Abstract

The Green Revolution led to an increased use of synthetic pesticides, causing environmental pollution. As an alternative, biopesticides made from entomopathogenic agents such as fungi have been sought. This study aimed to design and evaluate the performance of a harvester machine for efficiently collecting entomopathogenic spores of Metarhizium anisopliae and Beauveria bassiana grown on rice and corn substrates. The spore yield was estimated, and a spore count and a colony-forming unit (CFU) count were performed. Statistical analysis was conducted to compare the mean values of spores obtained from different combinations of solid substrate and fungi. The Corn-Metarhizium combination produced 34.15 g of spores per kg of substrate and 1.51 × 109 CFUs mL−1. Similarly, the Rice-Metarhizium combination produced 57.35 g per kg and 1.59 × 109 CFUs mL−1. Meanwhile, the Corn-Beauveria combination yielded 35.47 g per kg and 1.00 × 109 CFUs mL−1, while the Rice-Beauveria combination had a yield of 38.26 g per kg and 4.50 × 108 CFUs mL−1. Based on the reported results, the Rice-Metarhizium combination appears to be the most effective, yielding the highest number of harvested spores per kg of substrate. The study estimated a total cost of approximately $409.31 for manufacturing the harvester, considering only the cost of the materials. These results could potentially increase the availability and affordability of entomopathogenic fungi in integrated pest management.

1. Introduction

The Green Revolution significantly increased the use of synthetic pesticides, which, while causing an increase in agricultural production, also led to indiscriminate pollution in the air, soil, and water [1,2]. Due to this problem, alternative methods for controlling agricultural pests have been sought. Among them are biopesticides, which are made from entomopathogenic agents such as fungi, bacteria, or nematodes [3,4,5]. It is documented that their use reduces the use of chemical pesticides by 75% and increases production by 40% [6,7].

Entomopathogenic fungi are important biological control agents in integrated pest management programs. They are natural enemies of insects and can infect a wide range of pest species. They have several advantages over chemical insecticides, including high specificity, low toxicity to non-target organisms, and minimal environmental impact [8,9]. Additionally, they have the ability to persist in the environment, providing ongoing control of pests. They are also versatile in their application, as they can be used in various forms such as sprays, baits, and dust. Furthermore, they have the potential to be used in combination with other biocontrol agents, such as parasitoids and predators, to enhance their efficacy [10,11,12].

One of the key factors for their success in controlling insect pests is the ability to produce and harvest large quantities of conidia, the asexual spores that are responsible for infecting insects [13,14]. To achieve this, various techniques have been developed, including mechanical methods such as shaking, vortexing, and sieving. These techniques have shown promise in improving conidia yield and maintaining their viability [15,16]. The development of effective conidia harvesters is critical for the commercial production and application of entomopathogenic fungi. In the case of fungi, it is necessary to first produce the spores by inoculating the fungus in a solid substrate. Rice and corn are among the most commonly used substrates for their reproduction [17,18].

Conidia are the primary means of fungal propagation and their production is critical for the commercialization of fungal biopesticides [19]. However, there are challenges associated with the process. One of the main challenges is the fragile nature of the conidia, which can be easily damaged during harvesting. This can result in reduced efficacy of the fungi as biological control agents. Additionally, the high variability in conidia size and shape makes it difficult to optimize harvesting techniques for different fungal species. Furthermore, efficient and gentle harvesting techniques can increase the yield and quality of conidia, resulting in more effective pest control. In recent years, new technologies such as microfluidics and electrostatic methods have shown promise in improving conidia harvesting efficiency while minimizing damage to the spores [20,21,22].

Metarhizium anisopliae and Beauveria bassiana are filamentous fungi that belong to the orders Hypocreales, family Clavicipitaceae, and Cordycipitaceae, respectively [23,24,25]. These fungi have a cosmopolitan distribution and have been found in a variety of habitats, including soil, plant debris, and insect cadavers. These fungi have typical filamentous fungal morphology, with septate hyphae and conidiophores that produce conidia. In Metarhizium, the conidia are typically unicellular, cylindrical, and truncated, formed in very long chains, hyaline to olive green, measuring 3.5 to 9.0µ in length × 1.5 to 3.5µ in diameter [26], and have globose to sub-globose conidiogenous cells (2–3 × 2.0–2.5 μm) with a very short neck. In Beauveria, the conidiogenous structures form large, crowded groups, and the conidia are hyaline to cottony white, smooth, globose to ellipsoidal, and have a zigzag-shaped rachis [27]. These fungi also produce resting structures known as sclerotia, which can help them survive in adverse environmental conditions. The colony morphology of these fungi can vary depending on the growth conditions [28,29].

Metarhizium anisopliae and B. bassiana are two species of entomopathogenic fungi that have been extensively studied for their use in the biological control of insect pests. Both species are naturally occurring and have been found to infect a wide range of insect pests, making them versatile in their application. In addition to their broad host range, these fungi are also known for their high virulence and ability to persist in the environment. They have been shown to provide long-term control of insect populations, making them effective alternatives to chemical insecticides [30,31,32].

Designing a new harvester for entomopathogenic fungal conidia can involve significant costs, both in terms of time and resources. However, the potential benefits of a more efficient harvester that can increase conidia yield and reduce labor costs may outweigh the initial costs of design and implementation. It is important to consider the costs of designing a new harvester with reference to harvesters that may already be available on the market. Comparing the costs and benefits of different harvesters can help determine the feasibility of investing in a new design.

Our work is a contribution to the field of biopesticide production. While there are many studies that have investigated the use of entomopathogenic fungi for biopesticide development, this paper specifically focuses on the development and assessment of a spore harvester for these fungi. The paper presents an evaluation of the functional and quality aspects of the spore harvester, which is critical for the efficient and cost-effective production of biopesticides. This research is significant because it provides a novel and practical solution to a key challenge in the production of biopesticides, which has the potential to improve the sustainability and safety of agricultural practices.

This study aimed to create a machine that could harvest spores from entomopathogenic fungi. We evaluated the machine’s performance by measuring the number of spores it produced with different fungi and substrates (rice and broken corn), assessed the spores’ viability by counting colony-forming units (CFU), and estimated the cost of manufacture.

