Abstract

Background/Objectives: Incomplete cut marks produced during dismemberment are often interpreted as indicative of saw class characteristics. However, empirical validation of these associations remains limited, with prior studies examining six or fewer saws. Considering the wide variety of saws available, it is critical to assess the reliability of reported relationships between kerf features and saw classification using a larger sample, particularly in light of the serious legal consequences of erroneous conclusions. This study examines the statistical relationships between five incomplete cut traits—kerf profile shape (KPS), kerf length shape (KLS), floor dip (FD), kerf flare (KF), and floor striae (FS)—and saw class characteristics, including tooth set, tooth shape, teeth-per-inch, power, handle orientation, and cut direction. Methods: Kerf features were scored on a sample of 472 incomplete cuts made with 34 power and hand saws. Results: In reciprocating saws, W-shaped KPS was exclusively associated with crosscut, alternating saws (100%; p < 0.001), with hourglass-shaped KLS also primarily made by alternating sets (95.6%). Necked KLS was linked to wavy sets (76.8%; p < 0.001). FD, though rare, could be correctly assigned to teeth-per-inch groups (86.4%), and was also predominantly associated with alternating saws (90.9%; p < 0.001). Undulating FS were indicative of alternating saws with less than 20 teeth-per-inch (100%, p < 0.001). In contrast, KF showed no strong relationship with saw class characteristics, including handle side. Conclusions: The results of this large-scale analysis support most reported relationships in the saw mark literature but challenge assumptions that KF reliably indicates handle orientation or cut direction, suggesting instead that its location may reflect sawyer technique.

1. Introduction

Cut marks resulting from dismemberment are proposed to reflect specific saw characteristics, potentially aiding forensic investigations by narrowing down the type of tool used [1]. However, there is limited empirical evidence to support these assumptions, with much of the published information being anecdotal (e.g., [1]). Those studies using an empirical approach commonly employ experimental conditions that differ significantly from real-world forensic scenarios [2]. For example, studies often use defleshed bones, typically of non-human origin, which are stabilized in vices during cutting (e.g., [3,4,5,6,7,8,9,10,11,12,13,14]). These conditions fail to accurately replicate actual dismemberment cases, where factors such as soft tissue, differences in human and non-human anatomy, and body positioning/joint mobility may all influence the presence and expression of cut mark traits. Nogueria et al. [15] and Pelletti et al. [16] found significant differences between pig and human saw cut data and argue for the use of human models for the most reliable forensic data. Norman et al. [17] found significant differences in minimum kerf widths (MKWs) made in samples of fleshed and defleshed human limbs and also found significant differences between minimally restrained limbs and those controlled in a vice. They indicate that although logistically challenging, it is essential to use fleshed human remains and a free sawing action in toolmark research. The full effects of tissue and sawing methodology on other cut variables are not well understood.

Incomplete cuts in bone, sometimes referred to as false starts, are defined as those that do not completely transect the bone and result in a kerf floor and two kerf walls [18]. The kerf floor and walls capture several morphological traits that are commonly cited in the literature as being potentially informative about the tool, including kerf profile shape (KPS), kerf length shape (KLS), floor dip (FD), kerf flare (KF), and floor striae (FS).

Kerf profile shape (KPS) refers to the cross-sectional outline of an incomplete cut as viewed from the side. The profile shape of the kerf floor and walls is reported to be influenced by saw tooth shape [1,18]. Crosscut saws have beveled teeth that are filed at opposing angles. As such, the teeth act like a series of knives and are expected to produce W-shaped kerfs, with a peak in the kerf floor occurring between the two pointed teeth [18]. In contrast, rip saws have flat-edged teeth to chisel through the material and are expected to produce more U-shaped or rectangular profiles [1]. Recently, VanBaarle and Garvin [19] used elliptical Fourier analyses to quantitatively assess KPS and saw class characteristics, finding that all W-shaped kerfs were made by crosscut saws, while other kerf shapes could be made by crosscut or rip saws. Their quantitative outline analyses support the relationship between KPS and saw tooth shape but are not directly applicable to the visual assessments applied during casework.

The term kerf length shape (KLS) is used here to describe the shape of the kerf along its length, as viewed from above. This trait has been referred to in other publications as kerf floor shape [1], kerf wall shape [20], and kerf edge shape [15]. Kerf length shape (KLS) was adopted in the present study to alleviate any confusion with kerf profile shape, which also captures aspects of the kerf floor and walls. KLS is typically categorized as hourglass-shaped, pinched/necked, or straight, and is thought to reflect the saw’s tooth set pattern [1,15]. Alternating sets have consecutive teeth laterally angled in opposing directions. As each tooth enters the bone, it pulls the blade slightly toward its set side, creating a side-to-side motion that is expected to produce an undulating, hourglass-shaped kerf [1]. This directional change is referred to as blade drift or cut surface drift and at times can leave bony islands in the kerf center [1,20]. Wavy sets consist of a series of teeth set to one side at varying angles followed by a series of teeth set to the other side at varying angles, creating a wave-like pattern along the blade’s edge. Each group of teeth in a wavy set acts as a single tooth, reportedly resulting in a KLS that appears pinched or “necked” in the center region of the kerf length [1]. Raker sets, which incorporate regularly spaced unset teeth that function to clear debris, limit the lateral movement seen with alternating and wavy sets, and are expected to result in straight kerfs [1]. Research by Nogueria et al. [15] mostly supports the patterns described by Symes [1], although they found that straight walls did not have an association with any particular saw set. Their sample, however, consisted of only five hand-powered saws.

Floor dip (FD) refers to a series of peaks and troughs located at the kerf floor. As each consecutive tooth engages the bone, the blade is hypothesized to “hop” across the bone’s surface, creating a wavy appearance. The distance from FD peak-to-peak or trough-to-trough is thought to reflect tooth size and saw teeth-per-inch (TPI) [1]. Little research has been performed to assess the potential relationship between FD and other saw class characteristics.

Kerf flare (KF) refers to the widening that occurs on one end of the kerf length margin. This is different from KLS as it is reported to only occur on one side of the kerf and is believed to be created by a separate mechanism. KF is thought to be influenced by handle orientation and/or saw cut direction, with more lateral movement of the blade occurring at the handle side during the sawing process, thereby creating a flared or wider kerf length margin on the same side as the sawyer [18]. In saws that cut on the pull stroke, however, KF has been suggested to appear on the non-handle side [21].

