Abstract

In the present investigation, bending stress of a profile corrected altered tooth-sums gear train, for a constant center distance, is estimated. The number of teeth altered by ±4% is considered and bending stress is estimated for 25° and 20° pressure angle gears. Since the stress concentration depends on the type of fillet radius, in this work, the bending stresses are computed in the tooth for various fillet radii generated by rack cutters such as; sharp corner tip, rounded corner tip, protuberance tip, and fully rounded tip. It is found that the bending stress is less in the tooth radius generated by a fully rounded tip cutter.

1. Introduction

By considering the gear tooth as a cantilever beam under point load the bending stresses were estimated by Lewis, who developed an equation popularly called as Lewis equation for beam strength of gear tooth. Though this serves as a basis equation; further new version of Lewis equations is developed by AGMA (American Gear Manufacturer Association) and other researchers [1]. The main desired performance criteria considered during the dynamic running of the gears is the contact stress, bending stress and mesh stiffness [2] apart from transmission, vibration and noise effects. For better gear design, apart from the contact stress and stiffness the induced bending stress on the gear tooth is one of the important parameters that has to be considered for evaluating the gear performance.

From the literature, it is acknowledged that profile correction by profile shift method helps in reduction of bending stress in gear tooth when it is in operation. In this context Mohammad [3] has used an analytical solution to predict bending stress both in asymmetric and symmetric involute gear teeth. The bending stress with and without profile correction for various design parameters was investigated. Shanmugasundaram et al. [4] in their research work analyzed failure of circular root fillet gear tooth and trochoidal root fillet gear tooth. They have used the profile modification in their research. Tesfahunegn et al. [5] conducted numerical and experimental measurements on bending stress, contact stress on tooth shapes using profile modifications. Bending stresses at the tooth root of the spur gears was studied by Pradip et.al. [6] by comparing results using theoretical and other analysis software. It was concluded that the bending stresses were in line with the theoretical results obtained using analysis software. Bending stresses in spur gears were also studied by Ashu Jangid et.al. [7] using finite element method by a three dimensional model and concluded that the results of the finite element method was in line with AGMA.

While predicting the bending stress the critical section is an important design consideration. At the critical section, stresses are high due to sudden changes in cross section in the fillet radius of gear teeth [8]. Mallesh et al. [9] has estimated critical section in asymmetric and symmetric spur gear and compared the bending stresses using ANSYS software for various pressure angles. Using the principle of the Lewis equation as the basic reference, AGMA has developed a procedure using an elastic behavior model to estimate the critical section using the tangency point of the parabola [10,11,12]. Glodez and Andrews [13,14] estimated that the bending stress of gear tooth deviates from analytical value due to the heterogeneous structure of the material and crack propagation in real service of material due to high load and high speed. The influence of altering the tooth-sums by profile modification on bending stresses for varied loads has been studied by Rajesh et al. [15]. According to them the negative teeth alteration in tooth-sums is improved as related to positive alteration in tooth-sums. Seok et al. (2013) [16] have studied contact stress analysis at the lowest point of single tooth contact and compared these results considering AGMA standards using finite element method. They concluded that the results obtained using the finite element method are more accurate as compared to the AGMA equation.

The main aim of the innovative gear design trend in the present scenario is to develop gears with high specific load-carrying capacity [17]. Hence to enhance the specific load-carrying capacity of the gear tooth with lower bending stresses, it is required to manufacture the gear tooth by profile modification and further heat treatment. A large volume of published literature is available on spur gears correlated to the estimation of critical section and bending stresses. However, it is observed that very few literatures are available linked to bending stresses in altered tooth-sum gearing. Hence, in this context, authors have tried to study the effect of cutter tip radius by altering tooth-sums of a fixed center distance spur gear system.

2. Methodology

2.1. Parameters

The geometric parameters selected for the study of bending stresses are; pressure angle = 20° and 25°, face width = 20 mm, and module = 2 mm. Number of teeth = 100 and altered by ±4% [18]. Steel, with a Young’s modulus of elasticity of 200 GPa is selected as the gear material. For computation, the tangential load exerted on the gear tooth of 10 N·mm−1 of face width is considered.

2.2. Empirical Approach

To calculate the bending stresses in an altered-sum gear tooth the following procedure is adopted; The tooth-sum considered is 100 and it is altered by ±4% operating between a constant center distances of 100 mm [19,20].

