Abstract

A new construction of a custom-made, low-cost, electronic-nose-applying eight-TGS-type gas sensors manufactured by Figaro Inc. was assembled. The gas sensors were used to collect response signals caused by changes in gas composition from clean air to the studied odor, to which the sensors were exposed. In addition, modulation of sensor heater temperature was implemented in order to register complementary information useful for differentiation between the studied odor categories. An automatic mechanism was to open the gas sensor chamber, allowing sensors exposure to the studied gas and cleaning of sensors in the condition of a closed chamber. Sensor cleaning was conducted by forcing a clean air current through the application of a pneumatic pump. Three-dimensional printing was used to manufacture the sensor chamber. The Raspberry PI microcomputer was used for control of the measurement procedure and data collection. The operation of the device could be controlled by a web-based interface from a connected laptop or smartphone. The device was applied to the monitoring of the development of spoilage of soft fruits like strawberries and raspberries. Periodic measurements were performed in an automatic manner. A dedicated system of separation of the measured sample from the gas sensor array, preventing heat flow, was designed. Technical challenges encountered during the measurement are presented.

1. Introduction

Many techniques of chemical analysis of gases can be used for the analysis and detection of odors. The most detailed information can be obtained by classical chemical analytical methods such as gas chromatography combined with mass spectrometry (GC-MS), which identifies the individual chemical components and their relative concentrations present in the measured gas sample. In practice, GC-MS is limited to applications in laboratory conditions as it requires costly and bulky equipment and very experienced staff.

In an original proposal of an electronic nose device, Persuad et al. [1] introduced a new paradigm of detection and classification of odors by application of a series of nonspecific gas sensors with an overlapping gas detection range. Such a device is not capable of performing gas analysis and detection of the constituent individual chemical components. In electronic noses, pattern recognition methods supported by machine learning algorithms are used for differentiation between odor samples.

Various types of gas sensors, based on various physical mechanisms, have been used in the construction of electronic noses. When building a low-cost electronic nose, the choice of gas sensors is limited to the models commercially available on the market. In such a case, the most popular types are metal oxide sensors (MOS or MOX) [2].

Much research is focused on finding the dependence between gases emitted by fruits and the level of their ripeness or spoilage. Quiang Liu et al. [3] used a PEN3 electronic nose and hyperspectral imaging in the spectral range 400–1000 nm to identify microbial content on strawberries. A combination of these methods resulted in much better detection of colony-forming than any of them alone. Ghasemi-Varnamkhastia et al. [4] made a good comparison of metal-oxide sensors’ sensitivity to check the freshness of strawberries in different polymer packages. Pan et al. [5] used a PEN3 electronic nose and gas chromatography together with mass spectroscopy to determine potential fungal infection in freshly harvested strawberries. Self-built electronic nose, based on metal-oxide semiconductor sensors, allowed Qin et al. [6] to find mechanical damages in stored strawberries. Using the multi-tool platform of the electronic nose, attenuated total reflection-Fourier transform infrared spectroscopy, and image analysis allowed Palumbo et al. [7] to discriminate the ripening stage of strawberries, from half-red to red. Comparison of electronic senses (electronic nose and electronic tongue) with a sensory panel allows Moazzem et al. [8] to make an algorithm to predict sensory properties of strawberries. Another commercial electronic nose, Fox4000, together with GC-MS, was used by Rao et al. [9] to find strawberry damage caused by vibrations. Another possibility to use an electronic nose was reported by Gholami et al. [10]. During their research, they use their electronic nose to check and predict changes in the physico-chemical properties (such as color, pH, vitamin C, antioxidants, and others) of strawberries during 12-day storage. Wang et al. [11] compared many techniques that use AI and machine learning to determine the freshness and dehydration of many berry-type fruits like blueberries, strawberries, raspberries, blackberries, grapes, and currants. In their review, they presented such methods as nuclear magnetic imaging, hyperspectral imaging, infrared and thermal imaging, computer tomography, sound detectors, and electronic noses. Another usage of the Fox4000 electronic nose was reported by Cao et al. [12]. It was used to check the VOC composition change in mechanically damaged strawberries. A combination of PEN3 electronic nose and TS-5000Z electronic tongue was used by Zhang et al. [13] to measure parameters of freshly squeezed strawberry juice. This analysis allows them to predict bacterial growth and proves that changes in taste and smell are related to the growth of microorganisms.

