Abstract

Textile wastewater is a challenging area for treatment by membrane separation technology due to its complex structure and the presence of reactive components. Therefore, most of the conventional technologies appear incapable of offering satisfactory treatment for the effluents. This paper studies the application of activated carbon, carbon nanotubes, and graphene oxide base polymeric nanofiltration membranes (NF) in the textile industry, which usually produces large volumes of wastewater containing complex contaminants from its daily operation. Hence, it is accepted that NF membranes offer solutions to the problem. The primary performances of NF membranes have been examined in terms of dye rejection, salt rejection, permeate flux, and COD rejection. Some of the NF membranes achieved maximum separation of dye and salts while some attained higher flux. This is due to the large variability of the parameters of textile wastewater and the NF membranes selected. However, for all these attempts, the general issue of (bio)fouling represents a key barrier to full-scale industrial implementation. The low fouling tendency of NF membranes has lately gained substantial attention since they are an exciting addition to conventional technologies (i.e., adsorption, biological degradation, coagulation, and ultrafiltration). Polymers membrane blended with oxidized activated carbon, carbon nanotubes, and graphene oxide increased hydrophilicity, textile dyes, slat rejection, BSA rejection, antibacterial activity, and water flux enhancement from 60% to 100%. We present some nanocomposite membrane developments and demonstrate how they can be used to reduce textile dyes. In addition, the process of membrane fouling and the various approaches for preventing and controlling fouling are discussed.

1. Introduction

In all facets of life on Earth, water is a vital resource. Although water covers around 71 percent of the Earth’s surface, the majority of the water on the planet is salt water stored in the oceans. Freshwater makes up 2.5 percent of the total water volume, with just 0.3 percent of that in liquid form on the surface [1]. According to a recent UN water study, an estimated 3.6 billion people (almost half of the world’s population) live in locations where water is potentially scarce for at least one month every year [2]. According to a World Bank report, the textile sector contributes 20% of the wastewater produced by all industries of the world [3]. The textile sector is among those with the greatest water consumption rates, as it utilizes 230 to 270 tons of water to process one ton of product [4]. Hazardous chemicals, non-degradable organic compounds, surfactants, and salts are all included in the wastewater produced by finishing procedures. Additionally, this wastewater typically has high levels of total dissolved solids (TDS) and chemical oxygen demand (COD). The applicable techniques for treating textile wastewaters are physical (adsorption, ion exchange, and membrane processes), chemical (coagulation, electrocoagulation, and oxidation), and biological (aerobic and anaerobic) processes [5]. To eliminate dyes using membrane technology, several studies have been conducted. Since membranes’ small pore diameters can remove dye chemicals and release high-quality effluent, they are one of the best options for treating textile dye wastewater [6].

The main purposes of this review are: (i) to investigate the membrane technology for the treatment of textile wastewater, (ii) to examine the effect of AC, CNTs, and GO for filtration and fouling control process, and (iii) to highlight the needs for future research based on the current studies.

1.1. Current Water Treatment Capabilities

Membrane technology provides up to 53% of the world’s clean water production operations and is an effective water treatment method [7]. With the development of polymeric materials, water treatment technology has progressed substantially over the previous century [8]. Micro-, ultra-, and nanofiltration, as well as reverse osmosis, are all powered by hydraulic pressure, which drives water through the pores of the membrane, leaving the other constituents in the retentate behind. The type of membranes used in these procedures is determined by the pore size range and species selectivity of the membranes as shown in Figure 1 [9,10].

Figure 1.

Classification of membranes with regards to pore size.

1.2. Membrane Fabrication Methods

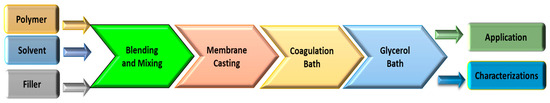

Although cellulose acetate (CA) was initially used as the casting solution when it was first invented by Loeb and Sourirajan in the 1960s [11], it may also be used with other polymers that can be dissolved into homogenous solutions. A polymer, a solvent, and a coagulation medium are the only three components typically needed for the phase inversion process (or non-solvent). Figure 2 illustrates the fabrication of a polymer membrane using the phase inversion method.

Figure 2.

Steps involved in the phase inversion method of membrane fabrication.

