Productivity Modeling and Analysis of Mono- and Bifacial PV Panels Under Different Weather Conditions and Reflection Surfaces for Application in the Agriculture Sector

Abstract

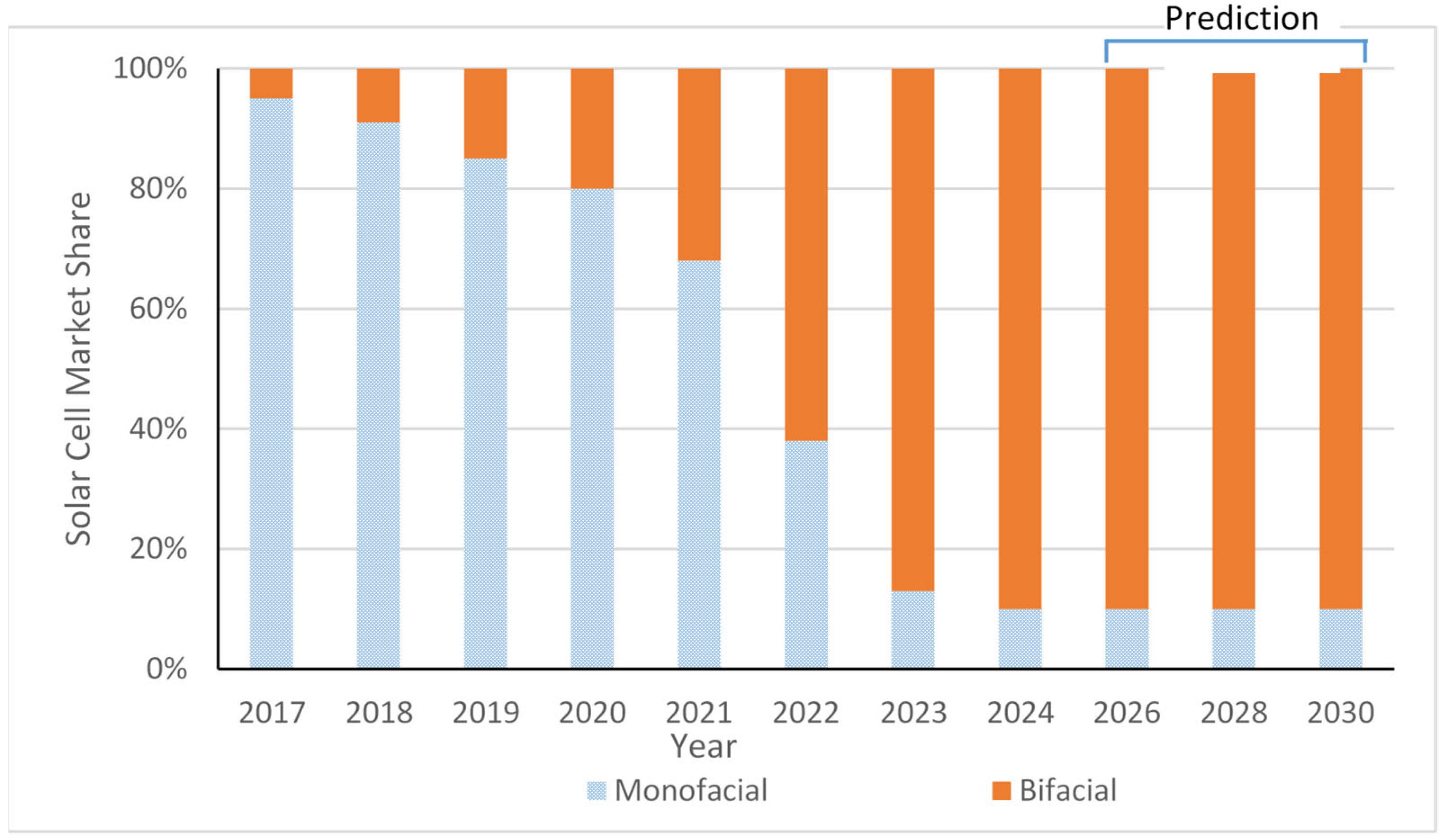

1. Introduction

- Using agrivoltaics [8];

- Increasing the efficiency of the photovoltaic generator.

2. Materials and Methods

2.1. Experimental Platform

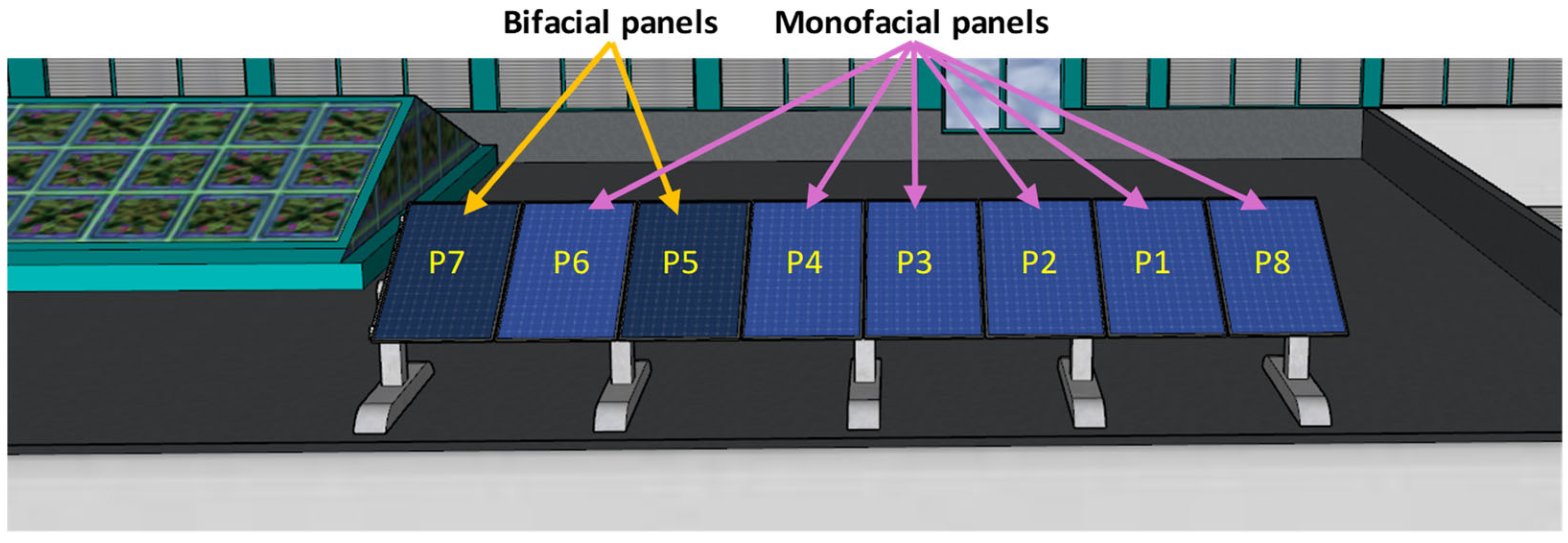

2.1.1. PV Generator

2.1.2. Power Converters

- The ability to use panels with different power ratings in one PV system, while ensuring practically independent operation of each panel at its maximum power point. In this case, it allows for the study of panel performance in various configurations—simultaneous operation of monofacial and bifacial panels; operation of bifacial panels using only the front side or only the rear side; operation with the rear side facing the sun and the front side shaded, etc.

- The optimizers measure and record the electrical operating parameters of each individual panel. The data is transmitted to the inverter and then to a cloud-based storage system.

- All panels operate under identical meteorological conditions, making comparisons between their performance accurate.

- There is the possibility for quick repositioning of the panels, enabling efficient experimentation.

