Justification of Complex Physical–Chemical Criteria for Flotation Processing Efficiency in Waste Recycling Using Paper De-Inking as an Example †

Abstract

1. Introduction

- ‑

- High fiber yield, i.e., low number of fine torn wood structures;

- ‑

- Selective recovery of dye particles and, as a consequence, de-inking of the obtained paper.

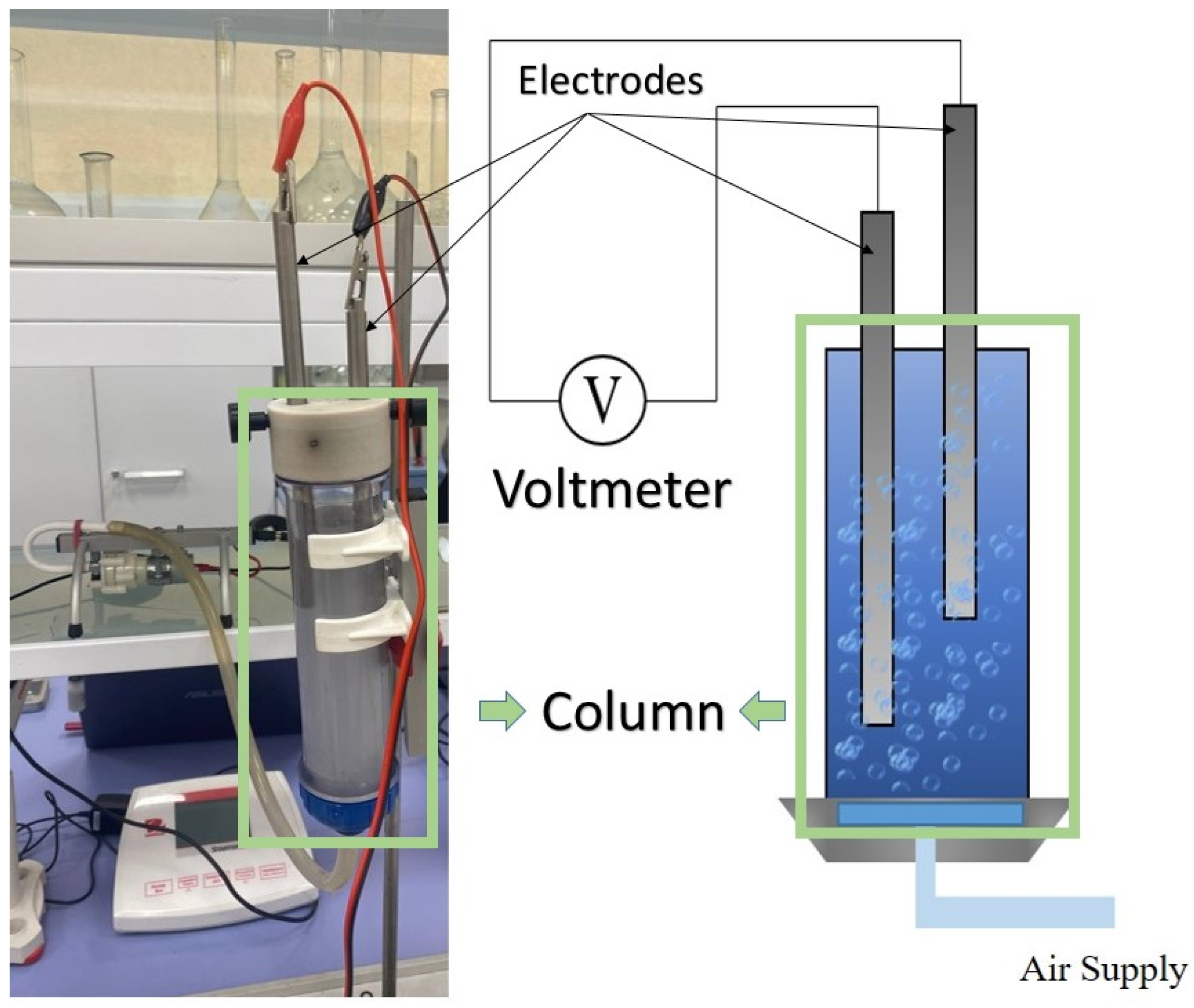

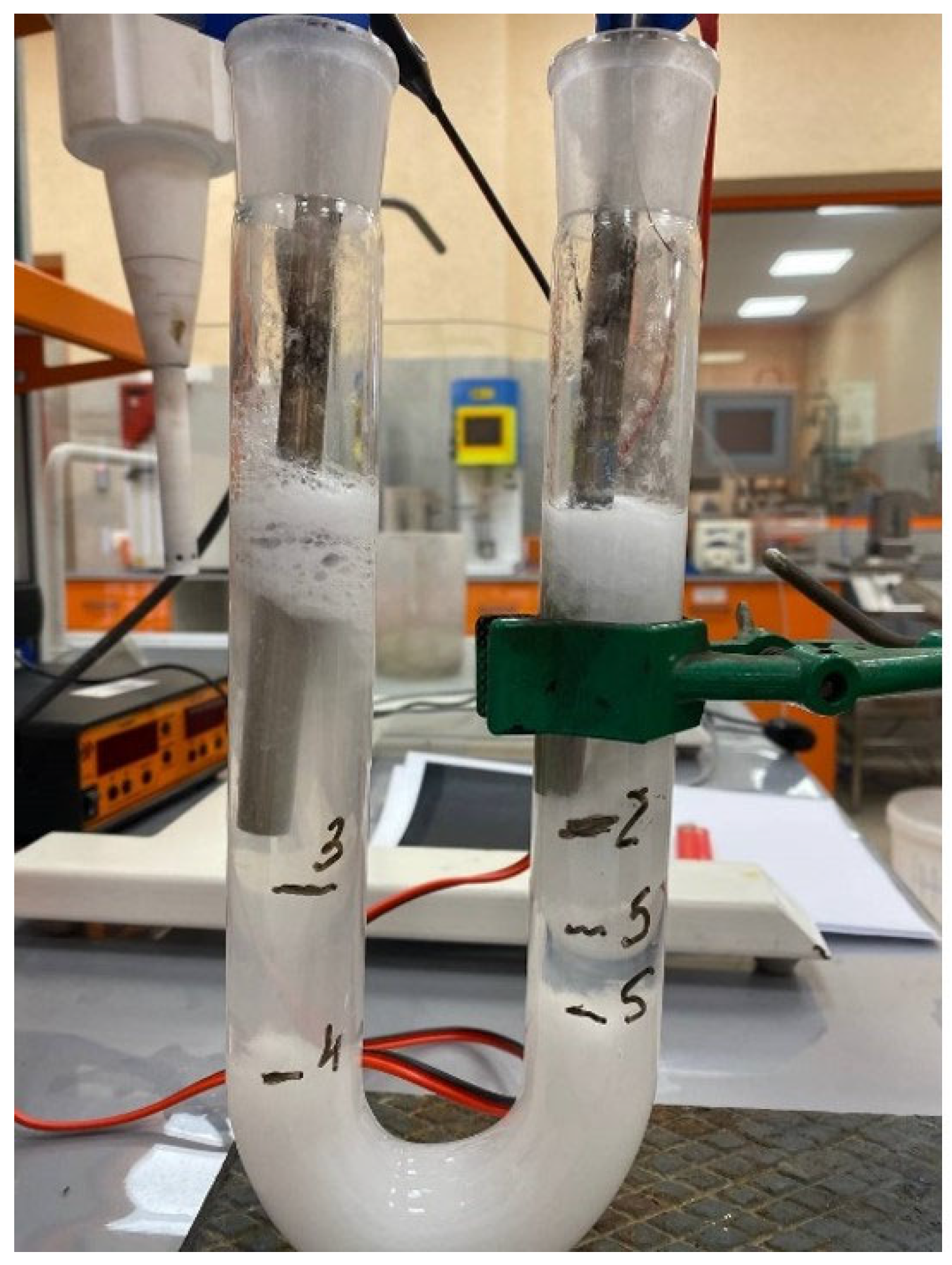

2. Materials and Methods

3. Results

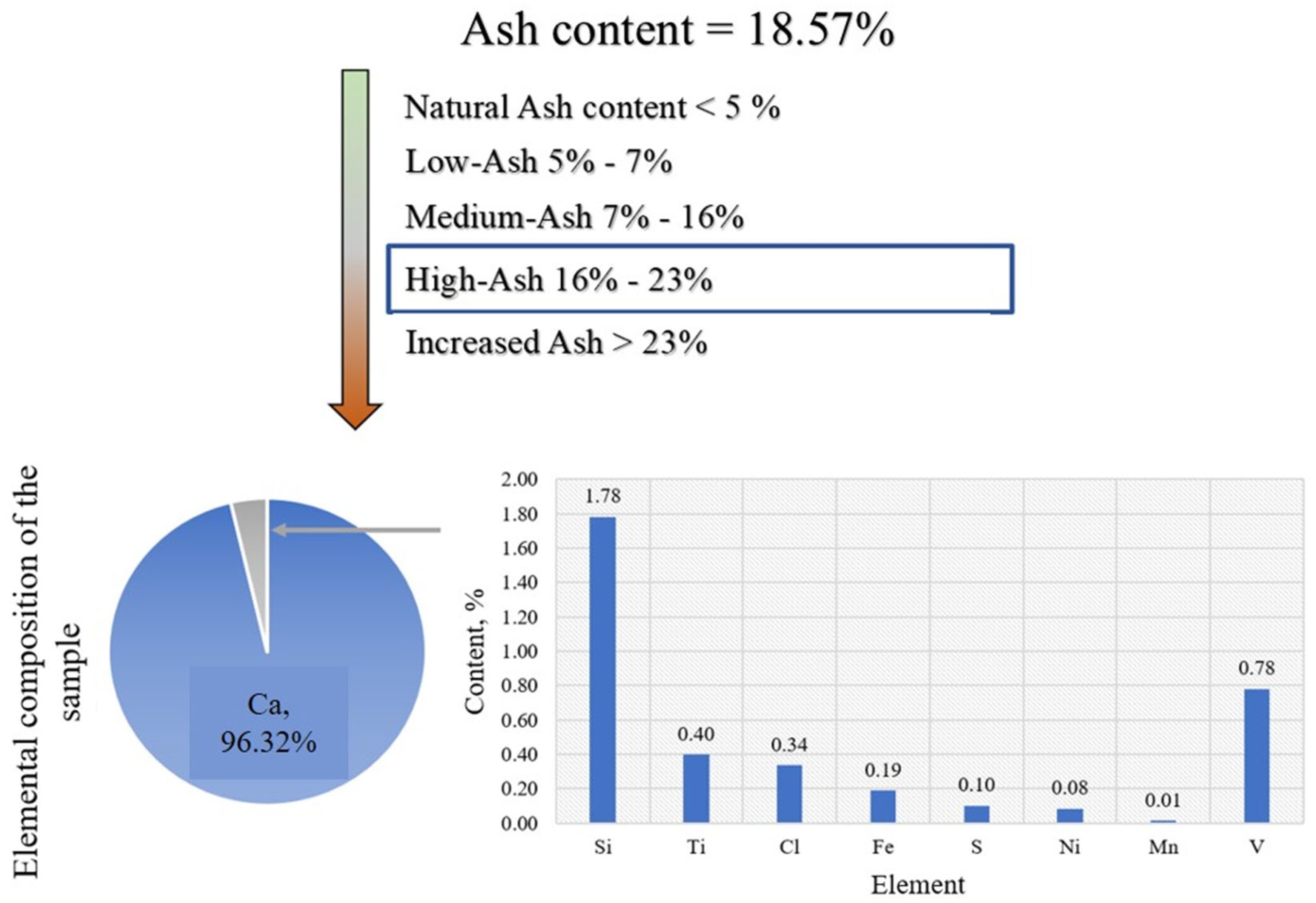