2. Materials and Methods

The design of the harvester was carried out in the Technological Development Workshop of the Interdisciplinary Research Center for Regional Integral Development, Oaxaca Unit National Polytechnic Institute (IPN-CIIDIR-Oaxaca) located in Santa Cruz Xoxocotlán, Oaxaca, Mexico.

2.1. Spore Harvester Design

The Haik and Shain [33] design methodology was employed in the development of the spore harvester. This approach involves identifying the main and secondary functions of the product, proposing alternatives to fulfill each function, generating design concepts, evaluating the concepts, and ultimately developing a detailed design. The design process was iterative, where each construction step was evaluated to ensure that the machine prototype was constructed with the desired characteristics.

In this study, we designed and constructed a spore harvester machine to collect harvested spores. The machine consisted of a rotary sieve with a general deposit, which operated within a hermetic stainless steel separation chamber with low-density polymer seals and a gate to feed the inoculated substrates. All machine components, except the structure and bearings, were made of stainless steel to prevent spore contamination. We calculated that a cylinder with a diameter of 0.25 m and a length of 0.6 m could hold up to 5 kg of rice or corn. The rotary sieve cylinder was designed to rotate at 30 rpm to optimize sieving efficiency while minimizing adherence between the meshes and the processed material. To ensure the machine’s versatility, we designed it to be fully detachable, with a screw-on structure to support the separation chamber, rotary sieve bearings, shaft, rotary sieve, and deposit.

The selection of suitable sieve mesh sizes for entomopathogenic fungus spores was based on their size. The dimensions of the solid culture medium were also considered in the mesh selection process. To determine appropriate mesh sizes, we consulted the literature of Jaronski and Jackson [34], which recommended the use of ASTM-20 meshes for harvesting spores from M. anisopliae and B. bassiana fungi. However, they reported that the harvested product was a mixture of spores and substrate particles. To minimize the passage of substrate particles during sieving meshes different mesh opening sizes were chosen: ASTM-20 (0.841 mm), ASTM-30 (0.595 mm), and ASTM-40 (0.420 mm). The selected meshes were made of AISI 304 stainless steel for durability and corrosion resistance.

2.2. Geometry, Material, and Power

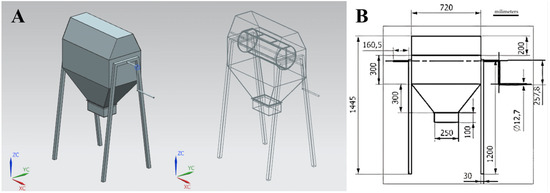

The machine is composed of several parts, including a machine structure made of a 31.75 mm gauge 18 square tubular profile, a separation chamber made of gauge 22 stainless steel sheet, a separation chamber lid also made of gauge 22 stainless steel sheet, a sieve structure made of 19.05 × 3.17 mm stainless steel flat bar, and a sieve nipple made of stainless steel round tube with an inner diameter of 15.87 mm (Figure 1).

Figure 1.

3D model (A) and geometric design (B) of the entomopathogenic fungi spore harvester.

The power required to operate a rotary machine was determined using the equation P = ((2πnT)/60) W [35,36], where n represents the revolutions per minute (rpm) and T represents the torque in Nm, where T = Fd (Nm), and F is the force in N and d is the lever arm in meters. The forces acting on the cylinder include 45.05 N from the 5 kg weight of the sieve and 49.05 N from the weight of the 5 kg of rice, resulting in a required power of 39.11 W. As the power required to operate the machine is low, it was calculated that a person can manually apply a torque of 12.45 Nm and rotate the cylinder at 30 rpm.

2.3. Fungal Isolate and Culture Conditions

The Metarhizium and Beauveria fungus isolates used in this study were obtained from a previously isolated culture collection from the Biological Control Laboratory of CIIDIR Oaxaca, which was isolated from the black weevil of the agave Scyphophorus acupunctatus (=interstitialis) (Coleoptera: Curculionidae) of the region. The isolates were maintained on potato dextrose agar (PDA) slants at 4 °C until use. The PDA media was prepared according to the manufacturer’s instructions, sterilized by autoclaving at 121 °C for 15 min, and allowed to cool before use. The fungal isolate was activated by transferring a small piece of the mycelial mat to the center of a fresh PDA plate using a sterile inoculation loop. The plates were then incubated at 28 °C for 5–7 days until the mycelium had fully developed and covered the surface of the agar. The purity of the culture was confirmed by microscopic examination and subculturing [37].

To obtain spores, sterile distilled water was added to the surface of the PDA plates, and the surface was gently scraped with a sterile inoculation loop to collect the spores. The spore suspension was then filtered through sterile gauze to remove mycelial debris and to achieve a homogeneous suspension. The spore concentration was determined using a hemocytometer, and the suspension was adjusted to a concentration of 1 × 108 spores/mL with sterile distilled water [38]. The spore suspension was stored at 4 °C.

2.4. Inoculation and Incubation for Mass Production

This study utilized local rice (Soriana®, protein content about 0.025, Oaxaca, Mexico) and corn (bolita race from Oaxaca, protein content about 0.615) as substrates for fungal growth experiments. The physical characteristics of the rice were investigated, with an average length ranging from 5.90 to 7.30 mm, a width ranging from 1.60 to 1.90 mm, a thickness ranging from 1.20 to 1.60 mm, and an approximate density ranging from 795 to 897 kg m−3 [39]. Before breaking, the corn had an approximate density ranging from 1204.30 to 1228.79 kg m−3 and an average length, width, and thickness of 11 mm, 7 mm, and 3 mm, respectively [40]. Following a 2 h soaking in water and subsequent draining, 200 g of each substrate was added to five plastic bags, which were sealed and fitted with a cotton and gauze plug in one of the corners.