2. Materials and Methods

2.1. Electronic Nose Construction

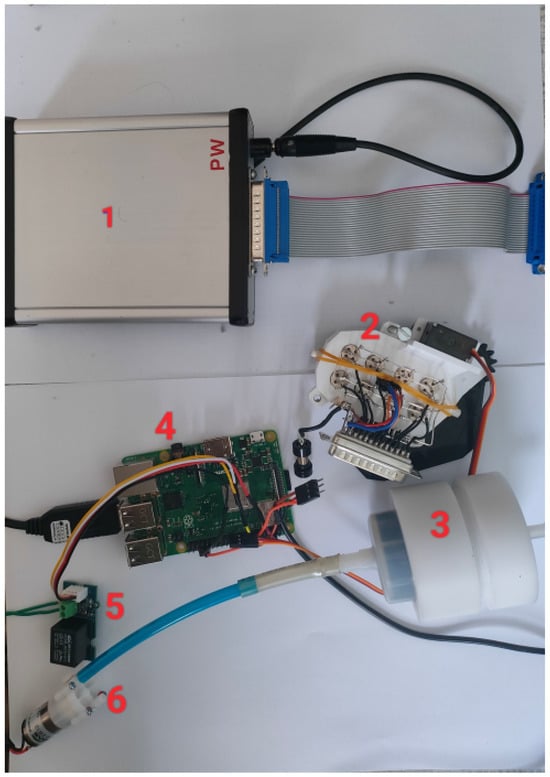

The electronic nose device (Figure 1) described in this report is an improved version of the previously used and described [14]. The main modifications consist of the development of a mechanism for the automatic opening of the gas sensor chamber, which facilitates manual operations. Another improvement is the application of a Raspberry PI microcomputer, instead of a laptop, for controlling the electronic nose operations, which allows reducing the size and requirements of electrical current supply and makes the device continuously monitor environmental odors.

Figure 1.

Electronic nose unit: 1—main unit, 2—sensors, 3—charcoal filter, 4—Raspberry Pi, 5—switch, 6—air pump.

2.1.1. Gas Sensors Array

The electronic nose consists of eight TGS series of gas sensor arrays manufactured by Figaro Engineering Inc. (Osaka, Japan) [15]. The list of the gas sensors and their target gases is presented in Table 1. In addition, a temperature LM35 (Texas Instruments, Dallas, TX, USA) and humidity sensor HIH 4031 (Honeywell, Charlotte, NC, USA) were mounted inside the sensor chamber.

Table 1.

List of sensor models used in electronic nose device and their target odors and gases [15].

In an MOX-type gas sensor, the sensing material, which is typically tin dioxide, is heated to a temperature of several hundred degrees Celsius. This is carried out using a built-in electric heater. After heating, when the sensor operates in clear air, oxygen is absorbed on the surface of the sensing material and attracts donor electrons. That reduces material connectivity and prevents electric current flow. When the sensor is exposed to the presence of reducing gases, oxygen reacts with the gas molecules, and electrons are released from the surface into the sensing material. That increases materials connectivity, which leads to electric current flow.

In the presented electronic nose device, the gas sensor response is collected using two modes of operation.

First of all, sensors respond to the presence of the measured gas by changing their resistance. For such a mode of operation, it is important to collect the sensor’s resistance versus time elapsed from the change in conditions from the sensor’s presence in the clean air conditions to conditions when the sensors are exposed to the measured odor. Importantly, for further analysis, one should not take an absolute magnitude of the sensor’s conductance but the magnitude relative to the conductance in clean air conditions [15] (, where is the sensor conductance at the t-moment and is the sensor conductance measured in clean air).

