Abstract

Brake squeal is an undesirable high-frequency noise caused by vibrations induced by friction in disc brake systems. The noise is strongly affected by temperature, as this influences the material properties of the friction pair and the dynamic behaviour of the brake components. This study investigates the effect of temperature changes on the squeal characteristics of a disc brake system under different operating conditions. Experiments are carried out using a laboratory-scale test setup comprising a rotating disc, pneumatically actuated callipers, and precise measurement equipment. A series of test combinations is performed by systematically varying three parameters: disc surface temperature (40, 55, 70, 85, 100 °C), brake pressure (4.0 bar), and disc rotational speed (50, 100, 150, 200 rpm). Acceleration data are acquired using an accelerometer mounted directly on the calliper, while sound pressure data are measured with a fixed-position microphone located 0.5 m from the disc surface. The collected data are analyzed in the time and frequency domain to identify squeal events and their dominant frequencies. The effect of temperature on brake squeal noise and vibration varies with operating conditions, showing different patterns at low and high disc speed at constant brake pressure. This highlights the importance of considering both thermal and mechanical factors together when addressing brake squeal.

1. Introduction

Comfort is considered an important performance criterion for vehicles. There are several factors that affect vehicle comfort, one of which is the noise level. Noise in road vehicles might occur due to different sources like the engine, tyre, exhaust, brake, drag, etc. Brake noise is the most distinct one among these noise sources and it can appear in different forms like a judder, groan, grunt, crunch, squeal, squeak, chirp etc. [1]. Brake squeal is one of the most studied forms of brake noise as it occurs between the 1 and 16 KHz frequency bands and can be very irritating for humans. Essentially, brake squeal is a dynamical instability problem caused by non-conservative friction forces. It may arise due to several physical phenomena: (1) stick-slip, (2) sprag-slip, (3) self-excited vibrations, (4) mode coupling or mode splitting, and (5) hammering [2,3,4]. Even though there is a great deal of information about the brake squeal problem, a general solution that can fit all kinds of brake systems has not been developed yet. Therefore, for each brake system, a specific solution should be applied to suppress the brake squeal problem.

The effect of temperature is important in the aspect of dynamic performance for braking systems. It affects braking systems in multiple ways such as material properties, contact mechanics, and the tendency of the system to generate effects like noise generation and friction-induced vibrations. Many studies have been performed to investigate the impact of thermal conditions on the behaviour of brake systems across various contexts.

Some of these studies are based on brake systems and brake squeal. Ahn et al. performed a finite element analysis on the disc brakes of an urban railway considering the effect of braking temperature [5]. The results showed that an increase in temperature could cause an uneven contact surface between the brake disc and brake pad, which may lead to brake squeal. The study proposed a reshaping method for brake pads in order to suppress temperature-dependent brake squeal. Maciel conducted a parametric study on the braking system of an off-road vehicle [6]. Their work showed that the rise in temperature increased the possibility of brake squeal occurrence and made the structural modes unstable. They concluded that thermal management in braking systems is essential. Gao et al. used a coupled finite element model with a complex eigenvalue in order to examine the effect of thermal sensitive contact stiffness on the generation of brake squeal [7]. They found that the changes in stiffness due to temperature altered the modal coupling and increased the tendency of noise occurrence within certain frequency ranges. Stevens and Tirovic showed that poor heat dissipation in stationary discs causes increases in operational temperatures and localized hot spots, which leads to a change in material properties like contact stiffness and damping [8]. As a result, the tendency for brake squeal increases due to these thermally induced variations in repeated braking events. Ouyang et al. performed a study focusing on transient analysis and thermal effects, including frictional heat flux and changes in the contact pressure [9]. Their findings indicate that the vibration levels are lower when the effects of temperature are taken into account in the model. Shofiah et al. studied the impact of temperature on the performance of braking systems by comparing the efficiency levels at four different temperatures [10]. They found that temperature has a significant impact on the braking performance by showing that an increase in temperature from 30 °C to 200 °C causes a drop in efficiency level from 75% to 35%.

