1. Introduction

Addressing pedestrian safety at night is important to help limit the number of accidents that occur. These accidents are largely due to the clothes worn and the conditions of darkness, which make it difficult for pedestrian visibility and driver recognition at night-time. Efforts have been made with material innovation, i.e., retro-reflective materials, which are effective in redirecting lights from their surfaces back to its source of origin [

1]. Several studies by [

2,

3,

4] have highlighted the ability of these retro-reflective materials to improve the visibility and recognition of the wearer on the road when they are placed as biomotion configurations on the clothing. Aside from this, lighting features, i.e., the use of light emitting diodes (LEDs), also play an important role in providing additional safety features which seek to improve the wearer’s visibility and the response rate of the driver on the road. These LEDs, when integrated in the clothing, will aid in limiting any pedestrian accidents. The available LEDs on the market are rigid and are easily sewn onto the garment at various positions using conductive threads. This largely makes it difficult to wash these garments. To adapt to this difficulty, advancements have been made to embed small LEDs into thin wires or conductive threads to form electronic yarns (e-yarns), which provides varying possibilities for integration in some clothing for different applications. Notable contributions for e-yarns are an automated manufacturing process of embedding LEDs to copper wires [

5], embedding surface mounting devices on conductive yarns by reflow soldering [

6], and using crimp beads to bond LEDs to the conductive yarns [

7]. These contributions have presented the opportunity to integrate LEDs into the structure of the garment which are capable of withstanding washing and mechanical stresses that may occur. Contributing to the growing efforts of making e-yarns, this study presents the development of low-cost e-yarns using common materials on the market for use in a woven fabric which is aimed to be used for smart pedestrian interactive safety clothing.

2. Materials and Methods

Here, adhesive tape, 0603 size light emitting diodes, contraction tubes of different sizes, stainless steel conductive yarns, and a hot air soldering machine were employed in the fabrication process. A simple technique of embedding LEDs in a series into conductive yarns was possible, where the contraction tube aided in effectively encapsulating the LEDs to the conductive yarns and also insulating one-side of the conductive yarns to prevent any short circuit when power is supplied. The fabricated e-yarn was further braided with 8-core retro-reflective yarn which was inserted into a woven fabric. The weaving process was made possible using a rapier loom.

3. Results and Discussion

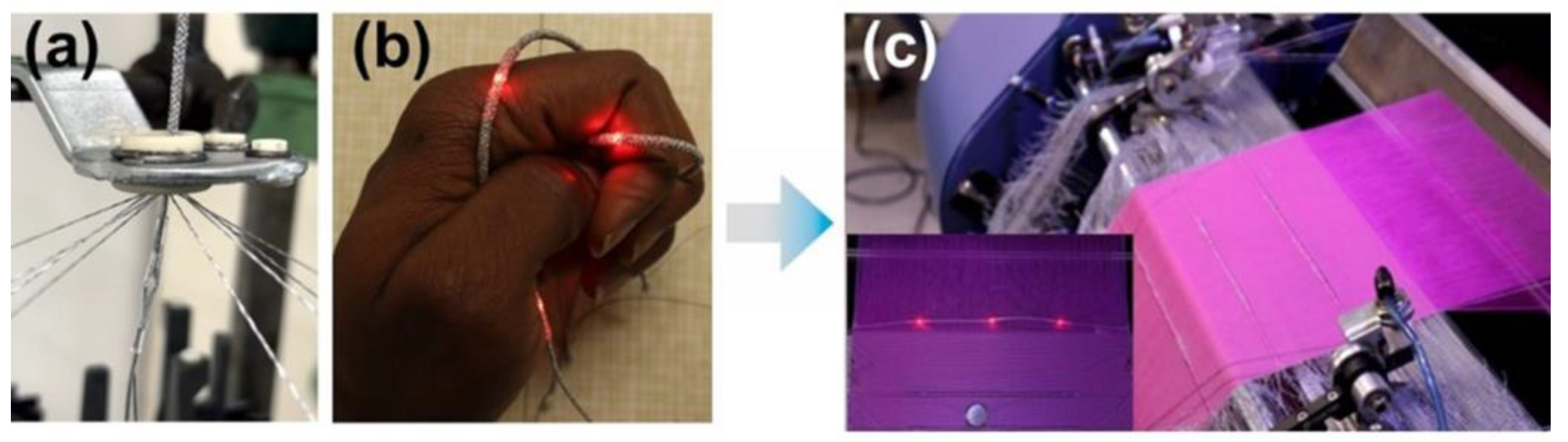

Two samples were produced with the use of 1.5 mm (named Set 1) and 0.6 mm (named Set 2) contraction tubes for braided e-yarns which were further woven into a fabric. Experimental test results showed the flexible nature of the Set 2 braided yarns and fabric when woven into the weave structure using a rapier loom (

Figure 1).