2.1.3. Monitoring System

- Horizontal solar irradiance;

- Solar irradiance on the front plane of the bifacial panels;

- Solar irradiance on the rear plane of the bifacial panels;

- Panel temperature;

- Ambient temperature.

2.1.4. Reflection Surfaces

- White nonwoven geotextile (WNG);

- Green artificial grass (GAG);

- Patinated sheet metal (PSM);

- Shiny aluminum foil (SAF).

3. Productivity Modeling of Mono- and Bifacial PV Panels

3.1. Original Durisch’s Model for PV Panels Efficency

- First, one that accounts for the influence of irradiance Ga on the efficiency with “weighting”coefficients p, q, and m;

- Second, one that considers the cell temperature Tc and air mass AM influence on the efficiency by “weighting”coefficients r, s and u.

- The model is relatively complex;

- Requires information about the exact location of the PV installation and the use of mathematical expressions to calculate air mass (AM);

- The coefficients must be determined on a daily basis, following which the average value of each coefficient is to be calculated;

- It is necessary to determine six empirical coefficients, which are not independent from each other, given that the influence of one coefficient can be compensated by adjusting another.

3.2. Proposed Productivity Modeling of Monofacial PV Panels

- It is less complex than the original Model (1);

- It has only four coefficients to be determined;

- The coefficients can be found using data for different days across the year without the need to know the exact geographical location of the studied PV panels;

- The influence of cell temperature on panel efficiency is clearly distinguished from the influence of solar irradiance.

3.3. Proposed Productivity Modeling of Bifacial PV Panels

3.4. Determination of Efficiency Model Coefficients Fom Mono- and Bifacial PV Panels

- solar irradiance in the front and rear plane of the bifacial panels,

- power output from the panels,

- cell temperature.

