Abstract

This paper presents the application of risk analysis associated with the multicriteria decision method, through the MAHP (Monte Carlo analytic hierarchy process) technique for mining. As an example of application, the problem of choosing an access and transportation route for an underground mine is addressed. A decision can be made based on a technical, economic, and social-environmental approach. As a topic of interest for the modeling of mining projects, this work presents how the technique can qualify the decision-making process, reducing its subjectivity. It is verified that in comparison with the traditional AHP (analytic hierarchy process) method, the risk analysis allows considering the variability of weights and preferences assigned to criteria and options. In the example case, the following options are evaluated: shaft, ramp by diesel or electric truck, and conveyor belt.

1. Introduction

In the mining sector, the initial stages of studies (conceptual, pre-feasibility, and feasibility) are of great importance for determining the necessary investments for project development. During these stages, decisions must be made regarding key options for the projects. In the case of underground mining, these options may include the adopted mining method, type of access, location of structures, beneficiation process, among others. These decisions may be left to the designer or project team; however, in terms of initial studies, these decisions can be made based on different criteria. Several tools are available to aid in decision-making in such stages. These range from cost-focused project modeling estimates [1,2,3], the incorporation of ESG—environmental-social-governance criteria [4,5]—to algorithms specifically designed for choosing mine access and transportation [6].

Given the variance in outputs that different models and tools tend to produce based on individual criteria, the prospect of incorporating multicriteria decision-making methods, including the well-established analytic hierarchy process (AHP) and others, becomes more intriguing. These methodologies offer a structured framework for decision-making that can effectively accommodate a range of diverse criteria simultaneously, leading to more comprehensive and well-informed decision-making processes.

By definition, the initial stages of projects carry a high degree of associated risk, meaning that the outcome may vary around the expected result. To incorporate this variability into analyses, among various techniques, the Monte Carlo simulation is already being applied and integrated into various processes in the mining sector [7,8,9].

Thus, by combining these two techniques, it is possible to incorporate and consider variabilities in the multicriteria decision-making process. To illustrate the application, this paper presents the process undertaken on a hypothetical underground mine case study, considering different criteria and the incorporation of ESG aspects.

Underground Mine Acess Selection

The choice of underground access types, including equipment access, personnel, supplies, and production flow, tends to take into account economic factors. Several authors have debated the topic, such as McCarthy and Livingstone [10], who present comparisons between shaft and inclined plane regarding the cost of execution and production flow. However, the initial choice tends to be based on cases of success or so-called ‘golden rules’, which are also structured based on successful cases, as compiled by Vergne [11].

According to Skrzypkowski et al. [12], the choice of mine access should primarily consider factors such as the type of access structure (related to rock/deposit composition, length of transport routes, mining method, and volume of excavated materials). Additionally, the authors mention that the increase in natural hazards with mining depth, such as pressure on rock masses and climatic conditions, significantly influences the selection and placement of the access [12].

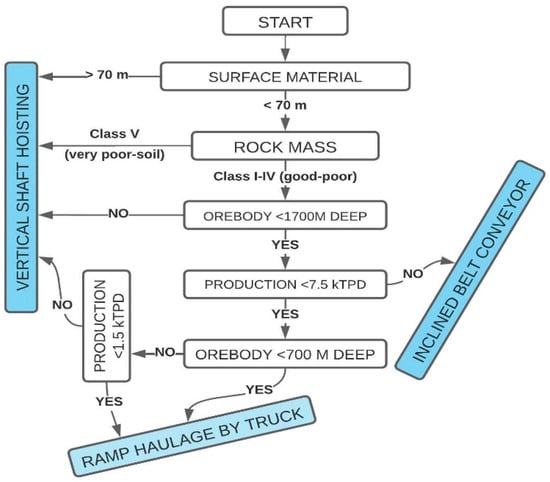

Another alternative for the choice of access and transportation is the use of flowcharts (Figure 1), as proposed by Vergne [11], Moser [13], and Cardozo [6], which presents an algorithm for determining the type of access to be operated, considering input parameters such as depth, production, and rock mass quality. Due to their practical applicability, such algorithms are widely used for conceptual studies in mining. However, it should be noted that their adherence rate is lower to 71% [6] for the update presented in Figure 1.

