1. Introduction

Member states of the United Nations adopted the second set of Sustainable Development Goals (SDG) in 2015 to end hunger and ensure access to safe, nutritious, and sufficient food all year round for all people, particularly those in poor and vulnerable situations, including infants. However, there are many challenges to achieving the vision of SDG 2—Zero Hunger by 2030 [

1]. The 50 × 2030 Initiative has acknowledged the requirement for precise and up-to-date agricultural and rural data, which could assist in the evaluation and creation of policies aimed at achieving zero hunger and other sustainable development objectives in developing and less-developed nations [

2].

The use of technology in achieving sustainable social, environmental, and economic development has become increasingly important through Industrial Revolution 4.0 (IR 4.0). IR 4.0 offers potential solutions to challenges and can contribute to improving quality of life by promoting sustainable products and services. Improvements in technologies that produce alternative methods, techniques, and end products are required to accelerate developments in all research areas [

3]. The creation of innovative technology and breakthrough solutions is essential to achieving the SDG targets, such as poverty eradication, improving food security, and reversing climate change. The integration of autonomous systems generated by machines and data networks has interconnected entire value chains [

4].

The research regarding agricultural robots and intelligent machines was reported more than three decades ago [

5]. Agricultural robotic systems are applied in various field operations: land preparation before planting, sowing/planting, weeding, seeding, plant treatment, disease detection, crop scouting, spraying, harvesting, and yield estimation and phenotyping for different farming environments [

6,

7]. This is because agricultural robotics addresses critical issues such as seasonal labor shortages and the growing concern for environmentally friendly practices. The agriculture industry offers poor pay, long work hours, and little chance for advancement. Older workers are leaving the industry, while newer generations show no interest in taking their place. Due to a lack of workers, operations have been delayed and sometimes abandoned. Thus, robotic systems have been designed to cover labor shortages, increase speed, and improve agricultural operation efficiency. The agricultural industry has seen the introduction of agricultural robots, which have proven capable of meeting the growing demand for food by automating farming tasks that were previously labor intensive [

7].

1.1. Unmanned Ground Vehicle (UGV)

UGV is next-generation technology for farming. Unmanned systems are equipped with wheels, mechanical legs, tracks, propellers, and other external devices that enable interaction with the operational environment and serve as locomotion systems [

8]. UGV is widely used in the military at the beginning of deployment to execute dangerous missions or to reach inaccessible places [

9]. Autonomously controlled tractors, using commercially available global positioning systems (GPS), and local/global sensors for use in row crops and orchards are already mature [

10]. UGV robotic systems are equipped with a range of sensors, including light detection and ranging (LIDAR), red–green–blue (RGB) cameras, time-of-flight (TOF) cameras, near-infrared (NIR) cameras, and stereo vision cameras, to facilitate data collection [

11]. In addition, UGV robots are increasingly being converted from internal combustion engines to electric motors.

This review focuses on robots used in harvesting, as they are better suited to agricultural tasks that traditionally require human intervention [

12]. Although mechanical harvesting has been around for many years, its impact on soil has come into focus due to erosion and compaction, as most of these machines are heavy. Harvesting is a significant operation, demanding, and challenging area for agricultural robotics. This has been the attention of agricultural experts for many years because of its diversity and complexity, and oftentimes requires different implements for different crops [

6,

13,

14,

15].

1.2. Harvesting Method

Manual harvesting involves using bare hands and, in some cases, cutting tools to remove leaves and branches from plants, to hold the fruit, and to pull it out of the plant. Manual harvesting is effective but only if performed by someone with experience, as a novice might accidentally damage the plants. On the other hand, humans have innate gripping ability thanks to their kinematics, sense of touch, and muscular power. They can quickly adjust to the form and texture of crops to apply the appropriate detaching force. However, human capabilities are constrained by exhaustion. Contrarily, harvesting robots can work dependably around the clock. Research has been conducted to create kinematic models for the motion of robotic arms and to build complicated end effectors with adequate sensors to manipulate crops [

16,

17].

Several excellent reviews of robotic harvesting end effectors have recently been published. Morar et al. presented their robotic end effector development analysis to different crops, e.g., apples, tomatoes, sweet peppers, and cucumbers [

16]. An improved manipulator and end effector technology was presented by Davidson et al. [

14]. Navas et al. presented recent advances in the design and use of soft grippers for agricultural harvesting [

18], while Vrochidou et al. used modern technologies as a reference to help choose appropriate end effectors for harvesting robots [

19,

20]. Zhang et al. provided an overview of robotic grippers, gripping methods, sensor-based control approaches, and their use in agriculture and food applications [

21].

