Design and Testing of Air-Separation-Type Tillage Layer Residual Film Recovery Machines

Abstract

1. Introduction

2. Materials and Methods

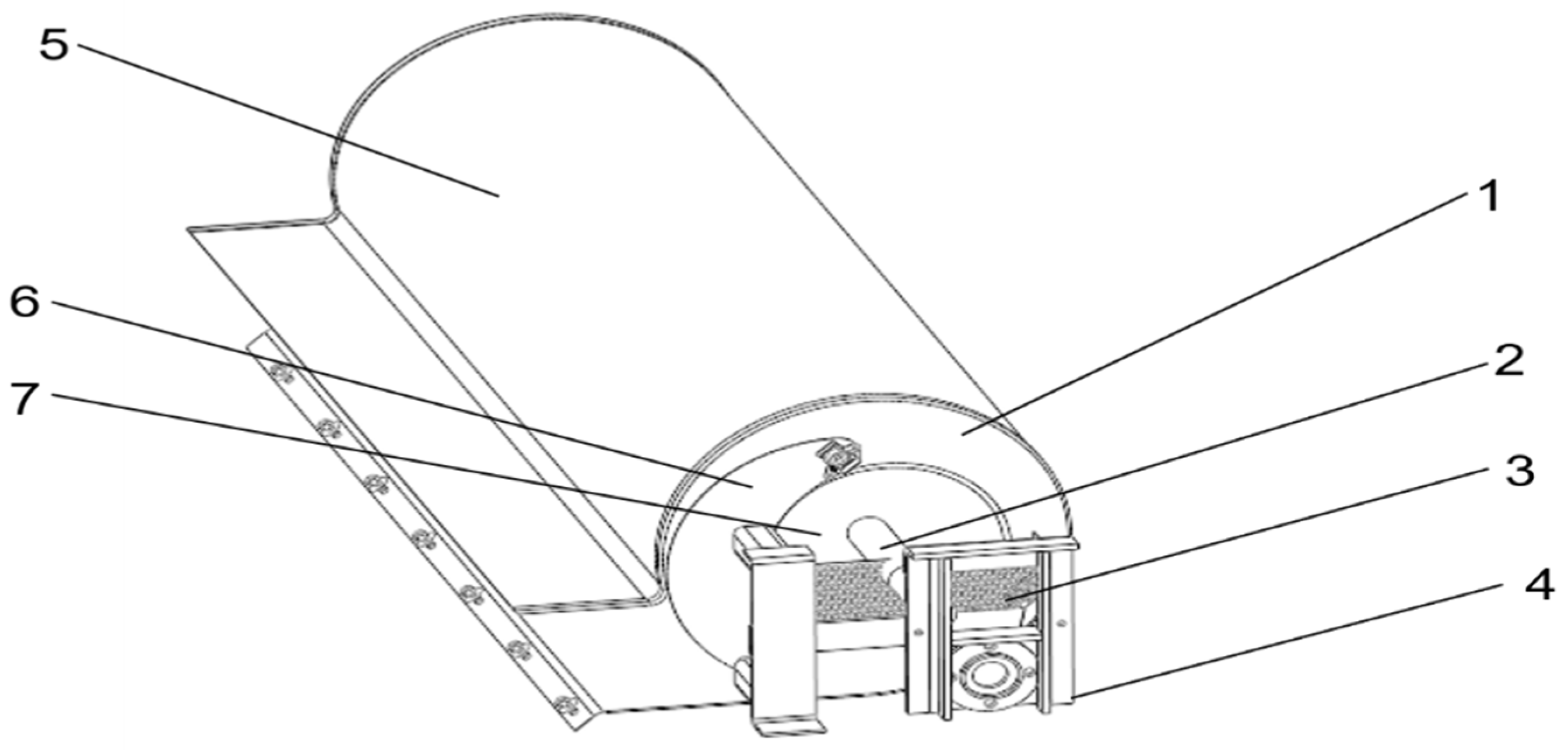

2.1. Structure and Working Principle

2.2. Working Principle

2.3. Motion Analysis and Key Devices of the Membrane Mixture

2.4. Through-Flow Fan Device

3. Field Experiment

3.1. Test Conditions and Equipment

3.2. Test Indicators

3.3. Test Protocol

4. Results and Discussion

4.1. Test Results

4.2. Analysis of Interactive Influencing Factors

4.3. Analysis and Discussion of Verification Results

5. Conclusions

- (1)

- In order to solve the problem of low residual film recovery rate and high impurity content during the operation of the residual film recycling machine, a membrane impurity separation device was designed, and the whole structure and working principle of the membrane impurity separation device were expounded.

