Abstract

This research paper presents a smart IoT-based COVID-19 vaccine supply chain, monitoring, and control system. This proposed system is designed to efficiently and effectively monitor COVID-19 vaccine storage sites by tracking their temperature, humidity, quantity, and location on a map across various supply chain categories. It ultimately aims to monitor and control temperatures outside the range at the tracked location. The approach utilized temperature, humidity, and ultrasonic sensors, a GPS module, a Wi-Fi module, and an Arduino Uno microcontroller. The system was designed and implemented using Arduino and Proteus integrated design environments (IDEs) and coded using the embedded C/C++ programming language. A real-life working system prototype was designed and implemented. The measured sensor readings can be viewed via a computer system capability or any mobile device, such as an Android phone, iPhone, iPad, or laptop, with the aid of a cloud-based platform, namely, Thingspeak.com. The experimentally measured sensor readings are stored in a data log file for subsequent download and analysis whenever the need arises. The data aggregation and analytics are coded using MATLAB and viewed as charts, and the location map of vaccine carrier coordinates is sent to the web cloud for tracking. An alarm message is sent to the monitoring and control system if an unfavorable vaccine environment exists in either the store or the carrier container. A suitable sensor-based interface architecture and web portal are provided, allowing health practitioners to remotely monitor the vaccine supply chain system. This method encourages health workers by reducing the high levels of supervision required by vaccine supervisors to ensure the smooth supply of vaccines to vaccine collection centers, by using a wireless sensor network and IoT technology. Experimental results from the implemented system prototype demonstrated the benefits of the proposed approach and its possible real-life health monitoring applications.

1. Introduction

A wireless sensor network (WSN) has invariably distributed independent sensors that work in synergy to monitor visible or environmental objects and conditions, such as temperature, humidity, distance, light, sound, vibration, pressure, motion, or pollutants. WSNs have played important roles in humans’ day-to-day activities for several decades [1]. It was asserted that the Internet of Things (IoT) does as much as it portrays. The IoT is a computing hub of immeasurable devices or things globally that are connected to the Internet and one another via wireless networks. This includes both physical and digital things that are invariably uniquely figured out or identified online [2,3].

The embedment of IoT technology brings resources such as smart devices, software, sensors, and other technologies together over the Internet to enable communication or exchange of data to take place without human-to-human interference. IoT can be understood basically by the communications that occur among things or objects with the embedding of Microcontrollers and transceivers. All these are achieved with the capabilities of the internet or any communication protocol. Industries have been transformed virtually due to the viability and strength of IoT, from the manufacturing segment to the smart homes or cities, industry, from eHealth to IT infrastructure, and also plays a key role in turning around the way we live and work, locally and globally. Managing IoT means that temperatures can also be monitored remotely through mobile devices (Android phone, iPhone, iPad, Tablet, etc.) while in transit, with the capability for alarms to be sent out should vaccine storage systems begin to operate out of measured parameters or fail for swift action to be taken—all this in the fight to save human lives [2].

The Internet of Things (IoT) is an emerging trend that has brought fresh opportunities in many areas of human endeavor, including smart cities and smart healthcare. Presently, the fundamental usage of the IoT in the area of healthcare is seen by the work it does through remote monitoring and real-time health systems. This is manifested by performing the work of controlling and managing dire situations, such as the one in 2020, when the coronavirus disease (COVID-19) showed up and took over the world. It was successfully overcome with the help of IoT systems, without imposing unwarranted restrictions on people and industries [4]. Lower-income countries are facing a great challenge in the vaccine supply chain due to a lack of adequate vaccine storage facilities. Despite the diversification of its source of energy through the introduction of solar-powered refrigerators and the use of new tools to monitor supply levels, this problem persists [5].

To make the vaccine supply chains responsive and agile at this trying time, communication of real-time data has to be adopted, and data visibility and interchangeability of data, as well as digitalization, are most necessary. The Nation’s cold chain system needs to take into cognizance the challenges and opportunities that exist. The problems plaguing the aforementioned system are diverse, ranging from a lack of sufficient infrastructure, inadequate capacity, and limited integration of recent technology to unavailability of updated information; these led to the accretion of problems, which are accentuated by the storage peculiarities of the Oxford AstraZeneca, Moderna, and Johnson and Johnson COVID-19 vaccines [6].

The potency of COVID-19 vaccines could be damaged by the use of outdated equipment and limited integration of technology, as many facilities still make use of stem thermometers, while the infrastructure and facilities that are also lacking at the storage sites include temperature trackers and loggers, as well as sensitive alarms whenever the temperature is out of range. As a result of these, occasioned by the aforementioned, out-of-range temperatures may occur undetected if, in any way, vaccine monitors are not present at the place where the vaccines are kept; this will culminate in a serious threat to human life, then its prevention [7].

Furthermore, temperature monitoring and control devices should be introduced into the cold chain system. These devices give real-time temperature, humidity, and depth of the vaccine storage, after which an alarm is sent to workers whenever out-of-range temperatures and depths are detected, causing them to intervene and ultimately preserve the potency of the vaccines to prevent wastage as well as check the quantity of the vaccine in the storage. IoT networks are expected to deliver reliable and secure services to end-users [7,8,9].

This study primarily focuses on smart IoT-based monitoring and control systems for COVID-19 vaccine distribution, with a specific emphasis on health monitoring applications. The major focus of this study is geared towards the COVID-19 vaccine supply chain, monitoring, and control system. This study will consider these by involving the capability of a smart IoT-based system and sensors for the monitoring and control of environmental parameters such as temperature, humidity, and quantity (depth) to ensure the vaccines are kept in good condition.

The salient contributions of this study are as follows:

- i.

