Abstract

The area of the old arsenopyrites concentrate storage area is located at the Olympias Mining Facilities. The area was formed in the 1970s as a temporary storage area for the produced concentrate of gold-bearing arsenopyrite of Olympias. The total area is 11 hectares, and in the 1980s, the concentrate was removed from the site and arsenopyrite residues, which remained on the deforested surface, were major sources of pollution of the surface and ground waters of the wider area. The remediation and restoration works of this area were initiated by Hellas Gold as a priority immediately after taking over the Kassandra Mines property. After the restoration of the area, a nursery was installed with more than 1,000,000 plants.

1. Introduction

The primary objective of environmental rehabilitation in mining areas is to restore the capacity of the soil to support life and to rebuild ecosystem function and environmental value (in economic, social, leisure and aesthetic terms). That restoration is primarily achieved through remediation of contaminated soils, by maintaining water quality, by integrating disturbed areas into the landscape and by creating self-sustaining ecosystems that ensure the sustainability of areas where mining activity has been carried out or is being carried out [1,2].

Contrary to what happened in the past, in modern times, planning to rehabilitate the environment in mining areas is an integral part of any business plan [3,4]. In an attempt to achieve sustainability and in line with the permitting terms and conditions for mining operations, mining undertakings are now implementing policies and programmes to improve socio-economic conditions, the environment and the development of the areas in which they operate [5]. These actions seek to drastically reduce the impacts of mining activities and to rehabilitate degraded soils while also helping to define the most suitable post-mining land uses and conditions required for them.

The design criteria for the restoration of a mining site are: the principle of creating stable ecological conditions and ensuring the development of the new biocommunity; the principle of chemical stability by using additional materials as soil improvers; the principle of protecting public health and the safety of people and the health of ecosystems in the area; and the principle of creating new stable geotechnical conditions through environmentally-friendly interventions.

The purpose of this paper is to outline the methodology for the restoration of an old arsenopyrites concentrate storage area at the Olympias Mining Facilities (the former METBA plot) and to evaluate the effectiveness of the project.

2. Materials and Methods

2.1. Study Area

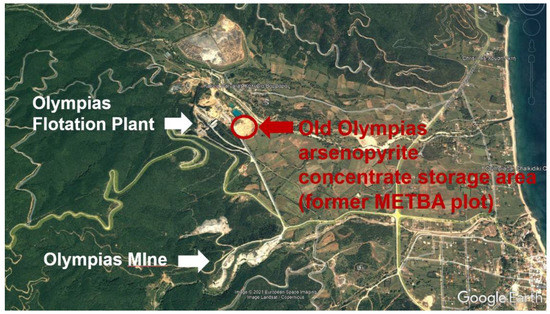

The area of the old arsenopyrites concentrate storage area (former METBA plot) is located within the Olympias Mining Facilities and, in particular, on the plot of the existing flotation plant (Figure 1). In the 1970s, the site was developed by the then mining company Hellenic Chemicals and Fertilisers Co. S.A. as a temporary storage area for the Olympias gold-bearing arsenopyrites concentrate, which was being produced, and was intended to be used in the future to recover the contained gold. In the mid-1980s, the concentrate was removed from the site in order to install the gold metallurgy plant planned at that time by Aegean Metallurgy Industries (METBA).

Figure 1.

Old arsenopyrites concentrate storage area (former METBA plot) at Olympias, Halkidiki (2004).

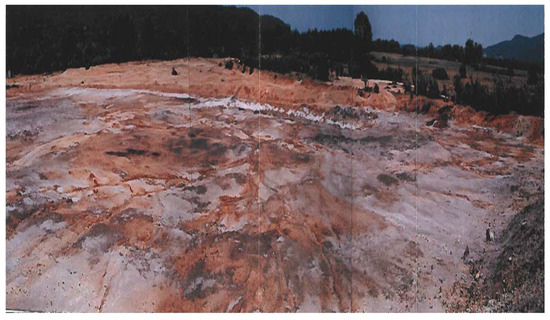

The area covers a total of 11 hectares and is located within the alluvial sediments of the Mavrolakkas creek. Pockets of arsenopyrites concentrate and its oxidised residues that remained on the deforested surface were major sources of pollution of surface and ground waters in the area for decades. The products of arsenopyrites oxidation were dissolved during periods of intense rainfall by the rainwater, which resulted in acid mine drainage generation with high concentrations of heavy metals (AMD run-off). Figure 2 shows the previous condition of the area where the pockets of the remaining arsenopyrites and its oxidised products can be distinguished.