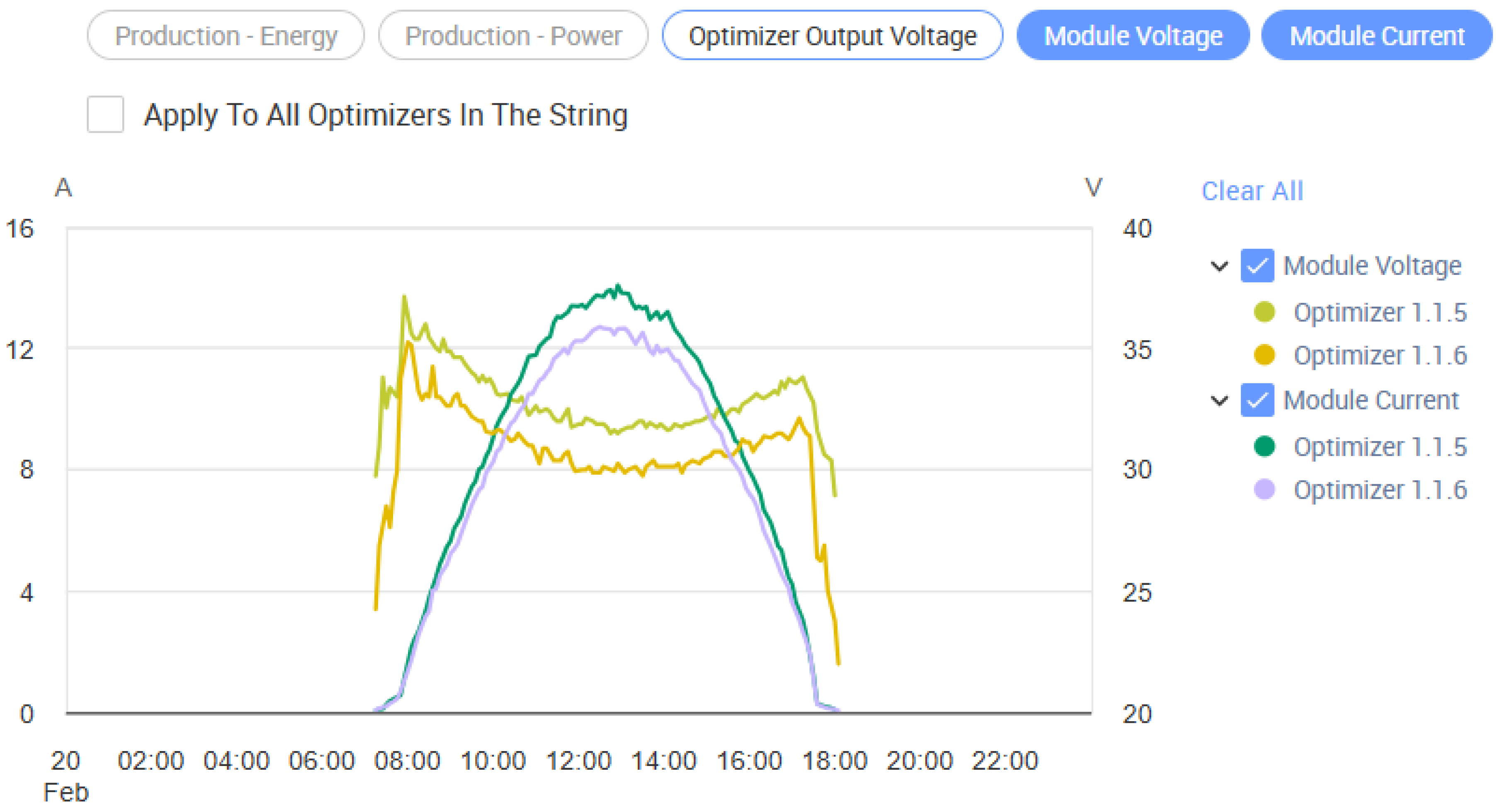

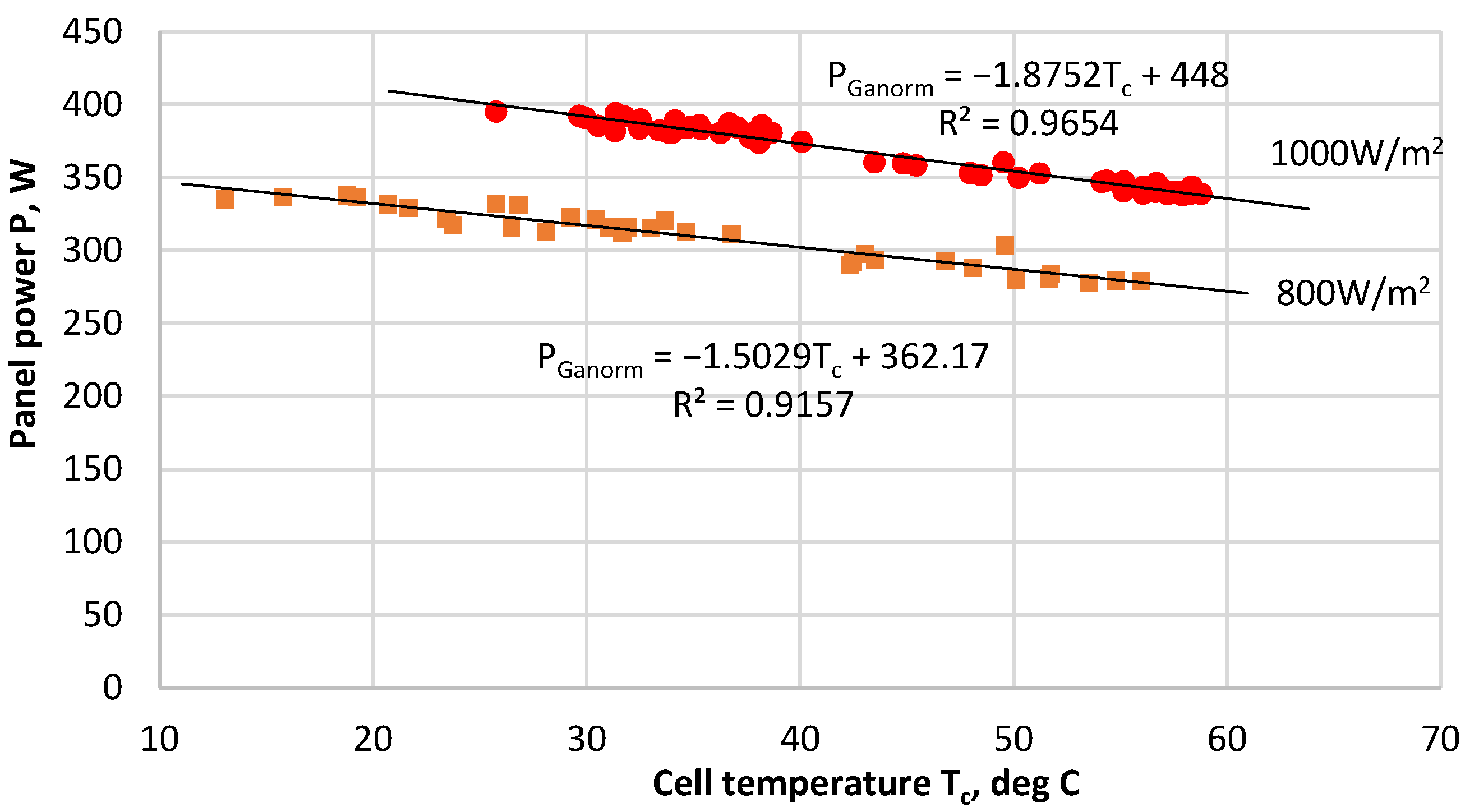

- For solar irradiance Ganorm = 800 W/m2: n = −1.5029, k = 362.17;

- For solar irradiance Ganorm = 1000 W/m2: n = −1.8752, k = 448.

- Experimental data must be available for the front and rear sides of the bifacial panel separately, including generated PV power, irradiance on each side, and panel temperature.

- Appropriate days are selected from the data set, prioritizing those with significant variation in panel temperature and solar irradiance. Typically, these are days from summer and winter in Bulgaria.

- The data for PV power and solar irradiance are divided into two subsets: 500–800 W/m2 and 800–1100 W/m2 and PV power values are normalized to 800 and 1000 W/m2 using Equation (9).

- The normalized PV power values are plotted against solar irradiance and linear regression is applied to both subsets to obtain fitting equations.

- The temperature coefficient r is calculated using Equation (16).

- All measured PV power values are normalized to a reference temperature of 25 °C using the calculated temperature coefficient and Equation (17).

- Panel efficiency is calculated using Equation (18).