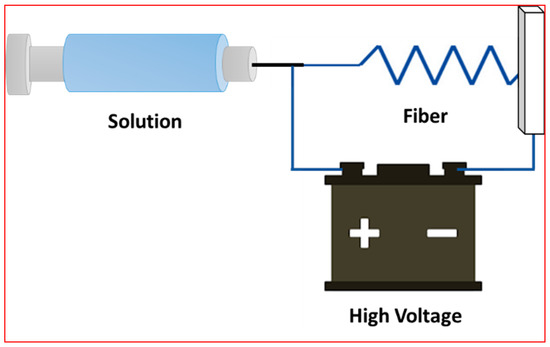

Another process, called “electrostatic spinning”, is a quick way to make nanofibers from a variety of polymeric materials for use in a variety of applications. First, the required material (such as PVDF) is introduced into the spinneret as a solution or melt (normally a syringe with a metallic needle attached). Next, voltage is applied across the conductive collector and spinneret (typically in the range of 10–40 kV) as shown in Figure 3. Once the solution is immediately drawn into microscopic fiber using a pump, it is quickly injected into the syringe and travels through the electric field from the spinneret to the collector Deposition of fibers on a grounded collector is the last step in the electrospinning process [12].

Figure 3.

Electrostatic spinning setup for membrane preparation.

1.3. Membrane Fouling

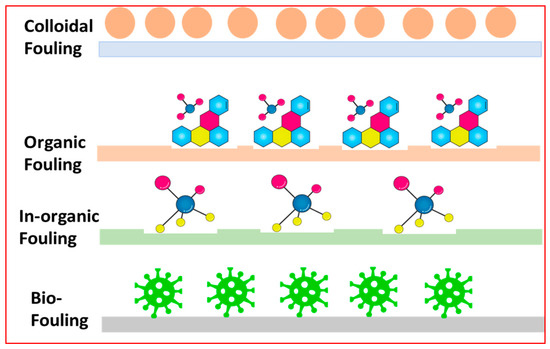

Membrane fouling has been a barrier in membrane water treatment technology since its inception, limiting process efficiency by reducing water permeation flux, degrading product water quality, and increasing energy usage. As per Figure 4, membrane fouling can be brought on by biological fouling, organic adsorption, cake formation, inorganic precipitation, pore-clogging, and other processes that all have the potential to temporarily or permanently reduce flow [13].

Figure 4.

Types of fouling in a water filtration membrane.

2. Carbon-Based Materials for Filtration

A series of carbon-based nanomaterials (CBNs) are cytotoxic to bacteria due to their distinct physicochemical characteristics, such as carbon nanotubes (CNTs) and graphene-based nanomaterials (GO), which in particular exhibit exceptional bacterial cytotoxicity [14]. The most common commercial adsorbent, activated carbon, is a porous substance with a large surface area. Because of the large surface area, the adsorption capacity of chemicals from gases and liquids is very high [15].

Meghmik et al. [16] prepared polysulfone-highly uniform activated carbon spherical mixed-matrix membranes by use of the wet casting of an ultrasonication-assisted dispersion with AC concentrations ranging from 0.5, 1, 3, and 7% with regards to the PSF weight. In comparison to the pristine membrane, the produced membrane (containing 7% AC) had considerably improved antifouling performance, with flux recovery ratios of 90%, dye rejection of 91.13%, and water flux increase of 209.84%.

Yasin et al. found that when mesoporous carbon nano-composite polyethersulfone membranes with 0.20 wt percent MCNs were synthesized, a strong antibacterial ability and protein rejection were reported. Mesoporous carbon PES nano-composite membranes showed higher water flow, hydrophilicity, and antibacterial activity.

Carbon nanotubes were synthesized using a novel approach by M. Mohammed et al. [17], who functionalized them with an OH group, purified them, and employed them as an adsorption medium to remove colors from wastewater. In the elimination of contaminants, the effects of pH, contact duration, CNT dose, and dye concentration were investigated. The removal effectiveness of textile colors was inversely proportional to dye concentration and directly related to contact duration, CNT concentration, and pH.

Tiraferri et al. [18] created a single-walled carbon nanotube composite with polyamide (PA) and found that it had a strong antibacterial action and a 60% reduction in bacterial adhesion. Yun et al. [19] studied the increased hydrophilicity, BSA rejection, and water flow from 60% to 100% in a polysulfone (PS) membrane mixed with oxidized CNTs.

