Abstract

This bibliometric review investigates the advancements in machine learning techniques for predictive maintenance, focusing on the use of Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs) for fault detection in wheelset axle bearings. Using data from Scopus and Web of Science, the review analyses key trends, influential publications, and significant contributions to the field from 2000 to 2024. The findings highlight the performance of ANNs in handling large datasets and modelling complex, non-linear relationships, as well as the high accuracy of SVMs in fault classification tasks, particularly with small-to-medium-sized datasets. However, the study also identifies several limitations, including the dependency on high-quality data, significant computational resource requirements, limited model adaptability, interpretability challenges, and practical implementation complexities. This review provides valuable insights for researchers and engineers, guiding the selection of appropriate diagnostic models and highlighting opportunities for future research. Addressing the identified limitations is crucial for the broader adoption and effectiveness of machine learning-based predictive maintenance strategies across various industrial contexts.

1. Introduction

In recent years, the advancements in artificial intelligence (AI) and machine learning (ML) have revolutionized various industrial applications, particularly in the realm of predictive maintenance through automation [1]. Predictive maintenance uses these technologies to anticipate and mitigate potential failures in machinery, thereby enhancing operational efficiency and reducing maintenance costs. One critical component within railway systems that benefits significantly from predictive maintenance is the wheelset axle bearing, whose failure can lead to catastrophic outcomes, including derailments.

Machine learning, a subset of AI, provides powerful tools for developing predictive models capable of identifying faults in axle bearings through the analysis of acoustic signal data. Among the number of existing ML techniques, Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs) stand out due to their robust performance in classification and regression tasks. ANNs, with their ability to model complex, non-linear relationships, are well-suited for handling large datasets, while SVMs handles data requiring high accuracy and precision, especially with small-to-medium-sized datasets [2].

Several predictive models are employed in the lifecycle of predictive maintenance, each serving distinct purposes. Some models focus on detecting anomaly sounds, while others predict potential faults and failures [3]. For instance, sound detection models aim to recognize whether recorded sounds indicate normal or irregular operations. Neural networks have been used in such applications due to their ability to model complex patterns and relationships within large datasets [4]. These networks consist of layers of interconnected nodes or neurons that learn to perform tasks by considering examples without task-specific programming [5]. For sequential data like time series, which are common in equipment condition monitoring, neural networks offer significant advantages [6].

Similarly, SVMs are well-regarded for their effectiveness in classification and regression tasks, particularly when dealing with small-to-medium-sized datasets [7]. SVMs are capable of modelling complex nonlinear relationships and are especially useful in fault classification tasks in predictive maintenance, where accuracy and precision are paramount [8]. These algorithms create hyperplanes in multidimensional spaces to separate different classes, making them highly valuable for accurately classifying faults in predictive maintenance scenarios [9].

This study aims to develop and compare the performance of ANN- and SVM-based diagnostic models for identifying faults in wheelset axle bearings using acoustic signal data. The comparison will provide insights into the relative strengths and limitations of each approach, guiding the selection of the most effective model for real-world application in the South African railway context. Predictive maintenance aims to anticipate equipment failures and schedule necessary repairs or replacements before issues become critical. By integrating these advanced diagnostic models, railway operators can achieve timely maintenance interventions, thereby enhancing safety, reliability, and operational efficiency.

The significance of this research lies not only in its potential to improve the maintenance strategies of railway systems but also in its broader contribution to the field of AI-driven predictive maintenance. The findings from this comparative analysis will offer valuable guidance to engineers and researchers in selecting appropriate diagnostic models, ensuring data-driven, precise maintenance actions that reduce unplanned downtime and associated costs.

1.1. Objectives

The use of machine learning in predictive maintenance has emerged as a prominent area of research. The integration of machine learning can significantly improve the effectiveness and efficiency of predictive maintenance strategies. This bibliometric analysis seeks to explore available literature on the use of machine learning in in predictive maintenance by looking at advancements in the field and suggesting emerging areas of research. This will be achieved through the following objectives:

- To identify and analyse the key research trends and patterns in the field of diagnostic models for predictive maintenance.

- To evaluate the contributions and impact of different machine learning techniques, particularly ANN and SVM, in the context of fault detection in axle bearings.

- To compare the effectiveness of ANN and SVM models based on bibliometric data, highlighting their strengths and limitations in predictive maintenance applications.