3.1. Results of Sample Elemental Composition Analysis

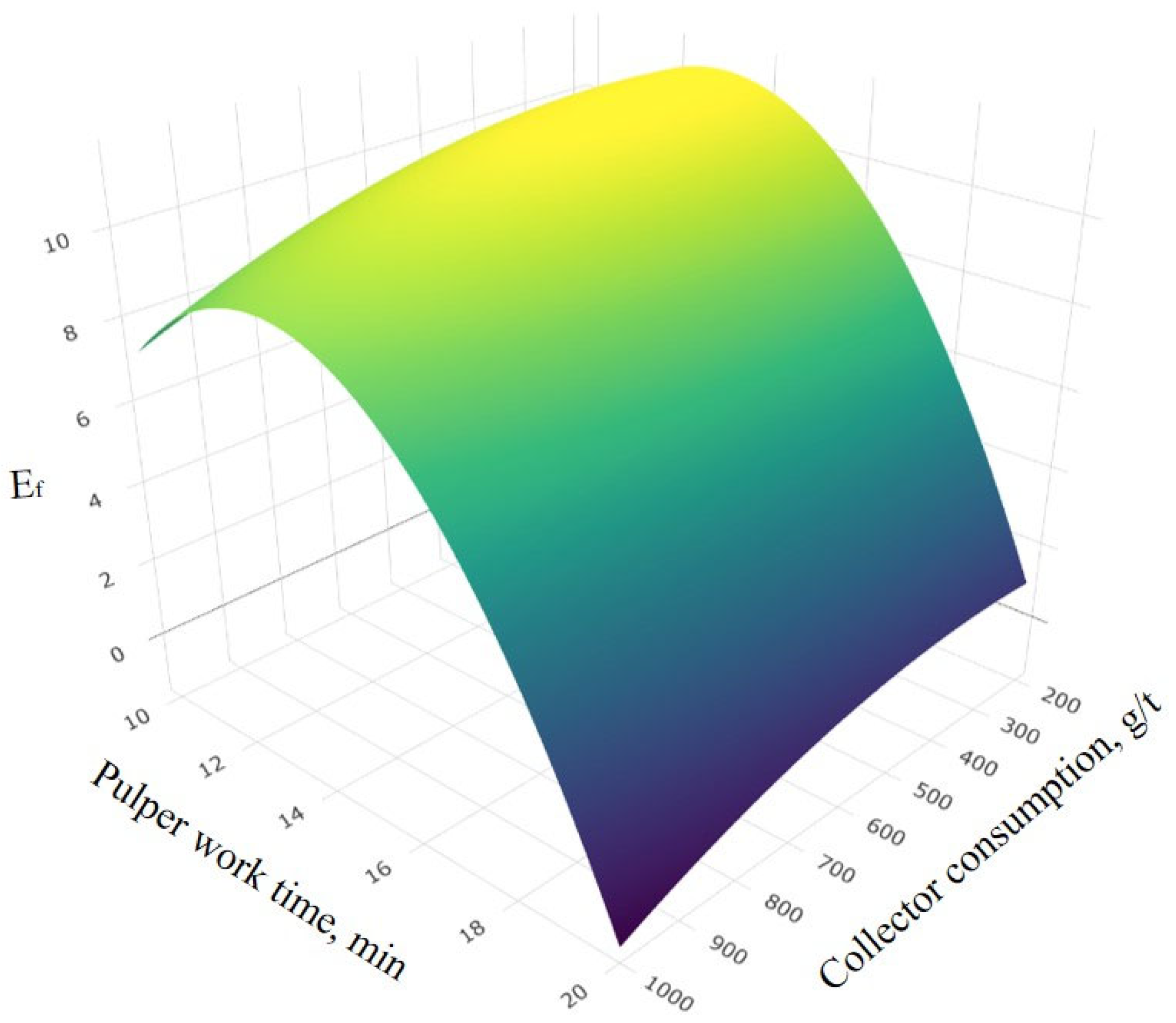

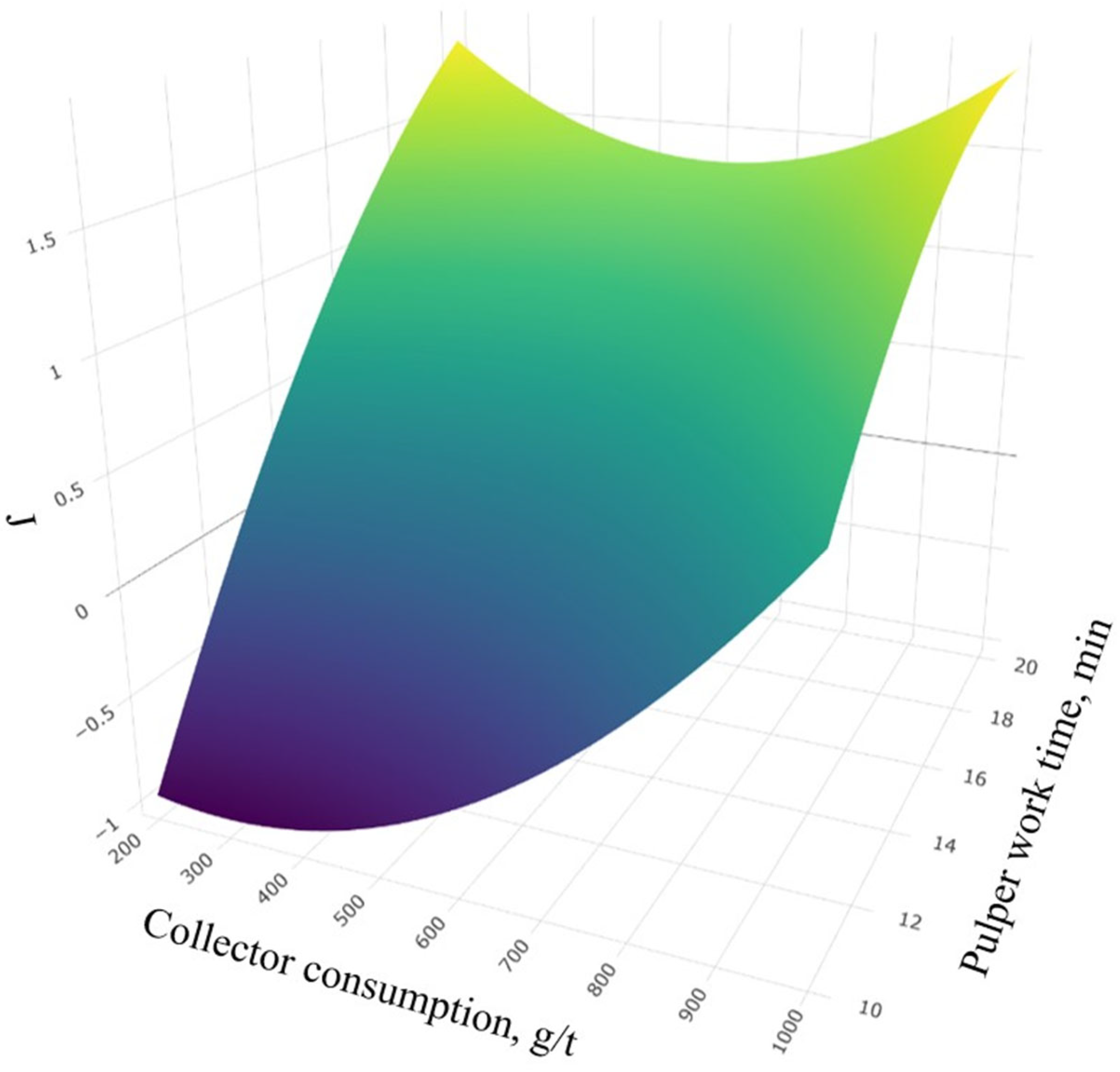

3.2. Results of Determination of Ef and J Criteria Under Variation of Collector Dosage and Sample Residence Time in the Pulper

