Abstract

Commercial solar cells can be embedded between textile layers by laminating to harvest energy in e-textile applications. However, techniques for connecting conductive textile wires to flexible and solid solar cells have not been studied in depth. Based on the literature and experimental validation, this study proposes a stitching connection technique for solar textiles. The feasibility of stitching was experimentally validated. First, the textile wires were joined to flexible solar cells by stitching with a sewing machine, and then embedded between fabric layers with TPU-lamination to simulate a real set-up in e-textile application. The machine washing durability of textile solar cell components with stitch-connected conductive textile wires was successfully verified.

1. Introduction

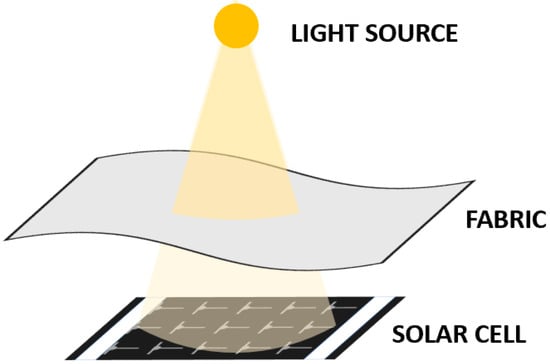

Among the many studies on solar textiles, the solar textile model is the best fit for the purpose of commercial production (Figure 1). Commercial solar cells are designed to be placed under the textile, replacing the solar cell integrated above the textile, and incorporating the principle of light passing through the fabric to reach the solar cell [1]. In existing solar textiles, the connection technology between solar cells and textile wires has not been sufficiently researched. Although the conductivity of some methods is very good, the operation steps are cumbersome and difficult to produce commercially. As in all electrical connections in e-textile applications, they must tolerate bending and twisting without breaking. Moreover, most techniques make the recyclability of the materials difficult after their life has ended. This study attempts to solve the problem of connecting solar cells to textile threads for the mass production of more sustainable solar textiles. It will facilitate research on solar textiles, which are expected to replace embedded batteries with solar cells within applications of e-textiles.

Figure 1.

Schematic of light passing through fabric to a solar cell.

2. Preparation of Samples

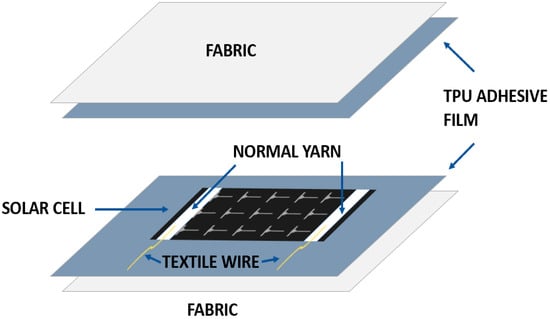

The connection samples were produced using a sewing machine (Figure 2). According to earlier studies of solar textiles [1,2], the textile wires were first connected to the solar cells and then embedded to the textile through TPU encapsulation (Figure 3). According to earlier research about embroidery methods with conductive yarn [3], the needle yarn is normal yarn and the bottom yarn is conductive yarn.

Figure 2.

Stitching of flexible solar cells.

Figure 3.

Layer structure of a waterproof textile-encapsulated solar cell module.

3. Validation Experiment of Stitching Connection

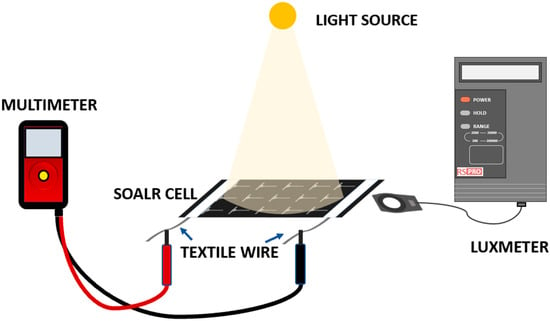

3.1. Measurement of Validation Experiment

The validation experiment was inspired by earlier research wherein textile-embedded solid solar cells and textile wires connected via tape have been shown to withstand 50 machine washings [2]. In this research, the solar cell textile components were delaminated after 15 machine washings, and the energy-harvesting capability was detected by measuring the direct current (DC) of individual solar cell components with an AMPROBE multimeter. All measurements were carried out with only one stable IKEA table lamp as the light source and in the same light position. The schematic of harvesting capacity measurement is shown in Figure 4. For each measurement, the density of light was measured with a luxmeter, which is Luxómetro RS PRO ILM1332A.

Figure 4.

Schematic of harvesting capacity measurement.

3.2. Result of Validation Experiment

Table 1 shows the DC between contact areas of the solar cells before and after the stitching method and after the textile embedding–15 machine washings–textile delamination process. The results show that the performance of the solar cells of each sample remains almost unchanged, which indicates the durability of the developed solar textile component.

Table 1.

Solar cell performance at every stage.

4. Conclusions

The study confirmed the suitability of the stitching method for connecting textile wires to conductive areas on flexible solar cells. Moreover, the performance of the solar cells after 15 washing machine cycles remains almost constant, which indicates the washing durability of the textile solar cell using stitching connection. Stitching is a potential method wherein textile encapsulation protects the solar cell from water.

The connection technology can be optimized by different stitch parameters, different flexible solar cells, and different textile wires.

In addition, 15 washes are not sufficient to replicate the needs of textile solar cell applications. The effect of humidity on long-term use should be studied; more washing and use cycles that simulate full application and the real conditions of use are required to verify the feasibility of the stitching connection method.

Author Contributions

Z.L.: Experimental, Data Curation, Writing—Original Draft; E.I.: Conceptualization, Methodology, Supervision, Writing—Review and Editing; M.A.: Conceptualization, Supervision, Writing—Review and Editing, Funding. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Research data will be available under request.

Acknowledgments

The authors acknowledge the support of Department de Recerca i Universitats de la Generalitat de Catalunya to the textile research group TECTEX (2021SGR01056).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ilén, E.; Halme, J.; Palovuori, E.; Blomstedt, B.; Elsehrawy, F. Sun-Powered Textiles: Designing Energy-Autonomous Electrotextile Systems with Solar Cells Sun-Powered Textiles; Aalto ARTS Books: Espoo, Finland, 2022. [Google Scholar]

- Ilén, E.; Elsehrawy, F.; Palovuori, E.; Halme, J. Washable textile embedded solar cells for self-powered wearables. Res. J. Text. Appar. 2024, 28, 133–151. [Google Scholar] [CrossRef]

- Roh, J.-S. Conductive Yarn Embroidered Circuits for System on Textiles. In Wearable Technologies; IntechOpen: London, UK, 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).