- To provide insights and recommendations for future research directions by identifying gaps and emerging themes in the literature.

By achieving these objectives, this bibliometric analysis aims to contribute to a deeper understanding of machine learning in predictive maintenance.

1.2. Overview

The rest of this review paper proceeds as follows: Section 2 presents the materials and methods embraced in this study, emphasizing the keywords and bibliometric review process. The review results are presented in detail in Section 3, along with the summaries of the most influential studies in literature. Section 4 then presents the thematic analysis, highlighting the relevant themes as well as the key developments under each theme. We conclude the paper in Section 5, presenting the main observations, the limitations, contributions of the work, as well as the direction for future studies.

2. Materials and Methods

This bibliometric review aims to systematically examine the literature on diagnostic models for predictive maintenance, with a particular focus on machine learning techniques such as Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs). A comprehensive search was conducted on Scopus and Web of Science. The search terms included “diagnostic model”, “machine learning”, “neural networks”, “support vector machine”, “predictive maintenance”, and “condition-based maintenance”. Table 1 summarizes the relationships between the keywords of the study as searched.

Table 1.

Keywords.

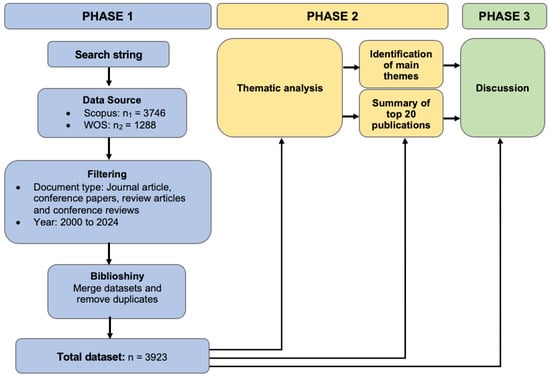

The search was limited to peer-reviewed journal articles, conference papers, conference reviews, and review articles published between 2000 and 2024, as these have been reviewed, ensuring the quality and merit of the articles. The study is not limited to any subject areas. The source type, source title, and other filters were also left unfiltered. The search yielded 1288 papers on Web of Science and 3746 papers on Scopus. This study used Biblioshiny to merge the data and remove duplicates, in which 1060 duplicates were removed. Microsoft Excel and Biblioshiny were used to analyse the data. The bibliometric analysis process is outlined in Figure 1.

Figure 1.

Bibliometric review process.

3. Results

The design science theoretical framework provides a structured approach to understanding the development and application of machine learning (ML) techniques for diagnostic models. This framework emphasizes the creation and evaluation of artifacts designed to solve identified problems, thereby contributing to both practical and theoretical knowledge [10]. This review uses the design science framework to examine the landscape of diagnostic models utilizing ML techniques, highlighting key trends, influential authors, and significant publications.

3.1. Main Publication Information

This section provides an overview of the main publication information related to diagnostic models using ML techniques. The analysis includes the annual scientific production, distribution of publications by country, the twenty most relevant authors, and the twenty most influential publications in the field. Table 2 presents the main publication information. The contribution of 10,942 authors has resulted in 3923 publications to 2638 journals and conferences between 2000 and 2004, with an annual growth rate of 18.44%.

Table 2.

Main publication information.

3.2. Annual Scientific Production

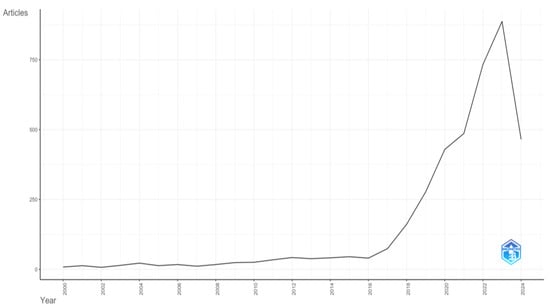

The annual scientific production of diagnostic models using ML techniques has shown a significant upward trend over the past decade. This increase reflects the growing interest and advancements in the application of ML for diagnostic purposes across various fields, including healthcare, engineering, and finance. Figure 2 illustrates the annual growth rate of publications within this field. Before 2017, there were minimal publications, with very slow growth. From 2017, there was noticeable growth of publications which were due to the advancements and increased interest in the application of machine learning techniques for diagnostics. In 2023, there was a peak in publications, and this was probably due to the improvements in computational power, data availability, and machine learning algorithms.

