Abstract

Landmines remain a significant hazard in contemporary warfare and post-conflict areas, jeopardizing the safety of both civilians and military personnel. This work suggests “Defence Pal,” a cost-effective and portable robotic prototype for landmine detection and environmental monitoring. Its primary objective is to minimize human risk while improving detection speed and accuracy. The system consists of a wireless-controlled vehicle equipped with a metal detector, gas sensors, and obstacle avoidance features, enabling real-time terrain surveillance while ensuring operator safety. Built with components including a Flysky FS-i6 transmitter and receiver, the prototype was tested under hazardous conditions. It demonstrated reliable detection of buried metallic objects and dangerous gases such as methane and carbon dioxide. The autonomous response system halts the robot and activates visual and auditory alarms upon detecting threats. Our experiments achieved average detection accuracies of 83% for metallic objects and 87% for hazardous gases, validating their performance. These results highlight the practicality and effectiveness of Defence Pal compared to conventional manual detection methods. The results confirm that Defence Pal is a practical, scalable, and cost-effective alternative to traditional manual detection methods for improving landmine identification and environmental hazard monitoring. Therefore, the novelty of this work lies in a low-cost dual-sensing prototype that enables simultaneous detection of gas and metal, providing a practical alternative to conventional single-target, high-cost systems.

1. Introduction

Landmines continue to imperil military personnel, civilians, and relief workers in post-conflict zones and modern fighting [1]. They are often buried or displayed. These concealed explosives detonate when pressure, vibration, or proximity is applied. Fatalities, significant injuries, psychological distress, and land use limitations for decades after hostilities end are devastating. Landmines hinder infrastructure restoration, agricultural growth, and the safe return of displaced persons in many affected regions [2]. Despite international efforts to demine and remove mines, including the 1997 Ottawa Treaty, which prohibits the use of anti-personnel mines, millions of these devices remain in use, often in regions with limited financial and technical resources [3]. Landmine clearance and identification are dangerous. Traditional manual detection methods require expert individuals to use portable metal detectors or probing equipment near explosives. While they can be helpful, these methods are time-consuming, laborious, and potentially hazardous. Dogs and rats can detect mines, but they require specialist training, ongoing care, and cautious monitoring, which may limit operational scalability. Even if they are effective, high-end robotic or sensor-based detection systems are expensive, require extensive maintenance, and involve proprietary technology that may not be accessible in low-resource environments [4].

Due to these challenges, research focuses on affordable, portable, and remotely operated robotic mine detectors. These technologies reduce human danger, improve detection, and enable deployment in resource-constrained settings. Defence Pal uses publicly available components, open-source development tools, and microcontroller-based technology to give a viable and economical choice. Defence Pal is a low-cost, portable robot for environmental monitoring and landmine detection. It can detect landmines as a remotely operated vehicle prototype equipped with a metal detector. Remote control using a wireless interface keeps operators from potential dangers, reducing the risk of injury or death. The device can also visually observe terrain to report hazards and environmental conditions. The system gains functionality beyond metal detection. Ultrasonic sensors and obstacle avoidance technology enable the robot to navigate busy, hilly terrain without human assistance. A gas sensor may also detect carbon dioxide and methane found in mine-affected areas, due to changes in soil composition or the presence of explosion remnants. A GPS-based location mapping module logs threat coordinates for systematic clearing and data collection. An automated response mechanism in the Defence Pal system activates when a threat is detected. When it senses metal or toxic gas, the robot stops moving, sends sonic alarms, and displays warnings via an LED and buzzer system. This rapid output ensures that operators are aware of potential hazards in real time and can take necessary safeguards.

The prototype utilizes reliable and affordable elements, including the Flysky FS-i6 transmitter-receiver module for long-range wireless communication, a metal detector sensor, and an MQ-series gas sensor. Cost and scalability are maintained, while this hardware combination ensures precise detection. The technology accurately identifies shallowly buried hazardous gases and metallic objects in controlled hazardous field testing. The Defence Pal’s testing results show it can replace manual detection methods. Defence Pal enables remote, secure, and effective surveying, enhancing safety over conventional approaches that require direct operator access to hazardous sites. Due to its open-source and modular architecture, the system may be upgraded with better camera systems, detection technologies, and navigation algorithms.