The total number of teeth on gear (Z2) and pinion (Z1) for a standard gearing is calculated using the equation; . Where, Z2 and Z1 are the number of teeth on the gear and pinion respectively. The standard center distance for the gear set is estimated by equation; . Where, m is the module (mm) and Z is the tooth-sum. By altering the standard tooth sum on the negative side with 4%, the altered tooth sum (Ze) Hence the number of teeth in gear (Z12) and pinion (Z11) for an altered tooth-sum gearing is 4. This altered tooth-sum is made to work with a constant center distance. But, as per the Maitra [18] due to the above alteration in tooth-sum, the number of teeth on the gear and pinion alters, which in turn alters the base circle. This leads to change of operating pressure angle (αW) as mentioned in Equation (1).

where, is the standard pressure angle.

The profile shift (Xe) which is required for the gear set to work satisfactorily is given by Equation (2). The tooth thickness at the gear pitch circle (S2) and pinion pitch circle (S1) is calculated as per Equations (3) and (4). The base circle radius of gear (Rb2) and pinion (Rb1) is estimated as per Equation (5). The allowable maximum radius (Rmax2) and (Rmax1) to avoid interference for selected gear set is estimated as per Equations (6) and (7) for the gear and pinion. The addendum circle radius Ra2 and Ra1 of the gear and pinion is estimated by Equations (8) and (9) respectively.

The radius of curvature at root or fillet radius is estimated by Kim et al. [1] and is as mentioned in Equation (10).

where, is circular tip of the rack cutter (Maximum 0.6 times module (18)), ar is the addendum radius which is equal to module, e is the profile shift and Rsg is the pitch circle radius of gear. The dedendum circle radius for pinion (df1) and gear (df2) is estimated as per Maitra [18] as mentioned in Equations (11) and (12).

The tooth thickness at the clearance circle (Sclear) is evaluated as per the Equation (13) [18].

where, , and

The stress concentration factor at the fillet is estimated by using the Equation (14) [1]

where, X and Y are coordinates of fillet radius (mm), YD is the coordinate of D (mm) and K1, K2 and K3 values are taken as 0.18, 0.15 and 0.45. As per Dolan and Broghamer, the X and Y values were taken to solve iterative process in the gear bending Equation (19) to maximize the bending stress within allowable range [1].