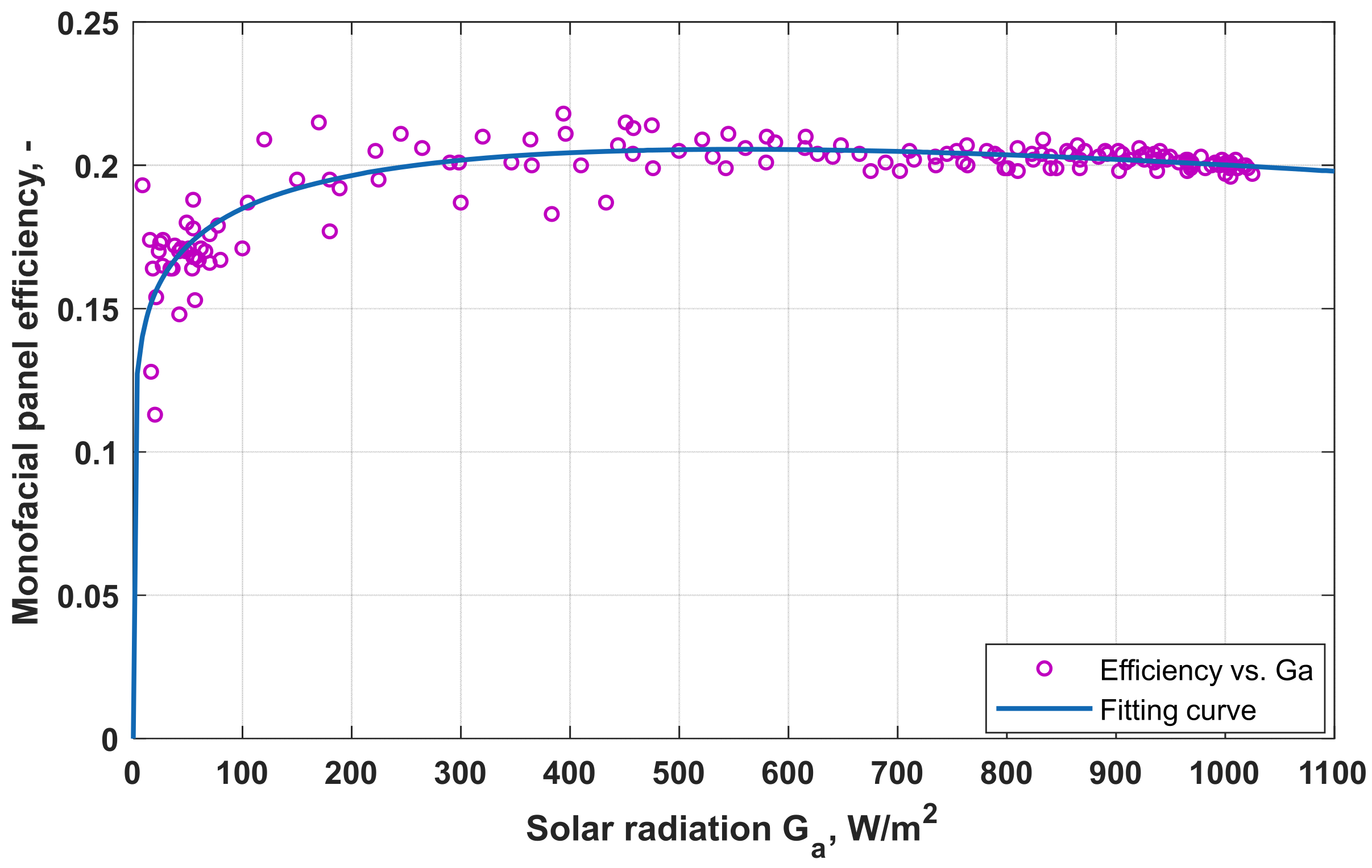

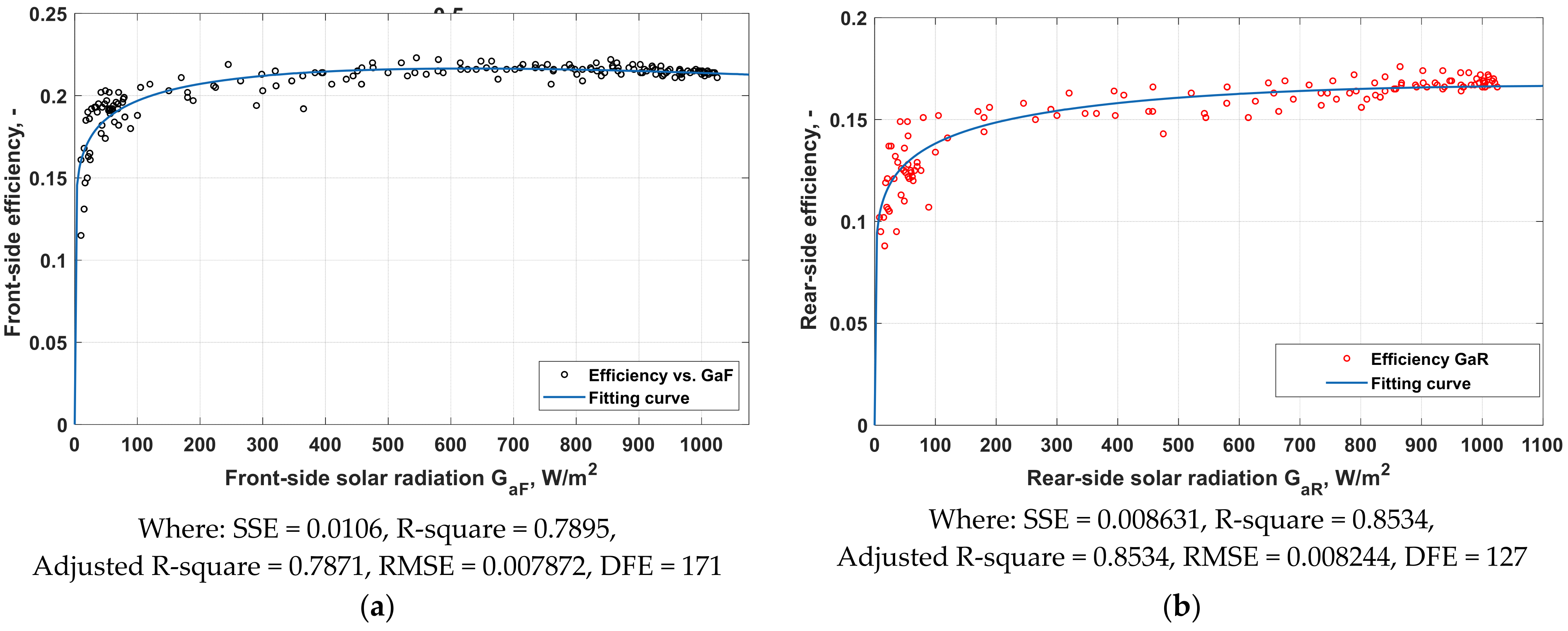

- Efficiency values are plotted against solar irradiance, and the data are fitted using Equation (19) to determine the coefficients p, q, and m.

- This procedure is applied separately to the front and rear sides of the bifacial panel.

- The final expression for the total power generation of the bifacial panel is the sum of the front and rear contributions, as given by Equation (7).

3.5. Evaluation Parameters

4. Model Validation and Experimental Results

4.1. Behavior Experimental Evaluation of Mono- and Bifacial PV Panels and of Various Reflecting Surfaces

4.2. Experimental Methods and Model Validation

- the front side of the first bifacial panel with covered rear side (P5);

- the rear side of the second bifacial panel facing the sun (P7), with covered front side;

- and the monofacial panel, located between them (P6).

- the generated power is corrected against the standard temperature of 25 °C by the temperature coefficient r using Equation (16).

- the resulting values are aligned to the rated power of the panels Prat—410 W for the monofacial panel (P6) and 430 W for the bifacial panel (P5):

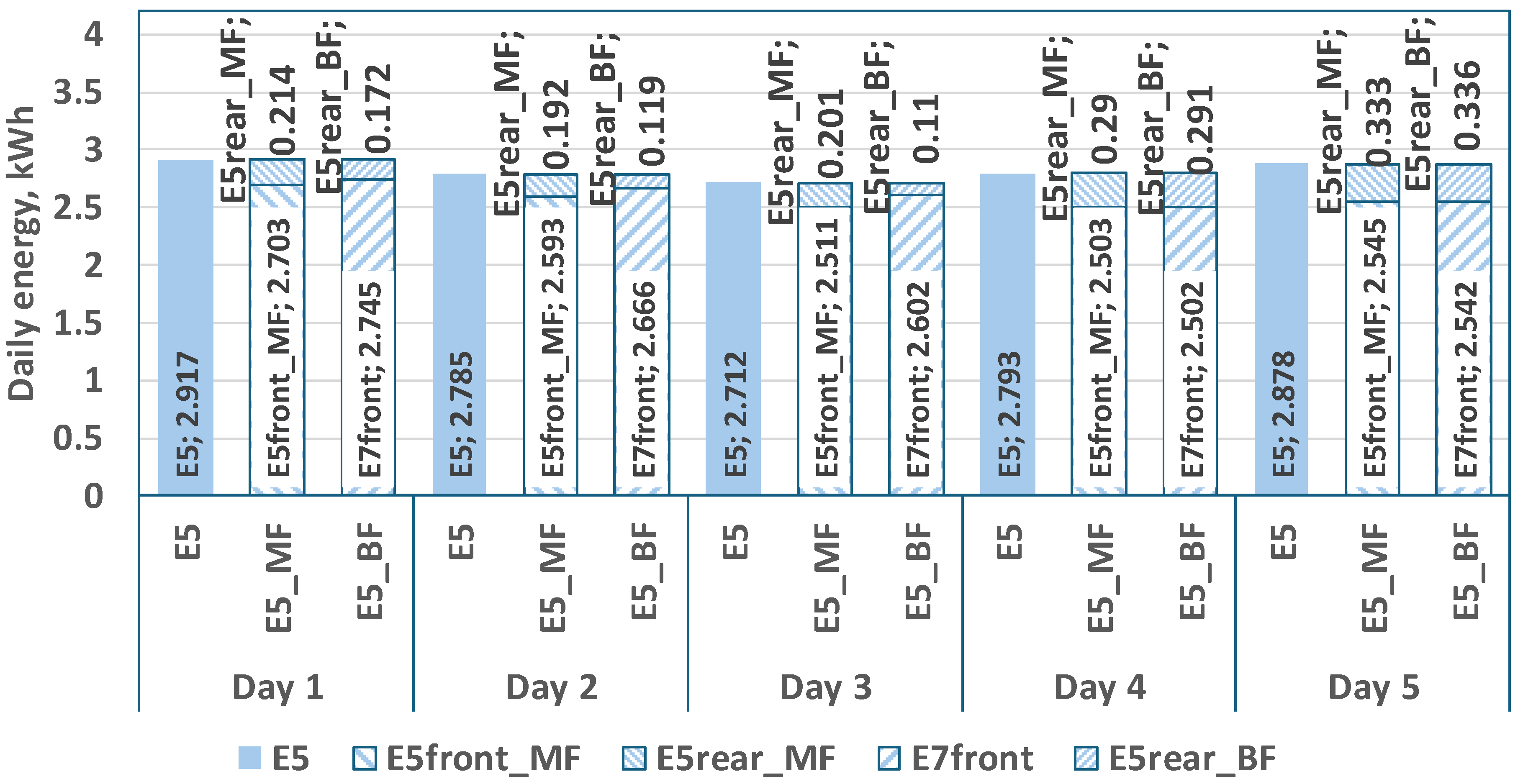

- Measured daily energy production of the bifacial panel (E5) operating under normal conditions with both sides illuminated.

- Separated daily energy using monofacial reference panel (E5_MF): The bar represents the sum of front-side energy derived from the monofacial panel (E5front_MF) calculated by (23) and rear-side energy (E5rear_MF), calculated as the difference between E5 and E5front_MF according to (22).

- Separated daily energy using bifacial panel with covered rear side (E5_BF): The same as the second method, but the front-side energy (E7front) is measured from the second bifacial panel with its rear side obscured.

5. Discussion

6. Conclusions

- The model is not subject to restrictions related to the position of the panels and is feasible provided that the solar irradiance in the plane of the front and rear sides of the panel is known.

- The proposed model demonstrates consistently good accuracy across a wide range of operating conditions, reflective surfaces, and seasons.

- The reflective surface type has a substantial impact on rear-side irradiance, with white non-woven geotextile and shiny aluminum foil providing the best results.

