Abstract

Iraq’s extreme summer temperatures pose critical challenges to pavement durability, as conventional asphalt mixtures often fail under prolonged thermal stress. This paper provides a comparative evaluation of the high-temperature performance of unmodified (40/50 penetration grade) and polymer-modified (PG 76-10) asphalt mixtures for the asphalt course layer. Marshall stability, flow, and stiffness were measured at elevated temperatures of 60 °C, 65 °C, 70 °C, and 75 °C after short-term (30 min) and extended (24 h) conditioning. Results show that while both mixtures experienced performance degradation as the temperature increased, the polymer-modified mixture consistently exhibited superior thermal resistance, retaining approximately 9% higher stability and 28% higher stiffness, and displaying 18% lower flow deformation at 75 °C compared to the unmodified mixture. Stability degradation rate (SDR), stiffness degradation rate (SiDR), and flow increase rate (FIR) analyses further confirmed the enhanced resilience of PG 76-10, showing nearly 39% lower FIR under thermal stress. Importantly, PG 76-10 maintained performance within specification thresholds under all tested conditions, unlike the conventional 40/50 mixture. These findings emphasize the necessity of adapting mix design standards to regional climatic realities and support the broader adoption of polymer-modified asphalt binders to enhance pavement service life in hot-climate regions like Iraq.

1. Introduction

Background. Asphalt pavement is a fundamental component of transportation infrastructure worldwide, especially in regions where road networks serve as the primary mode of transport for goods and passengers [1]. The performance and longevity of asphalt pavements are intrinsically linked to the characteristics of the asphalt mixture used [2], including its resistance to traffic-induced stresses and environmental influences. Iraq is characterized by an arid desert climate, classified under the Köppen–Geiger system as BWh, featuring long, extremely hot summers and short, mild winters. During peak summer months, surface temperatures frequently exceed 50 °C, particularly in the central and southern regions. Similar climatic conditions and temperature challenges are encountered in other countries located along the same geographical belt, including Saudi Arabia, Kuwait, the United Arab Emirates, and parts of Iran, where pavements are exposed to extreme heat and require enhanced thermal performance to ensure durability and serviceability [3].

Asphalt mixtures are typically composed of aggregates, bitumen, and air voids. The bitumen serves as a binding agent, providing cohesion to the aggregate skeleton [4]. However, conventional or unmodified bitumen performs poorly at elevated temperatures [5]. As the temperature rises, binder viscosity decreases, reducing mix stiffness and increasing susceptibility to permanent deformation, or rutting [6]. Rutting compromises the structural integrity of pavements and leads to a rough, unsafe driving surface, especially in heavily trafficked urban corridors [7].

To address these challenges, extensive research has focused on modifying the binder properties to improve the thermal stability and load-bearing capacity of asphalt mixtures. A key advancement is the use of polymer-modified bitumen (PMB), particularly those incorporating thermoplastic elastomers, such as styrene–butadiene–styrene (SBS) [8]. However, SBS is only one example among several widely used modifiers today. As summarized by Yang et al., recent research has highlighted the increasing use of plastomers, such as polyethylene (PE), polypropylene (PP), and ethylene-vinyl acetate (EVA), which improve stiffness, rutting resistance, and thermal stability, elastomers, such as styrene–butadiene rubber (SBR) and styrene–ethylene–butylene–styrene (SEBS), which offer excellent elasticity and aging resistance, and crumb rubber from recycled tires, which enhances ductility, elastic recovery, and environmental sustainability [8]. Together, these diverse modifiers offer tailored solutions for various performance requirements under different climatic and loading conditions [9]. In addition to binder modification, optimizing the aggregate gradation—particularly by balancing the coarse and fine fractions—is also a well-established approach to improve interlocking, reduce susceptibility to permanent deformation, and enhance high-temperature rutting resistance. As demonstrated by Lv et al., coarse particle gradation (aggregates > 4.75 mm) and fine particle gradation (<4.75 mm) both play critical roles in shaping the asphalt mix skeleton and controlling rutting behavior. A coarser gradation in the coarse fraction improves the stone-on-stone contact and skeleton strength, while a finer gradation in the fine fraction improves the filler effect without disrupting the coarse skeleton, ultimately improving resistance to shear deformation under elevated temperatures. Therefore, combining binder modification with careful gradation design offers a synergistic strategy for ensuring the durability and performance of asphalt mixtures in hot climates [10].

Despite the known benefits of PMB, its adoption in Iraq remains limited due to the cost, availability, and lack of local performance data [11]. Most asphalt mix design procedures in Iraq still largely follow conventional materials and testing standards developed in temperate regions [12]. The Marshall stability and flow test, for instance, is widely used for quality control and mix design. This test is conventionally conducted at 60 °C, a temperature standard that may not reflect the actual pavement surface conditions in Iraq during peak summer periods.

Recent meteorological studies in Iraq have reported road surface temperatures ranging between 65 °C and 75 °C during the hottest months, particularly in southern and central regions. This discrepancy between testing and real-world conditions may lead to underestimating the performance risks of unmodified asphalt mixtures. Consequently, there is a growing need to reassess current testing procedures and material selections by introducing region-specific parameters and performance evaluations at higher temperatures [13].

Previous studies have shown that PMB enhances mixture properties, such as improved Marshall stability and reduced flow under standard testing conditions. However, the effect of elevated temperatures on the mechanical performance of PMB compared to unmodified mixtures remains under-researched in the Iraqi context. Integrating such comparative analyses into pavement design and material selection processes can lead to more reliable and cost-effective infrastructure investments, particularly in high-stress, high-temperature environments.

Furthermore, transportation agencies in Iraq are increasingly exploring the modernization of design methodologies in line with global trends, such as Superpave and mechanistic-empirical approaches. These require more detailed performance data across a range of conditions. As such, generating localized empirical evidence to demonstrate the benefits of PMB under Iraqi climatic conditions is crucial for informing policy development, material standardization, and sustainable infrastructure planning.

Problem Statement. The current asphalt pavement design practices in Iraq largely rely on conventional methodologies that inadequately account for the extreme environmental conditions characteristic of the region. These practices typically employ unmodified 40/50 penetration-grade bitumen and rely on performance evaluations carried out at a standardized temperature of 60 °C, which may not accurately represent the operational stresses experienced by road pavements during the country’s hot summer months. These high-temperature conditions persist for about six months of the year, particularly affecting the central and southern regions of Iraq, which make up the majority of the country’s land area.