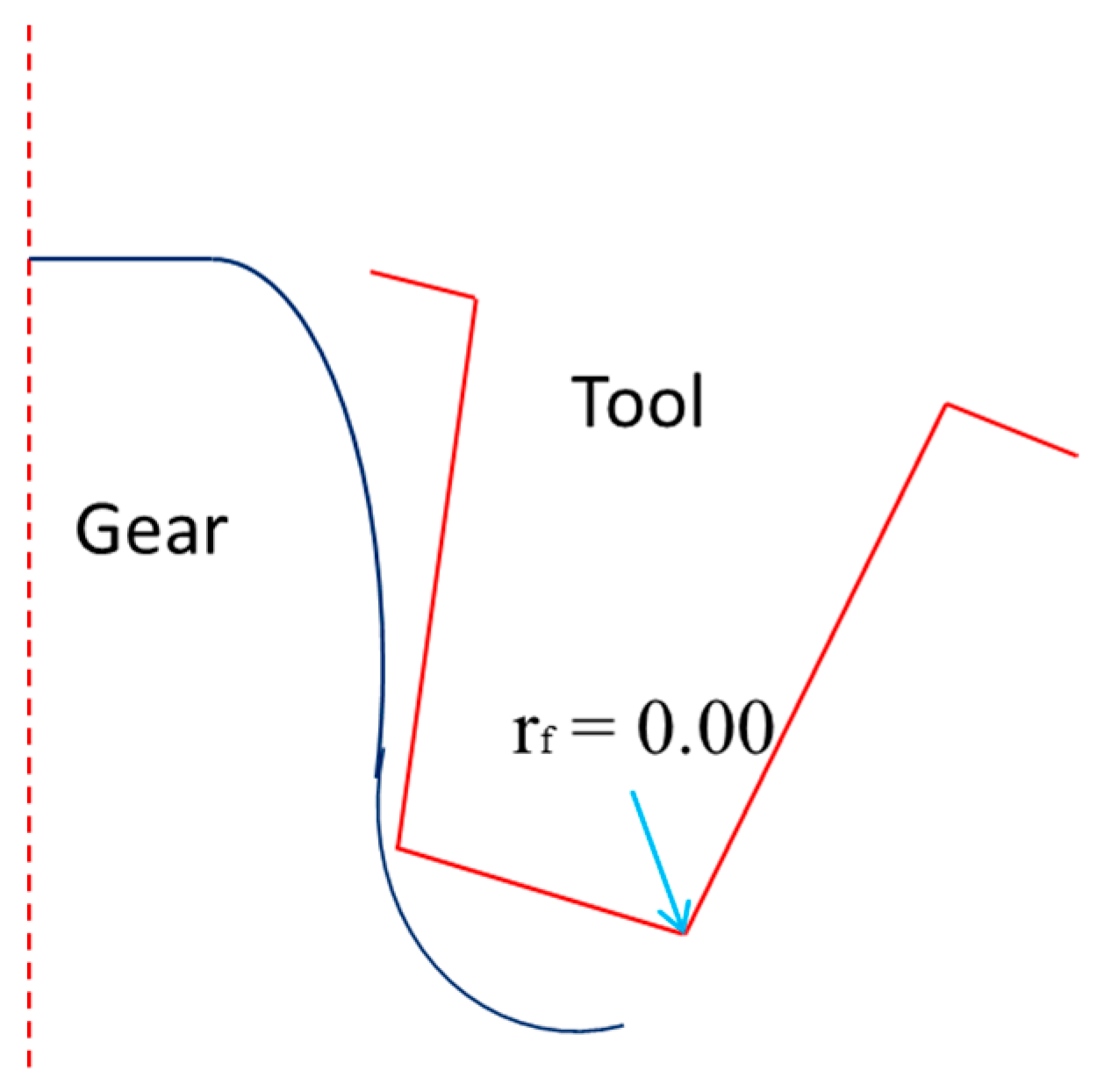

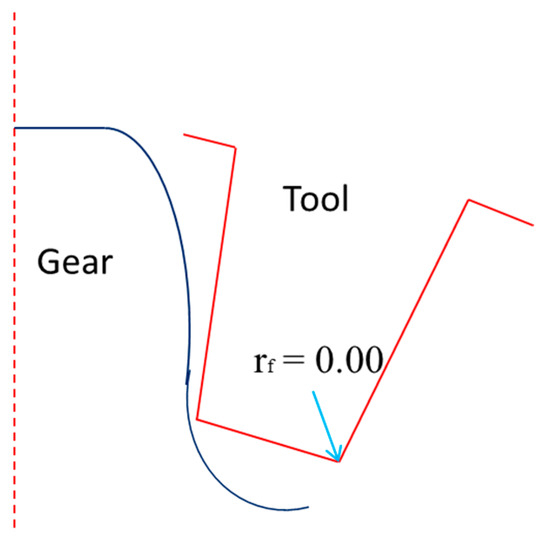

where, m is module (mm), F is the load Intensity (N) and γw = Angle between involute tangent and the tooth centerline at the load point. Finally, the bending stress along the feasible points on the fillet radius profile for the various circular tip of the rack cutter namely; Sharp corner tip (rrt = 0.0 m), rounded corner tip (rrt = 0.25 m), protuberance tip (rrt = 0.40 m) and fully rounded tip (rrt = 0.50 m) is calculated and is as shown in Figure 1 [13].

Figure 1.

Fillet Profile.

