC)

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, N.; Wang, H.; Hao, H.-F.; Rahman, F.U.; Zhang, Y.M. Research progress on polysaccharide components of Cistanche deserticola as potential pharmaceutical agents. Eur. J. Med. Chem. 2023, 245, 114892. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-L.; Zhang, Y.-L.; Su, X.-M.; Zou, P.-F.; Wang, X.-Y.; Chen, J.; Zhu, X. Effects of Two Kinds of Extracts of Cistanche deserticola on Intestinal Microbiota and Its Metabolis. Foods 2022, 11, 2897. [Google Scholar] [CrossRef] [PubMed]

- Ai, Z.P.; Xie, Y.K.; Li, X.Y.; Lei, D.W.; Ambrose, K.; Liu, Y.H. Revealing color change and drying mechanisms of pulsed vacuum steamed Cistanche deserticola through bioactive components, microstructural and starch gelatinization properties. Food Res. Int. 2022, 162, 112079. [Google Scholar] [CrossRef]

- Liu, X.J.; Wu, X.L.; Wang, S.Y.; Zhao, Z.Y.; Jian, C.; Li, M.Y.; Qin, X.M. Microbiome and metabolome integrally reveal the anti-depression effects of Cistanche deserticola polysaccharides from the perspective of gut homeostasis. Int. J. Biol. Macromol. 2023, 245, 125542. [Google Scholar] [CrossRef] [PubMed]

- Morikawa, T.; Xie, H.H.; Pan, Y.N.; Ninomiya, K.; Yuan, D.; Jia, X.G.; Yoshikawa, M.; Nakamura, S.; Matsuda, H.; Muraoka, O. A Review of Biologically Active Natural Products from a Desert Plant Cistanche tubulosa. Chem. Pharm. Bull. 2019, 67, 675–689. [Google Scholar] [CrossRef]

- Ai, Z.P.; Xie, Y.K.; Li, X.Y.; Zhu, G.F.; Peng, Z.K.; Liu, Y.H.; Mowafy, S.; Guo, J.L. Mechanism of freezing treatment to improve the efficiency of hot air impingement drying of steamed Cistanche deserticola and the quality attribute of the dried product. Ind. Crop. Prod. 2023, 195, 116472. [Google Scholar] [CrossRef]

- Lei, H.B.; Wang, X.Y.; Zhang, Y.H.; Cheng, T.F.; Mi, R.; Xu, X.K.; Zu, X.P.; Zhang, W.D. Herba Cistanche (Rou Cong Rong): A Review of Its Phytochemistry and Pharmacology. Chem. Pharm. Bull. 2020, 68, 694–712. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.Q.; Feng, D.; Zhou, Y.X.; Duan, H.; Jiang, Y.J.; Yan, W.J. Analysis of the active ingredients and health applications of cistanche. Front. Nutr. 2023, 10, 1101182. [Google Scholar] [CrossRef]

- Song, Y.L.; Zeng, K.W.; Jiang, Y.; Tu, P.F. Cistanches Herba, from an endangered species to a big brand of Chinese medicine. Med. Res. Rev. 2021, 41, 1539–1577. [Google Scholar] [CrossRef]

- Ul Ain, H.B.; Saeed, F.; Arshad, M.U.; Ahmad, N.; Nasir, M.A.; Amir, R.M.; Kausar, R.; Niaz, B. Modification of barley dietary fiber through chemical treatments in combination with thermal treatment to improve its bioactive properties. Int. J. Food Prop. 2018, 21, 2491–2499. [Google Scholar] [CrossRef]

- Fuller, S.; Beck, E.; Salman, H.; Tapsell, L. New Horizons for the Study of Dietary Fiber and Health: A Review. Plant Foods Hum. Nutr. 2016, 71, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.X.; Shah, B.R.; Li, J.; Liang, H.S.; Zhan, F.C.; Geng, F.; Li, B. A critical review on interplay between dietary fibers and gut microbiota. Trends Food Sci. Technol. 2022, 124, 237–249. [Google Scholar] [CrossRef]

