Abstract

This research investigates the energy consumption of buildings managed by traditional Building Management Systems (BMSs) and proposes the integration of Internet of Things (IoT) technology to enhance energy efficiency. Conventional BMSs often suffer from significant energy wastage and safety hazards due to sensor failures or malfunctions. These issues arise when building systems continue to operate under unknown conditions while the BMS is offline, leading to increased energy consumption and operational risks. The study demonstrates that integrating IoT systems with existing BMSs can substantially improve energy efficiency in smart buildings. The research involved designing a system architecture prototype, performing MATLAB simulations, and a real-life case study which revealed that IoT devices are effective in reducing energy waste, particularly in Heating, Ventilation, and Air Conditioning (HVAC) systems and lighting. Additionally, an auxiliary bypass system was incorporated in parallel with the IoT system to enhance reliability in the event of IoT system failures. Preliminary findings indicate that the integration of IoT systems with traditional BMSs significantly boosts energy efficiency and safety in smart buildings. Simulation results reveal an hourly average power savings of 36.8 kw with the integrated failsafe model for all scenarios. This integration offers a promising solution for advancing energy management practices and policies, thereby improving both operational performance and sustainability in building management.

1. Introduction

Urbanization has historically driven migration to cities for economic opportunities, healthcare, and education, significantly increasing water and energy consumption. In developed countries, urban buildings account for approximately 30% of national energy usage due to building operations [1]. Modern buildings employ Building Management Systems (BMSs) to enhance comfort, security, and energy management. The integration of the Internet of Things (IoT) with BMSs in smart buildings can reduce energy waste and improve overall performance and occupant safety [2,3,4]. A BMS is a computer-aided control system that manages electrical and mechanical appliances, such as HVAC systems, lighting, and fire safety equipment. By centralizing control and utilizing automated monitoring, a BMS optimizes operations, enhancing energy efficiency and occupant safety. Smart building automation, integrated with IoT platforms, facilitates real-time communication with users and building staff, outperforming conventional systems. Various subsystems, including electrical, HVAC, fire alarm, water leak detection, plumbing, access control, CCTV, smart parking, and lighting control, utilize communication devices, software, and technologies such as sensors, actuators, smart meters, thermostats, and PLCs [5,6,7]. They also detect false alarms and ensure fire safety and emergency evacuation, performing tasks like lift homing, fire damper shutdown, pressurized fan triggering, and access door opening in real time [8,9]. These components support energy savings, surveillance, healthy indoor conditions, and fire safety, performing real-time tasks like emergency evacuations and access control. IoT technologies—including wireless sensors, actuators, and data analytics—enhance operational efficiency, productivity, and decision making by connecting industrial equipment and enabling control and communication. Integrating IoT technologies with BMSs in smart buildings provides real-time monitoring of energy and water usage, improved security, predictive maintenance, and optimized space utilization [10,11]. Despite challenges such as interoperability and cybersecurity, implementing failsafe designs can increase the reliability and intelligence of smart building automation systems, thereby enhancing efficiency and reducing operational costs. In the existing Building Management System (BMS) of smart buildings, vulnerabilities related to energy wastage and safety hazards arise, particularly during instances of BMS failures or conventional sensor malfunctions. These failures can lead to scenarios where energy consumption remains unmonitored and uncontrolled, resulting in significant wastage, as building operations may continue to function without accurate oversight. Such uncontrolled operation not only exacerbates energy inefficiency but also exposes occupants to potential safety risks, as critical systems may operate under unknown conditions, thus compromising the integrity of the building’s environment. This research aims to systematically address these challenges by first formally defining the parameters and implications of BMS failures and sensor malfunctions. It will propose a comprehensive solution that incorporates advanced monitoring and control strategies to mitigate energy waste and enhance safety. Furthermore, the research will evaluate the effectiveness of the proposed solutions through rigorous testing and analysis, thereby contributing to the development of more resilient and efficient BMS architectures that ensure optimal energy usage and safeguard building operations against potential hazards.

The rest of the paper is organized as follows. Section 2 addresses background information on BMS systems and IoT technologies. Section 3 presents a comprehensive review of the relevant literature. Section 4 models the BMS and IoT integration system. Section 5 describes a case study of a building load profile under different failure scenarios. Section 6 presents analysis of the results. Section 7 concludes the paper.

2. Research Background

Energy management is a primary focus for IoT applications in smart buildings. By deploying sensors and actuators through IoT networks, building managers can monitor real-time data on energy usage and environmental conditions. This information serves as a crucial resource for enhancing building energy management systems.

Energy consumption within a building is influenced by a variety of factors. The impact on energy use can be direct or indirect. Common building services components such as HVAC, lighting, water heating, appliances and equipment, elevators and escalators, plug loads, ventilation systems, building envelope, and water consumption play a unique role in its overall energy consumption. These components influence overall energy efficiency, with each area offering opportunities for reducing consumption through advanced technologies, improved practices, and system optimization. Data from https://www.iea.org/reports/net-zero-by-2050 (accessed on 11 November 2024), https://www.iea.org/reports/energy-technology-perspectives-2017 (accessed on 11 November 2024), https://www.eia.gov/outlooks/aeo/ (accessed on 11 November 2024), and https://www.indicators.odyssee-mure.eu/ (accessed on 11 November 2024) show the percentage of the main building service total energy consumption where HVAC and Domestic Hot Water are the top-two consumers overall.

Addressing these factors and adopting energy-efficient technologies and strategies can significantly reduce a building’s energy consumption and environmental impact. Over the years, substantial case studies have focused on direct and indirect energy-saving measures.

