Abstract

Roads are exposed to solar radiation for the entire duration of their service life; depending on the season, the intensity and level of exposure can vary for different locations leading to differences in the magnitude of the damage. In Australia, many local road authorities have already started understanding that their roads are deteriorating faster due to non-load related effects (i.e., environmental damage). The present paper discusses the damage caused by UV radiation on bituminous binders and explores the protecting effect provided by the use of end-of-life tires in the form of crumb rubber. The results suggest that adding crumb rubber to bituminous binders has the potential to significantly reduce the non-load related environmental damage caused by the UV radiation of the Sun.

1. Introduction

Ensuring the durability of asphalt pavements is crucial to guaranteeing not only the performance of the road but also its safety as well as to reducing maintenance costs. The impact of traffic and extreme temperatures on the short- and long-term ageing of roads is well-known. Standard accelerated ageing tests are commonly used by the industry and the scientific community to assess the durability of binders and asphalt mixtures [1,2]. Weather events, such as heavy rains or sudden temperature changes, are expected to reduce the service life of roads; however, the impact of UV radiation has only been considered recently although roads are subjected to solar radiation during their entire service life.

Exposure to ultraviolet (UV) radiation is known to accelerate the ageing of a wide range of materials, such as polymers, by inducing chemical and physical changes which eventually lead to the deterioration of their mechanical properties [3]. A similar mechanism is known to occur in bitumen [4], but the complex composition of bitumen has contributed to delaying a comprehensive understanding of the real impact of UV on asphalt pavements. Polymers are known to be susceptible to oxidation and chain break-down, hence antioxidant additives are commonly used to prevent this phenomenon. For example, approx. 20–30% of carbon black (CB) is used in rubber tires to mitigate oxidation [5]. End-of-life tires can be recycled as crumb rubber (CR) and used in asphalt mixed as a bitumen modifier [6]; hence, the presence of CB in CR could prevent the photodegradation of bitumen and extend the service life of CR-modified roads, which would represent a significant economic benefit for road agencies.

Therefore, the aim of this study is to investigate the impact of crumb rubber, carbon black and its antioxidant potential on the ageing of CR-modified asphalt binders when exposed to UV radiation.

2. Materials and Methods

2.1. Bituminous Binders

Two base binders BB1 and BB2 were supplied by Australian and German suppliers, respectively. The crumb rubber (maximum particle size 0.5 mm) and carbon black used to modify the base bitumen were supplied from Rubber Recycling Overpelt (Pelt, Belgium) and Thermo Fisher Scientific (Belgium), respectively.

CR-modified binder (BB2 + CR) was produced by blending 15 wt% of CR per mass of binder in bitumen at 170 °C and 3500 rpm for 60 min. The same procedure was used to produce CB-modified binder (BB1 + CB) using 4 wt% of CB per mass of binder. A third blend was made by mixing both CR and additional 4 wt% CB in bitumen to produce a CB+CR modified binder (BB2 + CR + CB). In addition, the base binders BB1 and BB2 were also used as reference blends.

2.2. UV Ageing

Each of the five binders was poured into 50 × 50 × 1 mm moulds and exposed to solar radiation for 28 days using a SUNTEST XLS+ weathering chamber equipped with xenon lamps reproducing solar radiations at a controlled irradiance of 765 W/m2.

2.3. Binder Characterisation

The surface of all binders was characterised before and after ageing with Fourier transform infrared (FTIR) spectroscopy using a Perkin Elmer Frontier instrument to assess their degree of oxidation. At least three samples were tested. The carbonyl index of each binder was calculated by considering the ratio between the area of the carbonyl (C=O) characteristic band of bitumen at ≈1700 cm−1 and the area of the aliphatic characteristic bands (C-C) at ≈1450 and 1370 cm−1 [7,8,9]. The viscoelastic properties of the binders were investigated before and after ageing using a Dynamic Shear Rheometer (Anton Paar, MDSC Rheometer) following AASHTO T315 and AASHTO T350 standard test methods. Two replicates were used for each parallel plate (8 mm and 25 mm). Master curves, black diagrams, and the rheological parameter (R) of the samples were assessed.

