1. Introduction

The development of renewable energy projects is quickly growing in number and size to satisfy the increasing global demand for electricity while accomplishing established standards for a sustainable future. Electricity is a central element of modern growth, and the optimisation strategy in the design of these projects at an early stage of development is essential to achieve a cost-effective outcome [

1]. Among all the renewable energy sources, wind is the most developed and researched in terms of sustainability, life cycle, and cost-effectiveness, contributing to almost 7% of the global electricity generation in 2021 [

2,

3]. Consequently, the implementation of offshore wind energy systems is rising as a reliable renewable energy source and for big-scale offshore wind energy projects, the implementation of direct-drive generator structures has become popular in recent years due to their multiple advantages. The absence of a gearbox in these wind turbine configurations means direct-drive generators have fewer moving parts, simplifying the system’s complexity, reducing the structure’s total weight, and subsequently decreasing failure rate, downtime, and maintenance. These factors are crucial for offshore applications due to the inaccessibility of the systems and the harsh weather conditions in the open sea [

4]. The optimisation of these generators is an important focus of research due to the challenges of the structure’s mechanical design under working conditions with high loads at a low-speed of rotation. These generators demand high levels of stiffness to withstand the operational loads without losing their original shape, or in other words, the structure requires great resistance to deformation [

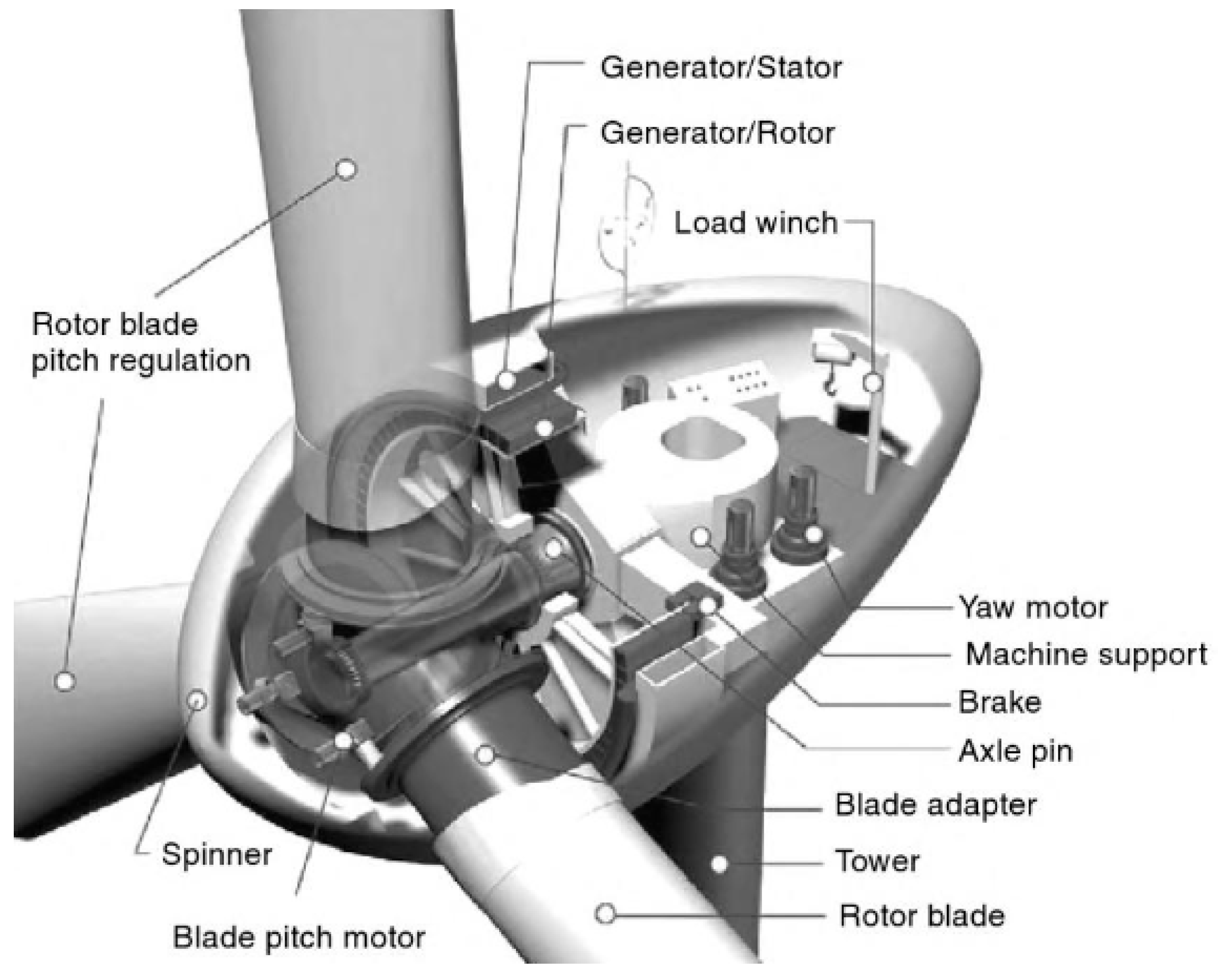

5]. A direct-drive wind turbine representation with the different components that constitute the system can be seen in

Figure 1.

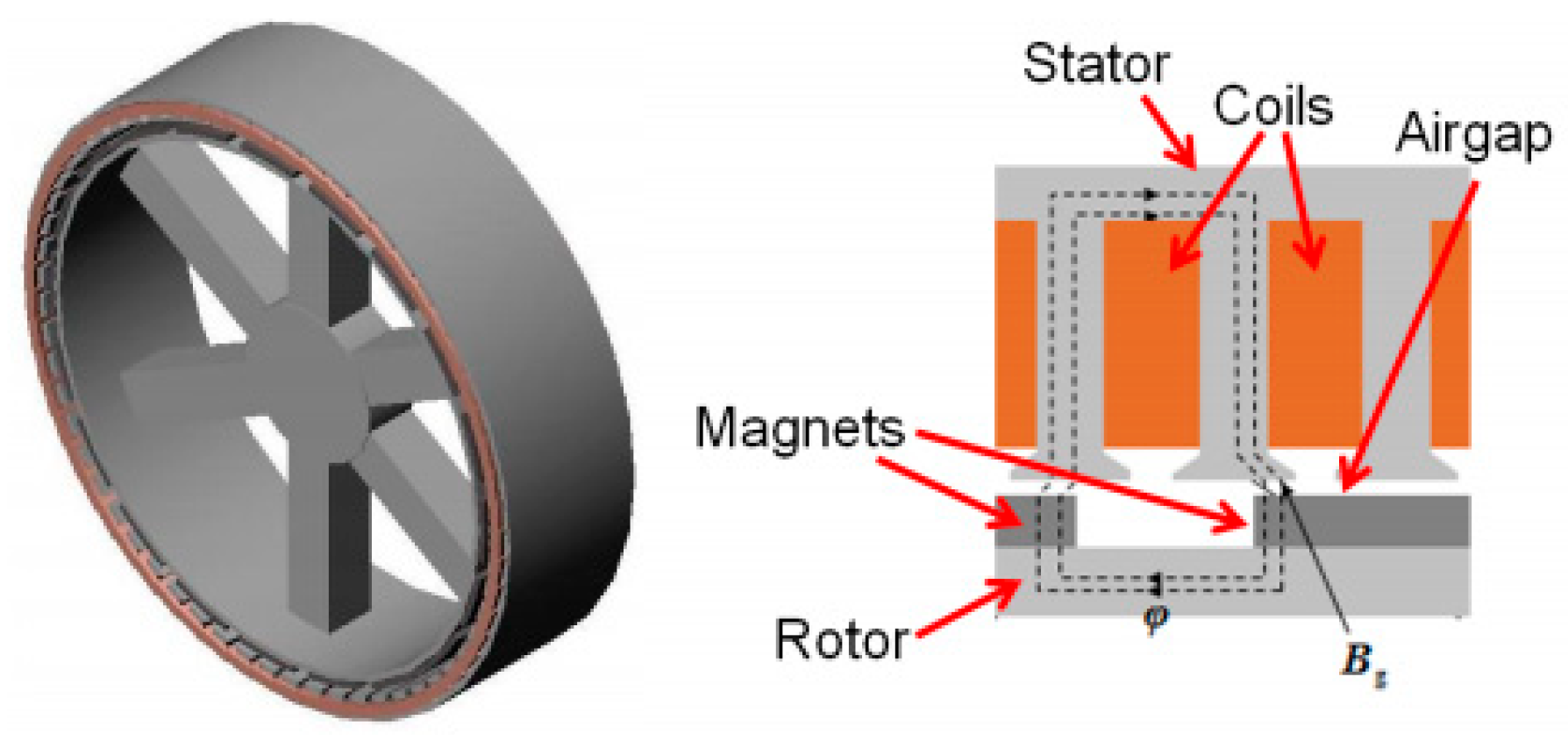

Implementing direct-drive wind turbines simplifies the overall design of the system, installation process, and maintenance, representing a great advantage for offshore applications. As part of this system, the direct-drive generator is an alternating current electrical machine that can be excited electrically or with permanent magnets. For offshore wind turbine generators, the use of permanent magnets with a radial flux has been a popular configuration choice in the industry for their high performance in weight reduction, compactness, and higher electrical efficiency. Permanent magnet-excited direct-drive generators, also known as “PMDDs”, are classified into three different types by the direction of the magnetic flux across the air gap between the rotor and the stator, these configurations being radial flux, axial flux, and traverse flux generators. A schematic representation of a PMDD radial flux generator supporting structure and its different elements can be seen in

Figure 2 [

6,

7].