Figure 1.

Algorithm for choosing access and transport.

The following Table 1 presents the compilation of the main works related to cost estimation and support for the choice of exploitation method. It is worth noting that works such as Salama [14], Gonen et al. [15], Rupprecht [16], and Elevli et al. [17] present discretized costs, which are compiled and presented in more detail by Cardozo [6]. As a reference for access cost estimates, the Mafmine 3.1 model [4] provides Capital Expenditure (CAPEX) and Operational Expenditure (OPEX) estimates for ramp, shaft, and conveyor belt for conceptual projects of underground mines. These estimates are based on updates of the O’Hara (1980) and O’Hara and Sobolewski [3] models.

Table 1.

Papers with cost approach in mine access and transportation.

However, there is not an absolute alignment between the choices indicated by algorithms and the choices made in real projects, as pointed out by Cardozo et al. [18]. This fact leads to the possibility of considering different criteria for decision-making, including criteria beyond the so-called technical-economic ones. Thus, creating a suitable scenario for the application of the multicriteria analysis methodology.

2. Materials and Methods

For the case study, the methodology was applied to a project in the initial stages of studying the option of a polymetallic underground mine. The location chosen was the region of Caçapava do Sul, RS, located approximately 350 km away from Porto Alegre.

The Caçapava do Sul region has a history of mining activity due to the occurrence of polymetallic deposits and fertilizers (limestone and phosphate). Both open-pit and underground mines (sublevel stoping) have been established in the region, with new projects being researched in recent years. The rural area has low population density and an economy focused on agricultural activities. The main water resource in the region is the Camaquã River, and the climate is considered temperate.

A deposit with a reserve of 20 million tons was considered, with an estimated average daily production of 7 kilotons, assuming 350 days per year. The resources were indicated as 1.8% of Zn, 0.08% of Cu, 27 g/t of Ag, and 1.89% of Pb [19]. In terms of geometry, a subvertical body is considered, with an average depth of 450 m and an average thickness of 6 m, mined with sublevel toping mining method. The geological formation consists of sedimentary and metamorphic rocks, conglomerates, gneisses, sandstones, shales, and marbles. The majority of the rock formations are outcropping, and the rock masses have good mechanical resistance. Thus, it is inferred that there is a small soil thickness, and the rock mass has a strength equal to or greater than class III (Rock Mass Rating—RMR greater than 41) on average. These characteristics are consistent with real projects proposed in the region. Based on these characteristics, pairwise comparisons of options were made against the criteria, and the relative importance of each criterion was evaluated.

2.1. Multicriteria Decision-Making

Parreiras [20] introduces us to the concept of optimality presented by Pareto (previously introduced) and also highlight the issue that multiple objectives have multiple optimal solutions. Although in a real application, in the case of choosing the execution of an alternative, only one is selected. Thus, the alternative that is more satisfactory across different criteria simultaneously is chosen.

In these terms, multicriteria analysis aims to assist the decision-maker and/or designer (or both) facing a problem that presents different choice criteria. It is common for cases where one alternative optimally meets one criterion, and another alternative is more attractive in another criterion. The classical approach to multicriteria analysis has its roots in mathematical models and rigid axioms, which have been criticized by the current field of operations research. This, in turn, currently focuses on decision-makers (actors). This approach forms the basis for the analytic hierarchy process (AHP) method proposed by Saaty [21].