- (2)

- The motion law of the membrane mixture was analyzed, and the kinematic equation of the membrane mixture separation zone was established. The main parameters affecting the separation effect of the membrane mixture were wind speed and wind inlet angle.

- (3)

- The orthogonal simulation test was designed by using Design-Expert’s Box–Behnken, and the interaction of various factors on the recovery rate and impurity content of the residual film was tested based on the orthogonal test results.

- (4)

- The proposed air-separation-type tillage layer residual film recovery machines achieved a 86.7% film recovery rate and a 3.4% impurity rate in the field test under the optimal parameter combination of 31° inlet angle, 1277 r/min fan speed, and 62% proportion of residual film quality. The relative error between the test results and the predicted values of Design-Expert 13 (88.1% recovery rate, 3.58% impurity rate) was less than 5%, and the relative error was smaller compared to the model’s predicted values, indicating that the parameter data is reliable. It significantly outperforms traditional mechanical screening-type recovery machines (such as the 82.6% film recovery rate reported by Shi et al. [11]).

- (5)

- The successful recovery of this machine has significantly reduced the presence of crop residual film, directly enhanced agricultural production efficiency, indirectly increased the yield of related crops, achieved remarkable environmental protection, and brought about obvious economic benefits. However, due to the small scale of use of the residual film recovery machine, the fact that it does not bring direct economic benefits to farmers in developing countries, and the insufficient government support, there are challenges in practical application. If the government can increase publicity efforts and improve supportive policies in the future, it will be more conducive to the development of this machine and create greater economic value.

- (6)

- Currently, most of the crop residue film recovery machines on the market are still at the stage of primary mechanical structure research. The mechanical recovery of crop residue films has strong randomness, which is also an important reason for the unstable recovery effect of crop residue film recovery machines. In the future development of crop residue film recovery machines, related technologies such as automation, vision, and sensors may be introduced to further improve the operation effect of the machine.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Z.; Han, Y. Application of Plastic Film Mulching on Agricultural Production. Liaoning Agric. Sci. 2024, 6, 82–86. [Google Scholar]

- Zhang, M.; Xu, Q. Research on Current Situation and Prevention and Control Measures of Residue Film Recycling in Farmland. Agric. Mach. Using Maint. 2024, 9, 57–60. [Google Scholar] [CrossRef]

- Yan, Z.; Xuegeng, C.; Haojun, W.; Xuan, Z.; Qi, N.; Jianming, K. Research Status and Prospect of Control Technology forResidual Plastic Film Pollution in Farmland. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–14. [Google Scholar]

- He, Z.; Dai, H. The degradation performance of degradable film and its effects on soil temperature, moisture, corn growth and development, and yield. Water Sav. Irrig. 2016, 28, 41–43. [Google Scholar]

- Xiaoting, Y. Distribution and Degradation Characteristics of Residual Film in Farmland Soil and Its Influence on Soil Physical and Chemical Properties. Master’s Thesis, China Agricultural University, Beijing, China, 2021. [Google Scholar]

- Yao, J.; Zhang, X.; Shi, Z.; Liu, X.; Kang, M.; Guo, L. Research status and development trend of tillage layer residual film recycling machine. J. Chin. Agric. Mech. 2024, 45, 290–295. [Google Scholar] [CrossRef]

- Liu, X. Design and Testing of Key Components of Roll Type Tillage Layer Residual Film Recovery Machine. Master’s Thesis, Xinjiang Agricultural University, Xinjiang, China, 2024. [Google Scholar]

- Zhang, Z. Design and Research of the Air Separation Type Reclaimer for the Residual Film of Plough Layer. Master’s Thesis, Shanxi Agricultural University, Shanxi, China, 2020. [Google Scholar]

- Liu, X.; Shi, Z.; Yao, J.; Zhang, X.; Yan, J.; Zhang, C.; Liu, L. Design and experiment of film unloading device for roller-type residual film recycling machine. Agric. Res. Arid Areas 2024, 42, 271–282. [Google Scholar]