The second mode of operation applied in the constructed electronic nose is the possibility of collecting the sensors’ response to the modulation of the sensor heater voltage. That is equivalent to the response to the modulation of the operation temperature. The heater voltage operation is performed when sensors are exposed to the conditions of the measured gas and are already in a stable state reached after a sufficiently long time of exposure [16,17].

2.1.2. Gas Sensor Chamber

One of the requirements of the electronic nose design is that the changes in the measured gas conditions, to which the gas sensors are exposed, should be abrupt and repeatable [18]. Usually, that is achieved by the design of a gas chamber equipped with a pneumatic system of gas supply. In our electronic nose, we follow a different concept of an open sensor chamber [14], in which gas sensors are directly exposed to the measured gas. A pneumatic system is used only to supply clean air for sensor cleaning.

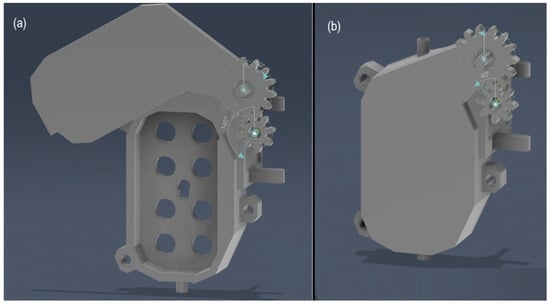

Three-dimensional printing was used to prepare a gas sensor chamber (Figure 2), which consists of a sensor holder and a shutter. The shutter movement is operated automatically by the Serwo MG-90S engine (Tower Pro, New Taipei, Taiwan).

Figure 2.

Three-dimensional printing design of a gas sensor chamber in (a) open and (b) closed positions of the shutter. In the (a), holes used for mounting gas sensors are visible.

A simple pneumatic system was used for cleaning the sensors. A pneumatic pump is used to blow air cleaned by the charcoal filter into the chamber when the chamber shutter is closed. A pump is automatically turned on at the closed chamber position and off when the shutter is opened, using a Grove Relay v1.3 switch (Seeedstudio, Shenzhen, China).

2.1.3. Operations Control and Automation

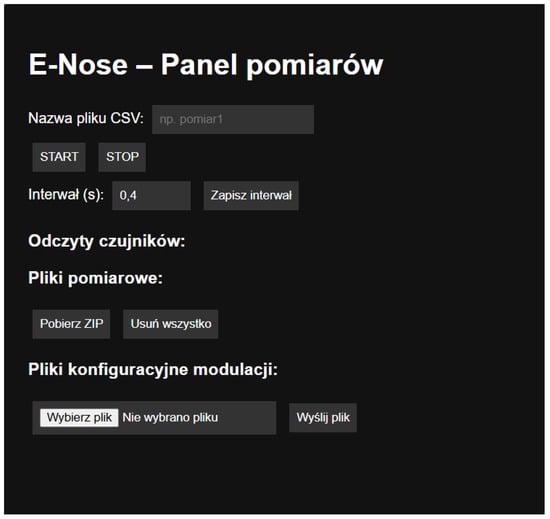

Control of operations of the electronic nose was performed using a Raspberry PI microcomputer (Raspberry Pi Holdings, Cambridge, UK). A web-based graphical user interface was created using the Flask framework in Python 3.12.7. The GUI (Figure 3) was designed to be accessible from a laptop or smartphone via a browser.

Figure 3.

Design of graphical user interface (in Polish) used for setting the electronic nose operations. User is able to (i) input the name of the CSV for output data, (ii) set the interval of sensor’s data collection, (iii) download a ZIP with output files or delete historical files, and (iv) select a file with the definition of the measurements profile.

It was assumed that the end user would not need to set the options of the measurement profile from the GUI. By a measurement profile, we mean a chain of operations that is performed by the electronic nose: (i) turning on/off the pneumatic pump used for sensor cleaning, (ii) automatic opening or closing of the sensor chamber shutter, and (iii) profiling the sensor heater voltage.