The methodological gap becomes particularly problematic when surface temperatures reach or exceed 65 °C to 75 °C, as is common in cities such as Basra, Baghdad, and Nasiriyah. At such high temperatures, conventional asphalt mixtures are prone to significant thermal softening, leading to rutting, bleeding, and other forms of permanent deformation. These distresses reduce the quality of rides, increase safety risks, escalate maintenance costs, and shorten the service life of the pavement.

Despite advancements in material technology, such as the availability of polymer-modified bitumen (PG76-10), there is a lack of empirical data comparing the performance of PMB and conventional mixtures under elevated temperature reflective of Iraq’s field conditions. Most global studies are based on climates that differ significantly from those found in Iraq. As a result, local engineers and policymakers lack the data needed to support the adoption of more advanced but costlier materials.

Moreover, while PMB has demonstrated improved pavement performance [14], its cost-effectiveness remains a concern [15]. Without localized performance validation, stakeholders may be hesitant to adopt modified binders on a broader scale. This hesitancy is further reinforced by the lack of region-specific specifications and standards that would otherwise mandate or recommend the use of PMB in high-temperature zones [16].

In addition to the above, current testing protocols, such as ASTM D1559 and ASTM D6927, which govern Marshall stability and flow assessments, may not adequately capture the degradation mechanisms occurring at elevated temperatures. Limiting these tests to 60 °C overlooks critical insights into how asphalt mixtures behave under the higher thermal loads typical of the Iraqi climate.

Therefore, the absence of comparative performance data for unmodified and modified asphalt mixtures at elevated temperatures represents a critical knowledge gap. While most international studies typically evaluate materials under moderate conditions, this research directly examines the performance of asphalt mixtures under the extreme thermal loads’ characteristic of Iraq. By doing so, it uniquely contributes localized, application-oriented evidence essential for updating Iraqi pavement design standards and supporting material selection decisions. Bridging this gap is essential not only for improving pavement performance but also for informing the development of new national guidelines that reflect Iraq’s climatic realities and engineering demands.

This research addresses these concerns by systematically evaluating the performance of unmodified and polymer-modified asphalt mixtures at temperatures of 60 °C, 65 °C, 70 °C, and 75 °C, thereby simulating the thermal range experienced by pavements during the Iraqi summer. By focusing on Marshall stability, flow, and stiffness, this study provides a practical, application-focused analysis that can be readily adopted by local agencies, consultants, and construction firms. The novelty of this work lies in providing the first empirical, high-temperature performance dataset for asphalt mixtures specifically tailored to Iraq’s extreme climatic conditions, which has not been directly addressed in previous research.

Objectives of the Study. The primary objective is to assess and compare the high-temperature performance characteristics of asphalt mixtures prepared for the asphalt course layer with conventional 40/50 penetration-grade bitumen and polymer-modified PG 76-10 binder. Specifically, the study aims to:

- Evaluate the effects of elevated temperatures (60 °C, 65 °C, 70 °C, and 75 °C) on the Marshall stability, flow, and stiffness of both mixture types.

- Analyze the influence of short-term (30 min) and extended (24 h) conditioning on the mechanical performance at high temperatures.

- Calculate and compare the stability degradation rate (SDR), stiffness degradation rate (SiDR), and flow increase rate (FIR) for each mixture to quantify thermal susceptibility.

- Determine the relative suitability of polymer-modified asphalt binders for improving pavement durability and service life under extreme climatic conditions typical of Iraq and other hot regions.

2. Literature Review

The performance of asphalt mixtures under extreme temperature conditions has been extensively studied, particularly in regions experiencing hot climates where pavement surfaces often exceed to temperatures exceeding standard testing norms [17]. A substantial body of research has evaluated the effectiveness of polymer modification in enhancing the thermal and mechanical behavior of asphalt mixtures. These studies have consistently demonstrated that polymer-modified asphalt binders, such as those incorporating SBS, HDPE, or recycled plastics, significantly improve high-temperature stability, rutting resistance, fatigue life, and moisture susceptibility compared to conventional bitumen [18]. Additionally, the choice of polymer type, dosage, and mixing technique significantly influences the final performance of the asphalt mix [19].

Moreover, recent studies increasingly emphasize the need to align laboratory test temperatures with actual field conditions, particularly in countries like Iraq, where road surfaces often reach 65 °C to 75 °C during summer. This shift toward climate-responsive pavement design highlights the necessity for localized performance evaluations and material specifications. The research efforts reviewed in this study span a broad geographical and methodological range, providing insights into material behavior, testing innovations, and practical applications of modified binders under elevated temperatures. A summary of relevant literature, outlining each study’s objectives, methodologies, and key findings of these studies, is presented in Table 1.

Table 1.

Summary of previous studies on the performance of unmodified and polymer-modified asphalt mixtures under elevated temperature conditions.

3. Materials and Methods

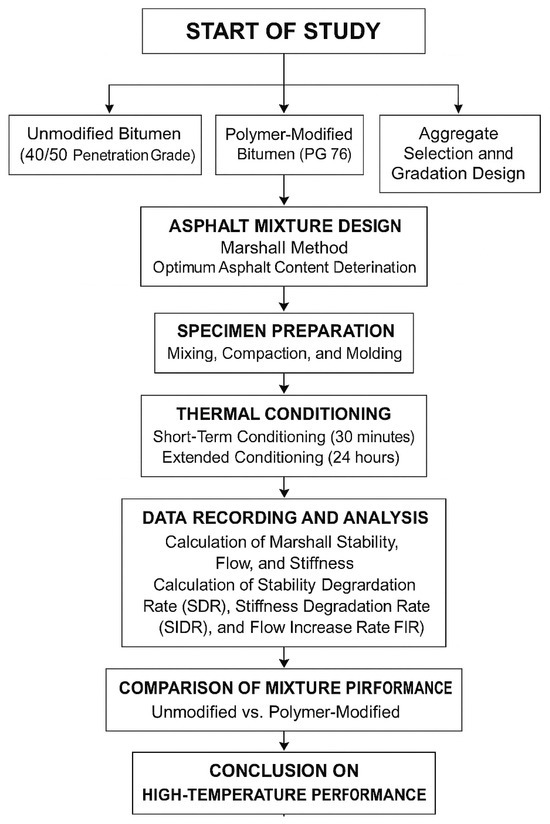

Overview. To clarify the experimental procedure, a summarized flowchart of the study methodology is presented in Figure 1. The flowchart outlines the key steps of the study, including material selection, asphalt mix design, specimen preparation, and the performance evaluation of unmodified and polymer-modified asphalt mixtures at various elevated temperatures.