This review paper covers the most recent harvesting robots’ concept design and system components. This paper reviews various studies on mechanical design principles, challenges, and limitations in characterizing the plant environment in the context of robotic harvesting and identifies possible directions for future research and development for cotton harvesting platforms. The main goal is to evaluate existing methods and concepts that could be used to develop an autonomous cotton harvesting robot. The design concepts of the harvesting methods are outlined in

Section 2, while the robotic system components are described in detail in

Section 3. Finally,

Section 4 discusses the results and suggests future work.

4. Discussions

Given the challenges and opportunities discussed in the previous sections, the development of a cotton harvesting robot requires a comprehensive understanding of the various subsystems that enable its operation. The cotton plant is characterized by being grown as a fiber crop for its soft, fluffy, and fibrous bolls. Cotton plants are generally grown in warm, humid climates and require a lot of water for growth. The cotton bolls are harvested and processed into cotton fiber, which is used to make a variety of textile products such as clothing, bedding, towels, and more. The design concept for such a robot requires careful consideration of the mobile platform, manipulators and end effectors, sensing and localization, and path planning and navigation.

4.1. Mobile Platform

The mobile platform plays a critical role in the efficiency and effectiveness of the cotton harvesting robot. It is important to choose a platform that is capable of negotiating rough terrain and uneven surfaces, which are common in cotton fields. In addition, the platform must be able to support the required weight of the robotic components, including manipulators and end effectors. The development of mobile platforms for unmanned ground vehicles (UGVs) in agriculture is a critical area of research that involves the development of specially designed platforms based on robotics principles. These platforms must address several factors, including the need to operate in wet conditions, keep costs low, and reduce complexity. Most harvesting robots are four-wheeled vehicles, but the use of tracked platforms allows them to operate in a variety of environmental situations, including muddy fields and wet soils. In addition, robotic platforms with tracked vehicles have been explored for greenhouse harvesting purposes. Recent innovations in mobile platforms offer further advantages in agility, crop and terrain adaptation, and flexibility. Mobile robots based on independent steering devices have the best maneuverability on sloping and irregular terrain. However, information on comparisons between the different types of systems or their applicability to agricultural terrain is rarely available. Overall, the development of mobile ground robots for agriculture is critical for smart agriculture and should be done using robotic concepts and taking advantage of the experience gained in the development of conventional tractors.

4.2. Manipulators and End Effectors

Manipulators and end effectors are critical components that allow the robot to interact with and harvest cotton plants. Manipulators must be designed to reach cotton plants and adapt to different plant heights and positions. End effectors must be designed to grip and pull off cotton bolls without damaging the plant or cotton. Arm manipulators that are able to move their end effector to a specific location with the required orientation to interact with an object are increasingly being used in agriculture. The type of end effector used depends on the agricultural task at hand. Different types of manipulators may have unique characteristics, such as rigid, soft, parallel, dual-arm, redundant, hyper redundant, or continuous manipulators. The literature describes different degrees of freedom for manipulators ranging from a three-DOF manipulator with rectangular coordinates to a seven-DOF manipulator. The literature provides an overview of different types of manipulators and end effectors for agricultural robots with different degrees of freedom. It is evident that different agricultural tasks require different types of manipulators and end effectors to be most effective.

4.3. Sensors and Localization

Sensors and localization are critical components for the cotton harvesting robot to navigate and avoid obstacles in the field. The use of sensors is an essential aspect of mobile robotics, allowing robots to perform various tasks such as tracking, navigation, and collision avoidance. Agricultural robots also rely heavily on sensors, as they require precise localization and mapping to operate effectively in an agricultural environment. However, it can be difficult to find reliable and easily accessible sensors. Therefore, researchers have used a variety of sensors, including tactile, force, torque, encoder, infrared, ultrasonic, sonar, active beacons, accelerometers, gyroscopes, laser rangefinders, vision systems, color tracking, contact and proximity sensors, and pressure and depth sensors. In particular, image sensor systems, including stereo cameras and machine learning-based object recognition systems, are widely used to estimate the location of plants and identify specific objects.