Parreiras [20] and others mention different multicriteria analysis methods that were subsequently developed to address different choice problems. It is well known that the preferences of human decision-makers derive, change, and are based on their particular concept of values, as well as on interactions with other decision-makers. Therefore, uncertainty, imprecision, and ambiguity are inherent aspects of decision-making. However, classical approaches based on binary logic tend to represent human preferences using simple models that take into account precise and well-defined human judgment [20].

According to Dahri and Abida [22], AHP represents a powerful tool for analyzing complex decision problems based on a multicriteria evaluation approach, generally involving incommensurable data or factors. The methodology presented by Saaty [21] involves the evaluation of criteria and options pairs to assign weights (w) to them and combine them into a final hierarchy. Saaty [21] proposes a reference scoring scale for preferences to standardize the application of the methodology, as illustrated by Table 2.

Table 2.

Saaty’s scale for pairwise comparison in AHP methodology.

2.2. Monte Carlo AHP

Most studies that address the Monte Carlo simulation to expand the traditional AHP method follow the sequential logic of AHP. The majority of these studies focus on simulating pairwise preferences [23,24,25], with some examining the variability presented directly in the weights; however, both paths should converge to the same result.

Applying the Monte Carlo simulation to the deterministic results obtained from AHP provides statistical tools, such as the coefficient of variation, which aids decision-makers in selecting options that may not differ significantly in numerical terms. Furthermore, it enables the assessment of uncertainty over the judgment and the incorporation of various opinions into the AHP decision matrix, from different specialists, as a probability function distribution.

A systematic literature review conducted in the principal engineering scientific databases did not find the application of the Monte Carlo simulation AHP methodology for the selection of underground mining accesses. On the other hand, the procedure was previously executed for mining method selection [26,27]. A comprehensive review of the use of multicriteria decision-making methods for mining method selection was presented by Namin, Ghadi, and Saki [28].

Hauser and Tadikamalla [29] propose one of the earliest risk approaches in AHP, suggesting that pairwise evaluations be randomly generated from predefined probability distributions (e.g., triangular and uniform distributions). This procedure differs from traditional AHP, in which pairwise comparisons are deterministic and specified by decision-makers with intervals between 1 and 9 on Saaty’s scale [21]. Other possibilities in MAHP extensions include sensitivity analysis to identify sources of variation [30].

In the most common approach, the consideration of a probability function is incorporated into each preference ( ), which, according to algebraic principles and probability theory, corresponds to a probability distribution in the weight vector ( .

Another option presented is the development of matrices (An) for pairwise evaluation, followed by the generation and adaptation of probability function for the weights ( based on the outputs obtained.

This second option is applicable when there is a range of n decision-makers to be considered; on the other hand, the first approach is well-suited to the case of a decision-maker who assumes variability in their pairwise preference decisions. It is worth noting that in both options, the summation of the weights (expected or mean) can result in values other than zero, unlike the traditional deterministic AHP.

3. Results and Discussion

3.1. AHP for Mine Acess Selection

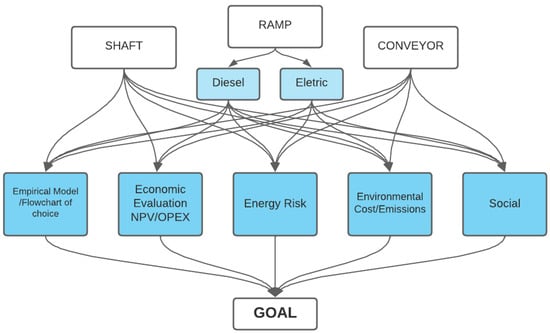

Considering the possibility of different criteria in different spheres for the selection of underground mine access type and transportation route, such as the problem of selecting the mining method, the AHP technique can be applied to consider different criteria in the decision-making process. Furthermore, it enables the integration of the ESG approach into the decision-making process. In this way, multicriteria analyses, particularly the hierarchical methodology, can evaluate non-stochastic criteria. When applying the AHP method to assess the relative importance of items, weights are assigned based on the understanding of their relevance. For instance, a company with a need for positioning in a zone or scope where sustainability is a significant factor will tend to assign greater weight to items related to emissions/environmental costs compared to another company operating in a short-term scope or where these factors are not considered relevant. The following figure (Figure 2) represents the structure of a multicriteria analysis for the choice of mine access based on different criteria, considering the options: ore hoisting via a vertical shaft, transport through a spiral ramp with electric or diesel trucks, and the use of an inclined belt conveyor (decline).