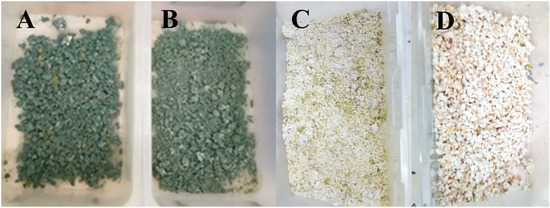

Under aseptic conditions, the spores from a petri dish that had reached full sporulation (≈7–14 days) were dislodged using a sterile loop and dispersed in 10 mL of 0.01% Tween-20 [41]. The mixture was vortexed at a speed of 1500 rpm for 1 min. This spore suspension was utilized as the inoculum. Viable spores within the suspension were quantified through a plate count method after undergoing serial dilution [42], with results showing a concentration of 1 × 108 spores/mL. A sterile syringe was used to add 10 mL of the solution to each bag in a laminar flow hood, and the bags were then stirred to ensure uniform distribution of the solution. For 15 days, the contents of the bags were stirred every two days to prevent substrate clumping and encourage fungal growth. After 15 days, the bags were emptied into trays and left for a week to reduce substrate moisture and allow for spore extraction using a harvester. Corn inoculated with B. bassiana was dried at 30 °C for 3 days due to environmental humidity and temperature variability [43,44] (Figure 2).

Figure 2.

Drying of broken corn (A), rice (B) that are inoculated with Metarhizium anisopliae, and rice (C) and broken corn (D) that are inoculated with Beauveria bassiana.

2.5. Harvester Performance and Spore Counting

To eliminate any possible contamination from the manufacturing process the equipment underwent a cleaning procedure involving water and 96% (v/v) ethyl alcohol. Afterward, the spore yield for each kilogram of the processed substrate was estimated. Subsequently, the contents of the bags containing rice and corn, respectively, and inoculated with fungi, were discharged into the ASTM-40 sieve of the harvester for the tests. The sieve door and separation chamber lid were sealed, and the harvester was operated for 15 min per load for rice and 20 min per load for broken corn. A spore count was performed to determine the spore concentration in each gram of harvested powder. To prepare the spore suspension, a 1 g sample of spore powder was mixed with 9 mL of 0.01% Tween in a test tube and homogenized by shaking. Four 1 mL dilutions of the mixture were prepared with distilled water. The third dilution was used to fill the Neubauer chamber (Brand, Wertheim, Germany) with a micropipette. The spores located at the right lateral limit, upper limit, and interior were counted under a compound microscope, excluding those in the lower and right lateral portions of the square. The average number of spores per 0.04 mm² square was multiplied by 25 to determine the total number of spores in 0.1 mm³ (volume of the chamber = 1 mm per side × 0.1 mm deep). Finally, the number of spores per mL−1 was calculated by multiplying this value by 10⁴ [45].

2.6. Colony-Forming Units

To enumerate the number of colony-forming units (CFUs), 0.1 mL of the sample dilution was extracted via a micropipette and uniformly spread onto an agar Petri dish. The dish was then incubated at an appropriate temperature and conditions for 24 h, following which the colonies formed were counted. The CFUs per mL of the sample were estimated using the formula CFU/mL = ((number of colonies) (dilution factor))/mL of the sample. The dilution factor (DF) was calculated as DF = 1/dilution = (total volume of liquid)/(volume of sample) [46].

2.7. Statistical Analysis

Statistical analysis was conducted to compare the mean values of spores obtained from different combinations of solid substrate and fungi. Multiple comparison tests were used to detect significant differences in the number of grams of spores harvested per kg of the processed substrate; a student’s t-test (p < 0.05) for a population mean with unknown variance was carried out for each combination of the solid substrate with M. anisopliae and B. bassiana fungi to determine if a higher yield was achieved than previously reported in the scientific literature.

3. Results

3.1. Harvester Operation Test

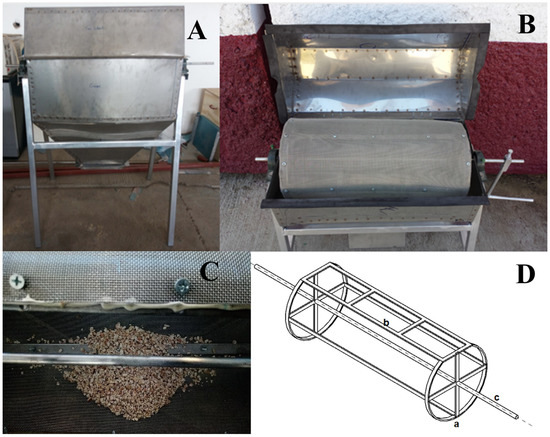

In this process, we estimated the average number of grams of spores obtained per kg of processed substrate. Before conducting the operational tests, the machine was washed with soap and water to remove any dirt acquired during the manufacturing process. The contents of a bag of broken corn inoculated with the fungus B. bassiana were emptied into the ASTM-40 sieve of the harvester, and the sieve flap and separation chamber lid were sealed. Once sealed, the harvesting machine was operated for 20 min, resulting in the first attempt with a yield of 36.86 g of spores per kg of the substrate (Figure 3).

Figure 3.

(A) Front view of the spore harvester; (B) Rotary sieve; (C) Load of broken corn inoculated with Beauveria bassiana fungus; and (D) Design of the parts of the rotary sieve, including a Combine rotary sieve body (a); Rotary sieve gate and cover (b); and a stainless steel shaft attached to the rotary sieve body (c).

3.2. Quality Testing of the Obtained Product

The fungus M. anisopliae yielded an average of 34.15 g of spore powder per kg of processed corn, while 57.35 g of powder was obtained per kg of processed rice. With the fungus B. bassiana, 35.47 g of spore powder per kg of corn and 38.26 g of spore powder per kg of rice were obtained (Table 1), indicating a significant increase in spore powder yield. A mean of 31.50 g of spores per kg of the processed solid substrate was the highest reported yield according to Jaronski [47].

Table 1.

Spore production obtained from functionality tests.

Notably, rice demonstrated the highest production of grams of M. anisopliae spores per kg of the processed substrate, thus showcasing its potential as a superior substrate. Furthermore, the spore concentration in g−1 was found to be similar in the harvested powder of corn and rice, indicating consistent and reliable results. Based on the statistical analysis using the student t-test for the different combinations of substrates and fungi, we have found sufficient evidence to reject the null hypothesis that the designed spore harvester would have an average yield equal to or less than the highest reported yield of 31.50 g per kg of processed substrate. This suggests that the designed harvester is capable of achieving a significantly greater yield of spores per kg of processed substrate.