4.4. Robot Operating System

The robot operating system (ROS) has also become a popular framework for robot development, with many researchers using either Python or C++ as the programming language. ROS offers five main modules, including visual perception, state estimation (localization and mapping), obstacle detection, task execution, and navigation. With the use of open-source platforms and decreasing sensor costs, the use of mobile agricultural robots is expected to increase in the coming years. The integration of sensors and localization technologies is critical to the development of effective agricultural robots. Researchers have used a wide range of sensors and machine learning-based systems to achieve accurate crop localization and identification, while ROS provides a robust framework for robotic development. It is expected that these advances in sensor technology and robotics will lead to more efficient and cost-effective agricultural practices.

4.5. Path Planning and Navigation

Path planning and navigation are critical components to ensure that the cotton harvesting robot can navigate fields efficiently and safely. Path planning algorithms must be designed to determine safe and efficient travel paths while avoiding obstacles and minimizing damage to crops. Navigation algorithms must allow the robot to accurately determine its position and plan a path to the cotton plants. Robot navigation requires the robot to determine its position in its reference frame and then plan a path to its destination. Navigation systems rely on representations of the environment, such as maps, and the ability to interpret those representations. Various sensors, such as GPS, cameras, and rails, can be used to track the robot’s position and navigate in the environment. In addition, there are recent studies that have introduced advanced methods, such as convolutional neural networks (CNN), for path planning and navigation in agriculture. The complexity of path planning increases when the robot has many degrees of freedom (DOF) to fulfill its purpose, such as in fruit harvesting. However, most path planning methods are more effective and successful when the number of degrees of freedom is optimized to be small enough. Therefore, the selection of appropriate path planning and navigation strategies for mobile robots is crucial to ensure safe and efficient integration in the agricultural industry.

4.6. Limitations and Gaps in the Field of Harvesting Robots

The development of harvesting robots has come a long way, but there are still many obstacles and gaps in technology. Some of the major limitations and gaps are as follows:

Crop variability: Harvesting robots need to be able to recognize and select different types of crops in different situations, such as different maturity levels and sizes. However, given the diversity of crops, this can be a difficult task, especially when dealing with complicated and delicate fruits and vegetables.

Complicated environments: Farms often have complex environments with a wide range of topography, lighting, and weather. These difficult environments require harvesting robots to function, which can be a significant barrier to their growth.

Cost: Harvest robots are currently quite expensive to develop and produce, which could discourage many farmers from using them. This could discourage smaller farmers from using harvesting robots.

Restricted crop varieties: Currently, harvesting robots are best suited for uniform and easy-to-harvest crops such as strawberries and lettuce. However, they may not be suitable for crops that require more specific harvesting methods.

Safety issues: The development of harvesting robots must consider safety for both the crops being harvested and the workers who are near them. Their success depends on being able to work safely in the agricultural environment.

Social acceptance: some farmers and customers may be opposed to the use of harvesting robots because they are concerned about how it will affect their jobs and conventional farming practices.

Addressing these limitations and shortcomings is critical to the continued development and use of harvesting robots in agriculture. Some of these limitations will likely be addressed as technology evolves, but this will take time and continued investment in research and development.

4.7. Summary

In summary, the development of a cotton harvesting robot requires careful consideration of the mobile platform, manipulators and end effectors, sensing and localization, and path planning and navigation. Each of these components plays a critical role in the efficiency and effectiveness of the robot, and their design must be optimized to work together seamlessly to ensure a successful cotton harvest.