Figure 2.

Multicriteria Analysis Model for Mine Access/Transportation Selection.

In the analysis, all options are evaluated against all selected criteria, each of which should have specific weights that are then weighted against the scores obtained by the options. One important detail to note is that although there may be a ranking and subsequent scoring for the economic evaluation criterion, resulting in a numerical outcome, in multicriteria analyses of projects, it is common for this criterion to be treated separately (given more weight).

3.2. Application of Traditional AHP for Mine Acess Selection

In the traditional analytic hierarchy process (AHP), pairwise comparisons of options are conducted for each criterion selected. The comparisons were carried out based on the proposed values by Cardozo [6], as shown in Table 3, Table 4, Table 5, Table 6 and Table 7, to establish a weighting system. Local priority for each option in the comparison matrix was determined as the mean value of the corresponding option row in a normalized version of the matrix. The normalized matrix is obtained by dividing each value in the comparison matrix by the sum of its respective column. The hierarchy derived from these comparisons is used for further decision-making processes.

Table 3.

Pairwise Comparison Matrix for the Flowchart Criteria.

Table 4.

Pairwise Comparison Matrix for the “Economic Evaluation” Criteria.

Table 5.

Pairwise Comparison Matrix for the “Energetic Risk” Criteria.

Table 6.

Pairwise Comparison Matrix for the “Emissions/Environmental Cost” Criteria.

Table 7.

Pairwise Comparison Matrix for the “Social” Criteria.

Banda [31] emphasizes the need for decision-makers to be professionals linked to the area. In the case of mining projects, it is recommended that the decision-makers are mining engineers, geologists, mining production engineers, managers, and directors, among others. In the example, the weights were discussed by the authors.

Considering the available and established information for the synthetic project, a pairwise comparison of the criteria was established. Table 8 below presents the decisions made to define the priority vector.

Table 8.

Normalized Criteria Matrix.

The process of analyzing the consistence of pairwise comparison was conducted in each matrix presented above. To achieve this, the procedure proposed by Saaty was utilized and the maximum eigenvalue ( ) of each matrix was calculated from Equation (3), where w is the local priority vector and A is the pairwise comparison matrix.

To obtain the Consistency Index (CI) of the matrices, Equation (4) was utilized, where n is the order of the matrix A.

None of the comparisons should have a Consistence Ratio (CR), higher than 0.1 (10%), which is the ratio of the matrix’s CI in relation to the RI index (CI/RI) proposed by Saaty for the matrix dimensions. The CR values obtained for Table 3, Table 4, Table 5, Table 6, Table 7 and Table 8 were 0.06, 0.05, 0.09, 0.01, 0.07 and 0.03, respectively.

Finally, by crossing the local priorities of the options with the criterion priority vector, the global priority vector of the options is obtained. It is observed that, for the example at hand, the global priority is achieved by the option of ramp by diesel truck, closely followed by the option of ramp by electric truck, as presented in Table 9.

Table 9.

Local Priorities Matrix and Global Priorities.

3.3. Application of MAHP for Access Selection

For the execution of the MAHP methodology, the previously presented proposal was utilized. The priority of criteria already defined in the traditional AHP (Table 9) was used, applying variability to the normalized priority vector. For considering the variability, normal distributions were chosen, and the limits suggested by Banda [32] from Table 10 were adopted, assuming these as the standard deviation for the criteria. The @Risk 8 software, by Palisade Help Resources, was employed for the operationalization of the Monte Carlo simulation, simulating 5000 scenarios. It is worth noting that the larger the number of simulations, the smaller the error associated with the analysis, as indicated by Silva, F. [33].