A variety of IoT technologies, including wireless protocols such as Zigbee, LoRaWAN, NB-IoT, Bluetooth Low Energy (BLE), Wi-Fi, Thread, and Z-Wave, along with platforms like Arduino, Raspberry Pi, and cloud technologies, have led to innovative methods for conserving energy in buildings.

3. Related Work

The following section will focus on a review of the literature on recent advancements in energy consumption control for smart buildings.

The integration of sensor technologies into energy consumption analysis has catalyzed the development of energy audits within smart buildings, as noted by [12]. These audits are designed to analyze consumption patterns, optimize efficiency, and reduce environmental impact. By gathering and interpreting data through advanced sensors, energy audits enable comprehensive building energy management, contributing to both environmental and financial savings over time. Several studies emphasize the role of the IoT in enhancing energy efficiency in smart buildings. Aliev et al. [13] integrated IoT sensor platforms with Advanced Fault Detection and Diagnosis (AFDD) systems to monitor Fan Coil Units (FCUs), leveraging Building Information Modeling (BIM) and Autodesk Forge’s 3D modeling for real-time data integration and predictive maintenance. Similarly, Hsiao et al. [14] proposed a cloud-based data analytics model using IoT-equipped circuit boards on sockets to collect real-time power data, which enhances personalized energy management and system reliability. Chenyan et al. [1] expanded on IoT applications in energy management by collecting real-time data, which were standardized and analyzed to automate energy management through the Internet of Building Energy Systems (iBES). De Freitas Melo et al. [15] presented an IoT-based smart water heating model to reduce water and energy waste, with promising efficiency results in a Brazilian multifamily building. Wireless technologies also play a pivotal role in supporting IoT-based building management systems. For example, Zigbee, with its low power consumption and mesh networking capabilities, enables cost-effective, battery-efficient communication among devices like thermostats and occupancy sensors [16]. Such connectivity, in conjunction with web applications, facilitates real-time monitoring, energy conservation, and water management solutions, especially in urban areas facing rapid growth. The recent adoption of affordable and user-friendly platforms like Arduino and Raspberry Pi further broadens IoT applications in smart home automation [17,18,19,20]. By combining microcontrollers, Wi-Fi modules, and real-time data displays, these systems provide remote control over devices, improved transparency, reduced manual intervention, and proactive energy management for both domestic and industrial users [21]. Recent research also delves into the IoT’s capability for scalable energy control in smart homes, utilizing machine learning and automation for predictive management. Raju et al. [22] developed an IoT system to monitor environmental variables and automate appliances, achieving notable energy reductions. Rathore and Sundaram [23] utilized Arduino and Raspberry Pi to analyze temperature and humidity data for energy optimization, and the work was further enhanced by ThingSpeak’s visualization capabilities. Additionally, components such as ESP8266 microcontrollers and NodeMCU modules are employed to streamline IoT connectivity, enabling flexible device control for enhanced industrial automation [24,25]. As IoT applications grow, communication technologies like LoRa and NB-IoT have become central to IoT-based energy management, addressing the limitations of older networks like 2G and 4G. These technologies, designed for low-power, wide-area data transmission, enhance efficiency in electrical distribution and support optimal fault location in power systems [26]. In another example, Al Sultan and Suleiman et al. [27] demonstrated effective electrical control and management using IoT-connected devices at Ninevah University, employing lightweight protocols to facilitate streamlined data communication. Despite its benefits, IoT integration in energy management systems presents challenges. Privacy risks and data security are significant concerns, particularly in multitenant environments where data confidentiality may be at risk. High sensor usage can lead to congestion, causing operational delays. Furthermore, transitioning to IoT-based Building Energy Management Systems (BEMSs) entails substantial costs in equipment, sensors, and workforce training, as well as complex integration requirements that may reduce system reliability in resource-constrained settings [28]. The absence of standardized protocols across IoT layers complicates device interoperability, highlighting the need for collaborative efforts from organizations such as the IEEE and ITU to develop uniform standards. The literature also indicates gaps in addressing failures within IoT-based Building Management Systems (BMSs), particularly regarding energy wastage and safety risks posed by sensor malfunctions. This underscores the importance of resilience-focused research to address these risks in IoT-driven building management systems. Emerging technologies, including digital twins, machine learning, and artificial intelligence, have been integrated into building energy management systems, as discussed in [29,30,31,32]. Studies addressing network attacks on Building Management Systems (BMSs), as well as related challenges and countermeasures, are available in [33]. Comprehensive reviews of smart building energy management are provided in [34,35,36,37]. Additionally, model-based assessments and information modeling of buildings, incorporating low-cost IoT perspectives, are presented in the literature [38,39,40,41]. These technologies, however, face challenges related to interoperability and integration across systems. In conclusion, while IoT and sensor technologies offer transformative potential for smart building energy management, ongoing research is needed to address the challenges associated with security, cost, and standardization. Establishing a comprehensive, failsafe IoT-based Building Management System will ensure safety, improve energy efficiency, and provide resilient energy solutions for the future.

4. IoT–BMS Integration Model

Below is the formal definition of the problem for smart building failure conditions that formulates the energy wastage occurring due to sensors or BMS failure.

4.1. The Problem Definition

In smart buildings, identifying and addressing energy wastage due to sensor errors or Building Management System (BMS) failures is crucial for enhancing energy efficiency. The energy consumption of each appliance or system is directly influenced by the operational status of its controlling sensors, whether they are functioning normally or experiencing a failure.

The total peak energy consumption (Etotal) of a building is generally the sum of the energy consumed by all Mechanical and Electrical systems, which can be expressed by the following equation:

where we have the following:

- Etotal is the total peak energy consumption over time (measured in kwh or Mwh).

