Abstract

The continuous rise in textile waste, driven by global population growth and the proliferation of fast fashion, has raised concerns about its efficient recycling and sustainable management. This study aims to assess the feasibility of recycling textile waste by incorporating recycled cotton fibres as reinforcement in polypropylene-based composites. Specifically, it examines the mechanical, thermal, and chemical properties of composites composed of 50% recycled polypropylene and 50% reinforcing fibres (either virgin or recycled cotton), with and without the addition of 5% maleic anhydride-grafted polypropylene as a compatibilizer to enhance fibre-matrix adhesion. Although the use of recycled cotton as reinforcement reduced the mechanical properties of the composite material, the addition of 5% compatibilizer improved these properties to levels comparable to those of composite reinforced with virgin cotton.

1. Introduction

The growing demand for sustainable materials across various industries has driven research into innovative approaches for repurposing waste to manufacture new products for diverse applications.

The rapid growth of the global population and the shift in consumer behaviour toward fast fashion have significantly increased textile production and consumption, resulting in a larger volume of textile waste [1,2]. This waste falls into three categories: post-industrial, pre-consumer, and post-consumer waste [3]. Post-industrial waste is generated during the manufacturing processes of yarns, nonwovens, fabrics, and garments. Pre-consumer waste consists of unused textiles (garments), while post-consumer waste includes worn-out textile products that their owners no longer need. Post-consumer waste, such as discarded clothing and textiles, often ends up in landfills or incinerators, despite the potential for recycling and reuse.

The most commonly used method for textile recycling that has been practiced for decades is mechanical recycling [4,5]. Traditionally, mechanical recycling involves shredding fabrics into fibres, which are then spun into yarns [6,7] or transformed into nonwoven fabrics [8,9,10]. The quality of recycled fibres is generally lower than that of virgin fibres, which is why recycled fibres are often blended with virgin fibres to enhance their properties [11]. Research has shown that yarns made from blends of recycled and virgin cotton have lower quality compared to yarns made entirely from virgin cotton [12]. With each additional recycling cycle, the degradation of fibre properties becomes more pronounced. This issue can be addressed by repurposing textile waste as reinforcement in polymer composites, rather than reincorporating it into textile products.

In recent years, studies have explored the use of textile waste, in the form of either small fabric pieces [13,14] or shredded fibres [15,16,17], as reinforcement in composite materials. In this study, we chose to use the reinforcing material in the form of fibres, as this allows for more consistent control of the composite properties, which primarily depend on the nature and characteristics of the fibres themselves. When the reinforcement is in the form of small fabric pieces, the properties of the composite material are influenced not only by the nature and characteristics of the fibres, but also by various other factors such as piece size, fabric type (woven or knitted), fabric structure and mass per unit area, yarn count, yarn twist, yarn structure (single or folded), and yarn manufacturing technology (e.g., open-end or ring-spun, carded or combed) [18]. This wide range of influencing factors leads to significant variability in the properties of the resulting composites.

The extensive use of polypropylene-based items has led to a significant accumulation of polypropylene waste, necessitating efficient recycling processes to mitigate environmental impact [19]. The most widely used method for polypropylene recycling is mechanical recycling [20,21]. Many researchers have investigated the structure and properties of recycled polypropylene and its applications as matrix in composites. Aurrekoetxea et al. found that recycled polypropylene exhibits lower melt viscosity, higher crystallinity and equilibrium melting temperature, and lower elongation at break and fracture toughness compared to virgin polypropylene [22,23].

One of the main issues with natural fibre-reinforced polymeric composites is the poor compatibility between the hydrophilic reinforcing fibres and the hydrophobic polymer matrix, which leads to weak interfacial bonding and negatively affects the mechanical properties of the composites [24]. Physical and chemical treatments have been applied to enhance the interfacial bonding between the matrix and reinforcing fibres, such as plasma treatment [25], gamma radiation [26], alkali treatment [27], acetylation [28], benzylation [29], propionylation [30], silane treatment [31], maleated coupling agent treatment [32,33], and other chemical treatments [34,35,36]. Coupling agents are additives that enhance the compatibility between dissimilar materials by forming stable chemical bonds [37]. This improved interaction between the matrix and the fibres results in significant enhancements in the composite properties. In this study, maleic anhydride-grafted polypropylene (MAPP) was chosen as the coupling agent due to its chemical compatibility with the polypropylene matrix and its proven effectiveness in enhancing interfacial adhesion with natural fibres through the interaction between the carbonyl groups of maleic anhydride and the hydroxyl groups of cellulosic fibres.

Various studies have reported the use of recycled cotton as reinforcement in polymer composites. Burgada et al. used post-consumer textile waste, primarily composed of cotton and polyester, in amounts ranging from 15% to 60%, to reinforce polyamide 6 composites produced by extrusion and injection moulding [38]. A 1% silane coupling agent was applied to bond the textile fibres with the polymeric matrix. The highest tensile strength (64.5 MPa) was achieved with a 60% textile waste loading, while the highest tensile modulus (approximately 63 MPa) was observed with a 30% textile waste loading. The results also indicated that the addition of textile waste slightly lowered the degradation temperature of the composites and increased their wettability.

Araújo and collaborators studied the properties of polypropylene composites reinforced with cotton waste fibres [39]. The fibres were obtained by cutting waste cotton denim yarns, followed by bleaching, milling, and sieving through a 1 mm screen. Fibre surface was modified using acetylation or silanization treatments. Polypropylene pellets and cotton waste fibres were mixed in a mini-extruder at ratios of 5%, 10%, and 20%, and the composites were subsequently formed through compression moulding. The tensile strength of the composites, ranging from 18 to 24 MPa, was higher than that of pure polypropylene (15 MPa); however, the chemical treatments did not result in a significant improvement in tensile strength. The addition of cotton fibres led to a decrease in the degree of crystallinity compared to neat polypropylene, but did not affect the melting and crystallisation temperatures.

Hussain et al. investigated the mechanical properties and damage behaviour of polypropylene composites reinforced with post-consumer cotton fibres, manufactured by injection moulding with fibre loadings ranging from 0 to 40% [40]. Tensile strength, tensile extension, breaking strength, flexural strength, energy at maximum load, and compressive extension decreased with increasing post-consumer cotton fibre content, whereas the modulus of elasticity increased with higher recycled cotton content.

Sezgin and collaborators used 70% cotton fibres, recovered from waste denim fabric, to reinforce composite materials in the form of an overlapped carded web [41]. The matrix, composed of polypropylene and polyethylene granules obtained by grinding bottle caps and packaging waste, was evenly distributed between the fibre layers. The composite materials were produced through hot pressing and exhibited good thermal and acoustic insulation properties.

Cotton waste has been used as reinforcing fibres to produce green composites for applications such as furniture and automotive components [42], household products (e.g., home decorations, food trays) [43], and acoustic panels for sound insulation in buildings [44].

In many of these studies, the recycled cotton fibres were shorter than 5 mm and were blended with the polymer matrix in pellet form, then processed into composites using either injection moulding or compression moulding. In injection moulding, fibre length is typically restricted to a few millimetres, primarily due to the high shear and mechanical stresses encountered during processing, which tend to break longer fibres [45,46]. Moreover, the use of longer fibres may lead to inadequate mixing, fibre entanglement, or clogging within the screw, gate, or sprue of the mould. In contrast, hot pressing does not impose restrictions on fibre length, although optimal fibre lengths have been identified to achieve improved composite performance [47].