3. Results

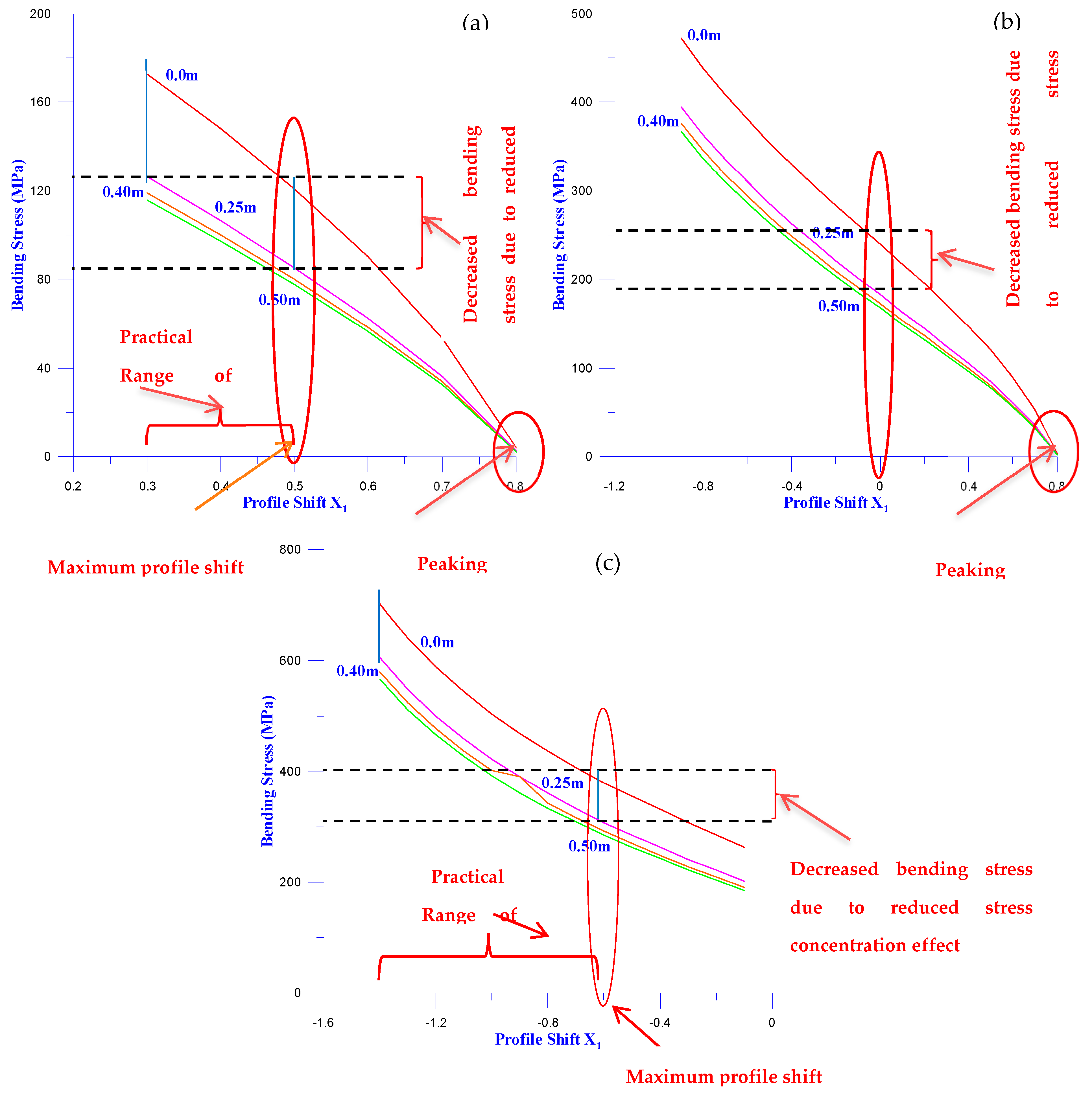

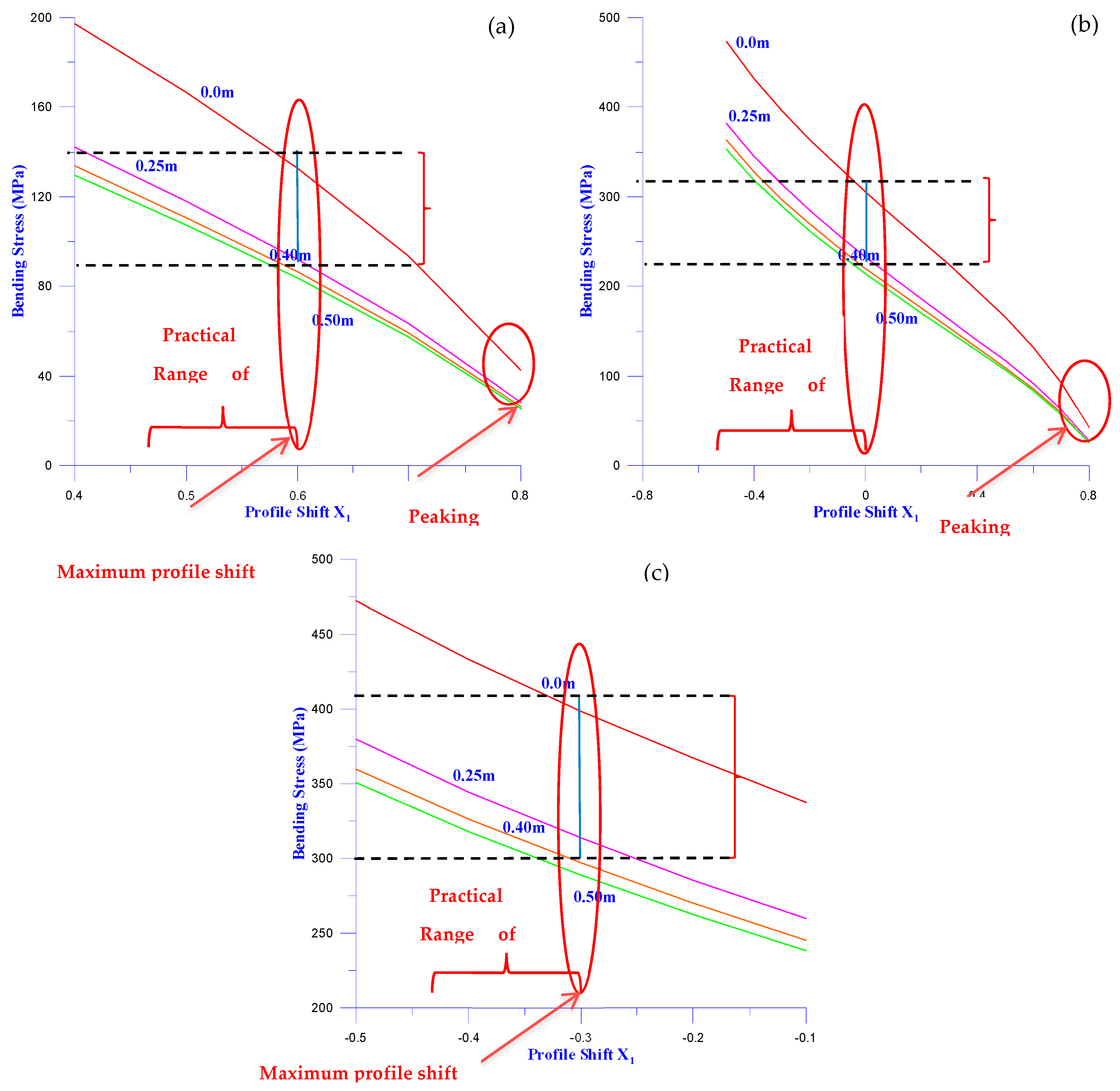

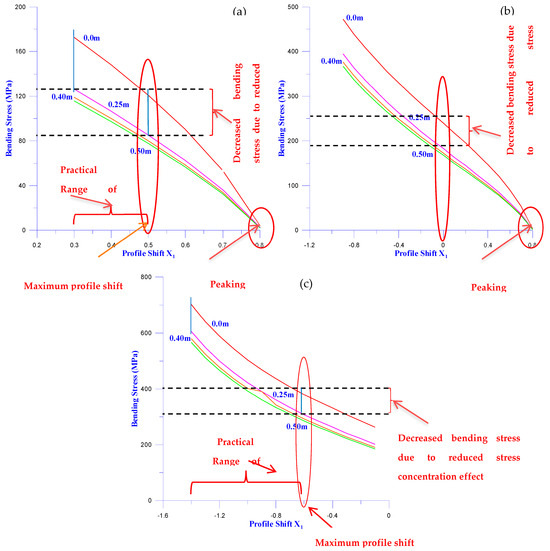

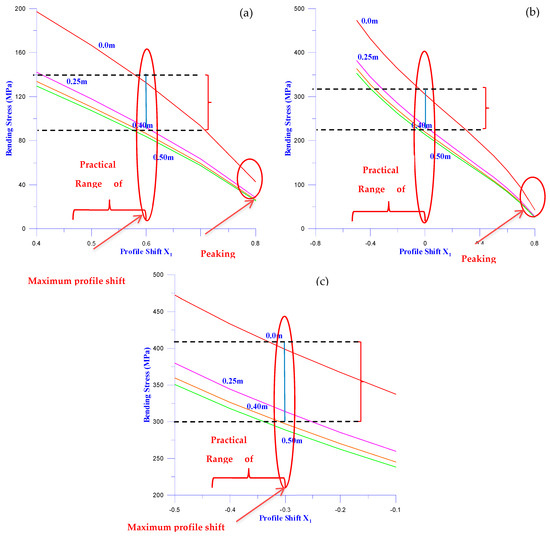

The maximum bending stress at the root of the gear tooth for tooth sum of 96, 100 and 104 with pressure angle 25° are plotted and is as shown in Figure 2a–c. Similarly, for 20° pressure angle they are plotted and shown in Figure 3a–c respectively. In both cases it is plotted for various fillet radiuses which were generated by rack cutters such as; sharp corner tip, rounded corner tip, protuberance tip and fully rounded tip.

Figure 2.

Maximum bending stress at various profile shift for tooth sum of: (a) 96 teeth, (b) 100 teeth and (c) 104 teeth for 25° Pressure angle.

