Abstract

Rail transport is a vital asset for U.S. Army distribution networks for movements of oversized and overweight vehicles and munitions. As the rail infrastructure ages on military installations, the reliability of these rail systems is a critical concern to support military power projection requirements. The Engineering Research and Development Center (ERDC) evaluates over 1500 miles of Army track approximately every four years. Many Army installations have significant problems with fouled ballast. These installations have few resources to remediate fouled ballast, and/or may not be aware of remediation techniques. The primary objective of this paper is to provide a list of remediation techniques for installations to implement with efforts to reduce fouled ballast and improve track maintenance.

1. Introduction

Fully inspecting, evaluating, and understanding rail substructure is vital to safe transport of military goods and sustaining critical missions. Ballast is a critical component for track stability and performance. Rail ballast has four primary functions: (1) provide adequate track drainage; (2) restrain the track laterally, longitudinally, and vertically; and (3) support the loads of the track and trains while distributing to the subgrade; and (4) allow adjustment of track line and surface/profile [1]. Fouled ballast is a significant maintenance issue that jeopardizes the performance of the rail system. Ballast fouling is often a result of poor drainage flow along the track. When fouling material accumulates over time and loose soil particles start filling voids, the ballast starts to degrade [2,3].

Figure 1 presents a photograph of fouled ballast at an Army installation. The ballast is covered with accumulated fines. Unfortunately, many military installations have limited resources to remediate fouled ballast and may not be aware of remediation techniques to implement within their budgets.

Figure 1.

Fouled Ballast located at an Army Installation.

EDRC’s rail inspection team inspects over 1500 miles of Army rail track every four years. Each year ten to twelve Army installations are inspected, and a report is provided to the installation identifying the track defects. This paper focuses on one primary defect, fouled ballast, which is identified within these reports. We also elucidate recommended fouled ballast remediation techniques that we would begin presenting to installations at final inspection report briefings. The overall objective is to better inform installations of available remediation techniques to improve track maintenance and performance.

2. Evaluation Methods

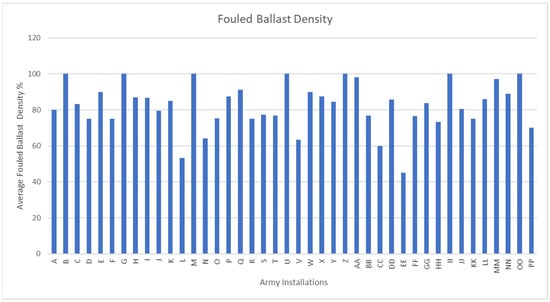

Figure 2 displays the average ballast defect density percentage identified by ERDC’s rail inspection team from inspecting 42 Army installations. The percentage of fouled ballast identified by the track inspector is subjective but based on experience and training. The track inspector provides each section a fouled ballast density percentage ranging from 0% to 100%. The average fouled ballast density percentage is calculated by dividing the percentage provided to each section by the total number of sections inspected.

Figure 2.

Fouled Ballast Density inspected on Army Installations.

Table 1 displays results by assessing the fouled ballast identified and determining the serviceability and reliability for continued track use. When the fouled ballast density falls in the range of (100–85%), it is classified as failed ballast. About 50% of the installations inspected met this criterion. The second highest fouled ballast density between (85–70%), is classified as serious, and 35.7% of the installations inspected met this criterion. None of the installations met the criteria for very fair, satisfactory, or good. These results show that fouled ballast is a significant maintenance issue for Army installations.

Table 1.

Fouled Ballast Condition Results.

3. Techniques for Remediating Fouled Ballast

Ballast performance is greatly affected by the accumulation of fouling materials and water retained by fouling particles [2,3]. When ballast degradation occurs under constant rail traffic over time, it is called breakdown fouling [2,3]. The result of the degradation causes the settlement rate of the ballast to increase [3,4]. Ballast degradation can also increase maintenance cost, a significant factor for installations when making budget decisions. However, implementing timely remediation techniques can lower maintenance costs over the lifetime of the ballast [3].

Techniques for remediating fouled ballast are not a defined standard of practice for the Army or industry. However, our discussions with rail industry representatives, academia, and certified track inspectors reveal that more emphasis on fouled ballast remediation is needed. Although there are techniques available for implementation, funding plays a major role in addressing fouled ballast in the short and long term.