Since fibre length is a key factor influencing effective stress transfer between the matrix and the fibre, and, therefore, the properties of composite materials, this study aimed to use recycled cotton fibres obtained through an intensive yet gentle fabric scrap opening process that preserved fibre length as much as possible. Furthermore, our study aimed to use a high fibre loading, in line with the findings of Hargitai et al., who reported an optimal fibre content of 40% to 50%, to enhance the sustainability and eco-friendliness of the recycled cotton-reinforced composites [48].

The objective of the paper is to investigate the feasibility of using recycled cotton as reinforcement in recycled polypropylene composites, with a primary focus on studying the influence of cotton fibre aspect ratio and compatibilizer on the properties of the composite materials. The recycled cotton fibres were blended with recycled polypropylene fibres to form a nonwoven fabric, and composite materials were subsequently produced by hot pressing the layered nonwoven fabrics. The composition of the nonwoven fabrics consisted of 50% recycled polypropylene (rPP) and 50% recycled cotton or, for comparison, virgin cotton. A percentage of 5% MAPP was added to each formulation to improve the interfacial adhesion between the reinforcing fibres and the matrix. The composite materials were evaluated based on their mechanical properties, crystallinity, thermal behaviour, and ATR-FTIR spectral analysis.

2. Materials and Methods

2.1. Materials

The recycled polypropylene fibres used as matrix were provided by Taparo Company (Târgu Lăpuș, Romania) and had the following characteristics: 9.9 dtex linear density, 82.2 mm average length, 25.2 cN/tex tenacity, 142.9% breaking elongation, 8.2 g/10 min melt flow index (at 230 °C under a 2.16 kg load), and 160 °C melting temperature.

The reinforcement of the composite materials consisted of virgin cotton and recycled cotton. The virgin cotton fibres provided by the Faculty of Industrial Design and Business Management (Iasi, Romania) were characterized by a diameter of 20 µm, an average length of 28 mm, and a tenacity of 12 cN/tex.

Recycled cotton fibres, provided by Taparo Company (Târgu Lăpuș, Romania), were obtained by shredding post-industrial waste in the form of cotton knitted fabric scraps generated during the garment manufacturing process. The cotton clippings were processed into fibres with a mean length of 15.2 mm and a diameter of 21.6 µm using a Margasa tearing line (Barcelona, Spain). Compared to virgin cotton, recycled cotton has a lower average fibre length.

Polybond 3200, a maleic anhydride-grafted polypropylene produced by Crompton Corporation (Middlebury, CT, USA) and supplied by S.C. Prociv SRL (Bucharest, Romania), was used to improve adhesion at the fibre-matrix interface.

2.2. Manufacturing of the Nonwoven Fabrics

Recycled polypropylene fibres and the reinforcing fibres were manually mixed in ratios of 50/50 virgin cotton/rPP and 50/50 recycled cotton/rPP. Each blend was processed twice on a Befama laboratory carding machine (Kalna, Poland) to ensure an intimate mixture of the components (Figure 1a). The resulting web was wound onto a cylinder until it reached a mass per surface area of 330 g/m2. The consolidation of the fibrous batt resulting from the second carding passage was carried out on a Bywater needle punching machine (Leeds, UK) provided with a down-stroking single needle board (Figure 1b). In needle punching, barbed needles repeatedly penetrate the batt, mechanically entangling the fibres and enhancing batt strength through inter-fibre friction. The obtained nonwoven fabrics had a punch density of 9 punches/cm2.

Figure 1.

Nonwoven manufacturing process. (a) Delivery zone of the woollen card; (b) Feeding zone of the needle punching machine.

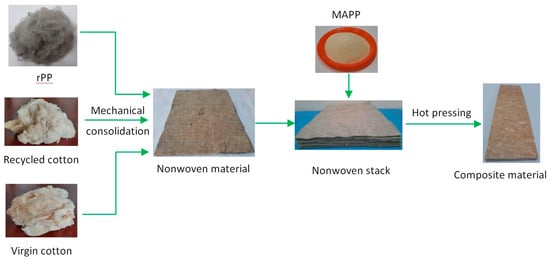

2.3. Manufacturing of the Composites

The composite materials were obtained by the hot pressing method, using a thermal press equipped with plates that can be electrically heated up to 300 °C, designed and built in the Research Center for Advanced Materials, Products and Processes (Faculty of Industrial Design and Business Management, Iași, Romania). The lower plate is equipped with a parallelepipedal mould with dimensions of 40 cm × 30 cm × 20 cm (length × width × height) and is operated by a hydraulic cylinder that applies a pressing force ranging from 0 to 30 US tons.

To produce the composite materials, eight pieces of nonwoven fabric were stacked in the thermal press mould (Figure 2). Since the tensile strength of needle-punched nonwoven fabric varies between the machine direction and the transverse direction, the nonwoven samples were cut both longitudinally and transversely. To ensure uniform properties in the composite material, the layers were then alternated in the stack.

Figure 2.

Composite production process flowchart.

To enhance the compatibility between the matrix and the reinforcing fibres, 5% MAPP was added. The MAPP granules were ground and evenly distributed between layers 2–3, 4–5, and 6–7.

Hot pressing was carried out at a temperature of 190 °C and a pressure of 0.735 MPa for 15 min, followed by cooling over a period of 10 min. The thickness of the composite materials was measured using a micrometre.

The experimental variants of the composite materials and their thicknesses are presented in Table 1.

Table 1.

Experimental variants of composite materials.

2.4. Mechanical Properties Testing

Both tensile and flexural tests were conducted using an LBG testing machine (Azzano San Paolo, Italy).

The specimen dimensions for tensile testing were determined according to the ISO 527-4:2023 standard, with a length of 250 mm and a width of 25 mm [49]. Testing was performed at a clamp spacing of 150 mm, with a testing speed of 2 mm/min.

The three-point flexural tests were conducted in accordance with the ISO 14125:1998 standard [50]. For class II composite materials, the recommended specimen width is 15 mm. The specimen length and the distance between the supports were selected based on the thickness of the composite material to maintain the ratios l /h = 20 and L/h = 16, where l is the specimen length, L is the distance between the supports, and h is the thickness of the composite material. The test speed was set at 2 mm/min.

For both tests, five measurements were taken for each composite material variant, and the results were reported as average values.

2.5. Thermal Properties

2.5.1. Thermogravimetric Analysis

The thermogravimetric analysis was performed on a Mettler Toledo TGA/SDTA 851 balance (Columbus, OH, USA). Samples of 1.9–5.3 mg were used for heating scans in the temperature domain from 25 °C to 700 °C in order to record the mass losses (TG) and the derivative thermogravimetric curves (DTG). The nitrogen flow was constant (20 mL/min) and the heating rate was 10 °C/min. According to the manufacturer’s specifications, the TGA/SDTA 851e module provides a temperature accuracy of ±0.25 °C and a reproducibility of ±0.15 °C, with a microbalance resolution down to 0.1 µg and noise below 1 µg (RMS). Only a single specimen was tested; therefore, potential sources of variability between samples that may arise from manufacturing inconsistencies, heterogeneity in material properties, or measurement uncertainty could not be assessed.