Figure 3.

Maximum bending stress at various profile shift for tooth sum of: (a) 96 teeth, (b) 100 teeth, and (c) 104 teeth for 20° Pressure angle.

From Figure 2a–c, it is observed that the maximum bending stress at the root fillet of the gear tooth generated by fully rounded corner tip cutter is lower and the maximum bending stress at the root fillet generated by sharp corner tip cutter is higher. Also, it is detected that a large difference of bending stress exists between the tooths generated by sharp corner tip radius cutter and tooths generated by other types of cutter (rounded corner, protuberance and fully rounded tip of rack cutter). These reduction in maximum bending stress in root fillets generated by rounded corner, protuberance and fully rounded tip of rack cutter is due to reduction of degree of stress concentration at the fillet radius.

From Figure 2a it is noticed that, the tooth bending stresses in case of all types of root fillet decreases with increased profile shift for 96 tooth sums. This is due to increased pitch circle radius which leads to increase of tooth thickness at the root. Because of this, an increased area resists to bending at the root of the tooth which causes reduction in bending stress. Further, it is also noticed that an increase of profile shift increases the root area of tooth, which is continuous until the tooth takes a shape of uniform strength beam. This is a theoretical condition. At this particular condition the bending stress at the root of the tooth becomes zero. But, as the shape of the tooth leads to uniform strength beam (maximum tooth thickness at the root with zero topland) results in pointed tip tooth (peaking). This kind of tooth practically is not possible to transmit power. However, for smooth power transmission the tip thickness should be ≥0.25 times the module [18]. As per Maitra [19] the profile shift will be practically useful only for the range 0 to 0.5 for 96 tooth sum gearing. Hence, the study of bending stress in profile shift range 0 to 0.5 is important. The fillet has the direct influence on the maximum bending stress at the root of the gear tooth and is determined by the gear cutting manufacturing process and cutting tool dimensions.

From Figure 2b it is noticed that, the tooth bending stress curves for all types of tooth root fillets of standard tooth-sum gears behaves as like tooth bending stresses curves of negative altered tooth-sum gears. But, the bending stress is in higher side in case of standard tooth-sum gearing as compared to negative altered tooth-sum gears. This is because of decreased area of resisting to bending which causes critical bending section.

It is observed from Figure 2c that similar kind of behavior of tooth bending stress curves and it is also noticed that, high bending stress in case of positive altered tooth-sum gears as compared to standard and negative altered tooth–sum gears (Figure 2a,b). In this case area resisting to bending is further reduced and lower as compared to standard and negative altered tooth-sum gears. In this study, it is observed that peaking in case of negative altered tooth-sum and standard gearing (Refer Figure 2a,b), the bending stress leads to zero, but in case of positive altered tooth-sum gearing the top land of gear tooth increases and no peaking effect is seen (Refer Figure 2c), and the bending stress does not lead to zero. But under cutting of tooth in case of positive altered tooth-sum gearing limits the profile shift selection.

The bending stress at various profile shift for 20° Pressure angle negatively altered toothsum, positively altered, and standard tooth sum gearing is shown in Figure 3. It is observed from Figure 3a that the tooth bending stress curves follow a similar trend with fillet radius at the root of the tooth as noticed in the case of 25° Pressure angle. In this instance the practical useful profile shift range is 0 to 0.6 for 96 tooth-sum gearing. Also, it is noticed from Figure 3b that a similar trend of bending stresses (as mentioned in 25° Pressure angle) with all tooth root fillet radius of standard tooth-sum gear is present. But, the bending stress is in higher side in case of standard tooth-sum gearing as compared to negative altered tooth-sum gears. This is because of decreased area of resisting to bending as mentioned earlier. It is detected from Figure 3c that there exists a high bending stress in the circumstance of positive altered tooth-sum gears as compared to standard and negative altered tooth–sum gears. In this instance also, area resisting to bending is further reduced and is lower as compared to standard and negatively altered tooth-sum gears. In the case of negative altered tooth-sum and standard gearing the peaking effect is as shown in Figure 3a,b. The possible practical range of profile shift and maximum profile shift in the occasion of negative and positive altered tooth-sum gearing systems are marked in Figure 3a,c respectively. It is found that the maximum tooth bending stress is 85–135 MPa (negative altered tooth-sum gearing), 205–303 MPa (standard gearing), and 285–400 MPa (positive altered tooth-sum gearing) at +0.6, 0, and −0.3 profile shift respectively for selected tooth fillets. A reduction of bending stress (56%) in the event of negatively altered tooth sum when likened to standard gearing is observed. Similarly, an increase in bending stress (32%) is noticed in the case of positive altered tooth-sum gearing as compared to standard gearing.