The Defence Pal is scalable, cost-effective, and suitable for environmental hazard monitoring and landmine detection in risky locations. Wireless remote operation, real-time detection, and safety-oriented design make this prototype a promising method for improving operational performance and saving lives in mine-affected areas. This work addresses a pressing humanitarian and defense need, demonstrating how freely accessible technology can provide meaningful solutions in resource-constrained environments.

The key contributions of the paper are:

- Development of “Defence Pal”, an economical, portable, and wireless-controlled robotic platform for landmine detection using a metal detector.

- Integration of multi-functional modules, including obstacle avoidance and gas sensing for hazardous environments.

- Implementation of an autonomous response system that halts movement and triggers audio-visual alarms upon detecting threats.

- Demonstrating a cost-effective, scalable, and better alternative to conventional manual detection methods enhances operational efficiency in dangerous environments.

2. Literature Study

A new evaluation of landmine-detection robot design emphasises cost and simplicity of maintenance for resource-constrained deployment, focusing on mobility, terrain flexibility, and real-time processing. An analysis of various landmine detection designs and characteristics is presented in [5], highlighting existing works and potential future directions. A robot equipped with an Arduino-based metal detector illustrates how coil-induction sensing, Arduino control, buzzer alarms, and simple user interfaces can facilitate low-cost detection, as discussed in [6]. The study shows that such devices can detect metallic objects at modest depths, validating the fundamental sensing technique [6]. A comprehensive assessment of Ground-Penetrating Radar (GPR) for mine detection, discussed in [7], highlights its superior performance against minimum-metal mines compared to conventional metal detectors. The study further identifies that the most successful developments occur when GPR is integrated with other sensors, particularly metal detectors [7]. In [8], a multi-stage sensor-fusion approach for landmine detection is presented, proposing the integration of complementary sensors (e.g., metal detectors and GPR) at the feature or decision level to reduce false positives and improve classification. The study introduces a modular architecture, featuring a central metal detector for coarse detection, as well as additional gas, ultrasonic, and GPS sensors to contextualize the warnings [8]. Decision-level sensor fusion for humanitarian demining, as presented in [9], demonstrates that combining a metal detector, an infrared camera, and a ground-penetrating radar enhances detection performance compared to using single sensors. The findings suggest that a progressive multi-sensor strategy—starting with metal detection and incorporating additional sensors as needed—can improve effectiveness without incurring prohibitive costs [9]. In Ref. [10], the authors tackle the challenge of enhancing mine detection accuracy and efficiency by introducing a deep learning architecture designed for pulse induction-based metallic mine detectors. Their results indicate that learned signal processing can improve the performance of even low-cost detectors, thereby reducing false alarms [10]. A recent study integrates robots, deep learning, and on-board vision for real-time surface landmine detection, demonstrating the potential of optical sensors [11]. While the system targets buried metallic objects, a key contribution lies in its approach to managing false positives, a common challenge in detection systems. In Ref. [12], a modern strategy for landmine detection is proposed, employing unmanned aerial vehicles (UAVs) equipped with thermal imaging cameras and a deep learning framework. The method leverages a lightweight yet effective model, offering a safe, cost-efficient, and rapid solution for mine detection. This work underscores the potential of combining UAVs and deep learning to address humanitarian and environmental challenges.

Contemporary research seldom integrates cost-effectiveness, maintainability, and modular scalability into a singular deployable demining platform. Research frequently concentrates on economical metal detection or sophisticated multi-sensor fusion, with minimal emphasis on modular, upgradable solutions. Deep learning demonstrates potential for minimising false positives; however, it is hardly utilised in low-power, real-time embedded systems. Optical AI-driven surface mine identification is often uncoordinated with subsurface mine detection, resulting in incomplete coverage. Limited studies evaluate sensor efficacy in terms of life-cycle expenses, terrain adaptation, and operator usability.