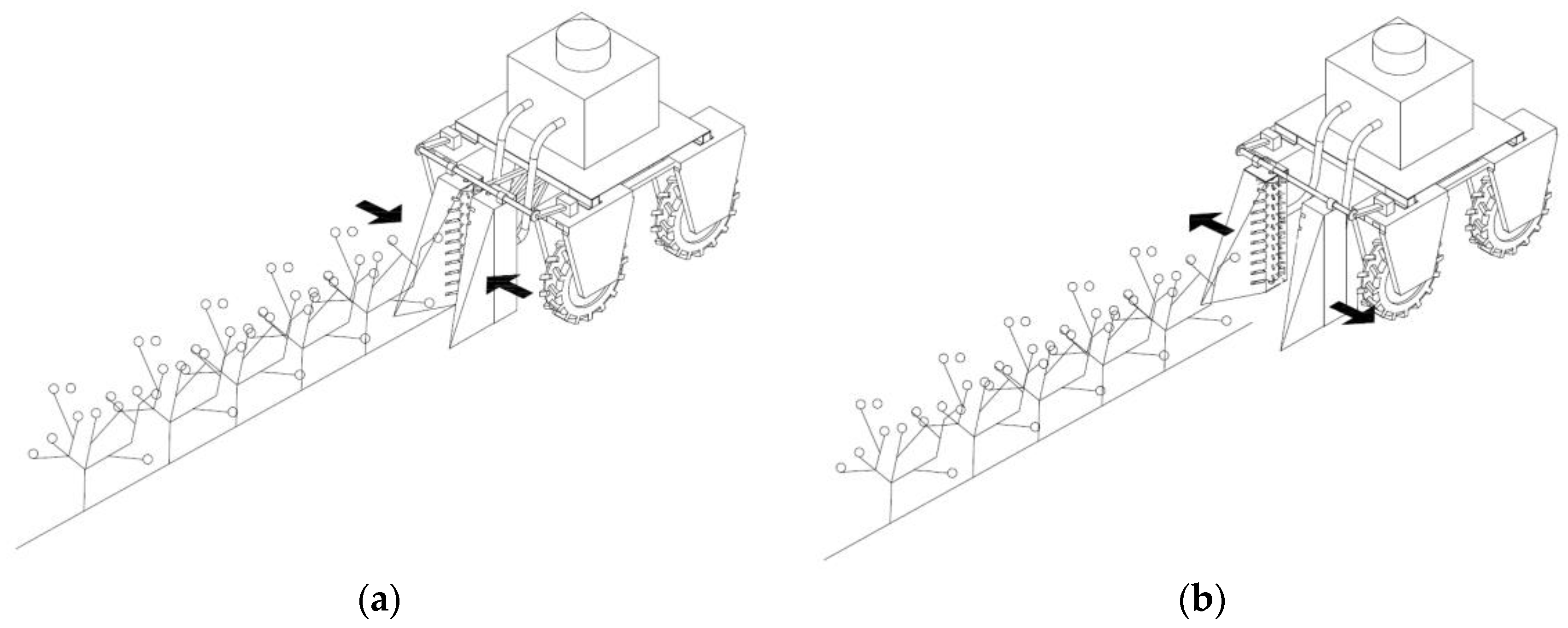

Therefore, our proposed proof of concept design of an autonomous cotton harvesting robot consists of a single-row harvesting module with a set of finger roller cotton stripper mechanisms attached to the front of the Amiga platform from Farm-NG. The Amiga platform is an all-electric 4 × 4 skid steer that can be configured for a differential drive. The height and width of the platform can be easily adjusted to suit different crops. The design includes a mechanism for pulling the cotton plant and then transporting the harvested bolls to the bucket in the center of the platform using suction motors and hoses. The selective harvesting function is enabled by use of two electric cylinders that control the retraction and extension movements of the harvesting modules (

Figure 9).

Overall, the proposed design is a promising approach for the development of an autonomous cotton harvesting robot, as it has a number of unique features that could significantly improve the efficiency of the harvesting process. The use of a single-row harvesting module in combination with the finger roller cotton stripper mechanism enables a precise and targeted approach to cotton plant harvesting. The transport mechanism with suction motors and hoses helps to ensure that the harvested bolls are not damaged during the harvesting process.

Moreover, the selective harvesting function enabled by the electric cylinders provides an additional advantage, as the robot can selectively harvest only mature bolls, improving the overall yield and quality of the harvested cotton. However, it should be noted that the proposed design has not yet been tested in the field. Further research and testing are needed to evaluate the effectiveness and feasibility of this concept under real harvesting conditions. In addition, potential challenges such as variations in cotton plant size and growth patterns, as well as possible technical problems with the electric cylinders or other components of the harvesting module, must be considered.