- Bifacial panels consistently outperform monofacial panels in energy yield, confirming their suitability for agricultural and hybrid energy systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

Abbreviations and Symbols

| AMkg/m3 | Air mass density |

| AM0, kg/m3 | Reference air mass |

| DFE | Degree of Freedom in the Error |

| E, Wh | Energy produced by the PV panel |

| E5, Wh | Daily energy production of the bifacial panel P5 |

| E5_BF, Wh | Separated daily energy using bifacial panel with covered rear side |

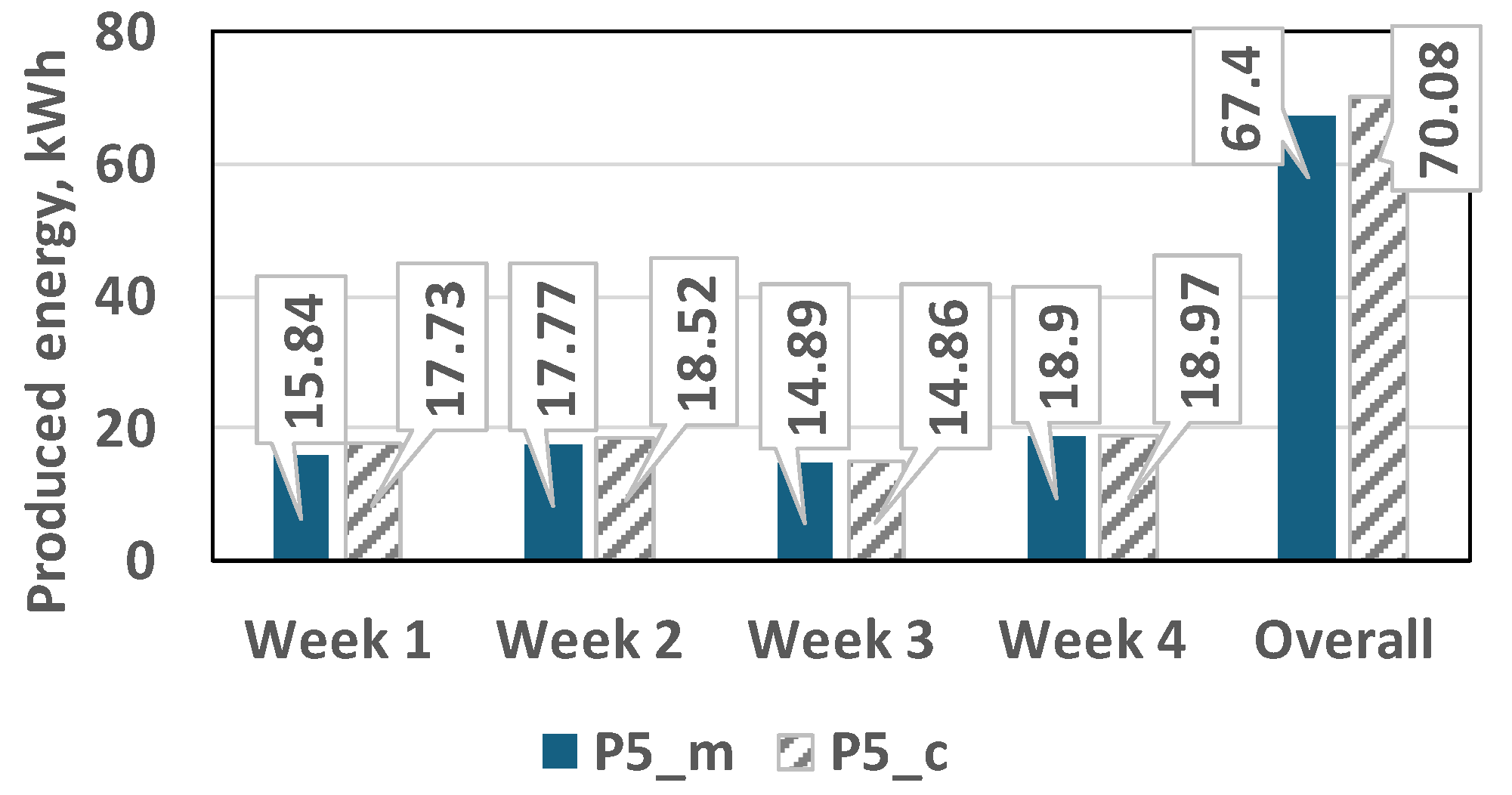

| E5_c, Wh | Calculated daily energy for the bifacial panel (P5) |

| E5_f_c, Wh | Calculated daily energy for the front side of the bifacial panel (P5) |

| E5_f_m, Wh | Measured daily energy for the front side of the bifacial panel (P5) |

| E5_m, Wh | Measured daily energy for the bifacial panel (P5) |

| E5_MF, Wh | Separated daily energy using monofacial reference panel |

| E5_r_c, Wh | Calculated daily energy for the rear side of the bifacial panel (P5) |

| E5_r_m, Wh | Measured daily energy for the rear side of the bifacial panel (P5) |

| E5front_MF, Wh | Front-side energy, derived from the monofacial panel |

| E5rear_MF, Wh | Rear-side energy |

| E6_c, Wh | Calculated daily energy for the monofacial panel (P6) |

| E6_m, Wh | Measured daily energy for the monofacial panel (P6) |

| E7front, Wh | Front-side energy, measured from the second bifacial panel with its rear side obscured |

| Ga, W/m2 | Solar irradiance in the panels’ plane |

| GaF, W/m2 | Solar irradiance on the front side of the panel |

| GAG | Green Artificial Grass |

| Gain b | Gain of the bifacial over the monofacial panel |

| Gain p | Gain of the externally placed bifacial panel P7 over the internally placed one P5 |

| GaR, W/m2 | Irradiance on the rear side of the panel |

| Garef, W/m2 | Reference solar irradiance |

| k | Intercept (power at 0 °C) at given solar irradiance value Ganorm |

| LCOE, $/kWh | Levelized Cost Of Energy |

| N | Number of intervals in the entire time period |

| n | Slope (change in power per °C) at given solar irradiance value Ganorm |

| Ne | Number of measured values |

| NOCT | Nominal Operating Cell Temperature |

| P, W | Electrical power generated by the PV panel |

| P(P6), W | Power of reference monofacial panel P6 |

| p, q, m, r, s, u | Empirical unitless coefficients specific to each PV panel type |

| PBF, W | Output power of the bifacial panel |

| pF, qF, mF, rF | Model unitless coefficients for the front side |

| Pfront, W | Power generated by the front side |

| PGa, W | Measured power of the panel at the actual irradiance Ga |

| PGanorm, W | Power the panel would produce at the solar irradiance Ganorm |

| Pj, W | Power during the j-th time interval |

| pR, qR, mR, rR | Model unitless coefficients for the rear side |

| Prat, W | Rated power of the panels |

| Prat(P5), W | rated power of the bifacial panel (P5) |

| Prat(P6), W | Rated power of the monofacial panel (P6) |

| Prear, W | Power generated by the rear side |

| PSM | Patinated Sheet Metal |

| PTcref, W | Panel power at the solar irradiance Ga and the reference cell temperature Tcref |

| PV | Photovoltaic |

| RMSE | Root Mean Square Error |

| RRMSE, % | Relative Root Mean Square Error |

| S, m2 | Panel surface area |

| SAF | Shiny aluminum foil |

| SSE | Sum of Squared Errors |

| STC | Standard Test Conditions |

| Tc, °C | Cell temperature |

| Tcref, °C | Reference cell temperature |

| ti, s, min, h, etc. | Time interval over which the energy is calculated |

| WNG | White Nonwoven Geotextile |

| , W or Wh | Mean value of the measured quantity |

| xi, W or Wh | Measured values of the compared quantities |

| yi, W or Wh | Calculated values of the compared quantities |

| Δt s, min or h etc. | Time step used for discretization |

| ηPV | Efficiency of a given photovoltaic panel |

| ηPVF | Efficiency of the front side |

| ηPVR | Efficiency of the rear side |

| ηPVTcref | Panel efficiency at the reference cell temperature Tcref |

References

- Food and Agriculture Organization of the United Nations. An issues note produced for the G20 Presidency of the Kingdom of Saudi Arabia. In Water and Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Tian, J.; Culley, S.A.; Maier, H.R.; Zecchin, A.C. Is renewable energy sustainable? Potential relationships between renewable energy production and the Sustainable Development Goals. NPJ Clim. Action 2024, 3, 35. [Google Scholar] [CrossRef]

- REN 21. Renewables 2024 Global Status Report: Global Overview, REN 21 Report. Available online: https://www.ren21.net/gsr-2024/ (accessed on 19 February 2025).

