Abstract

Microalgae have attracted wide attention due to their extensive application potential. Dewatering is a necessary work for the application of microalgae, especially in biofuel production, where forward osmosis (FO) research is relatively advanced but still faces technical bottlenecks hindering large-scale commercialization. Based on the current research in recent years, the research progress in the causes and control of membrane fouling, the development of membrane materials and optimization of membrane structure, and the energy saving and efficiency of the process are reviewed in this paper. We found that different species of algae have direct effects on membrane fouling. Chlorella vulgaris has a low membrane fouling trend, but the mechanisms of fouling need further investigation. The material development and structure optimization of membranes are the main research methods to reduce membrane fouling, but there are still some defects, such as complicated preparation and low water flux, which are difficult to apply on a large scale. The research progress of reducing costs by using seawater, urine, fertilizer, etc. as new draw solutions (DS) is reviewed. At present, many aspects of FO microalgae dewatering technology are still not well understood, and future research should focus on scaling up the existing technologies.

1. Introduction

As a kind of renewable resource, microalgae have the advantages of fast growth and no occupation of agricultural land. They can purify sewage, and have development potential in the field of sewage treatment and resource utilization. Microalgae can convert solar energy into hydrogen, hydrocarbons, alcohols, fats, and other renewable energy substances stored in cells, such as biodiesel [1], alcohol-based fuel [2,3], biological hydrogen [4], microalgae hydrocarbon production [5], biofertilizers [6,7], microalgae plastics [8], and other raw materials that can meet the needs of industrial and agricultural applications to a certain extent. In the face of the worldwide energy security crisis, microalgae, as the third-generation biofuel, have shown broader application prospects [9]. In order to achieve high biomass and lipid productivity in microalgal strains, microalgal cells must be isolated from the culture broth. Since microalgae are usually small in size (3–30 μm in diameter), have a density close to that of water, and carry negative charges on their surfaces, traditional methods such as filtration and centrifugation for algal-water separation are energy-intensive, costly, and economically unfeasible [10], traits which have long constrained the large-scale commercial production of microalgal fuels [11].

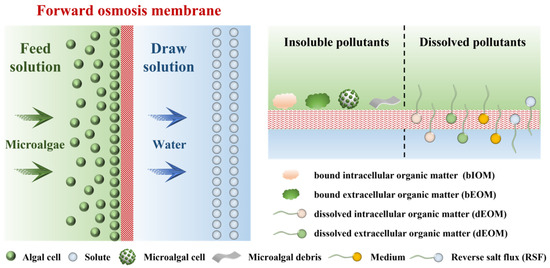

With the rise of FO technology in various research fields, there are more and more reports about its application in microalgae dewatering [12,13]. FO membrane processes are recognized as an emerging technology for wastewater reclamation, osmotic power generation, dewatering processes, etc. An FO process utilizes water transportation through a semipermeable membrane driven by an osmotic pressure difference between a relatively low concentration FS to a relatively high concentration DS. The use of FO for microalgae dewatering can replace external hydraulic pressure with osmotic pressure, which can be expected to achieve significant advantages such as lower energy consumption, excellent separation efficiency, no disruption of microalgae cell integrity, high microalgae cell recovery, and no introduction of external chemical components [14]. However, FO also has some constraints that are not suitable for widespread application, such as low water flux, unimpressive techno-economics, and low marketability. The advantages and disadvantages of different microalgae dewatering technologies are shown in Table 1.

Table 1.

Advantages and disadvantages of different microalgae dewatering technologies.

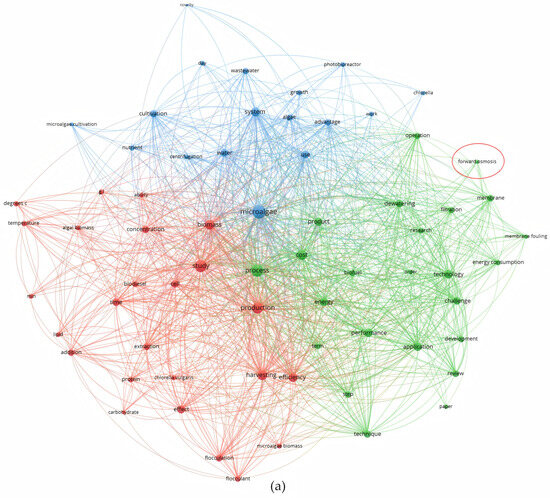

On Web of Science, we used the keywords “microalgae” and “dewatering” to identify 153 representative articles on microalgae dewatering published over the past five years. Through VOSviewer analysis, it was found that “forward osmosis (FO)” was the high-frequency term related to processing techniques among these 153 articles (Figure 1a). Subsequently, using the more specific keywords “microalgae” and “forward osmosis”, 41 representative articles focusing on microalgae FO dewatering in the past five years were selected (Figure 1b). These studies indicate a significant research effort in recent years aimed at enhancing the water flux of microalgae FO, exploring new DS, and reducing the overall operating costs of the process. The core purpose of this research was to improve the dewatering efficiency and economic feasibility of the microalgae FO process, thereby promoting its practical application. Based on the most recent five years of research on microalgae FO dewatering, the objective of this paper was to comprehensively review and discuss the causes and control of membrane fouling, the development of membrane materials and optimization of membrane structure, the energy savings and efficiency of the process, etc.

Figure 1.

Co-occurence network analysis. Network map of articles identified with the keywords: (a) “microalgae” and “dewatering”, (b) “microalgae” and “forward osmosis”, both from Web of Science.

2. FO Membrane Fouling: Causes and Control

Membrane fouling is an unavoidable critical issue in membrane treatment processes and one of the biggest obstacles to the widespread application of membrane separation processes. In the microalgae FO dewatering process, microalgae, as a kind of living organism, grow, metabolize, and secrete a variety of substances in the solution. As a result, the raw material liquid is often in a non-stable state, and its growth, metabolism, and secretion activities will lead to changes in cell density, extracellular polymers (EPS) content, flocculation behavior, and the chemical properties in the solution, which will have a significant impact on membrane fouling.