The Corn-Metarhizium combination produced 34.15 g of spores per kg of the substrate and 1.51 × 109 CFUs mL−1. Similarly, the Rice-Metarhizium combination produced 57.35 g per kg and 1.59 × 109 CFUs mL−1. Meanwhile, the Corn-Beauveria combination yielded 35.47 g per kg and 1.00 × 109 CFUs mL−1, while the Rice-Beauveria combination had a yield of 38.26 g per kg and 4.50 × 108 CFUs mL−1. Based on the reported results, the Rice-Metarhizium combination appears to be the most effective, yielding the highest number of harvested spores per kg of substrate. However, the other combinations also showed notable yields and may still be viable options depending on the specific goals and constraints of the experiment.

3.3. Manufacturing Costs

An estimated total cost of approximately 409.31 USD was calculated for the manufacture of the harvester, considering only the cost of the materials. The manufacturing materials were purchased from local distributors; therefore, over time, the total cost may vary. If the harvester is commercialized, it is necessary to estimate the selling price by adding the cost of the materials, the cost of intellectual labor, and the cost of specialized technical labor such as welders and others. An estimated 22 h of work are required to manufacture the harvester machine (Table 2).

Table 2.

Costs of manufacturing materials purchased for the production of the entomopathogenic fungi harvester.

For harvesting spores from rice, the machine should be activated at approximately 30 rpm for 15 min per load, with a 5 min rest before opening the spore collector. In spore harvesting from corn, the machine should be activated for 20 min per load, since the separation of the spores is slower due to the broken corn particles being less hard than rice. The spore harvester should be cleaned and stored in a dry place, free of dust and other contaminants.

4. Discussion

In the production of entomopathogenic biopesticides through solid-state fermentation, the process of spore separation presents low yield due to the lack of a specially designed machines for harvesting. Manual or vibratory sieving methods are used, which have low efficiency in spore production [48,49], causing material losses due to dispersion in the environment, and direct interaction with the spores affects the operator’s health [50]. Currently, the only spore harvester on the market is Mycoharvester, a machine developed and commercialized by the Centre for Agricultural Bioscience International (CABI) organization [51], which yields approximately twice as many spores per kg of processed material compared to manual and vibratory sieving methods [52], representing higher efficiency in the spore separation process, but its high cost makes it difficult to acquire the equipment.

The development of cost-effective and high-quality machines is a crucial aspect of manufacturing. Manufacturers must consider several factors, including the cost and quality of materials, to design and manufacture a machine that meets the desired standards. Regular monitoring of material costs and adjustments to production processes can help manufacturers maintain a competitive edge in the market. The entomopathogenic fungi harvester developed in this study represents a significant achievement in this regard, with a significantly lower cost compared to the Mycoharvester offered on the market [53]. The development of cost-effective machines such as the one presented here can have a profound impact on the availability and accessibility of technologies for the agricultural industry, particularly in developing countries where resources are limited. Therefore, the use of alternative materials and design strategies should be a key consideration for manufacturers looking to develop affordable and high-quality machines.

Designing and manufacturing an entomopathogenic fungus harvesting machine can have several implications, both positive and negative. On the positive side, such a machine could potentially increase the efficiency and productivity of harvesting entomopathogenic fungi, making it easier and quicker for farmers to produce these beneficial organisms. This could lead to increased availability and affordability of entomopathogenic fungi as a pest control solution for farmers. In addition, a well-designed and well-maintained machine could reduce the risk of contamination during the harvesting process, leading to a higher quality product and reduced risk of negative environmental impacts. However, there are also potential negative implications to consider. The use of a harvesting machine could require additional energy resources and contribute to carbon emissions, depending on the power source of the machine. Moreover, if the machine is not properly designed or maintained, it could potentially damage or destroy the entomopathogenic fungi during the harvesting process, reducing the effectiveness of the product and potentially causing economic losses for farmers. For these reasons, it is important to check each step of the manufacturing process, as has been done in our study.

Several studies have investigated the concentration of entomopathogenic fungal spores using various solid-state fermentation substrates. For instance, Pandey and Kanaujia [54] reported a spore count of 4.42 × 107 g−1 when cultivating M. anisopliae with corn as the solid substrate, while Sahayaraj and Karthick [55] found a concentration of 1.12 × 109 g−1 of B. bassiana with rice and 9.4 × 108 g−1 of B. bassiana with corn. Karanja et al. [56] reported a spore yield of 28.8 g of M. anisopliae per kg of rice and 14.72 g per kg of broken corn, while for B. bassiana, they obtained 29.52 g per kg of rice and 7.08 g per kg of broken corn. Similarly, Jaronski and Jackson [34] reported a yield of approximately 5 × 1010 spores g−1 for M. anisopliae cultivated in rice. According to Gómez et al. [57], a spore concentration of 1010 g−1 is suitable for field applications. The results indicate that rice is the most efficient substrate for producing entomopathogenic fungi, especially M. anisopliae and B. bassiana, through solid-state fermentation. Specifically, Karanja et al. [56] found that rice and broken corn were the most efficient substrates for producing M. anisopliae spores, with an average production of 28.80 g and 14.72 g per kg of the substrate, respectively. For B. bassiana, rice was the most efficient substrate, producing an average of 29.52 g of spores per kg of substrate.

The abundance of certain chemical groups in the culture media may enhance the growth and spore production of fungi [58,59]. For example, rice and corn are rich in carbohydrates, particularly starch and cellulose, which are the primary energy sources for fungal growth [60,61]. The low nitrogen content of rice and corn [62,63] is also advantageous, as excessive nitrogen can stimulate the growth of competing microorganisms such as bacteria [64]. Additionally, rice and corn have a low concentration of secondary metabolites, such as phenolics and terpenoids, which can inhibit fungal growth [65], making them ideal substrates for entomopathogenic mass production.

Another one is that glucose, a significant energy source for fungal growth, is readily available in rice and corn. During fungal fermentation, glucose is metabolized as a carbon and energy source for cellular metabolism, growth, and spore production [66]. Furthermore, minerals such as iron, magnesium, and zinc are vital for fungal growth and reproduction. These minerals participate in essential cellular processes such as enzymatic reactions, cellular respiration, and spore production, all of which are critical for entomopathogenic fungi’s growth and reproduction [67,68]. Thus, rice and corn, being excellent sources of these minerals, can support the growth and reproduction of entomopathogenic fungi.