- We developed a working system prototype of an IoT device, consisting of a robust sensor design, integrated with high levels of fault tolerance that can be deployed in harsh environments (rural areas) to assist medical health practitioners in remote vaccine monitoring and control supply chain systems.

- ii.

- The system was tested in a real-life COVID-19 vaccine storage container/carrier, and accurate sensor output was obtained; that is, the measurements for temperature, humidity, and depth level of vaccines inside storage containers were recorded in a data log file in real-time correctly with the corresponding year, month, day, and time stamped.

- iii.

- The developed system provides the capability of location tracking, which makes the proposed system work efficiently, uniquely, and interestingly, as location tracking occurs at every level of the supply chain. This enables the healthcare supervisor to know the position of the vaccine carrier at any given time to ensure that the pre-defined route during transportation is being followed. This is achieved with the aid of a GPS module incorporated in the designed prototype, which communicates with the satellite and the location coordinates (Latitude and Longitude).

- iv.

- The developed system provides the capability of a location map, which provides a visual representation of the tracked location where the vaccines are being supplied and also provides a clear understanding of its surroundings.

- v.

- An urgent notification/alerting system was integrated into the developed system. The beauty of the proposed system is the attention drawn whenever there is an ambiance change in the vaccine environment. The proposed COVID-19 vaccines, as provided in this study, have a specified temperature range from −20 °C to +8 °C; once the vaccine’s environment temperature begins to fall out of the specified range, an urgent notification is sent to the vaccine supervisor for prompt action to be taken to prevent vaccine efficacy, thereby avoiding wastage. The message comes as an SMS with an urgent inscription stamped with date, time, and location coordinates of the vaccine storage container.

- vi.

- Data logging capability was provided in the developed system. Each sensor sends data to the receiver module, and the receiver transmits it to the cloud server. Herein, data logging of temperature, humidity, and depth with their appending date and time is provided to the end user through web analytics and displayed using a serial terminal output.

- vii.

- A suitable sensor-based interface architecture and web portal are provided so that the health practitioners can monitor the vaccine supply chain system remotely. This method encourages health workers by reducing the high levels of supervision required by vaccine storage to ensure the smooth supply of vaccines to vaccine collection centers, by using a wireless sensor network and IoT technology.

The rest of this article is organized as follows: Section 2 discusses the review of the related literature; Section 3 discusses the design methodology. Section 4 presents the implemented system prototype, Section 5 presents the results and discussion, and Section 6 provides the concluding remarks and describes future work.

2. Review of the Literature

The IoT sensors play a vital role in securely preserving vaccines within temperature-controlled environments during storage and transportation. Additionally, the IoT is a revolutionary innovation that integrates a wide range of smart systems, devices, and sensors, taking advantage of quantum and nanotechnology for improved storage, sensing, and processing speed. These IoT sensors are seamlessly integrated into the ecosystem, granting users access to real-time insights on asset location and condition [2].

Hasanat et al. [4] proposed a real-time data-centric mechanism to monitor the transportation and distribution of vaccines. Their system focuses on managing and creating a supervision mechanism using humidity and temperature sensors. This mechanism effectively enhances vaccine distribution supervision and monitoring in various scenarios. It was emphasized that IoT-based systems offer the unique capability of creating and managing individual trips for vaccine transportation while continuously supervising temperature, humidity, and carrier depth. In case of temperature deviations, medical personnel are promptly alerted to re-refrigerate the carrier and prevent vaccine wastage, as well as address potential storage equipment issues. The readings from IoT sensors are crucial in ensuring the efficient delivery of vaccines.

Sorooshian et al. [8] developed a framework to minimize wastage during COVID-19 vaccination programs conducted by public healthcare centers. The framework aims to manage risks during vaccination projects by utilizing strategies, although it does not encompass risks throughout the entire supply chain. However, upcoming research is expected to address this limitation.

The COVID-19 pandemic is known to be caused by severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2), which has had devastating effects on both the economy and human beings in all countries that have undergone the pandemic. The severity of the disease is very high, being one of the worst pandemics ever, which, within one year, caused more than 100 million persons to be infected and over 2 million deaths recorded worldwide. Consequently, the availability of safe and effective vaccines against the virus, specialized diagnostic technologies, and therapeutics, along with being aware of warnings issued by government healthcare organizations through their platforms to follow social distancing measures to prevent new zoonotic introductions, will greatly help in saving lives. These can only be achieved when modern storage monitoring facilities are in place to ensure a well-preserved COVID-19 vaccine [10].

Rathee et al. [11] utilized Internet of Things (IoT) technology in a monitoring system to track vaccine carriers’ temperature and location. This system operates on a single platform, enabling trip management and sharing crucial information with healthcare supervisors through a mobile application. This approach ensures transparency and continuous monitoring of vaccines throughout the transportation process, minimizing the likelihood of human error or negligence. The study surveyed the use of IoT sensor technology to monitor the movement of COVID-19 vaccines worldwide. The sensors accompany the vaccines during transportation, ensuring that the temperature remains within the prescribed range and tracking their distribution in the supply chain.

Saranya [12] proposed a system centered on a blockchain-based digital supply chain and an IoT healthcare monitoring system for efficient COVID-19 vaccine distribution and management. Authorized clients, such as government or primary healthcare centers, can monitor the supply and secure transformation of vaccines using Wi-Fi sensors, mobile applications, and IoT technologies. The system ensures proper temperature storage and provides immutable distribution records. The study demonstrated the successful use of IoT sensors in biopharmaceutical logistics, where they efficiently monitor transit temperatures and flag potential issues. The generated data is analyzed to identify vulnerabilities in supply chains.