2.5.2. Differential Scanning Calorimetry (DSC)

A Mettler Toledo DSC1 differential scanning calorimeter (Columbus, OH, USA) was used to analyse the melting and crystallisation behaviour of the composites. The scanning of the samples took place in a temperature domain from 0 °C to 200 °C at a heating rate of 10 K/min. The samples were cooled at the same rate and then rescanned. The Mettler Toledo DSC1 device is capable of detecting temperature deviations of approximately ±0.25 K. Calibration was performed using certified standards to ensure accuracy and baseline stability. According to manufacturer specifications, the DSC-1 provides high sensitivity, stable baseline, and precise temperature control. Given these characteristics and the instrument’s internally calibrated sensor, the measurement was considered sufficiently precise for a single sample. However, the results may not fully reflect the inherent variability that could arise among multiple samples.

The flow rate of nitrogen was set at 20 mL/min. Composite materials are partially crystalline substances in which the crystalline domains and the amorphous domains coexist.

The crystallisation temperature (Tc), the crystallisation enthalpy (∆Hc), melting temperature (Tm) and melting enthalpy (∆Hm) were obtained from the heating-cooling-heating cycle of the sample. The crystallinity of the composite material, ꭕ%, is calculated as a ratio between the melting enthalpy of the composite material, ΔHm, and the melting enthalpy of a 100% crystalline polymer, .

The crystallinity of the samples was determined with the following equations:

and respectively

wherein: ∆Hc and, respectively, ∆Hm represent the enthalpy variation determined from the crystallisation curves or the melting curves; corresponds to the theoretical melting enthalpy of polypropylene, whose value according to literature data is 207 J·g−1 [51].

2.6. FTIR Spectroscopy

The chemical modifications occurring on the surface of the fibres and composite materials were analysed by FTIR-spectroscopy. The FTIR spectra were recorded in the range 4000–400 cm−1 at a resolution of 4 cm−1 on a Cary 630 FTIR (Santa Clara, CA, USA) spectrophotometer (the potassium bromide pellets technique at 1% content of finely ground samples was employed). Only one specimen was analysed; however, statistical sampling methods were applied prior to the preparation of the bromide pellet to ensure a representative characterization of the sample composition.

2.7. Statistical Analysis

The statistical significance of differences between the tested properties was evaluated using Minitab 22 (free trial version) with a significance level of 0.05. When the ANOVA indicated a significant difference among group means, a post-hoc Tukey test was performed to conduct pairwise comparisons between all groups.

3. Results and Discussion

3.1. Mechanical Properties

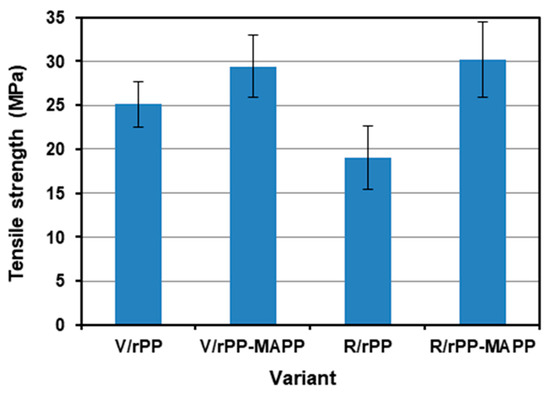

Figure 3 presents the tensile strength of the composite materials. Compared to the tensile strength of the V/rPP composite material, the use of recycled cotton as reinforcement in variant R/rPP resulted in a reduction of approximately 24%. This decrease in tensile strength can be attributed to the degradation of recycled cotton fibre properties, particularly fibre length, which occurs during the shredding process of the clippings. The recycled cotton exhibits an aspect ratio (length/diameter) approximately half that of virgin cotton (703 vs. 1400), indicating a lower reinforcing potential. The addition of 5% MAPP compatibilizer increased the tensile strength of variant V/rPP-MAPP by 17.2% compared to V/rPP, and of variant R/rPP-MAPP by 58% compared to R/rPP. This improvement in tensile strength can be explained by the enhanced interfacial adhesion between the reinforcing cotton fibres and the rPP matrix. The carbonyl groups of the maleic anhydride chemically interact with the hydroxyl groups present on the surface of cotton fibres, while the polypropylene backbone of MAPP is compatible with the matrix. Consequently, MAPP serves as a molecular bridge that strengthens the interfacial adhesion between the fibres and the matrix [52].

Figure 3.

Tensile strength of composite materials.

From Figure 3, it can be observed that the tensile strength of the recycled fibre composite samples with MAPP is similar to that of the virgin fibre composite samples with MAPP, whereas the version without MAPP is about 24% lower. Considering that one of the bonding mechanisms contributing to adhesion at the fibre–matrix interface is mechanical interlocking, a possible explanation for this behaviour could be the combined effect of the compatibilizer and the increased fibre surface irregularities generated during the shredding of the clippings.

The tensile strength of the composites showed statistically significant differences (p = 0.02). The post-hoc Tukey test revealed that the differences between V/rPP-MAPP and R/rPP composites (p = 0.036), as well as between R/rPP and R/rPP-MAPP composites (p = 0.024), were statistically significant.

The tensile strength of R/rPP composite is consistent with the findings of Araújo and collaborators, who reported values ranging from 18 MPa to 24 MPa for polypropylene-based composites reinforced with textile waste [39]. With the addition of MAPP compatibilizer, the tensile strength of the R/rPP-MAPP composite increased to 30.1 ± 4.3 MPa.

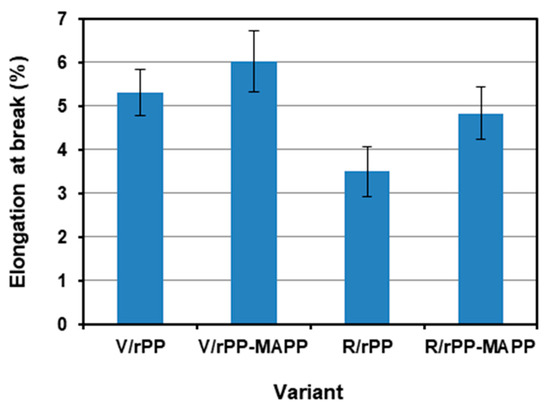

The elongation at break of the composite materials is presented in Figure 4. The use of recycled cotton fibres as reinforcement led to a decrease in the elongation at break of the composite materials. Compared to the V/rPP composite material, the elongation at break of the R/rPP composite material was reduced by approximately 34%. Similarly, the elongation at break of the R/rPP-MAPP composite material decreased by 20% compared to that of the V/rPP-MAPP composite material. This reduction can be attributed to the loss of fibre elasticity due to the mechanical stresses experienced during the opening of waste materials. The addition of the compatibilizer resulted in an increase in the elongation at break of the composite materials. This effect can be explained by the plasticizing role of MAPP, which separates the rPP chains and reduces the intermolecular forces between them, allowing the chains to move more freely relative to each other [53].

Figure 4.

Elongation at break of composite materials.

Statistically significant differences were observed in the elongation at break of the composites (p = 0.008). The Tukey post-hoc test indicated significant differences between V/rPP and R/rPP composites (p = 0.045), and between V/rPP-MAPP and R/rPP composites (p = 0.005).