The separation of spores from their solid substrate is a crucial step in the production of biopesticides using entomopathogenic fungi. Various methods have been employed to achieve this, but the absence of specialized equipment leads to an ineffective process, resulting in financial losses. The goal of the harvest and post-harvest phases is to obtain a refined spore powder that is appropriate for formulation [69].

One of the most common methods used for spore separation is hand sieving, which is inexpensive but results in up to 50% material loss due to spore dispersion. Additionally, the operator is exposed to spores, which poses a safety hazard. For medium-scale production, the Dan Johnson method, developed at the University of Lethbridge, Alberta, Canada, involves using a concrete mixer with an acrylic lid attached to it by magnets. By rotating the mixer, the spores separate from the rice and form a cloud that is then sucked into a vacuum cleaner. However, this method is labor intensive, and the vacuum cleaner needs to be decontaminated after each strain of fungi is harvested [47].

Another method is the vibrating sieve separation, where two or three sieves of different aperture sizes are stacked on top of a reservoir, mounted on a vibrating apparatus, and separated for 25–30 min. However, this method has low production efficiency, as the sieves become blocked, hindering adequate separation of the spores and substrate. Additionally, the insulating tape is required at the joints between sieves to prevent spore loss due to dispersion [70].

A more sophisticated machine for spore separation is the aforementioned Mycoharvester, which uses a fluidized bed and is washable, easy to clean, and decontaminate. This machine comes in various sizes, but one disadvantage is its high acquisition cost. Furthermore, the substrate must have 5% or less moisture for the machine to work correctly [51].

It is worth noting that the chemical composition of the substrate can significantly influence the quality and efficacy of the entomopathogenic fungi produced. Therefore, substrate composition, pH, moisture, and temperature are crucial factors that require careful consideration for optimal entomopathogenic fungi production. With their potential as effective and sustainable alternatives to chemical insecticides, entomopathogenic fungi production using rice and corn substrates can provide an eco-friendly solution to agricultural pest management.

Our study gives detailed cost reporting, which can provide manufacturers with insights into potential areas for cost savings and process improvements. By analyzing the cost breakdown of their equipment, manufacturers can identify opportunities to streamline their manufacturing processes, reduce waste, and negotiate more favorable pricing for raw materials and components. By providing transparent and accurate cost breakdowns, manufacturers can help farmers make informed decisions about which equipment to purchase, improve their manufacturing processes, and build trust and accountability with their target audience.

5. Conclusions

In this study, a low-carbon footprint spore harvester for M. anisopliae and B. bassiana was designed and fabricated. The harvester was manually operated and made locally with nationally available materials. Tests showed that the harvester performed well with solid rice and broken corn substrates, and it achieved higher yields than reported in the literature. The combination of rice and M. anisopliae yielded the best results, while broken corn required longer harvesting time. The harvester reduced environmental losses by working in a hermetic environment. However, spore yields depended not only on the harvester but also on factors such as the strain used and laboratory management during cultivation. The spore harvester design provides a significant contribution to the technology of entomopathogenic fungal-based biopesticide production processes. In the manuscript, we present an approximate manufacturing cost of the entomopathogenic fungi spore harvester, which is significantly lower than the costs of commercial harvesters. Future studies are necessary for the formulation of a biopesticide that meets international standards.

Author Contributions

Conceptualization, F.D.-N.; Data curation, T.A.-B.; Formal analysis, F.D.-N., A.D.-R., N.A.-H., F.A.-B. and M.B.L.-H.; Investigation, F.D.-N.; Methodology, F.D.-N., C.G.-E. and A.D.-R.; Software, C.G.-E., J.R.-V. and F.A.-B.; Supervision, F.D.-N., J.R.-V. and R.P.-P.; Validation, C.G.-E. and J.R.-V.; Visualization, C.G.-E., T.A.-B. and A.D.-R.; Writing—original draft, C.G.-E. and N.A.-H.; Writing—review & editing, C.G.-E., J.R.-V., T.A.-B., R.P.-P., A.D.-R., N.A.-H., F.A.-B. and M.B.L.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the associated data are available in the manuscript.

Acknowledgments

We extend our gratitude to the National Polytechnic Institute (IPN) CIIDIR Oaxaca for their valuable support, and the National Council of Science and Technology (CONACYT Mexico). We are also grateful to the Palabras-STEM-Mexico for the service provided in the edition and style of the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sharma, N.; Singhvi, R. Effects of Chemical Fertilizers and Pesticides on Human Health and Environment: A Review. Int. J. Agric. Environ. Biotechnol. 2017, 10, 675–680. [Google Scholar] [CrossRef]

- Khan, B.A.; Nadeem, M.A.; Nawaz, H.; Amin, M.M.; Abbasi, G.H.; Nadeem, M.; Ayub, M.A. Pesticides: Impacts on Agriculture Productivity, Environment, and Management Strategies. In Emerging Contaminants and Plants: Interactions, Adaptations and Remediation Technologies; Springer International Publishing: Cham, Switzerland, 2023; pp. 109–134. [Google Scholar]

- Glare, T.; Caradus, J.; Gelernter, W.; Jackson, T.; Keyhani, N.; Kohl, J.; Marrone, P.; Morin, N.; Stewart, A. Have Biopesticides Come of Age? Trends Biotechnol. 2012, 30, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Senthil-Nathan, S. A Review of Biopesticides and Their Mode of Action Against Insect Pests. In Environmental Sustainability; Springer: New Delhi, India, 2014; pp. 49–63. [Google Scholar] [CrossRef]

- Ferreira, J.M.; de Freitas Soares, F.E. Entomopathogenic Fungi Hydrolytic Enzymes: A New Approach to Biocontrol? J. Nat. Pestic. Res. 2023, 3, 100020. [Google Scholar] [CrossRef]

- Chandler, D.; Bailey, A.S.; Mark, G.T.; Davidson, G.; Greaves, J.; Grant, W.P. The development, regulation and use of bi-opesticides for integrated pest management (review). Phil. Trans. R. Soc. B 2011, 366, 1987–1998. [Google Scholar] [CrossRef]