The role of the electronic nose operator consists of inputting the name of the file in which the sensor’s outputs will be stored, selecting one of the predefined files with a measurement profile, and running the measurements.

The other operations that can be performed from the GUI are the ability to download output files to a connected laptop or delete historical output files from the device.

2.2. Measurements by Electronic Nose

2.2.1. Monitoring of Strawberry Spoilage in Sensor Heater Temperature Modulation Mode

The first experiment that was performed consisted of monitoring strawberry spoilage using only sensor heater temperature modulation. That means that in the electronic nose, the sensor chamber was open during the whole measurement, and the sensors were not cleaned. A goal of this experiment was the validation of a hypothesis of the possibility of using gas sensors for monitoring, without a sensor’s cleaning subsystem, which would allow for the reduction in the complexity of the device.

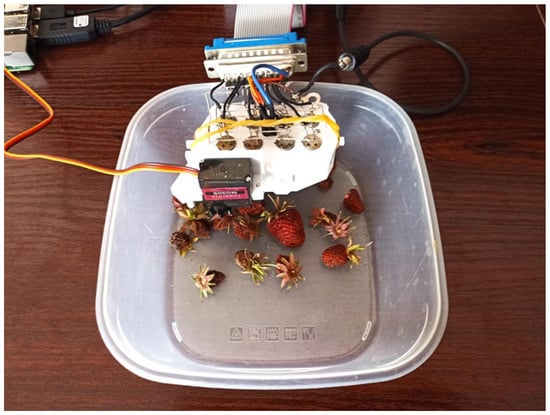

A handful of fresh strawberries was put inside a plastic box, and the electronic nose sensor array was applied to the box as it is presented in Figure 4. Clean air from the outside was able to enter the box during the measurements.

Figure 4.

Electronic nose during measurements of strawberries. Only sensor heater modulation was used.

The strawberries monitoring experiment lasted five days, so much longer than the expected time to observe the development of spoilage in strawberries. What was observed was that, instead of spoilage, all the fruits completely dried, which was caused by the environment heating due to the working sensors. The heated air-dried strawberries did not develop mold.

That was an important observation—that an application of MOS gas sensors for constant monitoring of the environment requires special attention to prevent changes in the environmental conditions by heating the air by the working sensors.

We do not present any results of this experiment as the influence of the measurement setup on the measured object prevented reaching the goals of monitoring fruit spoilage.

For further experiments, strawberries could not be used because these are seasonal fruits and were no longer available.

2.2.2. Monitoring of Raspberry Spoilage

In the second experiment, two modes of operation were exploited: sensors’ response to changes in gas conditions and exposure to measured odor as well as sensors’ response to heater voltage modulation.

Fresh raspberries were bought at the local market, and according to common practice, the fruits were collected the previous day, so we estimate the experiment started about 20–28 h after fruit picking.

The electronic nose setup was working continuously for 49 h to monitor the changes in volatiles emitted from a handful of raspberries. During that time, 87 measurement cycles were repeated and data collected, as described in the next section.

To minimize technical problems, which led to the failure of the strawberries experiment, some precautions were undertaken. First of all, the distance between the monitored fruits and sensors was increased to about 20 cm. Also, we used a plastic cylinder to streamline odor flow upwards towards the sensors. Inside a cylinder, a lid with holes was mounted, which, to some extent, prohibited the flow of hot air from the sensors to the measured fruits. Additionally, a sensor chamber shutter, when closed, separated heat flow from sensors for most of the time of the experiment (Figure 5).

Figure 5.

Experimental setup to measure raspberry odor.

At the end of the experiment, a strong raspberry odor was present. Clear mold colonies were visible on the surface of some of the fruits, but the mold odor was not detectable to the human nose (not trained).