Hernández et al. [13] introduced a methodology for designing humanitarian supply chains (HSCs) for immunization, specifically addressing COVID-19 vaccines. The study emphasizes the importance of agility and resilience in the involvement of capabilities and stakeholders in the distribution process. Lack of effective strategy through capabilities and stakeholder involvement can politicize vaccine distribution.

Kis [14] developed a kinetic model that conceptualizes and describes mRNA classes, particularly for manufacturing COVID-19 vaccines. The model incorporates temperature monitoring devices to record temperature and time readings at different distribution stages. It calculates critical quality attributes (CQAs) and the remaining shelf life of opened mRNA vaccines. However, the model does not encompass other COVID-19 vaccines, such as double-stranded vaccines, that are also thermosensitive.

An approach to addressing the challenges of supply chains worldwide, particularly in the administration and supply of critical medical supplies such as vaccines and drugs, where judicious distribution and maintaining integrity are crucial, was presented by Rinaldi et al. [15]. The approach presented an innovative method to improve the speedy administration of supply chains using blockchain technology and simulation-based modeling. The strategy aims to handle important aspects such as transparency, efficiency, and security, which are essential for handling logistics during crises. The authors presented a case study on the distribution of COVID-19 vaccines in Italy, relating to a vaccine rollout that is used to establish how blockchain technology can improve supply chain operations, lessen bottlenecks, and guarantee improved traceability and accountability during the distribution process. Their findings indicated that the integration of blockchain technology improved data integrity and security and also enabled real-time monitoring and decision making.

Shah et al. [16] presented a review that discusses the opportunity of manufacturing a particulate COVID vaccine, making use of nano or microparticles as platforms for oral administration or in sublingual or buccal film dosage forms appropriate to fast-track global vaccination. These platforms solved most of the prevailing vaccine storage limitations due to the fact that they are stable at room temperature, are low-cost to manufacture and distribute. Additionally, the vaccines can be administered orally and do not need cold chain storage for transportation or preservation. Naor et al. [17] presented an investigation on how to mitigate the spread of coronaviruses by swiftly launching an ultra-cold supply chain of vaccines.

Kandulu et al. [18] presented a scoping review of factors affecting COVID-19 vaccination uptake and distribution in the global healthcare systems. COVID-19 vaccines were developed and manufactured quickly and distributed in large quantities during the pandemic period. In the review, the authors identify and investigate the key healthcare system and policy factors that influenced the distribution and uptake of COVID-19 vaccinations worldwide.

The weaknesses of the COVID-19 pandemic vaccine supply chain and empowered post-pandemic analysis, highlighting the growing importance of supply chain resilience, were revealed by Hay et al. [19]. The authors analyze the weaknesses and potential for vaccine supply chain resilience from an industry perspective. Their findings aimed at helping managers and policy-makers build a more resilient vaccine supply chain. However, they conclude that infrastructures and best administration practices that enable improved transparency and partnership among stakeholders hold the utmost potential for strengthening the vaccines supply chain’s resilience to upcoming pandemics.

A literature review aimed to evaluate the existing literature on vaccine supply chain administration was presented by authors Joshi and Sharma [20]. The review considered all relevant articles between 2002 and 2022 and was analytically collected. The study will be of importance to policymakers and other stakeholders to understand the existing challenges in the vaccine supply chain system.

In summary, the integration of IoT technology and sensors in the vaccine supply chain management system enables enhanced monitoring, transparency, and data-driven decision making to ensure the safe and efficient delivery of vaccines. The use of IoT has revolutionized vaccine logistics, leading to improved preservation and distribution processes.

3. Design Methodology

3.1. Proposed System

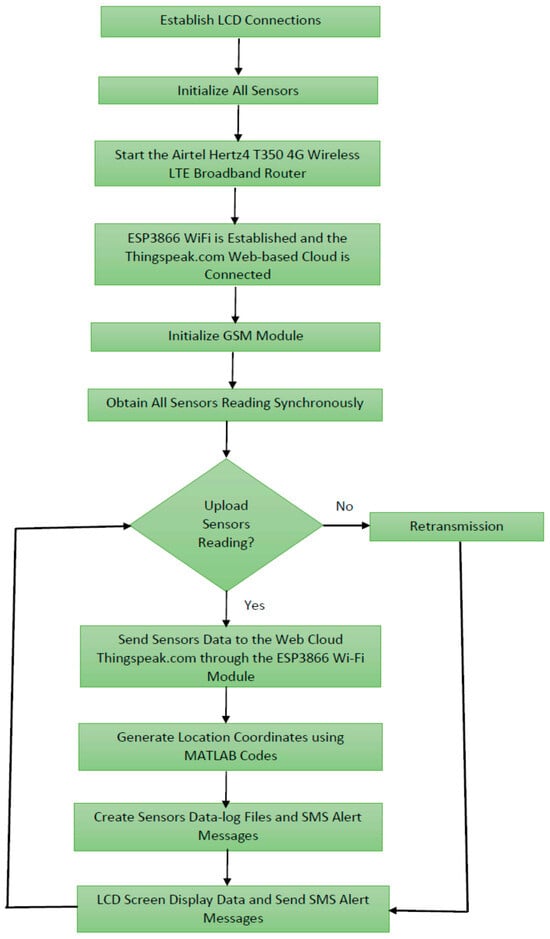

The primary objective of this study is to monitor and control COVID-19 vaccines within the supply chain. The successful implementation of this objective relies on the integration of a specific number of sensors and a microcontroller. As illustrated in Figure 1, the system starts on power-on, and the Liquid Crystal Display (LCD) and the communications ports are initialized. The LCD screen displays a system startup message on the vaccine monitoring and control system. Once the connection between sensors and microcontroller is established, the HDT22 and Ultrasonic sensors verify the connection and begin reading the temperature, humidity, and depth of the vaccine carrier. The obtained readings are then displayed on the LCD through the user interface window [21,22].

