Abstract

In an increasingly digitized environment, the deterioration of cell phone cables has led to a significant environmental impact due to the lack of adequate protection and care. This often results in cell phone charging cables being in poor condition. Cable damage can include situations such as dirt accumulation or incorrect bending, leading to breakage. As a result, the objective was determined to design a prototype of a cell phone holder with internal biodegradable cable winding. Ulrich and Eppinger served as the methodological basis for the design, following phases including customer needs identification, setting objective values, product concept generation, concept selection, concept testing, and final specification filtering. A survey of 100 individuals provided valuable data for validating certain metrics. Additionally, two focus groups with 15 users were conducted, two experts were interviewed, and a 72 h usage test was carried out, all supported by the agile Scrum methodology and the Scamper technique, allowing for feedback and validation of the initial concept. The final prototype was modeled in 3D using the Lumion 11 program and physically constructed, ensuring functionality and adaptability of the cell phone and charger. In conclusion, a cell phone holder with a cable winder was designed, facilitating easy transport and prolonging the lifespan of any charger cable.

1. Introduction

In a world where connectivity and mobility have become fundamental pillars of modern life, mobile devices have positioned themselves as indispensable tools in our daily lives. However, increasing dependence on these devices also presents challenges, and one of the common problems that smartphone and tablet users face is managing charging cables and organizing their devices while charging. It is in this context that our project was born: a cell phone holder with a cable winder.

1.1. Background

Consequently, Pedrero [1] maintains the following:

Beyond communication, gaming, photography, participation in social networks, music, television and downloading applications have come to configure the cell phone in a new and complex platform of various services, especially aimed at the youngest (2012, pp. 139–152).

In this regard, Fernández [2] tells us the following: Currently, according to a study carried out by the Supervisory Body for Private Investment in Telecommunications (OSIPTEL), 80% of the Peruvian population owns a smartphone. For this reason, the growth of accessories and protectors for their care will continue.

At the center of this proposal is a problem that goes unnoticed. The daily life of a modern person involves constant interaction with their mobile devices, whether it be to communicate, work, be entertained or search for information. However, managing charging cables is a constant source of frustration. Cables tend to tangle, deteriorate and ultimately fail. The result is a constant cycle of purchasing new cables, which not only generates unnecessary expenses but also a large amount of electronic waste.

Carhuavilca [3] maintains the following:

Mobile or cell phones have become the predominant means of communication among the population, the number of people who access the Internet from their mobile phones is increasing, it is used as a means to carry out electronic commerce transactions, mobile technology has changed the way of browsing the web, it is used to access social media accounts. In the context of the COVID-19 pandemic, digital technologies have become a fundamental element for the functioning of economic activity and society as a whole (2022, p. 84).

As describeb by Heredero G. [4]:

Designed a 3D-printed modular mounting kit for holding mobile phones. To achieve this, a market study was conducted to explore and understand the commercial landscape of similar products. An analysis of three different 3D printing technologies was also performed, along with an examination of mechanisms commonly used to secure mobile phones. Based on these findings, technical specifications and use cases were defined, enabling the preliminary design of the kit using SolidWorks (2021, p. 3).

1.2. Problem

Accelerated deterioration of cell phone charger cables in environments such as offices and universities.

1.3. Objective

Design a mobile phone holder with an internal winding biodegradable cable. This offers a practical and sustainable solution that will help to keep cables in good condition, prolong their useful life and reduce the generation of electronic waste.

2. Methodology

The methodology used was that of Ulrich and Eppinger [5], as they investigated the complete development of activities for the product through 6 phases while using multidisciplinary development as a basis. Through this process, customer needs, design for manufacturing, prototyping and industrial design can be identified. Ulrich and Eppinger [5] clearly present and detail a set of product development techniques. Integrative methods facilitate problem solving and decision making between people with different disciplinary perspectives, reflecting the current industry trend of conducting product design and development in cross-functional teams.