Finally, striae along the kerf floor (FS) have been previously scored as undulating, straight, or undulating/straight and proposed to be related to saw set [22,23,24]. These studies contend that undulating or undulating/straight striae are generally associated with alternating sets and thin, straight striae with wavy sets, although Bernardi et al. [23] found that thin, straight striae could also be made by alternating saws and hypothesize that this pattern is related to high TPI.

While these associations between incomplete kerf traits and saw class characteristics have been presented in several studies, none have been tested on a large sample created with a large, diverse set of saws. In fact, published studies statistically evaluating these traits have utilized six or fewer saws in their research designs. To address this gap, the present study examines the diagnostic value of the five aforementioned incomplete kerf morphological traits (KPS, KLS, KD, KF, and FS) by analyzing their statistical relationships with various saw class characteristics using 34 saws on human samples. Furthermore, this study evaluates the effects of soft tissue and sawing methodology on these kerf variables, using paired samples created in fleshed limbs with a free-sawing methodology and defleshed, viced bones. While potential relationships between kerf variables and all saw class characteristics are explored to avoid overlooking any unexpected relationships that may have been missed in smaller samples, the main research objective was to test the following relationships and compare the results with those proposed in the literature:

- Tissue presence and sawing methodology on kerf variable frequencies.

- Tooth shape and KPS.

- Saw set and KLS.

- TPI group and FD.

- Handle orientation/cut direction and KF.

- Saw set and FS.

2. Materials and Methods

To evaluate the effects of soft tissue presence and limb stabilization on incomplete kerf morphology, both fleshed and defleshed samples were created from human cadaveric limbs donated through Des Moines University’s (DMU) Body Donation Program, with all procedures conducted under institutional ethical approval (IRB 2023-30). Per program protocols, the donors had been preserved with a formaldehyde solution. Of the 11 donors, 6 were female and 5 were male, with ages ranging from 67 to 101 years (avg. = 81 yrs). The older ages of the donors are a limitation of the study but are representative of typical demographics in willed body donation programs.

For the fleshed sample, cuts were made by a single sawyer (HMG) in the right lower limbs of the donors, with all soft tissue intact and the lower limb still articulated with the torso, simulating real-life forensic scenarios. One saw was used per limb segment (e.g., one saw for the right tibia/fibula and a different saw for the right femur in a donor). Cuts were made from distal to proximal. As this sample is part of a larger project, alternating incomplete and complete cuts were made producing individual bone segments with incomplete cuts that could be blindly analyzed in this study.

For the defleshed sample, the soft tissues of the left lower limbs were dissected away and the bones were disarticulated at the ankle, knee, and hip. The bones were secured in a vice and cuts were made with the same model saw (with a new, unused blade) as was used on the antimere fleshed donor limb. This was true for all except one limb segment, in which a 24 TPI Dewalt hacksaw was used in place of an 18 TPI Dewalt hacksaw. In this manner, differences in tissue and sawing methodology could be assessed while controlling for donor variation.

All cut bone segments underwent hot water maceration with a small amount of detergent to assist with degreasing. The bones were then labeled with randomly generated numbers to facilitate blind scoring. In total, the fleshed sample consisted of 78 incomplete cuts produced through freehand sawing on intact limbs from 11 donors using 15 different saws (Table 1). The defleshed sample included 130 incomplete cuts made on antimere limbs devoid of soft tissue from the same 11 donors and stabilized in a vice using the same 15 saws (Table 1). Saws were selected to represent a broad range of types and combinations of class characteristics that can be readily purchased at hardware stores to better ensure their relevance to forensic casework (Table 2).

Table 1.

Sample size information by saw for Des Moines University (DMU) and Mercyhurst University (MU) Comparative samples. See Table 2 for additional saw information.

Table 2.

Class characteristics per saw.

A third sample, the Mercyhurst Comparative sample, was also included in the study to increase sample sizes and saw variability. In a previous grant-funded project (NIJ 2005-IJ-CX-K106), Symes et al. [18] created cuts in 19 human donor humeri and femora from the Lake Erie College of Osteopathic Medicine Willed Body Program using 27 saws. The cuts were made in defleshed, vice-controlled bones, and the bones were then macerated in hot water with small amounts of detergent and bleach. While their grant utilized approximately half of the sample, the other half was set aside as a “comparative collection” for future research [18]. The bony specimens in this comparative collection were made available for this study. Of the 27 Mercyhurst saws, 8 saws could not be physically located to confirm saw characteristics and thus were excluded from the current study. In total, the Mercyhurst Comparative sample used in this study comprised 264 incomplete cuts made with 19 saws (Table 1 and Table 2).

The saw class characteristics collected include tooth set (alternating, wavy, or raker), tooth shape (crosscut or rip), teeth-per-inch (low: ≤9 TPI; medium: 10–19 TPI; high: ≥20 TPI), power source (manual or mechanical), handle orientation, and cut direction (push or pull). Each incomplete cut was assessed by a single observer (SJC) for five incomplete morphological traits, KPS, KLS, FD, KF, and FS, using a macroscopic 3× magnifying lens or a Leica S9i stereoscope (zoom 6.10×–20×), when necessary. Any shallow cuts that did not present with two clear kerf walls and a kerf floor were excluded from the study. Kerf depths varied across the samples, and case-by-case exclusions were applied if certain traits could not be scored on specific specimens (e.g., inability to score FS in a cut that progressed into the medullary cavity).

KPS was categorized as W-shaped or not W-shaped (U-shaped or rectangular) (Figure 1). KLS was categorized as hourglass, necked, or straight (Figure 2) following Nogueria et al. [15]. Hourglass KLS was assigned to kerfs with undulating, wavy walls, while necked KLS had straight walls that appeared pinched mid-kerf. If a kerf floor was present and bony islands were observed, these were noted. FD was recorded as present or absent, with a designation of present requiring at least one complete cycle, peak-to-peak or trough-to-trough (Figure 3). When present, the TPI group associated with the FD was predicted (low, medium, or high) using visual assessment of the size and spacing of the peaks and troughs. KF was recorded as present or absent (Figure 4), and if present, whether it occurred on the handle side, non-handle side, or both sides. FS was scored as undulating, straight, or undulating/straight as presented in Nogueria et al. [22] (Figure 5). All traits were assessed directly from the bones, except for FD and FS, which were evaluated using AccuTrans, a silicone molding, to obtain a clearer view of the kerf floor.