Figure 1.

Proposed real-time device monitoring system flowchart.

The ESP8266 WiFi Module, which features a self-contained SOC with an integrated TCP/IP protocol stack, facilitates access to the WiFi network. It works either way, by taking out WiFi networking functions from another application processor or taking in applications into it. The ESP8266 processes and transfers the sensed data to the ThingSpeak cloud. Furthermore, to unequivocally provide a WiFi network to the ESP8266 WiFi Module, an Airtel 4G Router is used. The GSM Module retrieves data generated by the sensors and sends it to the vaccine monitor or supervisor (user) in the form of short message service (SMS) alerts, notifying them of any unwanted changes in the vaccine storage or carrier [23].

Both the HDT22 and Ultrasonic sensors started taking measurements on the specified parameters, namely, temperature, humidity, and depth. Another crucial protocol in this research work is Thingspeak.com cloud server, which enables data access through the cloud. Thingspeak enhances data measurement, analysis, and aggregation, allowing the tracked vaccine to be viewed automatically in the tracking field. Data values at specific intervals are transmitted to MATLAB R2016a using a channel ID and API key assigned by the service. Additionally, the system establishes location information and creates a data file that can be utilized in word processing applications. All the aforementioned data and features can be accessed and viewed through a Personal Computer (PC) or mobile devices such as Android phones, iPhones, or iPads [24,25].

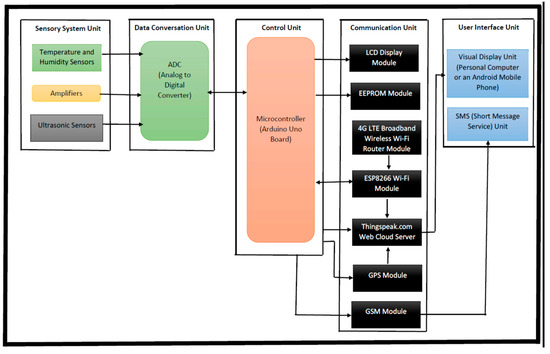

3.2. The Proposed System Architecture

Figure 2 illustrates the proposed system architecture. An integrated platform was used for the efficient and safe transformation of vaccines from sources to destinations on a global scale. A location-based system (GPS) was implemented for tracking, and a temperature sensor was implemented to record the COVID-19 vaccine storage temperature in a clinic during supply chain delivery. The proposed system will work as follows: the smart IoT-based system for COVID-19 vaccine monitoring and control consists of three inputs and two output systems. All electronic operation is controlled by a single microcontroller unit, which is programmed based on how other peripherals will behave. This device consists of three sensors: temperature and humidity (integrated in a single module), and an ultrasonic sensor. The DHT22 (temperature and humidity) sensor is responsible for taking real data readings for temperature and humidity and is always used to check and track ambient changes. An ultrasonic sensor is used to detect the quantity in the store or vaccine carrier [24,25].

Figure 2.

Proposed system architecture.

The GSM Module is used as the communication base between the system and the user. It keeps the user abreast of every bit of unwarranted changes that occur in the vaccine store or carrier. The readings of the sensors’ data come with a date and time stamp, as they are being taken into the microcontroller unit. The data will be uploaded into a data log file monitoring database on the ThingSpeak.com cloud server to provide users with real-time data. The ESP8266 Wi-Fi Module used in this study helps to process and transfer the sensed data to the ThingSpeak.com cloud through the internet. The data is accessible through a data field created by a Channel, being the primary functional feature of ThingSpeak.com. A Router that serves as a master of the network provider provides network service to the ESP8266 Wi-Fi Module to make it functional and viable.

The Thingspeak.com web cloud has an open API service that allows data to be transferred through the cloud. The most interesting primary feature of Thingspeak is called a Channel, which comes with a data field, a location field, a status field for a variety of sensed data, and a field that processes and visualizes information in MATLAB, and shows the trend of scenarios according to the parameters, and by extension, helps to predict future changes. The data stored in the web cloud (Thingspeak.com) is both in tables and graph form; consequently, it changes dynamically as new data keeps coming into the system [26].

The GPS module remarkably and automatically takes the coordinates (Latitude and Longitude) of the vaccine store or carrier. This system is cloud-based, and data can be sent to it through the internet. When the sent data was computed, the results of the computation were returned to the user’s computer or mobile device (a smartphone). The results carry the current temperature and humidity, location, status, and associated changes in the vaccine in the store or carrier. Sensors and other devices and modules used in the circuit development were chosen specifically to monitor the COVID-19 vaccine supply chain and to be able to control any abnormality that could occur in the vaccine storage or carrier. In sleep mode, the devices used in this research work consume less power [27,28].

3.3. The System and Modeling

The proposed system was simulated using the Proteus 8.5 professional edition and Arduino Uno microcontroller, which is the development board using the embedded C Programming Language as the software to analyze the performance of the system. Proteus 8.5 is a high-performance tool for simulating technical computing. It integrates computation, displays how the constructed system will work [29]. Arduino Uno, as the development board, provides an easy-to-use environment where problems and solutions are expressed in familiar mathematical notation, which, at the end of the day, will filter the workability of the hardware components [30,31].

The proposed system was simulated using the Proteus 8.5 professional edition and Arduino Uno microcontroller, which is the development board using the embedded C Programming Language as the software to analyze the performance of the system. Proteus 8.5 is a high-performance tool for simulating technical computing. It integrates computation, displays how the constructed system will work [29]. Arduino Uno, as the development board, provides an easy-to-use environment where problems and solutions are expressed in familiar mathematical notation, which, at the end of the day, will filter the workability of the hardware components [30,31].