Figure 2.

Annual growth rate (this review was completed mid-year 2024, explaining the drop in publications for 2024).

3.3. Most Influential Publications

The twenty most influential publications were determined based on citation metrics and their contribution (see Table 3). Key papers include foundational works on neural networks, Support Vector Machines, and ensemble methods, which have provided the theoretical and practical foundation for modern diagnostic models. These publications are summarized in Table 4.

Table 3.

Most influential publications.

Table 4.

Summary of the most influential publications.

The majority of the reviewed works primarily rely on sensor data such as from vibration sensors, thermal sensors, and/or acoustic signals. However, the study by Sipos et al. [27] focuses on analysing historical log data to predict maintenance needs, distinguishing it from the other studies. Equipment and/or log data provide a rich history of machine behaviour, but they often lack granularity compared to continuous sensor data. Combining log-based analysis with real-time IoT sensor data, as seen in Kanawaday and Sane [24], could provide a more comprehensive view of machine health. This hybrid approach could enable both immediate fault detection and long-term trend analysis, resulting in improved predictive capabilities.

Based on the works reviewed in this review, there are research gaps that exist that can inform future studies, with one being adaptability, which refers to the ability of models to generalize on unseen data, in this paper, referring to generalizing across varying operating conditions and machinery types [31]. While many studies, including those reviewed, have developed effective models for specific use cases—such as using Convolutional Neural Networks, LSTM networks, and neuro-fuzzy systems—these models often struggle when applied in different environments or machinery with varied operational parameters [23,30]. For instance, the reviewed works on wind turbine gearbox fault prediction and rolling bearing fault detection used tailored models that may not perform equally well under different load conditions or in environments with fluctuating operational characteristics [28,30]. However, there is progress being made on this gap through some research work, such as those focusing on transfer learning and domain adaptation. These demonstrate how predictive maintenance models can be tailored to different operational environments or changing working conditions, such as in the case of bearing fault diagnosis under variable loads and speeds. For instance, the paper on deep transfer learning for bearing fault diagnosis [22] highlights successful adaptability across different working conditions without requiring extensive labelled data, showcasing a model’s robustness in diverse industrial contexts. Similarly, current-based monitoring techniques in wind turbines, as discussed in the RUL prediction of wind turbine gearboxes [30], provide cost-effective, adaptable solutions that bypass the need for additional sensors, emphasizing the practicality of adaptability in reducing deployment complexity and costs. These studies demonstrate that while there is progress, more research is needed to improve the transferability of these models across different industries and machinery types.

The issue of explainability, which refers to the ability to interpret how machine learning models make decision, is another crucial research gap that has been inadequately addressed [32]. Machine learning models, particularly deep learning techniques such as Convolutional Neural Networks (CNNs) and Long Short-Term Memory (LSTM) networks used in fault prognosis, often function as “black boxes”, limiting their explainability [28]. The study on unsupervised learning for fault detection and infrared thermography [29] also demonstrates that while these models show high accuracy, they often lack interpretability, which could prevent their widespread application. This highlights the need for future research to focus on integrating explainable AI (XAI) techniques into predictive maintenance frameworks, providing clearer insights into how predictions are generated.

Table 5 shows the comparison between the different neural networks, SVM, and other methods, showing the advantages and disadvantages of each method.

Table 5.

Comparison table between the advantages and disadvantages of each method.

4. Thematic Analysis

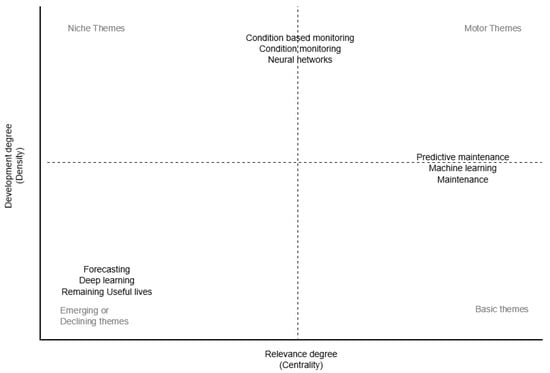

Figure 3 shows a thematic map related to predictive maintenance. The map categorizes themes into four quadrants: Niche Themes (low relevance, high development), Motor Themes (high relevance, high development), Basic Themes (high relevance, low development), and Emerging or Declining Themes (low relevance, low development).