4. Discussion

Considering the peaking phenomena of gear tooth and efficient gear transmission, the possible practical range of profile shift and maximum profile shift in the case of positive and negative altered tooth-sum gearing systems are marked in Figure 2a,c respectively. It is found that the maximum tooth bending stress is 80–120 MPa (negative altered tooth-sum gearing), 170–243 MPa (standard gearing), and 280–385 MPa (positive altered tooth-sum gearing) at +0.5, 0 and −0.5 profile shift respectively for selected tooth fillets. It is noticed that a remarkable improvement in the reduction of bending stress (51%) exists in the case of negative altered tooth sum compared to standard gearing. Similarly, a remarkable increase in bending stress (59%) is noticed in the case of positive altered tooth-sum gearing as compared to standard gearing. This is due to the change in area resistant bending as explained earlier.

The range of reduction of bending stress due to the change of cutter radius is mentioned as decreased bending stress due to the stress concentration effect in Figure 2a–c. It is noticed that 33% and 25% range of reduction of bending stress is observed due to the reduction of stress concentration effect by change in tooth root radius in case of negative and positive altered tooth-sum gearing. Hence it can be concluded that the effect of stress concentration due to radius of root fillet is more effective in case of negative altered tooth-sum gearing as compared to positive altered tooth-sum gearing.

From Figure 2a–c, the maximum bending stress at the root fillet of the gear tooth generated by a fully rounded corner tip cutter is lower and the maximum bending stress at the root fillet generated by a sharp corner tip cutter is higher. Also, it is observed that a large difference in bending stress exists between the tooths generated by sharp corner tip radius cutter and tooths generated by other types of cutter (rounded corner, protuberance, and fully rounded tip of rack cutter). These reductions in maximum bending stress in root fillets generated by rounded corner, protuberance, and fully rounded tip of rack cutter is due to the reduction of the degree of stress concentration at the fillet radius.

In the case of 25° pressure angle gears; the tooth generated by sharp corner tip cutter experiences maximum bending stress. Reduction of bending stress of 39% in negative altered tooth-sum gearing and 29% in positive altered tooth-sum gearing is observed due to change in cutter. In this case also radius of root fillet is more effective in case of negative altered tooth-sum gearing as equated to positive altered tooth-sum gearing.

From Figure 3a–c, It is observed that the reduction of bending stress is 56% in case of 20° pressure angle as compared to 51% in case of 25° pressure angle for negative alteration in tooth-sum compared to standard gearing. However, higher bending stress is observed in case of 20° pressure angle gear tooth. Also, it is observed that there is an increase in bending stress of 32% in case of 20° pressure angle as compared to 59% in case of 25° pressure angle for positive altered tooth-sum when linked to standard tooth-sum. In this case the maximum stress observed is in case of 25°pressure angle positive alteration in tooth-sum gearing. It is also observed that bending stress is lowest in case of 25° pressure angle negative alteration tooth-sum gearing as compared to other cases. Hence it is found that negative altered tooth sum gearing reduces the bending stress and negative altered tooth-sum gear with 25° pressure angle is more beneficial. Thus, combined effect of negative alteration tooth-sum and increased pressure angle contributes to reduction of bending stress.

5. Conclusions

In this research work, it is found that higher bending stresses is noticed in altered tooth-sum gear tooth generated by sharp corner tip (0.0 m) cutter compared to gear tooth generated by rounded corner tip cutter and other cutters. This is due to stress concentration effect. In addition to this, it is noticed that the bending stress in negative alteration tooth-sum gearing is low as compared to positive altered tooth-sum gearing. This is due to the increased root width of the gear tooth. Also, the bending stress induced depends on the profile shift of gear tooth. But in negative and standard tooth-sum gearing the profile shift is limited by the peaking effect. Hence, higher profile shift of pinion is not practically applicable. The combined effect of negative alteration tooth-sum and increased pressure angle contributes to reduction of bending stress. The negative altered tooth-sum type with 25° pressure angle gear tooth, generated by rounded corner tip cutter shows lowest bending stress in the practical working range of profile shift.

Author Contributions

S.H.K. was responsible for conceptualization and methodology along with formal analysis. R.K. was accountable for Writing—review and editing along with supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data is generated through a C program and has been represented in the article through suitable graphs.