Figure 1.

Flowchart of the experimental procedure for evaluating the high-temperature performance of unmodified and polymer-modified asphalt mixtures.

Materials. This study utilized two types of binders in the preparation of asphalt mixtures: conventional unmodified bitumen with a 40/50 penetration grade and PMB with a performance grade of PG 76-10. Each binder was thoroughly tested in accordance with ASTM and AASHTO standards to evaluate its physical and rheological properties and ensure its suitability for hot-climate pavement applications. The raw materials were sourced, asphalt mixture samples were prepared, and practical experiments were conducted in the laboratory of Basra University and Daewoo Engineering Company. The materials used in these experiments were specifically allocated for a 60 km road project connecting the Grand Port of Al-Faw to Umm Qasr, a major infrastructure project affiliated with the General Company for Iraqi Ports under the Ministry of Transport.

Unmodified Bitumen (40/50 Penetration Grade). The unmodified bitumen used in this research (trade name: Daewoo 40/50; manufacturer: Daewoo Engineering and Construction, Seoul, Republic of Korea; validated by: Engineering Consulting Bureau, University of Basrah, Basra, Iraq) has a penetration grade of 40/50, which is commonly employed in Iraqi road construction. Table 2 presents the test results for the 40/50 bitumen. The penetration at 25 °C was measured at 46 (1/10 mm), which is within the specification range of 40–50. The flash point exceeded 250 °C, indicating excellent thermal stability. The binder demonstrated ductility values greater than 100 cm at 25 °C and retained a ductility of 95 cm after aging via the thin-film oven test (T.F.O.T.), confirming good flexibility and aging resistance. Other key indicators, such as retained penetration after T.F.O.T. (55.2%) and a penetration drop (17%), fell within the required specification ranges. Additionally, the bitumen exhibited high purity and performance through properties such as a density of 1025 kg/m3, a softening point of 58 °C, and solubility in organic solvents of 99.3%.

Table 2.

Test results for unmodified bitumen (40/50 penetration grade).

Polymer-Modified Bitumen (PG 76-10). The polymer-modified bitumen used in this research (trade name: PG 76-10 E; manufacturer/supplier: Daewoo Engineering and Construction, Seoul, Republic of Korea; validated by: Engineering Consulting Bureau, University of Basrah, Basra, Iraq) has a performance grade of PG 76-10, designed for use in high-temperature pavement applications. This grade of bitumen was evaluated using AASHTO and ASTM procedures, including performance tests for original binder properties, short-term aging (RTFO), and long-term aging (PAV). The results are summarized in Table 3.

Table 3.

Test results for polymer-modified bitumen (PG 76-10).

The binder passed all performance criteria for PG 76-10. The average 7-day maximum pavement design temperature was below 76 °C, and the minimum temperature was above −10 °C, confirming its classification. The flash point exceeded 230 °C, and the viscosity at 135 °C was measured at 2.044 Pa·s, well below the 3 Pa·s threshold. The binder’s stiffness (G*/Sin δ) was measured at 2.59 kPa, exceeding the minimum requirement of 1.0 kPa.

During RTFO testing, the mass loss was 1.0%, and MSCR results showed excellent elastic recovery with Jnr 3.2 < 0.5 kPa−1. PAV testing revealed that the bitumen maintained desirable stiffness and elastic recovery properties with S = 148.5 MPa and M-value = 0.392, confirming its long-term performance under aging.

The comparative test results clearly indicate that PG 76-10 polymer-modified bitumen offers enhanced thermal and mechanical performance, making it highly suitable for applications where pavements are exposed to intense heat, traffic loads, and aging conditions, typical of Iraqi summers.

Aggregate. The coarse aggregates (gravel) used in this research (trade name: Amarah Crushed Gravel; supplier: Amarah Quarry, Maysan Province, Iraq) were sourced from a quarry located in Amarah Province, and prepared according to national specifications for asphalt mixtures. The fine aggregates (sand) were supplied from Zubair Sand Quarry, Basra, Iraq, and similarly processed to meet required gradation and cleanliness standards.

Marshall Stability and Flow Test. The Marshall stability, flow, and stiffness were measured at elevated temperatures of 60 °C, 65 °C, 70 °C, and 75 °C after short-term (30 min) and extended (24 h) conditioning. The tests were conducted using a Marshall Digital Machine (model: HD-508; manufacturer: Hyundai Precision Industry Co., Ltd., Seoul, Republic of Korea), as shown in Figure 2. The conditioning process, including water bath temperature measurement and specimen preparation, is illustrated in Figure 3 and Figure 4. This machine was used to determine the load and deformation characteristics of the asphalt mixtures under standardized conditions [53]. For each mixture type, temperature level, and conditioning period, three replicate Marshall specimens were prepared and tested to ensure the statistical validity and reproducibility of the results. This method, originally standardized by ASTM D1559, is widely utilized for determining the optimum bitumen content (OBC) and evaluating the resistance of asphalt mixtures to plastic deformation, particularly under heavy and repeated traffic loads.

Figure 2.

Marshall Digital Machine (model: HD-508; Hyundai Precision Industry Co., Ltd., Seoul, Republic of Korea).

Figure 3.

Measurement of the water bath temperature using a digital IR thermometer (Fluke 62 MAX) during Marshall specimen conditioning at 70 °C and 75 °C.

Figure 4.

Prepared Marshall specimens submerged in the water bath for temperature conditioning before stability and flow testing.

4. Results and Discussion

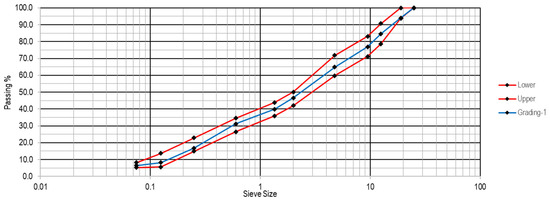

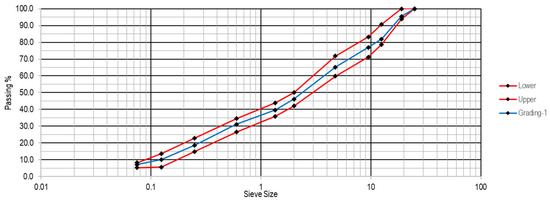

Aggregate Gradation. To ensure compatibility and proper structural performance, distinct aggregate gradation curves were used for the unmodified and polymer-modified asphalt mixtures. Each gradation was carefully designed to fall within the acceptable specification limits for dense-graded asphalt concrete. Gradation plays a vital role in determining the mechanical behavior of the mix, especially under high-temperature conditions, as it influences interlocking, void content, and load distribution.