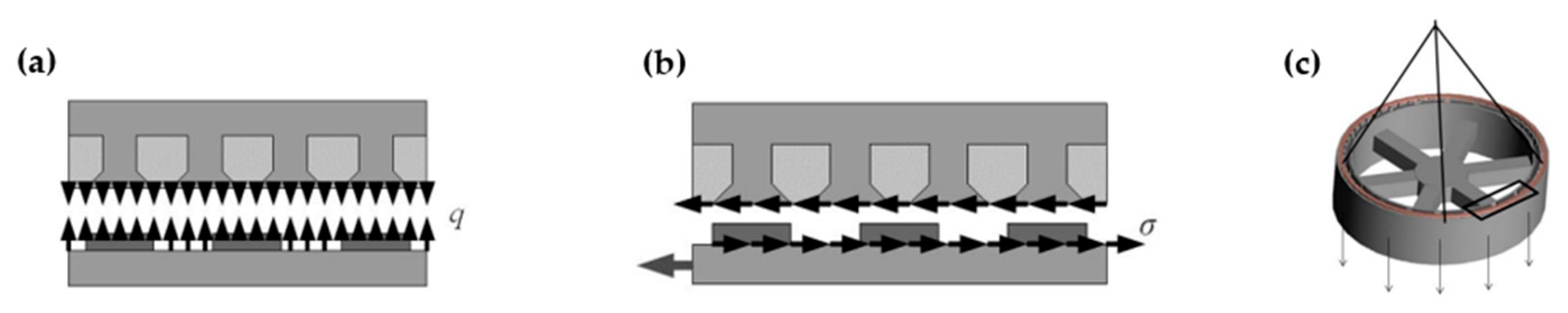

Even though the implementation of direct-drive wind turbines reduces the overall structural weight of the system, direct-drive generators are large steel structures that rotate at low speeds and work under extremely high torques which requires careful consideration of the mechanical design and analysis. While the electromagnetic design of these generators has been extensively investigated and optimised, the supporting structure of the PMDD generator contributes to 2/3 of the total mass, which opens an opportunity for further optimisation of the system. A mechanical design optimisation analysis of the structural stiffness is needed to keep the generator’s air gap under a limit of deformation. Under normal working conditions, high loads are generated across the air gap between the stator and rotor, an electromagnetic force known as Maxwell stress, with a “q” value of 200–400 kPa, and a shear stress value “σ” of 25–50 kPa. These loads and the consideration of the gravitational load for the structure are presented in

Figure 3 [

9,

10]. The rigorous analysis of the loads and the influence of these on the system are fundamental for efficient optimisation of the structure.

These generators are designed modularly, dividing the structure into smaller parts made of cast iron to simplify manufacturing, installation, and transportation challenges. A wide range of different topologies such as disks, cones, and arms have been studied and analysed for the supporting structure of direct-drive generators [

10]. Development in new technologies on mechanical design optimisation techniques, such as the implementation of generative design, open novel strategies to generate and analyse more complex topologies than using traditional methods [

11,

12,

13]. These new techniques on structural optimisation strategies allow the generation of new non-conventional topologies and the increase in the overall system efficiency when applied to optimise PMDD generator supporting structures [

14].

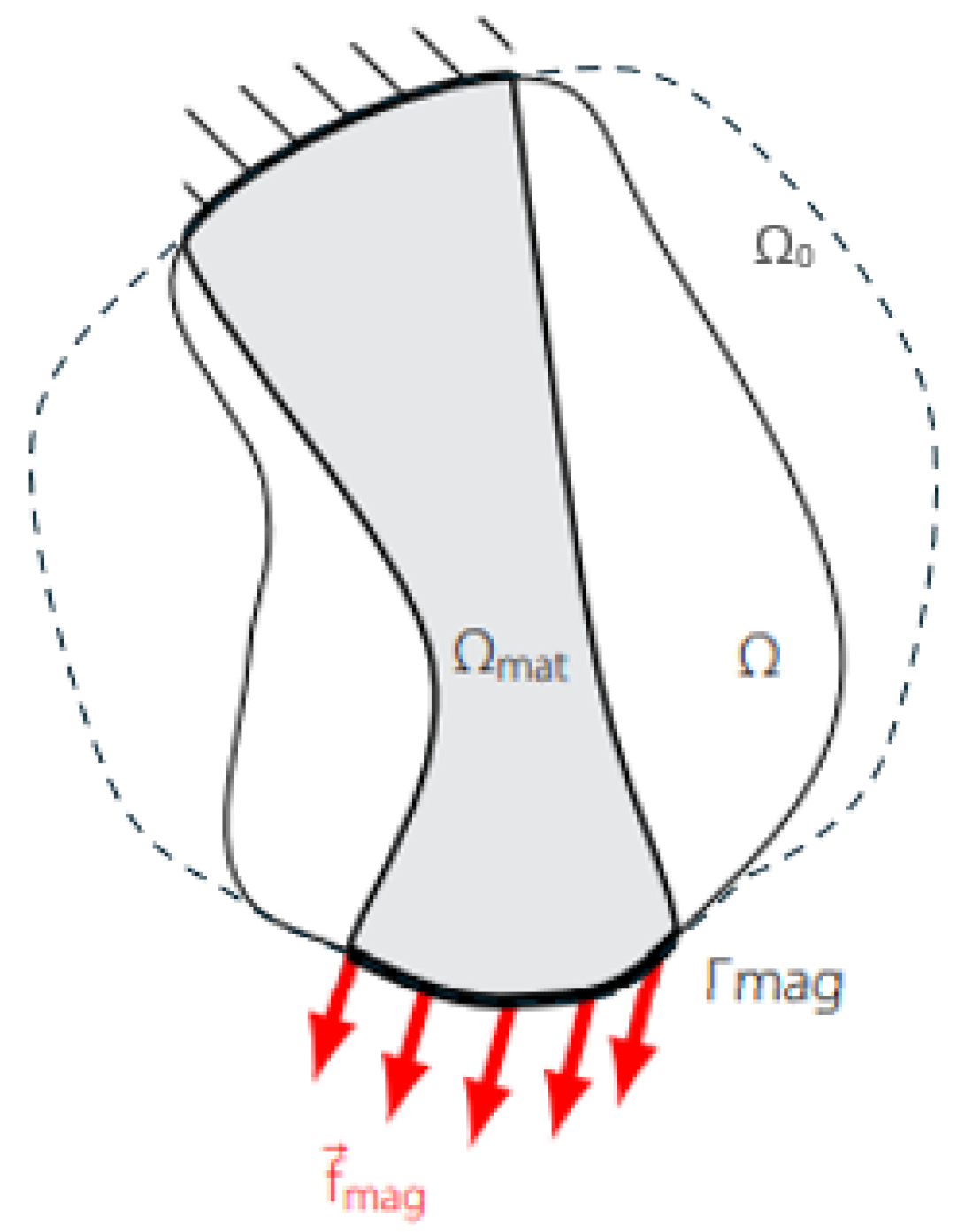

Ansys has been chosen as the most suitable piece of software to perform the structural optimisation process intended due to its complex multiphysics capabilities, as well as its wide range of analysis tools and cutting-edge AI-driven solutions. Ansys is one of the leading available software packages for engineering simulations. The structural optimisation algorithm of complex topologies can be represented mathematically with a set of functions, identifying different parameters of the optimisation strategy. As part of these optimisation parameters, an initial volume of optimisation needs to be determined manually or automatically, depending on the software used. A representation of a structural optimisation volume range can be seen in

Figure 4 [

15]. In Ansys, an initial optimisation volume needs to be determined to develop the structural optimisation strategy.

For complex structural optimisation strategies, a multi-objective optimisation can be developed, where the different objectives can be defined by mathematical functions and classify hierarchically by importance with a weight value. A multi-objective structural optimisation identifies the optimal material distribution, minimising the objectives functions within a volume range.

The most crucial structural feature for the optimisation of these generators is determined by keeping the air gap deformation between the rotor and the stator within the limit value. Therefore, the displacement normal to the air gap face needs to be determined as the primary criterion for the structural optimisation strategy. A representation of a structural optimisation function governed by a displacement output can be seen in Equation (1), where “Γ

mag” is the surface that the magnetic loads are applied to, and “u” is the displacement.

Another method to assess the displacement during the optimisation process is using a strain focused function, simplifying calculation times and reducing the computational process. In Equation (2), we can see a strain-based function used in structural optimisation, where “Ω

mat” represents the volume of the material, “ε” represents the strain, “u” is the displacement, and “σ” is the density.