Table 10.

Suggestions of Weights Assigned per Criterion and Possible Range of Variations.

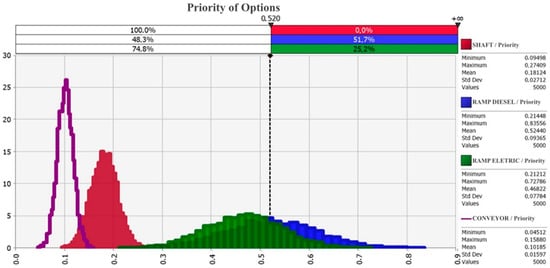

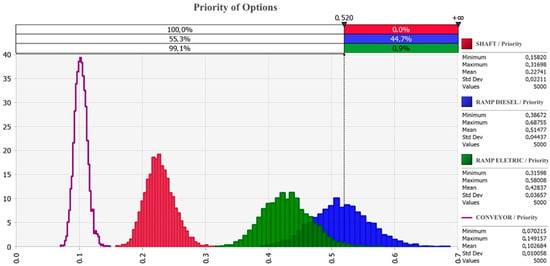

Figure 3 presents the results of the simulations of the priorities of the access and transport options. It is observable that the option of a ramp for diesel trucks remains the global priority over the others. It is noteworthy that in the probabilistic analysis, there are scenarios where the option for electric trucks presents a higher priority than the others. It is noticeable that the distributions of scenarios between the options for diesel and electric trucks are partially overlapping.

Figure 3.

Distributions of priorities presented in the Monte Carlo simulation by normal distribution.

It is worth noting the dispersion of the results, which is graphically expressed in the histograms and numerically in the standard deviations (a measure of variation) of the simulated values of each option.

Table 11 presents the statistical summary of the simulation compared to the deterministic priorities estimated by the traditional AHP. It is notable that due to the choice of using normal distributions in the priority vector of the criteria, the mean of the output distributions tended toward the deterministic value. However, it is observable that the differences in the standard deviations and subsequently in the coefficients of variation (the ratio between the standard deviation and the mean) presented by each option, which are relevant.

Table 11.

Summary of Global Priorities by MAHP (normal distribution) and statistics.

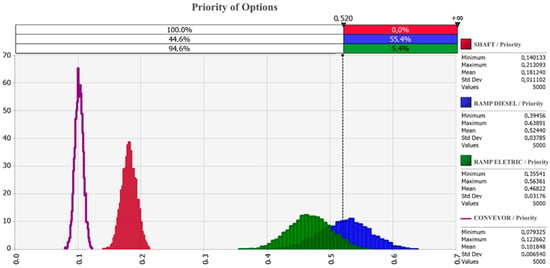

Figure 4 presents the priorities of the access/transport options obtained from the execution of the Monte Carlo simulation by a triangular distribution. It is evident that the option of a ramp for diesel trucks remains the global priority. Similar to the results from the normal distribution, scenarios are observed where the option for electric trucks presents a higher priority than the others. It is evident that the distributions of scenarios between the options for diesel and electric trucks partially overlap.

Figure 4.

Distributions of priorities presented in the Monte Carlo simulation by triangular distribution.

Table 12 presents the statistical summary of the simulation compared to the deterministic priorities estimated by the traditional AHP, as results from the application of the methodology through a triangular distribution. It is noticeable that the differences in the standard deviations and subsequently in the coefficients of variation presented by each option, are significantly lower than those present in Table 11, by the normal distributions. The lower values obtained are related to the characteristics of the distribution’s models.

Table 12.

Summary of Global Priorities by MAHP (triangular distribution) and statistics.