Figure 1.

Examples of W-shaped KPS (left) and non-W-shaped KPS (right).

Figure 2.

Examples of hourglass KLS (left), necked KLS (middle), and straight KLS (right).

Figure 3.

Examples of FD presence (top) and FD absence (bottom) on AccuTrans molds.

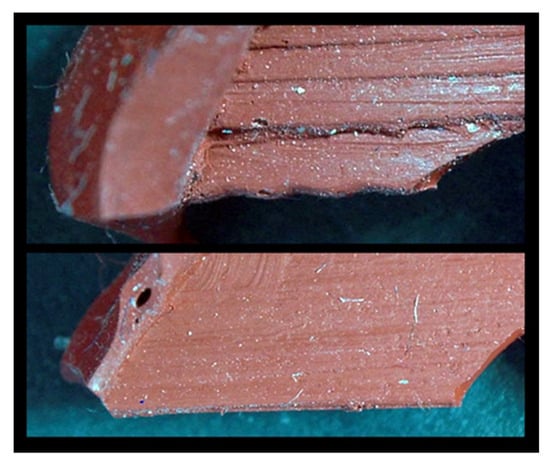

Figure 4.

Examples of KF absence (top) and KF presence (bottom).

Figure 5.

Examples of FS scored as undulating (left), straight (middle), and straight/undulating (right) on AccuTrans molds.

Trait scoring reliability was assessed via intra- and inter-observer analyses. A subset of 35 specimens from the Mercyhurst Comparative sample was randomly selected and the primary observer (SJC) blindly rescored the kerf variables. The same 35 specimens were also blindly scored by a second observer (HMG). Cohen’s Kappa was calculated to assess intra- and inter-observer agreement, interpreting the results according to Landis and Koch [25].

Fisher’s Exact (or in the case of multiple categories, Fisher–Freeman–Halton Exact) tests were run on the DMU fleshed and defleshed samples to assess the effects of soft tissue and sawing methodology (viced or freehand sawing) on trait frequencies. In cases of significant differences, trait relationships were analyzed separately for the fleshed and defleshed samples; for traits with nonsignificant results, the samples were pooled. Bar graphs were utilized to visualize the effects of tissue on the relationships between kerf variables and saw characteristics.

To test the relationship between the kerf variables and saw class characteristics, Fisher’s and Fisher–Freeman–Halton Exact tests were performed. In cases of more than two categories, column proportions were compared using z-tests with Bonferroni corrections. Specimens that could not be reliably scored for a particular trait (e.g., a cut into the medullary cavity precluding any evidence of FD) were excluded from analyses on a case-by-case basis. For evaluations of KF associations with cutting direction and handle side, statistical analyses were limited to those saws that cut on the push or pull only. The two pruning saws were excluded, as they cut on both the push and pull by design. Hacksaws and coping saws were also excluded from these analyses, as these blades can be placed in the saw frame in either direction, potentially cutting on either the push or pull depending on how the sawyer inserted the blade. Analyses were performed using SPSS (Version 29.0.2.0) statistical software.

3. Results

3.1. Scoring Reliability

The intra-observer analysis revealed perfect agreement for KPS, and almost perfect agreement for all other traits (Table 3). For the interobserver analysis, KPS, KLS, and FD returned almost perfect agreement, KF had substantial agreement, and FS had moderate agreement. Note that FS was scored based on three categories, undulating, straight, and undulating/straight, and agreement was assessed in the strict sense (i.e., if one person put straight and another put undulating/straight, there was no agreement). Seven of the eight disagreements in the FS inter-observer analysis were cases where one observer had put undulating/straight and the other had picked only one of those. Intra- and inter-observer differences for KF and KLS were primarily specimens with subtle trait expressions (e.g., very slight necking).

Table 3.

Results of the intra- and inter-observer analyses, including percent correct, Cohen’s Kappa values, and degree of agreement based on [25].

3.2. Fleshed Versus Defleshed

Only KF exhibited significant differences between the DMU fleshed and defleshed samples (p = 0.006; Supplementary Table S1), with the fleshed sample exhibiting a higher frequency of KF presence. Plots of kerf variable trait expressions in the fleshed and defleshed samples, including those clustered by saw characteristics, support these results (Supplementary Materials: Figures S1–S10). As a result, subsequent analyses were performed on the pooled sample for KPS, KLS, FD, and FS, but performed individually on the fleshed and defleshed samples for KF.

3.3. Kerf Profile Shape

KPS occurred almost exclusively with crosscut teeth (95.9%) and exclusively with alternating tooth sets (100%) (Supplementary Table S2). Because crosscut teeth are typically combined with alternating sets, it is difficult to determine if these results reflect the individual or combined effects of these two characteristics. Interestingly, the only rip-toothed saw that produced a W-shaped KPS was a circular saw with an alternating set appearance, where, although the cutting edges of the teeth were flat like a rip saw, the top edges were angled with their points oriented slightly to the left or right in an alternating sequence (Figure 6). This is referred to as an “alternate top bevel” in circular saws [26].

Figure 6.

Circular saw (left) with an “alternate top bevel” (center) and examples of the W-shaped KPS created by this circular saw (right).

While significant differences in KPS expression were also noted with power, TPI, and cut direction (all p < 0.001), the frequencies did not reveal any strong, predictable patterns that could be implemented in casework (Supplementary Table S2). These relationships, in part, may be an artifact of common co-occurrences of saw characteristics (e.g., push saws tend to have alternating crosscut teeth).

3.4. Kerf Length Shape

Almost all (95.6%) hourglass KLSs were associated with alternating sets (Supplementary Table S3). Necked KLSs were most often linked to wavy sets (76.8%). Straight KLSs showed a higher-than-expected presence with raker sets but were too variable to be confidently associated with any set type (Supplementary Table S3). A total of 49 kerfs expressed bony islands. Of these, 38 were associated with hourglass KLSs, 2 with necked KLSs, and 9 with straight KLSs. In all cases, regardless of KLS, the saws that produced islands exhibited alternating sets with crosscut teeth.