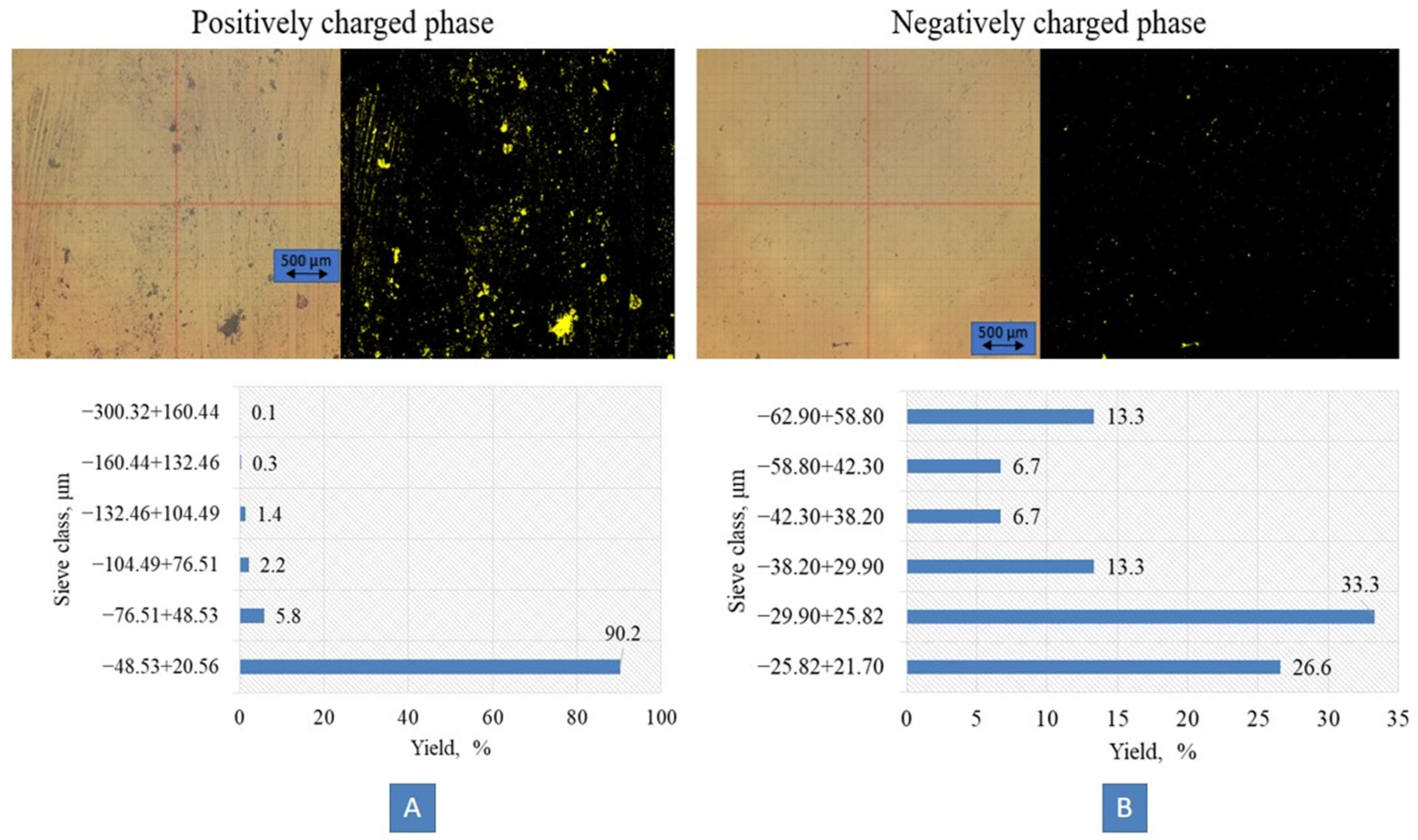

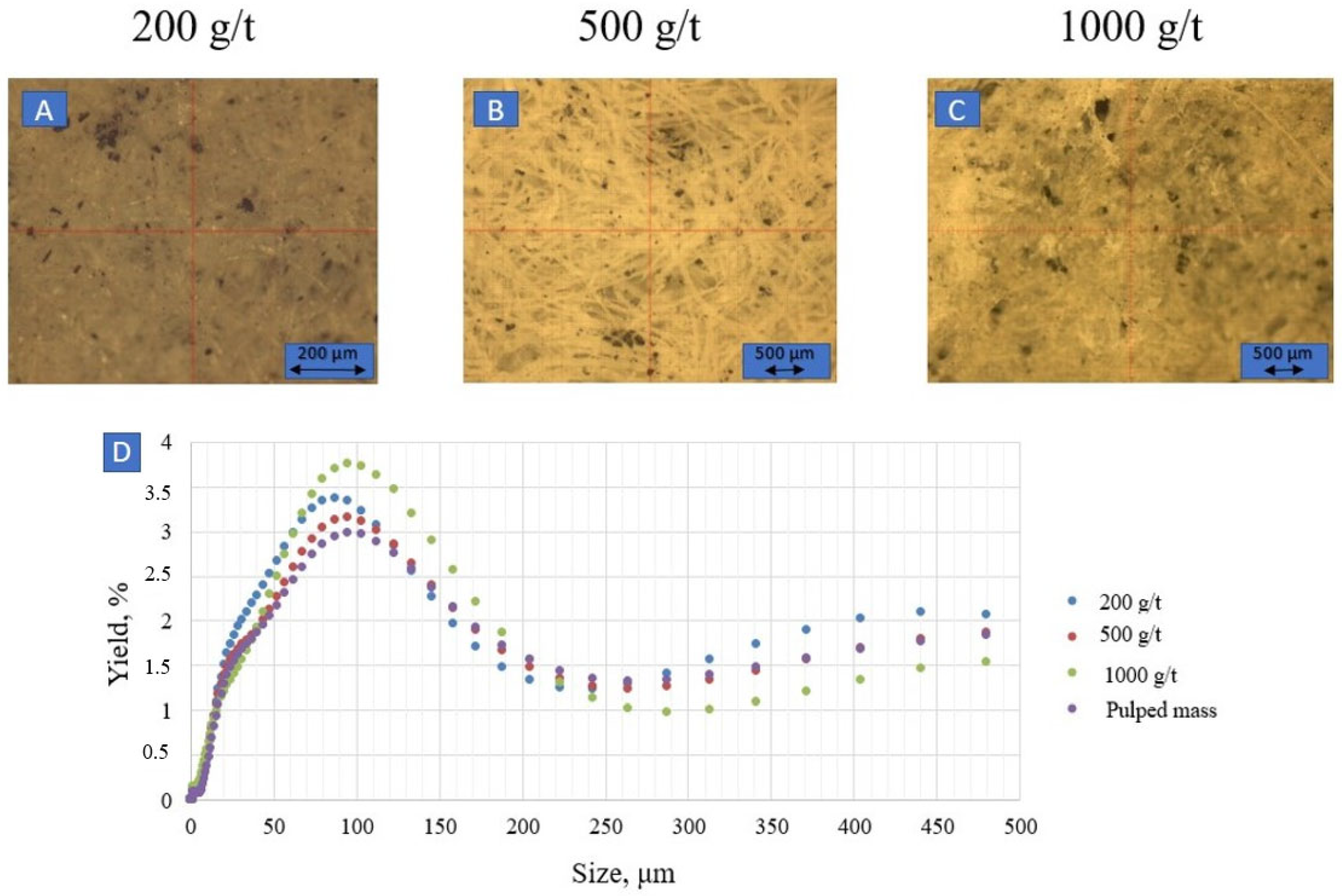

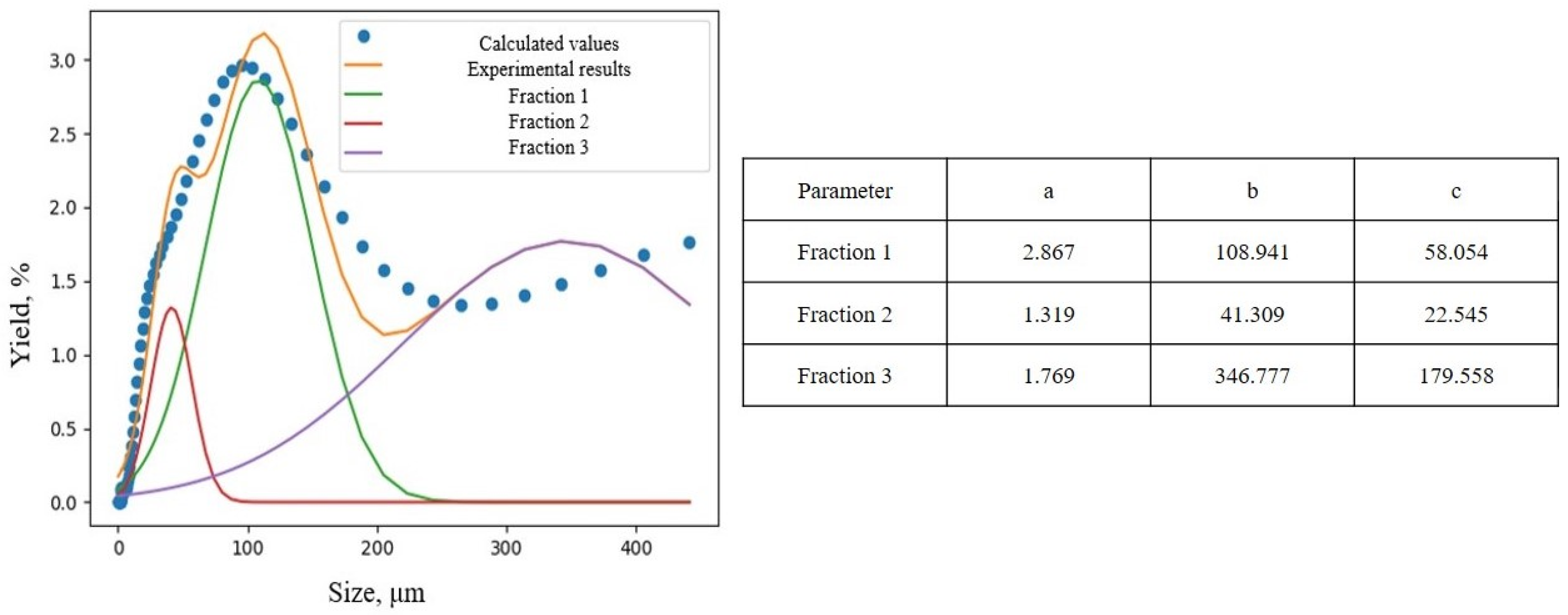

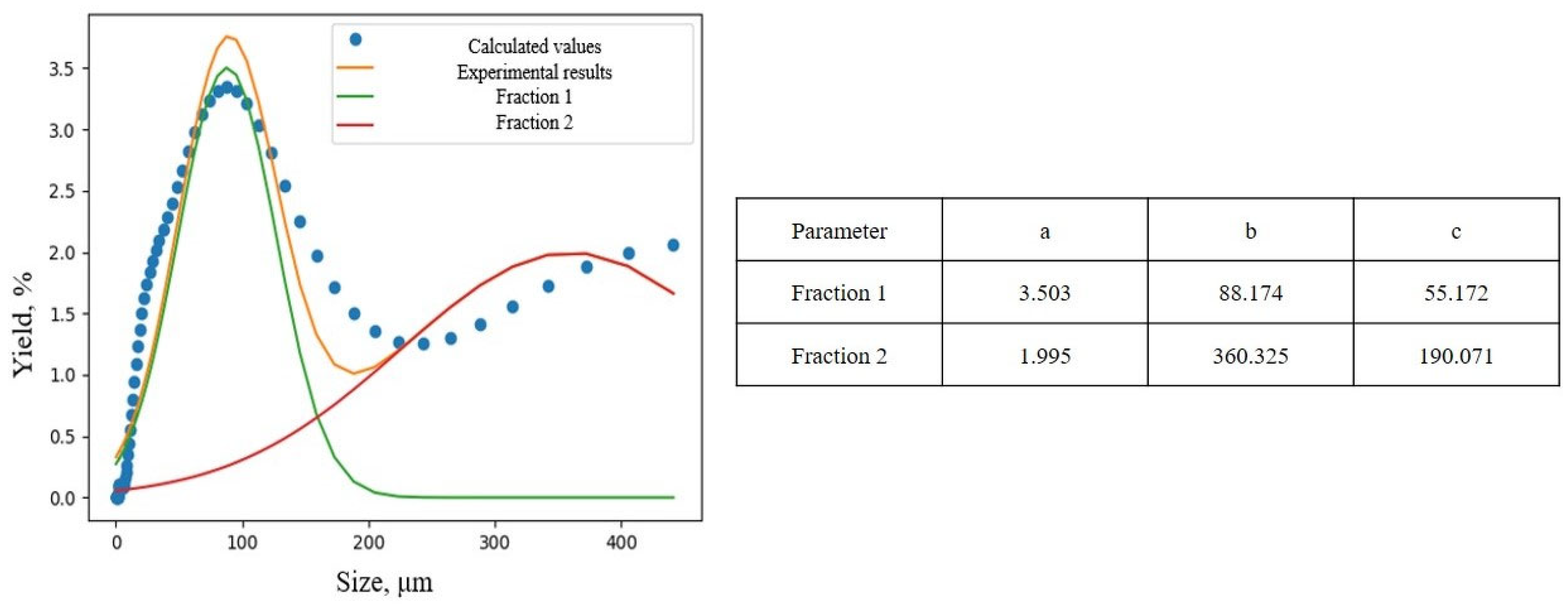

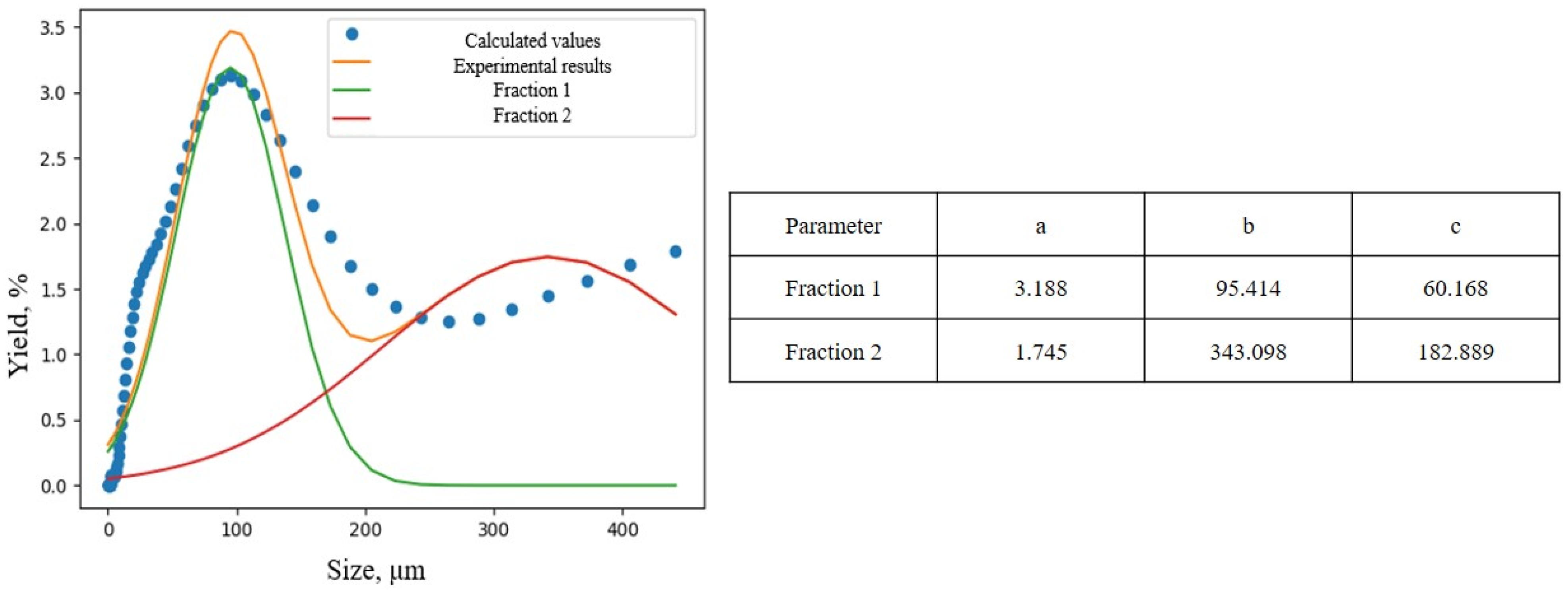

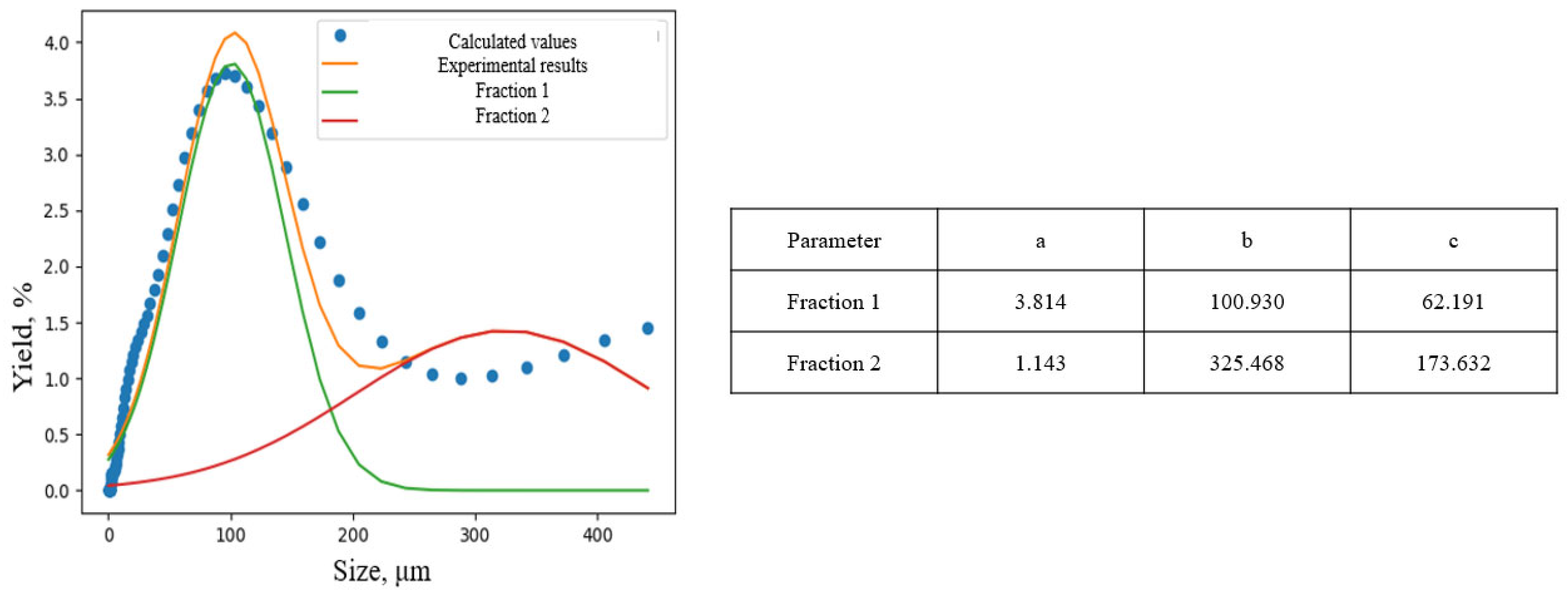

3.3. Results of Research of Flotation Purification Products of Waste Paper Pulp at Residence Time in the Pulper for Which the Maximum Values of the Criterion Are Achieved Ef

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chanturia, V.A.; Shadrunova, I.V.; Gorlova, O.E. Adaptation of separation processes of mineral processing to technogenic raw materials: Problems and solutions. Obogashchenie Rud 2012, 5, 43–50. [Google Scholar]

- Shadrunova, I.V.; Orekhova, N.N. Ecological and economic aspects processing of technogenic hydromineral raw materials. Min. Inf. Anal. Bull. 2014, S1, 161–179. [Google Scholar]