Multi-sensor fusion outperforms single sensors. Low-cost Arduino/embedded rovers are practical for shallow, high-metal detection and initial field surveys, and machine learning and signal-processing upgrades can significantly reduce false positives. Defence Pal, a pragmatic, modular remote rover equipped with metal detection, gas sensing, obstacle avoidance, and an upgrade path to sensor fusion and ML-based classification, bridges the operational gap between high-cost commercial systems and manual detection, which is often risky.

3. Suggested Model

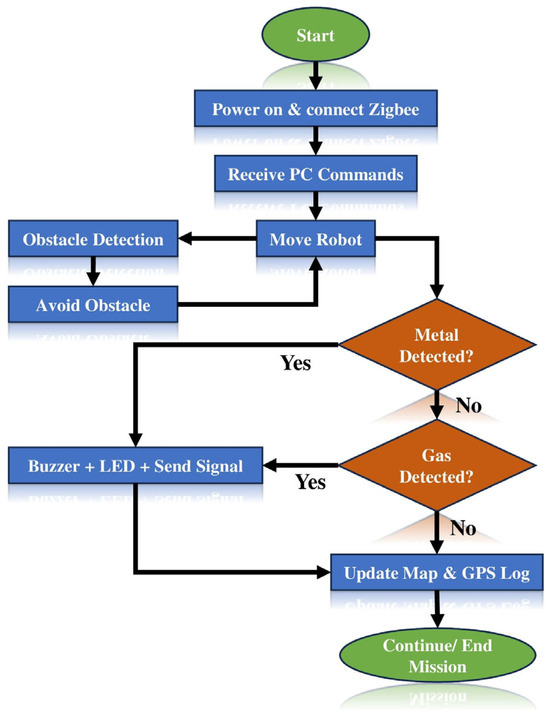

A landmine-detecting robot is essential in peacekeeping operations and for decontaminating regions affected by explosives. This method aims to enhance operator safety by enabling remote operation and precise threat detection, eliminating the need for direct human contact with hazardous areas. The proposed robot is operated remotely using a computer interface utilising a Zigbee communication module (Macfos LTD, Pune, India), facilitating long-range, low-latency control. The system’s foundation is an Arduino UNO microcontroller (Macfos LTD, Pune, India), which orchestrates and interprets data from all integrated modules. The robot incorporates an ultrasonic sensor (Erh India, Valsad, India) for obstacle identification, ensuring safe and efficient navigation by preventing collisions with objects or irregular terrain. A GPS module (Robocraze Bengaluru, India) delivers accurate location data in latitude and longitude, enabling operators to document and designate the specific locations of identified landmines for methodical removal. A metal detector (Robocraze, Bengaluru, India) is utilised to detect subterranean metallic landmines. Upon detecting a possible danger, the Arduino activates a buzzer to provide immediate audible alarms, while simultaneously notifying the operator through the PC interface. The robot’s body is composed of resilient materials designed to endure minor explosion impacts, providing a degree of physical protection for its components. The robot employs high-torque DC motors (Robocraze, Bengaluru, India), driven by an H-bridge motor driver circuit, allowing seamless multi-directional mobility across uneven terrain. All components are affixed to a small chassis and energised by a specialised power supply unit. The PC monitoring station manages navigation and presents detection data and GPS coordinates to accurately map mine placements on the map accurately. This cohesive methodology ensures that real-time detection, navigation, and position monitoring are effectively managed, making the system a dependable and secure option for hazardous field activities. The workflow of the suggested model is depicted in Figure 1.

Figure 1.

Flow chart of the proposed model.