There was also a significant and strong statistical relationship between KLS and tooth shape. Hourglass KLS was predominantly associated with crosscut teeth (80.2%), while necked and straight KLSs were predominantly linked to rip teeth (89.3% and 82.8%, respectively). This, however, could be the result of covarying saw traits, as all wavy and raker sets in the sample comprised rip teeth. Although significant effects of power, TPI, and cut direction were also revealed (all p < 0.001), there were no clear trends unrelated to tooth set (Supplementary Table S3).

3.5. Floor Dip

FD was observed relatively rarely, occurring in just 22 (5.1%) cases. Of these occurrences, the correct TPI group was assigned to 19 (86.4%). The three erroneous classifications occurred with the same saw, which had 9 TPI and fell right at the border of the low- and medium-TPI groups. FD may also be associated with alternating sets, which accounted for 90.9% of all FD cases (20/22). Fisher’s Exact tests indicated significant associations with tooth shape, tooth set, TPI group (p ≤ 0.001), and cut direction (p = 0.002) (Supplemental Table S4), but given the low frequency of occurrence, extreme caution is warranted in any interpretations without further analysis.

3.6. Kerf Flare

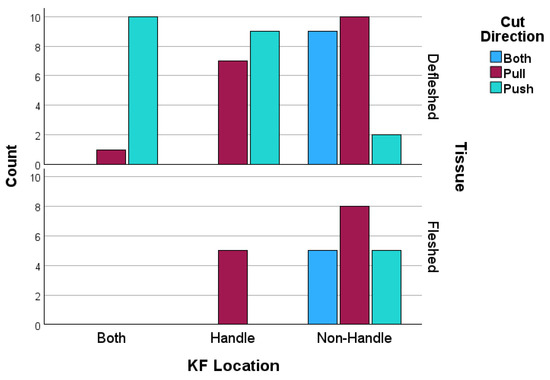

To specifically test whether KF occurs on the handle or non-handle side of push and pull saws, Fisher’s Exact tests were limited to cuts created by push or pull saws in which KF occurred only on one side. Saws that cut on both the push and pull (i.e., pruning saws) and those that could be easily reversed in the saw frame (e.g., hacksaws) were excluded from Fisher’s Exact tests but included in descriptive assessments. In both the fleshed and defleshed samples, cut direction had a significant effect on kerf flare presence (fleshed p = 0.025; defleshed p = 0.001), occurring in higher proportions with push saws (Supplementary Tables S5 and S6). Overall, however, KF was observed on the handle and non-handle side, as well as on both sides, in the defleshed sample regardless of whether the saw cut on the push or pull direction (Figure 7). In the DMU fleshed sample, KF occurred more frequently on the non-handle side overall (78.3%). The combined DMU and Mercyhurst defleshed samples had a higher overall presence of KF, with the location of occurrence more equally distributed across the handle, non-handle, and both sides (33.3%, 43.8%, and 22.9% respectively).

Figure 7.

Frequency of KF locations in fleshed and defleshed samples, categorized by the cutting direction of the saw. See Supplementary Tables S5 and S6 for additional details.

3.7. Floor Striae

Both tooth set and TPI appear to influence FS (p < 0.001; Supplementary Table S7). All undulating FS (n = 23) were made by saws with alternating sets, as were 27/31 (87.1%) of the cuts categorized as straight/undulating. The majority of FS were categorized as straight (83.0%). All cuts made with high-TPI saws (TPI > 19) produced straight FS. Straight FS, however, were also created by low- and medium-TPI saws, and were observed across all three tooth sets (alternating, wavy, and raker). Although Fisher’s Exact tests indicated significant effects of power (p = 0.036), tooth shape (p < 0.001), and cut direction (p = 0.002), no applicable patterns were noted (Supplementary Table S7).

4. Discussion

4.1. Scoring Reliability and Effects of Tissue and Sawing Methodology

Most saw mark analysis research has utilized non-human remains or defleshed, viced human bones, which do not accurately reflect true forensic dismemberment scenarios. The fleshed/defleshed comparisons in this study suggest that the presence of soft tissue and sawing methodology (vice-stabilized versus freehand sawing) do not have significant impacts on the expression or frequency of KPS, KLS, FD, or FS, indicating that research conducted on defleshed bones can be applied to forensic casework. However, significant differences were found between the samples in kerf flare presence, with kerf flare occurring more often in defleshed samples. It is possible that the lack of tissue permits greater movement of the saw blade while cutting. When kerf flare was observed, there was no distinct pattern of it occurring on the handle or non-handle side, regardless of saw cutting direction or the presence of tissue; thus, the interpretation of kerf flare remains the same regardless of tissue presence. Caution should still be exercised, however, regarding the other traits not included in this study, as Norman et al. [17] noted significant differences in MKW between fleshed and defleshed samples.

4.2. Comparison with Previous Literature

With one main exception, our results generally support the previously proposed associations between incomplete kerf variables and saw class characteristics, although with some nuances.

4.2.1. Kerf Profile Shape in Context

An association between KPS and tooth shape has been documented several times in the literature (e.g., [9,18,19,27]). Greathouse et al. [9] classified saws as crosscut if a W-shaped kerf was observed or rip if a U-shaped or flat kerf floor was observed. They report an overall correct classification rate of 94% across three observers, although they used defleshed, dry cow bones and only five hand saws. If we were to calculate the same statistics with our data, classifying all W-shaped kerfs as crosscut and all other kerfs as rip, we would obtain an overall correct classification rate of 95.9%. Bernardi et al. [23] had a 100% correct classification rate using two hand saws, with the crosscut saw creating all W-shaped kerfs and the rip saw (which was a hacksaw) creating all concave or flat kerfs. The elliptical Fourier analysis by VanBaarle and Garvin [19] returned an 88.0% overall correct classification rate for tooth shape but notably found that all W-shaped kerfs were made with crosscut saws.