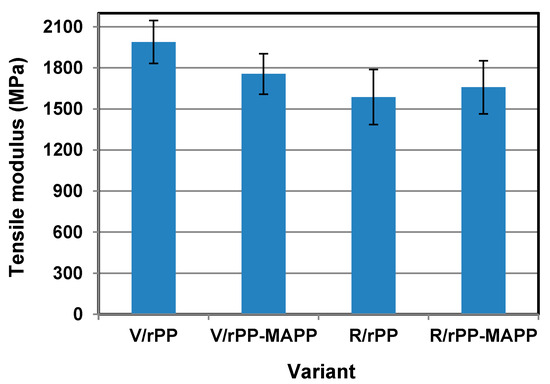

The tensile modulus of the composites reinforced with recycled cotton was lower than that of the composites reinforced with virgin cotton (Figure 5). However, one-way ANOVA revealed that the differences among several composite variants were not statistically significant and are likely due in part to natural variability.

Figure 5.

Tensile modulus of composite materials.

Figure 6 shows the flexural strength of the composite materials. The use of recycled cotton fibres as reinforcement led to a decrease in the flexural strength of the composite materials due to their lower aspect ratio (length/diameter). As a result, the R/rPP composite material exhibited a 48.3% lower flexural strength compared to the V/rPP composite material. However, the addition of the compatibilizer improved the interfacial bond between the reinforcement fibres and the polymer matrix, leading to an increase in flexural strength. The effect of MAPP was more pronounced in the composite material reinforced with fibres of lower aspect ratio (R/rPP-MAPP), which showed an 81.3% increase in flexural strength compared to the R/rPP variant.

Figure 6.

Flexural strength of composite materials.

One-way ANOVA indicated that the differences in the flexural strength of the tested composites were statistically significant (p = 0.000). Except for the difference between the V/rPP and R/rPP-MAPP composites, which was not significant (p = 0.83), all other differences were statistically significant, as follows: V/rPP vs. V/rPP-MAPP (p = 0.047), V/rPP vs. R/rPP (p = 0.001), V/rPP-MAPP vs. R/rPP (p = 0.001), V/rPP-MAPP vs. R/rPP-MAPP (p = 0.009), and R/rPP vs. R/rPP-MAPP (p = 0.001).

When compared with the findings of Hussain et al., the R/rPP-MAPP variant exhibits flexural strength similar to that of 30/70 post-consumer cotton fibre/recycled polypropylene composites produced by injection moulding [40].

Figure 7 shows that the flexural modulus decreased when reinforcing fibres with lower aspect ratios were used. This reduction could be attributed to the degradation of recycled cotton properties caused by the mechanical stresses experienced during waste shredding [54]. However, the one-way ANOVA indicated that the differences observed between several composite variants were not statistically significant and can be attributed in part to inherent variability.

Figure 7.

Flexural modulus of composite materials.

3.2. Thermogravimetric Measurements

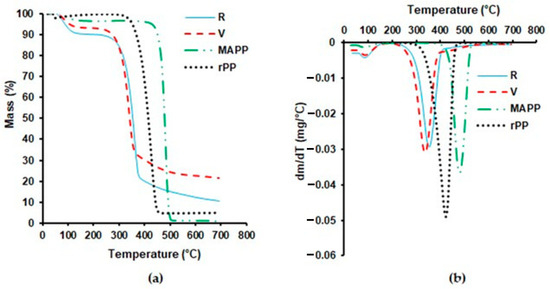

In the first stage, the thermogravimetric curves of the components that form the composite materials were analysed: virgin cotton (V), recycled cotton (R), recycled polypropylene and the maleic anhydride grafted on polypropylene (MAPP). In the second stage, the degradation temperature, mass loss, melting temperature, crystallisation temperature and the crystallinity degree for the composite materials were determined.

The most important thermogravimetric characteristics for each stage: Tonset—the starting temperature of the stage, Tpeak—the temperature corresponding to the maximum value of the mass loss, Tendset—the final temperature of each stage and the mass loss (%) of each stage are presented in Table 2.

Table 2.

Thermogravimetric values of the analysed samples.

The TG curves of virgin cotton and recycled cotton fibres are pretty similar, with the mass loss occurring in three stages. In the first stage, the mass loss is 7.5% for the virgin cotton (over the temperature range comprised between 57.7 and 126.5 °C) and, respectively, 10.7% for the recycled cotton (over the temperature range comprised between 60.1 and 113.2 °C). This mass loss can be attributed to the removal of moisture from the surface of the cotton fibres. Due to the fact that only one specimen per condition was tested and that the differences between the results are limited, no conclusions can be drawn from these results.

The highest mass loss occurs in the second stage (58% for virgin cotton and 67.6% for recycled cotton) and can be attributed to the degradation of cellulose and hemicellulose (the degradation rate being maximum at 334.8 °C for virgin cotton and 352.4 °C for recycled cotton). At temperatures between 376 °C and 542 °C and even higher, a further loss of mass occurs due to the degradation of cellulose residues and traces of lignin.

As regards the DTG curve, the peak from 85 to 86 °C can be attributed to the moisture loss of cotton fibres, while the sharp peaks from 465 °C can be attributed to the degradation of cellulose and hemicellulose.

The TG diagram of the rPP fibre shows that the maximum degradation of the fibre occurs in the temperature domain comprised between 432 and 483 °C, when there is a decrease in the sample mass of 99.9% (Figure 8a). The DTG diagram shows that the maximum degradation rate occurs at 461 °C (Figure 8b).

Figure 8.

TG (a) and DTG (b) curves of the composite raw materials.

The TG diagram of the MAPP copolymer shows two degradation stages wherein mass losses occur. Thus, in the first stage comprised between 58.5 and 112.8 °C, a mass loss of 4.4% occurs, which can be attributed to the removal of moisture from the polymer.

In the second stage, which proceeds in the temperature range comprised between 453.6 and 499.2 °C, the mass losses are 95.5%, since the polymer degradation occurs. The DTG diagram indicates that the maximum degradation rate occurs at 478.5 °C.

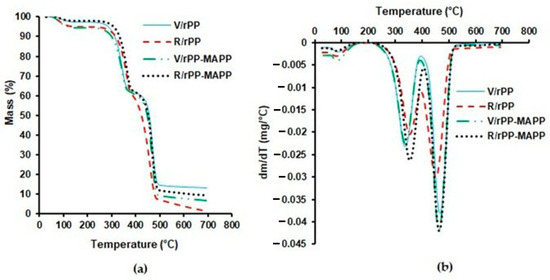

The TG diagrams of the composite materials show that the mass loss occurs in three stages (Figure 9a). In the first stage, the evaporation of moisture from the composite material occurs. The highest mass losses were recorded for the V/rPP-MAPP sample (a mass loss of 5.9% in the temperature range comprised between 67.4 and 119.9 °C with a maximum mass loss recorded at 83 °C) and for the R/rPP sample (a mass loss of 5.5% in the temperature range comprised between 58.6 and 115.6 °C with a maximum mass loss recorded at 81.9 °C). For the R/rPP-MAPP sample, the mass loss was 2.6% (with a maximum moisture removal rate at 81.6 °C), while for the V/rPP sample, the mass loss was 3.3% (with a maximum moisture removal rate at 89.3 °C), as can be seen in Figure 9b. However, since only one specimen was tested per condition, caution must be exerted regarding these observations.