- Chen, Y.; Xing, R.; Liu, X.; Zhang, H.; Li, H. Design and Test of Potato Seedling Killing and Residual Film Recycling Integrated Machine. Agronomy 2024, 14, 2269. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, X.; Liu, X.; Kang, M.; Yao, J.; Guo, L. Analysis and Test of the Tillage Layer Roll-Type Residual Film Recovery Mechanism. Appl. Sci. 2023, 13, 7598. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, A.; Shi, Q.; Ding, J.; Lu, J.; Li, D. Parameter Optimization and Experiment of the Combined Residual Film Reclaimer with Upper Conveyor Chain. J. Agric. Mech. Res. 2023, 45, 164–170. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, G.; Guo, H.; Jiang, Y.; Liu, X.; Niu, C. Parameter Optimization and Experiment of Film Transmission Mechanism of Spade Screen Recovery Machine. Mod. Manuf. Technol. Equip. 2018, 14, 68–69. [Google Scholar] [CrossRef]

- Guo, W.; He, X.; Wang, L.; Zhao, P.; Hu, C.; Hou, S.; Wang, X. Development of a comb tooth loosening and pneumatic stripping plough layer residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–10. [Google Scholar]

- Chrysler, R.W. Apparatus for Removing for Plastic Film from Raised Plant Beds. U.S. Patent US4796711, 10 January 1989. [Google Scholar]

- Khazimov, K.M.; Niyazbayev, A.K.; Shekerbekova, Z.S.; Urymbayeva, A.A.; Mukanova, G.A.; Bazarbayeva, T.A.; Nekrashevich, V.F.; Khazimov, M.Z. A novel method and device for plastic mulch retriever. J. Water Land Dev. 2021, 85–94. [Google Scholar] [CrossRef]

- Shen, S.; Zhang, J.; Jiang, Y.; Wang, Y.; Liu, X.; Li, J.; Dong, W. Tensile Properties of Residual Film in Tillage Layer Based on Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 132–141. [Google Scholar]

- Jiang, Z.; Zhang, J.; Lin, Y.; Tang, Y. Design and Numerical Simulation Study of Film Rod Reparation Device for Residual Film Recycling Machine. Appl. Sci. 2023, 14, 343. [Google Scholar] [CrossRef]

- Tao Nan, W.C. Approach to Mehod of Designing the Cross-flow Fan Used for Agriculture Cleaner. J. Zhejiang Univ. (Agric. Life Sci.) 1988, 14, 73–78. [Google Scholar]

- GB/T 25412-2021; Residual Film Recycling Machine. Standards Press of China: Beijing, China, 2021.

- Stat-Ease Inc. Design-Expert, Version 13; Stat-Ease Inc.: Minneapolis, MN, USA, 2021. Available online: https://www.statease.com (accessed on 25 May 2024).

| Serial | Angle of Entry Into the Wind (/°) | Fan Speed /(r/min) | Proportion of Residual Film Quality (/%) |

|---|---|---|---|

| −1 | 20 | 1000 | 40 |

| 0 | 30 | 1200 | 60 |

| 1 | 40 | 1400 | 80 |

| No. | Angle of Entry Into the Wind (/°) | Fan Speed /(r/min) | Proportion of Residual Film Quality Film to Impurities (/%) | Residual Film Recovery Rate (%) | Impurity Content (%) |