- Samada, L.H.; Tambunan, U.S.F. Biopesticides as Promising Alternatives to Chemical Pesticides: A Review of Their Current and Future Status. Online J. Biol. Sci. 2020, 20, 66–76. [Google Scholar] [CrossRef]

- Nava, P.E.; García, G.C.; Camacho, B.J.R.; Vázquez, M.E.L. Bioplaguicidas: Una opción para el control biológico de plaga. Ra Ximhai 2012, 8, 17–29. (In Spanish) [Google Scholar] [CrossRef]

- Mantzoukas, S.; Eliopoulos, P.A. Endophytic Entomopathogenic Fungi: A Valuable Biological Control Tool against Plant Pests. Appl. Sci. 2020, 10, 360. [Google Scholar] [CrossRef]

- Sabbour, M.; Abd-El-Aziz, S.; Sherief, M. Efficacy of Three Entomopathogenic Fungi Alone or in Combination With Diatomaceous Earth Modifications for the Control of Three Pyralid Moths in Stored Grains. J. Plant Prot. Res. 2012, 52, 359–363. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Hatcher, P.E. Combining entomopathogenic fungi and parasitoids to control the green peach aphid Myzus persicae. Biol. Control. 2017, 110, 44–55. [Google Scholar] [CrossRef]

- Javed, K.; Javed, H.; Mukhtar, T.; Qiu, D. Pathogenicity of some entomopathogenic fungal strains to green peach aphid, Myzus persicae Sulzer (Homoptera: Aphididae). Egypt. J. Biol. Pest Control 2019, 29, 92. [Google Scholar] [CrossRef]

- Fones, H.N.; Mardon, C.; Gurr, S.J. A role for the asexual spores in infection of Fraxinus excelsior by the ash-dieback fungus Hymenoscyphus fraxineus. Sci. Rep. 2016, 6, 34638. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.-H.; Dong, J.-C.; Gao, J.-J.; Li, X.-P.; Hu, S.-J.; Li, J.; Hu, W.-X.; Zhao, X.-Y.; Wang, J.-J.; Qiu, L. Three Chitin Deacetylase Family Members of Beauveria bassiana Modulate Asexual Reproduction and Virulence of Fungi by Mediating Chitin Metabolism and Affect Fungal Parasitism and Saprophytic Life. Microbiol. Spectr. 2023, 11, e04748-22. [Google Scholar] [CrossRef]

- Leland, J.E.; McGuire, M.R.; Grace, J.A.; Jaronski, S.T.; Ulloa, M.; Park, Y.H.; Plattner, R.D. Strain Selection of a Fungal Ento-mopathogen, Beauveria bassiana, for Control of Plant Bugs (Lygus spp.) (Heteroptera: Miridae). Biol. Control 2005, 35, 104–114. [Google Scholar] [CrossRef]

- Zulfiana, D.; Zulfitri, A.; Lestari, A.S.; Krishanti, N.P.R.A.; Meisyara, D. Production of Conidia by Entomopathogenic Fungi and Their Pathogenicity against Coptotermes sp. Biosaintifika J. Biol. Biol. Educ. 2020, 12, 1–9. [Google Scholar] [CrossRef]

- Krishna, C. Solid-State Fermentation Systems—An Overview. Crit. Rev. Biotechnol. 2008, 28, 101–168. [Google Scholar] [CrossRef]

- Mota, D.P.A.; Murcia, O.B. Hongos entomopatógenos como alternativa para el control biológico de plagas. Ambi-Agua 2011, 6, 77–90. (In Spanish) [Google Scholar]

- Park, H.-S.; Yu, J.-H. Developmental regulators in Aspergillus fumigatus. J. Microbiol. 2016, 54, 223–231. [Google Scholar] [CrossRef]

- Hopke, A.; Mela, A.; Ellett, F.; Carter-House, D.; Peña, J.F.; Stajich, J.E.; Altamirano, S.; Lovett, B.; Egan, M.; Kale, S.; et al. Crowdsourced analysis of fungal growth and branching on microfluidic platforms. PLoS ONE 2021, 16, e0257823. [Google Scholar] [CrossRef] [PubMed]

- Feldbaum, R.A.; Yaakov, N.; Mani, K.A.; Yossef, E.; Metbeev, S.; Zelinger, E.; Belausov, E.; Koltai, H.; Ment, D.; Mechrez, G. Single cell encapsulation in a Pickering emulsion stabilized by TiO2 nanoparticles provides protection against UV radiation for a biopesticide. Colloids Surf. B Biointerfaces 2021, 206, 111958. [Google Scholar] [CrossRef] [PubMed]

- Nonomura, T.; Toyoda, H. Electrostatic Spore-Trapping Techniques for Managing Airborne Conidia Dispersed by the Powdery Mildew Pathogen. Agronomy 2022, 12, 2443. [Google Scholar] [CrossRef]

- Roy, H.E.; Steinkraus, D.C.; Eilenberg, J.; Hajek, A.E.; Pell, J.K. Bizarre Interactions and Endgames: Entomopathogenic Fungi and Their Arthropod Hosts. Annu. Rev. Entomol. 2006, 51, 331–357. [Google Scholar] [CrossRef]

- Gandarilla, P.F.; Arevalo, N.K.; Galán, W.L.; Sandoval, C.C.; Quintero, Z.I. Evaluation of Conidia Production and Mycelial Growth in Solid Culture Media from Native Strains of Entomopathogenic Fungi Isolated from Citrus-Growing Areas of México. Afr. J. Biotechnol. 2012, 11, 14453–14460. [Google Scholar] [CrossRef]

- Imoulan, A.; Hussain, M.; Kirk, P.M.; El Meziane, A.; Yao, Y.-J. Entomopathogenic fungus Beauveria: Host specificity, ecology and significance of morpho-molecular characterization in accurate taxonomic classification. J. Asia-Pac. Èntomol. 2017, 20, 1204–1212. [Google Scholar] [CrossRef]

- Cañedo, V.; Ames, T. Manual de Laboratorio para el Manejo de Hongos Entomopatógenos; Centro Internacional de la Papa (CIP): Lima, Perú, 2004. (In Spanish) [Google Scholar]