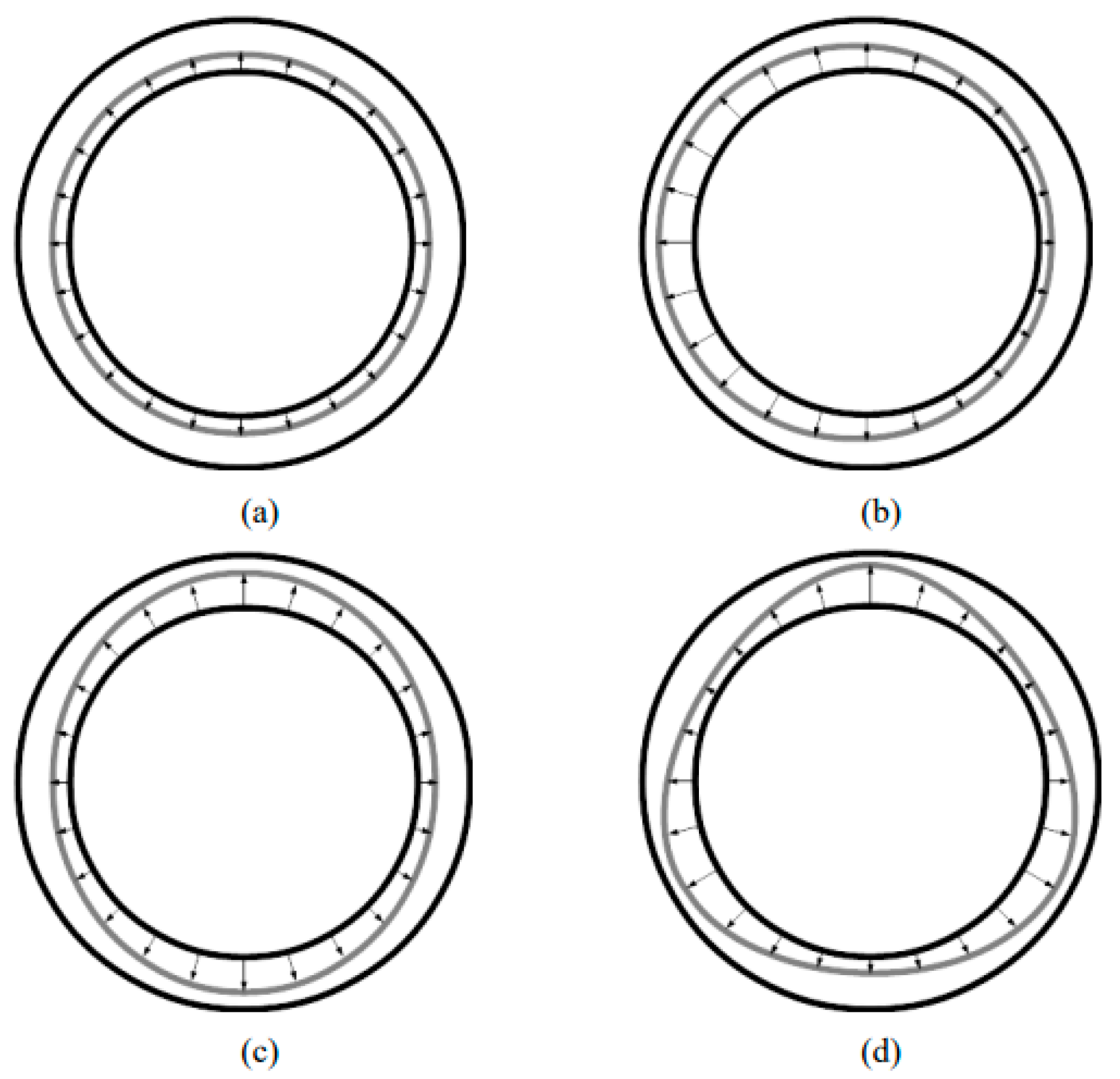

The study of the vibrations experienced under working conditions also needs to be considered while performing a structural optimisation due to its impact on the structural deformation. As an example, a simple representation of different modes of deflection in a radial direction is presented in

Figure 5. On a generator structure, changes in the design parameters cause variations in the natural frequencies and mode shapes of the deformation. A modal analysis of the generator aims to find and optimise the natural frequencies of the PMDD radial flux electrical machine and, therefore, to establish the vibrations of the structure to consider where these frequencies interfere with the ones generated by the rest of the system. Vibrations on a rotating machine could cause a system malfunction and catastrophic structural failures, generating resonance, fatigue, overload, and noise [

16]. These vibrations need to be managed by exhaustive design techniques and analysis. In PMDD radial flux generators, the excitation frequencies that could cause resonance with the structure’s natural frequencies are the wind turbine rotation speed, the electrical frequency, and the ones generated by the rotor blades [

17].

The analysis of the natural frequencies of simplified structures with only one degree of freedom can be made following the equation below (3), where “f” is the frequency, “k” is the stiffness, and “m” is the mass.

However, when a more complex system needs to be studied, for instance, a three-dimensional model, an advanced analysis technique is required to develop a modal analysis. A modal analysis approach consists of an evaluation of the excitation and natural frequencies of the generator structure, the number of frequency modes to analyse depends on the spectrum of the electrical generator working environment, the topology chosen, and its natural frequencies. In order to accurately identify the frequencies within the excitation spectrum affecting the dynamic behaviour of the structure, the energy contained for each frequency mode and the mass participation in a specific direction can be assessed. This method is known as the effective mass participation factor (EMPF), and at least 80% of the participation mass in any axis’s direction need to be evaluated. Any natural frequency which contributes over 1% of the EMPF within the operational range of the system needs to be analysed to avoid any resonance with the excitation frequencies [

8]. An example of the optimisation function used by a modal analysis algorithm can be seen in Equation (4), where “μ

r“ is the generalised mass of mode r, “Ω

mat” represents the volume of the material, “ϕ

r” is the load participation factor of mode r, “f

mag” is the spatial distribution of the displacement and magnetic force, “ω

r” is the frequency of mode r, and “ω

ext” is the harmonic excitation frequency [

15].

Combining all these previous optimisation functions into a multi-objective structural optimisation strategy generates an efficient and adaptative process to optimise and analyse a given structure. Nevertheless, the computing cost of these methods are directly proportional to the complexity of the function. One method to simplify the process involves the selection of a primary criterion to be optimised and the assignment of an importance weight for the other objectives and defining limit values for each of them [

15]. An example of optimisation for a multi-objective process can be seen in

Figure 6, following a combined objective convergence and a convergence response for the primary criterion.

For the mechanical design optimisation and analysis of a complex three-dimensional structure, advanced computer-aided finite element analysis software is necessary. A generative design process with an integrated static structural optimisation and modal analysis of a 3 MW PMDD radial flux offshore wind turbine electrical generator has been implemented in this study using the commercial software packages of ANSYS 2022, Autodesk Inventor, and Fusion 360 [

18]. In a previous study, generative design techniques were used as an innovative method of design optimisation to analyse PMDD radial flux generator structures [

14]. Generative design techniques implement an artificial intelligence-controlled process to create an iteration of models following a multi-objective fitting algorithm based on initial specifications and control parameters. These new techniques represent a revolution in the mechanical design optimisation and analysis of big structures at an early stage of large-scale projects. The use of generative design techniques facilitates the control and automation of complex structural optimisation processes tailored for the specific application requirements. As a continuation of the previous investigation in [

14], the resulting structure has been analysed alongside a novel approach as a structural optimisation strategy including the modal analysis as an input within the generative design process [

11].

2. Structural Optimisation Strategy

This study aims to simultaneously integrate static structural analysis and modal analysis into a generative design process, developing a multi-objective structural optimisation strategy for the rotor of an offshore wind turbine PMDD generator. This approach is based on the knowledge acquired in previous studies of the structural optimisation strategy conducted in [

14]. In that study, it was established that the best results were obtained using a preoptimized disc structure as the initial model for the generative design process. It was also observed that the cyclic symmetry parameter was the one having the greatest repercussion in the optimisation control of the generative design process. The cyclic symmetry parameter represented an efficient control method due to the impact of mass distribution in the inertia and natural frequencies of rotating structures. New advances in structural optimisation methods include some generative design features, increasing the adaptability of the process to specific objectives. In contrast with conventional topology optimisation techniques, recent structural optimisation processes not only decrease the mass, but they are also able to adapt with each iteration to the optimisation objectives, generating mass outside of the mesh analysis developed as it can be observed in

Figure 7, part of the study conducted in [

14].

The focus of the prior generative design process was the use of multiple initial models resulting in a wide range of original topologies. In this study, and based on the previous findings, the structural optimisation strategy has focused on the implementation of the most efficient initial model and control method found in [

14] while implementing the modal analysis as an additional parameter integrated into the generative design process. The solutions for the static structural analysis and the solution for the modal analysis function as individual inputs to the structural optimisation process, which repeats with each iteration of topology generation, satisfying the objectives of both static structural analysis and modal analysis, the established limit of deflection, and the frequencies to optimise, respectively.

The implementation of the modal analysis as a new parameter integrated into the generative design process was used to optimise the natural frequency behaviour of the resulting topologies, considered as an important addition to the structural optimisation strategy from the previous study [

14] due to the significance of frequency analysis in rotating machines [

16]. ANSYS allows us to select a single frequency mode or a range of frequency modes to maximise the natural frequencies of each generated structure in the iterative process of topology optimisation.