- Pashkevich, N.V.; Khloponina, V.S.; Pozdnyakov, N.A.; Avericheva, A.A. Analysing the problems of reproducing the mineral resource base of scarce strategic minerals. J. Min. Inst. 2024, 270, 1004–1023. [Google Scholar]

- Antoninova, N.Y.; Sobenin, A.V.; Usmanov, A.I.; Shepel, K.V. Assessment of the possibility of using iron-magnesium production waste for wastewater treatment from heavy metals (Cd2+, Zn2+, Co2+, Cu2+). J. Min. Inst. 2023, 260, 257–265. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B.; Aleksakhin, A.V.; Eliseeva, E.N.; Zhaglovskaya, A.V.; Klyuev, R.V.; Petrusevich, D.A. Modern Technologies Providing a Full Cycle of Geo-Resources Development. Resources 2023, 12, 50. [Google Scholar] [CrossRef]

- Penya, A.F.; Bazhin, V.Y.; Makushin, D.V. Valuable aluminum alloys obtained from secondary metallized raw materials. Ipolytech J. 2024, 28, 647–656. (In Russian) [Google Scholar] [CrossRef]

- Pashkevich, M.; Patokin, D.; Danilov, A. Processing the Nitrocellulose-containing Waste from the Chemical Industry to Obtain Mineral Soil Additives. Ecol. Ind. Russ. 2024, 28, 10–17. (In Russian) [Google Scholar] [CrossRef]

- Orekhova, N.N.; Fadeeva, N.V.; Musatkina, E.N. Study and justification of the combination of beneficiation processes for obtaining flake graphite from technogenic carbon-containing dusts. J. Min. Inst. 2024, 269, 777–788. [Google Scholar]

- Papagianni, S.; Moschovi, A.M.; Sakkas, K.M.; Chalaris, M.; Yakoumis, I. Preprocessing and Leaching Methods for Extraction of REE from Permanent Magnets: A Scoping Review. AppliedChem 2022, 2, 199–212. [Google Scholar] [CrossRef]

- Nikolaeva, N.V.; Kallaev, I.T. Features of copper–molybdenum ore grinding. MIAB. Mining Inf. Anal. Bull. 2024, 1, 52–66. (In Russian) [Google Scholar] [CrossRef]

- Efimov, D.A.; Gospodarikov, A.P. Technical and technological aspects of the use of Reuleaux triangular profile rolls in crushing units in the ore processing plant. MIAB. Mining Inf. Anal. Bull. 2022, 10-2, 117–126. (In Russian) [Google Scholar] [CrossRef]

- Nazari, S.; Li, J.; Khoshdast, H.; Li, J.; Ye, C.; He, Y.; Hassanzadeh, A. Effect of roasting pretreatment on micro-nanobubble-assisted flotation of spent lithium-ion batteries. J. Mater. Res. Technol. 2023, 24, 2113–2128. [Google Scholar] [CrossRef]

- Romashev, A.O.; Nikolaeva, N.V.; Gatiatullin, B.L. Adaptive approach formation using machine vision technology to determine the parameters of enrichment products deposition. J. Min. Inst. 2022, 256, 677–685. [Google Scholar] [CrossRef]

- Danilov, A.; Serdiukova, E. Review of Methods for Automatic Plastic Detection in Water Areas Using Satellite Images and Machine Learning. Sensors 2024, 24, 5089. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Li, P.; Peng, C.; Tian, E.; Wang, Y.; Huang, J.; Duan, C. Capture and extraction of gold from aqueous solution via the iron electrocoagulation method. ACS EST Eng. 2023, 3, 1188–1196. [Google Scholar] [CrossRef]

- Fischer, A. Deinking–How to Get the Ink Off the Paper. In Inkjet Printing in Industry: Materials, Technologies, Systems, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2022; Volume 1, pp. 449–463. [Google Scholar]

- Medvedeva, S.A.; Timofeeva, S.S.; Volchatova, I.V. Evaluation perspectives of scientific and practical potential complex treatment of living cells for modernization timber processing complex. Chem. Veget. Raw Mater. 2013, 4, 5–12. [Google Scholar] [CrossRef][Green Version]

- Yang, S.; Shen, J.; He, T.; Chen, C.; Wang, J.; Tang, Y. Flotation de-inking for recycling paper: Contrasting the effects of three mineral oil-free offset printing inks on its efficiency. Env. Sci. Poll. Res. 2022, 29, 89283–89294. [Google Scholar] [CrossRef]

- Kemper, M. State-of-the-art and new technologies in flotation deinking. Int. J. Min. Proc. 1999, 56, 317–333. [Google Scholar] [CrossRef]

- Gavrilović, T.; Despotović, V.; Zot, M.-I.; Trumić, M.S. Prediction of Flotation Deinking Performance: A Comparative Analysis of Machine Learning Techniques. Appl. Sci. 2024, 14, 8990. [Google Scholar] [CrossRef]

- Nyman, J.; Ivaska, A. Spectrophotometric determination of calcium in paper machine white water by sequential injection analysis. Anal. Chim. Acta 1995, 308, 286–292. [Google Scholar] [CrossRef]

- Rudolfs, W.; Hanlon, W.D. Color in Industrial Wastes: I. Determination by Spectrophotometric Method. Sew. Ind. Wastes 1951, 23, 1125–1132. [Google Scholar]

- Midukov, N.P.; Efremov, D.S.; Kurov, V.S.; Smolin, A.S. The preparation of fibers for cardboard production. Chem. Veget. Raw Mater. 2018, 3, 279–286. [Google Scholar] [CrossRef][Green Version]

- Midukova, M.A.; Smirnova, E.G.; Smolin, A.S. Improving of deinking technology of printing recovered paper. Izv. St.-Peterbg. Lesoteh. Akad. 2022, 238, 267–275. (In Russian) [Google Scholar] [CrossRef]

- Vashisth, S.; Bennington, C.P.; Grace, J.R.; Kerekes, R.J. Column Flotation Deinking: State-of-the-art and opportunities. Res. Conser. Rec. 2011, 55, 1154–1177. [Google Scholar] [CrossRef]

- Martsulevych, N.A.; Kazakov, A.V.; Flisiuk, O.M. Modeling of the flotation process in an industrial apparatus. Theor. Found. Chem. Eng. 2024, 58, 97–102. [Google Scholar] [CrossRef]

- Bloom, F.; Heindel, T.J. Modeling flotation separation in a semi-batch process. Chem. Eng. Sci. 2003, 58, 353–365. [Google Scholar] [CrossRef]

- Amand, F.J.S. Hydrodynamics of deinking flotation. Int. J. Min. Proc. 1999, 56, 277–316. [Google Scholar] [CrossRef]