- Ei represents the peak energy consumption of the ith sensor-controlled Mechanical and Electrical appliance (e.g., Air Conditioning and Mechanical Ventilation (ACMV), Fan Coil Units (FCUs), lighting).

- n is the total number of sensor-controlled Mechanical and Electrical appliances.

Equation (1) sums the energy consumption across all Mechanical and Electrical systems, where each system contributes to the total energy consumption. However, in a BMS-controlled building, the energy consumption (Ei) of each Mechanical and Electrical system is more accurately determined by the sensor’s functional status. The refined equation accounting for sensor status is given in Equation (2).

where we have the following:

- Fi is a binary variable indicating the system/appliance’s function status: 1 indicates failure mode, 0 indicates normal operation.

- Ewaste_i is the total wasted energy due to sensor failures.

The total wasted energy Ewaste_i depends on the sensor’s functioning as follows:

When a sensor fails (Fi = 1), the system remains ON, leading to maximum energy wastage during power-saving mode. Conversely, when the sensor operates normally (Fi = 0), the system is OFF, resulting in zero energy wastage. Equation (3) provides a more accurate calculation of the building’s total peak energy consumption, accounting for the impact of sensor functionality on the energy use of various Mechanical and Electrical systems. The total energy waste is the sum of the energy consumed by systems that remain ON due to sensor failures.

4.2. The IoT–BMS Integration Model

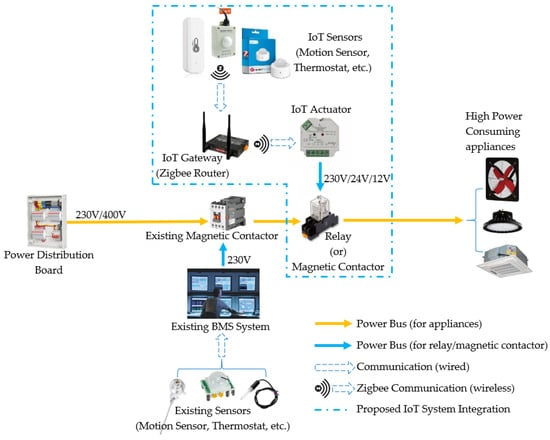

The proposed IoT–BMS integration model is described through a framework that details the operation of the IoT subsystem in conjunction with the existing BMS subsystem. The IoT subsystem is composed of IoT sensors, an IoT gateway, and IoT actuators, while the BMS subsystem comprises existing sensors, BMS actuators, and BMS software (MATLAB R2023B Simulink based on the “Simscape Electrical” toolbox component libraries). Both subsystems are interconnected via a shared power supply and communication bus. The failure events and consequences associated with the BMS subsystem have been modeled in Section 4.3. In the proposed integration model, the IoT subsystem interfaces with the shared supply and communication bus through an optocoupler or relay, as illustrated in Figure 1. Beyond the core components of the IoT subsystem, the model incorporates a contingency mode designed to manage potential IoT device malfunctions. The model’s comprehensive energy-saving strategy is detailed in the subsequent sections.

Figure 1.

The IoT–BMS integration system architecture.

- IoT Sensors and Actuators: When preset thresholds are reached, IoT sensors will wirelessly transmit control signals to the associated IoT end-device actuators. These actuators will subsequently manage the relay outputs connected between the control panel and appliances such as Fan Coil Units (FCUs), fans, and high bay lights.

- Backup System for Conventional Sensor Failures: In the event of a failure or malfunction of conventional sensors that leads to BMS failure and appliances operating in an abnormal state, the IoT actuators will take over to control and turn off the appliances, thereby providing a complementary system. This functionality is illustrated in the system architecture presented in Figure 1.

- Contingency Mode: Furthermore, a bypass device will be installed in parallel with the relay controlled by the IoT system, serving as a contingency mode in case of any IoT device malfunction.

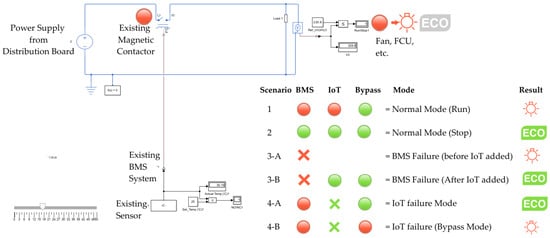

4.3. Simulation Model of the IoT–BMS Integration

The simulation model for IoT–BMS integration was constructed using MATLAB R2023b within the Simulink environment. The Simscape Multidomain Physical Systems Toolbox was utilized for modeling the Building Management System (BMS) components, while the sensors, actuators, user interface, and visualization tools were custom-built using core MATLAB libraries. Key simulation parameters include the total peak energy consumption over time (Etotal), the peak energy consumption of individual appliances (Ei), and the total number of controlled appliances (i). These parameters were sourced from a CSV file embedded within the model blocks. The model assumes a discrete sensor status, represented by “ON” and “OFF” states. The current BMS system, depicted in Figure 2, lacks mechanisms for detecting and responding to failures, whether they occur in the sensors or within the BMS software itself. To simulate a sensor failure, a threshold temperature of 25 °C was established, and a value exceeding this threshold (>25 °C) was introduced during the simulation. Figure 2 illustrates a scenario where the corridor temperature sensor in a building malfunctions, displaying a temperature above 25 °C, while the actual corridor temperature remains below 25 °C. The simulation results demonstrate that the Fan Coil Unit (FCU) continues to operate, failing to deactivate even after the target temperature of 25 °C has been achieved, thus negating the activation of the power-saving ECO mode and leading to unnecessary energy consumption. Furthermore, the simulation reveals that the system does not signal the magnetic contactor, as indicated by the red indicator light, highlighting a critical deficiency in the system’s fault detection and response capabilities.