|---|---|---|---|---|---|

| 1 | 1 | −1 | 0 | 85.7 | 5.2 |

| 2 | 0 | 1 | −1 | 86.6 | 5.7 |

| 3 | 0 | 0 | 0 | 87.9 | 3.6 |

| 4 | −1 | 0 | −1 | 84.8 | 5.6 |

| 5 | 0 | 1 | 1 | 87.1 | 5 |

| 6 | −1 | 1 | 0 | 86.3 | 5.6 |

| 7 | 1 | 0 | −1 | 86.1 | 5.3 |

| 8 | 0 | −1 | 1 | 85.5 | 5.3 |

| 9 | 0 | 0 | 0 | 88.1 | 3.6 |

| 10 | 1 | 0 | 1 | 86.8 | 5.1 |

| 11 | 0 | 0 | 0 | 87.9 | 3.6 |

| 12 | 0 | −1 | −1 | 84.5 | 5.3 |

| 13 | 0 | 0 | 0 | 88.1 | 3.5 |

| 14 | −1 | −1 | 0 | 83.9 | 5.7 |

| 15 | 1 | 1 | 0 | 87.8 | 5.6 |

| 16 | 0 | 0 | 0 | 87.6 | 3.6 |

| 17 | −1 | 0 | 1 | 85.1 | 5.1 |

| Source | Residual Film Recovery Rate (%) | Impurity Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SSQ | DF | MSE | F Value | p Value | SSQ | DF | MSE | F Value | F Value | |

| Model A | 29.53 1.91 | 9 1 | 3.28 1.91 | 79.06 46.05 | <0.0001 0.0003 | 12.06 0.0919 | 9 1 | 1.34 0.0919 | 52.1.30 35.74 | <0.0001 0.0006 |

| B | 4.71 | 1 | 4.71 | 113.54 | <0.0001 | 0.1237 | 1 | 0.1237 | 48.10 | 0.0002 |

| C | 5.93 | 1 | 5.93 | 142.91 | <0.0001 | 2.55 | 1 | 2.55 | 990.99 | <0.0001 |

| AB | 0.0225 | 1 | 0.0025 | 0.5422 | 0.4855 | 0.0625 | 1 | 0.0625 | 24.31 | 0.0017 |

| AC | 0.0400 | 1 | 0.0400 | 0.9639 | 0.3589 | 0.0225 | 1 | 0.0225 | 8.75 | 0.0212 |

| BC | 0.6250 | 1 | 0.0625 | 1.51 | 0.2594 | 0.1225 | 1 | 0.1225 | 47.64 | 0.0002 |

| A2 | 5.19 | 1 | 5.19 | 125.01 | <0.0001 | 3.78 | 1 | 3.78 | 1470.01 | <0.0001 |

| B2 | 3.30 | 1 | 3.30 | 79.46 | <0.0001 | 4.19 | 1 | 4.19 | 1629.05 | <0.0001 |

| C2 | 5.19 | 1 | 5.19 | 125.01 | <0.0001 | 2.35 | 1 | 2.35 | 914.92 | <0.0001 |

| Residuals | 0.2905 | 7 | 0.0415 | 0.0180 | 7 | 0.0026 | ||||

| Lack of Fit | 0.1225 | 3 | 0.0408 | 0.9722 | 0.4886 | 0.010 | 3 | 0.0033 | 1.67 | 0.3099 |

| Pure error | 0.1680 | 4 | 0.0420 | 0.0080 | 4 | 0.0020 | ||||

| Total sum | 29.82 | 16 | 12.08 | 16 | ||||||

| No. | Residual Film Recovery Rate | Impurity Content |

|---|---|---|

| 1 | 85.5 | 3.26 |

| 2 | 87.6 | 3.43 |

| 3 | 86.3 | 3.62 |

| 4 | 87.3 | 3.29 |

| average | 86.7 | 3.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Shi, A.; Zhang, M.; Liu, L.; Zhou, Z.; Ding, L. Design and Testing of Air-Separation-Type Tillage Layer Residual Film Recovery Machines. AgriEngineering 2025, 7, 262. https://doi.org/10.3390/agriengineering7080262

Xu Z, Shi A, Zhang M, Liu L, Zhou Z, Ding L. Design and Testing of Air-Separation-Type Tillage Layer Residual Film Recovery Machines. AgriEngineering. 2025; 7(8):262. https://doi.org/10.3390/agriengineering7080262

Chicago/Turabian StyleXu, Zechen, Aiping Shi, Mingquan Zhang, Lei Liu, Zhi Zhou, and Lijun Ding. 2025. "Design and Testing of Air-Separation-Type Tillage Layer Residual Film Recovery Machines" AgriEngineering 7, no. 8: 262. https://doi.org/10.3390/agriengineering7080262

APA StyleXu, Z., Shi, A., Zhang, M., Liu, L., Zhou, Z., & Ding, L. (2025). Design and Testing of Air-Separation-Type Tillage Layer Residual Film Recovery Machines. AgriEngineering, 7(8), 262. https://doi.org/10.3390/agriengineering7080262