In Figure 5, the variation option is presented, inserted over the weights assigned to each criterion, unlike the previous options where variability was introduced over the local priorities. For this purpose, a triangular distribution was used, as in the previous example. It is observed that in this option, there is a greater divergence between the values of the global priority of the first and second options (with less curve overlap).

Figure 5.

Distributions of priorities presented in the Monte Carlo simulation by triangular distribution on weights.

Table 13 presents the statistical summary of the triangular distribution simulation over the weights, compared to the priorities estimated by the traditional AHP deterministically. Although the overlapping of priorities has diminished, it is noticeable higher values of standard deviation and variation coefficient.

Table 13.

Summary of Global Priorities by MAHP and Statistics, obtained using a triangular distribution on the weights.

4. Conclusions

The application of the AHP methodology with deterministic values indicated that the option of using a ramp as mine access and diesel trucks for ore transport is the preferred choice for the case studied. Thus, its preference did not significantly differ numerically, with a value of 0.524, when compared to the 0.468 obtained by the ramp with electric trucks option. This result has implied the necessity of statistical tools, provided by the assessment of risk analysis, and the consideration of uncertainty with the addition of the Monte Carlo simulation.

The simulations carried out on the case study revealed a preference for the option of access and transportation via ramp and diesel trucks. The second preferred option was the use of a ramp using electric trucks, which showed a lower coefficient of variation dispersion in the simulations. In a scenario where the simulated priorities are similar, the coefficient of variation should be taken into account for decision-making. This suggests choosing the option that presents the lower variability in simulated priority.

Considering the simulations run with different probability distribution models it can be expected that differences occur in the variances of the results. In the example, the probability distributions considered were symmetrical and there were no differences between the priorities simulated. However, with non-symmetrical models, differences in the results would be expected.

The application of the Monte Carlo simulation in the multicriteria evaluation process is feasible for decision-making processes in mining, such as in the case of choosing the type of access. It is observed in the results that although the simulated priorities were virtually identical to the deterministic priorities (traditional AHP), obtaining distributions makes it possible to evaluate and compare the dispersions of the coefficient of variation. In the example, if the options between electric and diesel trucks presented similar priorities, MAHP would indicate the option of a ramp for electric trucks. However, the simulations conducted in different scenarios emphasize the necessity to define the input variability strategy and distribution model.

The simulations carried out indicate that normal distributions showed greater dispersion compared to the option of a triangular distribution. Compared to other applications, there is a similarity to the results and conclusions regarding the applicability in engineering studies and particularly in decision-making during initial stages in mining. It is evident that the quality of the results depends on the input data and the models adopted for simulations. Therefore, the application of MAHP in conceptual and pre-feasibility studies is recommended, even if based on primary data and/or industry estimates, as in the case discussed.

Suggestions for futures research on the application of the AHP and/or MAHP methodologies:

- Explore the adaptation and automation of procedures to enhance practicality for industrial applications.

- Address issues related to pairwise comparisons involving a large quantity of criteria.

- Evaluation of the best distribution model for criteria and weights adopted by stakeholders in the mining sector.

Author Contributions

Conceptualization, F.A.C.C.; methodology, F.A.C.C.; validation, F.A.C.C., H.J.S.C., C.O.P. and W.M.A.; formal analysis, F.A.C.C.; investigation, F.A.C.C.; resources, C.O.P. and W.M.A.; writing—original draft preparation, F.A.C.C. and H.J.S.C.; writing—review and editing, F.A.C.C. and H.J.S.C.; visualization, H.J.S.C.; supervision, C.O.P. and W.M.A.; project administration, F.A.C.C.; funding acquisition, C.O.P. and W.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Brazilian National Council for Scientific and Technological Development, grant number 407796/2022-3.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The authors acknowledge the Federal University of Rio Grande do Sul for the infra-structure and support in carrying out this work, as well as the CNPQ for funding the re-search and its dissemination.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Camm, T.; Stebbins, S. Simplified Cost Models For Underground Mine Evaluation: A Handbook for Quick Prefeasibility Cost Estimates. In Mining Engineering; Montana Tech: Butte, MT, USA, 2023; p. 70. [Google Scholar]