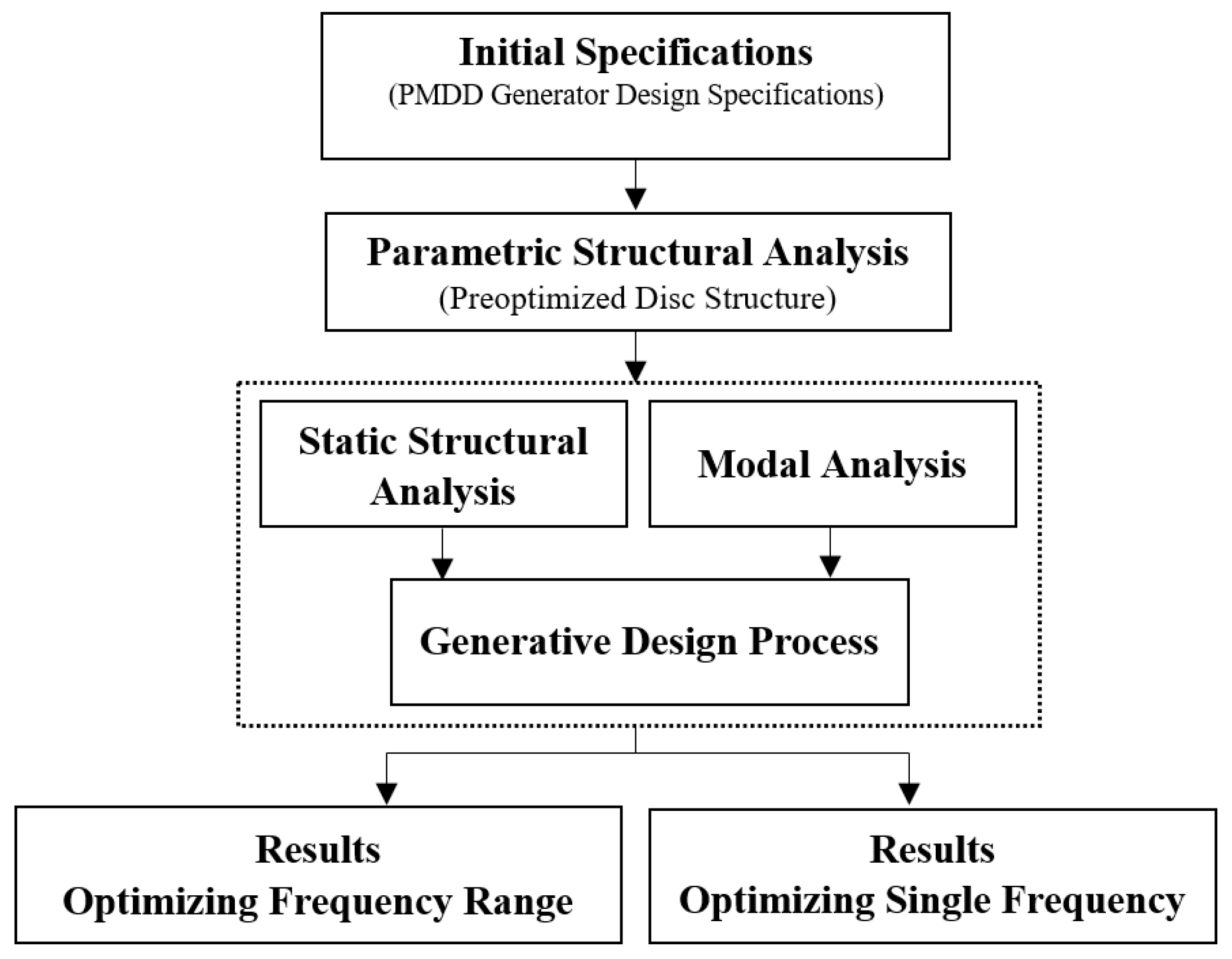

In order to understand the dynamic behaviour of the structure and to effectively implement the modal analysis into the generative design process, a preliminary modal analysis was considered to identify the natural frequencies of the initial model of the rotor that can be triggered by the excitation frequencies. Note that no loads were applied to the structure in this study. Using the information gathered in the preliminary modal analysis of the initial model, the dynamic analysis in [

8], and the results from the previous process in [

14], an innovative structural optimisation strategy including the natural frequencies of the structure has been assessed in this paper. A representation of this new structural optimisation algorithm used in the study can be seen in

Figure 8.

As a continuation of the earlier study conducted in [

14], the same electrical machine was chosen, a 3 MW PMDD radial flux generator. The electrical generator specifications and design parameters are defined in

Table 1, following the considerations in [

8]. The fixed support for the structure is established at the shaft while the working loads for the generator structure consist of a normal stress of 400 kPa, also known as Maxwell stress, applied perpendicular to the outer surface of the rotor and pointing outwards, a shear stress of 30 kPa applied on the outer cylindrical surface of the rotor structure, and a gravitational load of 9.81 m/s

2 applied at the centre of mass (see

Figure 8). A deflection limit is considered as 0.5 mm, i.e., 10% of the dimension of the air gap. The physical properties of the material are defined in

Table 1, with cast iron as the material selected for the optimisation analysis of the structure. The parameters needed for the development of the modal analysis are described as the excitation frequencies existing in the electrical generator during the working conditions. The assessment of these frequencies is critical for the optimisation of the wind turbine as they can create resonance with the natural frequencies of the structure causing system malfunction and structural failure. The excitation frequencies for a PMDD wind turbine generator are described as rotational frequency, electrical frequency, and the frequency of the rotating blades of the wind turbine [

17].

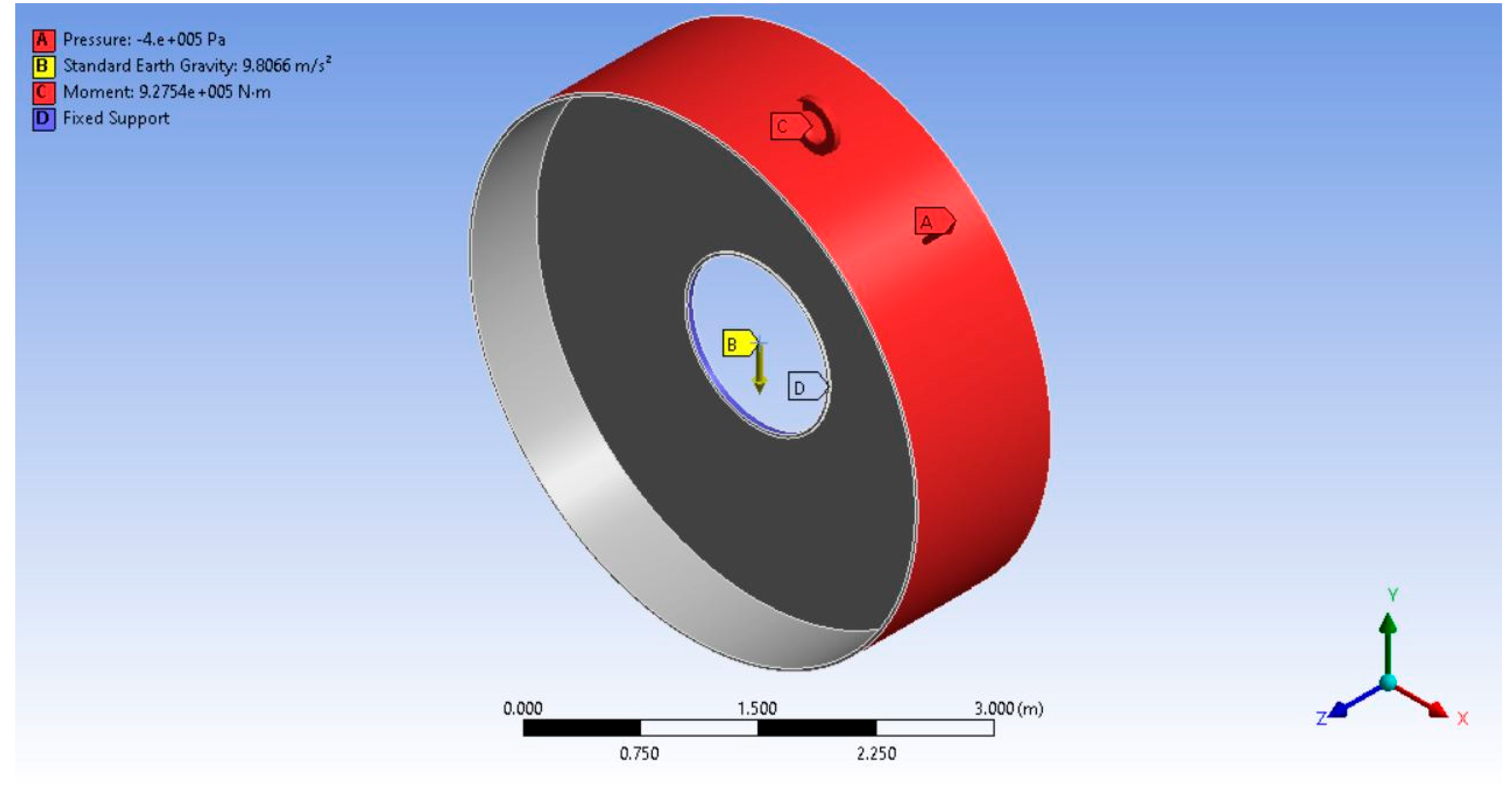

Based on the findings of [

14], a simple disc structure configuration has been selected as the initial model for the generative design process. A single fixed support is used in both modal and static structural analysis; and the three loads considered for the static structural analysis (normal stress, shear stress, and gravitational load) are presented in

Figure 9 as part of the analysis in ANSYS. The fixed support is applied to the surface contact with the wind turbine shaft as denoted in blue “D”, the gravitational load is applied to the centre of mass as denoted in yellow “B”, and both normal and shear stress are applied to the external surface of the cylinder, as denoted in red “A” and “C”, representing the forces generated in the gap between the rotor and generator structures.