Some of the studies have been conducted by taking the effect of temperature on vibrations as the main concern. Yu et al. focused on the vibrational behaviour of railway braking systems at −20 °C. The results they obtained showed that the vibration characteristic and wear behaviour of braking materials are strongly affected by the low temperature [11]. They suggested that brake pads with triangular-shaped friction blocks provide a more stable dynamic response and are more suitable for low-temperature operations. Wei et al. studied the effect of temperature on the stiffness of the rail pads. According to their work, friction-induced vibration profiles and friction responses both change significantly by temperature changes within the temperature range of −20 °C to 40 °C [12]. Júnior et al. developed a finite element model with complex eigenvalue analysis in order to inspect the effects of the friction coefficient, braking pressure, brake temperature, and wear on the dynamic stability of a brake system [13]. The results of their work state that the temperature reduces brake pad stiffness, altering the coupling mechanism between the rotor and pad, which can be useful in some cases to mitigate the instabilities and generated noise. Studies imply that temperature is a key factor in braking system performance. It influences material stiffness, damping properties, and the contact mechanism, all of which contribute to brake squeal and vibration instability. Effective thermal management and modelling are crucial for mitigating these problems. Nakae et al. investigated the generation mechanisms of brake squeal and chatter on a mountain bike disc brake [14]. Based on their results, squeal and chatter frequencies do not depend on temperature; however, enough of an increase in temperature can cause a superimposition of in-plane and out-of-plane vibrations of the disc, which leads to very strong vibration.

In this study, the effect of disc surface temperature on brake squeal behaviour is investigated through a detailed experimental approach. The analysis focuses on how thermal variations influence both vibration and noise characteristics under different rotational speeds, while keeping the brake pressure constant. Unlike many previous studies that rely heavily on numerical simulations or limited test conditions, this work offers a broader and more systematic experimental investigation. The test setup allows precise control and measurement of key parameters affecting squeal, supported by synchronized vibration and acoustic data. The main contribution of the study is to reveal the speed-dependent and nonlinear nature of thermal effects on brake dynamics. The findings are expected to support future efforts in brake system design and thermal management.

2. Materials and Methods

2.1. Disc Brake Test Rig Configuration

All experiments in this study are carried out on a custom-designed disc brake test rig (Figure 1) developed to reproduce dynamic conditions representative of brake squeal behaviour in automotive applications. The experimental investigation focuses on three key operational parameters that influence brake squeal behaviour: disc rotational speed (), brake pressure (), and disc temperature (). While the test rig allows for independent control of all three parameters, the study particularly examines how temperature variations under different speed and pressure conditions affect squeal generation. The test configuration, shown in Figure 1, was carefully designed to enable this parametric investigation while maintaining measurement accuracy.

Figure 1.

Experimental test rig for brake squeal investigation.

The experimental setup is designed to investigate brake squeal phenomena in disc brake systems under controlled conditions. As illustrated in Figure 1, the system consists of an electric motor (rated power: 11 kW, torque: 145.9 Nm, nominal speed: 720 RPM) driven by a frequency converter to simulate varying rotational speeds of a vehicle wheel. The motor’s output shaft is connected via a coupling to an axle, which rotates the brake disc. The braking force is applied pneumatically: compressed air from a 10 bar reservoir is regulated by a manual pressure control valve and directed to a pneumatic cylinder. This cylinder actuates the master brake cylinder, which engages the calliper and brake pads against the disc.

To minimize ambient acoustic and thermal interferences and to ensure high repeatability, all experiments were conducted in a semi-anechoic chamber equipped with thermal regulation. The controlled environment allowed for accurate acoustic noise measurements and ensured that the friction-induced thermal behaviour of the brake components remained uninfluenced by external factors.