The gradation curves for both mixtures are presented in Figure 5 and Figure 6. These figures illustrate the percentage of material passing through various sieve sizes, reflecting a well-graded structure suited for Marshall mix design.

Figure 5.

Aggregate gradation curve for the 40/50 mixture.

Figure 6.

Aggregate gradation curve for the PG 76-10 mixture.

These gradations were selected to optimize the performance characteristics of each mixture type. The unmodified mixture uses a traditional gradation pattern appropriate for general use, while the modified mixture benefits from a slightly adjusted gradation to complement the improved binder elasticity and enhance high-temperature rutting resistance.

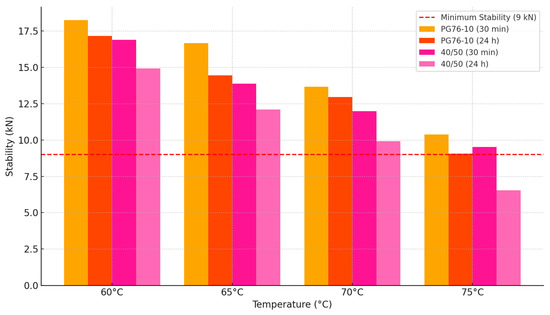

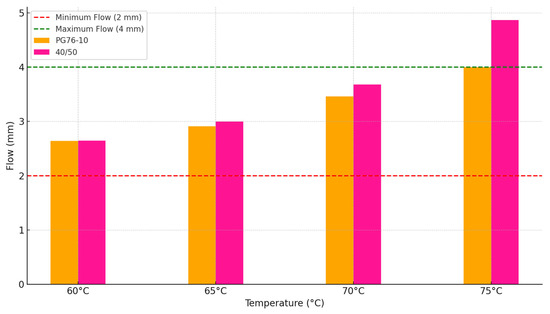

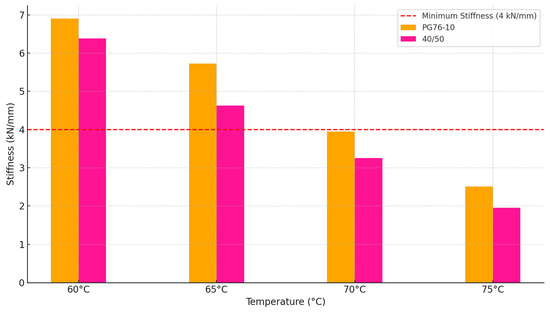

Marshall Stability and Flow Test. Figure 7, Figure 8 and Figure 9 present the Marshall stability, flow, and stiffness results for both the polymer-modified asphalt mixture (PG 76-10) and the unmodified asphalt mixture (40/50) under four elevated temperature conditions: 60 °C, 65 °C, 70 °C, and 75 °C. Each test was conducted after two conditioning durations: 30 min and 24 h. The values were compared against the standard performance requirements: a minimum stability of 9 kN, a flow range between 2 and 4 mm, and a minimum stiffness of 4 kN/mm.

Figure 7.

Marshall stability vs. temperature (with 30 min and 24 h side-by-side bars).

Figure 8.

Marshall flow vs. temperature (PG76-10 vs. 40/50).

Figure 9.

Marshall stiffness vs. temperature (PG76-10 vs. 40/50).

Results show that as the temperature and exposure time increased, both mixtures experienced a reduction in stability and stiffness, and a general increase in flow. However, the PG 76-10 mixture consistently exhibited better performance than the 40/50 mixture across all testing conditions. At 60 °C, PG 76-10 achieved the highest stability value of 18.240 kN after 30 min, while 40/50 recorded 16.890 kN. After 24 h at the same temperature, PG 76-10 retained 17.153 kN, still above the 9 kN minimum, whereas the 40/50 mixture dropped slightly to 14.919 kN. While the 24 h conditioning used in this study does not exactly replicate the daily thermal cycles that pavements typically experience in the field, it was intentionally selected to simulate severe prolonged thermal exposure. This approach reflects worst-case scenarios commonly encountered in urban heat islands or heavily trafficked roadways in Iraq, where surface temperatures can remain elevated even overnight. Extended laboratory conditioning is a recognized method for evaluating material durability under extreme stress and provides conservative insights into long-term field performance.

As temperatures rose to 75 °C, both mixtures showed reduced stability. However, PG 76-10 remained above the minimum requirement for 30 min (10.382 kN), while the 40/50 mixture barely met the limit (9.513 kN). After 24 h at 75 °C, the PG 76-10 mixture retained a borderline value of 9.068 kN, still within specification, but the 40/50 mixture fell to 6.529 kN—well below the required threshold.

Flow values increased with temperature, indicating greater deformation potential. PG 76-10 maintained acceptable flow between 2.640 mm and 4.142 mm, while 40/50 reached as high as 4.863 mm at 75 °C/24 h, exceeding the upper limit. The controlled flow behavior of PG 76-10 suggests a better resistance to rutting under high temperatures.

In terms of stiffness, PG 76-10 initially demonstrated superior performance, with 6.9 kN/mm at 60 °C/30 min, compared to 6.385 kN/mm for 40/50. However, as temperatures increased, stiffness declined for both mixtures. PG 76-10 dropped below the required 4 kN/mm at 70 °C/24 h and beyond, reaching 2.506 kN/mm at 75 °C/24 h. The unmodified mixture showed even lower stiffness, falling below the acceptable limit as early as 65 °C/30 min and reaching a minimum of 1.956 kN/mm at 75 °C/24 h. These results clearly indicate that while both mixtures softened under heat, the polymer-modified binder retained structural integrity significantly better.

Overall, the findings suggest that the PG 76-10 polymer-modified asphalt mixture offers superior stability, stiffness, and thermal durability, making it more suitable for high-temperature applications, particularly in hot-climate regions, such as Iraq. The enhanced performance of PG 76-10 under elevated temperatures aligns with earlier research by Oyelere et al. [52], who emphasized the importance of polymer content and composition in improving structural integrity and thermal resistance. Moreover, the study by Dimter et al. [54] demonstrated that the incorporation of polymers and alternative modifiers, such as waste plastic or wood ash can significantly boost Marshall stability and resistance to deformation at moderate temperatures. However, these studies also caution against performance degradation at higher modifier concentrations or under extreme heat conditions, reinforcing the importance of optimized mix design.