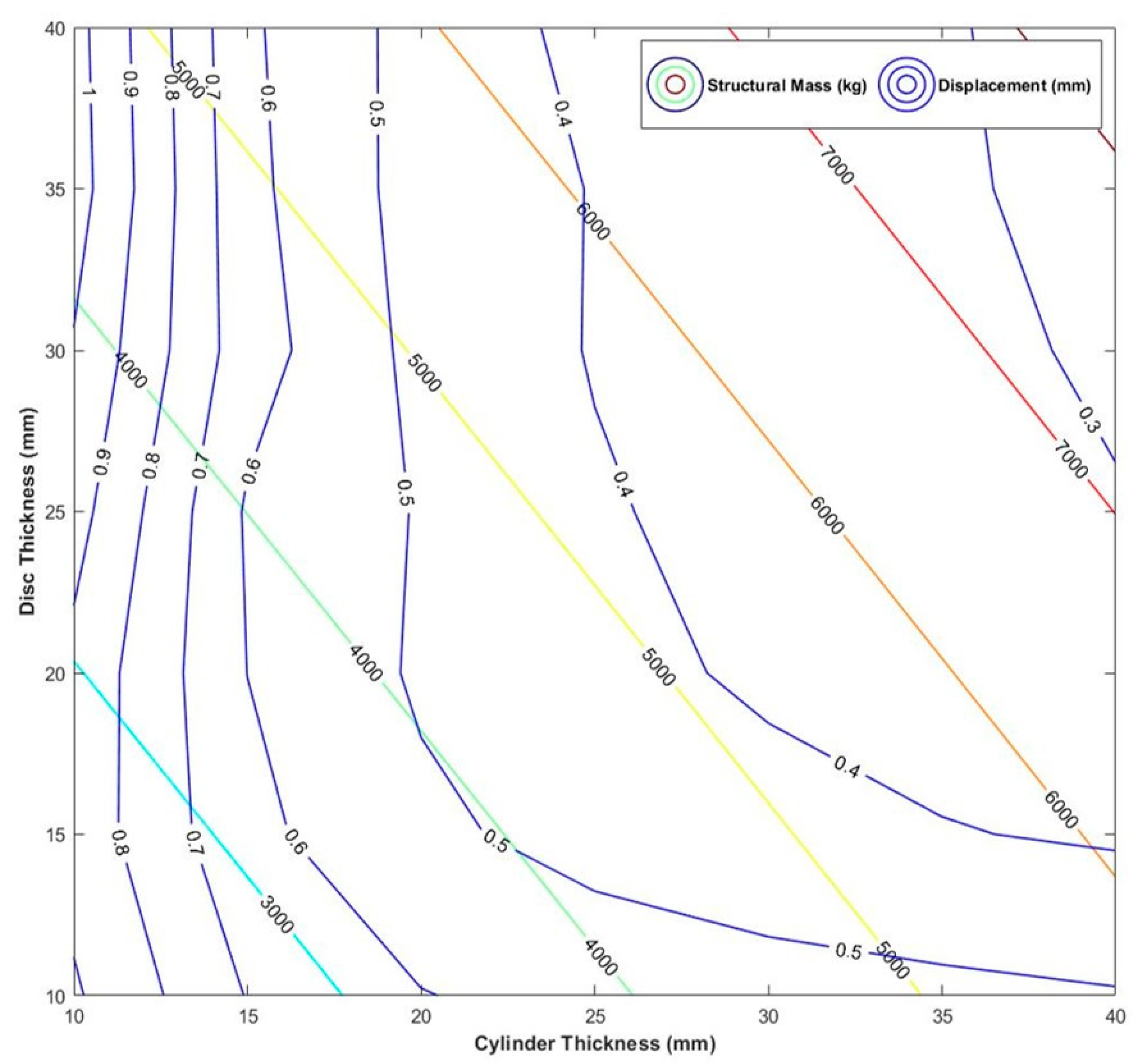

A parametric optimisation process was assessed in the previous study [

14] for a simple disc rotor structure to determine the initial model of the generative design method. In this process, an optimisation analysis was performed by varying the thickness of the disc and cylinder wall while minimising the mass and keeping the air gap deformation under the established limit of 0.5 mm. MATLAB was utilise to visualise the results. The visualisation of this process is presented in

Figure 10, where the variations in the wall thickness of the disc and cylinder structure are denoted in the Y and X axes accordingly. A representation of the structural mass and the deformation is plotted in the graph to identify the minimum mass complying with the limit of deformation established as 0.5 mm. In this parametric optimisation, a preoptimized topology is obtained to be used in the generative design process as the initial model.

2.1. Preliminary Modal Analysis

A preliminary modal analysis of the preoptimized disc rotor structure obtained in the generative design process from the previous study [

14] was assessed to identify and study the natural frequencies of the structure. This preliminary analysis was necessary to determine an effective implementation of the modal analysis into the generative design process. Understanding the natural frequencies of the initial model was critical to control the integration of the modal analysis and to find the best structure optimisation strategy.

Table 2 shows the results of this preliminary modal analysis.

The results of [

8] established that the frequency modes over 1% of EMPF for a simple disc structure are mode 3, with 13 Hz, and mode 12, with 111.8 Hz, the latter frequency mode remaining way above the electrical frequency for operational speeds of 0 to 20 rpm. In

Figure 11, a Campbell Diagram was developed to visualise all the frequencies acting on the generator structure with the limits of the operational range of the machine and the effects of different optimisation techniques [

8].

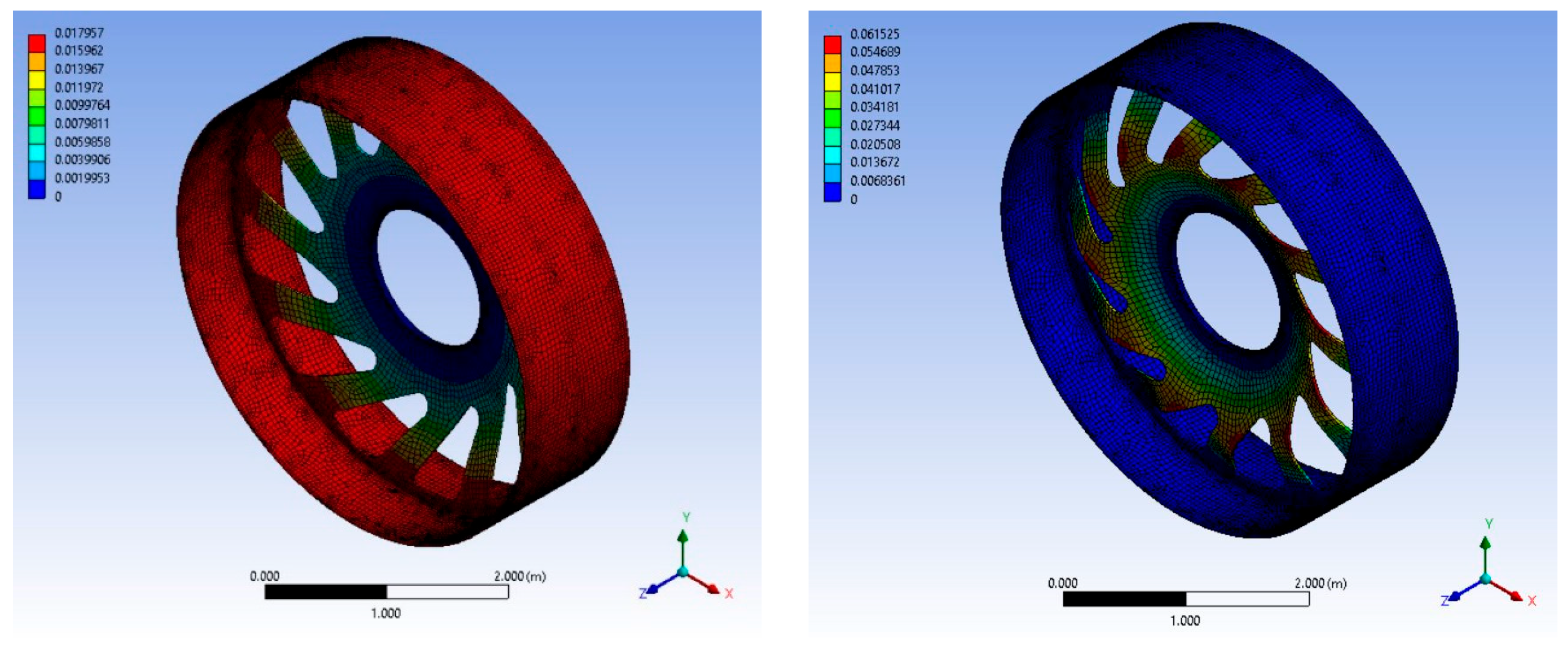

The two resultant natural frequency modes of the preoptimized disc rotor structure as part of the preliminary modal analysis using ANSYS can be seen in

Figure 12. In this figure, the deformation caused by the natural frequency modes was identified following the EMPF method, where the values of maximum and minimum deformation are presented in the figure in red and blue, respectively. One can observe that even though the frequency mode 3 has decreased from 13 Hz to 5.41 Hz in relation to a simple disc structure, the other active mode for this structure is mode 10 with 54.14 Hz instead of the mode 12 of the simple disc structure [

8].