2.2. Sensor Placement, Data Acquisition, and Testing Procedure

To capture the physical phenomena associated with brake squeal, the test rig is instrumented with multiple sensors strategically placed around critical components. The experimental setup is instrumented with sensors to monitor both the vibrational response of the system and the acoustic emissions. A triaxial accelerometer, with a sensitivity of 10 mV/g (±10%) and a measurement range of ±500 g (≈±4905 m/s2), is mounted on the brake calliper to obtain acceleration data in the tangential (), out-of-plane (), and normal () directions. The triaxial accelerometer’s measurement axes are strategically aligned to capture the brake system’s complete vibrational behaviour. The x-axis measures tangential accelerations parallel to the disc’s rotational direction, primarily sensing stick-slip vibrations generated during braking. Orthogonally, the y-axis detects normal vibrations perpendicular to the disc surface, reflecting fluctuations in contact pressure between the pad and disc. The z-axis completes the measurement system by recording out-of-plane lateral vibrations, which typically originate from calliper bending modes or torsional resonances. The device operates reliably across a frequency range of 0.4 to 10,000 Hz, allowing accurate detection of both low-frequency system dynamics and high-frequency instabilities. Acoustic emissions are recorded using a condenser microphone with a dynamic range of 14.6–144 dB SPL, frequency response between 6.3 and 20,000 Hz, and a sensitivity of 50 mV/Pa. The microphone is placed approximately 50 cm away from the disc-brake system, supported by a three-legged frame to maintain a consistent orientation throughout all tests.

The experimental setup incorporated synchronized measurements of three critical parameters: rotational speed, disc temperature, and braking pressure. Disc speed was precisely controlled and monitored using a laser tachometer (1–100,000 RPM range) mounted on a fixed tripod to maintain consistent optical alignment with the rotating disc surface. The tachometer’s encoder output was time-synchronized with the braking signal via the data acquisition system, enabling precise correlation between rotational dynamics (e.g., speed decay during braking) and squeal onset timing. Simultaneously, disc surface temperature was tracked using a non-contact infrared thermometer focused on a designated measurement point 30 cm from the disc surface, ensuring localized thermal monitoring (−50 to +500 °C range, ±1.5 °C accuracy). This configuration accounted for convective cooling effects while maintaining repeatable positioning across multiple braking cycles. Throughout the experimental trials, the disc surface temperature was continuously monitored from initial brake engagement to complete system cooldown. Hydraulic pressure in the braking circuit was measured downstream of the pneumatic actuator using a piezoresistive pressure transducer (0–14 bar range, 0.5–4.7 V output), providing real-time feedback on the applied normal force.

The experimental data is acquired using a DEWE-43A 24-bit Sigma-Delta ADC system with 8 synchronized analogue channels sampling at 200 kS/s. The system precisely captured time-aligned measurements from all sensors: triaxial accelerometer (vibration), microphone (acoustics), infrared thermometer (temperature), pressure transducer (hydraulic pressure), and laser tachometer (rotational speed). Integrated signal conditioning supported direct sensor connections while eliminating noise, and the DewesoftX software 2025.3 enabled real-time monitoring and synchronized data analysis of all parameters critical for brake squeal investigation.

Data acquisition is performed at a 20 kHz sampling rate, over 10 s per test, recording acceleration, sound pressure, rotational speed, temperature, and brake pressure. To ensure signal fidelity, anti-aliasing filters are applied and spectral leakage is mitigated using a Hanning window. Analyses are performed in the time and frequency domains. The use of the Fast Fourier Transform (FFT) enables the identification of vibration modes and super harmonics, while time–frequency representations provided insights into transient phenomena and parameter-dependent instabilities. Signal processing routines are performed using MATLAB software (MATLAB_R2024b). The raw acceleration signals are first filtered using a 4th-order Butterworth bandpass filter (10 Hz to 10 kHz) to remove low-frequency drift and suppress high-frequency noise. The FFT is then applied to each acceleration axis to construct the vibration spectrum, allowing the identification of characteristic modes and harmonic structure in the system response.

Testing is conducted under steady-state conditions after all system variables (disc rotational speed, brake pressure, and disc temperature) reach the desired levels. A total of braking events are carried out under various operating conditions: brake pressure of ; disc speed of ; and surface temperature of . The measured temperature values represent the disc surface temperatures at brake initiation. During braking events, temperature increases are observed across all test conditions, with a maximum recorded temperature rise of relative to initial values. Before each test sequence, background noise is recorded under identical disc speed but without braking engagement to characterize non-squeal acoustic contributions.