Figure 3.

Thematic map showing relevance and development of themes.

The map highlights the importance and focus on predictive maintenance, using machine learning, and overall maintenance practices as core themes driving current research and development. Niche themes like condition-based maintenance and neural networks show high development but may need to integrate more into mainstream relevance. Declining themes like forecasting are considered less central to current trends in maintenance practices. Table 6 presents the themes derived by Biblioshiny of the 3923 papers. There are three separate themes with 12 occurrences for each, which is a cut number from the 250 code occurrences from the combined themes.

Table 6.

Thematic analyses.

5. Conclusions

This bibliometric review has explored the advancements in machine learning techniques for predictive maintenance, with a particular focus on diagnostic models using Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs). The analysis outlines the progress made in applying these techniques to predict and mitigate potential failures in machinery. The review emphasizes the performance of ANNs in handling large datasets and modelling complex, non-linear relationships, making them suitable for detecting anomalies in acoustic signal data. SVMs, on the other hand, have shown high accuracy and precision in fault classification tasks, especially with small-to-medium-sized datasets, owing to their ability to create effective hyperplanes in multidimensional spaces.

5.1. Limitations

Despite these advancements, the review identified several limitations that must be addressed to improve the practical application of these models. These include the following:

- Data quality: Many models, such as those by Ali et al. [11] and Mahamad et al. [18], heavily depend on the quality and quantity of condition monitoring data like vibration signals. This dependency can be a significant drawback if such data are not readily available or is noisy, affecting the model’s accuracy and generalizability.

- Significant computational resources: Approaches like those proposed by Tian et al. [14] and Zhang et al. [15] often require significant computational resources for training and inference, posing a challenge for implementation in environments with constrained resources.

- High computational power: The complexity of models such as the transformer-based approach by Chen [16] and the digital-twin-assisted method by Xu et al. [13] demand high computational power and huge amounts of data, which might not always be accessible.

- Adaptability of these models to different machinery and operational conditions: For instance, the methodologies developed by Tran et al. [17] and Tian et al. [12] might not generalize well across different types of equipment without customization to the data and parameter tuning.

- Interpretability and underlying assumptions: Models such as those by Xiao et al. [19] and Wu et al. [20] also face challenges related to model interpretability and the assumptions underlying their predictive maintenance strategies. The proportional hazard model combined with SVM by Tran et al. [17] assumes proportionality, which may not always hold, while the cost matrix approach by Wu et al. [20] assumes constant maintenance costs, which might not reflect the dynamic nature of real-world scenarios.

These limitations highlight the need for further research to improve the robustness, interpretability, and applicability of predictive maintenance models in diverse industrial contexts.

There are also limitations to this study which includes access to data only being through Scopus and web of science which might have excluded other papers which are not available through these databases. The review may not capture the full breadth of research in predictive maintenance, potentially overlooking significant contributions from other academic and industrial sources. This limitation suggests the need for a more comprehensive literature search that includes additional databases and grey literature to provide a holistic view of the field.

5.2. Contributions

The work makes three major contributions to the body of knowledge, as follows:

- Providing insights on which model, between the two, is more accurate, reliable, and computationally efficient;

- Analysing patterns that exists within the field, therefore identifying research trends in predictive maintenance;

- Providing an understanding of the strengths and limitations of ANN and SVM models, through which stakeholders can make informed decisions about selecting and implementing the most appropriate diagnostic models for their specific needs.

5.3. Future Work

While machine learning-based predictive maintenance models are promising for improving operational efficiency and safety in industrial applications, addressing their current limitations through continued research and development is essential. This will facilitate the broader adoption of these advanced techniques, ultimately leading to more reliable and cost-effective maintenance strategies across various industries. The directions for future work can include the following:

- Development of more efficient algorithms that require less computational power without compromising accuracy;

- Applying transfer learning techniques to adapt models trained on one type of machinery to another, therefore allowing adaptability of developed models.