2.1. Planning

Identification of Opportunities

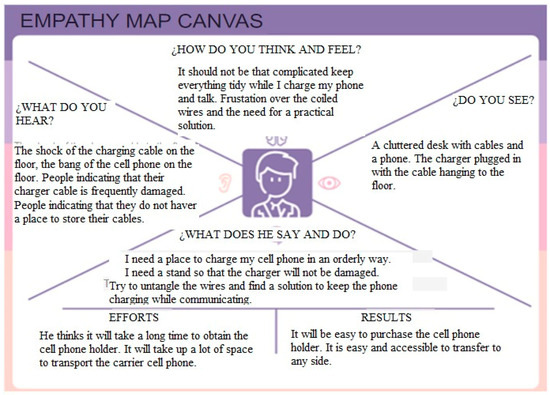

In this stage, tools such as an empathy map (Figure 1), hierarchical needs table and Customer Journey were used (Table 1). With the support of these tools, it was identified that cable management and the organization of mobile devices while charging represent a significant opportunity to improve the user experience and reduce costs associated with the constant acquisition of new cables.

Figure 1.

Empathy map of the customer who purchases the cell phone holder with cable winder.

Table 1.

Needs of the customer who purchases the product.

Finally, it was concluded that the opportunity lies in the creation of an innovative product that not only solves the aforementioned problems but also transforms the way people interact with their mobile devices.

2.2. Concept Development

2.2.1. Identification of Needs

The interviewed users have several needs related to charging their cell phones and caring for their charger cables. They want a product that prevents the cable from being damaged, holds their phone while charging, allows for manipulation of the phone while charging and is flexible. They are also looking for an accessory that is environmentally friendly and easy to transport. The recommended product is our charger and cell phone cable holder, which meets all these needs.

2.2.2. Generation of the Product Concept

The cell phone holder with cable winder is used to support the phone while it is charging. It has a coil that will wind the cable, and this will not only serve as a support but will also, when the cell phone is not charging, keep the cable safely preserved by allowing for it to be wound up for better care rather than being left neglected on the ground. For the generation of the product, the TRIZ (Theory of Inventive Problem Solving, which focuses on systematic innovation) and SCAMPER (a creativity tool based on questioning and improving existing ideas) (Table 2) tools were used to support the Ulrich and Eppinger methodology [5].

Table 2.

Scamper cell phone holder with cable winder.

2.2.3. Proof of Concept

Define Purpose

The purpose of our concept is to create a versatile and adaptable cell phone holder that meets the needs of people who frequently charge their mobile device. It provides a convenient place to hold the phone during charging and includes a feature for coiling the cable, ensuring better care after the charging process is completed. The support is adaptable to various environments, as it is easy to transport and features a reusable sticker. The development of this concept aims to determine whether this holder is the best alternative compared to other products, helping us identify potential improvements to efficiently meet customer needs and estimate market demand, thus enabling us to decide whether to proceed with further development.

Population and Sample

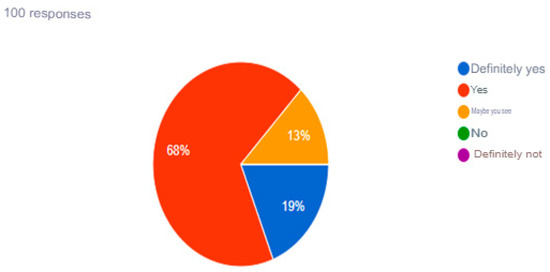

A sample of 100 people from the south sector of Lima, aged 26 to 45 and who were part of the Socioeconomic Levels A and B, were surveyed to measure the frequency of purchasing technological goods. The cell phone holder is aimed at people who are passionate about technology and who have an active lifestyle. Therefore, we have decided that our market segmentation is B2C (Figure 2).

Figure 2.

Survey question: Would you be willing to buy a cell phone and cable holder that you can take everywhere and that allows you to protect both the charger cable and your smartphone while it is plugged in and charging the battery?

Survey Results

Of the 100 respondents, 68.00% would be willing to buy, 18.00% would definitely buy and 13.00% would perhaps be willing to buy the cell phone holder and cable for their cell phone.