Figure 2.

Old arsenopyrites concentrate storage area (former METBA plot).

2.2. Quantitative and Quality Characteristics of the Old Arsenopyrites Concentrate Storage Area

After the removal of the arsenopyrites stockpile, residues and contaminated soils were left of the surface, which were degrading the area. In order to determine the level of pollution in the area, surface soil samples from the storage area were collected using trenches up to 2 m deep on a 50 m × 50 m grid. Figure 3 shows the locations of the trenches, and Figure 4 shows indicative photographs of trenches in the area before cleaning and remediation.

Figure 3.

Soil sampling grid at the old arsenopyrites concentrate storage area (former METBA plot) before remediation.

Figure 4.

Indicative trenches at the old arsenopyrites concentrate storage area (former the METBA plot) before remediation.

The results of chemical analyses of the soil samples are summarised in Table 1. For the sake of comparison, the same table also shows the reference values for soil quality in the wider Olympias area upstream and outside the mining facilities, which were used to determine the necessity and depth of soil remediation, and in taking measures to reduce the solubility of metals and metallic minerals in the soil.

Table 1.

Heavy metal content of surface soil samples from the old arsenopyrites concentrate storage area (former METBA plot) before remediation (mg/kg).

In addition, soil samples were tested to determine the acid generation potential using the ABA method and leachability tests in line with Directive 2003/33/EC; the results are summarised in Table 2 and Table 3.

Table 2.

Acid generation potential. Acid Base Accounting (ABA) tests for the soil samples from the old arsenopyrites concentrate storage area (former METBA plot) before remediation.

Table 3.

Leachability of metals in the soil samples from the old arsenopyrites concentrate storage area (former METBA plot) before remediation (mg/kg).

Lastly, as part of the environmental monitoring programme, samples of surface run-off from the specific area were taken, and the results of chemical analyses are summarised in Table 4.

Table 4.

Chemical analysis of run-off water from the old arsenopyrites concentrate storage area (mg/L).

From the above data, it is shown that the soil in the area of the old storage area contains significant quantities of arsenic due to the arsenopyrites residues, which remained on the surface after the stockpile was removed. The S content is high and has a high acid generation potential (NNP < 0). The relatively high S(SO4) content and the very low pH indicate that oxidation and acid generation had begun, which is confirmed by the quality of run-off in the area during periods of intense rainfall. Lastly, As and Zn levels in the samples exceed the limits for disposing of in non-hazardous waste disposal facilities.

Restoration of this area was essential to achieve environmental improvements in the wider area around the Olympias mining facilities. Hellas Gold planned the restoration works in the area as a matter of priority.

3. Determination of Depth of Remediation

Based on chemical analyses of the soil samples, it was determined that the minimum excavation depth for soil remediation purposes was on average 50 cm, while in locations it was up to 1.3 m.

4. Rehabilitation Design

The measures designed to rehabilitate the area included four phases: removal of contaminated soil (remediation), the addition of soil improvers (lime), the addition of soil and finally the creation of a nursery.

4.1. Remediation of the Site

As part of the first phase, the contaminated surface layer was removed from the site that had been used as a storage area. The soil was removed to a depth of 50 cm so that the remaining soil would have metal concentrations below background values. In cases where arsenopyrites were found at greater depths, excavation continued until all material was removed. After the removal of the contaminated soil, a new soil sample was taken in order to characterise the remaining soil (Figure 5).

Figure 5.

Indicative soil trenches after remediation of the old arsenopyrites concentrate storage area (former METBA plot).

The total quantity of arsenopyrites concentrate and contaminated soil removed from the area was 120,000 tonnes. Materials from cleaning the site were initially disposed of in the nearby area of the Olympias old arsenopyrites concentrate stockpiles, and all those materials that were not used were transported for final disposal to the Kokkinolakkas extractive waste management facility, which is Category A. That means that the contaminated materials were disposed of in a tailings management facility designed properly for the environmentally safe disposal of hazardous wastes (Directive 2006/21/EC on the management of waste from the extractive industries, Annex III). The site was then re-landscaped and laid out to ensure a uniform gradient.