Additionally, the work of Mu et al. [38] confirmed that polymer-modified asphalt mixtures exhibit improved elasticity, reduced rutting susceptibility, and better aging resistance compared to conventional binders, particularly when subjected to sustained thermal stress. For example, Mushtaq et al. [55] reported that mixtures modified with PET and PE wastes achieved Marshall stability values of up to 42.98 kN, significantly surpassing the performance of unmodified mixtures, while also improving flow and stiffness properties under elevated temperatures. Similarly, Habbouche et al. [56] demonstrated that high-polymer (HP)-modified asphalt could reduce asphalt layer thickness by up to 40% without compromising structural integrity, highlighting not only mechanical but also economic advantages. Dalhat and Al-Adham [57] showed that PE-modified binders exhibited superior rutting and cracking resistance under high-temperature conditions, consistent with the reduced stability degradation rate (SDR) and flow increase rate (FIR) observed in our PG 76-10 mixtures. These collective findings support the conclusion that polymer-modified binders like PG 76-10 offer a reliable solution for extending the pavement life in regions where conventional mixtures may fail due to temperature-induced softening and loss of mechanical strength.

Thermal Degradation Rate Analysis. The thermal stability of asphalt mixtures can be quantified by examining how key Marshall parameters—stability, stiffness, and flow—change with temperature. As temperature increases, binder viscosity drops and the mixture softens, reducing stiffness and increasing rutting susceptibility. Polymer modification is known to mitigate these effects, as polymer-modified asphalt tends to maintain higher stiffness at elevated temperatures and to deform less under load.

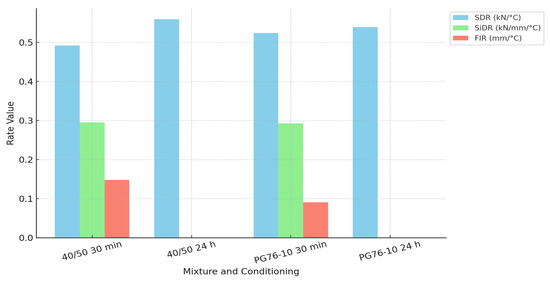

In this study, we introduced the stability degradation rate (SDR), stiffness degradation rate (SiDR), and flow increase rate (FIR), computed from the 60 °C and 75 °C test values for each mixture and conditioning period, to quantify the temperature sensitivity of performance. These degradation rate calculations follow a conceptual approach similar to the penetration index (PI) described by Pfeiffer and Van Doormaal [58], where the slope or rate of change of a key property across two temperatures is used to express thermal sensitivity. Specifically, higher SDR or SiDR values indicate a faster decline in stability or stiffness with increasing temperature, while higher FIR values indicate a faster rise in flow (deformation).

The degradation rates are defined as follows:

Here, S(60 °C) and S_(75 °C) are the Marshall stability in kN at 60 °C and 75 °C, respectively (for a given conditioning time), and stiffness and flow are similarly taken at 60 °C and 75 °C. The denominator 75 − 60 = 15 °C normalizes the change per °C (all values use standard units: stability in kN, stiffness in kN/mm, and flow in mm). All rates are shown in Figure 10 below.

Figure 10.

Grouped bar chart of SDR, SiDR, and FIR for 40/50 and PG76-10 mixtures under 30 min and 24 h of conditioning.

The results showed that the polymer-modified PG 76-10 mixture consistently exhibited slower increases in flow (lower FIR) compared to the 40/50 mix, based on the 30 min data. The PG 76-10 mix’s FIR value (0.0907 mm/°C) was lower than that of the 40/50 mix (0.1479 mm/°C), indicating better resistance to temperature-induced deformation.

Stability degradation (SDR) was relatively similar for both mixtures, with the polymer-modified blend losing stability at about 0.5239 kN/°C (30 min) compared to 0.4918 kN/°C for the 40/50 mix. After prolonged conditioning (24 h), the unmodified mixture showed a slightly higher SDR (0.5593 kN/°C) than the PG 76-10 mixture (0.5390 kN/°C), reflecting a greater overall loss of strength at 75 °C.

Stiffness degradation (SiDR) calculations were only available for the 30 min condition and showed that the 40/50 mix lost stiffness slightly faster (0.2953 kN/mm/°C) compared to the PG 76-10 mix (0.2929 kN/mm/°C). Although this difference is small, it suggests that polymer modification provides a minor advantage in maintaining stiffness during thermal exposure. Overall, however, the polymer-modified mixture retained much higher absolute stiffness values at both 60 °C and 75 °C, meaning that even similar degradation rates correspond to better mechanical performance.

These findings are consistent with the study’s observations that the PG 76-10 mixture “consistently outperformed” the 40/50 mix under high temperatures. In particular, the polymer-modified asphalt maintained Marshall stability values above the 9 kN specification limit even at 75 °C/30 min, whereas the conventional mix fell below acceptable limits. The lower FIR value for PG 76-10 also aligned with the report that its flow values increased more gradually (“more controlled deformation”) than those of the 40/50 asphalt.

In summary, the calculated degradation rates quantitatively confirmed that the PG 76-10 mixture had superior thermal resistance: it lost strength and stiffness more slowly per degree of temperature rise and underwent less additional deformation (flow) than the unmodified mixture. This enhanced performance under heat supports the recommendation of polymer-modified binders for hot climates.

5. Conclusions

This paper evaluated the high-temperature performance of asphalt mixtures prepared with conventional 40/50 penetration-grade bitumen and polymer-modified PG 76-10 binder under thermal conditions typical of Iraqi summers. Marshall stability, flow, and stiffness were assessed across temperatures of 60 °C, 65 °C, 70 °C, and 75 °C, following both short-term (30 min) and extended (24 h) conditioning periods.

Results demonstrated that elevated temperatures significantly degraded the mechanical performance of asphalt mixtures, with declines in stability and stiffness and corresponding increases in flow deformation. However, the polymer-modified mixture consistently outperformed the unmodified 40/50 mix under all testing conditions. Specifically, at 75 °C, the PG 76-10 mixture showed approximately 9% higher stability, 28% higher stiffness, and 18% lower flow deformation compared to the conventional 40/50 mixture. Furthermore, the calculation of the stability degradation rate (SDR), stiffness degradation rate (SiDR), and flow increase rate (FIR) provided quantitative evidence of the enhanced thermal resistance imparted by polymer modification, with PG 76-10 exhibiting nearly 39% lower FIR compared to the unmodified mix. Importantly, PG 76-10 mixtures maintained Marshall stability values above critical specification thresholds even at 75 °C, while conventional mixtures fell below.