The programming language favorable to drive the circuit or devices to be at their optimum performance, the embedded C programming language was the choice, as it has less than 1% failure rate when developed to interact with hardware components. Proteus 8.5 is an environment that has the uniqueness of having a dual purpose for system simulation and model-based design, and its features change. It provides an interactive graphical environment and a customizable set of block libraries that provide facilities, which, by way of optimization, facilitate the design, simulation, implementation, and testing of a variety of time-varying systems, including communications, controls, signal processing, GSM control, Wi-Fi establishment, location tracking, storage, and wireless sensors integration and processing [8,9]. Figure 3 illustrates the system design using the Proteus integrated design environment.

Figure 3.

The proposed system prototype circuit diagram.

4. The Implemented System Prototype

In this section, the proposed system will be depicted, along with its operational processes, to ensure that it meets the user’s adequate operational requirements for use and evaluation. The constructed system is set up either in a vaccine store or a carrier, where the network of sensors will monitor its environment. The sensors’ readings can be viewed via a computer system capability or any mobile device, e.g., Android phone, iPhone, iPad, or any computer device with the aid of a web cloud server called Thingspeak.com. The sensors’ readings are stored in a data-log file for subsequent download and analysis whenever the need arises. The data aggregation and analytics are viewed in MATLAB as charts, and the location of vaccine carrier coordinates is sent to the Thingspeak server for tracking; an alarm message is sent to the vaccine officer in charge should there exist an unfavorable vaccine environment in either the store or carrier. The user will be trained to have the conceptual knowledge to handle the newly designed system, and also ensure it is well understood, for the user knows their role to play. There is also a need to educate the user on the need and use of the developed system. This is only achievable by a way of having specialized in-house, on-the-job training. Thus, the system implementation can be successful through the use of on-the-job training, computer-based training, and the use of a system manual [32,33]. The fully designed and implemented prototype is shown in Figure 4.

Figure 4.

The implemented system prototype (device and casing).

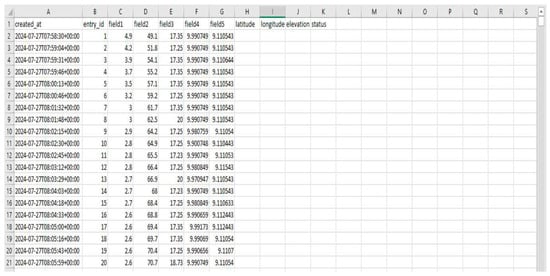

4.1. System Testing

One of the vital parts in system development is testing to ascertain the level of its integrity, and this is often demonstrated to show that the program works perfectly without errors. An essential technique in software system design is testing; the purpose of system testing is to detect the presence of errors in the system. Testing is the process of executing a program with the intent of finding errors [34]. When this system was tested, accurate output was given; that is, the measurements for temperature, humidity, and depth were recorded in the data log file in the web cloud server (Thingspeak) correctly, with the corresponding year, month, day, and time, as well as the location map (longitude and latitude), as illustrated in Figure 5.

Figure 5.

The reference clinic location is tracked by the implemented system prototype.

The implemented prototype system circuit was set up in a vaccine carrier chamber equipped with temperature, humidity, and depth checking ultrasonic sensors for the continuous monitoring and control of the sensed parameters, and the monitored data is sent to the microcontroller unit, which records it and sends the recorded data to the web server (Thingspeak.com) at a regular time interval. The carrier chamber is equipped with six ice packs, which are laid beneath the carrier before the vaccine vials are loaded on top and covered with two ice packs. Then the container is closed to maintain the vaccines’ temperatures. The set up involved running the prototype inside the vaccine carrier for 28 h at the Angware Primary Healthcare Clinic, Jos East LGA, Plateau State, Nigeria, to evaluate the device’s workability in a real-life situation [31,32]. This is illustrated in Figure 6.

Figure 6.

Prototype testing using COVID-19 vaccines in Gio’s style vaccine carrier.

4.2. Location Tracking

The part of the system that makes this proposed prototype work efficiently, uniquely, and interestingly is location tracking at every level of the supply chain. This enables the supervisor to know the position of the vaccine carrier at any given time to ensure that the pre-defined route during transportation is being followed.

This is achieved with the aid of a GPS module incorporated in the implemented system prototype, which communicates with the satellite, and the location coordinates (Latitude and Longitude) are sent to the Thingspeak.com server [31,32,33]. The coordinate values are copied and entered into the location channel, after which they automatically redirect to the location map, as shown in Figure 7.

Figure 7.

Data logging of temperature, humidity, and ultrasonic depth sensors readings.

4.3. System Notification (Urgent SMS Alert Messaging)

An important feature and capability provided by the proposed system is the attention drawn whenever there is an ambiance change in the vaccine environment. The proposed system of monitoring and control of vaccines, as depicted in Figure 5, has a specified temperature range from −20 °C to +8 °C; once the vaccine’s environment temperature begins to fall out of the specified range, an urgent notification is sent to the vaccine supervisor for prompt action to be taken to prevent vaccine efficacy, thereby avoiding wastage.

The message comes as an SMS with an urgent inscription stamped with date, time, and location coordinates, for instance (Attention! Vaccine Temp out of range Temp:33.00 °C, at Location 9.990749, 9.110543). This comes to fruition through the capability of the GSM Module incorporated in the proposed system. The choice of GSM Module was conceived out of the availability of mobile network connectivity to almost every nuke and cranny of human inhabitants.