Author Contributions

Conceptualization, N.L.V. and C.C.; methodology, N.L.V.; software, C.C.; formal analysis, N.L.V.; investigation, N.L.V.; resources, N.L.V.; data curation, N.L.V.; writing—original draft preparation, N.L.V.; writing—review and editing, C.C.; visualization, N.L.V.; supervision, C.C.; project administration, C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Acknowledgments

The work was carried out as part of a Master of Applied Data Science qualification under the university of Johannesburg.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kasmi, S. Unleashing the Potential of Artificial Intelligence (AI) Growth Rate Worldwide—Statistics & Facts. A Guide to the Future Tech. 8 January 2024. Available online: https://www.linkedin.com/pulse/unleashing-potential-artificial-intelligence-ai-growth-cherry-stefin-bwwcf/ (accessed on 4 November 2024).

- Luo, G. PredicT-ML: A tool for automating machine learning model building with big clinical data. Health Inf. Sci. Syst. 2016, 4, 5. [Google Scholar] [CrossRef] [PubMed]

- Bowes, D.; Hall, T.; Gray, D. Comparing the performance of fault prediction models which report multiple performance measures: Recomputing the confusion matrix. In Proceedings of the 8th International Conference on Predictive Models in Software Engineering, Lund, Sweden, 21–22 September 2012; Association for Computing Machinery: New York, NY, USA, 2012; pp. 109–118. [Google Scholar]

- Zhao, J. Anomalous Sound Detection Based on Convolutional Neural Network and Mixed Features. In Journal of Physics Conference Series; IOP Publishing: Bristol, UK, 2020; Volume 1621. [Google Scholar]

- Ognjanovski, G. Everything You Need to Know About Neural Networks and Backpropagation—Machine Learning Easy and Fun. Available online: https://towardsdatascience.com/everything-you-need-to-know-about-neural-networks-and-backpropagation-machine-learning-made-easy-e5285bc2be3a (accessed on 7 July 2024).

- Serradilla, O.; Zugasti, E.; Zurutuza, U. Deep learning models for predictive maintenance: A survey, comparison, challenges and prospect. Appl. Intell. 2022, 52, 10934–10964. [Google Scholar] [CrossRef]

- Kar, A.; Nath, N.; Kemprai, U. Performance Analysis of Support Vector Machine (SVM) on Challenging Datasets for Forest Fire Detection. Int. J. Commun. Netw. Syst. Sci. 2023, 17, 11–29. [Google Scholar] [CrossRef]

- Brereton, R.G.; Lloyd, G.R. Support Vector Machines for classification and regression. Analyst 2010, 135, 230–267. [Google Scholar] [CrossRef]

- Sabat-Tomala, A.; Raczko, E.; Zagajewski, B. Comparison of Support Vector Machine and Random Forest Algorithms for Invasive and Expansive Species Classification Using Airborne Hyperspectral Data. Remote Sens. 2020, 12, 516. [Google Scholar] [CrossRef]

- Hevner, A.R.; March, S.T.; Park, J.; Ram, S. Design science in information systems research. MIS Q. 2004, 28, 75–105. [Google Scholar] [CrossRef]

- Ali, J.B.; Chebel-Morello, B.; Saidi, L.; Malinowski, S.; Fnaiech, F. Accurate bearing remaining useful life prediction based on Weibull distribution and artificial neural network. IEEE Trans. Ind. Electron. 2015, 63, 1686–1694. [Google Scholar]

- Tian, Z.; Jin, T.; Wu, B.; Ding, F. Condition based maintenance optimization for wind power generation systems under continuous monitoring. Renew. Energy 2011, 36, 1502–1509. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Internet Things J. 2020, 7, 4362–4371. [Google Scholar] [CrossRef]

- Tian, Z. An artificial neural network approach for remaining useful life prediction of equipments subject to condition monitoring. J. Intell. Manuf. 2012, 23, 227–237. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, S.; Li, W. Bearing performance degradation assessment using long short-term memory recurrent network. Chin. J. Aeronaut. 2019, 32, 215–224. [Google Scholar] [CrossRef]

- Chen, X. A novel transformer-based DL model enhanced by position-sensitive attention and gated hierarchical LSTM for aero-engine RUL prediction. Neural Comput. Appl. 2022, 34, 7721–7735. [Google Scholar] [CrossRef] [PubMed]