These findings confirmed that the use of polymer-modified binders like PG 76-10 is crucial for improving the durability, serviceability, and cost-effectiveness of pavements exposed to extreme heat. Evidence strongly supports revising national specifications in Iraq and other hot-climate regions to promote the broader adoption of performance-graded polymer-modified asphalt binders. In doing so, road agencies can significantly reduce maintenance needs, enhance pavement lifecycles, and deliver safer, more reliable transportation infrastructure. Specifically, the results of this study can inform the development of updated Iraqi pavement design guidelines that mandate the use of polymer-modified binders like PG 76-10 in asphalt mixtures for regions where summer surface temperatures regularly exceed 60 °C, alongside adjustments to specification thresholds, material selection protocols, and performance verification tests to reflect local climatic realities.

6. Limitations and Future Work

This study is subject to several limitations. All evaluations were conducted under controlled laboratory conditions, without incorporating field trials or traffic simulations that could capture the complex effects of real-world loading, environmental variability, and long-term aging. While the laboratory results provide critical baseline insights, they offer only a conservative estimate of material performance and require validation under practical conditions.

Future research should address these limitations by incorporating in situ performance monitoring, cyclic loading tests (including rutting, fatigue, and tensile strength assessments), and lifecycle cost analyses to fully confirm the laboratory-based conclusions and support large-scale implementation. Importantly, the novelty of this study lies in delivering region-specific evidence on the performance of polymer-modified versus conventional asphalt mixtures under the elevated temperature range of 60 °C to 75 °C, realistically reflecting Iraq’s summer pavement conditions and filling an important local data gap. Additionally, exploring alternative polymer modifiers and conducting extended field trials under real traffic and climate conditions are recommended to further optimize asphalt mixture designs for hot-climate regions.

Author Contributions

Conceptualization, M.M.J. and A.A.; methodology, M.M.J. and A.A.; software, M.A. and A.A.; validation, M.M.J., M.A. and A.A.; formal analysis, M.A. and A.A.; investigation, M.M.J., M.A. and A.A.; resources, M.M.J., M.A. and A.A.; data cu-ration, M.M.J., M.A. and A.A.; writing—original draft preparation, M.A. and A.A.; writing—review and editing, M.M.J., M.A. and A.A.; visualization, M.M.J., M.A. and A.A.; supervision, M.M.J. and A.A.; project administration, M.M.J., M.A. and A.A.; funding acquisition, M.M.J., M.A. and A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors. However, the authors acknowledge the financial support provided by the Iraqi Engineers Union for the Article Processing Charges (APC).

Data Availability Statement

All the data used in this article are provided throughout the article.

Acknowledgments

The authors would like to express their sincere gratitude to the General Company for Ports of Iraq for their valuable support in facilitating the asphalt testing procedures. We also extend our appreciation to the Iraqi Engineers Union for their financial support in covering the Article Processing Charges (APC) of this publication.

Conflicts of Interest

Author Mustafa Mohammed Jaleel is employed by Italian Technital Company. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Deng, Z.; Li, W.; Dong, W.; Sun, Z.; Kodikara, J.; Sheng, D. Multifunctional asphalt concrete pavement toward smart transport infrastructure: Design, performance and perspective. Compos. Part B Eng. 2023, 265, 110937. [Google Scholar] [CrossRef]

- Almusawi, A.; Nasraldeen, S.T.; Albdairi, M.; Norri, H.H. Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study. Buildings 2025, 15, 306. [Google Scholar] [CrossRef]

- Al-Atroush, M. Structural behavior of the geothermo-electrical asphalt pavement: A critical review concerning climate change. Heliyon 2022, 8, e12107. [Google Scholar] [CrossRef]

- Abouelsaad, A.; White, G. Review of Asphalt Mixture Ravelling Mechanisms, Causes and Testing. Int. J. Pavement Res. Technol. 2022, 15, 1448–1462. [Google Scholar] [CrossRef]

- Penki, R.; Rout, S.K. Next-generation bitumen: A review on challenges and recent developments in bio-bitumen preparation and usage. Biomass- Convers. Biorefinery 2023, 13, 9583–9600. [Google Scholar] [CrossRef]

- Walubita, L.F.; Mahmoud, E.; Fuentes, L.; Prakoso, A.; Lee, S.I.; Souliman, M.; Komba, J.J. Correlating the asphalt-binder high-temperature properties (DSR) to HMA permanent deformation (RLPD) and field rutting: A laboratory-field study. Constr. Build. Mater. 2020, 262, 120761. [Google Scholar] [CrossRef]

- Amani, M.J.; Alampoor, A.; Piri, M.; Golroo, A.; Rezaeimanesh, M. A Review on the Impact of Pavement Condition on Traffic Safety. Available online: https://doi.org/10.2139/ssrn.5050295 (accessed on 9 June 2025).

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A review of polymer-modified asphalt binder: Modification mechanisms and mechanical properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Ishaq, M.A.; Giustozzi, F. Effect of polymers and micro fibres on the thermo-chemical and rheological properties of polymer modified binders. Aust. J. Civ. Eng. 2023, 21, 34–49. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Zheng, M.; Sadek, H.; Zhang, Y.; Yan, C. Influence of gradation on asphalt mix rutting resistance measured by Hamburg Wheel Tracking test. Constr. Build. Mater. 2020, 238, 117674. [Google Scholar] [CrossRef]

- Almusawi, A.; Shoman, S.; Lupanov, A.P. Assessment of the effectiveness and the initial cost efficiency of hot recycled asphalt using polymer modified bitumen. Case Stud. Constr. Mater. 2023, 18, e02145. [Google Scholar] [CrossRef]

- Jaf, H.; Mamhusseini, A.A. Enhancing Asphalt Mix Performance through the Incorporation of Crumb. Eurasian J. Sci. Eng. 2024, 10, 138–149. [Google Scholar] [CrossRef]

- Hassan, W. Climate change projections of maximum temperatures for southwest Iraq using statistical downscaling. Clim. Res. 2021, 83, 187–200. [Google Scholar] [CrossRef]