2.2.3. Electronic Nose Measurement Cycles During Monitoring

The electronic nose was set up for continuous monitoring, and during that, several cycles of operations were performed automatically according to a prepared setup file.

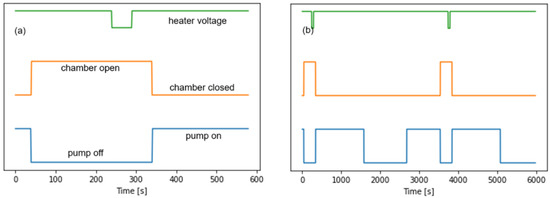

A schematic description of a single measurement cycle, during which data from sensors were collected, is presented in Figure 6a.

Figure 6.

Schematic diagram of profile of electronic nose operations during (a) one cycle of measurement and (b) two cycles of measurements. Hydraulic pump on and off states, chamber opening, and sensor heater profile are indicated in Figure (a).

Each measurement cycle (Figure 6a) started from a time period during which a pneumatic pump was on, and the sensor chamber was closed. That means that the electronic nose was in a state when clean air flow was forced inside the sensor chamber, and sensors were cleaned and prepared for measurements [14]. After that, the pump was switched off, and the sensor chamber automatically opened. That allowed rapid exposure of the gas sensor to the measured volatiles and caused a change in the sensor’s resistance, which was measured as a sensor response. After a delay, during which time length was chosen to allow the sensor’s response to reach a stable state, the sensor’s heater voltage was modulated to collect the sensor’s response to that type of change in conditions. Sensor’s heater voltage modulation had a rectangular shape of drop from 5 V (nominal voltage recommended by the manufacturer) to 4.75 V, as presented in Figure 6. A measurement cycle was finished with the closed sensor chamber and pneumatic pump on, allowing sensor cleaning.

Such measurement cycles were repeated in a loop with some delay (Figure 6b), during which the sensor chamber remained closed but the hydraulic pump was turned off. During that delay, sensors were heated with nominal heater voltage as recommended by the manufacturer.

3. Results of the Raspberry Monitoring Experiment

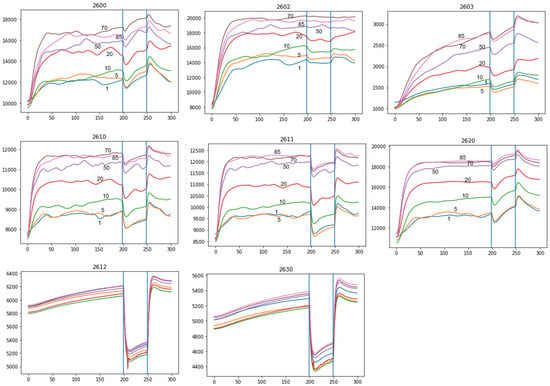

In Figure 7, we present examples of sensor responses during a period when the sensor chamber was opened, so sensors were exposed to the measured odor. Raw data are presented, so values on the y-axis are values read from an analog–digital converter of voltage read on a resistor, which allows for measuring sensor resistance at a given time moment [16,19,20]. Sensor response curves collected during several cycles of measurements are presented to demonstrate the character of sensor response during the duration of the experiment.

Figure 7.

Example of sensor response profile during a cycle, when sensors were exposed to the measured gas. Sensor type is indicated above the subfigures. Vertical lines indicate the period of sensor heater voltage modulation. In the subfigures, numbers of cycles are indicated. Sensor response is expressed in raw, read from the device, magnitudes of voltage, which are related to the sensor’s conductance.

The first important observation that can be noticed in Figure 7 is that the starting point for sensor response, which corresponds to sensor response in clean air, is very close for all curves. This demonstrates the stability of the measurements, efficient sensor cleaning between measurement cycles, and small sensor drift during the two days of measurements.

The second observation is that most of the sensors’ responses reached steady state after at most 50 s, and after that, a constant level with some fluctuations was recorded. An exception is sensor TGS 2603, for which the sensor response was not flat. However, according to our previous experiences, such behavior of this sensor is common.