Acknowledgments

The authors wish to acknowledge the support rendered from both institutes for the computational work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, N.H.; Stoker, K. A Comparison of Spur Gear Response under Non-Ideal Loading Conditions; SAE technical paper 2009-01-1258; SAE: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- del Rincon, A.F.; Viadero, F.; Iglesias, M.; García, P.; de-Juan, A.; Sancibrian, R. A model for the study of meshing stiffness in spur gear transmissions. Mech. Mach. Theory 2013, 61, 30–58. [Google Scholar] [CrossRef]

- Abdullah, M.Q. Analytical solution of bending stress equation for symmetric and asymmetric involute gear teeth shapes with and without profile correction. Innov. Syst. Des. Eng. 2012, 3, 19–33. [Google Scholar]

- Sankar, S.; Raj, M.S.; Nataraj, M. Profile modification for increasing the tooth strength in spur gear using CAD. Sci. Res. Eng. 2010, 2, 740–749. [Google Scholar] [CrossRef][Green Version]

- Tesfahunegn, Y.A.; Rosa, F.; Gorla, C. The effects of the shape of tooth profile modifications on the transmission error, bending and contact stresses of spur gears. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2010, 224, 1749–1758. [Google Scholar] [CrossRef]

- Adake, P.B.; Patil, A.N. Determination of true bending stresses in spur gears by KISSSOFT, FEM and Experimental setup. Int. Eng. Res. J. (IERJ) 2015, 2, 976–984. [Google Scholar]

- Jangid, A.; Kumar, S. Modelling and simulation analysis for bending stresses in involute spur gears by finite element method. Int. J. Appl. Eng. Res. 2018, 13, 10914–10923. [Google Scholar]

- Shunmugam, M.S.; Siva Prasad, N. Prediction of stress in fillet portion of spur gears using artificial neural networks. Artif. Intell. Eng. Des. Anal. Manuf. 2008, 22, 41–51. [Google Scholar] [CrossRef]

- Mallesh, G.; Math, V.B.; Gajanan; Uttesh; Sridhar. Estimation of critical section and bending stress analysis for Asymmetric spur gear tooth. In Proceedings of the 14th National conference on machines and mechanism (NaCoMM09), Durgapur, India, 17–18 December 2009; pp. 107–112. [Google Scholar]

- Calculated Bending Load Capacity of Powder Metallurgy (P/M) External Spur Gears; AGMA 930-A05; American Gear Manufacturers Association: Alexandria, VA, USA, 2005.

- Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth; AGMA information sheet 908-B89; American Gear Manufacturers Association: Alexandria, VA, USA, 1989.

- Aziz, E.-S.S.; Chassapis, C. Probabilistic simulation approach to evaluate the tooth-root strength of spur gears with FEM-based verification. Engineering 2011, 3, 1137–1148. [Google Scholar] [CrossRef]

- Glodez, S.; Sraml, M.; Kramberger, J. Computational model for determination of service life of gears in regard to bending fatigue in a gear tooth root. Int. J. Fatigue 2002, 24, 1013–1020. [Google Scholar] [CrossRef]

- Andrews, J.D. Finite element analysis of bending stresses induced in external and internal spur gears. J. Strain Anal. 2002, 26, 153–163. [Google Scholar] [CrossRef]

- Rajesh, A.R.; Gonsalvis, J.; Venugopal, K.A. Load sharing analysis of bending strength in altered tooth-sum gears operating between a standard center distance and module. Eur. J. Eng. Technol. 2015, 3, 50–61. [Google Scholar]

- Hwang, S.-C.; Lee, J.-H.; Lee, D.-H.; Han, S.-H.; Lee, K.-H. Contact stress analysis for a pair of mating gears. Math. Comput. Model. 2013, 57, 40–49. [Google Scholar] [CrossRef]

- Gonsalvis, J. (St. Joseph Engineering College, Mangalore, India); Rayudu, G.V.N. (Tech Mechanical Eng., IIT Madras, Chennai, India). Personal communication, 1994.

- Gitin, M.M. Handbook of Gear Design, 2nd ed.; Tata McGraw Hill Education Private Limited: New Delhi, India, 2011. [Google Scholar]

- Kumar, P.; Hirani, H.; Agrawal, A.K. Online condition monitoring of misaligned meshing gears using wear debris and oil quality sensors. Ind. Lubr. Tribol. 2018, 70, 645–655. [Google Scholar] [CrossRef]

- Sachidananda, H.K.; Raghunandana, K.; Gonsalvis, J. Design of spur gears using profile modification. Tribol. Trans. 2015, 58, 736–744. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).