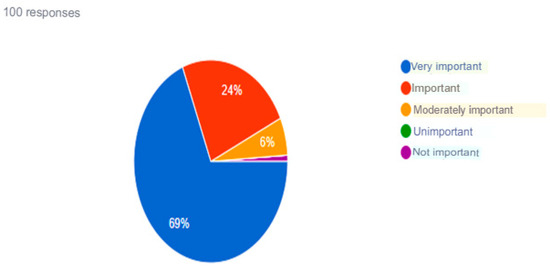

Of the 100 respondents, 69.00% felt that it is very important, 24.00% felt that it is important, 6.00% felt that it is moderately important and only 1.00% felt that it is not important to protect their mobile device and smartphone charger cable (Figure 3).

Figure 3.

Survey question: How important is it to protect your mobile device and your smartphone’s charger cable?

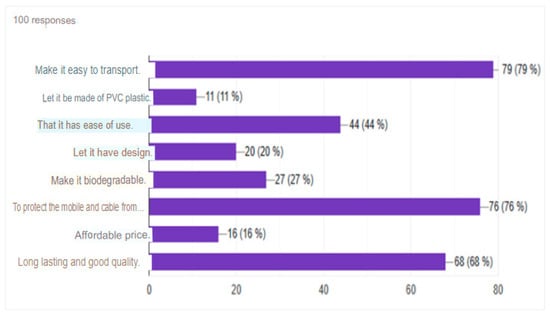

Of the 100 respondents, in terms of the characteristics that the wall cell phone holder should have, 79.00% would prefer it to be easy to transport, 76.00% would prefer it to protect their cell phone and cell phone cable, 68.00% would prefer it to be long-lasting and of good quality, 44.00% would prefer it to be easy to use, 27.00% would prefer that it be biodegradable, 20% would prefer it to have designs and 11.00% would prefer it to be made of PVC plastic (Figure 4).

Figure 4.

Survey question: What features do you think a wall cell phone holder with cable winder should have?

2.3. System Level Design

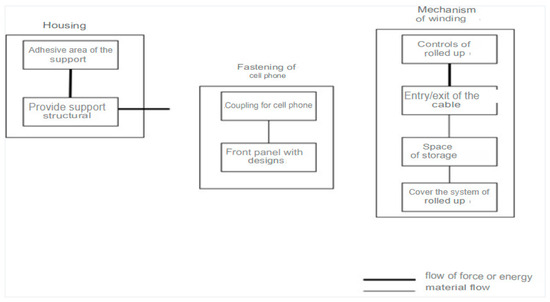

First, the features were identified; it was then determined how these features will translate into actual physical components. This involves grouping related functions and determining which components or parts of the product will perform them (Figure 5).

Figure 5.

Functional grouping diagram of the cell phone holder with cable winder.

The functions “Coiling controls” and “Cover winding system” with the cell phone could be grouped and translated into a specific physical component: the “coiling mechanism”. This mechanism would be responsible for connecting the cable from the cell phone holder to the phone, the mobile transmitting of the electric current and ensuring that the cell phone charges correctly.

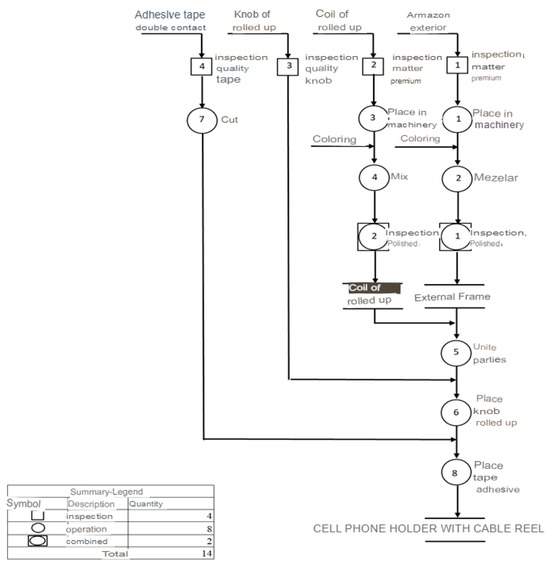

2.4. Detail Level Design

For the production process of the cell phone holder with cable winder, the main raw material is polyethylene plastic; it is a recyclable polymer, and the base color is white, which is why it is mixed with the colors of the design, namely blue for the holder and black for the knob and coil (Figure 6).