Another observation is that we can observe here a trend in registered sensor response over time of the experiment. Sensor responses in later repetitions of measurement cycles are stronger, which indicates the presence of some gases to which gas sensors react.

The last observation that we would like to mention here is the level of fluctuations observed during the steady-state sensor response. To obtain a more reliable magnitude of sensor response, a steady-state average over time is possible. However, such fluctuations make a less reliable determination of other, more advanced features that could be extracted from the sensor response curves and used for further data analysis or building machine learning models. In our opinion, these fluctuations also make the features extracted from the sensor response during the heater voltage phase of the experiment less reliable. That is caused by the weak precision of the determination of the starting level when heater voltage modulation begins. For that reason, in the present manuscript, we do not present an analysis of the data collected during that phase of data collection.

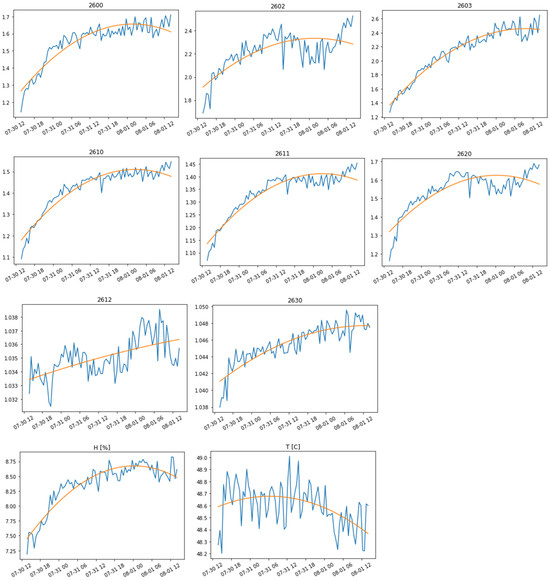

In Figure 8, we present trends of sensor response collected during the experiment of monitoring raspberry spoilage. As a main characteristic of sensor response, we chose the magnitude of the steady state of the response after a sufficiently long time of sensor exposure to the monitored odor. In order to minimize the influence of temporary fluctuations of sensor response, we calculated the average of the response during the last minute before the change in sensor heater voltage. Also, since it is recommended by the manufacturer to use the sensor response, its conductance relative to the baseline level of response in clean air, such a transformation was used.

Figure 8.

Trends of sensor steady state response to the presence of measured gas, expressed as the mean of the response measured during the last minute before heater modulation. Sensor response relative to the response in clean air is presented (). The type of sensor is indicated above the subfigures. The orange curve is presented as an eye-guide and is a second-order polynomial fit to the data. The date and hour of measurement are presented on the x-axis. The last row of subfigures presents readings from the humidity and temperature sensor.

As one can observe in Figure 8, for most of the gas sensors, their response increased until reaching a steady state level after about one day of monitoring.

Besides the gas sensors’ response, we also monitored temperature and humidity in the vicinity of the sensors. Due to heat generation by sensor heaters, the measured temperature was relatively high, about 48 °C, but also quite stable, with registered changes in the order of less than one Celsius degree.

More interesting is the examination of the humidity trend. Overall humidity registered in the vicinity of sensors is quite low, in the range of about 7.5–8.5%. Even if the change in humidity was of the order of 1% point, it is important to note that, compared to the humidity level at the beginning of the experiment, the relative change was of about 13.5%. The observed trend in humidity change during monitoring of the raspberry was very similar to the trends observed in the response of gas sensors. An increase in observed humidity may be explained by the commonly known experience that one of the first signs of aging and spoilage of soft fruits is the release of juice, which occurs much earlier than the appearance of other symptoms of deterioration, such as visible mold colonies. It should be noted that such a low level of humidity was measured in the vicinity of the sensors and not near the fruits.

In our opinion, the last observation may indicate that the observed gas sensor response could be caused mainly by the change in humidity, and the influence of released volatiles was much smaller. That is also consistent with human nose sensing, that at the end of monitoring, only the strong smell of raspberries was present, without a noticeable odor of mold.