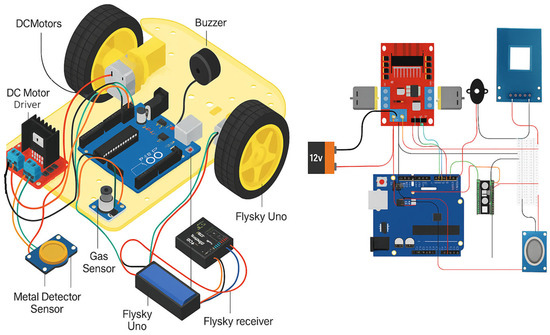

The novelty of this work introduces a low-cost, portable robot that detects both buried metallic objects and hazardous gases in real time. It integrates multiple functions—metal detection, gas sensing, obstacle avoidance, and mapping—into a single wireless-controlled platform. An autonomous safety system halts movement and triggers alarms upon detecting a threat, thereby improving safety over manual methods. The schematic of the working model used in the experiment, along with the corresponding circuit connection diagrams, is shown in Figure 2.

Figure 2.

Schematics of the proposed working model and connections.

4. Results and Analysis

The Defence Pal prototype was rigorously tested in controlled experimental conditions to evaluate its performance in landmine detection and environmental hazard monitoring. The trials highlighted the effective integration of hardware and software modules, demonstrating the system’s ability to operate reliably in scenarios that replicate real-world hazards. The results are divided into three parts: metal detection, hazardous gas detection, and operation reliability, as discussed below.

4.1. Metal Detection Performance

The metal detection module consistently identified buried metallic objects with an overall average accuracy of 83.08%. The accuracy varied slightly across test cases, influenced by soil composition, burial depth, and object size, but the performance remained above 80% in all instances. The test cases are presented in Table 1. The soil composition was kept constant for experimental purposes due to availability constraints, while other parameters were varied.

Table 1.

Various conditions for test cases (soil composition is kept constant).

Notably, the system provided immediate hazard response: whenever a metallic object was detected, the robot stopped its movement and activated visual and auditory alarms through an LED-buzzer system. The case-wise analysis (Table 2) shows that detection accuracy ranged from 80.43% to 85.96%, with Case 4 recording the highest reliability at 85.96%. The highest reliability was achieved when the object was large and buried at greater depth. This is because, near the surface, metallic impurities other than the target object are more prevalent, whereas at deeper levels, such impurities are reduced. As a result, detection becomes easier and the number of false detections decreases. Correct identifications per trial varied between 37 and 52, while false detections remained comparatively low, ranging from 8 to 11. These results demonstrate that the prototype maintains consistent accuracy, which is sufficient for practical field use in hazardous conditions where reliability is critical.

Table 2.

Accuracy of the robot in a controlled environment for metal detection.

4.2. Hazardous Gas Detection Performance

The integrated MQ-series gas sensor effectively detects combustible and toxic gases, such as methane and carbon dioxide, which are often present in mine-affected zones due to soil disturbances or explosive remnants. The gas sensing system achieved an average accuracy of 86.72%, outperforming the metallic detection module and exhibiting stable sensitivity across all test conditions. The case-wise breakdown (Table 3) indicates that accuracies ranged from 84.85% to 89.36%, with Case 4 yielding the highest detection rate of 89.36%. Gas production was relatively high at medium depth with a large object size. Gases mix with air near the surface, whereas they tend to become trapped at greater depths. Correct identifications ranged from 42 to 56, with false alarms ranging from 5 to 10. This robust gas-sensing capability highlights the system’s potential for mine detection and broader environmental hazard monitoring, extending its utility beyond military applications to disaster management and civilian safety operations.

Table 3.

Accuracy of the robot in a controlled environment for combustible or toxic gases.

4.3. Operational Reliability

Beyond detection accuracy, the operational robustness of the Defence Pal prototype was a key aspect of the evaluation. The wireless control system, utilizing the Flysky FS-i6 transmitter and FS-iA6 receiver, maintained a stable operating range of 20–30 cm in open field conditions, ensuring operators remained safe from potential hazards. The robot’s four-wheel drive configuration, powered through an L298N motor driver, provided sufficient torque and stability to traverse varied terrains, including gravel, mud, and uneven ground, with minimal slippage. Moreover, integrating the Arduino Uno enabled seamless real-time communication between sensors and actuators, ensuring that the robot’s responses to detected threats were instantaneous. This rapid responsiveness further enhances operator safety by reducing the likelihood of accidental exposure to hazardous environments.