- Nagle, A.J. Aide a l’Estimation des Parametres Economiques d’un Projet Minier dans les Etudes de Prefaisabilite. Ph.D. Thesis, École Nationale Supérieure des Mines de Paris, ENMP, Paris, France, 1988. [Google Scholar]

- O’Hara, T.A.; Suboleski, S.C. Costs and Cost Estimation. In SME Mining Engineering Handbook; Society for Mining Metallurgy and Exploration: Englewood, CO, USA, 1992; Volume 1, pp. 405–424. [Google Scholar]

- Petter, C.; Young, A.; Araújo, V.I.; Cantini, F.; Petter, R.; Oppermann, J.; Fernandez, T.; Darrigo, R.; da Costa, I.G.; Lenz, V.; et al. A Quick Evaluation Tool for CAPEX and OPEX Applied to Mining Operations and ESG Mitigation. In Proceedings of the SME Annual Conference and Expo 2022, Salt Lake City, UT, USA, 27 February–2 March 2022; pp. 307–309. [Google Scholar]

- Martins, M.A.K. Uso da Dinâmica de Sistemas em Projetos de Mineração: Estudo Exploratório Integrando Aspectos Técnicos e não Técnicos. Master’s Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brasil, 2020. [Google Scholar]

- Cardozo, F.A.C. Modelagem de Escavações Subterrâneas: Contribuições para Escolha de Acessos de Mina. Ph.D Thesis, Universidade Federal do Rio Grande do sul, Porto Alegre, RS, Brasil, 2023. [Google Scholar]

- Cardozo, F.A.C.; Petter, C.O.; Cordova, D.P. Risk Analysis by Monte Carlo Simulation in Underground Rock Excavation Projects. DYNA 2022, 89, 24–30. [Google Scholar] [CrossRef]

- Charbel, P.A. Gerenciamento de Risco Aplicado à Diluição de Minério. Ph.D. Thesis, Departamento de Engenharia Civil e Ambiental, Universidade de Brasília, Brasilia, DF, Brasil, 2015. [Google Scholar]

- Vargas, J.P.; Koppe, J.C.; Pérez, S. Monte Carlo Simulation as a Tool for Tunneling Planning. Tunn. Undergr. Space Technol. 2014, 40, 203–209. [Google Scholar] [CrossRef]

- McCarthy, P.L.; Livingstone, R. Shaft or Decline? An Economic Comparison. Open Pit Undergr. Mak. Transit. 1993, 14, 45–56. [Google Scholar]

- Vergne, J.L. Hard Rock Miner’s Handbook, 3rd ed.; Andersen, S.L., Ed.; McIntosh Engineering: Tempe, AZ, USA; North Bay, ON, Canada, 2003; ISBN 0-968006-1-6. [Google Scholar]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Sengani, F. Access to Deposits as a Stage of Mining Works. Energies 2022, 15, 8740. [Google Scholar] [CrossRef]

- Moser, P. Primary Development of Underground Hard Rock Mines. In Proceedings of the Symposium on Mine Planning and Equipment Selection, Sầo Paulo, Brazil, 22–25 October 1996. [Google Scholar]

- Salama, A. Haulage System Optimization for Underground Mines: A Discrete Event Simulation and Mixed Integer Programming Approach. Ph.D. Thesis, Lulea University of Technology, Luleå, Sweden, 2014. [Google Scholar]

- Gonen, A.; Malli, T.; Kose, H. Selection of Ore Transport System for a Metalliferous Underground Mine/Dobór Systemu Transportu Rud w Kopalni Podziemnej Rud Metalu. Arch. Min. Sci. 2012, 57, 779–785. [Google Scholar] [CrossRef]