Figure 2.

MATLAB simulation of existing sensor failure in BMS-only system.

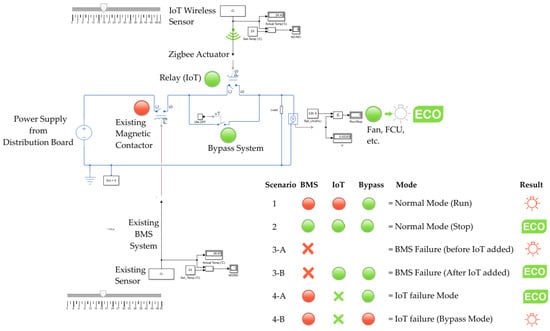

Figure 3 presents the simulation model for the integration of the IoT subsystem with the existing BMS system. In this model, the IoT subsystem interfaces with the BMS from Figure 2 via an optocoupler/relay. The simulation of a BMS failure scenario, as described in Figure 2, is repeated but with the IoT subsystem integrated. In this scenario, the IoT sensor detects the threshold condition and activates the relay, as evidenced by the green indicator during the simulation shown in Figure 3. This action prevents the Fan Coil Unit (FCU) from operating, thereby triggering the power-saving mode, as indicated by the green signal. This occurs despite the magnetic contactor, controlled by the faulty sensor, failing to deactivate the FCU circuit.

Figure 3.

MATLAB simulation of IoT–BMS integration system during existing sensor failure.

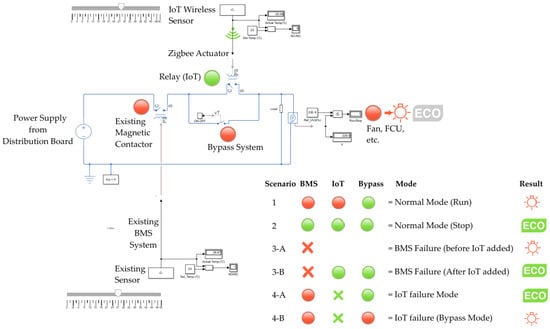

The contingency mode was simulated to evaluate the resilience of the integrated system, particularly its ability to manually bypass the IoT subsystem in the event of a failure. In a scenario where the IoT sensor malfunctions—such as when the room temperature exceeds 25 °C, but the sensor fails to correctly detect this and does not signal the magnetic contactor to activate the Fan Coil Unit (FCU)—the system will display a green indicator (normally open), demonstrating its reliability in run mode. Figure 4 illustrates the IoT sensor failure scenario with contingency mode. In this case, the bypass system, indicated by the red signal in the simulation, will manually take over, ensuring that the system continues to operate in contingency mode despite any IoT device malfunction.

Figure 4.

MATLAB simulation of IoT–BMS integration model bypass mode during IoT sensor failure.

The green symbol indicates the relay is in the “off” position, representing a Normally Open (NO) condition. A green circle means that the relay is open with no connection when the sensor is operating normally. In contrast, a green cross shows that the relay remains open without a connection due to a sensor malfunction or abnormal condition.

The red symbol indicates the relay is in the “on” position, representing a Normally Closed (NC) condition. A red circle means the relay is closed and connected when the sensor is operating normally. In contrast, a red cross shows that the relay remains closed and connected due to a sensor malfunction or abnormal condition.

The simulated failure events presented in the preceding sections illustrate the robustness of the proposed IoT–BMS integration model, demonstrating that the reliability and efficiency of a Building Management System (BMS) can be substantially enhanced. This integration ensures sustained energy savings even in the event of sensor or system failures. The simulation results suggest that incorporating an IoT subsystem into the existing BMS can significantly reduce power consumption and optimize building operations.

5. Case Study: Building Load Profile During Single Sensor Failure

In this case study, the proposed framework was evaluated using real-world building power consumption data over varying time periods. Three office buildings with comprehensive and typical electricity consumption data were selected for the case study. The data for each building were extracted from reference [42]. These data contain approximately 300 daily profiles, covering the period from 1 August 2012 to 20 August 2013. Additionally, basic information for each building was collected from the ECMP, including details such as floor area, number of floors, year of construction, and the type of heating and cooling system details, which can be found in [42]. For the purpose of this study, the above data were further segmented into four categories, namely, 4 h, 8 h, 12 h, and 24 h datasets. The original dataset consists of four key time periods: 00:00–06:00 (off-time), 07:00–10:00 (rise-time), 11:00–17:00 (daytime), and 18:00–23:00 (evening). These periods were designed to reflect different phases of daily activity. However, for our analysis, a more refined segmentation was required to accurately capture the practical implications of sensor failures and typical contractor repair time frames. Consequently, the mean electricity consumption for each segment was recalculated. Additionally, the dataset provides daily electricity consumption profiles, whereas our model requires hourly time series data. To convert daily consumption into corresponding hourly values, we applied the Load Profile-Based Distribution method. This approach utilizes a typical hourly electricity consumption profile for office buildings to distribute the total daily consumption across 24 h. By multiplying the daily consumption by the proportion allocated to each hour, we generated an hourly time series. This method accounts for fluctuations in load throughout the day, producing more realistic hourly estimates. A statistical analysis of the datasets reveals that building loads typically peaked around 10 a.m., reaching 92% of full capacity, and decreased to below 20% of full capacity during the night. This baseline energy consumption is largely attributed to the continuous operation of security lighting, cleaning and maintenance activities, server rooms, and IT equipment in non-residential buildings, along with refrigerators and freezers in residential buildings. In this study, assuming a building full load capacity of 1000 kVA, a hypothetical scenario was considered where a sensor or Building Management System (BMS) malfunction in a corridor prevents the activation of power-saving modes for the corridor’s Fan Coil Units (FCUs) and lighting, which represents less than 5% of the peak load. Failures in power-saving modes, often caused by sensor malfunctions, are critical in building management. However, these issues may not be immediately apparent or reported, particularly in commercial and non-residential buildings. Typically, it is the end users, rather than visitors or occupants, who detect these issues and report them to building management. Since sensor malfunctions are not as critical as failures in fire or smoke detectors, they are frequently excluded from routine maintenance checklists. The delay in detecting and repairing these issues can result from procedural steps such as emailing, cost approval, and contractor coordination, potentially extending the resolution time from half a day to over a week. This study examines the impact of motion sensor failures of varying durations (4 h, 8 h, 12 h, and 24 h).