Figure 6.

DOP of the cell phone holder with cable winder.

Then, the injection machine that uses the injection molding process exclusively for plastic products is programmed, separately throwing the support, knobs and coils to finally be assembled, obtaining the first batch of 500 products for distribution.

2.5. Testing and Refinement

2.5.1. Focus Group

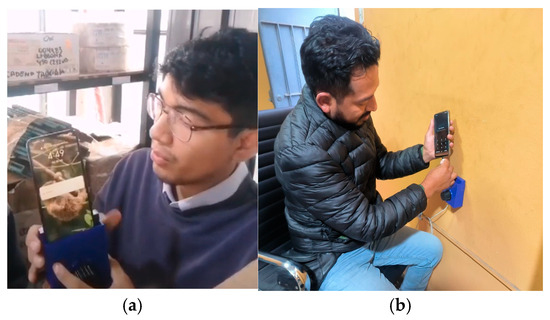

A focus group was carried out group with eight people who corresponded with the target audience. The prototype was presented and valuable information was collected. One suggestion was to attach bolts to the prototype so that it could be fixed to the wall instead of being portable, reflecting that some users might prefer to keep it stationary. Additionally, it was recommended to reduce the size of the knob to improve its physical appearance and ease of interaction (Figure 7).

Figure 7.

Focus photo group 1.

2.5.2. Interview with Experts

Interviews were conducted with two experts; the first was Edward Arqueros Llanos, 28 years old, a design graduate who works as an engineering assistant at Remael SRL with 5 years of experience. The second expert was Carlos Eduardo Barrantes Porras, 34 years old, who has a degree in Systems Engineering and an MBA from the UPC; he is head of logistics at Zona Cel and has specialized in importing cell phone accessories, having 10 years of experience in introducing and expanding new products in the market. These experts validated the design and its functionality, providing improvements such as the sticker, which they say should be more resistant, and making the knob smaller (Figure 8).

Figure 8.

(a) Expert 1 testing prototype; (b) Expert 2 testing prototype.

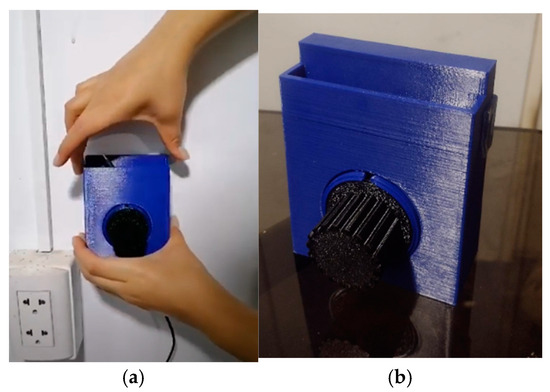

2.5.3. Field Testing

The 72 h test was carried out by Natalia Jazmín Tovar Ferreyros; she is 26 years old and is currently a student studying communications. She works as an administrative assistant at the company Autoespar SA and has 2 years of experience in her professional field (Figure 9).

Figure 9.

(a) Photo of the cable winding process; (b) front photo of the prototype.

User Natalia Tovar recommends that they offer more colors with pre-printed or factory designs. She also indicates that having a manual winding knob takes a certain amount of time to wind; however, it is feasible for the mechanism to be automatic so that, with just one button, you can wind the wire. She also recommended that the manufacturer’s website and/or manual mention the durability of the product and its ability for reuse (Figure 10).

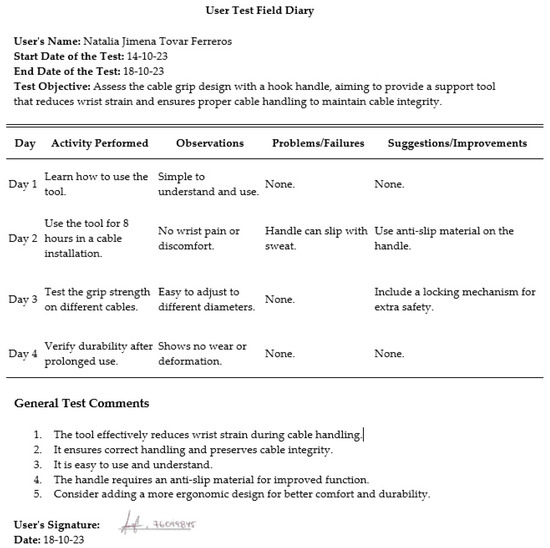

Figure 10.