5. Discussion

The results confirm that the Defence Pal prototype delivers dependable performance across multiple domains of hazard detection. The system achieved an average accuracy of 83.02% for metallic objects and 86.55% for hazardous gases, which are pretty effective for field deployment. Its ability to automatically halt movement and trigger alerts upon detection ensures a built-in layer of operator safety, while its wireless range and terrain adaptability strengthen its suitability for practical use in real-world conditions.

These outcomes underscore the value of Defence Pal as a practical, low-cost, and scalable platform for detecting landmines and other hazards. While the current prototype is limited to shallow metal detection and controlled environmental conditions, its modular design allows future upgrades, such as deeper detection mechanisms, improved gas-sensing accuracy, and advanced sensor fusion techniques powered by artificial intelligence. Such enhancements would further elevate its applicability in defence and humanitarian operations, making it a promising solution for safer and more efficient hazard mitigation in resource-constrained environments.

6. Performance Comparison

Table 4 presents a comparison of the current work’s performance with previously reported literature.

Table 4.

Comparative performance analysis of the current study and previously reported works.

The examined research indicates that other works typically report superior performance, with GPR offering more depth at intermediate accuracy (~80%) [14], and UAV magnetometry (97.8%) [13] and pulse-induction with deep learning (93.5%) [10] obtaining the best accuracy. Neutron interrogation [16] offers deeper penetration but remains limited to laboratory settings (~85%), whereas multi-sensor fusion systems (90%) [8] provide a more balanced performance.

Although these techniques excel in accuracy, they frequently focus on single-target detection or need costly, sophisticated setups. The Defence Pal prototype, on the other hand, is unique in integrating gas and metal detection within a single, low-cost system, albeit with somewhat lower accuracies—83.08% for metals and 86.72% for gases at shallow depths (4–6 cm). It is a valuable and adaptable solution for real-world applications where cost-effectiveness and multi-threat detection are crucial, due to its dual capabilities and affordability. Hence, the novelty of this work stems from its integrated dual-sensing capability for both gas and metal detection within a single, low-cost prototype, offering a practical and affordable multi-threat detection solution that differs from existing single-target, high-cost systems.

7. Conclusions

The Defence Pal prototype demonstrates a practical, low-cost, and scalable approach to landmine detection and environmental hazard monitoring, addressing critical safety challenges in conflict and post-conflict zones. The system ensures effective hazard identification while minimising human risk by integrating metal detection, gas sensing, and obstacle avoidance into a wireless, remotely operated platform. Controlled tests confirmed reliable detection performance, with average accuracies exceeding 83% for metallic objects and 87% for hazardous gases. It was observed that Defence Pal is capable of a deeper detection mechanism. The modular, open-source design enables adaptability for diverse operational scenarios and allows for future enhancements such as advanced sensor fusion and AI-based classification. Defence Pal offers a viable and efficient alternative to traditional manual detection methods, contributing to safer, faster, and more sustainable demining and hazard mitigation efforts in resource-constrained environments. In short, the novelty of this work originates from the development of a low-cost, dual-sensing prototype capable of simultaneous gas and metal detection, offering a feasible and efficient alternative to conventional, single-target, high-cost detection systems for real-world, multi-threat applications.

Author Contributions

Conceptualisation, A.K. and U.N.T.; methodology, A.K. and U.N.T.; software, U.N.T.; validation, U.N.T.; formal analysis, U.N.T. and S.M.; investigation, A.K. and U.N.T.; resources, A.K.; data curation, U.N.T.; writing—original draft preparation, A.K. and S.M.; writing—review and editing, A.K. and U.N.T.; visualisation, A.K. and U.N.T.; supervision, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bechtel, T.; Truskavetsky, S.; Pochanin, G.; Capineri, L.; Sherstyuk, A.; Viatkin, K.; Byndych, T.; Ruban, V.; Varyanitza-Roschupkina, L.; Orlenko, O.; et al. Characterisation of Electromagnetic Properties of In Situ Soils for the Design of Landmine Detection Sensors: Application in Donbass, Ukraine. Remote Sens. 2019, 11, 1232. [Google Scholar] [CrossRef]