- Tan, Z.B.; Meng, Y.; Li, L.; Wu, Y.R.; Liu, C.; Dong, W.G.; Chen, C.Z. Association of Dietary Fiber, Composite Dietary Antioxidant Index and Risk of Death in Tumor Survivors: National Health and Nutrition Examination Survey 2001–2018. Nutrients 2023, 15, 2968. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Su, W.; Mu, Y.C. Modification of bamboo shoot dietary fiber by extrusion-cellulase technology and its properties. Int. J. Food Prop. 2018, 21, 1219–1232. [Google Scholar] [CrossRef]

- Zhu, Y.; He, C.H.; Fan, H.X.; Lu, Z.X.; Lu, F.X.; Zhao, H.Z. Modification of foxtail millet (Setaria italica) bran dietary fiber by xylanase-catalyzed hydrolysis improves its cholesterol-binding capacity. LWT-Food Sci. Technol. 2019, 101, 463–468. [Google Scholar] [CrossRef]

- Ul Ain, H.B.; Saeed, F.; Ahmed, A.; Khan, M.A.; Niaz, B.; Tufail, T. Improving the physicochemical properties of partially enhanced soluble dietary fiber through innovative techniques:a coherent review. J. Food Process. Pres. 2019, 43, e13917. [Google Scholar] [CrossRef]

- Bashir, S.; Ahmad, A.; Abbasi, K.S.; Akram, Z. Optimization of ultrasonic-assisted extraction of insoluble dietary fiber from wheat bran and its characterization. J. Food Process. Pres. 2022, 46, 16419. [Google Scholar] [CrossRef]

- Grosse, C.S.; Cope, V.C. Dietary Fibre Intake and Bowel Habits After Bariatric Surgery: A Structured Literature Review. Obes. Surg. 2019, 29, 2247–2254. [Google Scholar] [CrossRef]

- Zhang, S.S.; Duan, J.Y.; Zhang, T.T.; Lv, M.; Gao, X.G. Effect of compound dietary fiber of soybean hulls on the gel properties of myofibrillar protein and its mechanism in recombinant meat products. Front. Nutr. 2023, 10, 1129514. [Google Scholar] [CrossRef]

- Vilcapoma, W.; de Bruijn, J.; Elias-Penafiel, C.; Espinoza, C.; Farfan-Rodriguez, L.; Lopez, J.; Encina-Zelada, C.R. Optimization of Ultrasound-Assisted Extraction of Dietary Fiber from Yellow Dragon Fruit Peels and Its Application in Low-Fat Alpaca-Based Sausages. Foods 2023, 12, 2945. [Google Scholar] [CrossRef]

- Dong, W.J.; Wang, D.D.; Hu, R.S.; Long, Y.Z.; Lv, L.H. Chemical composition, structural and functional properties of soluble dietary fiber obtained from coffee peel using different extraction methods. Food Res. Int. 2020, 136, 109497. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.J.; Meng, P.; Liu, S.D.; Tan, Z.M.; Yang, X.; Liang, L.H.; Xie, F.; Zhang, H.; Wang, G.Q.; Xiong, Z.Q.; et al. Structural and Potential Functional Properties of Alkali-Extracted Dietary Fiber From Antrodia camphorate. Front. Microbiol. 2022, 13, 921164. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.H.; Ramachandraiah, K.; Wu, Z.G.; Ameer, K. The Influence of Different Extraction Methods on the Structure, Rheological, Thermal and Functional Properties of Soluble Dietary Fiber from Sanchi (Panax notoginseng) Flower. Foods 2022, 11, 1995. [Google Scholar] [CrossRef]