In our study, if excluding the circular saws, 100% of W-shaped kerfs were made by saws with crosscut, alternating teeth. The one circular saw that created W-shaped kerfs had teeth with a flat forward cutting surface and therefore was classified as a “rip” saw in this research. However, the tops of the teeth exhibit an alternating bevel, referred to as “alternate top bevel” (https://circularsawblade.net/atb, accessed 18 September 2025 [28]) (Figure 6). This characteristic explains why the kerf profile created by this type of saw would be W-shaped. In fact, this alternate top bevel is described as a feature imparted to ease cutting across the grain of wood, as crosscut saws are designed to do [26]. Symes et al. [18] similarly noted that some circular saws may produce W-shaped kerfs, presumably because of such alternating top bevel teeth. Future studies should likely categorize these saws along with crosscut alternating blades.

Although all W-shaped kerfs were produced by crosscut saws (or a circular saw with an alternate top bevel), these saws did not always produce W-shaped kerfs. Several studies similarly note that crosscut saws can make more variable KPSs and warn against possibly misclassifying a saw by assuming that the lack of a W-shaped KPS means it is a rip saw [8,9,19,24].

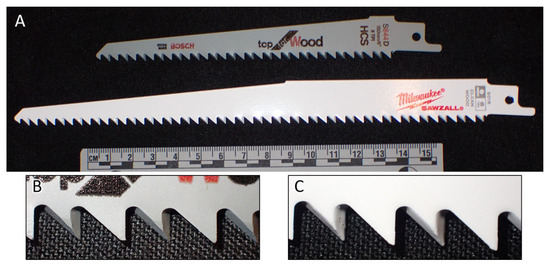

Finally, there are two published studies that reported having a reciprocating rip saw that created W-shaped kerfs. Bernardi et al. [24] reported only observing W-shaped kerfs in cuts made with their “Blade 2” and “Saw 1”. Saw 1 was listed as a crosscut, alternating hand saw, so it would be expected to create W-shaped kerfs. Blade 2, however, was reported as a mechanically powered reciprocating saw with rip teeth and an alternating set. Further details (such as manufacturer or model) are not provided in the paper. They do, however, provide a photograph of the saws. A reverse image search reveals the saw to likely be a Bosch, high-carbon steel blade, with 6 TPI, and 6 inches in length (model S644D), which is advertised by the manufacturer as having “sharp-ground teeth” (https://www.bosch-professional.com/ao/en/s-644-d-top-for-wood-recip-blades-2867578-ocs-ac/, accessed 18 September 2025 [29]). We purchased this saw blade and determined that it is actually a crosscut saw, not a rip saw, and thus the W-shaped kerfs are as expected (Figure 8).

Figure 8.

Crosscut blades that appear to have been misidentified as rip saws in Bernardi et al. [24] (A—top: gray Bosch blade) and Berger et al. [4] (A—bottom: white Milwaukee blade). (B) Close-up of teeth in the Bosch blade used by Bernardi et al. [24]. (C) Close-up of teeth in the Milwaukee blade used by Berger et al. [4]. Note the beveled edges visible on every other tooth.

There is a similar issue with Berger et al. [4]. They report only observing W-shaped kerfs in two blades: a Diablo reciprocating blade with crosscut teeth, which would be expected, and a Milwaukee reciprocating blade with rip teeth and an alternating set. Blade model numbers are not provided in the paper, but the poster by Berger et al. [30] does show a “5016” model number on the Milwaukee blade. The model number and image of the saw match a Milwaukee blade model 48-00-5016 (https://www.milwaukeetool.com/products/48-00-5016; https://www.acehardware.com/departments/tools/saw-blades/reciprocating-saw-blades/2094860, accessed 18 September 2025 [31,32]). The manufacturer’s image suggests the teeth are beveled and it is advertised as having “unique fleam ground teeth.” We purchased this blade and, again, confirmed it is actually a crosscut saw (Figure 8).

If these discrepancies are corrected, then the pattern holds true that reciprocating rip saws do not produce W-shaped kerfs. All of the aforementioned studies used six saws or fewer. The fact that this relationship held true in our sample of 34 saws provides confidence in the utility of W-shaped KPS in identifying kerfs made by crosscut saws.

4.2.2. Kerf Length Shape in Context

In terms of KLS, Symes [1] suggests that alternating sets create an hourglass KLS with bony islands, raker sets create a straight KLS, and wavy sets create a necked KLS, although he provides no empirical data to support these associations. Nogueira et al. [15] assessed KLS (referred to as “shape of the walls”) in a sample of cuts made with five saws and found that all hourglass KLSs were made by alternating sets, and all necked KLSs were made by wavy sets, but that straight KLSs could be made by raker, alternating, or wavy sets. Bernardi et al. [24] reported similar results across their five saws. Hourglass KLSs were only created by alternating sets. While their wavy set saw did create a necked KLS, a necked KLS was also observed with two of the alternating saws, and straight KLSs were observed across all five saws.

Our results are similar to those of Nogueira et al. [15] and Bernardi et al. [24] and support general trends, although no exclusionary relationships between KLS and saw set. Over 95% of the hourglass KLSs were made by alternating saws (87/91), and 100% of hourglass KLSs that also exhibited bony islands were made by alternating saws. Of the observed necked KLSs, 76.8% were made by wavy sets. While 94.1% of the raker sets made straight KLSs, straight KLSs were also commonly observed with alternating and wavy sets.

4.2.3. Floor Dip in Context

Comparing the results obtained for FD with the current literature is challenging, as this trait is reported to be rarely observed (e.g., [4,27]). This was also true in our sample, with FD occurring in only 5.1% of incomplete cuts. Berger et al. [4] found a tentative association between FD and power, with more FD occurring with mechanical saws; however, their sample included only one hand saw, a hacksaw, and five mechanical saws. In contrast to these findings, the results of the current study do not show any association with power, but do show a potential relationship with TPI, with smaller, more closely spaced FD features associated with high-TPI saws. In this study, the correct TPI group was predicted in 19/22 FDs, with the three errors associated with a single 9 TPI saw, right at the cutoff of our assigned low- and medium-TPI groups. Metric TPI comparisons are beyond the scope of this paper, but the ability to accurately predict saw tooth size from FD deserves further investigation.