- Shabila, N.P.; Taha, H.I.; Al-Hadithi, T.S. Landmine injuries at the emergency management center in Erbil, Iraq. Confl. Health 2010, 4, 15. [Google Scholar] [CrossRef] [PubMed]

- Goose, S.D. The Ottawa process and the 1997 Mine Ban Treaty. In Yearbook of International Humanitarian Law; Peters, K., Ed.; T.M.C. Asser Press: Den Haag, The Netherlands, 1998; Volume 1, pp. 269–291. [Google Scholar] [CrossRef]

- Petrişor, S.M.; Simion, M.; Bârsan, G.; Hancu, O. Humanitarian demining serial-tracked robot: Design and dynamic modeling. Machines 2023, 11, 548. [Google Scholar] [CrossRef]

- Panwar, V.S.; Moujan, I.; Kazi, A.; Kale, P.; Rode, S.; Pandey, A.; Mogal, S. A review on design and characteristics of landmine detection robot. Evergr. Jt. J. Nov. Carbon Resour. Sci. Green Asia Strategy 2024, 11, 900–912. [Google Scholar] [CrossRef]

- Mujiarto; Sambas, A.; Haerudin, I. Design of Arduino-based metal detector robot. Solid State Technol. 2020, 63, 12401–12411. [Google Scholar]

- Daniels, D.J. A review of GPR for landmine detection. Sens. Imaging Int. J. 2006, 7, 90–123. [Google Scholar] [CrossRef]

- Larionova, S.; Marques, L.; de Almeida, A.T. Multi-stage sensor fusion for landmine detection. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Beijing, China, 9–15 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 3435–3440. [Google Scholar] [CrossRef]

- Cremer, F.; Schutte, K.; Schavemaker, J.G.M.; den Breejen, E. A comparison of decision-level sensor-fusion methods for anti-personnel landmine detection. Inf. Fusion 2001, 2, 187–208. [Google Scholar] [CrossRef]

- Minhas, S.F.; Shah, M.H.; Khaliq, T. Deep learning-based classification of anti-personnel mines and sub-gram metal content in mineralised soil (DL-MMD). Sci. Rep. 2024, 14, 10830. [Google Scholar] [CrossRef] [PubMed]

- Vivoli, E.; Bertini, M.; Capineri, L. Deep learning-based real-time detection of surface landmines using optical imaging. Remote Sens. 2024, 16, 677. [Google Scholar] [CrossRef]

- Heuschmid, D.; Wacker, O.; Zimmermann, Y.; Penava, P.; Buettner, R. Advancements in landmine detection: Deep learning-based analysis with thermal drones. IEEE Access 2025, 13, 91777–91794. [Google Scholar] [CrossRef]

- Barnawi, A.; Kumar, K.; Kumar, N.; Alzahrani, B.; Almansour, A. A Deep Learning Approach for Landmines Detection Based on Airborne Magnetometry Imaging and Edge Computing. Comput. Model. Eng. Sci. 2024, 139, 2117–2137. [Google Scholar] [CrossRef]

- Stadler, S.; Schennen, S.; Hiller, T.; Igel, J. Realistic simulation of GPR for landmine and IED detection including antenna models, soil dispersion and heterogeneity. Near Surf. Geophys. 2024, 22, 188–205. [Google Scholar] [CrossRef]

- Abhijith, U.; Sreeja, S. Land Mine Detection Robot. Int. J. Adv. Res. Comput. Commun. Eng. 2024, 13, 34–46. [Google Scholar] [CrossRef]

- Rahmani, F.; Ghal-Eh, N.; Bedenko, S.V. Landmine-identification system based on the detection of scattered neutrons: A feasibility study. Radiat. Phys. Chem. 2022, 199, 110264. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).