- Wen, Y.; Niu, M.; Zhang, B.; Zhao, S.; Xiong, S. Structural characteristics and functional properties of rice bran dietary fiber modified by enzymatic and enzyme-micronization treatments. LWT-Food Sci. Technol. 2017, 75, 344–351. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Wang, Q.; Huang, J.Q.; Fang, D.Y.; Zhuang, W.J.; Luo, X.L.; Zou, X.B.; Zheng, B.D.; Cao, H. Hypoglycemic effect of dietary fibers from bamboo shoot shell: An in vitro and in vivo study. Food Chem. Toxicol. 2019, 127, 120–126. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Xiong, M.; Bai, T.M.; Chen, D.W.; Zhang, Q.; Lin, D.R.; Liu, Y.T.; Liu, A.P.; Huang, Z.Q.; Qin, W. Comparative study on the structure, physicochemical, and functional properties of dietary fiber extracts from quinoa and wheat. LWT-Food Sci. Technol. 2021, 149, 111816. [Google Scholar] [CrossRef]

- Tang, Z.J.; Huang, G.L.; Huang, H.L. Ultrasonic/cellulase-assisted extraction of polysaccharide from Garcinia mangostana rinds and its carboxymethylated derivative. Ultrason. Sonochemistry 2023, 99, 106571. [Google Scholar] [CrossRef]

- Lin, B.B.; Fan, Y.M.; Huang, G.L. Preparation, analysis and properties of shaddock ped polysaccharide and its derivatives. Carbohydr. Res. 2023, 533, 108932. [Google Scholar] [CrossRef]

- Huang, H.R.; Chen, J.J.; Chen, Y.; Xie, J.H.; Liu, S.; Sun, N.; Hu, X.B.; Yu, Q. Modification of tea residue dietary fiber by high-temperature cooking assisted enzymatic method: Structural, physicochemical and functional properties. LWT-Food Sci. Technol. 2021, 145, 111314. [Google Scholar] [CrossRef]

- Dong, Y.F.; Li, Q.; Zhao, Y.H.; Cao, J.X. Effects of ultrasonic assisted high-temperature cooking method on the physicochemical structure characteristics and in vitro antioxidant capacities of dietary fiber from Dendrocalamus brandisii Munro shoots. Ultrason. Sonochemistry 2023, 97, 106462. [Google Scholar] [CrossRef]

- Kaur, B.; Panesar, P.S.; Thakur, A. Extraction and evaluation of structural and physicochemical properties of dietary fiber concentrate from mango peels by using green approach. Biomass Convers. Biorefinery 2021, 1–10. [Google Scholar] [CrossRef]

- Sang, J.Q.; Li, L.; Wen, J.; Gu, Q.Q.; Wu, J.J.; Yu, Y.S.; Xu, Y.J.; Fu, M.Q.; Lin, X. Evaluation of the Structural, Physicochemical and Functional Properties of Dietary Fiber Extracted from Newhall Navel Orange By-Products. Foods 2021, 10, 2772. [Google Scholar] [CrossRef]

- Zhang, W.M.; Zeng, G.L.; Pan, Y.G.; Chen, W.X.; Huang, W.Y.; Chen, H.M.; Li, Y.S. Properties of Soluble Dietary Fiber-Polysaccharide from Papaya Peel Obtained Through Alkaline or Ultrasound-Assisted Alkaline Extraction. Carbohydr. Polym. 2017, 172, 102–112. [Google Scholar] [CrossRef] [PubMed]

- Jia, M.Y.; Chen, J.J.; Liu, X.Z.; Xie, M.Y.; Nie, S.P.; Chen, Y.; Xie, J.H.; Yu, Q. Structural characteristics and functional properties of soluble dietary fiber from defatted rice bran obtained through Trichoderma viride fermentation. Food Hydrocoll. 2019, 94, 468–474. [Google Scholar] [CrossRef]