- Vysotskaya, M.; Kharlamov, E.; Denisov, V.; Kurlykina, A. PMB quality problems based on its morphology and used equipment. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 135, p. 03035. [Google Scholar] [CrossRef]

- Binti Joohari, I.; Giustozzi, F. Hybrid Polymerisation: An Exploratory Study of the Chemo-Mechanical and Rheological Properties of Hybrid-Modified Bitumen. Polymers 2020, 12, 945. [Google Scholar] [CrossRef] [PubMed]

- Mokoena, R.; Mturi, G.; Maritz, J.; Mateyisi, M.; Klein, P. African Case Studies: Developing Pavement Temperature Maps for Performance-Graded Asphalt Bitumen Selection. Sustainability 2022, 14, 1048. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, L.; Wu, J.; Xiu, Z.; Wang, L.; Miao, Y. Review of regulation techniques of asphalt pavement high temperature for climate change adaptation. J. Infrastruct. Preserv. Resil. 2022, 3, 9. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable Polymers from Recycled Waste Plastics and Their Virgin Counterparts as Bitumen Modifiers: A Comprehensive Review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Zhai, J.; Huang, W. A review of design methods for cold in-place recycling asphalt mixtures: Design processes, key parameters, and evaluation. J. Clean. Prod. 2022, 370, 133530. [Google Scholar] [CrossRef]

- Sargand, S.; Kim, S. Performance evaluation of polymer modified and unmodified Superpave mixes. In Proceedings of the Second International Symposium on Maintenance and Rehabilitation of Pavements and Technological Control. Segundo Simposio Sobre Manutencao e Rehabilitacao de Pavimentos e Controle Technologico. Auburn, AL, USA, 29 April–1 August 2001, Auburn University; University of Mississippi; ASCE; IRF; DOTRSPA; NAPA; FREMIX Fresagem de Pavimentos, 2001; no. 01-147. Available online: https://trid.trb.org/View/701383 (accessed on 9 June 2025).

- Ali, M.F.; Siddiqui, M.N. Changes in asphalt chemistry and durability during oxidation and polymer modification. Pet. Sci. Technol. 2001, 19, 1229–1249. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martínez-Boza, F.J.; Gallegos, C. High temperature stability of different polymer-modified bitumens: A rheological evaluation. J. Appl. Polym. Sci. 2007, 103, 1166–1174. [Google Scholar] [CrossRef]

- Von Quintus, H.L.; Mallela, J.; Buncher, M. Quantification of Effect of Polymer-Modified Asphalt on Flexible Pavement Performance. Transp. Res. Rec. J. Transp. Res. Board 2007, 2001, 141–154. [Google Scholar] [CrossRef]

- Shaffie, E.; Ahmad, J.; Abdul Rahman, M.Y. Temperature Effects on Stripping Performance of Superpave Design Mix. Sci. Res. J. 2008, 5, 11–20. [Google Scholar] [CrossRef]

- Reyes Lizcano, F.A.; Lizarazo, C.M.; Figueroa, A.S.; Candia, M.; Flintsch, G.W. Dynamic characterization of hot-mix asphalt mixtures using modified and conventional asphalts in Colombia. Presented at the 88th Annual Meeting of the Transportation Research Board (TRB), Washington, DC, USA, 11–15 January 2009; Available online: https://www.researchgate.net/publication/279861315_Dynamic_Characterization_of_Hot-Mix_Asphalt_Mixtures_Using_Modified_and_Conventional_Asphalts_in_Colombia (accessed on 9 June 2025).

- Yao, Z.; Zhao, D.; Lei, M. Evaluation of Polymer-Modified Hot-Mix Asphalt: Laboratory Characterization. J. Mater. Civ. Eng. 2009, 21, 163–170. [Google Scholar] [CrossRef]

- Khan, K.M.; Asghar, A. Performance of Pavements under Extreme Loading and Temperature Conditions using Polymer Modified Bitumen. Univ. Eng. Technol. Taxila Tech. J. 2013, 18, 52. Available online: https://www.proquest.com/openview/e845a40c68643a77e6844dcd49688a41/1?cbl=2032486&pq-origsite=gscholar (accessed on 9 June 2025).

- Al-sabagh, A.M.; Abdel_Hai, F.; Abd El Rhman, A.M.; EL-Shafie, M.; Ibrahim, I.M.; Mohammedy, M.M. A Study on Marshall Properties for Polymer Modified Bitumen in Diffferent Molar Ratios. Al-Azhar Bull. Sci. 2014, 25, 23–38. [Google Scholar] [CrossRef]

- Kabbash, O.M. The Design of Hot Mixture Thin Surfacing Containing Asbuton Modified Bitumen Fro Hot and Erid Region. Ph.D. Thesis, UNS (Sebelas Maret University), Surakarta, Indonesia, 2014. [Google Scholar]

- Micaelo, R.; Gameiro, A.; Quaresma, L.; Picado-Santos, L. Production of Hot-Mix Asphalt with PMB: Compactability and mechanical behaviour characterization. In Proceedings of the 8th RILEM Inter-National Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015; Springer: Dordrecht, The Netherlands, 2016; pp. 231–242. [Google Scholar] [CrossRef]

- Albrka, S.I.; Ismail, A.; Yusoff, N.; Alhamali, D.I.; Musbah, A. Performance properties of ASA polymer modified asphalt binders and mixtures. J. Eng. Sci. Technol. 2016, 11, 1155–1164. Available online: https://jestec.taylors.edu.my/Vol%2011%20issue%208%20August%202016/11_8_7.pdf (accessed on 9 June 2025).

- Jan, H.; Aman, M.Y.; Tawab, M.; Ali, K.; Ali, B. Performance evaluation of hot mix asphalt concrete by using polymeric waste polyethylene. In Modeling, Simulation, and Optimization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 91–99. [Google Scholar] [CrossRef]

- Asmael, N.M.; Waheed, M.Q. Investigation of using polymers to improve asphalt pavement performance. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2018, 39, 38–48. Available online: https://asrjetsjournal.org/index.php/American_Scientific_Journal/article/view/3768 (accessed on 9 June 2025).