Figure 9.

TG (a) and DTG (b) curves of the composite materials.

In the second degradation stage, the temperature corresponding to the maximum degradation rate ranges from 336 °C for the V/rPP sample to 354.1 °C for the R/rPP-MAPP sample. During this stage, mass loss varies between 35.7% (V/rPP) and 36.8% (R/rPP-MAPP).

In the third stage, significant mass losses are observed: 48.5% for V/rPP (with a peak degradation rate at 466.1 °C), 54% for V/rPP-MAPP (at 463.2 °C), 58.1% for R/rPP (at 451.7 °C), and 51.6% for R/rPP-MAPP (at 463.9 °C). This stage is characterized by extensive degradation of both recycled polypropylene (rPP) and cellulose from the cotton fibres.

It is worth noting that composites containing virgin fibres (V/rPP and V/rPP-MAPP) retain a higher amount of residual mass at the end of the analysis (around 8–10%), whereas composites prepared with recycled fibres (R/rPP and R/rPP-MAPP) show almost no residue. This behaviour may be explained by the lower structural degradation of virgin cotton fibres, which favors char formation, while recycled fibres are more susceptible to complete thermal degradation due to structural damage and the higher content of amorphous regions generated during the recycling process. Additionally, the possible presence of inorganic impurities or additives in the virgin fibre system could contribute to the higher residual fraction. These aspects suggest differences in thermal stability between virgin and recycled fibres, which are consistent with the observed TG profiles. However, since only one specimen was tested per condition, these observations should be interpreted with caution.

3.3. DSC Analyses

The behaviour of the composite materials during the melting and the crystallisation processes was studied by differential scanning calorimetry (DSC), the obtained diagrams being graphically presented in Figure 10 and Figure 11.

Figure 10.

DSC curves (heating process) for the raw materials (a) and the obtained composites (b).

Figure 11.

DSC curves (cooling process) for the raw materials (a) and the obtained composites (b).

The crystallisation temperature (Tc), crystallisation enthalpy (∆Hc), melting temperature (Tm) and melting enthalpy (∆Hm) were obtained from the heating—cooling—heating cycle of the samples. These parameters were determined from the DSC thermograms, where the first heating removes thermal history, the cooling phase reveals crystallisation behaviour, and the second heating allows accurate assessment of melting characteristics. The obtained results are presented in Table 3. The crystallinity of the composite material was calculated using Equations (1) and (2). It should be noted that analyses were performed on single samples; therefore, the results should be considered indicative and not statistically validated.

Table 3.

DSC values for rPP and for the composite materials.

During the heating process, virgin cotton fibres show an endothermic peak located around 86.6 °C, and recycled cotton fibres show an endothermic peak located around 85.2 °C, which corresponds to the evaporation process of moisture from the fibres. For higher temperatures, no changes occur in either the heating or cooling process.

From the analysis of the DSC diagrams, it is observed that the melting temperatures of the composite materials V/rPP and R/rPP are almost identical and are lower than the melting temperature of the rPP matrix (after the second heating). The melting temperatures of the samples V/rPP-MAPP and R/rPP-MAPP, to which the MAPP compatibilizer was added, are higher than those of the samples V/rPP and R/rPP. These values appear consistent with a slight increase in the degree of crystallinity of the samples (Figure 10), although the differences are limited and may also reflect sample variability.

The difference between the melting temperature of rPP and the melting temperatures of the composite materials is approximately 5.5 °C, ranging from 168.8 °C (rPP) to 163.3 °C (R/rPP). By adding the compatibilizer, the melting temperatures of the obtained composites increase slightly, which may be related to a higher degree of compaction of the material. The calculated degree of crystallinity shows an increase from 16.5% to 18.9% (V/rPP vs. V/rPP-MAPP) and from 19.7% to 20.7% (R/rPP vs. R/rPP-MAPP). However, given the small magnitude of these differences and the absence of replicate measurements, they should be interpreted with caution and regarded as indicative trends rather than statistically significant changes.

Analysing the values of the melting enthalpies (ΔHm) of the composite materials, it can be concluded that their values are lower than the value obtained for the rPP matrix. This allows us to state that virgin cotton fibres or recycled cotton fibres produce a decrease in the value of the melting enthalpy of the composite materials, and hence in their degree of crystallinity. A similar behaviour has been reported by Techawinyutham et al. [55].

These results are also consistent with the values obtained for the physical-mechanical indices, whose values increase by adding compacting agents to the structure of composite materials.

The DSC curves obtained during the cooling process (Figure 11a,b) indicate for the cotton fibres a heat flow that is almost constant in the analysed temperature range. During cooling, the crystallisation process of rPP fibres occurs at a temperature of 117.5 °C, while for MAPP, crystallisation occurs at a temperature of 112.6 °C.

The difference between the crystallisation temperature of rPP and the crystallisation temperatures of the composite materials is approximately 3.9 °C (crystallisation temperatures vary from 117.5 °C for rPP to 121.4 °C for V/rPP). By adding a compatibilizing agent (MAPP), the crystallisation temperatures of the obtained composite materials show a slight decrease compared to untreated materials.

The degree of crystallinity shows a slight increase in composite materials containing MAPP. In all cases, the degree of crystallinity of rPP is higher than that of the composite materials.

Overall, the DSC results suggest that the addition of MAPP leads to small increases in melting temperature and crystallinity, as well as a slight reduction in crystallisation temperature. However, because the observed differences are modest and experiments were conducted without replicates, these variations cannot be considered statistically significant. The results, therefore, indicate possible tendencies rather than definitive effects, and further investigation with replicate analyses would be needed to confirm the trends.

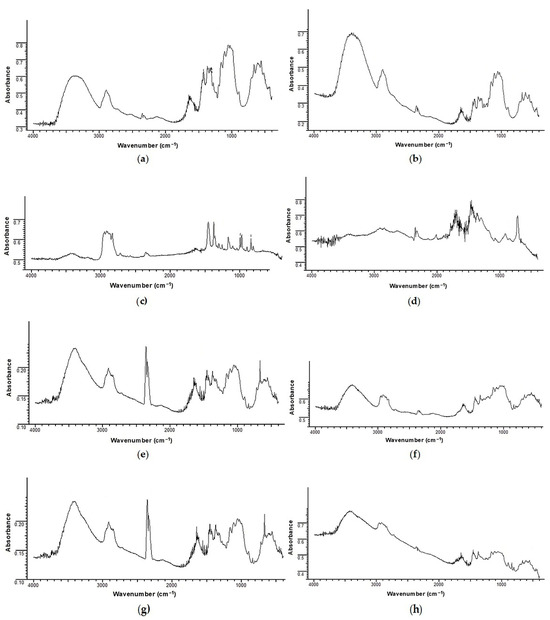

3.4. FTIR Spectroscopy Analysis

The FTIR spectra for the virgin cotton fibres (V), recycled cotton fibres (R), the recycled polypropylene fibres (rPP), the maleic anhydride grafted on polypropylene (MAPP) and for the composite materials: virgin cotton + rPP (V/rPP), virgin cotton + rPP + MAPP (V/rPP-MAPP), recycled cotton + rPP (R/rPP) and recycled cotton + rPP + MAPP (R/rPP-MAPP) are shown in Figure 12.