- Wang, K.L.; Li, M.; Wang, Y.X.; Liu, Z.H.; Ni, Y.Y. Effects of extraction methods on the structural characteristics and functional properties of dietary fiber extracted from kiwifruit (Actinidia deliciosa). Food Hydrocoll. 2020, 110, 106162. [Google Scholar] [CrossRef]

- Chu, J.X.; Zhao, H.Z.; Lu, Z.X.; Lu, F.X.; Bie, X.M.; Zhang, C. Improved physicochemical and functional properties of dietary fiber from millet bran fermented by Bacillus natto. Food Chem. 2019, 294, 79–86. [Google Scholar] [CrossRef]

- Lin, Y.A.; Chen, K.; Tu, D.; Yu, X.N.; Dai, Z.Y.; Shen, Q. Characterization of dietary fiber from wheat bran (Triticum aestivum L.) and its effect on the digestion of surimi protein. LWT-Food Sci. Technol. 2018, 102, 106–112. [Google Scholar] [CrossRef]

- Dong, J.L.; Wang, L.; Lu, J.; Zhu, Y.Y.; Shen, R.L. Structural, antioxidant and adsorption properties of dietary fiber from foxtail millet (Setaria italica) bran. J. Sci. Food Agric. 2019, 99, 3886–3894. [Google Scholar] [CrossRef]

- Zhang, S.S.; Xu, X.L.; Cao, X.; Liu, T.T. The structural characteristics of dietary fibers from Tremella fuciformis and their hypolipidemic effects in mice. Food Sci. Hum. Wellness 2022, 12, 503–511. [Google Scholar] [CrossRef]

- Ding, Q.Z.; Li, Z.K.; Wu, W.; Su, Y.Y.; Sun, N.Z.; Luo, L.; Ma, H.L.; He, R.H. Physicochemical and functional properties of dietary fiber from Nannochloropsis oceanica: A comparison of alkaline and ultrasonic-assisted alkaline extractions. LWT-Food Sci. Technol. 2020, 133, 110080. [Google Scholar] [CrossRef]

- Ma, R.; Chen, J.N.; Zhou, X.J.; Lin, H.; Gao, Q.; Peng, X.; Tanokura, M.; Xue, Y.L. Effect of chemical and enzymatic modifications on the structural and physicochemical properties of dietary fiber from purple turnip (Brassica rapa L.). LWT-Food Sci. Technol. 2021, 145, 111313. [Google Scholar] [CrossRef]

- Song, L.W.; Qi, J.R.; Liao, J.S.; Yang, X.Q. Enzymatic and enzyme-physical modification of citrus fiber by xylanase and planetary ball milling treatment. Food Hydrocoll. 2021, 121, 107015. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.C.; Lai, P.F.H.; Chen, J.S.; Xie, F.; Xia, Y.J.; Ai, L.Z. Fractionation, chemical characterization and immunostimulatory activity of β-glucan and galactoglucan from Russula vinosa Lindblad. Carbohydr. Polym. 2021, 256, 117559. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Dai, J.; Zhong, Y.; Wei, X.L.; Wu, M.X.; Zhang, Y.X.; Huang, A.; Wang, L.J.; Huang, Y.K.; Zhang, C.S.; et al. Characterization of insoluble dietary fiber from three food sources and their potential hypoglycemic and hypolipidemic effects. Food Funct. 2021, 12, 6576–6587. [Google Scholar] [CrossRef]

- Zhang, Y.; Qi, J.R.; Zeng, W.Q.; Huang, Y.X.; Yang, X.Q. Properties of dietary fiber from citrus obtained through alkaline hydrogen peroxide treatment and homogenization treatment. Food Chem. 2020, 311, 125873. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.L.; Wang, Q.; Fang, D.Y.; Zhuang, W.J.; Chen, C.H.; Jiang, W.T.; Zheng, Y.F. Modification of insoluble dietary fibers from bamboo shoot shell: Structural characterization and functional properties. Int. J. Biol. Macromol. 2018, 120, 1461–1467. [Google Scholar] [CrossRef] [PubMed]