2.1. Causes of FO Membrane Fouling

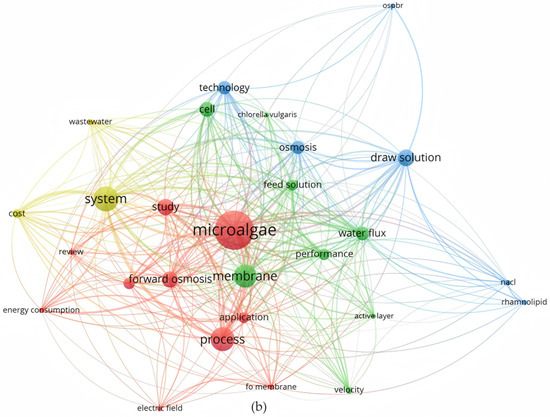

Currently, a wide variety of microalgae species are available for biofuel preparation, and their rich diversity is not only reflected in shape and size, but also in cell wall composition, metabolites, and response to environmental conditions. These characteristics directly determine the degree and type of membrane fouling. To be specific: (1) physical properties, such as the shape, size, surface area, stiffness, hydrodynamic properties, etc. of the membrane and larger cells or special forms (such as filaments, chains) of microalgae are more likely to cause membrane pore blockage. (2) Chemical components, such as the cell wall composition, lipid content, etc. components in the cell walls of microalgae (e.g., polysaccharides, proteins, lipids, etc.) can affect their interactions with membrane materials, and some components may increase the risk of membrane fouling. (3) Surface charge attributes, in addition to the fiber algae and other microalgae. While a very small number of microalgae carry a positive charge [18], the vast majority of microalgae (such as Chlorella vulgaris, Scenedesmus obliquus, etc.) carry a negative charge, which directly affects the intermolecular force between microalgae and an FO membrane surface and has a great impact on the development trend of membrane fouling. (4) Metabolic secretions, the algal organic matters (AOMs) secreted by different algal cells are different. According to the differences in their sources and locations, AOMs are mainly divided into two categories: extracellular organic matters (EOMs) and intracellular organic matters (IOMs) [19]. Dissolved AOMs are also known as dissolved algal products (SAPs). These secretions constitute the main source of biofouling of microalgal membranes.

Microalgae characteristics on degree and type of membrane fouling (Figure 2) is shown below.

Figure 2.

Schematic diagram of the effect of microalgae characteristics on degree and type of membrane fouling.

The physical properties and charge attributes of different species of microalgae affect how easily algal cells are caught in the membrane pores or deposited on the membrane surface. For example, Guruvaiah et al. found that the permeability of the shuttle-shaped and large-sized Phaeodactylum tricornutum was always higher than that of the spherical and small-sized Nannochloropsis oculate [20]. Phaeodactactus triangularis will make more cells and EPS enter the membrane pores, resulting in internal blockage, which increases the difficulty of cleaning. It is difficult for Nannochloropsis oculata to plug the membrane pores directly, but after long-term operation, fine cells and EPS may gradually accumulate, forming a dense filter cake layer, which ultimately affects the membrane’s performance. Ma et al. investigated the different behavior of the Phaeodactylum tricornutum, Chlorella vulgaris, Scenedesmus obliquus, and Microcystis aeruginosa during FO dewatering, and found that there were depositional differences among different microalgae [21]. The microalgae of large size or having strong flocculation (such as Phaeodactina triangulata and Scenedesmus obliquus) more easily cause structural fouling and biofilm fouling, resulting in a rapid decrease of membrane flux and difficult cleaning. However, microalgae with smaller cells (such as Chlorella vulgaris) mainly show the fouling of a filter cake layer, and the decline rate of membrane flux is relatively slow, though it will still affect the membrane’s performance after long-term operation. Because of its strong flocculation and EPS secretion ability, Microcystis aeruginosa easily forms serious biofilm fouling, and it is one of the most difficult microalgae to deal with.

The membrane fouling caused by physical properties such as size and shape between the above microalgae membranes mainly belongs to the category of reversible membrane fouling, which can be removed by simple backwashing [22]. Membrane biological fouling triggered by the different chemical compositions and metabolic secretions of microalgae falls into the category of irreversible fouling, which is difficult to be remove using physical cleaning alone, and it directly threatens the application cycle and service life of FO membranes. Therefore, the research on the influence of chemical composition of algae species and their metabolic secretion composition on membrane fouling has been the focus of attention in this field, and SAPs are one of the core issues of such research [23]. Zhou et al. investigated the membrane fouling mechanism of Chlorella vulgaris and the FO dewatering of Scenedesmus obliquus [24]. The results showed that both microalgal cells and their secreted SAPs constituted membrane pollutants. Through an Extended Derjaguin–Landau–Verwey–Overbeek theory analysis, it was found that the higher the interfacial energy between the algal cells, SAPs, the medium, and the membrane, the faster the decrease of water flux caused by membrane fouling. Ma et al. investigated the effect of coexisting components (such as Ca2+, natural organic humic acid, and inorganic particles of kaolinite) on the membrane fouling of the FO in an algal-rich water body [25]. The results showed that the coexisting components increased the attraction between pollutants and membranes and between different pollutants to varying degrees, accelerating the development of membrane fouling. These studies showed that the synergistic or competitive relationships existing among SAPs was inconsistent due to different algal cells. When the feedstock solution contained algal cells, algal fragments, various algal secretions, media components, and inorganic ions introduced by the DS in the reverse salt flux (RSF) process, these coexisting components were dispersed in the solution environment in which the FO membranes were located and had different effects on the generation and acceleration of membrane fouling.

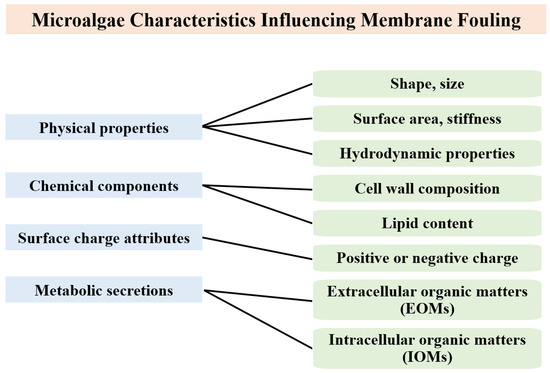

In recent years, some studies have pushed the knowledge of the relationship between SAPs and membrane fouling to a deeper level. For example, Ma et al. investigated the membrane fouling of Chlorella FO dewatering [26]. The results showed that the water flux was optimal when the solution contained algal cells, dissolved extracellular organic matter (dEOM), and bound extracellular organic matter (bEOM). Conversely, the water flux was the worst when only algal cells and bEOM were present in the solution. This occurred because the bEOM had less negative zeta potential, which usually resulted in less electrostatic repulsion when the bEOM was transported toward the membrane surface. The solution containing algal cells + bEOM carried a less negative surface charge, resulting in stronger adhesion between substances in the solution and the membrane surface, which increased the resistance of water passing through membrane during the early stage. Adding dEOM raised the zeta potential of the cells + bEOM + dEOM solution, increasing the electrostatic repulsion between the solution and the membrane surface. Consequently, it was less likely that this mixture would adhere to the membrane in the early stages. Finally, they all formed a cake layer, which reduced the water flux to varying degrees. Ji et al. compared the membrane fouling behaviors of Chlorella and Scenedesmus obliquus during FO dewatering and concluded that, due to the small and regular morphology of the cells, Chlorella vulgaris is more likely to cause higher fouling rates. Furthermore, compared with the membrane fouling behaviors of soluble extracellular polymers (sEPS), algal cells, and medium, Chlorella vulgaris and Scenedesmus obliquus were more sensitive to membrane fouling [27]. The binding extracellular polymers (bEPS) of Chlorella and Scenedesmus obliquus were the primary factors contributing to the decrease in flux compared to the sEPS, algal cells, and culture medium. Unsurprisingly, both sEPS and bEPS are forms of extracellular organic matter, subordinate to dEOM, and can be regarded as subsets of dEOM/bEOM. Since previous studies in the field of SAPs only penetrated to the level of relative molecular mass classification [13,23], Ma and Ji advanced the current research on algae species and membrane fouling control to a more microscopic level when they focused their study on the synergistic effect between the two subsets of dEOM/bEOM (sEPS/sEPS) and the algal cells and media (Figure 3) [26,27].