- Castillo, C.E.; Cañizalez, L.M.; Valera, R.; Godoy, J.C.; Guedez, C.; Olivar, R.; Morillo, S. Caracterización morfológica de Beauveria bassiana, aislada de diferentes insectos en Trujillo—Venezuela. Rev. Acad. 2012, 11, 275–281. (In Spanish) [Google Scholar]

- Mascarin, G.M.; Jaronski, S.T. The production and uses of Beauveria bassiana as a microbial insecticide. World J. Microbiol. Biotechnol. 2016, 32, 177. [Google Scholar] [CrossRef] [PubMed]

- Rivas-Franco, F.; Hampton, J.G.; Altier, N.A.; Swaminathan, J.; Rostás, M.; Wessman, P.; Glare, T.R. Production of micro-sclerotia from entomopathogenic fungi and use in maize seed coating as delivery for biocontrol against Fusarium graminearum. Front. Sustain. Food Syst. 2020, 4, 606828. [Google Scholar] [CrossRef]

- Meyling, N.V.; Eilenberg, J. Ecology of the entomopathogenic fungi Beauveria bassiana and Metarhizium anisopliae in temperate agroecosystems: Potential for conservation biological control. Biol. Control 2007, 43, 145–155. [Google Scholar] [CrossRef]

- Rios-Velasco, C.; Pérez-Corral, D.A.; Salas-Marina, M.; Berlanga-Reyes, D.I.; Ornelas-Paz, J.J.; Muñiz, C.H.A.; Cambero-Campos, J.; Jacobo-Cuellar, J.L. Pathogenicity of the Hypocreales Fungi Beauveria Bassiana and Metarhizium Anisopliae against Insect Pests of Tomato. Southwest. Entomol. 2014, 39, 739–750. [Google Scholar] [CrossRef]

- Bapfubusa Niyibizi, I.A.; Hanna, R.; Kekeunou, S.; Membang, G.; Fiaboe, K.K.M.; Mahot, H.C.; Nchinda, V.P.; Tchoum-bougnang, F.; Kuate, J.; Ndjomatchoua, F.T.; et al. Potential of Cameroon-indigenous isolates of the ento-mopathogenic fungi Beauveria bassiana and Metarhizium anisopliae as microbial control agents of the flea beetle Nisotra uniformis. Biocontrol Sci. Technol. 2023, 33, 1–15. [Google Scholar] [CrossRef]

- Haik, Y.; Shahin, T.M. Engineering Design Process, 3rd ed.; Cengage Learning: Stanford, CA, USA, 2018. [Google Scholar]

- Jaronski, S.T.; Jackson, M.A. Mass Production of Entomopathogenic Hypocreales; Academic Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Kumar, E.V. Design and analysis of rotor shaft assembly of hammer mill crusher. Int. J. Eng. Manag. Res. 2013, 3, 22–30. [Google Scholar]

- Ojo, O.T.; Mohammed, T.I. Development of a Screw Press Briquette Making Machine. J. Adv. Appl. Sci. (JAAS) 2015, 3, 1–10. [Google Scholar]

- Senthamizhlselvan, P.; Sujeetha, J.A.R.; Jeyalakshmi, C. Growth, Sporulation and Biomass Production of Native Ento-mopathogenic Fungal Isolates on a Suitable Medium. J. Biopestic. 2010, 3, 466–470. [Google Scholar]

- Oghaz, N.A.; Hatamzadeh, S.; Rahnama, K.; Moghaddam, M.K.; Vaziee, S.; Tazik, Z. Adjustment and quantification of UV–visible spectrophotometry analysis: An accurate and rapid method for estimating Cladosporium spp. spore concentration in a water suspension. World J. Microbiol. Biotechnol. 2022, 38, 183. [Google Scholar] [CrossRef] [PubMed]

- Ghadge, P.N.; Prasad, K. Some Physical Properties of Rice Kernels: Variety PR-106. J. Food Process Technol. 2012, 3, 175. [Google Scholar] [CrossRef]

- Kumar, A.B.; Rao, P.V.; Edukondalu, L. Physical propieties of maize of grains. Int. J. Agric. Sci. 2017, 9, 4338–4434. [Google Scholar]

- Sandhya, C.; Sumantha, A.; Szakacs, G.; Pandey, A. Comparative evaluation of neutral protease production by Aspergillus oryzae in submerged and solid-state fermentation. Process. Biochem. 2005, 40, 2689–2694. [Google Scholar] [CrossRef]

- Amadi, O.; Onyema, N.; Nwagu, T.; Moneke, A.; Okolo, B.; Agu, R. Evaluating the Potential of Wild Cocoyam “Caladium Bicolor” for Ethanol Production Using Indigenous Fungal Isolates. Procedia Environ. Sci. 2016, 35, 809–817. [Google Scholar] [CrossRef]

- Jiang, X.; Fang, W.; Tong, J.; Liu, S.; Wu, H.; Shi, J. Metarhizium robertsii as a promising microbial agent for rice in situ cadmium reduction and plant growth promotion. Chemosphere 2022, 305, 135427. [Google Scholar] [CrossRef]

- Mathulwe, L.L.; Malan, A.P.; Stokwe, N.F. Mass Production of Entomopathogenic Fungi, Metarhizium robertsii and Metarhizium pinghaense, for Commercial Application against Insect Pests. J. Vis. Exp. 2022, 181, e63246. [Google Scholar]

- Gava, C.A.T.; Pereira, C.A.; Tavares, P.F.d.S.; da Paz, C.D. Applying antagonist yeast strains to control mango decay caused by Lasiodiplodia theobromae and Neofusicoccum parvum. Biol. Control. 2022, 170, 104912. [Google Scholar] [CrossRef]

- Bhuyan, S.; Yadav, M.; Giri, S.J.; Begum, S.; Das, S.; Phukan, A.; Priyadarshani, P.; Sarkar, S.; Jayswal, A.; Kabyashree, K.; et al. Microliter spotting and micro-colony observation: A rapid and simple approach for counting bacterial colony forming units. bioRxiv 2022. [Google Scholar] [CrossRef]

- Jaronski, S.T. Chapter 11—Mass Production of Entomopathogenic Fungi: State of the Art. In Mass Production of Beneficial Organisms; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Jenkins, N.E.; Heviefo, G.; Langewald, J.; Cherry, E.J.; Lomer, C.J. Development of mass production technology for aerial conidia for use as mycopesticides. Biocontrol News Inf. 1998, 19, 21–31. [Google Scholar]