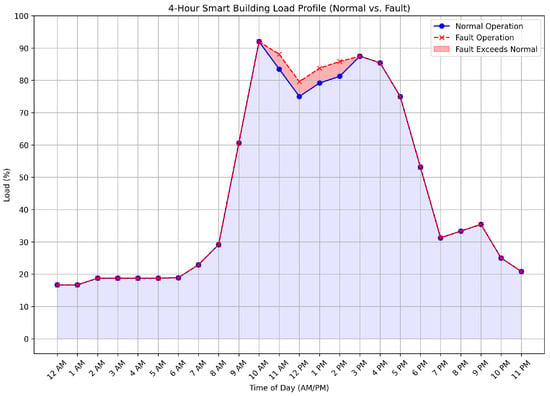

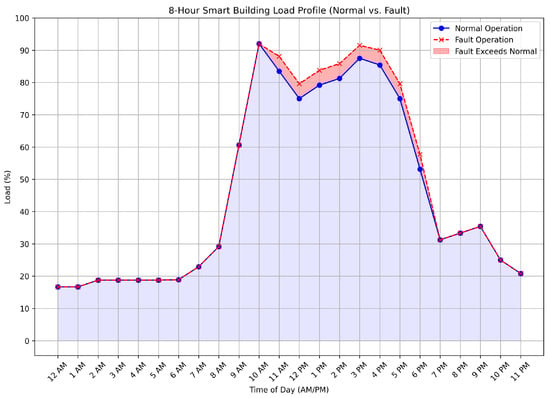

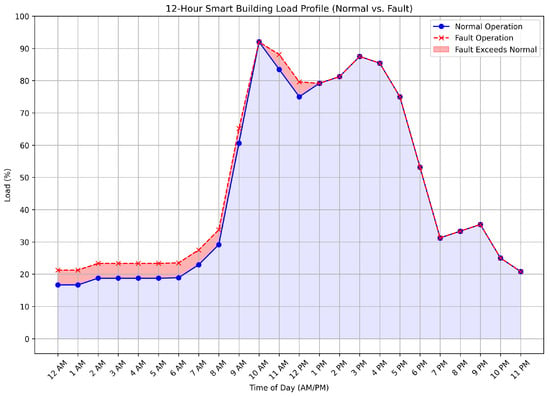

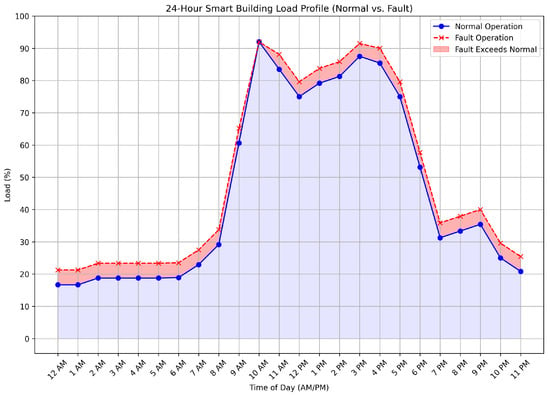

In the first scenario simulating a 4 h sensor failure, the malfunction of the existing corridor temperature sensor occurs at 10:00 a.m. and is repaired by 2:00 p.m. the following day, resulting in a total failure duration of 4 h before the system returns to normal operation. Given a full load capacity of 1000 kVA and assuming a power factor of 0.8, the corresponding full load in kilowatts (kw) is 800 kw. Considering that the peak load is 92% of the full load, this results in a peak load of 736 kw. Assuming a single sensor failure for 4 h during the peak load resulting in 5% of peak loads, this indicates that 147.2 kwh of energy is lost. Consequently, 5% of this peak load amounts to 36.8 kw, representing the power consumption affected by the sensor malfunction. In the second scenario, a malfunction in the existing corridor motion sensor occurs at 10:00 a.m. and is resolved by 6:00 p.m. the same day, resulting in an 8-h failure period before the system resumes normal operation. In the third scenario, the motion sensor error occurs at midnight (12:00 a.m.) and is repaired by noon (12:00 p.m.) the same day, leading to a 12 h interruption before the system is restored. In the fourth and final scenario, the sensor malfunction occurs at noon (12:00 p.m.) and is repaired by noon (12:00 p.m.) the following day, with the system returning to normal operation afterward. For all the four scenarios, a single sensor failure resulting in 5% of the peak loads is assumed. The results of the above scenarios are presented in the accompanying graphs in the results and analysis section, which illustrates the linear relationship between the duration of the malfunction and the corresponding energy consumption.