Figure 3.

Schematic diagram of microalgae FO dewatering membrane contaminants. There are 8 main pollutants that affect the generation and acceleration of membrane fouling, which are divided into insoluble pollutants and dissoluble pollutants.

In addition to freshwater microalgae such as Chlorella and Scenedesmus obliquus, there are also some FO dewatering studies on seawater microalgae. For example, Manrique et al. studied the FO dewatering of seawater microalgae Chlorella vulgaris and evaluated the effect of salinity on its dewatering performance [28]. Microalgal FO/PRO fouling was more severe and less reversible when divalent Mg2+ ions were present in the feed solution (FS) and the DS. The use of Mg2+-based DS can result in severe fouling due to the reverse diffusion of Mg2+ into the FS, even if Mg2+ is not present in the original FS. The use of FS spacers was beneficial in enhancing the initial flux as well as reducing the tendency toward membrane fouling. Hafiz et al. studied the dewatering performance of seawater Tetragonolactis spp. in an ultrafiltration-forward osmosis (UF-FO) hybrid system, and obtained a maximum algal concentration ratio of 37.3, which is rare in freshwater microalgae dewatering studies [29]. Moreover, FO exhibited high resistance to fouling where the water flux was completely retrieved after washing the membrane with distilled water. The energy consumption of the UF-FO hybrid system was 24% less than that of the UF-UF two-stage ultrafiltration system. The emergence of this type of seawater microalgae FO study has expanded the application field of FO dewatering and provided more references.

Table 2 summarizes some microalgae FO dewatering studies in the last five years. It can be seen that Chlorella vulgaris has the highest application ratio in the selection of algal species, whereas Scenedesmus obliquus, Chlamydomonas reinhardtii, etc. and Chlorella vulgaris are often included as research objects to compare the various types of differences between different algal species in the dewatering process. The advantages and disadvantages of different arrangement mode are shown in Table 3.

Table 2.

Microalgae FO dewatering studies in recent five years.

Table 3.

Advantages and disadvantages of different arrangement mode.

The reason for this may be that Chlorella vulgaris does not contain fructose or galactose like Chlamydomonas reinhardtii, and the tendency toward membrane fouling of Chlorella vulgaris during the FO process is lower, which means it does not easily trigger serious water flux loss [39].

2.2. Control of FO Membrane Fouling

At present, in order to effectively control membrane fouling, researchers have adopted a variety of strategies, which includes osmotic backwashing, ultrasound, chemical cleaning, and air sparging. Osmotic backwashing is performed by reversing the flow of water and membrane sides. Some studies also have been reported on using ultrasound to generate acoustic cavitation, which induces shear stress to effectively remove foulants. Fouling mitigation using chemical cleaning has also been studied. In chemical cleaning methods, the membranes are soaked in a cleaning solution such as sodium hypochlorite, sodium hydroxide, or sodium chloride and washed either via forward or backward flushing for foulant removal [25,26,36].

In general, Chlorella vulgaris, Scenedesmus obliquus, Chlamydomonas reinhardtii, and Nannochloropsis oculata are still more suitable for biofuel production, and the above algae species have been applied more in the relevant experimental studies of FO dewatering [40,41]. In the future, it will be necessary to further analyze the properties of microalgae and their products to determine the key components affecting the formation of the filter cake layer and to grasp the underlying mechanism of membrane fouling so as to adopt appropriate means for effective control. At the same time, analysis can also provide useful references for the preliminary selection of microalgae fuel preparation methods.

3. FO Membrane: Material Development and Structure Optimization

The inherent characteristics of the separation membrane determine the degree and type of membrane fouling in an FO process to a large extent, which is one of the key factors affecting membrane fouling. These characteristics include membrane pore size, hydrophilicity, surface charge, chemical stability, and antifouling ability, etc., which work together to affect the interaction between microalgae and their metabolites and the membrane surface, thereby determining the occurrence and development of membrane fouling. Since membrane fouling and concentration polarization (CP) are the main factors of FO water flux decline, they have been the main research targets in the development of membrane materials and optimization of membrane structure in recent years.

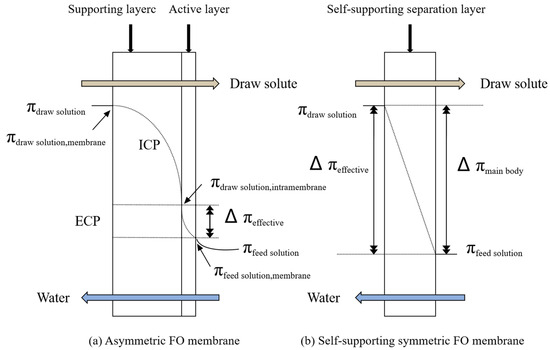

Concentration polarization is a dynamic process and one of the common technical obstacles in membrane separation processes. In the process of microalgae FO dewatering, the external concentration polarization (ECP) can be alleviated by increasing the mis-flow velocity or the degree of turbulence on the membrane surface. Internal concentration polarization (ICP) occurs inside the support layer, which is a unique phenomenon of asymmetric membranes. It cannot be eliminated by means of operation optimization, etc., and can only be suppressed by changing the structure of the membrane itself [42,43,44,45,46,47].

3.1. Structure Optimization of FO Membranes

At present, substrate enhancement by phase transition is a common approach to modifying membrane structures and properties, with the core objective of providing good hydrophilicity and wettability of the membrane support layer to achieve water flux enhancement while minimizing the mechanical damage caused by the bending of the membrane. Among them, hydrophilicity is highly beneficial in alleviating ICP. With the increase of hydrophilicity, wettability increases simultaneously, while wettability can promote the diffusion of the feed solution in the membrane pores [42]. Previous studies have used phase transition methods to adjust the polysulfone sublayer of a TFC-FO flat sheet membrane to modify its thickness and chemistry to reduce mass transfer resistance [43]. More recently, cellulose triacetate (CTA) ultrafiltration membranes with higher porosities were prepared by using a dioxane and acetone mixture as a solvent and a lactic acid and methanol mixture as a non-solvent through different phase conversion conditions [44]. However, the preparation of these “substrate-improved membranes” often requires a multi-step, intricate process that results in variable membrane quality [45]. This complexity and lack of consistency have considerably hindered further research and the broader application of such membranes.