- Deng, M.; Lin, Y.S.; Dong, L.H.; Jia, X.C.; Shen, Y.L.; Liu, L.; Chi, J.W.; Huang, F.; Zhang, M.W.; Zhang, R.F. Physicochemical and functional properties of dietary fiber from pummelo (Citrus grandis L. Osbeck) and grapefruit (Citrus paradisi Mcfad) cultivars. Food Biosci. 2021, 40, 100890. [Google Scholar] [CrossRef]

- Benitez, V.; Rebollo-Hernanz, M.; Hernanz, S.; Chantres, S.; Aguilera, Y.; Martin-Cabrejas, M.A. Coffee parchment as a new dietary fiber ingredient: Functional and physiological characterization. Food Biosci. 2019, 122, 105–113. [Google Scholar] [CrossRef]

- Ma, M.M.; Mu, T.H. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef]

| Level | X1 NaOH Concentration (%) | X2 Extraction Temperature (°C) | X3 Extraction Time (min) | X4 Solid–Liquid Ratio |

|---|---|---|---|---|

| −1 | 3 | 60 | 80 | 1:30 |

| 0 | 4 | 70 | 90 | 1:35 |

| 1 | 5 | 80 | 100 | 1:40 |

| Run | X1 | X2 | X3 | X4 | Yield (%) |

|---|---|---|---|---|---|

| 1 | 4 | 70 | 90 | 35 | 19.57 |

| 2 | 4 | 70 | 100 | 40 | 16.12 |

| 3 | 3 | 80 | 90 | 35 | 16.94 |

| 4 | 4 | 70 | 80 | 30 | 17.89 |

| 5 | 5 | 70 | 90 | 30 | 14.65 |

| 6 | 4 | 80 | 80 | 35 | 15.63 |

| 7 | 4 | 70 | 90 | 35 | 19.27 |

| 8 | 4 | 60 | 80 | 35 | 16.31 |

| 9 | 4 | 70 | 90 | 35 | 18.95 |

| 10 | 4 | 80 | 90 | 30 | 17.71 |

| 11 | 3 | 70 | 90 | 30 | 17.15 |

| 12 | 5 | 70 | 80 | 35 | 15.36 |

| 13 | 3 | 70 | 90 | 40 | 16.62 |

| 14 | 4 | 60 | 90 | 30 | 15.12 |

| 15 | 4 | 80 | 90 | 40 | 16.61 |

| 16 | 4 | 60 | 90 | 40 | 15.43 |

| 17 | 3 | 60 | 90 | 35 | 14.31 |

| 18 | 3 | 70 | 80 | 35 | 17.28 |

| 19 | 4 | 70 | 90 | 35 | 19.6 |

| 20 | 4 | 80 | 100 | 35 | 16.13 |

| 21 | 3 | 70 | 100 | 35 | 17.41 |

| 22 | 4 | 60 | 100 | 35 | 14.61 |

| 23 | 4 | 70 | 90 | 35 | 19.62 |

| 24 | 5 | 80 | 90 | 35 | 13.65 |

| 25 | 5 | 70 | 100 | 35 | 13.82 |

| 26 | 5 | 70 | 90 | 40 | 13.62 |

| 27 | 4 | 70 | 80 | 40 | 17.51 |

| 28 | 5 | 60 | 90 | 35 | 13.31 |

| 29 | 4 | 70 | 100 | 30 | 17.48 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 97.93 | 14 | 7.00 | 33.40 | <0.0001 | ** |