Another potential association was observed between FD and set, with 90.9% of the cuts displaying FD having been made by alternating sets. However, since only 22 occurrences of FD were recorded, small sample sizes preclude firm conclusions.

4.2.4. Kerf Flare in Context

Similarly to FD, comparing KF results from this study with current literature is difficult, as most previous studies found KF to be too rarely observed to perform statistical analyses (e.g., [4,27]). A potential reason for the comparatively larger occurrence of KF in the present study (n = 113; 23.9% of the sample) is that a complete floor was not required for analysis. Although Love et al. [33] have stated that KF should only be recorded in very shallow cuts, since KF occurs at the cut margins, sufficient cortical bone was deemed all that was required to confidently observe its expression.

KF has been stated to occur on the handle side of the cut [18]. Berger [21] has specified that this expectation is true particularly for push saws, but in cases of pull saws, KF should instead occur on the non-handle side. The results of the current study do not corroborate these assumptions, as KF occurred on the handle and non-handle sides in both the fleshed and defleshed samples and saw cut direction could not explain the variance. It is important to note that it is possible to insert a saw blade backward in a removable handle (e.g., hacksaw blades), either intentionally or unintentionally, thereby creating a pull saw from a push saw and vice versa. For this reason, hacksaw and coping saw blades were not included in these analyses, as the way in which the blade was inserted in the frame in a forensic case would be unknown. Additionally, it is interesting to note that KF has previously been stated to only occur on one side of the cut [21]. In the current study, KF occurred on both sides of the cut in 11 cases from the defleshed sample, but only unilaterally in the fleshed sample.

4.2.5. Floor Striae in Context

Consistent with previous studies [22,23,24], saws with alternating sets created all undulating FS (100%) and the majority of straight/undulating FS (87.1%). These studies also claim that straight FS are indicative of a wavy set; while all saws with wavy sets did create straight FS, straight FS also made up 69.7% of the alternating set cuts and 92.5% of the raker set cuts. Bernardi et al. [23] also noted that straight FS could be seen with alternating sets and suggested that this could be the result of high TPI. In our study, 43 of the straight FS were created with alternating sets and low TPIs (<10), indicating that TPI cannot explain this occurrence. All high (>19)-TPI saws did create straight FS but so did many medium- and low-TPI saws. Overall, straight FS was the predominant expression (83.0% of all cuts) and was observed commonly across all saw characteristics. While previous studies [22,23,24] mention that raker saws will create striae arranged in threes, none provide any further information on what is meant by “arranged in threes,” and despite their claims, none of the studies included a raker saw in their experimental design. As such, this feature was not assessed in the present study, but further research may want to explore additional FS categories.

4.3. Incomplete Kerf Variables in Forensic Practice

Statistical analyses are important for deciphering true relationships and effects from noise and random errors. The Supplementary Materials provide all statistical results between the kerf variables and saw class characteristics examined in this study. The mere attainment of a significant p-value, however, does not mean that a trait or relationship should be applied to forensic casework. The interrelatedness of various saw characteristics means that significant p-values can be obtained when another trait is driving the relationship (e.g., hacksaws tend to have rip teeth, wavy sets, and high TPIs). Likewise, pooled correct classification rates may not be the most appropriate statistic to report; it is possible that certain morphological forms of a kerf variable are informative, while the other form(s) do not correspond with specific saw characteristics. Here, we discuss the applicable results to casework, which are summarized in Table 4.

Table 4.

Incomplete kerf feature expressions and their reportable relationship with saw class characteristics, as observed in this study. Only those relationships that were both statistically significant and forensically applicable are presented. Counts per category are provided, as well as overall percentages.

We can confidently conclude that W-shaped kerf profiles are the result of crosscut, alternating saws with near-perfect accuracy. In casework, practitioners may be able to first differentiate whether their kerf was made by a reciprocating or circular saw, as circular saws create curved cutting striae [1,18]. If unable, they may conclude that the W-shaped kerf was made either with a crosscut, alternating reciprocating saw or an alternate top bevel circular saw (100% accuracy). If the KPS is not W-shaped, no conclusions should be drawn about the tooth shape or set.

If an hourglass-shaped KLS is observed, there is a high probability that it was created with an alternating set (95.6% accuracy), and if bony islands are also present, it can confidently be classified as an alternating set (100% accuracy). A necked KLS indicates a moderately high probability that a wavy set was used (76.8% accuracy). No conclusions should be drawn from a straight KLS.

If FD is present, it is possible to report that it could indicate an alternating set, but we suggest caution in using this trait to draw any strong conclusions given the low frequency of occurrence. The presence of FD could provide corroborative evidence of an alternating set if other alternating set features are observed (e.g., hourglass KLS). Floor dip size does appear to be related to TPI and tooth size, but further research is needed to assess the direct relationship between FD and saw tooth metrics.

Kerf flare was observed on the handle and non-handle sides of cuts created by push and pull saws in both the fleshed and defleshed samples. Therefore, no case conclusions should be drawn from kerf flare expression.

Finally, if FS are clearly undulating, practitioners can confidently conclude that a saw with an alternating set and TPI < 20 was used (100% accuracy). If a straight/undulating appearance is present, the practitioner may report that it was likely made with an alternating set saw with TPI < 20 (87.1% accuracy). When straight FS are observed, however, no conclusions can be drawn, as this is a common expression across all saw characteristics.

4.4. Limitations and Future Studies

By utilizing 34 saws to analyze 472 cuts, this research represents the largest and most comprehensive study on incomplete kerf morphology. However, this study still does not encompass the full range of possible saw variations, as manufacturers are continuously introducing saw blade modifications to beat competitor models. At the same time, several saw class characteristics tend to covary, making it difficult to determine which individual saw characteristic is responsible for creating a particular kerf trait, or if the combined effects of multiple characteristics are required. Future studies may want to assess the relationship between kerf variables and certain groups of traits or saw types (e.g., utility saw, hack saw, demolition saw). This becomes complicated, however, as delineations between saw types are not always clear. Even the core class characteristics described throughout the saw mark analysis literature can be more difficult to assign than implied, and as illustrated by the potential misclassifications of saw tooth shape in Berger et al. [4] and Bernardi et al. [24]. This is further illustrated by the circular saw with the alternating top bevel that acted like a reciprocating crosscut, alternating set saw in the current study. Saw blades can have variable TPIs or dual-set teeth. Some crosscut alternating saws have occasional unset, yet crosscut, teeth. These teeth are not generally categorized as “raker” teeth, as they do not have a flat surface to remove debris and only occur every eight or so teeth. VanBaarle and Garvin [19] previously illustrated that these saws are best classified as alternating sets and this is how they were treated in this study. Since saws’ characteristics are not always clearly indicated by the manufacturer, it is imperative that a suspected saw be evaluated for its characteristics before being ruled in or out as the potential tool used in a dismemberment.