To purify artificial wastewater, S. Leaper et al. [20] examined the efficacy of PVDF mixed-matrix membranes integrating graphene oxide and GO functionalized with Aminopropyl-triethoxysilane (APTS). The surface porosity and mean pore size were found to be greatly enhanced by the addition of very small volumes. The highest-performing membranes overall produced flux improvements of 52% and 86% for GO and GO-APTS membranes, respectively, above the pure PVDF membrane. Due to increased hydrophilicity and greater pore size at higher loading concentrations, the GO membrane’s rejection performance somewhat decreased. It was shown that during the phase inversion process, the interactions between the nanofiller and the polymer solution accelerated the rate of inter-diffusion between the solvent and non-solvent. As a result, a structure with high porosity develops, leading to greater flux values.

Later on, S. Leaper et al. [21] investigated the impact of reduced graphene oxide with various degrees of reduction on membrane structure and performance. The observed flux increased from 6.4 to 7 LMH when the carbon to oxygen (C/O) ratio of the GO flakes increased from 2.30 (for GO) to 5.45 (for rGO). However, the flow decreased to 3.9 LMH at a greater level of reduction (C/O = 7.36), showing less favorable pore-forming properties with the further elimination of the oxygen functions. It has been shown in some instances that the pore-forming behavior of GO materials enhances the membranes’ porosity and pore structure while simultaneously enhancing their mechanical properties. The high strength of the nanomaterial and its successful interaction with the matrix material are responsible for this.

3. Conclusions

This review paper concentrated on using membrane technology to treat textile effluent and address the issue of water scarcity. Fouling and biofouling are two major issues with membranes that can be mitigated by the creation of polymer-nanocomposite membranes. The technology of phase inversion is frequently used to cast membranes from several new carbon-based nanomaterials. In comparison to bare membranes, nanocomposite membranes perform better overall. The size, shape, surface qualities, and composition of nanoparticles, as well as the kind of polymers used, have a significant influence on the ultimate performance of nanocomposite membranes. According to the literature, there is an ideal concentration of nanoparticles and membrane materials for each combination of nanoparticles and polymeric membrane materials. Higher nanofiller concentrations do not always imply improved performance. To attain the best results, detailed experimental evaluations of particular combinations of nanoparticles and polymeric membranes are always required. Nanocomposite membranes’ long-term stability and performance are yet unknown. Furthermore, the scaling-up of nanocomposite membrane production has not been well examined. Nanocomposite membranes will benefit tremendously from advances in mechanistic knowledge of nanoparticle polymer matrix interactions and scalable fabrication. For various applications, future efforts should focus on building more stable, high-performing, and scalable nanocomposite membranes.

Author Contributions

Conceptualization, I.A.K.; methodology, I.A.K.; writing—original draft preparation and writing, I.A.K.; review and supervision; N.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Higher Education Commission (HEC) of Pakistan, under NRPU Project # 6020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

School of Chemical and Materials Engineering (SCME), National University of Sciences and Technology (NUST), H-12 Sector, Islamabad 44000, Pakistan.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mekonnen, M.; Hoekstra, A.Y. Sustainability: Four billion people facing severe water scarcity. Sci. Adv. 2016, 2, e1500323. [Google Scholar] [CrossRef] [PubMed]

- Brusseau, M.L.; Ramirez-Andreotta, M.; Pepper, I.L.; Maximillian, J. Environmental Impacts on Human Health and Well-Being, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128147191. [Google Scholar]

- Tavangar, T.; Jalali, K.; Alaei Shahmirzadi, M.A.; Karimi, M. Toward real textile wastewater treatment: Membrane fouling control and effective fractionation of dyes/inorganic salts using a hybrid electrocoagulation—Nanofiltration process. Sep. Purif. Technol. 2019, 216, 115–125. [Google Scholar] [CrossRef]

- Tahri, N.; Masmoudi, G.; Ellouze, E.; Jrad, A.; Drogui, P.; Ben Amar, R. Coupling microfiltration and nanofiltration processes for the treatment at source of dyeing-containing effluent. J. Clean. Prod. 2012, 33, 226–235. [Google Scholar] [CrossRef]

- Keskin, B.; Ersahin, M.E.; Ozgun, H.; Koyuncu, I. Pilot and full-scale applications of membrane processes for textile wastewater treatment: A critical review. J. Water Process Eng. 2021, 42, 102172. [Google Scholar] [CrossRef]