4. Summary and Conclusions

An electronic nose applying the Figaro TGS series of gas sensors was constructed. The electronic nose consists of a sensor chamber equipped with a shutter allowing automatic opening and exposure of the sensors to the environmental gas. Operations of the electronic nose are controlled by a Raspberry PI microcomputer.

In the first performed experiment, the electronic nose was applied to a sample of fresh strawberries with sensors constantly exposed to the sample odor. Monitoring lasted several days, and it was observed that the heat generated by the gas sensor so strongly influenced the investigated sample that the strawberry dried and did not exhibit any signs of spoilage.

For the second experiment, a dedicated setup was constructed, which helped in the separation of fruits from the influence of heated air from the sensor chamber. The monitoring procedure involved opening the sensor chamber for a short time during measuring cycles. The experiment consisted of constant monitoring of the behavior of the raspberry during two days, and after that time, several mold colonies were visible in the fruits. However, for an untrained human nose, only the strong smell of raspberry could be noticed without the mold odor.

Analysis of collected data demonstrated a clear trend of increase in gas sensor response over time, reaching a quasi-steady level after about one day of observation. It was also observed that during the experiment, the humidity observed in the vicinity of the gas sensors increased by about 13.5% and had a very similar shape to the gas sensor response. We attribute it to juice release from fruits, which is the first sign of the raspberry spoilage, appearing much earlier than other signs of spoilage, like the appearance of visible mold colonies.

The presented results have a rather negative character, as in our opinion, the performed experiments were not able to detect early signs of raspberry spoilage by examination of released volatiles measured by gas sensors. However, in our opinion, the report of such negative results and the encountered technical challenges during the experiment may be interesting for other researchers.

Author Contributions

Conceptualization, T.G., M.T. and P.B.; methodology, T.G. and P.B.; software, T.G., K.B., P.S. and P.B.; validation, T.G., M.T. and P.B.; formal analysis, M.T. and R.T.; investigation, P.S., K.B., R.T. and T.G.; resources, P.S., K.B., R.T. and T.G.; data curation, K.B. and P.S.; writing—original draft preparation, R.T., K.B., P.S. and P.B.; writing—review and editing, P.B. and R.T.; visualization, K.B., P.S., R.T. and P.B.; supervision, T.G. and P.B.; project administration, T.G. and P.B.; funding acquisition, T.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Centre for Research and Development by the grant agreement BIOSTRATEG3/347105/9/NCBR/2017.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article. Further inquiries can be directed to the authors. The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Meng, Q.H.; Lilienthal, A.J.; Qi, P.F. Development of compact electronic noses: A review. Meas. Sci. Technol. 2021, 32, 062002. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, K.; Zhao, N.; Yang, J.; Zhang, Y.; Ma, C.; Pan, L.; Tu, K. Information fusion of hyperspectral imaging and electronic nose for evaluation of fungal contamination in strawberries during decay. Postharvest Biol. Technol. 2019, 153, 152–160. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohammad-Razdari, A.; Yoosefian, S.H.; Izadi, Z.; Rabiei, G. Selection of an optimized metal oxide semiconductor sensor (MOS) array for freshness characterization of strawberry in polymer packages using response surface method (RSM). Postharvest Biol. Technol. 2019, 151, 53–60. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, W.; Zhu, N.; Mao, S.; Tu, K. Early detection and classification of pathogenic fungal disease in post-harvest strawberry fruit by electronic nose and gas chromatography–mass spectrometry. Food Res. Int. 2014, 62, 162–168. [Google Scholar] [CrossRef]

- Qin, Y.; Jia, W.; Sun, X.; Lv, H. Development of electronic nose for detection of micro-mechanical damages in strawberries. Front. Nutr. 2023, 10, 1222988. [Google Scholar] [CrossRef] [PubMed]