After the preliminary modal analysis and the results of [

8] for a simple disc structure, it was established that the frequency modes interfering with the excitation frequency are mode 12 for a simple disc structure and mode 10 for the preoptimized disc generative design model. The consideration of these results was used to develop the modal analysis of the new structural optimisation algorithm for the generative design process.

2.2. Structural Optimisation Process Including Modal Analysis

In this new approach of the generative design process using ANSYS, the piece of software generates an iteration of models satisfying the working conditions and fitting requirements of static structural analysis (normal stress, shear stress, gravitational load, and deflection limit) together but in parallel with the optimisation of the frequency modes using modal analysis. This generative design process was created as a structural optimisation strategy following the results of the previous study [

14] and the observations of the preliminary modal analysis. The preoptimized rotor disc structure was used as the initial model and the frequencies to be maximised are targeted using two different approaches available in ANSYS: one approach maximising a single frequency mode (mode 12 of the initial model), and another approach maximising a frequency mode range (mode 8 to 15 of the initial model). An assessment of the new generative design process was performed by determining the variables and the mesh analysis parameters. The strategy for the generative design variables was optimised after the findings of the previous study for the effectiveness of the process. These variables are stated in

Table 3, in which the mesh analysis is also presented. The mesh analysis in this process varies in relation to the initial optimisation volume domain chosen; in the case of the preoptimized rotor disc structure, special consideration has been developed with the objective to obtain a good convergence in the resulting model, implementing a hexagonal method and a good mesh resolution for a more uniform mesh.

The topologies produced by the generative design iterative process including a modal analysis and using as a control method cyclic symmetry are arranged into two groups representing the two objective approaches of the modal analysis with ANSYS. The first group of generated topologies is the one resulting from the approach of using a modal analysis with a frequency mode range, modes 8 to 15 of the initial model.

Figure 13 presents these generated topologies and their evolution while modifying the parameter of cyclic symmetry during the generative design process.

The second group of generated topologies is the one resulting from the approach of using a modal analysis with a single frequency mode, the mode 12 of the initial model.

Figure 14 presents the generated topologies of this second approach.

Table 4 describes different topologies generated using both approaches and their structural mass. The most efficient topology obtained by the new generative design method was processed to be assessed and discussed using dynamic analysis. A dynamic analysis of the most efficient topology obtained in this new process was then compared with the previous topology generated by [

14].

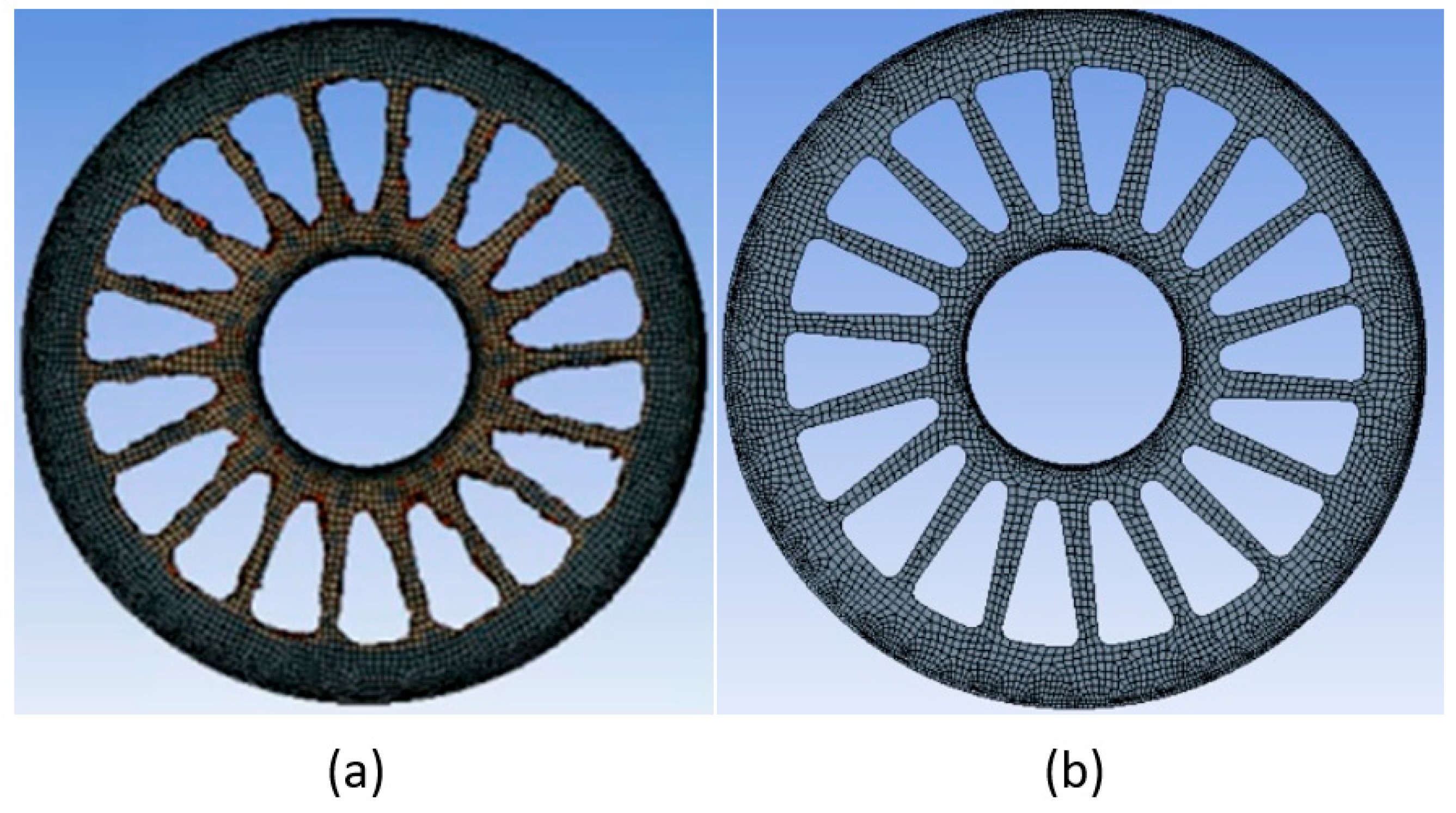

3. Modal Analysis Discussion

A modal analysis was used in this study to discuss and assess the results obtained in the new structural optimisation strategy. A comparison has been made with the result obtained in the previous study [

14] in which the optimisation was carried out looking at the results from the static structural analysis only. The most efficient topology of the new generative design process was observed to be created while using an 18-cycle symmetry and maximising a single frequency mode instead of a frequency mode range. As part of the generative design process, ANSYS produces an organic topology following the manufacturing constraint of cyclic symmetry. Although the manufacturing constraint helps to simplify and control the topology generation process, to create a smooth and uniform structure, further processing is needed. In

Figure 15, the discretisation of the generated topology (a), and a processed topology (b), are presented. In

Figure 15a, it can be observed that the generated topology has converged after the iterative process following the objectives of the structural optimisation strategy developed. In

Figure 15b, it can also be observed that the mesh of the structure was developed following a hexagonal method with a sufficient resolution of elements in order to obtain accurate results.

The processing method performed to simplify the structure uses the generated topology as a reference to manually create a smooth and uniform model with Autodesk Inventor. This processed topology, presented in

Figure 15b, was assessed using dynamic analysis and compared with the results achieved in the previous study [

14].

After processing the topology created by the new generative design method including modal analysis, the structural mass increased from 3618.7 to a final mass of 3675.9 kg, with a maximum stress of 52.33 MPa and a limit of deflection of 0.4993 mm. The integration of the modal analysis in the generative design method produced a significant improvement in the optimisation of the generator supporting structure.