3. Results

This section presents and interprets the experimental results obtained from the disc brake test rig under controlled variations in disc surface temperature and rotational speed, while maintaining constant brake pressure. The analysis focuses on two primary response quantities: vibration signals measured via triaxial acceleration and acoustic emissions characterized by sound pressure levels. The goal is to reveal how thermal conditions influence the onset and severity of brake squeal and associated vibrational behaviours across different operating scenarios. By systematically evaluating both time-domain signals and statistical measures such as RMS acceleration and SPL, the findings aim to establish correlations between squeal characteristics and thermo-mechanical parameters.

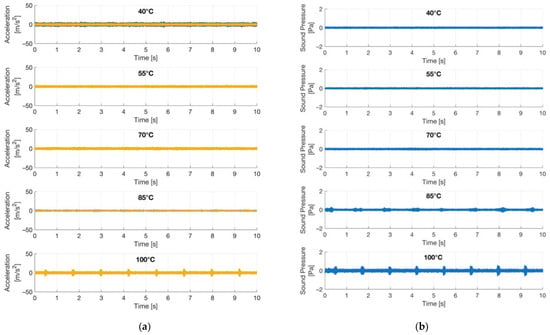

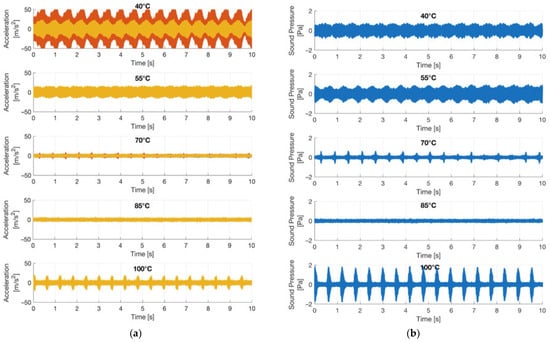

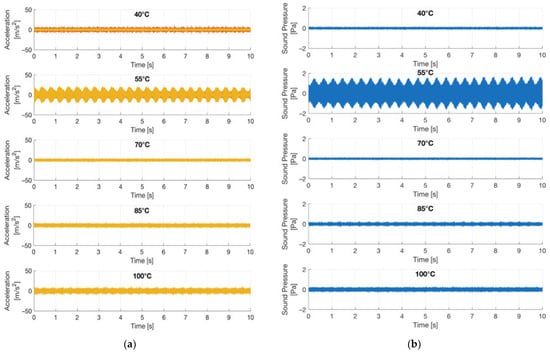

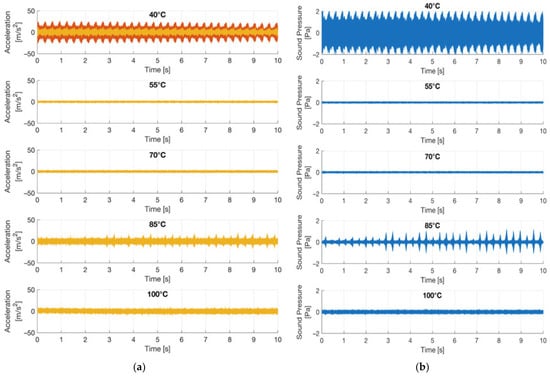

Figure 2, Figure 3, Figure 4 and Figure 5 display the time-domain tri-axial acceleration signals (Figure 2a, Figure 3a, Figure 4a and Figure 5a) and corresponding sound pressure responses (Figure 2b, Figure 3b, Figure 4b and Figure 5b) recorded during braking events at four rotational speeds () under constant brake pressure () and varying disc surface temperatures. At (Figure 2), all three acceleration components (, , ) exhibit relatively low amplitude, and the sound pressure signal remains smooth with minimal fluctuation across the tested temperature range. This indicates that at low rotational speed, temperature has a limited impact on dynamic instability and squeal generation. However, at (Figure 3), distinct bursts appear in the acceleration signals, particularly in the and directions, with corresponding intermittent peaks in the sound pressure trace. These disturbances become more pronounced at lower temperatures (e.g., ), suggesting that the system is more prone to squeal under cooler disc conditions where the friction coefficient and contact stiffness tend to be higher. At (Figure 4), sustained oscillations with higher amplitudes are observed in all directions, and the acoustic signal reveals sharp periodic peaks, especially around mid-temperature levels (notably ), indicating the activation of unstable vibration modes strongly coupled with friction-induced excitation. This highlights a critical speed–temperature interaction that promotes squeal generation. At (Figure 5), although acceleration signals remain elevated, the sound pressure waveform becomes more irregular and less periodic, implying a shift in squeal characteristics. At higher temperatures (e.g., ), both vibration and noise amplitudes decrease slightly, possibly due to thermal softening effects, reduced frictional stiffness, or changes in pad–disc contact behaviour. Overall, the results demonstrate that squeal events are not solely speed-dependent but are significantly modulated by disc temperature, with specific combinations of speed and thermal state leading to the amplification or suppression of friction-induced instabilities.