4.4. Sensor Data Logging

Figure 7 represents the data logging capability of the proposed system prototype. Each sensor sends sensed data to the receiver (data log file), and the receiver transmits it to the web server (Thingspeak.com) [31,33]. Here, data logging of temperature, humidity, and depth with their appending date and time at run time (device operation) is shown in a serial terminal output as illustrated in Figure 7. The output has samples of 3556 entries that were received within 28 h of device operations.

5. Results and Discussion

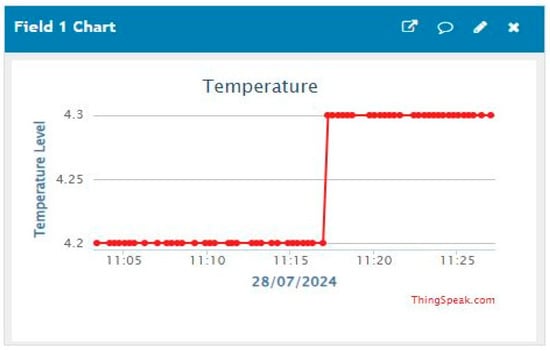

This section discusses the results of the tested implementation of the proposed system prototype. The measurements for the three sensors and the sensed parameters, as stored in the data log file as provided in Figure 8, and onward transmitted to the web cloud server (Thingspeak.com) for further analysis and visualization [31]. The results presented in this section are for three parameters, namely, temperature, humidity, and depth, and it is very important to have them discussed here to prove the proposed system’s workability, efficiency, and data integrity. This will increase public confidence in the continuous acceleration of technology advancement, especially in an effort to digitize vaccine monitoring and control through improvement in innovation and creativity.

Figure 8.

Temperature level versus time.

Table 1 shows the comparison with previous works [4,6,11,12,13,14,15,17,19]. The comparison with the state of the art proved to be difficult; this is evident that there are a lot of differences in terms of the sensors, microcontrollers, web cloud platforms, and designed system prototypes provided by the respective authors. Some of the proposed approaches did not provide detailed information regarding their implementations and tools. Furthermore, the web cloud and technology provided by the previous approaches are different from one implementation to another. However, the comparison results shown in Table 1 help to acknowledge the efficiency and flexibility of the proposed approach compared with the state of the art.

Table 1.

Comparison of sensors, microcontrollers, web cloud platforms, and designed system prototypes provided by respective authors.

5.1. Temperature Sensor Measurement Results

Figure 8 shows that the y-axis represents the temperature level (rising and falling) while the x-axis represents the date and time stamp interval. The temperature readings were obtained from 27 to 28 July 2024. It can be observed that the temperature reading samples were taken on the 28th day of testing. This will allow the ice block to start melting and to monitor the temperature and humidity variations.

It can be observed that the plotted graph accommodates data entry from 11:05 a.m. to 11:30 a.m. with an interval of 5. The purpose of taking a record of the graph by that interval on the second day was to ascertain the duration of the ice parks in the vaccine carrier chamber. However, the device had been running for 28 h from 7:58 a.m. the first day till 11:03 a.m. the second day, with measurements running for 3556 samplings (entries) in the data log file taken every 1 min as an interval continuously. At the time of capturing the graph reading, the temperature readings remained stable. After 15 min, the temperature had a swing of 0.1 °C between 11:17 a.m. and 11:30 a.m. and remained stable again.

5.2. Humidity Sensor Measurement Results

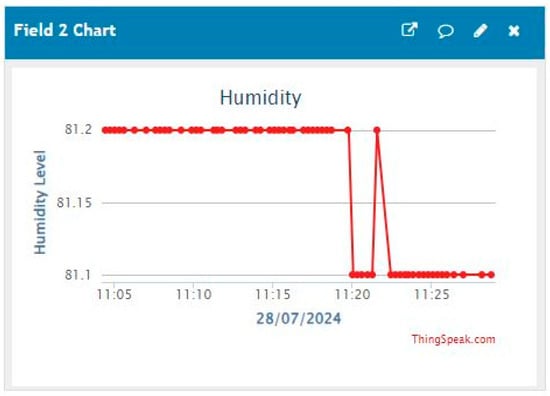

Figure 9 shows that the y-axis represents the humidity level (rising and falling), while the x-axis represents date and time interval. It can be observed that the humidity appears to be high as a result of air moisture in the vaccine carrier chamber due to the presence of ice packs. As observed from Figure 10, the humidity had a rising swing of 81.20% between 11:05 a.m. and 11:20 a.m., while there was a falling swing of 81.10% between 11:20 a.m. and 11:22 a.m., as well as a tiny sharp rising swing of 81.20%, but it immediately fell to 81.10% between 11.23 a.m. and 11:30 a.m., respectively. This shows that the device keeps track of the vaccine carrier humidity variations and maintains a safe environment for the vaccine storage.

Figure 9.

Humidity level versus time.

Figure 10.

The vaccine carrier depth level versus time.

5.3. Ultrasonic Sensor Measurement (Depth) Results

Figure 10 shows the variation in vaccine carrier depth level (rising and falling) against date and time interval. It can be observed that the depth level continuously changes between 17 m and 20 m with their corresponding time stamp, as the quantity of the vaccine varies in the vaccine carrier chamber, creases, and momentarily reduces. The falling and rising of the depth indicate how the vaccines are removed and added to the vaccine carrier. This shows how accurately the system monitors and controls the vaccine volume inside the carrier (container).

6. Conclusions

This study presents a smart IoT-based COVID-19 vaccine supply chain, monitoring, and control system. This proposed system is designed to efficiently and effectively monitor COVID-19 vaccine storage sites by tracking their temperature, humidity, depth (quantity), and location on a map across various supply chain categories. It ultimately aims to monitor and control temperatures outside the range at the tracked location. We developed a working system prototype of an IoT device, consisting of a robust sensor design, integrated with high levels of fault tolerance that can be deployed in harsh environments (rural areas) to assist medical health practitioners in remote vaccine monitoring and control supply chain systems.