3.2. Material Development of FO Membrane

In addition, some studies focus on “embedded membrane” structures optimization, in which hydrophilic additives or nanomaterials (e.g., TiO2, carbon nanotubes, etc.) are embedded in the polymer matrix to prepare novel FO membranes [45], which are beneficial to alleviate the ICP and improve the water flux [46,47]. However, there is a common problem in this kind of research, that is, the large amount of nanoparticle aggregation in the membrane layer will most likely cause defects in the membrane material itself, resulting in increased ICP and reduced water flux. This is a technical bottleneck that is currently hindering the deeper exploration and advancement of similar research. On the other hand, aquaporin membranes, which are also “embedded membranes”, are a successful product of this research idea. Munshi et al. [48,49] conducted a series of dewatering experiments on Chlorella vulgaris using a water channel protein polyethersulfone membrane, and the experimental results confirmed the advantages of this membrane in water flux, providing a new application option for the study of microalgae FO dewatering.

In addition to the optimization of the support layer, the modification of the active layer is also a common means of membrane structure optimization and performance improvement. Usually, hydrophilic substances (such as polyether amine, ethylenediamine, polyethylene glycol derivatives, and graphene oxide, etc.) are used to modify the surface of the membrane to increase the hydrophilicity of the membrane surface, so as to improve the permeability and fouling resistance of the membrane [47,50,51]. Akther et al. modified the surface of TFC membranes in situ by adding silica to improve the fouling resistance of the original membranes [52]. Huang et al. developed highly negatively charged and hydrophilic membranes using bioadhesion and layer-by-layer self-assembly technology to mitigate the fouling of microalgae FO membranes [53]. These studies can provide useful references for the interfacial charge modification of membrane materials in the future. The advantages and disadvantages of different FO membrane types are shown in Table 4.

Table 4.

Advantages and disadvantages of different FO membrane types.

In summary, the development of FO membrane materials and the optimization of membrane structures to achieve CP inhibition and membrane fouling control are important research areas to improve or maintain the dewatering flux of microalgal FO. However, from the perspective of specific application examples (Table 2), most microalgal FO studies in recent years have tended to adopt commercial CTA or TFC flat membranes. This may not only be related to the availability and stable quality of commercial CTA or TFC membranes, but also to the difficulty of large-scale production of new membranes with guaranteed quality control.

In recent years, a “self-supporting symmetric FO membrane” has been developed (Figure 4), which completely eliminates the effect of ICP on OF membranes and has been further investigated recently. Li et al. proposed a COOH-derived poly(oxadiazole) (PTAODH) copolymer FO membrane with a thickness of only 8 μm and a water flux of up to 12 L/(m2∗h) without the effect of ICP [54]. Liang et al. followed up by preparing a series of self-supported symmetric FO membranes of carboxylated poly(arylene ether sulfone) (PAES–COOH) material, with a reduced film thickness of 2.5 μm, which also showed advantages in mechanical strength and permeation selectivity [55]. If this symmetric membrane technology is successfully developed, FO applications will usher in a revolutionary leap. However, it should be noted that the ultra-thin homogeneous membranes, while improving their permeability, also increase their structural defect ratio. Due to the disappearance of the support layer, the structure of such symmetric membranes is generally extremely fragile and difficult to adapt to medium- and long-term applications, which have not been reported in industrial practice. In the future, it will still be necessary to improve membrane robustness and durability and strengthen the research and application in microalgae FO to solve the technical defect of low water flux.

Figure 4.

Asymmetric FO membrane and Self-supporting symmetric FO membrane. Self-supporting symmetric FO membrane completely eliminated the effect of ICP on OF membranes by removing the support layer.

4. FO Dewatering Process Energy Efficiency

Currently, to effectively control membrane contamination, researchers have adopted a variety of strategies. Although these methods have alleviated membrane fouling to a certain extent, they still face problems such as high cleaning frequency and increased costs during long-term operation. Therefore, considering process energy savings and efficiency improvements is of significant importance for enhancing the overall performance and economic viability of the system.

4.1. Influence of Drawing Solution Selection on Cost Compression

The choice of DS is critical to the efficiency and stability of the FO process. Studies have shown that the FO process will have a great advantage in energy saving if the regeneration and reuse aspects of DS are not considered [10,12]. As another important component of microalgae FO dewatering process, the rational selection of DS is precisely the preferred target for energy saving and the efficiency of the microalgae FO dewatering process.

NaCl, as a traditional inorganic type drawing solution, has been mostly used as a DS reference in microalgal FO dewatering studies in recent years. For example, Ma et al. investigated the dewatering of microalgae by three DSs of NaCl, MgCl2, and CaCl2 solution. It was found that the water flux decreased faster when a CaCl2 solution was used as the DS, while an MgCl2 solution did not show serious membrane fouling when acting as a DS. [21]. This was not consistent with the findings of Zou et al. [56]. This may have been caused by the differences in surface charge, functional groups, and free energy between different species of algae, and the differences in algae species and DS types should be considered comprehensively in specific applications.

With the in-depth research on FO processes, natural seawater and sea salt are often used as DSs, considering the availability, convenience, and economy of DS disposal. By establishing microalgae aquaculture plants near the coastline and taking advantage of the characteristics of seawater, which is abundant, does not need to be diluted, and is very easy to obtain, the seawater can be used as a DS and injected back into the sea afterwards, which can significantly reduce energy consumption and operating costs. Nawi et al. investigated the use of seawater as a DS for membrane fouling control by aeration in an FO system. The result showed that aeration is effective to enhance the water flux even at a low rate (i.e., 67% at a rate of 0.4 NL∗min−1) via membrane vibration and scour-off the foulant [34]. Seawater is used as a disposable DS, saving the energy needed to recover the DS, and this waste liquid can be discharged directly into the sea without causing additional pollution. However, in some countries, such as China, high-salinity waste liquids (salinity above 15,000 mg/L) are classified as hazardous waste and require additional treatment before disposal.

Also for cost-saving reasons, some waste streams (such as reverse osmosis concentrated waste brine) that have lost their original utilization value, are used as DSs, which can reduce costs and mitigate environmental toxic effects. Molitor et al. used reverse osmosis seawater desalination waste brine as a DS for FO isolation of the Scenedesmus obliquus [33]. However, these DSs often face some practical problems in microalgae application. In the case of a seawater DS, in addition to the limitations in the application location, due to the complexity of its own components, the DS itself often causes serious membrane fouling in the application [57].