- Osama, A.; Tina, G.M.; Mannino, G.; Cucuzza, A.V.; Bizzarri, F. Experimental and Numerical Performance Assessment of East-West Bifacial Photovoltaic Floating System in Freshwater Basins. IEEE Access 2024, 12, 141425–141447. [Google Scholar] [CrossRef]

- NREL, Best Research—Cell Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 21 February 2025).

- IEA PVPS. Annual Report 2023. Available online: https://iea-pvps.org/wp-content/uploads/2024/05/PVPS_Annual_Report_2023_v4-6.pdf (accessed on 25 February 2025).

- Rokicki, T.; Perkowska, A.; Klepacki, B.; Bórawski, P.; Bełdycka-Bórawska, A.; Michalski, K. Changes in Energy Consumption in Agriculture in the EU Countries. Energies 2021, 14, 1570. [Google Scholar] [CrossRef]

- Trommsdorff, M.; Dhal, I.S.; Özdemir, Ö.E.; Ketzer, D.; Weinberger, N.; Rösch, C. Agrivoltaics: Solar Power Generation and Food Production. In Solar Energy Advancements in Agriculture and Food Production Systems; Gorjian, S., Campana, P.E., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 159–210. [Google Scholar] [CrossRef]

- Goetzberger, A.; Zastrow, A. On the Coexistence of Solar-Energy Conversion and Plant Cultivation. Int. J. Sol. Energy 1982, 1, 55–69. [Google Scholar] [CrossRef]

- Waller, R.; Kacira, M.; Magadley, E.; Teitel, M.; Yehia, I. Evaluating the Performance of Flexible, Semi-Transparent Large-Area Organic Photovoltaic Arrays Deployed on a Greenhouse. AgriEngineering 2022, 4, 969–992. [Google Scholar] [CrossRef]

- Höhendinger, M.; Krieg, H.-J.; Dietrich, R.; Rauscher, S.; Hartung, C.; Stumpenhausen, J.; Bernhardt, H. Requirements and Economic Implications of Integrating a PV-Plant-Based Energy System in the Dairy Production Process. AgriEngineering 2023, 5, 2196–2215. [Google Scholar] [CrossRef]

- Neto, A.J.S.; Lopez, D.C.; Nascimento, S.T. Potential of Grid-Connected Photovoltaic Systems in Brazilian Dairy Farms. AgriEngineering 2022, 4, 122–133. [Google Scholar] [CrossRef]

- Ndukwu, M.C.; Usoh, G.; Akpan, A.; Akuwueke, L.; Ecop, I. Development of a Small Dual-Chamber Solar PV-Powered Evaporative Cooling System for Fruit and Vegetable Cooling with Techno-Economic Assessment. AgriEngineering 2024, 6, 2553–2576. [Google Scholar] [CrossRef]

- Gomez-Soto, D. Integration of Crops, Livestock, and Solar Panels: A Review of Agrovoltaic Systems. Agronomy 2024, 14, 1824. [Google Scholar] [CrossRef]

- Anusuya, K.; Vijayakumar, K.; Leenus, J.M.; Manikandan, S. Agrophotovoltaics: Enhancing Solar Land Use Efficiency for Energy-Food-Water Nexus. Renew. Energy Focus 2024, 50, 100600. [Google Scholar] [CrossRef]

- Sasaya, S.; Liangling, Y.; Hoshino, Y.; Noguchi, T. Development of an Automatic Harvester for Wine Grapes by Using Three-Axis Linear Motion Mechanism Robot. AgriEngineering 2024, 6, 4203–4219. [Google Scholar] [CrossRef]

- Bastos, K.M.; Barcelos, J.P.; Orioli, G.F.; Nascimento, S.T. Use of Drones for Trough Reading, Animal Counting, and Production Monitoring in Feedlot Systems. AgriEngineering 2024, 6, 4460–4475. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Longo, S.; Miccichè, G.; Cellura, M.; Ferraro, M. A Critical Review of the Environmental Performance of Bifacial Photovoltaic Panels. Energies 2024, 17, 226. [Google Scholar] [CrossRef]

- Jamil, U.; Bonnington, A.; Pearce, J.M. The Agrivoltaic Potential of Canada. Sustainability 2023, 15, 3228. [Google Scholar] [CrossRef]

- IEA PVPS. Best Practices for the Optimization of Bifacial Photovoltaic Tracking Systems. Available online: https://iea-pvps.org/key-topics/best-practices-for-the-optimization-of-bifacial-photovoltaic-tracking-systems/ (accessed on 7 March 2025).

- Braga, D.S.; Kazmerski, L.L.; Cassini, D.A.; Camatta, V.; Diniz, A.S.A.C. Performance of Bifacial PV Modules under Different Operating Conditions in the State of Minas Gerais, Brazil. Renewable. Energy Environ. Sustain. 2023, 8, 23. [Google Scholar] [CrossRef]

- VDMA. International Technology Roadmap for Photovoltaic (ITRPV). Available online: https://www.vdma.org/international-technology-roadmap-photovoltaic (accessed on 6 March 2025).

- Kopecek, R.; Libal, J. Bifacial Photovoltaics 2021: Status, Opportunities and Challenges. Energies 2021, 14, 2076. [Google Scholar] [CrossRef]

- Mouhib, E.; Micheli, L.; Almonacid, F.M.; Fernández, E.F. Overview of the Fundamentals and Applications of Bifacial Photovoltaic Technology: Agrivoltaics and Aquavoltaics. Energies 2022, 15, 8777. [Google Scholar] [CrossRef]

- Patel, M.T.; Khan, M.R.; Sun, X.; Alam, M.A. A Worldwide Cost-Based Design and Optimization of Tilted Bifacial Solar Farms. Appl. Energy 2019, 247, 467–479. [Google Scholar] [CrossRef]

- Riaz, M.H.; Imran, H.; Butt, N.Z. Optimization of PV Array Density for Fixed Tilt Bifacial Solar Panels for Efficient Agrivoltaic Systems. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; pp. 1349–1352. [Google Scholar] [CrossRef]

- Cha, H.L.; Bhang, B.G.; Park, S.Y.; Choi, J.H.; Ahn, H.K. Power Prediction of Bifacial Si PV Module with Different Reflection Conditions on Rooftop. Appl. Sci. 2018, 8, 1752. [Google Scholar] [CrossRef]

- Asgharzadeh, A.; Deline, C.; Stein, J.; Toor, F. A Comparison Study of the Performance of South/North-Facing vs East/West-Facing Bifacial Modules under Shading Condition. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 1730–1734. [Google Scholar] [CrossRef]