- Tran, V.T.; Pham, H.T.; Yang, B.S.; Nguyen, T.T. Machine performance degradation assessment and remaining useful life prediction using proportional hazard model and support vector machine. Mech. Syst. Signal Process. 2021, 25, 1846–1858. [Google Scholar] [CrossRef]

- Mahamad, A.K.; Saon, S.; Hiyama, T. Predicting remaining useful life of rotating machinery based on artificial neural network. Comput. Math. Appl. 2010, 60, 1078–1087. [Google Scholar] [CrossRef]

- Xiao, S.; Yan, J.; Yang, X.; Zha, H.; Chu, S.M. Modeling the intensity function of point process via recurrent neural networks. In Proceedings of the AAAI Conference on Artificial Intelligence, San Francisco, CA, USA, 4–9 February 2017; Volume 31. Number 1. [Google Scholar]

- Wu, S.J.; Gebraeel, N.; Lawley, M.A.; Yih, Y. A Neural Network Integrated Decision Support System for Condition-Based Optimal Predictive Maintenance Policy. IEEE Trans. Syst. Man Cybern.-Part A Syst. Hum. 2007, 37, 226–236. [Google Scholar] [CrossRef]

- Unal, M.; Onat, M.; Demetgul, M.; Kucuk, H. Fault diagnosis of rolling bearings using a genetic algorithm optimized neural network. Meas. J. Int. Meas. Confed. 2014, 58, 187–196. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, N.; Shen, C. A new deep transfer learning method for bearing fault diagnosis under different working conditions. IEEE Sens. J. 2020, 20, 8394–8402. [Google Scholar] [CrossRef]

- Essien, A.; Giannetti, C. A deep learning model for smart manufacturing using convolutional LSTM neural network autoencoders. IEEE Trans. Ind. Inform. 2020, 16, 6069–6078. [Google Scholar] [CrossRef]

- Kanawaday, A.; Sane, A. Machine learning for predictive maintenance of industrial machines using IOT Sensor Data. In Proceedings of the 2017 8th IEEE International Conference on Software Engineering and Service Science (ICSESS), Beijing, China, 24–26 November 2017. [Google Scholar] [CrossRef]

- Paolanti, M.; Romeo, L.; Felicetti, A.; Mancini, A.; Frontoni, E.; Loncarski, J. Machine Learning Approach for predictive maintenance in industry 4.0. In Proceedings of the 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Oulu, Finland, 2–4 July 2018. [Google Scholar] [CrossRef]

- Amruthnath, N.; Gupta, T. A research study on unsupervised machine learning algorithms for early fault detection in predictive maintenance. In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications (ICIEA), Singapore, 26–28 April 2018. [Google Scholar] [CrossRef]

- Sipos, R.; Fradkin, D.; Moerchen, F.; Wang, Z. Log-based predictive maintenance. In Proceedings of the 20th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 24–27 August 2014. [Google Scholar] [CrossRef]

- Hinchi, A.Z.; Tkiouat, M. Rolling element bearing remaining useful life estimation based on a convolutional long-short-term memory network. Procedia Comput. Sci. 2018, 127, 123–132. [Google Scholar] [CrossRef]

- Huda, A.S.N.; Taib, S. Application of infrared thermography for predictive/preventive maintenance of thermal defect in Electrical Equipment. Appl. Therm. Eng. 2013, 61, 220–227. [Google Scholar] [CrossRef]

- Cheng, F.; Qu, L.; Qiao, W. Fault prognosis and remaining useful life prediction of wind turbine gearboxes using current signal analysis. IEEE Trans. Sustain. Energy 2018, 9, 157–167. [Google Scholar] [CrossRef]

- Connor, S.; Li, T.; Roberts, R.; Thakkar, S.; Liu, Z.; Tong, W. Adaptability of AI for Safety Evaluation in Regulatory Science: A Case Study of drug-induced liver injury. Front. Artif. Intell. 2022, 5, 1034631. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Abuhmed, T.; El-Sappagh, S.; Muhammad, K.; Alonso-Moral, J.M.; Confalonieri, R.; Guidotti, R.; Del Ser, J.; Díaz-Rodríguez, N.; Herrera, F. Explainable artificial intelligence (XAI): What we know and what is left to attain trustworthy artificial intelligence. Inf. Fusion 2023, 99, 101805. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).