3. Results and Discussion

3.1. Impact of UV on Rheological Properties

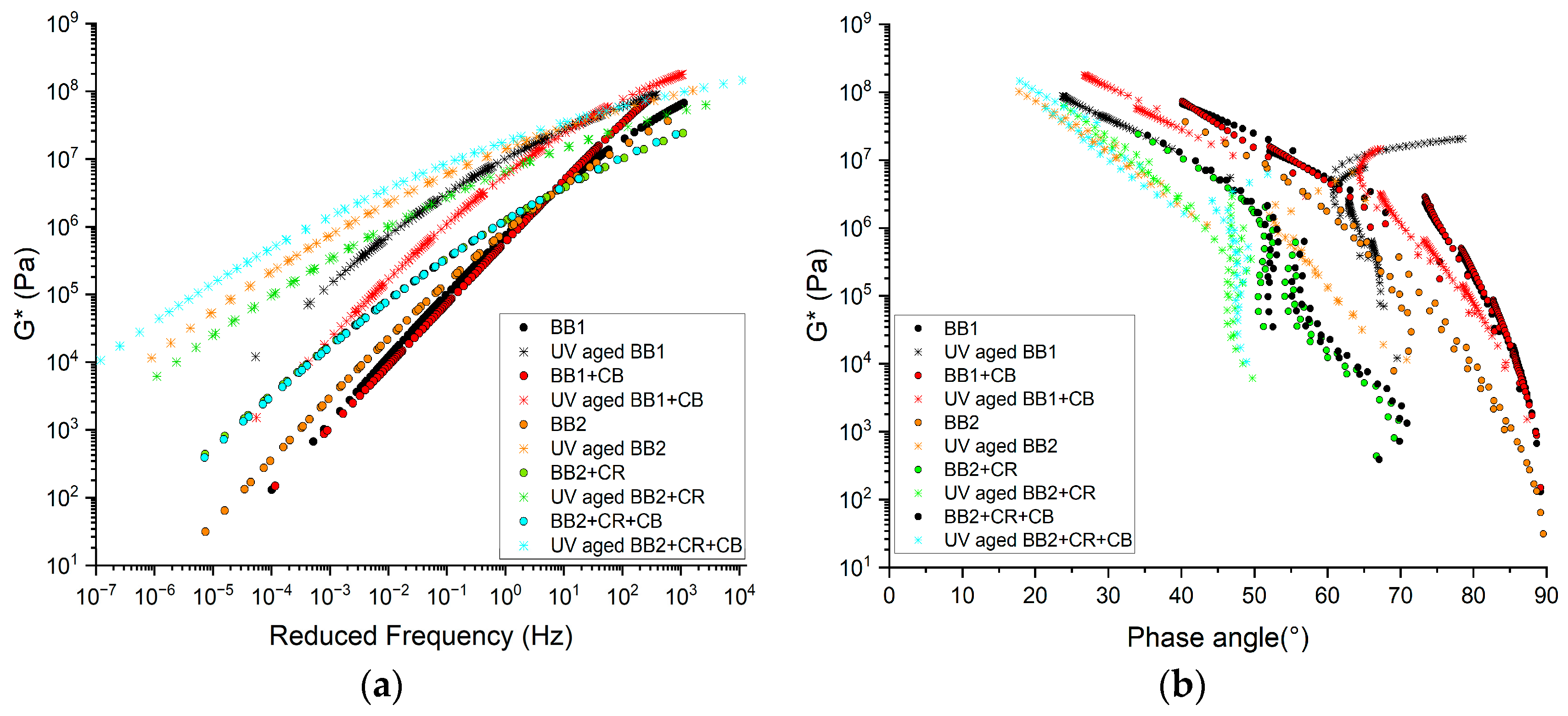

To evaluate the effect of CB on the rheological properties of unmodified bitumen and crumb rubber modified binders, frequency sweep tests were performed. After UV ageing, it is expected that the complex modulus (G*) increases due to the hardening of the binder, particularly in the lower frequency domain. This trend can easily be seen in the master curves for all samples shown in Figure 1a. The presence of CB and CR in the binder reduced the relative increase in G* compared to the neat binder.

Figure 1.

(a) Complex modulus master curves and (b) Black diagram for a temperature range between +10 °C and +60 °C.

To further assess the activity of CB and CR on the binders, the Black diagram of the samples is presented in Figure 1b. The response of the samples became more elastic with UV ageing, which can be observed as a shift towards lower phase angle values. Blends containing CR and/or CB showed a smaller decrease in phase angle after UV ageing compared to the unmodified binders BB1 and BB2 exposed to the same ageing treatment, hence demonstrating a better resistance to UV ageing.