Figure 2.

Time-domain signals measured during braking event under and operational conditions: (a) tri-axial acceleration responses (x, y, z) recorded by the accelerometer mounted on the brake calliper; (b) sound pressure signal captured by a microphone placed 50 cm away from the brake disc.

Figure 3.

Time-domain signals measured during braking event under and operational conditions: (a) tri-axial acceleration responses (x, y, z) recorded by the accelerometer mounted on the brake calliper; (b) sound pressure signal captured by a microphone placed 50 cm away from the brake disc.

Figure 4.

Time-domain signals measured during braking event under and operational conditions: (a) tri-axial acceleration responses (x, y, z) recorded by the accelerometer mounted on the brake calliper; (b) sound pressure signal captured by a microphone placed 50 cm away from the brake disc.

Figure 5.

Time-domain signals measured during braking event under and operational conditions: (a) tri-axial acceleration responses (x, y, z) recorded by the accelerometer mounted on the brake calliper; (b) sound pressure signal captured by a microphone placed 50 cm away from the brake disc.

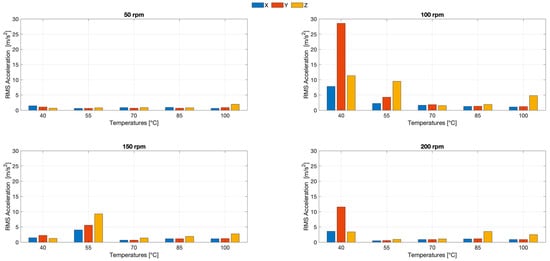

Figure 6 shows that disc temperature has a significant yet speed-dependent impact on vibration levels. At , RMS acceleration values remain low across all temperatures, indicating stable dynamics. At , vibration amplitudes peak at lower temperatures (around ), suggesting that cooler conditions increase the likelihood of squeal. The most critical behaviour is observed at , where a sharp rise in RMS values at reflects strong dynamic instability. At , vibration levels are moderately high but tend to decrease with increasing temperature. Overall, the results highlight that squeal-related vibrations are most pronounced at intermediate temperatures and speeds, where frictional and modal interactions are most sensitive to thermal variations. The tabulated RMS values (Table 1, Table 2, Table 3 and Table 4) confirm that temperature effects are strongly speed-dependent. At low speed (50 rpm), vibration levels remain low across all temperatures. At 100 and 200 rpm, colder conditions (~40 °C) lead to higher amplitudes, particularly in the y-axis. The most pronounced instability occurs at 150 rpm around 55 °C, where all axes show sharp increases, indicating strong modal interactions.

Figure 6.

Variation in RMS acceleration values in the , , and directions at different disc surface temperatures () for 4 rotational speeds () under constant brake pressure ().

Table 1.

Variation in RMS acceleration values in the , , and directions at different disc surface temperatures () for a rotational speed under constant brake pressure ().

Table 2.

Variation in RMS acceleration values in the , , and directions at different disc surface temperatures () for a rotational speed under constant brake pressure ().

Table 3.

Variation in RMS acceleration values in the , , and directions at different disc surface temperatures () for a rotational speed under constant brake pressure ().

Table 4.