- Posada, F.F. Production of Beauveria bassiana fungal spores on rice to control the coffee berry borer, Hypothenemus hampei, in Colombia. J. Insect Sci. 2008, 8, 41. [Google Scholar]

- Labarrete, S.N.; Ávila, R.I.; Orozco, M.J.E.; Pauste, R.H.; Fernández, L.B.L.; Guevara, A.M.E.; Díaz, P.H. Afecciones limitantes para trabajar en la elaboración de bioplaguicidas fúngicos producidos sobre sustratos sólidos. Rev. Cubana Salud Trab. 2014, 15, 21–24. (In Spanish) [Google Scholar]

- Bateman, R. Dropdata. El nuevo MycoHarvester (Versión 2017). Available online: http://www.dropdata.net/mycoharvester/MycoHarvester6_Spanish.pdf (accessed on 1 March 2023).

- Elósegui, C.; Fernández, L.O.; Ponce, E.; Borgues, G.; Rovesti, L.; Jimenez, J. Colecta de Esporas de Trichoderma Harzianum Rifai Cepa A-34 por Lecho Fluidizado y Ciclón Dual y por Tamizaje Vibratorio. Fitosanidad 2009, 13, 265–270. (In Spanish) [Google Scholar]

- DROPDATA Sites (2023). Available online: http://www.dropdata.net/mycoharvester/mhspec.htm (accessed on 27 February 2023).

- Pandey, A.K.; Kanaujia, K.R. Effect of different grains as solid substrates on sporulation, viability and pathogenicity of Metarhizium anisopliae (Metschnikoff) Sorokin. J. Biol. Control 2008, 22, 369–374. [Google Scholar]

- Sahayaraj, K.; Namasivayam, S.K.R. Mass Production of Entomopathogenic Fungi Using Agricultural Products and By Products. Afr. J. Biotechnol. 2008, 7, 1898–1906. [Google Scholar]

- Karanja, L.W.; Phiri, N.A.; Oduor, G.I. Effect of different solid substrates on mass production of Beauveria bassiana and Metarhizium anisopliae entomopathogens. In Proceedings of the 12th KARI Biennial Science Conference, Nairobi, Kenya, 8–12 November 2010; pp. 789–797. [Google Scholar]

- Gómez, H.R.; Zapata, A.G.; Torres, E.D.; Tenorio, M.C. Manual de Producción y Uso de Hongos Entomopatógenos; SENASA: La Molina, Perú, 2014. (In Spanish) [Google Scholar]

- Cabral, J.P. Can we use indoor fungi as bioindicators of indoor air quality? Historical perspectives and open questions. Sci. Total. Environ. 2010, 408, 4285–4295. [Google Scholar] [CrossRef]

- Harirchi, S.; Rousta, N.; Varjani, S.; Taherzadeh, M.J. Sampling, Preservation, and Growth Monitoring of Filamentous Fungi. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2023; pp. 149–180. [Google Scholar]

- Saha, B.C.; Cotta, M.A. Enzymatic saccharification and fermentation of alkaline peroxide pretreated rice hulls to ethanol. Enzym. Microb. Technol. 2007, 41, 528–532. [Google Scholar] [CrossRef]

- Navarro, D.M.D.L.; Abelilla, J.J.; Stein, H.H. Structures and characteristics of carbohydrates in diets fed to pigs: A review. J. Anim. Sci. Biotechnol. 2019, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Gregorich, E.G.; Monreal, C.M.; Schnitzer, M.; Schulten, H.-R. Transformation of Plant Residues into Soil Organic Matter: Chemical Characterization of Plant Tissue, Isolated Soil Fractions, and Whole Soils. Soil Sci. 1996, 161, 680–693. [Google Scholar] [CrossRef]

- Nayak, S.K.; Behera, G.R.; Mishra, P.C. Physio-chemical characteristics of Punnang oil and rice husk-generated producer gas. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 291–298. [Google Scholar] [CrossRef]

- Liu, H.; Wu, M.; Gao, H.; Liu, Z.; Gao, J.; Wang, S. Crude oil removal by Meyerozyma consortium and nitrogen supplement: Hydrocarbon transformation, nitrogen fate, and enhancement mechanism. J. Environ. Chem. Eng. 2023, 11, 109034. [Google Scholar] [CrossRef]

- Fan, M.; Yuan, S.; Li, L.; Zheng, J.; Zhao, D.; Wang, C.; Wang, H.; Liu, X.; Liu, J. Application of Terpenoid Compounds in Food and Pharmaceutical Products. Fermentation 2023, 9, 119. [Google Scholar] [CrossRef]

- Reischke, S.; Rousk, J.; Bååth, E. The effects of glucose loading rates on bacterial and fungal growth in soil. Soil Biol. Biochem. 2014, 70, 88–95. [Google Scholar] [CrossRef]

- Cuero, R.; Ouellet, T.; Yu, J.; Mogongwa, N. Metal ion enhancement of fungal growth, gene expression and aflatoxin synthesis in Aspergillus flavus: RT-PCR characterization. J. Appl. Microbiol. 2003, 94, 953–961. [Google Scholar] [CrossRef]

- Rousta, N.; Larsson, K.; Fristedt, R.; Undeland, I.; Agnihotri, S.; Taherzadeh, M.J. Production of fungal biomass from oat flour for the use as a nutritious food source. NFS J. 2022, 29, 8–15. [Google Scholar] [CrossRef]

- Jenkins, N.E.; Grzywacz, D. Towards the standardization of quality control of fungal and viral biological control agents. In Quality Control and Production of Biological Control Agents: Theory and Testing Procedures; CAB International: Wallingford, UK, 2003; pp. 247–263. [Google Scholar]

- Elósegui, C.O.; Fernández-Larrea, V.O.; Ponce, G.E.; Borges, M.G.; Rovesti, L.; Jiménez, R.J. Collect of Trichoderma harzianum Rifai Cepa A34 spores using the method os separation by a fluid-bed and dual cyclone machine, and separation by electric vibratory sieving. Fitosanidad 2009, 13, 265–270. (In Spanish) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).