The system was tested in a real-life COVID-19 vaccine storage container/carrier, and accurate sensor output was obtained; that is, the measurements for temperature, humidity, and depth level of vaccines inside storage containers were recorded in a data log file in real-time correctly with the corresponding year, month, day, and time stamped. The developed system provides the capability of a location map, which provides a visual representation of the tracked location where the vaccines are being supplied as well as a clear understanding of its surroundings. A suitable sensor-based interface architecture and web portal are provided so that the health practitioners can monitor the vaccine supply chain system remotely. This method encourages health workers by reducing the high levels of supervision required by vaccine storage to ensure the smooth supply of vaccines to vaccine collection centers, by using a wireless sensor network and IoT technology.

Future work will focus on the use of a field programmable gate array (FPGA) and system-on-chip (SoC)-based architecture and Python programming language for Zynq devices. This will reduce the high levels of supervision required by vaccine storage to ensure the smooth supply of vaccines to vaccine collection centers and will enhance high-performance device monitoring and control when deployed to rural areas.

Author Contributions

Conceptualization, S.A. and I.N.M.; methodology, S.A.; software, I.N.M.; validation, S.A. and I.N.M.; formal analysis, S.A.; investigation, S.A. and I.N.M.; resources, S.A. and I.N.M.; data curation, S.A. and I.N.M.; writing—original draft preparation, S.A.; writing—review and editing, S.A.; visualization, S.A. and I.N.M.; supervision, S.A.; project administration, S.A.; funding acquisition, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data associated with this study are provided within the article.

Acknowledgments

The authors wish to express their propound gratitude and thanks to the Abdussalam International Centre for Theoretical Physics (ICTP), Trieste, Italy, and Iain Darby of the International Atomic Energy Agency (IAEA), Vienna, Austria, for the ICTP workshop/Seminar SMR 3143, “Joint ICTP-IAEA School on Zynq-7000 SoC and its Applications for Nuclear and Related Instrumentation”, August–September 2017, Trieste, and the Advanced Workshop on FPGA-based Systems-On-Chip for Scientific Instrumentation and Reconfigurable Computing, from 26 November 2018 to 7 December 2018, Trieste, Italy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tapia, D.I.; Rodríguez, S.; Bajo, J.; Corchado, J.M.; García, Ó. Wireless Sensor Networks for data acquisition and information fusion: A case study. In Proceedings of the 2010 13th International Conference on Information Fusion, Edinburgh, UK, 26–29 July 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Sachin, K.; Prayag, T.; Mikhail, Z. The Internet of Things is a revolutionary approach for future technology enhancement. J. Big Data 2019, 6, 111. [Google Scholar] [CrossRef]

- Uppal, M.; Gupta, D.; Mahmoud, A.; Elmagzoub, M.A.; Sulaiman, A.; Reshan, M.S.A.; Shaikh, A.; Juneja, S. Fault Prediction Recommender Model for IoT-Enabled Sensors-Based Workplace. Sustainability 2023, 15, 1060. [Google Scholar] [CrossRef]

- Hasanat, R.T.; Rahman, M.A.; Mansoor, N.; Mohammed, N.; Rahman, M.S.; Rasheduzzaman, M. An IoT-based Real-time Data-centric Monitoring System for Vaccine Cold Chain. In Proceedings of the 2020 IEEE East-West Design & Test Symposium (EWDTS), Varna, Bulgaria, 4–7 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Ekundayo, S.; Melissa, H.; Shanta, W.; Roger, M. Reorganizing Nigeria’s Vaccine Supply Chain Reduces Need for Additional Storage Facilities, but More Storage is Required. Health Aff. 2016, 35, 293–300. [Google Scholar]

- Ibrahim, D.; Kis, Z.; Tak, K.; Papathanasiou, M.M.; Kontoravdi, C.; Chachuat, B.; Shah, N. Model-Based Planning and Delivery of Mass Vaccination Campaigns against Infectious Disease: Application to the COVID-19 Pandemic in the UK. Vaccines 2021, 10, 1460. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Oyadiran, O.T.; Usman, S.A.; Osoba, M.E.; Olukorode, S.O.; Lucero-Prisno, D.E., III. Towards effective and efficient COVID-19 vaccination in Nigeria. J. Glob. Health Rep. 2021, 5, e2021023. [Google Scholar] [CrossRef]

- Sorooshian, S.; Abbaspour, A.; Jahan, A. A System View of the Risks of COVID-19 Vaccination Projects. Appl. Syst. Innov. 2022, 5, 20. [Google Scholar] [CrossRef]

- Ling, N.; Mei-Xia, D. Design of a Remote Data Monitoring System Based on Sensor Network. Int. J. Smart Home 2015, 9, 23–30. [Google Scholar] [CrossRef]

- O’Shea, J.; Prausnitz, M.R.; Rouphael, N. Dissolvable Microneedle Patches to Enable Increased Access to Vaccines against SARS-CoV-2 and Future Pandemic Outbreaks. Vaccines 2021, 9, 320. [Google Scholar] [CrossRef]

- Rathee, G.; Garg, S.; Kaddoum, G.; Jayakody, D.N.K. An IoT-Based Secure Vaccine Distribution System through a Blockchain Network. IEEE Internet Things Mag. 2021, 4, 10–15. [Google Scholar] [CrossRef]

- Saranya, S. Go-Win: COVID-19 Vaccine Supply Chain Smart Management System Using Blockchain, IoT, and Cloud Technologies. Turcomat 2021, 12, 1460–1464. [Google Scholar]