In addition, human urine has the advantages of high osmotic pressure (about 3.01 MPa in comparison to seawater’s osmotic pressure of 2.50 MPa), extremely low cost, and easy access, and can be used as a microalgae growth medium after dilution. Volpin et al. used urine as a DS to conduct FO experiments on Chlorella vulgaris, which also produced positive results in water flux enhancement and operating cost compression [58]. The disadvantage is that urine contains ammonium ions (NH4+), which forms a certain degree of reverse osmosis to the feedstock liquid in the case of RSF, inhibiting the growth of microalgae and affecting the effectiveness of the subsequent bioenergy preparation. Therefore, in recent years, studies on urine as a DS have been sporadic and have not yet become mainstream.

It is also important to mention fertilizer draw forward osmosis (FDFO). Munshi et al. studied the dewatering of Chlorella vulgaris using three different DSs—NaCl, KCl, and NH4Cl solution—and proved that the fertilizer-based DS of NH4Cl solution was superior to the traditional inorganic DS of NaCl solution [49]. Subsequently, Munshi et al. continued to study the dewatering of microalgae under an applied electric field using the above mentioned DSs, which further confirmed the dehydrating and energy-saving properties of fertilizer-based DSs [48]. However, although FDFO does not require DS purification and recovery, it is also necessary to control the feedstock liquid fouling and microalgae growth inhibition brought about by nutrient RSF, which may be an important reason why FDFO is not the preferred choice for microalgae dewatering applications at present. The real-time or subsequent effects of microalgae reverse osmosis in FDFO still need to be studied and revealed. It remains to be studied and revealed what the real-time or subsequent effects of the reverse osmosis of microalgae in FDFO will be.

In addition, there are FO processes driven by medium nutrients. Ryu et al. investigated the microalgal FO dewatering performance using glucose and artificial seawater as DSs, and the results showed that the glucose DS had better dewatering performance, and its dilution can be directly reused as a microalgae culture medium, which greatly reduces the system’s cost and energy consumption [31]. In principle, this process is a variant of FDFO and could be used as an energy-saving alternative to FDFO in the future.

There are some other DSs, such as waste glycerol, that have been used in microalgae FO dewatering before, although they are also in line with the application of cost compression, but there has been no follow-up in recent years. As a by-product of algal biodiesel production, the osmotic pressure of waste glycerol can reach 9.20 MPa [59]. Sobczuk et al. conducted a study on FO dewatering of marine microalgae using crude glycerol as a DS, which proved the reliability of the process, realized the utilization of wastes, and reduced the negative impact on the environment [60]. However, it is not clear whether glycerol has significant interactions with the culture medium or microalgae species, and its effects remain to be confirmed through further research.

Similarly, gel-stimulated response draws were not found to be used for microalgae dewatering. This is due to the additional processing energy consumption (such as electricity consumption) in use, which goes against the original purpose of DS selection of reducing operating costs [61]. Moreover, the complex preparation process and limited lifetime of these materials further hinder their practical application. Inorganic DSs [62,63] with added surfactants also have not seen similar applications. This may be due to the fact that the effect of surfactants on the subsequent preparation steps of microalgal biofuels is still unclear and remains to be investigated.

In summary, NaCl solution, seawater and reverse osmosis salt brine, urine, and fertilizer (KCl and NH4Cl solution) are the more widely used types of DS in microalgae FO dewatering processes. Seawater, urine, and fertilizer-type DSs can effectively eliminate the subsequent recovery and reuse processes and have obvious advantages in reducing operating costs. MgCl2 and CaCl2 solutions should not be used as DSs in microalgae dewatering due to their tendency to increase the membrane fouling. Glycerol, gel-type stimulation response extracts, and inorganic DS with surfactants are not suitable to be used as DS due to their high cost and unknown effects on microalgae. The advantages and disadvantages of different DS are shown in Table 5.

Table 5.

Advantages and disadvantages of different DS.

4.2. Influence of Process Conditions and Operating Parameters on Process Efficiency Gains

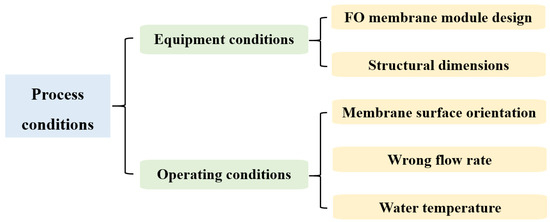

Process conditions can be divided into equipment conditions and operating conditions. Equipment conditions include, i.e., FO membrane module design and structural dimensions, etc. Operating conditions refer to the FO microalgae dewatering process using the relevant operating parameters, such as membrane surface orientation, wrong flow rate, and water temperature [64]. Process conditions are another important factor affecting the performance of FO microalgae dewatering systems [21,65].

In terms of equipment conditions, flat-plate type modules are still the mainstay of laboratory-scale microalgae FO dewatering. However, some tubular and spiral-wound membrane modules have also begun to be put into application (Table 2). For example, Wang et al. employed TFC hollow fiber membranes in an osmotic photobioreactor system, which compensated for the poor filling density of plate-and-frame flat-plate membrane modules and could handle a larger volume of feed streams in the short term [35]. However, the disadvantage was the poor resistance to membrane fouling; continuous operation was difficult to sustain. Blandin et al. developed a new operation mode, which first mentioned the problem of “mass transfer limitation” in the operation of a submerged osmosis system and put forward proposals and suggestions for optimizing the design and operation of such systems [66]. Ma et al. designed a hybrid dead-end/staggered flow FO filtration system for microalgae dewatering [21]. Then, Ma et al. developed a new gravity settling-FO hybrid reactor. The development of these new types of reactors provides a broader research space for microalgae FO dewatering research and provides a very useful inspiration for the continuous optimization and innovation of process equipment conditions [26].

The electro-assisted FO system is also a typical application of process condition optimization in recent years. Munshi et al. [48] systematically studied the dewatering of Chlorella vulgaris using electrically assisted FO, and the results showed that the water flux of the electrically assisted FO system could be enhanced by 2.2–3.8 times and the water flux recovery rate could reach 99% compared with that of the unassisted FO system. Xu et al. [30] constructed an electrically assisted FO system that effectively mitigated the decline of the water flux and enhanced the microalgae recovery rate and lipid extraction rate. In the future, this electrically assisted FO microalgae dewatering system may be considered in conjunction with photovoltaic technology to fully utilize solar energy as an electricity source, which may play a more active role.

The combination of FO systems with microalgae culture photobioreactors is also a field of interest to researchers. Wang et al. developed an osmotic photobioreactor system with fertilizer-based dissolved disodium phosphate as the DS, which consumed the nutrients from the RSF in the FO system via the fast-growing microalgae in the photobioreactors, keeping the osmotic photobioreactor system functioning with a low nutrient accumulation [35]. Larronde-Larretche et al. combined two FO components with a microalgae photobioreactor via lateral flow and submerged approaches to evaluate the system treatment performance [32]. The results showed that the lateral flow FO + PBR approach is more suitable for a continuous and efficient microalgae dewatering process.