5. Conclusions

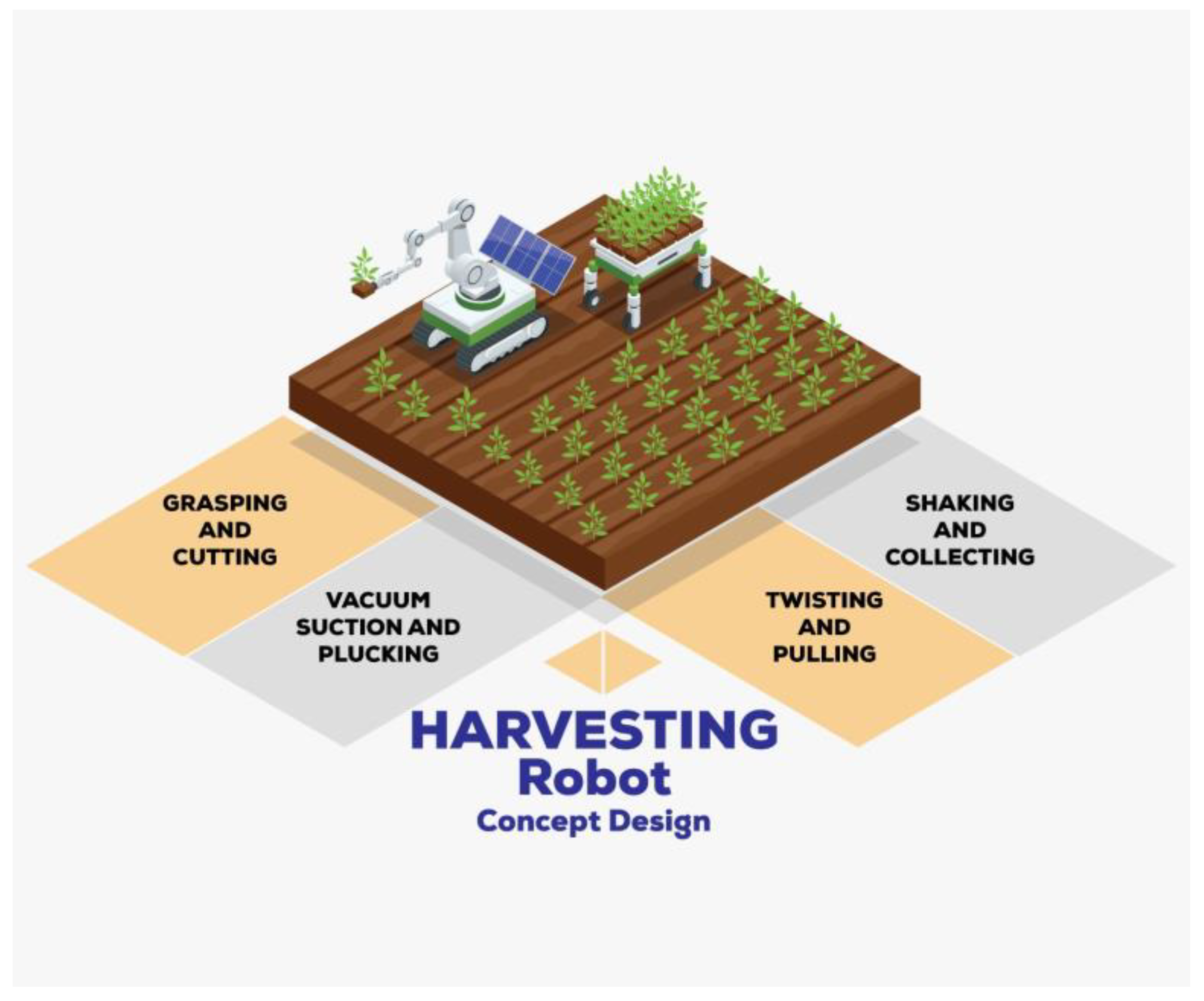

In conclusion, harvesting machines have become established for crops such as wheat, soybeans, and corn, while fruit and horticultural crops are still mostly harvested manually. However, recent research has investigated various mechanisms for harvesting fruit, including grasping and cutting, vacuum suction and plucking, twisting and pulling, and shaking and collecting. With this in mind, a proof of concept autonomous cotton robot was developed using a single-row harvesting module with a series of fingers and a cotton stripping mechanism attached to the front of the Amiga platform. This design effectively pulls the plant and harvests the bolls, which are then transported to a bucket in the center of the platform using two hoses and suction motors attached to the harvesting module. The retraction and extension of the harvesting modules are controlled by two electric cylinders, allowing for selective harvesting. Ultimately, this proposed design could serve as the basis for developing an efficient and autonomous cotton harvesting robot that could increase productivity.