4.2. Addition of Soil Improvers (Limestone)

As part of the second phase, after the removal of arsenopyrite residues and contaminated soils, limestone with a granularity of 8 to 16 mm was laid as a soil improver to prevent any AMD generation and ensure the effectiveness of the remediation. Lime was laid in a layer 10 cm thick, and the total quantity laid was 10,000 m3. This was followed by ploughing of the surface to mix the lime into the topsoil.

4.3. Addition of Soil

As part of the third phase, the entire area was laid with clean soil in a layer 40 cm thick, and the area was landscaped to restore the original terrain. The soil used to lay the site came from a topsoil borrow pit in the area. In order to check the suitability of these healthy soils, samples were collected for chemical analysis, the results of which are shown in Table 5 below. The same table also shows the soil reference values for the wider Olympias area.

Table 5.

Chemical analysis of soil used to cover the site after remediation (ppm).

The analyses showed that the specific soil samples meet the specifications laid down for the soils in the wider Olympias area and consequently can be used safely to rehabilitate the area.

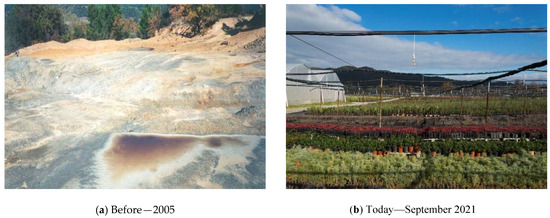

4.4. Creation of a Nursery

Immediately after the site was rehabilitated, a nursery facility with more than 1 million plants was set up (see Figure 6). The nursery is one of the largest in Greece and produces 320 different species of forest and ornamental plants, covering the need for local flora species for all Hellas Gold’s rehabilitation projects and supporting local stakeholders. The seeds are collected from the surrounding area, and after proper handling, young saplings are grown that are then used in rehabilitation works. All categories of plants are suitable for the climatic conditions in the wider area. Moreover, the nursery also implements controlled irrigation and fertilisation programmes during the growing period, taking all necessary protective measures daily to ensure problem-free operation. In the context of maximising recycling and sustainable operation of the mining facilities, nursery plants are irrigated exclusively using water pumped from the Olympias underground mine after it is treated. At the same time, around 20 new jobs have been created, thereby bolstering economic activity in the area.

Figure 6.

Restoration of the old arsenopyrites concentrate storage area (formerly METBA plot).

5. Measurements—Monitoring

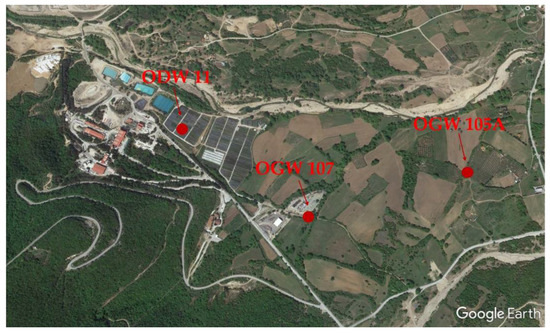

In order to check the effectiveness of remediation and restoration work at the old Olympias arsenopyrites concentrate storage area (former METBA plot), a network of ground-water monitoring stations has been established in the immediate area (Figure 7). Every month at each monitoring piezometer the aquifer level is measured, and a sample of water is taken, on which full analyses of physico-chemical properties and heavy metals are carried out.

Figure 7.

Monitoring of ground waters in the immediate area of the old Olympias arsenopyrites concentrate storage area (former METBA plot).