A non-destructive evaluation method that can be used to identify fouled ballast layers under the rail is Ground Penetrating Radar (GPR) [5]. While the technology has some limitations, GPR has become a cost-efficient method for determining fouled ballast layer depth. The capability to quantify the amount to fouled ballast with greater certainty allows for integrating remediation techniques to improve maintenance planning practices.

The following is a list of proven remediation techniques that will be provided to the army for review:

- Track Undercutting—Track undercutting is performed by removing existing ballast beneath the rail ties. Once the ballast is removed from the track. The fines are removed from the ballast and can be either reused or discarded. Undercutting is a valuable method when the track is not raisable due to possible overhead utilities or bridge structures [1].

- Repair/Improve Track Side Drainage—poor drainage is a problem that increases ballast fouling. The ability to divert rainwater away from the track lessens the accumulation of fines. The ability to maintain proper drainage structures, side ditches, and other drainage appurtenances reduces subgrade problems, track deterioration, and ballast fouling.

- Shoulder Cleaning—Shoulder cleaning is a process of removing the existing ballast outside the rail ties, mechanically cleaning the fines from the ballast, and replacing good ballast back onto the shoulder area. This is a cost-effective processes that is less disturbing to the existing ballast sections. It can be performed on longer sections, and typically several miles can be cleaned in one day.

- Geotextile Fabrics—geotextiles are typically used for reinforcement and separation between two materials [6]. The use of geotextile fabric between the sub-ballast and sub-grade reduces the accumulation of fines entering the sub-ballast and fouling.

4. Recommendations/Conclusions

Many factors can influence ballast fouling, such as the gross weight of the load, type of ballast materials, transportation type (freight or passenger), regional climate, and the environmental factors [5]. All of these factors make predicting ballast fouling and ballast layer degradation difficult [5]. The Army has recognized that ballast fouling is a serious issue for its rail system. This paper evaluated past inspections reports from 42 Army installations, focusing on fouled ballast density, as identified by the track inspectors. Nearly 50% of the installations inspected had a condition index ranging from (100–85%), which is classified as ballast failure.

This paper provided recommendation techniques for the Army to review, and possibly implement to extend the life of their rail systems. Track undercutting and shoulder cleaning are proven remediation techniques, but each require labor and funding resources. As rail infrastructure continues to age, implementing maintenance strategies is critical to improve the performance of the rail system over time. Track rehabilitation is costly and identifying funding resources is difficult. The ability to maintain track systems over time will allow the Army to sustain their critical missions with minimal interruptions to rail service.

Author Contributions

Each author contributed to the conceptualization, methodology, investigation, data analysis, and manuscript writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data results are provided within the manuscript from an ERDC vendor. The datasets are not publicly provided to protect the privacy of the vendor.

Acknowledgments

The authors would like to acknowledge Barret Baldwin and ERDC’s rail inspection team for providing the ballast data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- UFC 4-860-03 Railroad Track Maintenance and Safety Standards. 2008. Available online: https://wbdg.org/ (accessed on 9 February 2023).

- Hyslip, J.; Kashani, H.F. Ballast Life and Effective Parameters. In Proceedings of the 2018 Joint Rail Conference, Pittsburg, PA, USA, 18–20 April 2018. [Google Scholar]

- Selig, E.T.; Waters, J.M. Track Geotechnology and Substructure Management; Thomas Telford Publications: New York, NY, USA, 1994. [Google Scholar]

- Hyslip, J.; Kashani, H.F.; Trosino, M. Ballast State of Good Repair. In Proceeding of the 2017 AREMA Annual Conference and Exposition, Indianapolis, IN, USA, 17–20 September 2017. [Google Scholar]

- Guo, Y.; Liu, G.; Jing, G.; Qu, J.; Wang, S.; Qiang, W. Ballast fouling inspection and quantification with ground penetrating radar (GPR). Int. J. Rail Transp. 2022, 11, 151–168. [Google Scholar] [CrossRef]

- Rollings, M.P.; Rollings, R.S. Geotechnical Materials in Construction; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).