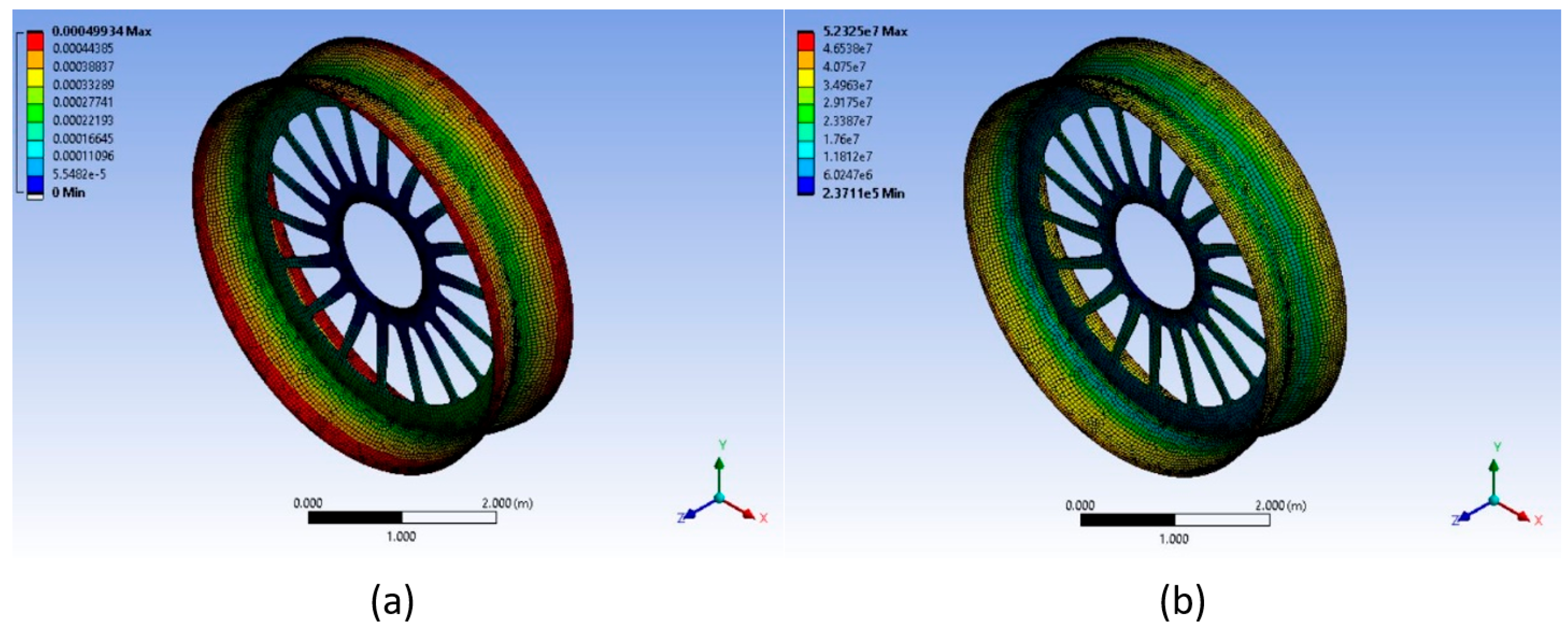

In

Figure 16, the visual representation of the results for the structural analysis of the processed topology of the new generative design process including modal analysis can be observed.

Figure 16a presents the maximum deflection of the resulting structure using the methodology presented in this paper. Moreover,

Figure 16b presents the maximum Von Mises stress experience by the structure. The maximum deformation obtained was 0.4993 mm, satisfying the limit of deformation for the airgap between the rotor and stator structures of 0.5 mm with a maximum Von Mises stress value of 52.33 MPa.

In

Table 5, a comparison between the generated topologies of the different studies is presented with the values of structural mass, Von Mises stress, and total displacement. A better structural optimisation in the generated topology is observed for the process including the modal analysis, with a decrease in structural mass of over 7% in comparison with the preoptimized disc structure.

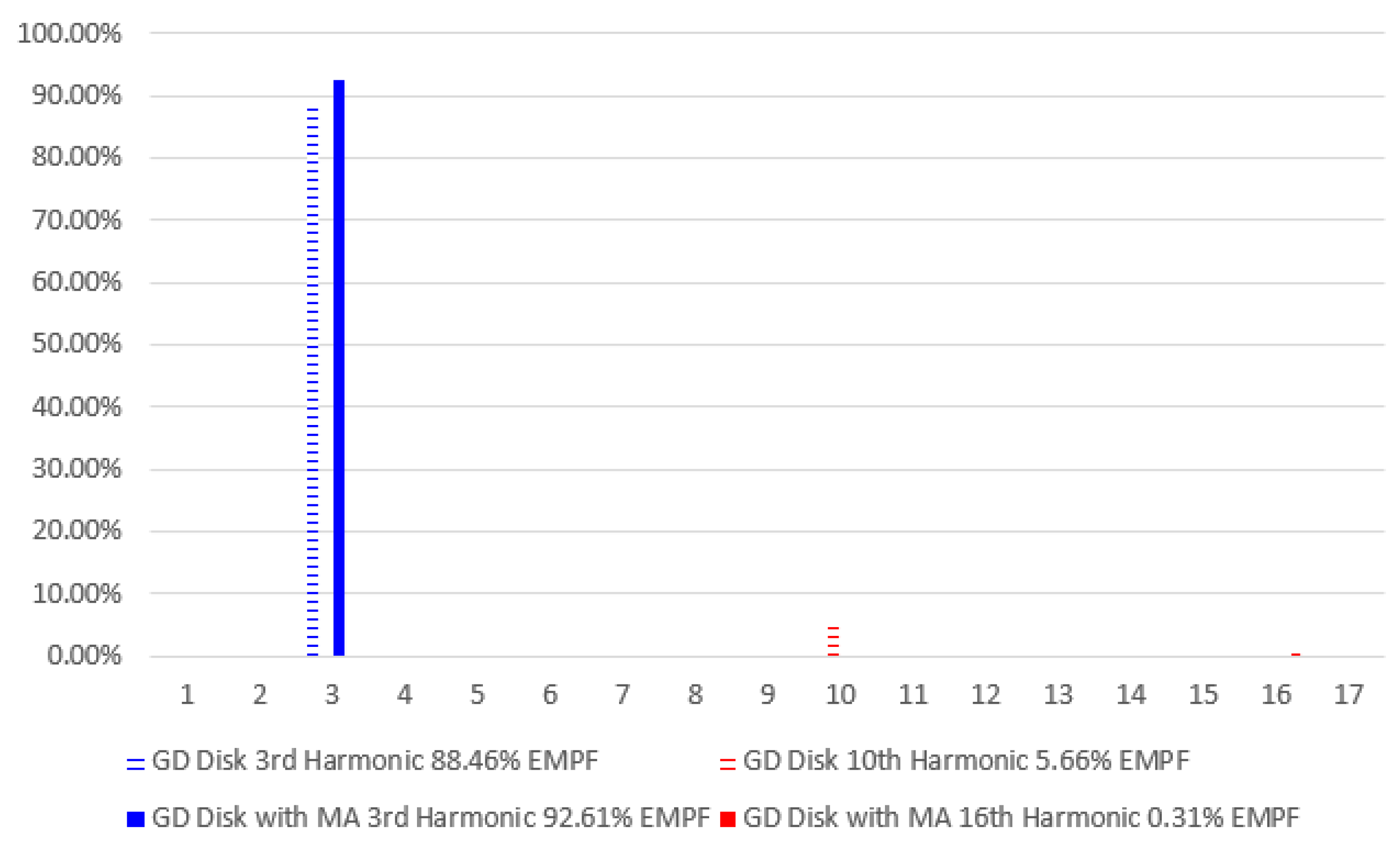

A dynamic analysis for the processed topology of the generative design with modal analysis was assessed. Using an effective mass participation factor (EMPF) technique, two frequency modes were identified as interfering with the excitation frequencies of the generator. The analysis showed an increase in the frequency of mode 16, with 79.63 Hz, and, even though unexpected, an advantageous reduction in the frequency of mode 3, with 4.87 Hz, in comparison with the preoptimized initial disc model.

Table 6 presents the effective mass participation factor results for the processed topology of generative design including modal analysis.