The donors utilized in this study were preserved with a formaldehyde solution and were of older ages. Neither are ideal when replicating real forensic dismemberment scenarios but represent the logistical challenges of empirical saw mark analysis research on ethically sourced human donors. It is unclear whether formaldehyde solutions affect the bone biomechanics or tissue texture substantially enough to alter trait frequencies or expressions. The fact, however, that the fleshed and defleshed samples produced similar trait frequencies and expressions for most traits suggests that the embalmed soft tissue did not have a significant effect on their occurrence or presentation. Regarding the age range of the sample, it is possible that older donors may exhibit less cortical bone due to degenerative changes, which in turn could result in lower trait frequencies being observed. This is an issue across all studies utilizing donated human remains, with donors in Bernardi et al. [23] having an average reported age of 85 years and those in Bernardi et al. [24] described as “elderly.” Ideally, dismemberment research would be carried out on unembalmed human remains with a wider range of ages, but this is typically not possible.

5. Conclusions

The results of this study demonstrate the utility of incomplete kerf morphology resulting from dismemberment, especially KPS, KLS, FS, and potentially FD, in predicting specific saw class characteristics, particularly tooth set and tooth shape. Notably, the results challenge assumptions that KF is a reliable indicator of handle side or cut direction, suggesting instead that its presence and location may be more reflective of sawyer technique. While several studies have tested associations between these kerf variables and saw class characteristics, e.g., [15,16,17,20,21,22,23,24,27,33], their results are based on limited samples, created with a maximum of six saws. This study tested these relationships on a sample of 472 incomplete cuts made with 34 saws, covering a wide array of saw characteristic combinations. The results are interpreted in terms of casework applicability, focusing on what conclusions can be accurately drawn and with what confidence when a specific incomplete kerf variable is observed. When performing casework, conclusions about dismemberment tool characteristics should only be presented in cases in which kerf variables are strongly associated with the saw trait, and levels of confidence should be reported alongside the prediction.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/forensicsci5040057/s1, Spreadsheet: Study data. Supplementary Document containing additional study results to include Table S1: Fisher’s and Fisher–Freeman–Halton Exact test results assessing the effects of tissue on kerf trait frequencies; Figures S1–S10: Bar graphs of kerf variable trait expressions in fleshed and defleshed samples; Tables S2–S7: Fisher’s Exact test results for kerf variables and saw class characteristics.

Author Contributions

Conceptualization, H.M.G.; methodology, H.M.G. and S.J.C.; formal analysis, H.M.G. and S.J.C.; resources, H.M.G.; data curation, S.J.C. and H.M.G.; writing—original draft preparation, S.J.C.; writing—review and editing, H.M.G.; supervision, H.M.G.; project administration, H.M.G.; funding acquisition, H.M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This project was supported by Award No. 15PNIJ-23-GG-04215-SLFO, awarded by the National Institute of Justice, Office of Justice Programs, U.S. Department of Justice. The opinions, findings, and conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect those of the Department of Justice.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Review Board of Des Moines University (IRB 2023-30, 18 October 2023).

Informed Consent Statement

All body donors provided first-person, written consent gifting their body for anatomical education and research without restriction through the Des Moines University Body Donation Program, to include images and publication. This research and publication do not include any identifying information.

Data Availability Statement

The original contributions presented in this study are included in the Supplementary Materials. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank Mercyhurst University and Mercyhurst University faculty and students that assisted in providing the Mercyhurst Comparative Collection and information about the previous 2010 NIJ study. Alexandra Klales, Ashley Maxwell, Erin Chapman, Lauren Butaric, Alexis VanBaarle, and Meghan Gast contributed to preliminary discussions on trait definitions and scoring. Finally, we would like to thank all those who donate their body to science and make this type of research possible.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Symes, S.A. Morphology of Saw Marks in Human Bone: Identification of Class Characteristics. Ph.D. Dissertation, University of Tennessee, Knoxville, TN, USA, 1992. [Google Scholar]

- McKay, B.; Cole, S.; Gast, M.; Garvin, H. The Statistical Relationship of Breakaway Spurs and Notches with Saw Class Characteristics in Experimental Dismemberments. In Proceedings of the 77th Annual Conference of the American Academy of Forensic Sciences, Baltimore, MA, USA, 17–22 February 2025. [Google Scholar]

- Bailey, J.A.; Wang, Y.; van de Goot, F.R.W.; Gerretsen, R.R.R. Statistical analysis of kerf mark measurements in bone. Forensic Sci. Med. Pathol. 2011, 7, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Berger, J.M.; Pokines, J.T.; Moore, T.L. Analysis of class characteristics of reciprocating saws. J. Forensic Sci. 2018, 63, 1661–1672. [Google Scholar] [CrossRef] [PubMed]

- Collord-Stalder, H.G. Digital Microscopic Methods for Sharp Force Trauma in Burned Human and Nonhuman Remains. Master’s Thesis, Texas State University, San Marcos, TX, USA, 2020. [Google Scholar]

- Freas, L.E. Assessment of wear-related features of the kerf wall from saw marks in bone. J. Forensic Sci. 2010, 55, 1561–1569. [Google Scholar] [CrossRef] [PubMed]

- Greer, S.Y. Quantifying variation in kerf wall striations created by hacksaws and reciprocating saws. Forensic Anthropol. 2018, 1, 160–169. [Google Scholar] [CrossRef]

- Hughes, E. Variation of Tool Mark Characteristics in Frozen Bone as it Relates to Dismemberment. Master’s Thesis, University of Montana, Missoula, MT, USA, 2018. [Google Scholar]