- Palumbo, M.; Cozzolino, R.; Laurino, C.; Malorni, L.; Picariello, G.; Siano, F.; Stocchero, M.; Cefola, M.; Corvino, A.; Romaniello, R.; et al. Rapid and Non-Destructive Techniques for the Discrimination of Ripening Stages in Candonga Strawberries. Foods 2022, 11, 1534. [Google Scholar] [CrossRef] [PubMed]

- Moazzem, M.S.; Hayden, M.; Kim, D.J.; Cho, S. Assessment of Changes in Sensory Characteristics of Strawberries during 5-Day Storage through Correlation between Human Senses and Electronic Senses. Foods 2024, 13, 3269. [Google Scholar] [CrossRef] [PubMed]

- Rao, J.; Zhang, Y.; Yang, Z.; Li, S.; Wu, D.; Sun, C.; Chen, K. Application of electronic nose and GC–MS for detection of strawberries with vibrational damage. Food Qual. Saf. 2020, 4, 181–192. [Google Scholar] [CrossRef]

- Gholami, R.; Aghilinategh, N.; Rabbani, H. Investigating the Physicochemical Properties of Strawberries and Classification by an E-Nose During Storage. J. Food Process. Preserv. 2025, 2025, 2322442. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Mujumdar, A.S.; Yu, D. Advanced Detection Techniques Using Artificial Intelligence in Processing of Berries. Food Eng. Rev. 2021, 14, 176–199. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Y.; Lin, M.; Wu, D.; Chen, K. Non-Destructive Detection of Damaged Strawberries after Impact Based on Analyzing Volatile Organic Compounds. Sensors 2022, 22, 427. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.W.; Pan, L.Q.; Tu, K. Growth Prediction of the Total Bacterial Count in Freshly Squeezed Strawberry Juice during Cold Storage Using Electronic Nose and Electronic Tongue. Sensors 2022, 22, 8205. [Google Scholar] [CrossRef] [PubMed]

- Borowik, P.; Grzywacz, T.; Tarakowski, R.; Tkaczyk, M.; Ślusarski, S.; Dyshko, V.; Oszako, T. Development of a Low-Cost Electronic Nose with an Open Sensor Chamber: Application to Detection of Ciboria batschiana. Sensors 2023, 23, 627. [Google Scholar] [CrossRef] [PubMed]

- Figaro Engineering Inc. MOS Type Sensors Operating Principle. Available online: https://www.figarosensor.com/technicalinfo/principle/mos-type.html (accessed on 30 June 2025).

- Borowik, P.; Tarakowski, R.; Tkaczyk, M.; Ślusarski, S.; Oszako, T. Application of a Low-Cost Electronic Nose to Detect of Forest Tree Pathogens: Fusarium oxysporum and Phytophthora plurivora. IEEE Access 2022, 10, 93475–93487. [Google Scholar] [CrossRef]

- Borowik, P.; Tkaczyk, M.; Pluta, P.; Okorski, A.; Stocki, M.; Tarakowski, R.; Oszako, T. Distinguishing between Wheat Grains Infested by Four Fusarium Species by Measuring with a Low-Cost Electronic Nose. Sensors 2024, 24, 4312. [Google Scholar] [CrossRef] [PubMed]

- Burlachenko, J.; Kruglenko, I.; Snopok, B.; Persuad, K. Sample handling for electronic nose technology: State of the art and future trends. TrAC Trends Anal. Chem. 2016, 82, 222–236. [Google Scholar] [CrossRef]

- Cervera Gómez, J.; Pelegri-Sebastia, J.; Lajara, R. Circuit Topologies for MOS-Type Gas Sensor. Electronics 2020, 9, 525. [Google Scholar] [CrossRef]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Wacławik, P.; Oszako, T.; Ślusarski, S.; Tkaczyk, M. Development of a Low-Cost Electronic Nose for Detection of Pathogenic Fungi and Applying It to Fusarium oxysporum and Rhizoctonia solani. Sensors 2021, 21, 5868. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).