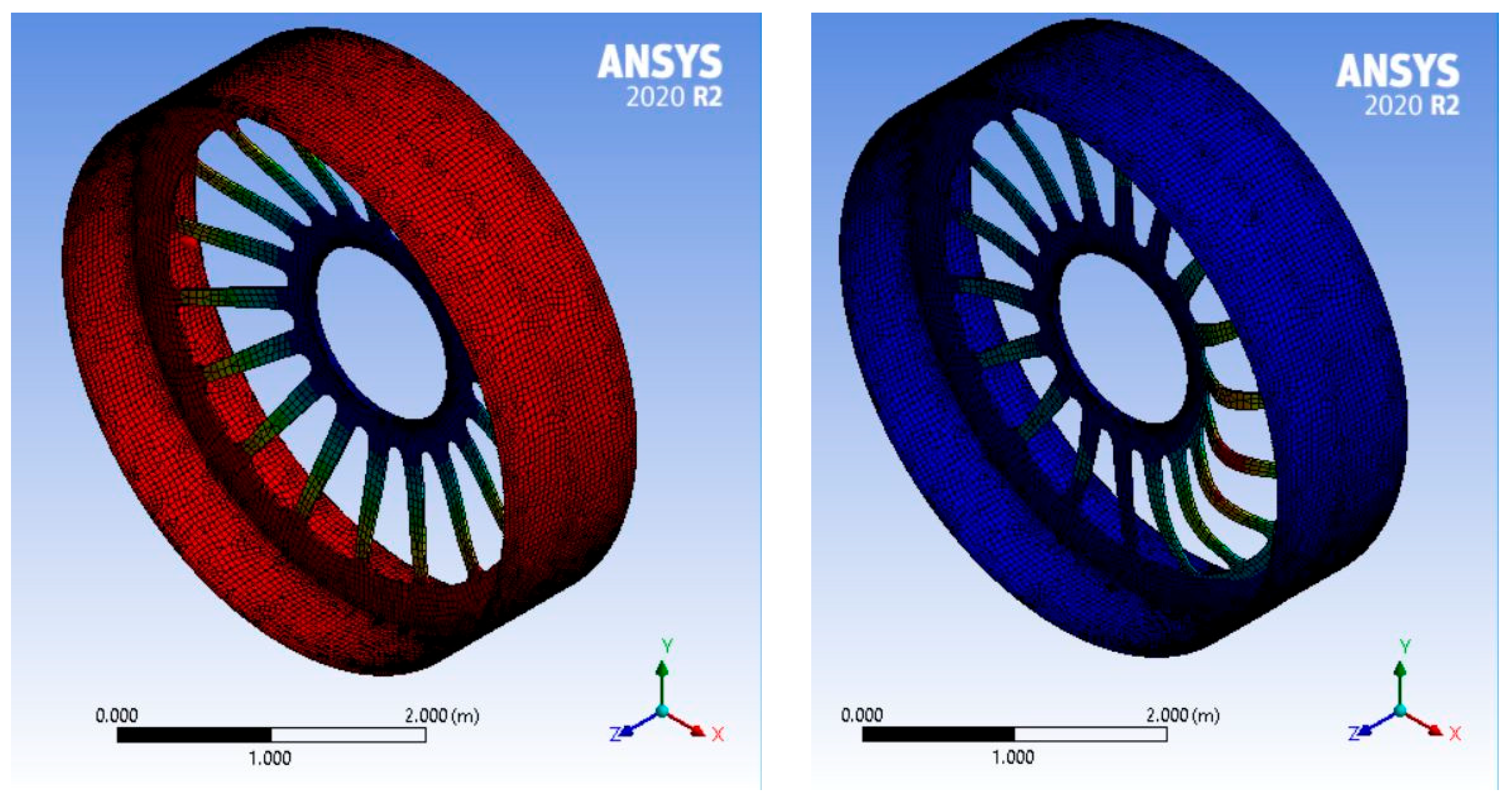

The visual representation of these frequency modes, mode 3 with 4.873 Hz, and mode 16 with 79.63 Hz, can be seen in

Figure 17. The values of maximum and minimum deformation are represented in the figures in red and blue, correspondingly.

Figure 18 presents a comparison of the effective mass participation factor of the two topologies assessed; the topology of the generative design process without modal analysis, and the topology of the new generative design process including modal analysis. The implementation of a modal analysis as part of the generative design process allowed the generation of the topologies with the aim of maximising a designated frequency mode. It is observed that even though the natural frequency mode of the initial disc structure interferes with the excitation frequencies and the one selected as an objective to maximise is mode 12, changes in the topology during the generative design process resulted in alterations in the frequency mode, interfering with the excitation frequencies. Although the frequency mode changes from frequency mode 12 in the initial model to frequency mode 16 in the generated topology, the software accomplishes the objective of maximising the frequency as part of the process.

As part of the dynamic analysis and comparison of the two generated topologies, a Campbell diagram (

Figure 19) was used to represent different frequencies involved in the operational range of the wind turbine generator. The Campbell diagram shows an increase in the frequency obtained for the upper limit of vibrations in comparison with the previous topology. The generative design process including modal analysis and the resulting optimisation of the dynamic behaviour of the structure produced not only an extension of the operational range on the upper limits of the rotation speed, increasing the frequency of the 16th mode from 54.14 Hz to 79.63 Hz, but also in the lower limits by decreasing the frequency of the 3rd mode from 5.41 Hz to 4.87 Hz. This increment in operational range translates into an increase in energy-gathering capability of 39%. As seen in

Figure 17, it is possible to capture energy at lower and higher rotor speeds that corresponds to lower and higher wind speeds, respectively.

Note that considering how the Von Mises stress spreads across the structure and that the effective mass participation factor in the axial, “Z”, direction is the largest, further analysis was attempted by introducing a fillet union of various radii between the optimised disc and cylinder, and between the disc and the shaft of the rotor structure. However, no significant variations in the harmonic behaviour of the structure were observed.

Computation Sustainability

The rapid development of design and analysis tools represents a great opportunity to increase efficiency on design processes. The consideration of sustainable practices on these new design process is fundamental, together with the acknowledgement of the effects in terms of sustainability when implementing these novel approaches. With these new techniques, more efficient, automatic and complete design analysis at a very early stage of large-scale projects can be achieved with the subsequent impact on sustainability on the next phases of the projects. The highly adaptable and efficient computer simulations allow not only the optimisation of the structure but also the optimisation of the overall design process, decreasing the computational time and power consumption, and extending the accessibility to a vast amount of design data in comparison with the conventional iterative manual processes typically used for these types of structures. The integration of sustainable principles into computational techniques is essential to achieve a more climate-conscious usage of computing resources and to raise awareness of the environmental impact of these processes while responding to the demand for more powerful systems. Computing sustainability, also called green computing, aims to use computational resources while maximising energy efficiency and minimising the environmental footprint of the process [

19]. Conventional mechanical design optimisation techniques often focus on the performance of the method ignoring the sustainability of the procedure. Generative design techniques utilise the power of artificial intelligence and machine learning algorithms on a multi-objective design optimisation process to explore a vast range of solutions that otherwise would be impossible to obtain through conventional methods without using an immense quantity of resources.

Although the entire structural optimisation strategy was carefully assessed for the efficiency of the process, the implementation of the modal analysis to the existing static structural analysis, the multiple optimisation objectives, and the number of topology iterations resulted in a time-consuming computing process. Computer simulations conducted in this new process required an average time of 9 h per simulation, in comparison with an average of 3 h per simulation in the previous generative design process without modal analysis. The total weight of the digital data collected at the end of the structure optimisation process for this study was over 75 gigabytes. Even though the computing time and the weight of the data stored for the new optimisation study are greater than those of the previous optimisation study, it can be discussed whether the generation of a more efficient topology delivers sustainable consequences overall in these large-scale projects, such as the increment of operational range and energy gathering from the wind; the reduction in material usage and manufacturing processes; and more efficient logistic plans of transportation. Furthermore, the implementation of cloud computing could reduce the environmental impact of heavy computer simulations even further by increasing performance at a low-cost while reducing hardware equipment, carbon emissions, and electronic waste [

20].

4. Conclusions

The implementation of generative design techniques as a new method of optimisation for big structures represents a revolution as a cost-effective assessment at an early stage of the design process for large-scale projects. The application of these generative design-controlled processes to PMDD generator structures resulted in an innovative optimisation method for multi-MW offshore wind turbine generators. The flexibility of the generative design process allows the use of different inputs as part of the automated process of topology generation, simultaneously applying in this study not only a static structural analysis optimisation but also a dynamic analysis optimisation, considering the natural and excitation frequencies while complying with the working conditions of the generator. The adaptability of this technique makes the research of non-conventional topologies possible by generating an iteration of models while following a set of rules designed with fittest-for-purpose criteria. This novel technique of wind turbine generator analysis also provides a vast range of relevant structural design information at an early stage of project development.

In previous studies, the application of cavities as a method of weight reduction optimisation was investigated. The process of designing cavities is often used to obtain lightweight topologies. However, this could also reduce the stiffness and the harmonic behaviour of the structure. The use of innovative mechanical design optimisation methods allows the exploration of original topologies difficult to generate using conventional design methods. The addition of modal analysis as part of the generative design automated process produces new topologies while taking into consideration the dynamic behaviour of the structure, not only achieving the optimisation of the structure while adding cavities but also keeping the maximum level of stress low under working conditions, increasing the life cycle of the system. This is a crucial requirement for offshore large-scale projects.

The addition of a modal analysis as part of the generative design process to the structural optimisation strategy of previous studies resulted in a further extension of the wind turbine generator operational range of 39%, from 18 rpm as the upper limit obtained in the previous study, to 25 rpm with the new structural optimisation strategy process.

The rapid development and growth of offshore wind energy projects require an equal development of modern technologies and design techniques. With the scale of wind turbines increasing, novel methods of project assessment and analysis need to be explored to adapt to bigger and more extreme generator working conditions. This study proved that the use of non-conventional mechanical design computer-aided methods are powerful tools that can help to solve the challenges encountered in the project development of offshore wind turbine generators. The implementation of a generative design technique represents an effective and innovative design approach that uses an automated and application-adapted process with a visual and analytical assessment of numerous original models for structural analysis optimisation. This might be coupled with rapid prototyping in order to ease the manufacturing stage and increase not only the energy gathering capability and the life cycle of the turbine as stated, but also the scale and speed of production. Modularity and reuse are also options that can be taken into consideration with these designs, opening the door to other circular economy opportunities.

In conclusion, the effects of the novel structural optimisation strategy presented in this study are noticed in different aspects throughout the process, not only with a direct impact on weight reduction and increase in operational range, but also with an indirect impact on computational power consumption, decrease on the design time-scale in comparison with conventional methods, and on the large amount of valuable design analysis data collected. This greatly adaptable methodology allows the designer to automate the optimisation process while using as inputs the knowledge of previous design analysis, resulting in a highly efficient process.