- Khurshid, M.B.; Qureshi, N.A.; Hussain, A.; Iqbal, M.J. Enhancement of Hot Mix Asphalt (HMA) Properties Using Waste Polymers. Arab. J. Sci. Eng. 2019, 44, 8239–8248. [Google Scholar] [CrossRef]

- Gc, H.; Souliman, M.I.; Zeiada, W.; Isied, M. Mechanistic Assessment of Fatigue Performance and Cost Analysis of Pavement Overlays: Comparison between Conventional Hot Mixed Asphalt, Asphalt Rubber, and Polymer-Modified Mixtures. Adv. Civ. Eng. Mater. 2019, 8, 611–622. [Google Scholar] [CrossRef]

- Sarnowski, M.; Kowalski, K.J.; Król, J.B.; Radziszewski, P. Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties. Materials 2019, 12, 610. [Google Scholar] [CrossRef]

- Yan, K.; You, L.; Wang, D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers 2019, 11, 1404. [Google Scholar] [CrossRef]

- Mu, Y.; Fu, Z.; Liu, J.; Li, C.; Dong, W.; Dai, J. Evaluation of High-Temperature Performance of Asphalt Mixtures Based on Climatic Conditions. Coatings 2020, 10, 535. [Google Scholar] [CrossRef]

- Amin, I.; Alabasey, R.; Azam, A.; EL-Badawy, S.M.; Gabr, A. Evaluation of Polymer Modified Asphalt Mixtures in Pavement Construction. MEJ-Mansoura Eng. J. 2015, 40, 74–82. Available online: https://journals.ekb.eg/article_104955_42d4c391e1766c5c3cdcb8c83f69c48f.pdf (accessed on 9 June 2025). [CrossRef]

- Yu, J.Y.; Zhang, H.L.; Sun, P.; Zhao, S.F. Laboratory performances of nano-particles/polymer modified asphalt mixtures developed for the region with hot summer and cold winter and field evaluation. Road Mater. Pavement Des. 2020, 21, 1529–1544. [Google Scholar] [CrossRef]

- Chen, C.; Wu, H.; Zhang, W.; Mao, Y.; Zhang, C. Investigation of High Temperature Performance and Viscosity Characteristics of Modified and Unmodified Color Asphalt. Exp. Tech. 2022, 46, 317–333. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Investigating the performance of polymer and warm mix modified asphalt binders and mixtures. Int. J. Pavement Eng. 2022, 23, 3691–3705. [Google Scholar] [CrossRef]

- Badry, M.M.; Dulaimi, A.; Shanbara, H.K.; Al-Busaltan, S.; Abdel-Wahed, T. Effect of Polymer on the Properties of Bitumen and Pavement Layers, Case Study: Expressway No. 1, Republic of Iraq. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1090, p. 012032. [Google Scholar] [CrossRef]

- Rincón-Estepa, J.A.; González-Salcedo, E.V.; Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G. Mechanical Behavior of Low-Density Polyethylene Waste Modified Hot Mix Asphalt. Sustainability 2022, 14, 4229. [Google Scholar] [CrossRef]

- Joni, H.H.; AL-Rubaie, A.H. Enhancement of the Rutting Resistance of Asphalt Mixtures at Different High Temperatures Using Waste Polyethylene Polymer. Eng. Technol. J. 2022, 40, 1432–1440. [Google Scholar] [CrossRef]

- Yin, F.; West, R.; Powell, B.; DuBois, C. Short-Term Performance Characterization and Fatigue Damage Prediction of Asphalt Mixtures Containing Polymer-Modified Binders and Recycled Plastics. Transp. Res. Rec. J. Transp. Res. Board 2023, 2679, 742–759. [Google Scholar] [CrossRef]

- Gu, M. Analysis of the Discriminability of High-Temperature Performance Indices of Modified Asphalt Mixtures. In Proceedings of the International Conference on Innovative Solutions in Hydropower Engineering and Civil Engineering, HECE 2022, Hangzhou, China, 25–27 September 2022; Springer Nature Singapore: Singapore, 2022; pp. 243–251. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Liyanapathirana, S.; Yeaman, J.; Egwurube, J. Performance of Hot-Mix Asphalt and Modified Binders Containing Polyethylene. J. Transp. Eng. Part B Pavements 2023, 149, 04023001. [Google Scholar] [CrossRef]

- Saleh, M.; Ahmed, N.; Moghaddam, T.B.; Hashemian, L. Towards a high-performance asphalt concrete for extreme climatic conditions using asphaltenes and polyethylene terephthalate fibres. Constr. Build. Mater. 2024, 420, 135573. [Google Scholar] [CrossRef]

- Ullah, S.; Qabur, A.; Ullah, A.; Aati, K.; Abdelgiom, M.A. Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt. Polymers 2024, 16, 2399. [Google Scholar] [CrossRef] [PubMed]

- Junus, S.; Renreng, I.; Syahid, M.; Hayat, A. Identifying the Effect of Polymer Composition in Hot Mix Asphalt Modification. East.-Eur. J. Enterp. Technol. 2024, 128, 20–30. [Google Scholar] [CrossRef]

- Oyelere, A.; Wu, S.; Rodriguez, E. Evaluation of High-Temperature Rheological and Aging Characteristics in Asphalt Binders Modified with Recycled High-Density Polyethylene and Recycled Polypropylene. Adv. Civ. Eng. Mater. 2024, 13, 134–150. [Google Scholar] [CrossRef]

- İbiş, A.B.; Şengöz, B.; Almusawi, A.; Özdemir, D.K.; Topal, A. Mechanical Characteristics of Environmentally Friendly Permeable Pavement: Enhanced Porous Asphalt. Jordan J. Civ. Eng. 2024, 18, 212–223. [Google Scholar] [CrossRef]

- Dimter, S.; Šimun, M.; Zagvozda, M.; Rukavina, T. Laboratory Evaluation of the Properties of Asphalt Mixture with Wood Ash Filler. Materials 2021, 14, 575. [Google Scholar] [CrossRef]

- Mushtaq, F.; Huang, Z.; Shah, S.A.; Zhang, Y.; Gao, Y.; Azab, M.; Hussain, S.; Anwar, M.K. Performance Optimization Approach of Polymer Modified Asphalt Mixtures with PET and PE Wastes: A Safety Study for Utilizing Eco-Friendly Circular Economy-Based SDGs Concepts. Polymers 2022, 14, 2493. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Adham, K. Review on laboratory preparation processes of polymer modified asphalt binder. J. Traffic Transp. Eng. Engl. Ed. 2023, 10, 159–184. [Google Scholar] [CrossRef]

- Pfeiffer, J.P.; Van Doormaal, P.M. The rheological properties of asphaltic bitumens. J. Inst. Pet. Technol. 1936, 22, 414–440. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).