- Hernández Gress, E.S.; Hernández-Gress, N.; Contla, K.S. Methodology for Designing Humanitarian Supply Chains: Distribution of COVID-19 Vaccines in Mexico. Adm. Sci. 2021, 11, 134. [Google Scholar] [CrossRef]

- Kis, Z. Stability Modelling of mRNA Vaccine Quality Based on Temperature Monitoring throughout the Distribution Chain. Pharmaceutics 2022, 14, 430. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Rinaldi, M.; Caterino, M.; Riemma, S.; Macchiaroli, R.; Fera, M. Emergency Supply Chain Resilience Enhanced Through Blockchain and Digital Twin Technology. Logistics 2025, 9, 43. [Google Scholar] [CrossRef]

- Shah, S.M.; Alsaab, H.O.; Rawas-Qalaji, M.M.; Uddin, M.N. A Review on Current COVID-19 Vaccines and Evaluation of Particulate Vaccine Delivery Systems. Vaccines 2021, 9, 1086. [Google Scholar] [CrossRef]

- Naor, M.; Pinto, G.D.; Davidov, P.; Abdrbo, L. Rapidly Establishing an Ultra-Cold Supply Chain of Vaccines in Israel: Evidence for the Efficacy of Inoculation to Mitigate the COVID-19 Pandemic. Vaccines 2023, 11, 349. [Google Scholar] [CrossRef]

- Kandulu, C.C.; Sahm, L.J.; Saab, M.M.; O’Driscoll, M.; McCarthy, M.; Shorter, G.W.; Berry, E.; Moore, A.C.; Fleming, A. A Scoping Review of Factors Affecting COVID-19 Vaccination Uptake and Deployment in Global Healthcare Systems. Vaccines 2024, 12, 1093. [Google Scholar] [CrossRef]

- Hay, M.; Teichert, A.; Kilz, S.; Vosen, A. Resilience in the Vaccine Supply Chain: Learning from the COVID-19 Pandemic. Vaccines 2025, 13, 142. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.; Sharma, M. A Literature Survey on Vaccine Supply Chain Management Amidst COVID-19: Literature Developments, Future Directions and Open Challenges for Public Health. World 2022, 3, 876–903. [Google Scholar] [CrossRef]

- Ankita, T.; Chatterjee, S. Liquid Crystal Display: Environment & Technology. Int. J. Environ. Eng. Sci. Technol. Res. 2019, 1, 110–123. [Google Scholar]

- Ambarapu, S.; Gaddi, N.; Modala, P.S.; Maya, V.; Vasala, N.; Bodapati, V.R. Transmission line fault analysis using actuating relays and Atmega 328P controller. Int. J. Appl. Power Eng. 2023, 12, 190–195. [Google Scholar] [CrossRef]

- Nuba, S.M.; Vassil, T.V.; Myasar, T. Low-Cost, Easy-to-Use IoT and Cloud-Based Real-Time Environment Monitoring System Using ESP8266 Microcontroller. Int. J. Internet Things Web Serv. 2021, 6, 30–44. [Google Scholar]

- Khalilpoor, S.; Kamran, M.A.; Solimanpur, M. Resilient COVID-19 vaccine supply chain: An optimization and simulation approach for multi-objective management. Transp. Res. Part E Logist. Transp. Rev. 2025, 201, 104168. [Google Scholar] [CrossRef]

- Zhmud, V.A.; Kondratiev, N.O.; Kuznetsov, K.A.; Trubin, V.G.; Dimitrov, L.V. Application of ultrasonic s ensors for measuring distances in robotics. J. Phys. 2018, 1015, 032189. [Google Scholar] [CrossRef]

- Pilati, F.; Tronconi, R.; Nollo, G.; Heragu, S.S.; Zerzer, F. Digital Twin of COVID-19 Mass Vaccination Centers. Sustainability 2021, 13, 7396. [Google Scholar] [CrossRef]

- Zhao, Y.-X.; Hsieh, Y.-Z.; Lin, S.-S.; Pan, C.-J.; Nan, C.-W. Design of an IoT-Based Mountaineering Team Management Device Using Kalman Filter Algorithm. J. Internet Technol. 2020, 21, 2085–2093. [Google Scholar] [CrossRef]

- Oyebola, B.O.; Odueso, V.T. GSM Module in Remote Electrical Loads Control. Asian J. Electr. Sci. 2017, 6, 29–35. [Google Scholar] [CrossRef]

- Labcenter Electronics Ltd. Proteus Design Suite 8.5 Professional. Available online: http://www.labcenter.com (accessed on 10 February 2024).

- Arduino Integrated Design Environment. Available online: http://www.arduino.cc (accessed on 8 February 2024).

- ThingSpeak for IoTprojects: Data Collections in the Cloud with Advanced Data Analysis Using MATLAB. Available online: https://thingspeak.mathworks.com (accessed on 6 February 2024).

- Sani, A.; Beauty, P.E. Smart Framework for Environmental Pollution Monitoring and Control System Using IoT-Based Technology. Sens. Transducers 2019, 229, 84–93. [Google Scholar]

- Abba, S.; Wadumi Namkusong, J.; Lee, J.-A.; Liz Crespo, M. Design and Performance Evaluation of a Low-Cost Autonomous Sensor Interface for a Smart IoT-Based Irrigation Monitoring and Control System. Sensors 2019, 19, 3643. [Google Scholar] [CrossRef]

- Pankaj, J. An Integrated Approach to Software Engineering, 2nd ed.; Springer: New York, NY, USA, 1997; pp. 1–508, eBook ISBN 978-0-387-28132-2, Softcover ISBN 978-1-4419-3544-1. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).