Variation in RMS acceleration values in the , , and directions at different disc surface temperatures () for a rotational speed under constant brake pressure ().

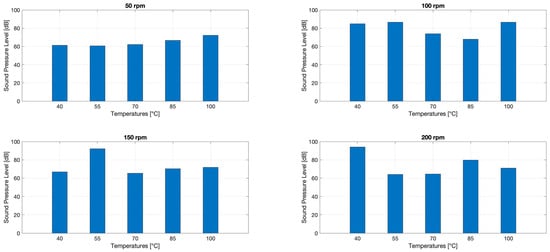

Figure 7 demonstrates that disc temperature significantly influences the sound pressure levels associated with brake squeal. At and , SPL peaks are observed around , indicating a critical thermal zone where squeal noise is most severe. At low speed (), SPL values remain relatively stable across all temperatures, showing minimal sensitivity to thermal effects. In contrast, at , the highest SPL occurs at and decreases with rising temperature, suggesting that thermal softening reduces squeal intensity at high speeds. These results confirm that brake squeal is most prominent within specific temperature ranges, particularly at mid-level temperatures where frictional and structural interactions are dynamically amplified.

Figure 7.

Sound pressure level (SPL) measurements at varying disc surface temperatures () for four different disc rotational speeds () under a constant brake pressure of .

The corresponding numerical values for the SPL measurements are provided in Table 5, Table 6, Table 7 and Table 8 for clarity. These tables allow a more precise interpretation of the bar chart data presented in Figure 7. At 50 rpm, SPLs vary only slightly with temperature, ranging from approximately dB at 40 °C to dB at 100 °C, confirming the low thermal sensitivity noted earlier. At 100 rpm, the peak value of dB is recorded at 55 °C, which aligns with the critical temperature range identified for squeal occurrence. Similarly, at 150 rpm, SPL reaches its maximum of dB at 55 °C, before decreasing at both lower and higher temperatures. In contrast, at 200 rpm, the highest SPL of dB occurs at 40 °C, followed by a progressive reduction as the temperature rises, supporting the observation that thermal softening diminishes squeal intensity at higher speeds.

Table 5.

Sound pressure level (SPL) measurements at varying disc surface temperatures () for disc rotational speeds under a constant brake pressure of .

Table 6.

Sound pressure level (SPL) measurements at varying disc surface temperatures () for disc rotational speeds under a constant brake pressure of .

Table 7.

Sound pressure level (SPL) measurements at varying disc surface temperatures () for disc rotational speeds under a constant brake pressure of .

Table 8.

Sound pressure level (SPL) measurements at varying disc surface temperatures () for disc rotational speeds under a constant brake pressure of .

4. Conclusions

In this study, the effect of disc surface temperature on brake squeal behaviour is experimentally investigated using a laboratory-scale test rig equipped with a rotating disc, pneumatically actuated callipers, and precise vibration and acoustic measurement systems. A total of braking tests are performed by systematically varying disc rotational speed and surface temperature under constant brake pressure, and both acceleration and sound pressure responses are recorded.

The experimental results clearly show that temperature is a critical factor influencing the onset and severity of brake squeal. At low speed (), temperature variations have minimal impact on vibration and noise levels. However, at intermediate speeds (), specific temperature ranges—particularly around —triggered significant increases in RMS acceleration and SPL values, indicating strong dynamic instability and high squeal tendency. At higher temperatures (), a general reduction in vibration and noise amplitudes was observed, suggesting that thermal softening, reductions in the dynamic friction coefficient, and changes in contact damping can suppress squeal. These findings highlight the nonlinear and speed-dependent nature of temperature effects on brake dynamics.

Future work may focus on extending the analysis to transient braking scenarios and incorporating contact surface imaging or thermographic monitoring to better understand localized thermal effects. Additionally, numerical modelling supported by experimental validation can provide further insights into the coupled thermo-mechanical behaviour of brake components under varying load and temperature conditions.