| A-X1 | 19.51 | 1 | 19.51 | 93.13 | <0.0001 | ** |

| B-X2 | 4.79 | 1 | 4.79 | 22.86 | 0.0003 | ** |

| C-X3 | 1.62 | 1 | 1.62 | 7.74 | 0.0147 | * |

| D-X4 | 1.39 | 1 | 1.39 | 6.66 | 0.0218 | * |

| AB | 1.31 | 1 | 1.31 | 6.26 | 0.0254 | * |

| AC | 0.70 | 1 | 0.70 | 3.33 | 0.0895 | |

| AD | 0.063 | 1 | 0.063 | 0.30 | 0.5935 | |

| BC | 1.21 | 1 | 1.21 | 5.78 | 0.0307 | * |

| BD | 0.50 | 1 | 0.50 | 2.37 | 0.1458 | |

| CD | 0.24 | 1 | 0.24 | 1.15 | 0.3024 | |

| A2 | 42.09 | 1 | 42.09 | 200.93 | <0.0001 | |

| B2 | 35.59 | 1 | 35.59 | 169.89 | <0.0001 | |

| C2 | 8.11 | 1 | 8.11 | 38.74 | <0.0001 | |

| D2 | 7.48 | 1 | 7.48 | 35.69 | <0.0001 | |

| Residual | 2.93 | 14 | 0.21 | |||

| Lack of Fit | 2.60 | 10 | 0.26 | 3.08 | 0.1445 | Not significant |

| Pure Error | 0.34 | 4 | 0.084 | |||

| Cor Total | 100.87 | 28 | ||||

| R-Squared | 0.9709 | |||||

| Adj R-Squared | 0.9419 | |||||

| Adeq Precision | 18.908 | |||||

| C.V. % | 2.78 |

| Monosaccharide Composition% | IDF | SDF |

|---|---|---|

| Fucose, Fuc | 0.30% | 0.00% |

| Rhamnose, Rha | 1.22% | 3.83% |

| Arabinose, Ara | 9.61% | 23.02% |

| Galactose, Gal | 3.97% | 7.03% |

| Glucose, Glc | 68.47% | 63.28% |

| Xylose, Xyl | 6.80% | 1.10% |

| Mannose, Man | 1.52% | 0.00% |

| Galacturonic Acid, Gal-UA | 8.10% | 1.20% |

| Glucuronic Acid, Glc-UA | 0.00% | 0.53% |

| WHC (g/g) | OHC (g/g) | |

|---|---|---|

| CK | 3.68 ± 0.07 a | 2.68 ± 0.11 c |

| IDF | 1.78 ± 0.09 c | 4.84 ± 0.08 a |

| SDF | 2.56 ± 0.12 b | 3.26 ± 0.09 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Zhao, Y.; Zhang, Z.; Wang, L.; Du, J.; Zhang, S. Optimization of Chemical Extraction Conditions of Dietary Fiber from Cistanche deserticola Residues and Its Structural Characteristics and Physicochemical and Functional Properties. Molecules 2023, 28, 7604. https://doi.org/10.3390/molecules28227604

Sun Z, Zhao Y, Zhang Z, Wang L, Du J, Zhang S. Optimization of Chemical Extraction Conditions of Dietary Fiber from Cistanche deserticola Residues and Its Structural Characteristics and Physicochemical and Functional Properties. Molecules. 2023; 28(22):7604. https://doi.org/10.3390/molecules28227604

Chicago/Turabian StyleSun, Ziming, Yuanyuan Zhao, Zhen Zhang, Li Wang, Jianming Du, and Shengxiang Zhang. 2023. "Optimization of Chemical Extraction Conditions of Dietary Fiber from Cistanche deserticola Residues and Its Structural Characteristics and Physicochemical and Functional Properties" Molecules 28, no. 22: 7604. https://doi.org/10.3390/molecules28227604

APA StyleSun, Z., Zhao, Y., Zhang, Z., Wang, L., Du, J., & Zhang, S. (2023). Optimization of Chemical Extraction Conditions of Dietary Fiber from Cistanche deserticola Residues and Its Structural Characteristics and Physicochemical and Functional Properties. Molecules, 28(22), 7604. https://doi.org/10.3390/molecules28227604