The evolution of UV ageing can also be analyzed by the increase in the rheological parameter (R), which is calculated as the difference between the log of the glassy modulus and the log of the crossover modulus (the point where the loss modulus coincides with the storage modulus). This rheological parameter is related to the width of the relaxation spectrum; hence, higher R values represent longer stress relaxation times and, therefore, a higher susceptibility to thermal cracking. As can be seen in Table 1, it is evident that all binders had an increase in R value after UV ageing but to a different extent. While the R values of BB1 and BB2 increased by 77 and 82%, respectively, the blends with CB and CR showed an increase of only 5 and 23%, respectively. Combining CB and CR led to a similar increase to that with CR only. Hence, the binder containing CB had the shortest relaxation time, followed by the binder modified with CR; thus, they outperformed the other blends in terms of resistance to UV. Adding CB to CR-modified bitumen did not seem to improve the UV resistance of the binder further, thus suggesting that an optimal content of CB could be used for anti-ageing purposes in bitumen.

Table 1.

Rheological parameter R of each binder before and after UV ageing.

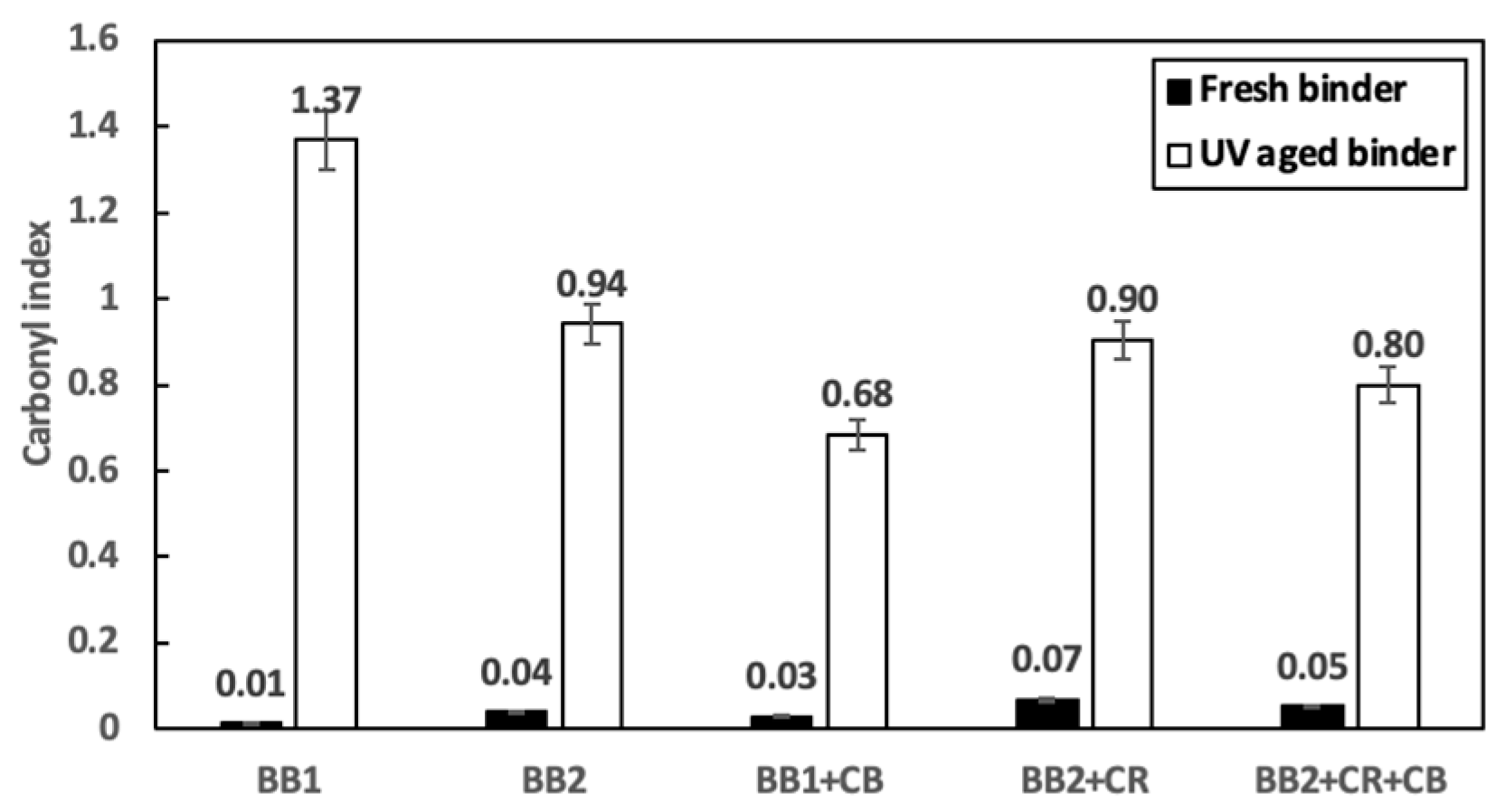

3.2. Role of Crumb Rubber in UV Ageing of Bitumen

ATR FTIR was employed to compare the oxidation levels of bitumen before and after UV ageing. It can be observed in Figure 2 that samples BB1 and BB2 had the highest values for Ico after UV ageing followed by the binders containing CR. The binder with CB has the lowest carbonyl index after UV ageing, confirming that the antioxidant properties of CB slowed down the formation of C=O groups in bitumen and, thus, the oxidative hardening of the binder. This is consistent with the rheological performance of the binder containing CB. CR slightly reduced the oxidation of the binder after UV ageing, most likely due to the presence of CB in CR material.

Figure 2.

Carbonyl index of fresh and UV aged binders.

4. Conclusions