In terms of operating conditions, for the widely used asymmetric FO membranes, the orientation issue is basically well established. In most cases, the active level is better oriented toward the feed solution than toward the draw solution. In addition, the cross-flow velocity is another focus of the study of operating conditions. Cross-flow velocity is beneficial in disturbing and eroding the surface fouling layer of the membrane and promoting membrane fouling mitigation. However, this enhancement of cross-flow velocity and shear stress can only mitigate membrane fouling and ECP. It is ineffective to reduce ICP, which is related to the structural properties of the membrane itself [67].

Due to the microscopic specificity of the experiments for operating conditions, some researchers have started to use Computational Fluid Dynamics (CFD) tools to model the fluid flow conditions. In earlier studies, Ramon et al. analyzed the possible influence mechanism of the support layer on the fouling characteristics of the active layer by CFD [68]. In recent years, Itliong et al. [69] investigated the ion transport mechanism during microalgal FO dewatering using CFD. Wen et al. used a CFD method to simulate the influence of inlet flow rates of different membrane components on the FO process [70]. Ryu et al. established a microalgae water flux prediction model based on the Carman–Kozeny resistance model [71]. Such studies are indicative, enlightening, and provide theoretical bases and modeling examples for subsequent in-depth studies of microalgal FO dewatering processes.

Process conditions and operating parameters (Figure 5) is shown below.

Figure 5.

Schematic diagram division of process conditions and operating parameters.

Equipment conditions and operating conditions need to be determined in conjunction with the content of specific FO experiments. In practice, results can not simply be replicated based on the operating conditions while ignoring the specific requirements of the actual situation in terms of the type of algae, the performance of the FO membrane, the composition of the DS, and the composition of the system process.

5. Summary and Prospects

In recent years, an increasing number of studies have demonstrated the applicability of FO technology in microalgae dewatering, highlighting its great potential in energy saving and efficiency improvement, with very broad prospects for future applications. In this paper, through an in-depth analysis of the performance of different microalgae species in the FO process, the key factors affecting membrane fouling were identified and effective control strategies were proposed, which is of great significance for improving dewatering efficiency and extending the service life of the membrane. Furthermore, the progress of the development of novel membrane materials and structure optimization was also discussed, especially the development potential of ICP-free self-supporting symmetric FO membranes, which can significantly increase microalgae dewatering flux. At the same time, through the study of the energy consumption and efficiency of the processing system, a series of innovative improvement schemes which will help to reduce overall operational costs and improve the economic benefits were proposed. This work provides a solid scientific basis for the application of FO technology in the field of microalgae dewatering, promotes the use of the technology in more extensive practical applications, and points out focus and development directions for future research.

The specific summary and prospects are as follows:

- (1)

- Microalgae species such as Chlorella vulgaris and Scenedesmus obliquus are widely used in the research, which can provide useful references for the subsequent research into and application of algae species selection. The membrane fouling trend of Chlorella vulgaris was lower than that of Scenedesmus obliquus, Chlamydomonas reinhardtii, and Nannochloropsis oculata, and C. vulgaris did not easily cause serious water flux loss. In the future, it will still be necessary to further analyze the properties of microalgae and their products, determine the key components that affect the formation of filter cake layers, and master the final mechanisms of the formation and development of membrane fouling.

- (2)

- FO membrane material development and membrane structure optimization work still revolves around enhancing water flux, fouling resistance, and other directions. At present, most of the research still focuses on commercial CTA/TFC membranes, but water channel protein membranes are also involved in the applications as a mature product of membrane structure optimization technology. In addition, ICP-free self-supporting symmetric FO membranes have begun to attract attention, but the technical defects in their toughness have not yet been effectively overcome, and their application in microalgae dewatering is still challenging. In the future, it will still be necessary to improve the robustness and durability of the new membrane, strengthen research into its application in microalgae FO, and solve the technical defects of low water flux.

- (3)

- In terms of process energy saving and the efficiency of DS researches, some new process systems have been developed and validated, but there is still a long way to go before they can be widely applied. CFD, as an inspiration and supplement to experiments, has continued to emerge in recent years. In the future, the CFD model may be combined with practice to determine the equipment conditions and operating conditions under different conditions according to the specific requirements of actual algae species, FO film performance, DS composition, and system process composition.

- (4)

- In conclusion, the current FO microalgae dewatering technology still has many cognitive blind spots and long-term and detailed techno-economic comparisons with the traditional microalgae dewatering process are still lacking. Most of the studies stay at the laboratory level, which need to be expanded to larger scales in the future. Coupling the FO technology directly with the microalgae culture process to form an osmotic photobioreactor system and thus moving the microalgae dewatering process forward to the microalgae culture process should be a promising research direction in the future. In addition, the optimization of membrane materials and membrane structure still needs to be continuously studied, especially the increasing improvement of ICP-free self-supporting symmetric FO membranes, which will greatly improve the unfavorable status of low dewatering flux of microalgae in FO.

Author Contributions

Writing—original draft preparation, S.Z.; writing—review and editing, W.A.; visualization, R.L., X.Z. and H.G.; Conceptualization, methodology, resources, supervision, project administration, funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [the Natural Science Foundation of Shanghai] grant number [No. 22ZR1443200] and [Projects of International Cooperation Shanghai] grant number [STCSM 23230711300].

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FO | forward osmosis |

| DS | draw solution |

| EPS | extracellular polymers |

| AOMs | algal organic matters |

| EOMs | extracellular organic matters |

| IOMs | intracellular organic matters |

| SAPs | dissolved algal products |

| RSF | reverse salt flux |

| dEOM | dissolved extracellular organic matter |

| bEOM | bound extracellular organic matter |

| sEPS | soluble extracellular polymers |

| bEPS | binding extracellular polymers |

| UF-FO | ultrafiltration-forward osmosis |

| FS | feed solution |

| CP | concentration polarization |

| ECP | external concentration polarization |

| ICP | internal concentration polarization |

| CFD | computational fluid dynamics |

References

- Wang, J.; Hu, X.; Chen, J.; Wang, T.; Huang, X.; Chen, G. The Extraction of β-Carotene from Microalgae for Testing Their Health Benefits. Foods 2022, 11, 502. [Google Scholar] [CrossRef]

- Alavijeh, R.S.; Tabandeh, F.; Tavakoli, O.; Karkhane, A.; Shariati, P. Enzymatic Production of Biodiesel from Microalgal Oil Using Ethyl Acetate as an Acyl Acceptor. J. Oleo Sci. 2015, 64, 69–74. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Chen, H.; Zhou, D.; Luo, G.; Zhang, S.; Chen, J. Macroalgae for Biofuels Production: Progress and Perspectives. Renew. Sustain. Energy Rev. 2015, 47, 427–437. [Google Scholar] [CrossRef]