Use-test field diary.

The image shows the tester who has used the prototype for 72 h installing the cable and manually turning the knob to wind it.

3. Results

3.1. Product Metrics

Below are the final metrics of the prototype expressed in Table 3.

Table 3.

Cell phone support metrics.

3.2. Product Views

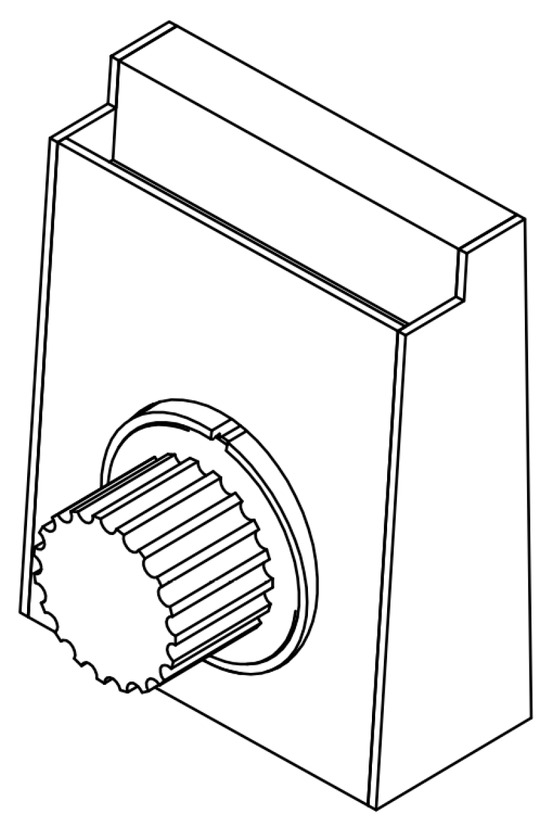

Three-dimensional representation of the cell phone holder with cable winder, which exhibits the integral design and highlights its attributes and utilities. This prototype was conceived using Autodesk Inventor (Figure 11 and Figure 12).

Figure 11.

Front view of the cell phone holder with finished cable winder.

Figure 12.

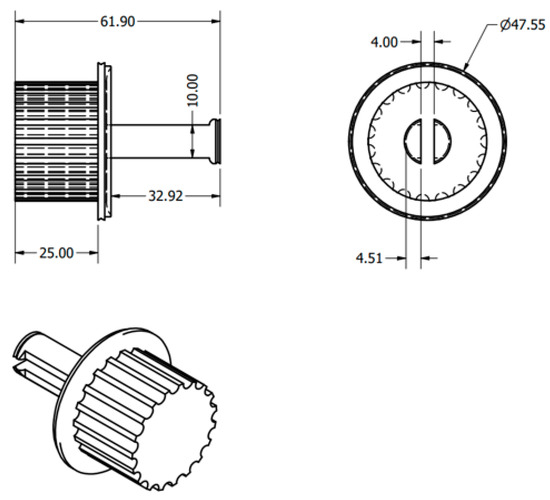

Winder knob base.

Detailed diagram of the platform with the area for the winding knob, highlighting its purpose (Figure 13).

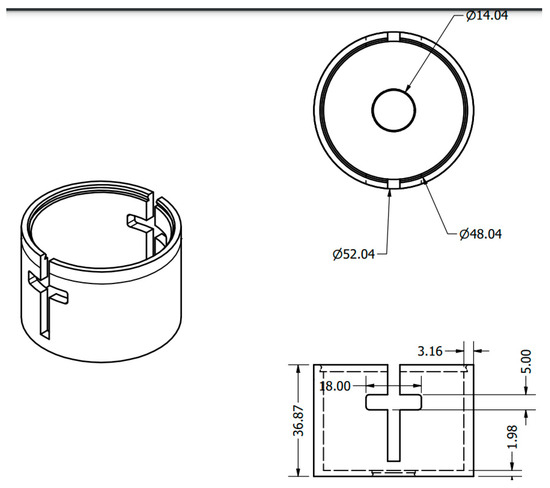

Figure 13.