6. Results and Analysis

As anticipated, energy consumption increased proportionally with the duration, confirming the direct impact of prolonged malfunctions on overall energy usage. This analysis underscores the critical importance of timely detection and correction of malfunctions within building management systems to mitigate excessive energy consumption. If repairs extend beyond a single day, the failure of power-saving modes could lead to energy consumption exceeding 1 Mwh (1000 kwh). This scenario highlights the urgent need for rapid responses to system malfunctions to prevent significant energy waste and ensure the efficient operation of building management systems. However, addressing such issues within a single working day or just a few hours is often impractical, necessitating the exploration of more effective alternatives.

Figure 5 illustrates the normal operation energy consumption, as well as 4 h fault-condition operation energy cost as a percentage of peak load. The highlighted region shows the energy saving achieved through the IoT integration.

Figure 5.

Building load profile during an existing corridor temperature sensor failure for 4 h.

Figure 6 illustrates the normal operation energy consumption, as well as 8 h fault-condition operation energy cost as a percentage of peak load. The highlighted region shows the energy saving achieved through the IoT integration.

Figure 6.

Building load profile during an existing corridor motion sensor failure for 8 h.

In Figure 7, the normal operation energy consumption and 12 h fault-condition operation energy cost as a percentage of peak load are shown. The highlighted region shows the energy saving achieved through the IoT integration.

Figure 7.

Building load profile during an existing corridor motion sensor failure for 12 h.

Figure 8 illustrates the normal operation energy consumption compared to 24 h fault-condition operation energy cost as a percentage of peak load. The achieved energy saving through the IoT integration is highlighted.

Figure 8.

Building load profile during an existing corridor motion sensor failure for 24 h.

The energy consumption associated with the peak load power of 36.8 kw was analyzed across four specific durations: 4 h, 8 h, 12 h, and 24 h. The findings are as follows:

- For a duration of 4 h, the wasted energy consumption totaled 147.2 kwh.

- For a duration of 8 h, the wasted energy consumption was 294.4 kwh.

- For a duration of 12 h, the wasted energy consumption was 441.6 kwh.

- For a duration of 24 h, the wasted energy consumption amounted to 883.2 kwh.

As demonstrated in the analysis of various sensor failure durations, significant energy savings can be realized. Given that repairs may take anywhere from one day to a week, the proposed solution has the potential to save 883.2 kwh over the course of a single day and up to 6.18 Mwh over the span of a week. Table 1 further summarizes the total anticipated energy savings achievable for an entire weekend by the proposed system.

Table 1.

Estimated energy savings over time upon sensor failure duration.

7. Conclusions

This study evaluated the integration of Internet of Things (IoT) systems into existing Building Management Systems (BMSs) and demonstrates its potential to significantly enhance energy efficiency in smart buildings. By addressing BMS failures and sensor malfunctions, the proposed solution mitigates energy wastage and reduces operational costs. In commercial and non-residential buildings, issues such as sensor malfunctions often go undetected for extended periods, leading to substantial increases in energy consumption. This study found that a single sensor failure, if undetected, could result in energy usage increases of up to 6.1 Mwh over the course of a week, highlighting the importance of timely monitoring and detection. The research involved the design of a system architecture prototype and MATLAB simulations, illustrating that IoT devices can effectively reduce energy waste, especially in HVAC and lighting systems. Additionally, a backup bypass system was introduced to maintain system reliability in the event of IoT failures, further strengthening energy security. Through a real-world case study, this integration was shown to contribute to energy conservation and reduce carbon emissions, making it a viable solution for sustainable energy management in smart buildings. As the study’s data pertain to non-residential buildings, the results may not be directly transferable to residential contexts. Future research should therefore expand to include residential buildings, where unique operational dynamics contribute significantly to overall energy consumption. Additionally, real-time datasets collected from IoT devices should be prioritized to enable more accurate assessments of energy usage patterns and system performance in dynamic, real-world settings. For seamless interoperability in IoT systems, the adoption of standardized data formats and communication protocols is crucial. Although formats like JSON and XML and protocols such as BACnet, Modbus, and ZigBee have gained popularity, a universally accepted standard format remains to be established. Ensuring such standardization will support the future scalability and effectiveness of IoT-integrated BMS solutions across various building types.

Author Contributions

Conceptualization, Validation, Formal Analysis, Investigation, Resources, Review and Edit, Supervision, Project Administration, H.S.; Methodology, Visualization, Software, H.S. and T.T.; Data curation, writing—original draft preparation, T.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BMS | Building Management System |

| IoT | Internet of Things |

| AFDD | Advanced Fault Detection and Diagnosis |

| ACMV | Air Conditioning and Mechanical Ventilation |

| FCU | Fan Coil Unit |

| BIM | Building Information Modelling |

References

- Chenyan, L.; Jing, N.; Hui-Wei, S. Research of Carbon Emission Reduction on the Green Building Based on the Internet of Things. In Proceedings of the 2019 International Conference on Smart Grid and Electrical Automation (ICSGEA), Xiangtan, China, 10–11 August 2019; pp. 83–87. [Google Scholar]

- Sidid, S.; Gaur, S. Smart grid building automation based on Internet of Things. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–4. [Google Scholar]

- Verma, N.; Jain, A. Energy Efficient Building Automation System. In Proceedings of the 2019 2nd International Conference on Power Energy, Environment and Intelligent Control (PEEIC), Greater Noida, India, 18–19 October 2019; pp. 27–32. [Google Scholar]

- Stamatescu, G.; Stamatescu, I.; Arghira, N.; Fagarasan, I. Cybersecurity Perspectives for Smart Building Automation Systems. In Proceedings of the 12th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Bucharest, Romania, 25–27 June 2020; pp. 1–5. [Google Scholar]