- Dias, F.G.; Vargas, J.V.C.; Martins, L.S.; Rosa, M.P.; Balmant, W.; Mariano, A.B.; Parise, J.A.R.; Ordonez, J.C.; Kava, V.M. Modeling, Simulation, and Optimization of Hydrogen Production from Microalgae in Compact Photobioreactors. Algal Res. Biomass Biofuels Bioprod. 2023, 71, 103065. [Google Scholar] [CrossRef]

- Jackson, B.A.; Bahri, P.A.; Moheimani, N.R. Repetitive Non-destructive Milking of Hydrocarbons from Botryococcus braunii. Renew. Sustain. Energy Rev. 2017, 79, 1229–1240. [Google Scholar] [CrossRef]

- Lorentz, J.F.; Calijuri, M.L.; Assemany, P.P.; Alves, W.S.; Pereira, O.G. Microalgal Biomass as a Biofertilizer for Pasture Cultivation: Plant Productivity and Chemical Composition. J. Clean. Prod. 2020, 276, 124130. [Google Scholar] [CrossRef]

- Chittora, D.; Meena, M.; Barupal, T.; Swapnil, P.; Sharma, K. Cyanobacteria as a Source of Biofertilizers for Sustainable Agriculture. Biochem. Biophys. Rep. 2020, 22, 100737. [Google Scholar] [CrossRef]

- Laurens, L.M.L.; Markham, J.; Templeton, D.W.; Christensen, E.D.; Van Wychen, S.; Vadelius, E.W.; Chen-Glasser, M.; Dong, T.; Davis, R.; Pienkos, P.T. Development of Algae Biorefinery Concepts for Biofuels and Bioproducts; a Perspective on Process-compatible Products and Their Impact on Cost-reduction. Energy Environ. Sci. 2017, 10, 1716–1738. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from microalgae—A Review of Technologies for Production, Processing, and Extractions of Biofuels and Co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Singh, G.; Patidar, S.K. Microalgae Harvesting Techniques: A review. J. Environ. Manag. 2018, 217, 499–508. [Google Scholar] [CrossRef] [PubMed]

- Bilad, M.R.; Arafat, H.A.; Vankelecom, I.F.J. Membrane Technology in Microalgae Cultivation and Harvesting: A Review. Biotechnol. Adv. 2014, 32, 1283–1300. [Google Scholar] [CrossRef] [PubMed]

- Buckwalter, P.; Embaye, T.; Gormly, S.; Trent, J.D. Dewatering Microalgae by Forward Osmosis. Desalination 2013, 312, 19–22. [Google Scholar] [CrossRef]

- Yazdanabad, S.K.; Samimi, A.; Shokrollahzadeh, S.; Kalhori, D.M.; Moazami, N.; Gonzalez, M.J.I.; Sobuczk, T.M.; Grima, E.M. Microalgae Biomass Dewatering by Forward Osmosis: Review and Critical Challenges. Algal Res. Biomass Biofuels Bioprod. 2021, 56, 102323. [Google Scholar] [CrossRef]

- Honda, R.; Rukapan, W.; Komura, H.; Teraoka, Y.; Noguchi, M.; Hoek, E.M.V. Effects of Membrane Orientation on Fouling Characteristics of Forward Osmosis Membrane in Concentration of Microalgae Culture. Bioresour. Technol. 2015, 197, 429–433. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.K.; Garg, S.; Li, Y.; Malekizadeh, A.; Schenk, P.M. Critical analysis of current Microalgae dewatering techniques. Biofuels 2013, 4, 397–407. [Google Scholar] [CrossRef]

- Ting, C.; Stephen, Y.P.; Yebo, L. Nutrient recovery from wastewater streams by microalgae: Status and prospects. Renew. Sustain. Energy Rev. 2013, 19, 360–369. [Google Scholar] [CrossRef]

- Ki, H.M.; Dong, H.K.; Mi-Ran, K.; Seung, P.P. Recent progress in flocculation, dewatering, and drying technologies for microalgae utilization: Scalable and low-cost harvesting process development. Bioresour. Technol. 2022, 344 Pt B, 126404. [Google Scholar] [CrossRef]

- Lananan, F.; Yunos FH, M.; Nasir, N.M.; Abu Bakar, N.S.; Lam, S.S.; Jusoh, A. Optimization of Biomass Harvesting of Microalgae, Chlorella sp Utilizing Auto-flocculating Microalgae, Ankistrodesmus sp as Bio-flocculant. Int. Biodeterior. Biodegrad. 2016, 113, 391–396. [Google Scholar] [CrossRef]

- Zhou, S.; Shao, Y.; Gao, N.; Deng, Y.; Li, L.; Deng, J.; Tan, C. Characterization of Algal Organic Matters of Microcystis aeruginosa: Biodegradability, DBP Formation and Membrane Fouling Potential. Water Res. 2014, 52, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Guruvaiah, M.; Narra, M.; Dixit, G.; Karawadia, P.; Shah, D. Isolation, Screening and Optimization of Estuary Region (Khambhat, Gujarat) Microalgae for Lipid/Oil Production. Int. J. Appl. Sci. Biotechnol. 2015, 3, 197–201. [Google Scholar] [CrossRef]

- Ma, C.; Huang, J.; Wang, L.; Zhao, B.; Zhang, Z.; Zhang, H. Microalgae Dewatering Using a Hybrid Dead-end/Cross-flow Forward Osmosis System: Influence of Microalgae Properties, Draw Solution Properties, and Hydraulic Conditions. Algal Res. Biomass Biofuels Bioprod. 2020, 48, 101899. [Google Scholar] [CrossRef]

- Rios, S.D.; Salvado, J.; Farriol, X.; Torras, C. Antifouling Microfiltration Strategies to Harvest Microalgae for Biofuel. Bioresour. Technol. 2012, 119, 406–418. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, L.-L.; Wu, Y.-H.; Espinosa VM, D.; Zhang, T.-Y.; Dao, G.-H.; Hu, H.-Y. Soluble Algal Products (SAPs) in Large Scale Cultivation of Microalgae for Biomass/Bioenergy Production: A Review. Renew. Sustain. Energy Rev. 2016, 59, 141–148. [Google Scholar] [CrossRef]

- Zhou, H.; Ji, C.-C.; Li, J.-Q.; Hu, Y.-X.; Xu, X.-H.; An, Y.; Cheng, L.-H. Understanding the Interaction Mechanism of Algal Cells and Soluble Algal Products Foulants in Forward Osmosis Dewatering. J. Membr. Sci. 2021, 620, 118835. [Google Scholar] [CrossRef]

- Ma, C.; Li, Q.; Liu, J.; Bao, H.; Wang, L.; Zhao, B.; Zhang, Z. Forward Osmosis Treatment of Algal-rich Water: Characteristics and Mechanism of Membrane Fouling. J. Hazard. Mater. 2022, 423, 126984. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Wang, G.; Liu, X.; Li, Y.; Huang, J.; Zhang, P.; Chu, X.; Wang, L.; Zhao, B.; Zhang, Z. A Novel Gravity Sedimentation—Forward Osmosis Hybrid Technology for Microalgal Dewatering. Chemosphere 2022, 308, 136300. [Google Scholar] [CrossRef]