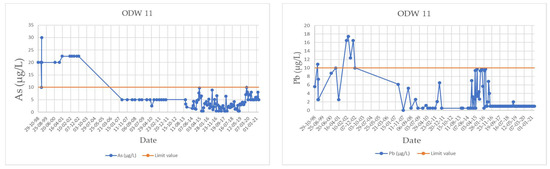

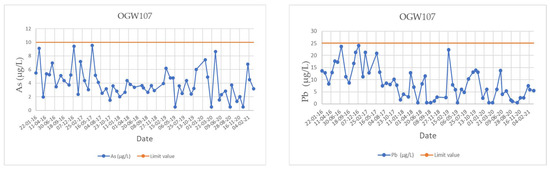

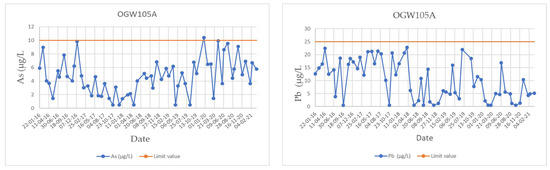

Figure 8, Figure 9 and Figure 10 show the long-term concentration of As and Pb at the sampling location ODW11 located within the nursery area and the locations OGW107 and OGW105A situated 250 and 750 m, respectively, downstream from the old Olympias arsenopyrites concentrate storage area (former METBA plot).

Figure 8.

As and Pb in the ground waters vs. time within the old Olympias arsenopyrites concentrate storage area (ODW11 monitoring station).

Figure 9.

As and Pb in ground waters vs. time 250 m downstream from the old Olympias arsenopyrites concentrate storage area (OGW107 monitoring station).

Figure 10.

As and Pb in ground waters vs. time 750 m downstream of the old Olympias arsenopyrites concentrate storage area (OGW105A monitoring station).

The above data demonstrate that there is a clear reduction in the concentration of metals in ground waters within the old storage area and downstream from it, with concentrations systematically in compliance with the legislative environmental quality limits.

6. Conclusions

The objective of this project is the environmental restoration of an old arsenopyrites concentrate storage area at the Olympias Mining Facilities (the former METBA plot). It was an open-air temporary storage area for the Olympias gold-bearing arsenopyrites concentrate formed in the 1970s by the Hellenic Chemicals and Fertilisers Co. S.A., and due to the arsenopyrites, oxidised residues were a major source of pollution of surface and ground waters in the area for decades.

Hellas Gold, immediately after the acquisition of the Kassandra Mines, proceeded with priority to the restoration of the above old storage area. The methodology applied includes the total removal of the old arsenopyrite concentrate remnants and the contaminated soils followed by limestone gravel addition on the released surface as a soil improver, and finally, the addition of a clean soil layer to reconstruct the original relief of the area. On the restored surface, a nursery facility was set up to cover the need for local flora species for all Hellas Gold’s rehabilitation projects, supporting local stakeholders and creating new jobs.

The effectiveness of the restoration project is confirmed by the results of ground water monitoring program carried out in the area through a network of piezometers installed inside and downstream of the project. The monitoring data demonstrate a significant reduction of the heavy metals’ concentration in the ground waters inside the project area immediately after the completion of the restoration project and the subsequent continuous compliance of the ground waters both inside and downstream of the project area, with the legislative environmental quality standards.

In conclusion, the restoration of the old Olympias arsenopyrites concentrate-storage area contributed to the improvement and protection of the environment while also enabling it to be utilised to host new production activities.

Author Contributions

Conceptualization: V.G. and D.D.; Methodology: V.G.; Validation: D.D.; Formal analysis: A.G.; Investigation: V.G., A.G.; Data curation: V.G. and A.G.; Writing—original draft preparation: A.G.; Writing—review and editing: V.G. and D.D.; Visualization: D.D.; Supervision: V.G.; Project administration: V.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The results of the measurements—monitoring are available on Hellas Gold website, https://environmental.hellas-gold.com/ (23 August 2021).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heikkinen, P.M.; Noras, P.; Salminen, R. Mine Closure Handbook: Environmental Techniques for the Extractive Industries; Vammalan Kirjapaino Oy: Espoo, Finland, 2008. [Google Scholar]

- Ranängen, H.; Lindman, A. A path towards sustainability for the Nordic mining industry. J. Clean. Prod. 2017, 151, 43–52. [Google Scholar] [CrossRef]

- Warhurst, A.; Noronha, L. Corporate strategy and viable future land use: Planning for closure from the outset of mining. In Natural Resources Forum; Wiley Online Library: Hoboken, NJ, USA, 2000. [Google Scholar]

- McKenna, G. Sustainable Mine Reclamation and Landscape Engineering. Ph.D. Dissertation, University of Alberta, Edmonton, AB, Canada, 2002. [Google Scholar]

- Hilson, G.; Murck, B. Sustainable development in the mining industry: Clarifying the corporate perspective. Resour. Policy 2000, 26, 227–238. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).