- Debauche, O.; Mahmoudi, S.; Moussaoui, Y. Internet of Things Learning: A Practical Case for Smart Building Automation. In Proceedings of the 5th International Conference on Cloud Computing and Artificial Intelligence: Technologies and Applications (CloudTech), Marrakesh, Morocco, 24–26 November 2020; pp. 1–8. [Google Scholar]

- Hayduk, G.; Kwasnowski, P.; Mikos, Z. Building management system architecture for large building automation systems. In Proceedings of the 17th International Carpathian Control Conference (ICCC), High Tatras, Slovakia, 29 May–1 June 2016; pp. 232–235. [Google Scholar]

- Khanchuea, K.; Siripokarpirom, R. A Multi-Protocol IoT Gateway and WiFi/BLE Sensor Nodes for Smart Home and Building Automation: Design and Implementation. In Proceedings of the 10th International Conference on Computing and Communications Technologies (ICCCT), Bangkok, Thailand, 25–27 March 2019; pp. 1–6. [Google Scholar]

- Somani, S.; Solunke, P.; Oke, S.; Medhi, P.; Laturkar, P.P. IoT Based Smart Security and Home Automation. In Proceedings of the Fourth International Conference on Computing Communication Control and Automation (ICCUBEA), Pune, India, 16–18 August 2018; pp. 1–4. [Google Scholar]

- Bhutta, E.M. Application of Smart Energy Technologies in Building Sector—Future Prospects. In Proceedings of the 2017 International Conference on Energy Conservation and Efficiency (ICECE), Lahore, Pakistan, 22–23 November 2017; pp. 1–6. [Google Scholar]

- Schrom, H.; Schwartze, J.; Diekmann, S. Building Automation by an Intelligent Embedded Infrastructure: Combining Medical, Smart Energy, Smart Environment and Heating. In Proceedings of the 2017 International Smart Cities Conference (ISC2), Wuxi, China, 14–17 September 2017; pp. 1–4. [Google Scholar]

- Jain, M.; Kaushik, N.; Jayavel, K. Building automation and energy control using IoT—Smart campus. In Proceedings of the 2nd International Conference on Computing and Communications Technologies (ICCCT), Chennai, India, 23–24 February 2017; pp. 353–359. [Google Scholar]

- Tee, B.T.; Lim, S.C.J.; Siew, P.W.; Lee, M.F. Application of Sensor Technology for Energy Consumption Analysis: A Case Study in a Smart Office Building. In Proceedings of the 2023 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 18–21 December 2023; pp. 913–917. [Google Scholar]

- Aliev, K.; Antonelli, D.; Bruno, G.; Piantanida, P.; Villa, V. Building system diagnostics through a network of smart local sensors. In Proceedings of the 6th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Preveza, Greece, 24–26 September 2021; pp. 1–6. [Google Scholar]

- Hsiao, T.C.; Chen, T.L.; Kang, T.C.; Wu, T.Y. The Implementation of Smart Home Power Management: Integration of Internet of Things and Cloud Computing. In Proceedings of the 2019 IEEE Eurasia Conference on Biomedical Engineering, Healthcare and Sustainability (ECBIOS), Okinawa, Japan, 31 May–3 June 2019; pp. 21–23. [Google Scholar]

- De Freitas Melo, D.; De Souza Lage, E.; Rocha, A.V.; De Jesus Cardoso, B. Improving the consumption and water heating efficiency in smart buildings. In Proceedings of the 13th International Conference and Expo on Emerging Technologies for a Smarter World (CEWIT), Stony Brook, NY, USA, 7–8 November 2017; pp. 1–6. [Google Scholar]

- Masrani, E.; Patel, D.; Khatri, M.; Martis, E.; Gaur, N. Smart Living Solution to Optimize Building Systems for Efficient Energy Usage and Prediction. In Proceedings of the 2023 International Conference on Communication System, Computing and IT Applications (CSCITA), Mumbai, India, 31 March–1 April 2023; pp. 204–208. [Google Scholar]

- De Las Morenas, J.; Da Silva, C.M.; Barbosa, J.; Leitao, P. Low Cost Integration of IoT Technologies for Building Automation. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 2548–2553. [Google Scholar]

- Raju, L.; Adhil, M.; Logeshwaran, S.; Sanjana, M.; Praveena, V.K. IoT Based Advanced Building Automation and Energy Management. In Proceedings of the 2022 IEEE World Conference on Applied Intelligence and Computing (AIC), Sonbhadra, India, 17–19 June 2022; pp. 478–481. [Google Scholar]

- Abhishek, A.S.; Bhasker, M.; Ponraj, A.S. IoT Based Control System for Home Automation. In Proceedings of the 2021 IEEE 2nd International Conference on Technology, Engineering, Management for Societal Impact Using Marketing, Entrepreneurship and Talent (TEMSMET), Pune, India, 2–3 December 2021; pp. 1–5. [Google Scholar]

- Nirmala, A.P.; Asha, V.; Chandra, P.; Priya, H.; Raj, S. IoT Based Secure Smart Home Automation System. In Proceedings of the 2022 IEEE Delhi Section Conference (DELCON), New Delhi, India, 11–13 February 2022; pp. 1–7. [Google Scholar]

- Mahmud, S.; Ahmed, S.; Shikder, K. A Smart Home Automation and Metering System using Internet of Things (IoT). In Proceedings of the 2019 International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 10–12 January 2019; pp. 451–454. [Google Scholar]

- Raju, L.; Praveena, V.K.; Sai Akash, A.S.; Vaishnavi, V.; Bharathraj, V. Building Energy Management and Conservation using Internet of Things. In Proceedings of the 2022 International Conference on Sustainable Computing and Data Communication Systems (ICSCDS), Erode, India, 7–9 April 2022; pp. 970–974. [Google Scholar]