Figure 12.

FTIR spectra of the materials: (a) V; (b) R; (c) rPP; (d) MAPP; (e) V/rPP; (f) R/rPP; (g) V/rPP-MAPP; (h) R/rPP-MAPP.

When comparing the FTIR spectrum of virgin cotton (Figure 12a) with that of recycled cotton (Figure 12b), no significant differences can be observed, as the recycled cotton was derived from virgin cotton using only mechanical treatments. Similar conclusions can be drawn from the comparison of the FTIR spectra of composite materials reinforced with virgin cotton and those reinforced with recycled cotton. The strong and wide absorption band located around 3400 cm−1 is attributed to the stretching vibrations of the O−H bonds from the hydroxyl groups present in the cotton fibre (Figure 12b). The peaks that occur in the range 2920–2837 cm−1 in the FTIR spectra of R, rPP, R/rPP and R/rPP-MAPP samples can be assigned to the symmetrical and asymmetrical stretching vibrations of the C−H bonds from the CH2 groups present in the macromolecular compounds investigated [56,57]. The peaks noticed at 1435 cm−1, 1454 cm−1, 1457 cm−1, 1457 cm−1 and 1461 cm−1 in the FTIR spectra of the R, rPP, R/rPP, R/rPP-MAPP and MAPP samples, correspond to the bending vibrations of the C–H bonds from the CH2 groups in the cellulose and, respectively, to the bending vibrations of the C–H bonds from the CH2 and CH3 groups in the polypropylene macromolecular chain [56,58]. The peaks located at 1377 cm−1 correspond to the stretching vibrations of C−H bonds present in cellulose and to the asymmetric stretching vibrations of the C−H bonds from the CH2 and CH3 groups of the polypropylene.

The peak recorded at around 1060 cm−1 in the FTIR spectrum of the R fibre and, respectively, in the FTIR spectra of the composites containing R fibres is attributed to the stretching vibration of the C−O−C glycoside bonds present in cellulose [56]. The peak located at 1166 cm−1 in the FTIR spectrum of polypropylene is attributed to the rocking vibrations of the C−H bonds in the CH2 and CH3 groups.

In the case of the R/rPP-MAPP composite, the decrease in the intensity of this band is due to the presence of MAPP in low concentration (5 wt%) in the composite. The formation of intermolecular hydrogen bonds between the hydroxyl groups of cellulose and the carbonyl groups of maleic anhydride and the resulting steric hindrances could also contribute, but to a lesser extent [59]. The peaks recorded at 1636 cm−1 for R and R/rPP samples, and, respectively, at 1653 cm−1 for R/rPP-MAPP sample, are due to stretching vibrations of the O−H bonds from water molecules adsorbed on cotton containing materials. The peaks noticed at around 898 cm−1 are assigned to the asymmetric stretching vibrations of C1−O−C4 β-glycosidic linkage [56]. The peak located at 841 cm−1 is characteristic of the rocking vibrations of the C−H bond from polypropylene.

4. Conclusions

Rapid population growth and increasing industrialization are putting immense pressure on the world’s limited resources, posing a threat to future generations and resulting in the production of vast amounts of waste. Waste recycling alleviates pressure on natural resources, lowers raw material costs, helps reduce the space needed for waste storage, and decreases pollution.

This paper presents an approach to repurposing both cotton waste and polypropylene waste for the production of composite materials. The composites were fabricated by hot pressing layered nonwoven fabrics composed of 50% recycled polypropylene and either 50% recycled cotton or, for comparison, 50% virgin cotton, with and without the addition of 5% maleic anhydride-grafted polypropylene as a compatibilizer. The recycled cotton fibres were obtained from knitted fabric scraps through an opening process optimized to preserve fibre length.

The findings indicate that using recycled cotton as reinforcement led to a reduction in tensile strength, elongation at break, tensile modulus, flexural strength, and flexural modulus of the composites compared to those reinforced with virgin cotton. One-way ANOVA revealed statistically significant differences in tensile strength, elongation at break, and flexural strength, while variations in tensile and flexural modulus were attributable to natural variability. The addition of the compatibilizer had a beneficial effect, improving the mechanical characteristics to levels comparable to those of the composites reinforced with virgin cotton.

Thermogravimetric analysis indicates that the composite materials remained thermally stable up to 120 °C, a range in which only surface moisture was removed with negligible degradation.

Differential Scanning Calorimetry analysis revealed that recycled polypropylene exhibited a higher melting temperature and a lower crystallization temperature compared to the virgin and recycled cotton-reinforced composites. The incorporation of maleic anhydride grafted polypropylene increased both the melting temperature and the degree of crystallinity of the composites, while slightly decreasing the crystallization temperature. However, the overall crystallinity of the composite materials remained lower than that of the rPP matrix alone.

FTIR spectra confirmed the peak changes in the analysed composite materials. The FTIR spectra of composite materials reinforced with recycled cotton and those reinforced with virgin cotton did not show significant differences, as the recycled cotton was derived from virgin cotton using only mechanical treatments.

The research findings demonstrate that reinforcing recycled polypropylene-based composites with recycled cotton fibres is a viable and innovative strategy for repurposing waste into new products. This approach offers an environmentally friendly solution for managing textile waste, reducing environmental impact while providing a cost-effective method for developing customized composite materials for diverse applications. The potential applications for recycled cotton-reinforced composites could be: automotive (interior panels, seat backs), construction and building materials (wall panels, partition boards, ceiling tiles), packaging (pallets and crates), consumer goods (storage bins and containers, toolboxes), furniture (upholstered chairs, cabinet drawers), electronics (enclosures and mounts). The ability of the polymeric composites to be moulded into various shapes provides greater flexibility in designing product components with complex geometries.

Further research on recycled fibre-reinforced composites should be focused on hybrid composites that combine recycled cotton with other natural or synthetic fibres. This direction is supported by the fact that blends of cotton and man-made fibres are more commonly used in textile applications than 100% cotton blends. Moreover, hybridization may enhance performance and broaden the application potential of the composite materials. Research should also address recyclability and end-of-life strategies to enhance circularity, alongside comprehensive life cycle assessments to quantify environmental benefits.

Author Contributions

Conceptualization, M.I. and E.I.M.; methodology, investigation, formal analysis, data curation, M.I., E.I.M., G.L., F.C. and A.C.P.; writing—original draft preparation, M.I., E.I.M. and G.L.; writing—review and editing, M.I., E.I.M., G.L. and F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted as part of COP Project No. 267/22.06.2020, MySMIS 121434—“Creating a Center of Excellence in the Field of Composite Materials at SC TAPARO SA”, funded by the European Union through the European Regional Development Fund and the Romanian Government.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The datasets analysed during the study have been uploaded to a shared drive: https://drive.google.com/drive/folders/1xravvlEVG_xh7oDL_a4qB4FqmqVtXypr?usp=drive_link, accessed on 17 October 2025.

Acknowledgments

We gratefully acknowledge Taparo Company and S.C. Prociv SRL for generously supplying the materials used in this study.