Crumb rubber and carbon black were used in this study as antioxidant additives to reduce the effects of ageing in bituminous binders when exposed to UV radiation. It can be concluded that CB showed a great potential to reduce the effects of ageing, slowing down the oxidation of the binder and making it less stiff and less susceptible to thermal cracking compared to the base binders. CR also improved the performance of the binder after UV ageing compared to non-modified binders, likely due to the presence of CB in CR. Hence, reusing CR in asphalt could improve the long-term resistance of roads against UV ageing.

Author Contributions

Conceptualization, F.G. and M.E.; methodology, M.E. and J.B.B.; formal analysis, M.E. and J.B.B.; writing—original draft preparation, M.E. and J.B.B.; writing—review and editing, F.G., M.E., J.B.B., J.B. and C.V.; supervision, F.G. and M.E.; funding acquisition, F.G., J.B.B., C.V. and J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Green.er funds managed by the King Baudouin Foundation, grant number KBS/2019-E1170430-212694, and by an FWO (Fund of Scientific Research Flanders) research stay, grant V429622N.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors thank TotalEnergies Belgium N.V. and TotalEnergies Germany N.V. for providing bitumen for this study, and Rubber Recycling Overpelt (RRO) for its support by providing crumb rubber samples.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shen, J.; AmirkhaniaN, S.; Tang, B. Influence of accelerated aging test temperature on the properties of binders. Int. J. Pavement Eng. 2006, 7, 191–198. [Google Scholar] [CrossRef]

- Hu, Y.; Si, W.; Kang, X.; Xue, Y.; Wang, H.; Parry, T.; Airey, G.D. State of the art: Multiscale evaluation of bitumen ageing behaviour. Fuel 2022, 326, 125045. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef] [PubMed]

- Petersen, J.C.; Glaser, R. Asphalt Oxidation Mechanisms and the Role of Oxidation Products on Age Hardening Revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2015, 124, 729–741. [Google Scholar] [CrossRef]

- Ge, D.; Chen, S.; You, Z.; Yang, X.; Yao, H.; Ye, M.; Yap, Y.K. Correlation of DSR Results and FTIR’s Carbonyl and Sulfoxide Indexes: Effect of Aging Temperature on Asphalt Rheology. J. Mater. Civ. Eng. 2019, 31, 04019115. [Google Scholar] [CrossRef]

- Marsac, P.; Piérard, N.; Porot, L.; Van Den Bergh, W.; Grenfell, J.; Mouillet, V.; Pouget, S.; Besamusca, J.; Farcas, F.; Gabet, T.; et al. Potential and limits of FTIR methods for reclaimed asphalt characterisation. Mater. Struct. 2014, 47, 1273–1286. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).