- Keskin, B.; Ağtaş, M.; Ormancı-Acar, T.; Türken, T.; Imer, D.Y.; Ünal, S.; Menceloğlu, Y.Z.; Uçar-Demir, T.; Koyuncu, I. Halloysite nanotube blended nanocomposite ultrafiltration membranes for reactive dye removal. Water Sci. Technol. 2021, 83, 271–283. [Google Scholar] [CrossRef] [PubMed]

- Obotey Ezugbe, E.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes 2020, 10, 89. [Google Scholar] [CrossRef] [PubMed]

- Kyzas, G.Z.; Mitropoulos, A.C. Polymeric Materials for Water and Wastewater Management. Polymers 2021, 13, 168. [Google Scholar] [CrossRef] [PubMed]

- Baker, R.W. Membrane Technology Enhanced Reader, 3rd ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Kochkodan, V.; Johnson, D.J.; Hilal, N. Polymeric membranes: Surface modification for minimizing (bio)colloidal fouling. Adv. Colloid Interface Sci. 2014, 206, 116–140. [Google Scholar] [CrossRef] [PubMed]

- Strathmann, H. The Formation Mechanism of Phase Inversion Membranes. Desalination 1977, 21, 241–255. [Google Scholar] [CrossRef]

- Yu, F.; Shi, H.; Shi, J.; Teng, K.; Xu, Z.; Qian, X. High-performance forward osmosis membrane with ultra-fast water transport channel and ultra-thin polyamide layer. J. Memb. Sci. 2020, 616, 118611. [Google Scholar] [CrossRef]

- Kochkodan, V.; Hilal, N. A comprehensive review on surface modified polymer membranes for biofouling mitigation. Desalination 2015, 356, 187–207. [Google Scholar] [CrossRef]

- Francois, P.; Andreia, F.; Menachem, E. Antimicrobial Properties of Graphene Oxide Nanosheets Why Size Matters. ACS Nano 2015, 9, 7226–7236. [Google Scholar] [CrossRef]

- Li, Z.; Hanafy, H.; Zhang, L.; Sellaoui, L.; Schadeck Netto, M.; Oliveira, M.L.S.; Seliem, M.K.; Luiz Dotto, G.; Bonilla-Petriciolet, A.; Li, Q. Adsorption of congo red and methylene blue dyes on an ashitaba waste and a walnut shell-based activated carbon from aqueous solutions: Experiments, characterization and physical interpretations. Chem. Eng. J. 2020, 388, 124263. [Google Scholar] [CrossRef]

- Manoukian, M.; Fashandi, H.; Tavakol, H. Polysulfone-highly uniform activated carbon sphere mixed-matrix membrane intended for efficient purification of dye wastewater. Mater. Res. Express 2019, 6, 055313. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Abdul Razak, A.A.; Hussein Al-Timimi, D.A. Modified multiwalled carbon nanotubes for treatment of some organic dyes in wastewater. Adv. Mater. Sci. Eng. 2014, 2014, 201052. [Google Scholar] [CrossRef]

- Tiraferri, A.; Vecitis, C.D.; Elimelech, M. Covalent binding of single-walled carbon nanotubes to polyamide membranes for antimicrobial surface properties. ACS Appl. Mater. Interfaces 2011, 3, 2869–2877. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.X.; Gao, Y.; Yang, C.; Wang, Z.Q.; Xue, G. Facile and controllable assembly of multiwalled carbon nanotubes on polystyrene microspheres. Chin. J. Polym. Sci. Engl. Ed. 2014, 32, 711–717. [Google Scholar] [CrossRef]

- Leaper, S.; Abdel-Karim, A.; Faki, B.; Luque-Alled, J.M.; Alberto, M.; Vijayaraghavan, A.; Holmes, S.M.; Szekely, G.; Badawy, M.I.; Shokri, N.; et al. Flux-enhanced PVDF mixed matrix membranes incorporating APTS-functionalized graphene oxide for membrane distillation. J. Memb. Sci. 2018, 554, 309–323. [Google Scholar] [CrossRef]

- Leaper, S.; Abdel-Karim, A.; Gorgojo, P. The use of carbon nanomaterials in membrane distillation membranes: A review. Front. Chem. Sci. Eng. 2021, 15, 755–774. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).