Conflicts of Interest

The authors declare no conflicts of interest. Taparo Company and S.C. Prociv SRL supplied materials and had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| V | Virgin cotton |

| R | Recycled cotton |

| rPP | Recycled Polypropylene |

| MAPP | Maleic Anhydride-Grafted Polypropylene |

References

- Olivar Aponte, N.; Hernández Gómez, J.; Torres Argüelles, V.; Smith, E.D. Fast fashion consumption and its environmental impact: A literature review. Sustain. Sci. Pract. Policy 2024, 20, 2381871. [Google Scholar] [CrossRef]

- Abrishami, S.; Shirali, A.; Sharples, N.; Kartal, G.E.; Macintyre, L.; Doustdar, O. Textile Recycling and Recovery: An Eco-friendly Perspective on Textile and Garment Industries Challenges. Text. Res. J. 2024, 94, 2815–2834. [Google Scholar] [CrossRef]

- Com4 Recycling Spinning System. Available online: https://www.rieter.com/products/system-applications/recycling-spinning-system (accessed on 9 March 2025).

- Abtew, M.A.; Atalie, D.; Dejene, B.K. Recycling of cotton textile waste: Technological process, applications, and sustainability within a circular economy. J. Ind. Text. 2025, 55, 1–85. [Google Scholar] [CrossRef]

- Kanan, M.; Wanassi, B.; Azzouz, B.; Hassen, M.; Assaf, R.; Barham, A. Cotton recycling: An experimental study of the mechanical preparation process. Case Stud. Chem. Environ. Eng. 2024, 10, 100849. [Google Scholar] [CrossRef]

- Pensupa, N. Recycling of end-of-life clothes. In Sustainable Technologies for Fashion and Textiles; Rajkishore, N., Ed.; Woodhead Publishing: Cambridge, UK, 2020; pp. 251–309. [Google Scholar] [CrossRef]

- Ütebay, B.; Çelik, P.; Çay, A. Effects of cotton textile waste properties on recycled fibre quality. J. Clean. Prod. 2019, 222, 29–35. [Google Scholar] [CrossRef]

- Halimi, M.T.; Ben Hassen, M.; Wannassi, B. Optimization and valorization of recycled fiber in non-woven fabric. Ind. Text. 2019, 69, 440–445. [Google Scholar] [CrossRef]

- Sharma, R.; Goel, A. Development of Nonwoven Fabric from Recycled Fibers. J. Text. Sci. Eng. 2017, 7, 2. [Google Scholar] [CrossRef]

- Rodrigues, L.; Marques, R.; Dias, J.C.; Magalhães, B.; Santos, A.; Amorim, C.; Carta, A.M.; Pinto, P.; Silva, C.J. Added-Value of Cotton Textile Waste for Nonwoven Applications. Textiles 2024, 4, 309–327. [Google Scholar] [CrossRef]

- Haider, S.Z.; Nawab, Y.; Qadir, B.; Hussain, M. Impact of post-industrial and post-consumer waste on the characteristics of denim fabric made from recycled yarns. J. Ind. Text. 2025, 55, 1–27. [Google Scholar] [CrossRef]

- Ichim, M.; Sava, C. Study on recycling cotton fabric scraps into yarns. Bul. AGIR 2016, 3, 65–68. [Google Scholar]

- Ailenei, E.C.; Loghin, M.C.; Ichim, M.; Hoblea, A. New composite materials using polyester woven fabric scraps as reinforcement and thermoplastic matrix. Ind. Text. 2021, 62, 62–67. [Google Scholar] [CrossRef]

- Gómez Gómez, J.F.; González Madariaga, F.J.; Rosa Sierra, L.A.; León Morán, R.M. Scrap denim-PP composites as a material for new product design. In Libro de Actas—Systems & Design: Beyond Processes and Thinking (IFDP—SD2016); Universitat Politècnica València: Valencia, Spain, 2016. [Google Scholar] [CrossRef]

- Bateman, S.A.; Wu, D.Y. Composite materials prepared from waste textile fiber. J. Appl. Polym. Sci. 2001, 81, 3178–3185. [Google Scholar] [CrossRef]

- Mishra, R.; Behera, B.; Militky, J. Recycling of textile waste into green composites: Performance characterization. Polym. Compos. 2014, 35, 1960–1967. [Google Scholar] [CrossRef]

- Lahtela, V.; Kumar, A.; Kärki, T. The Impact of Textile Waste on the Features of High-Density Polyethylene (HDPE) Composites. Urban Sci. 2021, 5, 59. [Google Scholar] [CrossRef]

- Zonatti, W.F.; Guimarães, B.M.G.; Duleba, W.; Ramos, J.B. Thermoset composites reinforced with recycled cotton textile residues. Text. Cloth. Sustain. 2015, 1, 1. [Google Scholar] [CrossRef]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Environmental impacts of polypropylene (PP) production and prospects of its recycling in the GCC region. Mater. Today Proc. 2022, 56, 2245–2251. [Google Scholar] [CrossRef]

- EuRIC—Plastic Recycling Factsheet. Available online: https://euric.org/resource-hub/reports-studies/plastic-recycling-factsheet (accessed on 1 November 2024).

- Nisar, J.; Aziz, M.; Shah, A.; Shah, I.; Iqbal, M. Conversion of Polypropylene Waste into Value-Added Products: A Greener Approach. Molecules 2022, 27, 3015. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Fracture behaviour of virgin and recycled isotactic polypropylene. J. Mater. Sci. 2001, 36, 5073–5078. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Efects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Ichim, M.; Muresan, E.I.; Codau, E. Natural-Fiber-Reinforced Polymer Composites for Furniture Applications. Polymers 2024, 16, 3113. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Sawangrat, C.; Kanthiya, T.; Thipchai, P.; Kaewapai, K.; Suhr, J.; Worajittiphon, P.; Tanadchangsaeng, N.; Wattanachai, P.; Jantanasakulwong, K. Effect of Plasma Treatment on Bamboo Fiber-Reinforced Epoxy Composites. Polymers 2024, 16, 938. [Google Scholar] [CrossRef]

- Motaleb, K.Z.M.A.; Milašius, R.; Ahad, A. Influence of Gamma Radiation on Mechanical Properties of Jute Fabric-Reinforced Polymer Composites. Fibers 2020, 8, 58. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Study of the Effects of Alkali Treatment and Fiber Orientation on Mechanical Properties of Enset/Sisal Polymer Hybrid Composite. J. Compos. Sci. 2023, 7, 37. [Google Scholar] [CrossRef]

- Chung, T.-J.; Park, J.-W.; Lee, H.-J.; Kwon, H.-J.; Kim, H.-J.; Lee, Y.-K.; Tai Yin Tze, W. The Improvement of Mechanical Properties, Thermal Stability, and Water Absorption Resistance of an Eco-Friendly PLA/Kenaf Biocomposite Using Acetylation. Appl. Sci. 2018, 8, 376. [Google Scholar] [CrossRef]

- Thamarai Selvi, S.; Sunitha, R.; Ammayappan, L.; Prakash, C. Impact of Chemical Treatment on Surface Modification of Agave Americana Fibres for Composite Application—A Futuristic Approach. J. Nat. Fibers 2023, 20, 2142726. [Google Scholar] [CrossRef]

- Tserki, V.; Zafeiropoulos, N.E.; Simon, F.; Panayiotou, C. A study of the effect of acetylation and propionylation surface treatments on natural fibres. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1110–1118. [Google Scholar] [CrossRef]