- Huber, P.; Rousset, X.; Zeno, E.; Vazhure, T. Parameters of deinking efficiency in an industrial flotation bank. Ind. Eng. Chem. Res. 2011, 50, 4021–4028. [Google Scholar] [CrossRef]

- Matveeva, T.N.; Gromova, N.K.; Lantsova, L.B. Promising reagents for the extraction of strategic metals from difficult-to-enrich mineral raw materials. J. Min. Inst. 2024, 269, 757–764. [Google Scholar]

- Mishurina, O.A.; Mullina, E.R.; Chuprova, L.V.; Ershova, O.V.; Chernyshova, E.P.; Permyakov, M.B.; Krishan, A.L. Chemical aspects of hydrophobization technology for secondary cellulose fibers at the obtaining of packaging papers and cardboards. Int. J. Appl. Eng. Res. 2015, 10, 44812–44814. [Google Scholar]

- Fuerstenau, D.W. Zeta potentials in the flotation of oxide and silicate minerals. Adv. Colloid Interface Sci. 2005, 114, 9–26. [Google Scholar] [CrossRef]

- Dorn, E. On the propagation of electricity through flowing water in pipes and related phenomena. Ann. Phys. 1880, 246, 46–77. [Google Scholar] [CrossRef]

- Booth, F. Sedimentation Potential and Velocity of Solid Spherical Particles. J. Chem. Phys. 1954, 22, 1956–1968. [Google Scholar] [CrossRef]

- Usui, S.; Sasaki, H.; Matsukawa, H. The dependence of zeta potential on bubble size as determined by the dorn effect. J. Colloid Interface Sci. 1981, 81, 80–84. [Google Scholar] [CrossRef]

- Aleksandrova, T.N.; Kuznetsov, V.V.; Shlykov, N.A. Physicochemical criteria for assessing the efficiency of flotation paper deinking technologies. In Proceedings of the 2025 VI Russian National Scientific and Practical Conference “Modern Trends in the Development of Chemical Technology, Industrial Ecology and Environmental Safety”, Saint-Petersburg, Russia, 10–11 April 2025. [Google Scholar]

- Aleksandrova, T.N.; Kuznetsov, V.V.; Prokhorova, E.O. Investigation of Interfacial Characteristics as a Key Aspect of the Justification of the Reagent Regime for Coal Flotation. Minerals 2025, 15, 76. [Google Scholar] [CrossRef]

- Aleksandrova, T.N.; Kuznetsov, V.V. A New Approach to Determining Aeration Intensity in Flotation. J. Min. Sci. 2022, 58, 812–822. [Google Scholar] [CrossRef]

- Aleksandrova, T.N.; Kuznetsov, V.V.; Shlykov, N.A. Method for Potentiometric Determination of Interphase Characteristics in Flotation Systems. Patent No. 2835415 C1, 17 July 2024. [Google Scholar]

| Flotation Parameters | Ef Mean, mV/s | Standard Deviation | ||

|---|---|---|---|---|

| Collector Consumption, g/t | Residence Time in Pulper, min | Cell Product Yield, % | ||

| 0 | 10 | - | 5.32 | 0.46 |

| 200 | 10 | 83.2 | 6.61 | 0.47 |

| 500 | 10 | 77.5 | 14.40 | 0.91 |

| 1000 | 10 | 74.8 | 0.58 | 0.05 |

| 0 | 20 | - | 4.47 | 0.18 |

| 200 | 20 | 75.1 | 4.71 | 0.16 |

| 500 | 20 | 73.1 | 10.65 | 0.69 |

| 1000 | 20 | 69.2 | 0.09 | 0.01 |

| Sum of Squares of the Difference | Degrees of Freedom | RMS Deviations | Value of Fisher’s Criterion | |

|---|---|---|---|---|

| Total | 487.50 | 23 | 21.20 | - |

| Intragroup interaction of indicators | 483.89 | 7 | 69.13 | - |

| Factor A—Collector Consumption | 455.93 | 3 | 151.98 | 673.51 |

| Factor B—Residence time in the pulper | 18.36 | 1 | 6.12 | 27.12 |

| Interaction of factors | 9.60 | 3 | 3.20 | 14.19 |

| Errors | 3.61 | 16 | 0.23 | - |

| Flotation Parameters | J Mean | Standard Deviation | ||

|---|---|---|---|---|

| Collector Consumption, g/t | Residence Time in Pulper, min | Cell Product Yield, % | ||

| 0 | 10 | - | −1.87 | 0.25 |

| 200 | 10 | 83.2 | −1.48 | 0.17 |

| 500 | 10 | 77.5 | 0.70 | 0.13 |

| 1000 | 10 | 74.8 | 1.31 | 0.17 |

| 0 | 20 | - | 0.00 | 0.00 |

| 200 | 20 | 75.1 | 0.78 | 0.68 |

| 500 | 20 | 73.1 | 1.15 | 0.14 |

| 1000 | 20 | 69.2 | 1.52 | 0.01 |

| Sum of Squares of the Difference | Degrees of Freedom | RMS Deviations | Value of Fisher’s Criterion | |

|---|---|---|---|---|

| Total | 35.85 | 23 | 1.56 | - |

| Intragroup interaction of indicators | 34.63 | 7 | 4.95 | - |

| Factor A—Collector Consumption | 21.39 | 3 | 7.13 | 93.32 |

| Factor B—Residence time in the pulper | 8.57 | 1 | 2.86 | 37.41 |

| Interaction of factors | 4.67 | 3 | 1.56 | 20.36 |

| Errors | 1.22 | 16 | 0.08 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrova, T.; Kuznetsov, V.; Shlykov, N. Justification of Complex Physical–Chemical Criteria for Flotation Processing Efficiency in Waste Recycling Using Paper De-Inking as an Example. AppliedChem 2025, 5, 20. https://doi.org/10.3390/appliedchem5030020

Aleksandrova T, Kuznetsov V, Shlykov N. Justification of Complex Physical–Chemical Criteria for Flotation Processing Efficiency in Waste Recycling Using Paper De-Inking as an Example. AppliedChem. 2025; 5(3):20. https://doi.org/10.3390/appliedchem5030020

Chicago/Turabian StyleAleksandrova, Tatyana, Valentin Kuznetsov, and Nikita Shlykov. 2025. "Justification of Complex Physical–Chemical Criteria for Flotation Processing Efficiency in Waste Recycling Using Paper De-Inking as an Example" AppliedChem 5, no. 3: 20. https://doi.org/10.3390/appliedchem5030020

APA StyleAleksandrova, T., Kuznetsov, V., & Shlykov, N. (2025). Justification of Complex Physical–Chemical Criteria for Flotation Processing Efficiency in Waste Recycling Using Paper De-Inking as an Example. AppliedChem, 5(3), 20. https://doi.org/10.3390/appliedchem5030020