Biopolymers and Biobased Polymers: Chemistry and Engineering

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Biobased and Biodegradable Polymers".

Submission Status: Closed | Viewed by 96008Editors

Interests: polymers from renewable resources; natural polymers; biopolymers; biodegradable polymers; biobased polymers; polysaccharides; starch; cellulose; chitosan; chitin; protein; polymer processing; polymer engineering; polymer physics; polymer blends; polymer composites; polymer nanocomposites; sustainable materials; biodegradable materials; functional materials; bioplastics; processing-structure-property relationship

Special Issues, Collections and Topics in MDPI journals

Interests: natural polymers for food and high-value materials; SAXS/SANS insights into starch; multi-level structure characterization of starch and related modelling; biosynthesis-structure-functionality relationships of starch; real-time structural evolutions of polymers during processing

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

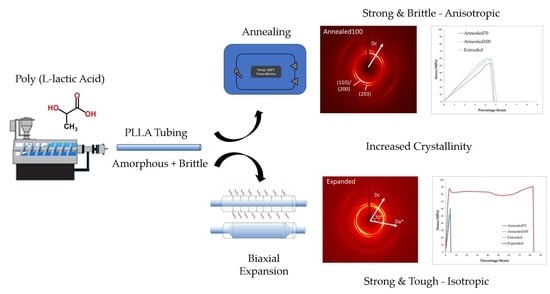

Petroleum-derived polymers have been popular for decades due to their interesting attributes, such as their lightness and strong mechanical properties, which makes them extremely useful for a wide range of application areas, such as packaging, transportation, household, construction, and aerospace. Despite this, in recent years there has been a strong research focus on a new class of polymers, namely, biopolymers (e.g., polysaccharides and proteins) and biobased polymers (e.g., polylactide and bio-polyesters). Much effort has already been devoted to replacing traditional oil-based polymers with these biopolymers and biobased polymers. In this regard, a major reason is that the heavy use of non-degradable synthetic polymers for decades has negatively influenced people’s health and caused irreversible damage to the environment. Given this, our human society urgently needs sustainable solutions to address the issues induced by the traditional ‘produce–use–discard’ practice. The other motivation to embrace biopolymers and biobased polymers is associated with their unique properties and appealing functionality. In particular, these polymers present enormous potential for environmental and biomedical applications due to their biodegradability, nontoxicity, chemical versatility and reactivity, biocompatibility, and bioresorbability.

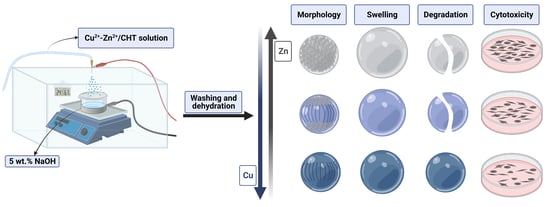

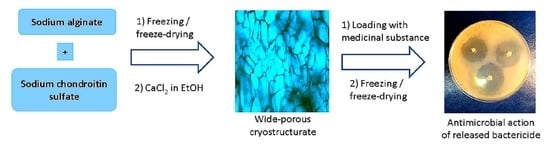

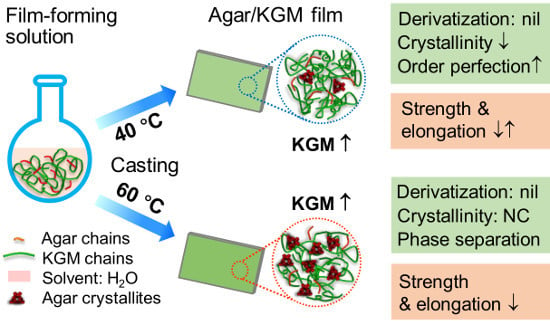

Despite their enormous potential, challenges remain for the application of biopolymers and biobased polymers. Engineering difficulties may exist for these ‘green’ polymers that prevent them from being cost-effectively processed into materials with desired forms and structures. Besides this, the resultant materials from biopolymers and biobased polymers may exhibit unsatisfactory properties (e.g., mechanical) for certain applications. Numerous studies have therefore been undertaken to enhance the competitiveness of biopolymers and biobased polymers by various means such as molecular design, chemical modification, material hybridisation, and process innovation. This Topical Collection is concerned with the chemistry and engineering aspects of different biopolymers (e.g., cellulose, chitosan/chitin, starch, proteins, and pectins) and biobased polymers (e.g., polylactide and polyhydroxyalkanoates). The collection provides an opportunity to discuss the trends in the field of biopolymers and biobased polymers, addresses the fundamental understanding of the structure–processing–property relationship for materials design, and highlights new, advanced, and functional materials developed from these sustainable polymers for diverse and emerging applications.

Dr. Fengwei Xie

Dr. Binjia Zhang

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- polymers from renewable resources

- natural polymers

- biopolymers

- polysaccharides

- biobased polymers

- bio-polyesters

- biomass-derived polymers

- agro-polymers

- biodegradable polymers

- polymer engineering

- polymer composites

- sustainable materials

- biodegradable materials

- biosafe materials

- environmentally-friendly materials

- functional materials

- bioplastics

- chemical modification

- structural modification

- sustainable processes

- processing technologies

- processing–structure–property relationships