- Greathouse, H.; Chapman, E.; Maxwell, A.; Klales, A.R. Identifying handsaw tooth shape based on the micro- and macroscopic analysis of the kerf floor contour. Forensic Anthropol. 2021, 4, 20–29. [Google Scholar] [CrossRef]

- Marciniak, S.M. A preliminary assessment of the identification of waw marks on burned bone. J. Forensic Sci. 2009, 54, 779–785. [Google Scholar] [CrossRef] [PubMed]

- Martlin, B.; Rando, C. An assessment of the reliability of cut surface characteristics to distinguish between hand-powered reciprocating saw blades in cases of experimental dismemberment. J. Forensic Sci. 2020, 66, 444–455. [Google Scholar] [CrossRef] [PubMed]

- Menschel, M.; Pokines, J.T.; Reinecke, G.M. Correlation between saw blade width and kerf width. J. Forensic Sci. 2021, 66, 25–43. [Google Scholar] [CrossRef] [PubMed]

- Vegh, E.I.; Rando, C. Effects of heat as a taphonomic agent on kerf dimensions. Archaeol. Environ. Forensic Sci. 2017, 1, 105–118. [Google Scholar] [CrossRef]

- Young, C.D. An Examination of Electric Chainsaw Class Characteristics in Bone and the Effects of Thermal Alteration. Master’s Thesis, Boston University, Boston, MA, USA, 2019. [Google Scholar]

- Nogueira, L.; Quatrehomme, G.; Rallon, C.; Adalian, P.; Alunni, V. Saw marks in bones: A study of 170 experimental false start lesions. Forensic Sci. Int. 2016, 268, 123–130. [Google Scholar] [CrossRef] [PubMed]

- Pelletti, G.; Viel, G.; Fais, P.; Viero, A.; Visentin, S.; Miotto, D.; Montisci, M.; Ceccchetto, G.; Giraudo, C. Micro-computed tomography of false starts produced on bone by different hand-saws. Leg. Med. 2017, 26, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Norman, D.G.; Baiera, W.; Watson, D.G.; Burnett, B.; Painter, M.; Williams, M.A. Micro-CT for waw mark analysis on human bone. Forensic Sci. Int. 2018, 23, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Symes, S.A.; Chapman, E.N.; Rainwater, C.W.; Cabo, L.L.; Myster, S.M.T. Knife and Saw Toolmark Analysis in Bone: A Manual Designed for the Examination of Criminal Mutilation and Dismemberment; National Institute of Justice Report Document Number 232227; National Institute of Justice: Washington, DC, USA, 2010.

- VanBaarle, A.L.; Garvin, H.M. A quantitative assessment of saw kerf floor shape patterns using outline analysis. J. Forensic Sci. 2025, 369, 112434. [Google Scholar] [CrossRef] [PubMed]

- Love, J.C. Sharp force trauma analysis in bone and cartilage: A Literature Review. Forensic Sci. Int. 2019, 299, 119–127. [Google Scholar] [CrossRef]

- Berger, J. Reciprocating Saws as Tools of Dismemberment: Analysis of Class Characteristics and Practical Utility. Master’s Thesis, Boston University, Boston, MA, USA, 2017. [Google Scholar]

- Nogueira, L.; Alunni, V.; Bernardi, C.; Quatrehomme, G. Saw marks in bones: A study of “secondary features” of false start lesions. Forensic Sci. Int. 2018, 290, 157–161. [Google Scholar] [CrossRef] [PubMed]

- Bernardi, C.; Nogueira, L.; Cabusat-Mailliet, C.; Carle, G.; Alunni, V.; Quatrehomme, G. Analysis of false start lesions on human bones produced by two hand saws with high TPI. Int. J. Leg. Med. 2020, 134, 613–618. [Google Scholar] [CrossRef]

- Bernardi, C.; Nogueira, L.; Carle, G.F.; Alunni, V.; Quatrehomme, G. Comparison of microscopic features of bone false starts produced by reciprocating saw blades and handsaws of the same class. Leg. Med. 2022, 59, 102152. [Google Scholar] [CrossRef] [PubMed]

- Landis, J.; Koch, G. An application of hierarchical kappa-type statistics in the assessment of majority agreement among multiple observers. Biometrics 1977, 33, 363–374. [Google Scholar] [CrossRef] [PubMed]

- Nagypál, H. Herman: Saw Blade Teeth for Circular Saws and Their Most Common Combinations. Available online: https://www.hermantools.com/blog/saw-blade-teeth-for-circular-saws-and-their-most-common-combinations (accessed on 18 September 2025).

- Love, J.C.; Derrick, S.M.; Wiersema, J.M.; Peters, C. Microscopic saw mark analysis: An empirical approach. J. Forensic Sci. 2015, 60, S21–S26. [Google Scholar] [CrossRef] [PubMed]

- Circular Saw Blades: ATP. Available online: https://circularsawblade.net/atb (accessed on 18 September 2025).

- Bosch: S 644 D Top for Wood Reciprocating Saw Blade for Reciprocating Saws. Available online: https://www.bosch-professional.com/ao/en/s-644-d-top-for-wood-recip-blades-2867578-ocs-ac/ (accessed on 18 September 2025).

- Berger, J.M.; Pokines, J.; Moore, T.L. Reciprocating Saws as Tools of Dismemberment. In Proceedings of the 69th Annual Conference of the American Academy of Forensic Sciences, New Orleans, LA, USA, 13–18 February 2017. [Google Scholar]

- Milwaukee: 9” 6 TPI Fleam Ground SAWZALL® Blades (5 Pk). Available online: https://www.milwaukeetool.com/products/48-00-5016 (accessed on 18 September 2025).

- ACE: Milwaukee Sawzall 9 in. Bi-Metal Clean Wood Reciprocating Saw Blade 6 TPI 5 pk. Available online: https://www.acehardware.com/departments/tools/saw-blades/reciprocating-saw-blades/2094860 (accessed on 18 September 2025).

- Love, J.C.; Derrick, S.M.; Wiersema, J.M. Independent Validation Test of Microscopic Saw Mark Analysis; National Institute of Justice Report Document Number 241745; National Institute of Justice: Washington, DC, USA, 2013.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).