- Asgharzadeh, A.; Marion, B.; Deline, C.; Hansen, C.; Stein, J.S.; Toor, F. A Sensitivity Study of the Impact of Installation Parameters and System Configuration on the Performance of Bifacial PV Arrays. IEEE J. Photovolt. 2018, 8, 798–805. [Google Scholar] [CrossRef]

- Mikofski, M.A.; Darawali, R.; Hamer, M.; Neubert, A.; Newmiller, J. Bifacial Performance Modeling in Large Arrays. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1282–1287. [Google Scholar] [CrossRef]

- Evans, D.L. Simplified Method for Predicting Photovoltaic Array Output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Abe, C.F.; Notton, G.; Faggianelli, G.-A.; Dias, J.B.; Wander, P.R. Adapting the Durisch Model for Bifacial Silicon and High Concentration Multijunction Photovoltaic Modules Efficiency Prediction. Renew. Energy 2025, 238, 122034. [Google Scholar] [CrossRef]

- Durisch, W.; Bitnar, B.; Mayor, J.C.; Kiess, H.; Lam, K.H.; Close, V. Efficiency model for photovoltaic modules and demonstration of its application to energy yield estimation. Sol. Energy Mater. Sol. Cells 2007, 91, 79–84. [Google Scholar] [CrossRef]

- Mannino, G.; Tina, G.M.; Jiménez-Castillo, G.; Cacciato, M.; Bizzarri, F.; Canino, A. Nonlinear and Multivariate Regression Models of Current and Voltage at Maximum Power Point of Bifacial Photovoltaic Strings. Sol. Energy 2024, 269, 112357. [Google Scholar] [CrossRef]

- Bouchakour, S.; Valencia-Caballero, D.; Luna, A.; Roman, E.; Boudjelthia, E.A.K.; Rodríguez, P. Modelling and Simulation of Bifacial PV Production Using Monofacial Electrical Models. Energies 2021, 14, 4224. [Google Scholar] [CrossRef]

- Ahmed, E.M.; Aly, M.; Mostafa, M.; Rezk, H.; Alnuman, H.; Alhosaini, W. An Accurate Model for Bifacial Photovoltaic Panels. Sustainability 2023, 15, 509. [Google Scholar] [CrossRef]

- Yakubu, R.O.; Ankoh, M.T.; Mensah, L.D.; Quansah, D.A.; Adaramola, M.S. Predicting the Potential Energy Yield of Bifacial Solar PV Systems in Low-Latitude Region. Energies 2022, 15, 8510. [Google Scholar] [CrossRef]

- Deotti, L.; Silva Júnior, I.; Honório, L.; Marcato, A. Empirical Models Applied to Distributed Energy Resources—An Analysis in the Light of Regulatory Aspects. Energies 2021, 14, 326. [Google Scholar] [CrossRef]

- Li, C.; Zhang, W.; Liu, F.; Li, X.; Wang, J.; Li, C. Multi-Objective Optimization of Bifacial Photovoltaic Sunshade: Towards Better Optical, Electrical and Economical Performance. Sustainability 2024, 16, 5977. [Google Scholar] [CrossRef]

- Ayadi, O.; Rinchi, B.; Al-Dahidi, S.; Abdalla, M.E.B.; Al-Mahmodi, M. Techno-Economic Assessment of Bifacial Photovoltaic Systems under Desert Climatic Conditions. Sustainability 2024, 16, 6982. [Google Scholar] [CrossRef]

- Jakobsen, M.L.; Thorsteinsson, S.; Behrensdorff Poulsen, P.; Rødder, P.M.; Rødder, K. Vertical Reflector for Bifacial PV-Panels. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 2678–2681. [Google Scholar] [CrossRef]

- Cosgun, A.E.; Demir, H. Investigating the Effect of Albedo in Simulation-Based Floating Photovoltaic System: 1 MW Bifacial Floating Photovoltaic System Design. Energies 2024, 17, 959. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, H.; Liu, H. The Influence of the Installation Condition and Performance of Bifacial Solar Modules on Energy Yield. Energies 2023, 16, 7396. [Google Scholar] [CrossRef]

- Lee, S.-M.; Lee, E.-C.; Lee, J.-H.; Yu, S.-H.; Heo, J.-S.; Lee, W.-Y.; Kim, B.-S. Analysis of the Output Characteristics of a Vertical Photovoltaic System Based on Operational Data: A Case Study in Republic of Korea. Energies 2023, 16, 6971. [Google Scholar] [CrossRef]

- Santos de Araújo, J.V.; de Lucena, M.P.; da Silva Netto, A.V.; Gomes, F.d.S.V.; Oliveira, K.C.d.; de Souza Neto, J.M.R.; Cavalcante, S.L.; Morales, L.R.V.; Villanueva, J.M.M.; Macedo, E.C.T.d. Solar Tracking Control Algorithm Based on Artificial Intelligence Applied to Large-Scale Bifacial Photovoltaic Power Plants. Sensors 2024, 24, 3890. [Google Scholar] [CrossRef] [PubMed]

- Riedel-Lyngskær, N.; Berrian, D.; Alvarez Mira, D.; Aguilar Protti, A.; Poulsen, P.B.; Libal, J.; Vedde, J. Validation of Bifacial Photovoltaic Simulation Software against Monitoring Data from Large-Scale Single-Axis Trackers and Fixed Tilt Systems in Denmark. Appl. Sci. 2020, 10, 8487. [Google Scholar] [CrossRef]

- Zdyb, A.; Sobczyński, D. An Assessment of a Photovoltaic System’s Performance Based on the Measurements of Electric Parameters under Changing External Conditions. Energies 2024, 17, 2197. [Google Scholar] [CrossRef]

- Pike, C.; Whitney, E.; Wilber, M.; Stein, J.S. Field Performance of South-Facing and East-West Facing Bifacial Modules in the Arctic. Energies 2021, 14, 1210. [Google Scholar] [CrossRef]

- Cho, J.; Park, S.M.; Park, A.R.; Lee, O.C.; Nam, G.; Ra, I.-H. Application of Photovoltaic Systems for Agriculture: A Study on the Relationship between Power Generation and Farming for the Improvement of Photovoltaic Applications in Agriculture. Energies 2020, 13, 4815. [Google Scholar] [CrossRef]

- Jang, J.; Lee, K. Practical Performance Analysis of a Bifacial PV Module and System. Energies 2020, 13, 4389. [Google Scholar] [CrossRef]

- Park, H.; Chang, S.; Park, S.; Kim, W.K. Outdoor Performance Test of Bifacial n-Type Silicon Photovoltaic Modules. Sustainability 2019, 11, 6234. [Google Scholar] [CrossRef]

- Mahmood, K.; Hussain, A.; Arslan, M.; Tariq, B. Experimental Investigation of Impact of Cool Roof Coating on Bifacial and Monofacial Photovoltaic Modules. Eng. Proc. 2023, 45, 38. [Google Scholar] [CrossRef]

- González-Moreno, A.; Mazzeo, D.; Dolara, A.; Ogliari, E.; Leva, S. Outdoor Performance Comparison of Bifacial and Monofacial Photovoltaic Modules in Temperate Climate and Industrial-like Rooftops. Appl. Sci. 2024, 14, 5714. [Google Scholar] [CrossRef]

- Bowersox, D.; TamizhMani, G. Design and Construction of Controlled Back Reflectors for Bifacial Photovoltaic Modules. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 1735–1740. [Google Scholar] [CrossRef]

- Carbone, R.; Borrello, C. A Building-Integrated Bifacial and Transparent PV Generator Operated by an “Under-Glass” Single Axis Solar Tracker. Energies 2023, 16, 6350. [Google Scholar] [CrossRef]