Both the Set 1 and Set 2 braided yarns still showed functional performance after washing. The wash durability test showed the functioning of all the sets of braided yarns (embedded with three LEDs) in its yarn form. In its fabric form however, woven fabrics made from Set 1 and Set 2 braided e-yarns experience faults or non-functionality from 10 to 20 cycles and at 20 cycles, respectively. The non-functioning nature of these LEDs was due to the non-contact nature of their solder pads to the conductive yarns for the effective supply of power to light up the LEDs. The preliminary results demonstrate the ability to integrate these woven fabrics (e-textiles) in the developed interactive system with micro-controllers and sensors to produce safety alert features. It was shown that the developed output proved a preliminary success for further research geared towards enhancing night-time safety for pedestrians.

4. Conclusions

In this experimental work, we present an alternative approach to producing low-cost, flexible, and strong e-yarns with performance qualities suitable for integration into woven fabrics. These e-textiles are suitable for developing pedestrian safety clothing connected to a developed interactive system to ensure the safety of pedestrians at night-time with three key safety features.

Author Contributions

Conceptualization, R.K.S.; methodology, R.K.S.; formal analysis, R.K.S.; investigation, R.K.S.; writing—original draft preparation, R.K.S.; writing—review and editing, R.K.S.; supervision, S.J.; funding acquisition, S.J. All authors have read and agreed to the published version of the manuscript.

Funding

The research received the financial support of the Hong Kong Polytechnic University which is provided by the Research Grant Council in the form of postgraduate award and project (P0039254).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The authors acknowledge the financial support of the Hong Kong Polytechnic University which is provided by the Research Grant Council in the form of postgraduate award and project (P0039254). This paper forms part of a PhD research project that aims to develop smart interactive clothing with inherent retro-reflective abilities to improve pedestrian safety at night-time.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Glombikova, V.; Komarkova, P.; Vik, M.; Adamcova, J.; Nemcokova, R.; Vikova, M.; Havelka, A. Approach to performance rating of retroreflective textile material considering production technology and reflector size. Autex Res. J. 2021, 22, 446–457. [Google Scholar] [CrossRef]

- Fylan, F.; Bentley, L.A.; Brough, D.; King, M.; Black, A.A.; King, N.; Wood, J.M. Designing cycling and running garments to increase conspicuity. Int. J. Fash. Des. Technol. Educ. 2021, 14, 263–271. [Google Scholar] [CrossRef]

- Seidu, R.K.; Sun, L.; Jiang, S. A systematic review on retro-reflective clothing for night-time visibility and safety. J. Text. Inst. 2023, 1–13. [Google Scholar] [CrossRef]

- Black, A.A.; Duff, R.; Hutchinson, M.; Ng, I.; Phillips, K.; Rose, K.; Ussher, A.; Wood, J.M. Effects of night-time bicycling visibility aids on vehicle passing distance. Accid. Anal. Prev. 2020, 144, 105636. [Google Scholar] [CrossRef] [PubMed]

- Hardy, D.A.; Anastasopoulos, I.; Nashed, M.-N.; Oliveira, C.; Hughes-Riley, T.; Komolafe, A.; Tudor, J.; Torah, R.; Beeby, S.; Dias, T. Automated insertion of package dies onto wire and into a textile yarn sheath. Microsyst. Technol. 2022, 28, 1409–1421. [Google Scholar] [CrossRef]

- Simegnaw, A.A.; Malengier, B.; Getnet, M.; Van Langenhove, L. Connecting surface-mounted electronic elements with amber strand metal-clad conductive fibers by reflow soldering. Text. Res. J. 2023, 93, 4068–4079. [Google Scholar] [CrossRef]

- Simegnaw, A.A.; Malengier, B.; Tadesse, M.G.; Van Langenhove, L. Development of Stainless Steel Yarn with Embedded Surface Mounted Light Emitting Diodes. Materials 2022, 15, 2892. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).