Plan of the views of the cell phone holder.

In this space, representations of the support cover are presented, providing dimensions and specifications that describe this section intended to safeguard the winding mechanism.

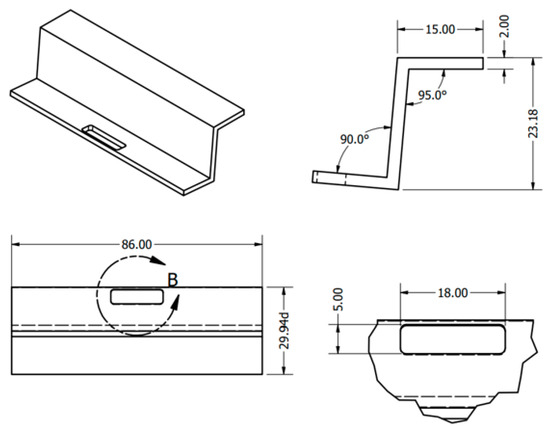

The back of the support is displayed along with its structure, highlighting the ease of access and the design of the back cover (Figure 14).

Figure 14.

Winding knob plan.

We can see details of the knob used for the winding system, with measurements and characteristics that allow for easy use when winding the cable.

4. Conclusions

In relation to the design, it stands out that the adhesive is resistant and capable of holding an iPhone 13 effectively; the double contact tape is reusable and easy to wash, adding ecological and economic value to the product; the support knob is detachable, making it easy to carry; and the product is versatile, making it useful for holding a phone during online meetings.

Finally, it is concluded that the project presents an effective solution to the problem of managing charging cables for mobile devices and organizing them while they are charging. It successfully addresses the need to extend the life of cables and reduces unnecessary expenses associated with constantly purchasing new cables.

Author Contributions

Conceptualization, D.V.C.P. and J.C.S.; methodology, R.F.V.E.; formal analysis, R.F.V.E.; investigation, D.V.C.P.; resources, J.C.S.; data curation, D.V.C.P.; writing—original draft preparation, D.V.C.P.; writing—review and editing, D.V.C.P. and J.C.S.; visualization, R.F.V.E.; supervision, R.F.V.E.; project administration, J.C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. For further inquiries, please contact the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pedrero, E.; Rodríguez, M.; Ruíz-Sánchez, J. Mobile phone addiction or abuse. Literature Review. Addictions 2012, 24, 139–152. Available online: https://www.adicciones.es/index.php/adicciones/article/view/107/104 (accessed on 14 September 2023).

- Fernandez Aguirre, C.L.R.; Panduro Lope, M.Y.; Rodriguez Segovia, A.G.; Sangay Tanta, F.; Velasquez Avalos, S.F. Production and Marketing of Cell Phone Support. Bachelor’s Thesis, Universidad San Ignacio de Loyola, Lima, Peru, 2019. Available online: https://repositorio.usil.edu.pe/server/api/core/bitstreams/aee54026-3333-4c0e-b377-de4a7a8dcc78/content (accessed on 14 September 2023).

- Carhuavilca, D. Access and Use of Information and Communication Technologies in Homes and by the Population 2010–2021. 2022. Available online: https://www.inei.gob.pe/media/MenuRecursivo/publicaciones_digitales/Est/Lib1827/libro.pdf (accessed on 14 September 2023).

- Heir, G. Design of a 3D Printed Modular Assembly Kit for Mobile Phones. Bachelor’s Thesis, Escola Tècnica Superior d’Enginyeria Industrial de Barcelona, Barcelona, Spain, 2021. Available online: https://upcommons.upc.edu/bitstream/handle/2117/353137/memoriatfg-gabrielgutierrez.pdf?sequence=1&isAllowed=y (accessed on 14 September 2023).

- Ulrich, K.; Eppinger, S. EBOOK: Product Design and Development; McGraw Hill: New York, NY, USA, 2011. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).