- Jardon-Maximino, N.; Dehonor Gómez, M.; Villa Moreno, R.; Baeza-Alvarado, M.D.; Lugo Uribe, L.E. Optimization of the Alkali-Silane Treatment of Agave lechuguilla Fibers (Ixtle) for Potential Reinforcement in Polymeric Composites. Fibers 2023, 11, 86. [Google Scholar] [CrossRef]

- El-Sabbagh, A. Effect of coupling agent on natural fibre in natural fibre/polypropylene composites on mechanical and thermal behaviour. Compos. B Eng. 2014, 57, 126–135. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Stelte, W. Effect of the Characteristics of Maleic Anhydride-Grafted Polypropylene (MAPP) Compatibilizer on the Properties of Highly Filled (85%) Kenaf-Polypropylene Composites. Mater. Res. 2023, 26, e20220428. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Szostak, M. The effect of two-step surface treatment by hydrogen peroxide and silanization of flax/cotton fabrics on epoxy-based laminates thermomechanical properties and structure. J. Mater. Res. Technol. 2020, 9, 13813–13824. [Google Scholar] [CrossRef]

- Kavitha, S.A.; Priya, R.K.; Arunachalam, K.P.; Avudaiappan, S.; Saavedra Flores, E.I.; Blanco, D. Experimental investigation on strengthening of Zea mays root fibres for biodegradable composite materials using potassium permanganate treatment. Sci. Rep. 2024, 14, 12754. [Google Scholar] [CrossRef]

- Wang, W.; Fu, R.; Deng, Q.; Wang, X.; Wang, Y.; Zhang, Z.; Xian, G. Surface Modification of Flax Fibers with Isocyanate and Its Effects on Fiber/Epoxy Interfacial Properties. Fibers Polym. 2020, 21, 2888–2895. [Google Scholar] [CrossRef]

- Zárate-Pérez, C.; Ramírez-Aguilar, R.; Franco-Urquiza, E.A.; Sánchez-Alvarado, C. The Role of Coupling Agents in the Mechanical and Thermal Properties of Polypropylene/Wood Flour Composites. Macromol 2023, 3, 65–78. [Google Scholar] [CrossRef]

- Burgada, F.; Arrieta, M.P.; Borrell, B.; Fenollar, O. Development of Eco-Efficient Composite from Textile Waste with Polyamide Matrix. Polymers 2024, 16, 2061. [Google Scholar] [CrossRef] [PubMed]

- Araújo, R.S.; Rezende, C.C.; Marques, M.F.V.; Ferreira, L.C.; Russo, P.; Emanuela Errico, M.; Avolio, R.; Avella, M.; Gentile, G. Polypropylene-based composites reinforced with textile wastes. J. Appl. Polym. Sci. 2017, 134, 45060. [Google Scholar] [CrossRef]

- Hussain, A.; Goljandin, D.; Podgursky, V.; Abbas, M.M.; Krasnou, I. Experimental mechanics analysis of recycled polypropylene-cotton composites for commercial applications. Adv. Ind. Eng. Polym. Res. 2023, 6, 226–238. [Google Scholar] [CrossRef]

- Sezgin, H.; Kucukali-Ozturk, M.; Berkalp, O.B.; Yalcin-Enis, I. Design of composite insulation panels containing 100% recycled cotton fibers and polyethylene/polypropylene packaging wastes. J. Clean. Prod. 2021, 304, 127132. [Google Scholar] [CrossRef]

- Kamble, Z.; Behera, B.K.; Mishra, R.; Behera, P.K. Influence of cellulosic and non-cellulosic particle fillers on mechanical, dynamic mechanical, and thermogravimetric properties of waste cotton fibre reinforced green composites. Compos. B Eng. 2021, 207, 108595. [Google Scholar] [CrossRef]

- Charoen, N.; Kampeerapappun, P.; Charoenlarp, K.; Petchwattana, N.; Jansri, E. Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization. Recycling 2022, 7, 78. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [PubMed]

- Bravo, A.; Vieira, D. Design and Manufacturing of Sustainable Composites. In Handbook of Composites from Renewable Materials; Thakur, V.K., Thakur, M.K., Kessler, M.R., Eds.; Scrivener Publishing: Beverly, MA, USA, 2017; pp. 533–602. [Google Scholar]

- Ball, P. Manufacturing processes. In Handbook of Polymer Composites for Engineers; Hollaway, L., Ed.; Woodhead Publishing: Cambridge, UK, 1994; pp. 73–98. [Google Scholar]

- Ramesh, G.; Subramanian, K.; Sathiyamurthy, S.; Jayabal, S. Study on influence of fiber length and fiber weight proportion in mechanical behavior of Calotropis gigantea fiber-Epoxy composites. Polym. Compos. 2020, 41, 4899–4906. [Google Scholar]

- Hargitai, H.; Rácz, I.; Anandjiwala, R. Development of Hemp Fibre Reinforced Polypropylene Composite. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar] [CrossRef]

- ISO 527-4:2023; Plastics—Determination of Tensile Properties. Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. Edition 3, International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 14125:1998; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties, Edition 1. International Organization for Standardization: Geneva, Switzerland, 1998.

- Salazar-Cruz, B.A.; Chávez-Cinco, M.Y.; Morales-Cepeda, A.B.; Ramos-Galván, C.E.; Rivera-Armenta, J.L. Evaluation of Thermal Properties of Composites Prepared from Pistachio Shell Particles Treated Chemically and Polypropylene. Molecules 2022, 27, 426. [Google Scholar] [CrossRef] [PubMed]

- Saad, M.J. Effect of Maleated Polypropylene (MAPP) on the Tensile, Impact and Thickness Swelling Properties of Kenaf Core—Polypropylene Composites. J. Sci. Technol. 2010, 2, 33–44. [Google Scholar]

- Dong, Y.; Bhattacharyya, D. Dual role of maleated polypropylene in processing and material characterisation of polypropylene/clay nanocomposites. Mater. Sci. Eng. A 2010, 527, 1617–1622. [Google Scholar] [CrossRef]

- Doh, S.J. A Study on the Effects of Textile Processing on Tensile Properties of Single Cotton Fibers—From Raw Cotton to Washed Garments. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

- Techawinyutham, L.; Frick, A.; Siengchin, S. Polypropylene/Maleic Anhydride Grafted Polypropylene (MAgPP)/Coconut Fiber Composites. Adv. Mech. Eng. 2016, 8, 5. [Google Scholar] [CrossRef]

- Chung, C.; Lee, M.; Choe, E.K. Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr. Polym. 2004, 58, 417–420. [Google Scholar] [CrossRef]

- Arman Alim, A.A.; Baharum, A.; Mohammad Shirajuddin, S.S.; Anuar, F.H. Blending of Low-Density Polyethylene and Poly(Butylene Succinate) (LDPE/PBS) with Polyethylene–Graft–Maleic Anhydride (PE–g–MA) as a Compatibilizer on the Phase Morphology, Mechanical and Thermal Properties. Polymers 2023, 15, 261. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless Melt-Electrospinning of Polypropylene Nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Hong, C.K.; Kim, N.; Kang, S.L.; Nah, C.; Lee, Y.S.; Cho, B.H.; Ahn, J.H. Mechanical properties of maleic anhydride treated jute fibre/polypropylene composites. Plast. Rubber Compos. 2008, 37, 325–330. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).