Author Contributions

Conceptualization, A.Y. and O.T.S.; methodology, A.Y. and O.T.S.; software, T.G.; formal analysis, T.G.; investigation, A.Y., O.T.S., M.E.K., and T.G.; resources, M.E.K.; data curation, T.G.; writing—original draft preparation, A.Y., O.T.S., M.E.K., and T.G.; writing—review and editing, A.Y., O.T.S., M.E.K., and T.G.; visualization, A.Y., O.T.S., M.E.K., and T.G.; supervision, A.Y. and O.T.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Scientific and Technological Research Council of Türkiye (TÜBİTAK) through the 1004—Center of Excellence Support Program under the grant number 22AG018.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Akay, A. Acoustics of friction. J. Acoust. Soc. Am. 2002, 111, 1525–1548. [Google Scholar] [CrossRef] [PubMed]

- Yavuz, A.; Sen, O.T. Stability analysis of a mass-sliding belt system and experimental validation as motivated by the brake squeal problem. J. Vib. Eng. Technol. 2023, 12, 395–414. [Google Scholar] [CrossRef]

- Yavuz, A.; Sen, O.T. Investigation of friction induced vibrations on a nonlinear two degree of freedom mathematical model and experimental validation. Int. J. Non-Linear Mech. 2024, 165, 104799. [Google Scholar] [CrossRef]

- Yavuz, A.; Sen, O. Investigation of the pad stiffness effects on the initiation of brake squeal phenomenon. J. Theor. Appl. Mech. 2023, 61, 219–232. [Google Scholar] [CrossRef]

- Ahn, S.; Sohn, C.; Choi, S.; Nam, C. Study on reduction of squeal noise of disc brake system considering braking temperature of urban railway vehicle. J. Mech. Sci. Technol. 2023, 37, 2253–2262. [Google Scholar] [CrossRef]

- Maciel, M.H.C.; Rodrigues, R.D.N.; Costa, C.A.S.; De Araujo Bezerra, R.; Gonçalves, V.V.; De Freitas, T.V.A. Parametric analysis on temperature influence on brake squeal generation in a single-seater off-road vehicle’s disc brake. Noise Vib. Worldw. 2023, 54, 570–586. [Google Scholar] [CrossRef]

- Gao, P.; Du, Y.; Ruan, J.; Yan, P. Temperature-dependent noise tendency prediction of the disc braking system. Mech. Syst. Signal Process. 2020, 149, 107189. [Google Scholar] [CrossRef]

- Stevens, K.; Tirovic, M. Heat dissipation from a stationary brake disc, Part 1: Analytical modelling and experimental investigations. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 1707–1733. [Google Scholar] [CrossRef]

- Ouyang, H.; Bakar, A.R.A.; Li, J. A combined analysis of heat conduction, contact pressure and transient vibration of a disk brake. Int. J. Veh. Des. 2009, 51, 190. [Google Scholar] [CrossRef]

- Shofiah, S.; Syah, I.N.; Hadi, S.; Widiandaru, N.O.; Asmin, L.O. Statistical Analysis of temperature Effects on brake force and efficiency in vehicle braking Systems: A Comprehensive study. E3S Web Conf. 2025, 622, 01003. [Google Scholar] [CrossRef]

- Yu, Z.; Feng, S.; Zhang, Q.; Tang, B.; Mo, J.; Zhu, S.; Jin, W. The effects of friction block shape on Friction-Induced wear, vibration, and noise of train brake interface at low temperature. Tribol. Lett. 2024, 72, 97. [Google Scholar] [CrossRef]

- Wei, K.; Wang, F.; Wang, P.; Liu, Z.X.; Zhang, P. Effect of temperature- and frequency-dependent dynamic properties of rail pads on high-speed vehicle–track coupled vibrations. Veh. Syst. Dyn. 2016, 55, 351–370. [Google Scholar] [CrossRef]

- Júnior, M.T.; Gerges, S.N.Y.; Jordan, R. Analysis of brake squeal noise using the finite element method: A parametric study. Appl. Acoust. 2007, 69, 147–162. [Google Scholar] [CrossRef]

- Nakae, T.; Ryu, T.; Sueoka, A.; Nakano, Y.; Inoue, T. Squeal and chatter phenomena generated in a mountain bike disc brake. J. Sound Vib. 2010, 330, 2138–2149. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.