- Cabral, D.; Hayati, A.; Gomes, J.; Gorouh, H.A.; Nasseriyan, P.; Salmanzadeh, M. Experimental Electrical Assessment Evaluation of a Vertical n-PERT Half-Size Bifacial Solar Cell String Receiver on a Parabolic Trough Solar Collector. Energies 2023, 16, 2007. [Google Scholar] [CrossRef]

- Abdallah, A.A.; Kivambe, M.; Aïssa, B.; Figgis, B.W. Performance of Monofacial and Bifacial Silicon Heterojunction Modules under Desert Conditions and the Impact of PV Soiling. Sustainability 2023, 15, 8436. [Google Scholar] [CrossRef]

- Bhaduri, S.; Kottantharayil, A. Mitigation of Soiling by Vertical Mounting of Bifacial Modules. IEEE J. Photovolt. 2019, 9, 240–244. [Google Scholar] [CrossRef]

- Kim, S.M.; Jung, S.H.; Choi, R.-W.; Kim, Y.B.; Kang, M.G.; Sonp, H.-E.; Choi, G.-S. A Study of Performance Characterization with Rear Light Source in Conventional Bifacial Solar Cells. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 2723–2727. [Google Scholar] [CrossRef]

- Newman, B.K.; Carr, A.J.; Jansen, M.J.; Goma, E.G.; Kloos, M.J.H.; de Groot, K.M.; van Aken, B.B. Comparison of Bifacial Module Measurement Methods with Optically Optimized Bifacial Modules. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 3593–3597. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, F.; Xu, C.; Yue, X.; Yang, S. Applying Artificial Cover to Reduce Melting in Dagu Glacier in the Eastern Qinghai-Tibetan Plateau. Remote Sens. 2023, 15, 1755. [Google Scholar] [CrossRef]

- The Engineering ToolBox. Materials—Light Reflecting Factors. Available online: https://www.engineeringtoolbox.com/light-material-reflecting-factor-d_1842.html (accessed on 11 August 2025).

- Kaarsberg, T.; Akbari, H. Cool Roofs Cool the Planet; Home Energy Magazine: Berkeley, CA, USA, 2006; pp. 38–41. Available online: https://eta-publications.lbl.gov/sites/default/files/HomeEnergy06%20(Cool%20Roofs%20Cool%20the%20Planet).pdf (accessed on 11 August 2025).

- Yaghoobian, N.; Kleissl, J.; Krayenhoff, E.S. Modeling the Thermal Effects of Artificial Turf on the Urban Environment. J. Appl. Meteorol. Climatol. 2010, 49, 332–345. [Google Scholar] [CrossRef]

- Zarkov, Z.; Stoyanov, L.; Kanchev, H.; Milenov, V.; Lazarov, V. Study of Photovoltaic Systems’ Performances with Different Module Types. Mater. Sci. Forum 2016, 856, 279–284. [Google Scholar] [CrossRef]

- IEC 61215-1:2021; Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval—Part 1: Test Requirements. IEC: Geneva, Switzerland, 2021.

- Seo, Y.; Park, H.; Yoo, Y.; Kim, M.; Oh, S.-Y.; Alhammadi, S.; Chang, S.; Park, S.-H.; Lee, J.; Mun, S.; et al. Effect of Front Irradiance and Albedo on Bifacial Gain in 1 8kW Bifacial Silicon Photovoltaic System. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1298–1301. [Google Scholar] [CrossRef]

| Parameter | Monofacial OPTONICA FV410-A1 | Bifacial SUNRISE SR-54M430NHLPro |

|---|---|---|

| Maximum power, W | 410 | 430 |

| Open circuit voltage, V | 37.30 | 38.58 |

| Short circuit current, A | 13.93 | 14.25 |

| Maximum power voltage, V | 31.40 | 31.88 |

| Maximum power current, A | 13.06 | 13.49 |

| Number of cells | 108 | 108 |

| Module efficiency (front side), % | 21.00 | 22.03 |

| Reflective Surface | Albedo | Reference |

|---|---|---|

| WNG | 0.39–0.71 | [61] |

| SAF | 0.55–0.75 | [62] |

| PSM | 0.15–0.25 | [63] |

| GAG | 0.1–0.25 | [64] |

| Coefficient r | At 1000 W/m2 | At 800 W/m2 | Average |

|---|---|---|---|

| Monofacial panel r | −0.00467 | −0.00463 | −0.00465 |

| Front side rF | −0.00341 | −0.00365 | −0.00353 |

| Rear side rB | −0.00312 | −0.00294 | −0.00303 |

| Monofacial panel | r = −0.00465 | p = 0.2514 | q = −0.2040 | m = 0.1216 |

|---|---|---|---|---|

| Front side of BF panel | rF = −0.00353 | pF = 0.2507 | qF = −0.1471 | mF = 0.0969 |

| Rear side of BF panel | rR = −0.00303 | pR = 0.1847 | qR = −0.1003 | mR = 0.1201 |

| Shiny Aluminum Foil | White Nonwoven Geotextile | |||||||

|---|---|---|---|---|---|---|---|---|

| Panel | Summer | Autumn | Winter | Spring | Summer | Autumn | Winter | Spring |

| Error P6, % | 3.15 | −0.74 | −4.75 | −0.96 | 1.97 | 0.00 | −4.68 | 0.38 |

| RRMSE P6, % | 8.43 | 3.39 | 5.93 | 3.42 | 5.15 | 3.66 | 5.73 | 3.64 |

| Error P5, % | 3.86 | −1.71 | −7.08 | −1.22 | 3.30 | 2.24 | −3.36 | 0.94 |

| RRMSE P5, % | 8.70 | 3.51 | 7.81 | 3.54 | 5.39 | 5.12 | 5.35 | 5.11 |

| Green Artificial Grass | Patinated Sheet Metal | |||||||

| Error P6, % | 4.17 | −0.51 | 3.65 | −0.86 | 1.67 | −1.47 | 5.31 | −1.77 |

| RRMSE P6, % | 8.46 | 3.49 | 9.48 | 3.52 | 5.41 | 3.18 | 9.07 | 3.19 |

| Error P5, % | 0.47 | −5.41 | −1.26 | −5.93 | −1.36 | −5.24 | 1.15 | −5.18 |

| RRMSE P5, % | 5.38 | 6.09 | 11.38 | 6.13 | 3.36 | 5.93 | 6.48 | 5.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoyanov, L.; Bachev, I.; Milenov, V.; Zarkov, Z.; Lazarov, V. Productivity Modeling and Analysis of Mono- and Bifacial PV Panels Under Different Weather Conditions and Reflection Surfaces for Application in the Agriculture Sector. AgriEngineering 2025, 7, 319. https://doi.org/10.3390/agriengineering7100319

Stoyanov L, Bachev I, Milenov V, Zarkov Z, Lazarov V. Productivity Modeling and Analysis of Mono- and Bifacial PV Panels Under Different Weather Conditions and Reflection Surfaces for Application in the Agriculture Sector. AgriEngineering. 2025; 7(10):319. https://doi.org/10.3390/agriengineering7100319

Chicago/Turabian StyleStoyanov, Ludmil, Ivan Bachev, Valentin Milenov, Zahari Zarkov, and Vladimir Lazarov. 2025. "Productivity Modeling and Analysis of Mono- and Bifacial PV Panels Under Different Weather Conditions and Reflection Surfaces for Application in the Agriculture Sector" AgriEngineering 7, no. 10: 319. https://doi.org/10.3390/agriengineering7100319

APA StyleStoyanov, L., Bachev, I., Milenov, V., Zarkov, Z., & Lazarov, V. (2025). Productivity Modeling and Analysis of Mono- and Bifacial PV Panels Under Different Weather Conditions and Reflection Surfaces for Application in the Agriculture Sector. AgriEngineering, 7(10), 319. https://doi.org/10.3390/agriengineering7100319