- Rupprecht, S. Mine Development—Access to Deposit; The Southern African Institute of Mining and Metallurgy: Rosebank, South Africa, 2011. [Google Scholar]

- Elevli, B.; Demerci, A.; Dayi, O. Underground Haulage Selection: Shaft or Ramp for a Small-Scale Underground Mine. J. South. Afr. Inst. Min. Metall. 2002, 102, 255–260. [Google Scholar]

- Cardozo, F.A.C.; Petter, C.O.; Petter, R.A.; de Araújo, V.I.A.B.; de Souza, H.L. Choice of Access for Underground Mining for Feasibility Studies. Int. Eng. J. 2023, 76, 187–193. [Google Scholar] [CrossRef]

- NEXA. MRMR Report; NEXA: Luxembourg, 2021. [Google Scholar]

- Parreiras, R.O. Algoritmos Evolucionários e Técnicas de Tomada de Decisão em Análise Multicritério. Ph.D. Thesis, Universidade Federal de Minas Gerais, Belo Horizonte, MG, Brasil, 2006. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Dahri, N.; Abida, H. Monte Carlo Simulation-Aided Analytical Hierarchy Process (AHP) for Flood Susceptibility Mapping in Gabes Basin (Southeastern Tunisia). Environ. Earth Sci. 2017, 76, 302. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of Application of Analytic Hierarchy Process (AHP) in Construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Marins, C.; Souza, D.; Barros, M. O Uso do Método de Análise Hierárquica (AHP) na Tomada de Decisões Gerenciais—Um Estudo de Caso. In Proceedings of the XLI SBPO 2009—Pesquisa Operacional na Gestão do Conhecimento 2009, Porto Seguro, BA, Brazil, 1–4 September 2009. [Google Scholar]

- Shim, J.P. Bibliographical Research on the Analytic Hierarchy Process (AHP). Socio-Econ. Plan. Sci. 1989, 23, 161–167. [Google Scholar] [CrossRef]

- Ataei, M.; Shahsavany, H.; Mikaeil, R. Monte Carlo Analytic Hierarchy Process (MAHP) Approach to Selection of Optimum Mining Method. Int. J. Min. Sci. Technol. 2013, 23, 573–578. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Jiang, C.Y.; Wu, G.Y.; Liu, Q.Z. Monte Carlo Analytic Hierarchy Process for Selection of the Longwall Mining Method in Thin Coal Seams. J. South. Afr. Inst. Min. Metall. 2019, 119, 1005–1012. [Google Scholar]

- Namin, F.S.; Ghadi, A.; Saki, F. A Literature Review of Multi Criteria Decision-Making (MCDM) towards Mining Method Selection (MMS). Resour. Policy 2022, 77, 102676. [Google Scholar] [CrossRef]

- Hauser, D.; Tadikamalla, P. The Analytic Hierarchy Process in an Uncertain Environment: A Simulation Approach. Eur. J. Oper. Res. 1996, 91, 27–37. [Google Scholar] [CrossRef]

- Bañuelas, R.; Antony, J. Application of Stochastic Analytic Hierarchy Process within a Domestic Appliance Manufacturer. J. Oper. Res. Soc. 2007, 58, 29–38. [Google Scholar] [CrossRef]

- Banda, W. A Fuzzy Techno-Financial Methodology for Selecting an Optimal Mining Method. Nat. Resour. Res. 2020, 29, 3047–3067. [Google Scholar] [CrossRef]

- Banda, W. An Integrated Framework Comprising of AHP, Expert Questionnaire Survey and Sensitivity Analysis for Risk Assessment in Mining Projects. Int. J. Manag. Sci. Eng. Manag. 2019, 14, 180–192. [Google Scholar] [CrossRef]

- Silva, F.M.P. Da Aperfeiçoando Decisões de Investimento em Condições de Risco com uso de Método de Monte Carlo: Análise da Infraestrutura Urbana. Master’s Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brasil, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).