- Rathore, A.; Sundaram, S. Building Energy Management Through Load Control Using Internet of Things. In Proceedings of the 2021 Innovations in Power and Advanced Computing Technologies (i-PACT), Kuala Lumpur, Malaysia, 27–29 November 2021; pp. 1–6. [Google Scholar]

- Kodali, R.K.; Yerroju, S. Energy Efficient Home Automation Using IoT. In Proceedings of the 2018 International Conference on Communication, Computing and Internet of Things (IC3IoT), Chennai, India, 15–17 February 2018; pp. 151–154. [Google Scholar]

- Arulprakash, N.M.P.; Ayyannan, M.; Pokhariyal, N.M.R.; Maranan, R. Intelligent Smart Home Automation System using Internet of Things. In Proceedings of the 7th International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Kirtipur, Nepal, 11–13 October 2023; pp. 31–36. [Google Scholar]

- Tang, J.; Li, J.; Zhong, A.; Xiong, B.; Bian, X.; Li, Y. Application of LoRa and NB-IoT in Ubiquitous Power Internet of Things: A Case Study of Fault Indicator in Electricity Distribution Network. In Proceedings of the 4th International Conference on Intelligent Green Building and Smart Grid (IGBSG), Yichang, China, 6–9 September 2019; pp. 380–383. [Google Scholar]

- Al Sultan, O.K.T.; Suleiman, A.R. Simulation of IoT Web-based Standard Smart Building Using Packet Tracer. In Proceedings of the 7th International Engineering Conference “Research & Innovation amid Global Pandemic” (IEC), Erbil, Iraq, 24–25 February 2021; pp. 48–53. [Google Scholar]

- Naqbi, A.A.; Alyieliely, S.S.; Talib, M.A.; Nasir, Q.; Bettayeb, M.; Ghenai, C. Energy Reduction in Building Energy Management Systems Using the Internet of Things: Systematic Literature Review. In Proceedings of the 2021 International Symposium on Networks, Computers and Communications (ISNCC), Dubai, United Arab Emirates, 31 October–2 November 2021; pp. 1–7. [Google Scholar]

- Piras, G.; Muzi, F.; Tiburcio, V.A. Enhancing Space Management through Digital Twin: A Case Study of the Lazio Region Headquarters. Appl. Sci. 2024, 14, 7463. [Google Scholar] [CrossRef]

- Eneyew, D.D.; Capretz, M.A.M.; Bitsuamlak, G.T. Toward Smart-Building Digital Twins: BIM and IoT Data Integration. IEEE Access 2022, 10, 130487–130506. [Google Scholar] [CrossRef]

- Lee, S.; Seon, J.; Hwang, B.; Kim, S.; Sun, Y.; Kim, J. Recent Trends and Issues of Energy Management Systems Using Machine Learning. Energies 2024, 17, 624. [Google Scholar] [CrossRef]

- Marinakis, V.; Doukas, H. An Advanced IoT-based System for Intelligent Energy Management in Buildings. Sensors 2018, 18, 610. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, B.H.; Sallehudin, H.; Mohamed, S.A.; Satar, N.S.M.; Hussain, A.H.B. Internet of Things-Building Information Modeling Integration: Attacks, Challenges, and Countermeasures. IEEE Access 2022, 10, 74508–74522. [Google Scholar] [CrossRef]

- Chataut, R.; Phoummalayvane, A.; Akl, R. Unleashing the Power of IoT: A Comprehensive Review of IoT Applications and Future Prospects in Healthcare, Agriculture, Smart Homes, Smart Cities, and Industry 4.0. Sensors 2023, 23, 7194. [Google Scholar] [CrossRef] [PubMed]

- Al-Obaidi, K.M.; Hossain, M.; Alduais, N.A.M.; Al-Duais, H.S.; Omrany, H.; Ghaffarianhoseini, A. A Review of Using IoT for Energy Efficient Buildings and Cities: A Built Environment Perspective. Energies 2022, 15, 5991. [Google Scholar] [CrossRef]

- de Oliveira Cavalcanti, G.; Pimenta, H.C.D. Electric Energy Management in Buildings Based on the Internet of Things: A Systematic Review. Energies 2023, 16, 5753. [Google Scholar] [CrossRef]

- Aliero, M.S.; Asif, M.; Ghani, I.; Pasha, M.F.; Jeong, S.R. Systematic Review Analysis on Smart Building: Challenges and Opportunities. Sustainability 2022, 14, 3009. [Google Scholar] [CrossRef]

- Metallidou, C.K.; Psannis, K.E.; Egyptiadou, E.A. Energy Efficiency in Smart Buildings: IoT Approaches. IEEE Access 2020, 8, 63679–63699. [Google Scholar] [CrossRef]

- Mataloto, B.; Ferreira, J.C.; Cruz, N. LoBEMS—IoT for Building and Energy Management Systems. Electronics 2019, 8, 763. [Google Scholar] [CrossRef]

- Abdulhamid, A.; Rahman, M.M.; Kabir, S.; Ghafir, I. Enhancing Safety in IoT Systems: A Model-Based Assessment of a Smart Irrigation System Using Fault Tree Analysis. Electronics 2024, 13, 1156. [Google Scholar] [CrossRef]

- Borkowski, A.S. Low-Cost Internet of Things Solution for Building Information Modeling Level 3B—Monitoring, Analysis and Management. J. Sens. Actuator Netw. 2024, 13, 19. [Google Scholar] [CrossRef]

- Liu, X.; Ding, Y.; Tang, H.; Xiao, F. A data mining-based framework for the identification of daily electricity usage patterns and anomaly detection in building electricity consumption data. Energy Build. 2021, 231, 110601–110622. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).