- Ji, C.-C.; Chen, K.-Y.; Deng, S.-K.; Wang, J.-X.; Hu, Y.-X.; Xu, X.-H.; Cheng, L.-H. Fouling Evolution of Extracellular Polymeric Substances in Forward Osmosis Based Microalgae Dewatering. Water Res. 2023, 229, 119395. [Google Scholar] [CrossRef] [PubMed]

- Manrique, R.B.; Ubando, A.T.; David, M.Y.; Arboleda, N.B.; Villagracia AR, C.; Chang, J.S.; Chen, W.-H.; Culaba, A.B.J. Dewatering of Nannochloropsis Sp Via Forward Osmosis: A Molecular Dynamics Study. SSRN Electron. J. 2020, 1, 3607811. [Google Scholar] [CrossRef]

- Hafiz, M.A.; Hawari, A.H.; Das, P.; Khan, S.; Altaee, A. Comparison of Dual Stage Ultrafiltration and Hybrid Ultrafiltration-forward Osmosis Process for Harvesting Microalgae (Tetraselmis Sp.). Biomass. Chem. Eng. Process. Process Intensif. 2020, 157, 108112. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, H.; Gao, T.; Teng, J. Impacts of Applied Voltage on Forward Osmosis Process Harvesting Microalgae: Filtration Behaviors and Lipid Extraction Efficiency. Sci. Total Environ. 2021, 773, 145678. [Google Scholar] [CrossRef] [PubMed]

- Ryu, H.; Kim, K.; Cho, H.; Park, E.; Chang, Y.K.; Han, J.-I. Nutrient-driven Forward Osmosis Coupled with Microalgae Cultivation for Energy Efficient Dewatering of Microalgae. Algal Res. Biomass Biofuels Bioprod. 2020, 48, 101880. [Google Scholar] [CrossRef]

- Larronde-Larretche, M.; Jin, X. The Influence of Forward Osmosis Module Configuration on Nutrients Removal and Microalgae Harvesting in Osmotic Photobioreactor. Membranes 2022, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Molitor, H.R.; Schaeffer, A.K.; Schnoor, J.L. Sustainably Cultivating and Harvesting Microalgae through Sedimentation and Forward Osmosis Using Wastes. ACS Omega 2021, 6, 17362–17371. [Google Scholar] [CrossRef] [PubMed]

- Nawi, N.I.M.; Arifin, S.N.H.M.; Hizam, S.M.; Rampun, E.L.A.; Blad, M.R.; Elma, M.; Khan, A.L.; Wibisono, Y.; Jaafar, J. Chlorella vulgaris Broth Harvesting via Standalone Forward Osmosis Using Seawater Draw Solution. Bioresour. Technol. Rep. 2020, 9, 100394. [Google Scholar] [CrossRef]

- Wang, Z.; Lee, Y.-Y.; Scherr, D.; Senger, R.S.; Li, Y.; He, Z. Mitigating Nutrient Accumulation with Microalgal Growth Towards Enhanced Nutrient Removal and Biomass Production in an Osmotic Photobioreactor. Water Res. 2020, 182, 116038. [Google Scholar] [CrossRef]

- Vrasna, D.K.; Goh, P.S.; Ahmad, N.A.; Gonzales, R.R.; Wong, K.C.; Lim, J.W.; Lau, W.J.; Othman, M.H.; Ismail, A.F.; Matsuyama, H. Thin Film Nanocomposite Forward Osmosis Membrane with Exfoliated Layered Double Hydroxide Nanosheets Embedded Support for Fouling-resistant Microalgae Dewatering. J. Water Process Eng. 2024, 58, 104800. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, L.; Zhang, L.; Zhang, X.; Luo, X.; Xu, J.; Wu, D.; Liang, H. Promoting Algae Separation of Forward Osmosis by Peracetic Acid and Chitosan Quaternary Ammonium Salt: Purification Efficiency, Membrane Fouling Alleviation, and Lipid Production. Sep. Purif. Technol. 2025, 359, 130501. [Google Scholar] [CrossRef]

- Al Bazedi, G.; Soliman, N.; Sewilam, H. Biofouling Mechanism and Cleaning Procedures for Spirulina platensis as an Organic Fertilizer Draw Solution. Environ. Sci. Pollut. Res. 2023, 30, 91355–91368. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Bokhary, A.; Maleki, E.; Liao, B. A Review of Membrane Fouling and its Control in Algal-related Membrane Processes. Bioresour. Technol. 2018, 264, 343–358. [Google Scholar] [CrossRef]

- Zainan, N.H.; Srivatsa, S.C.; Li, F.; Bhattacharya, S. Quality of Bio-oil from Catalytic Pyrolysis of Microalgae Chlorella vulgaris. Fuel 2018, 223, 12–19. [Google Scholar] [CrossRef]

- Zhang, Y.; Kong, X.; Wang, Z.; Sun, Y.; Zhu, S.; Li, L.; Lv, P. Optimization of Enzymatic Hydrolysis for Effective Lipid Extraction from Microalgae Scenedesmus sp. Renew. Energy 2018, 125, 1049–1057. [Google Scholar] [CrossRef]

- Ren, J.; McCutcheon, J.R. Polyacrylonitrile Supported Thin Film Composite Hollow Fiber Membranes for Forward Osmosis. Desalination 2015, 372, 67–74. [Google Scholar] [CrossRef]

- Bruggen, B.V.D. Chemical Modification of Polyethersulfone Nanofiltration Membranes: A Review. J. Appl. Polym. Sci. 2009, 114, 630–642. [Google Scholar] [CrossRef]

- Li, G.; Li, X.-M.; He, T.; Jiang, B.; Gao, C. Cellulose Triacetate Forward Osmosis Membranes: Preparation and Characterization. Desalin. Water Treat. 2013, 51, 2656–2665. [Google Scholar] [CrossRef]

- Ghanbari, M.; Emadzadeh, D.; Lau, W.J.; Riazi, H.; Almasi, D.; Ismail, A.F. Minimizing Structural Parameter of Thin Film Composite Forward Osmosis Membranes Using Polysulfone/Halloysite Nanotubes as Membrane Substrates. Desalination 2016, 377, 152–162. [Google Scholar] [CrossRef]

- Liu, X.; Ng, H.Y. Fabrication of Layered Silica-polysulfone Mixed Matrix Substrate Membrane for Enhancing Performance of Thin-film Composite Forward Osmosis Membrane. J. Membr. Sci. 2015, 481, 148–163. [Google Scholar] [CrossRef]

- Salehi, T.M.; Peyravi, M.; Jahanshahi, M.; Lau, W.-J.; Rad, A.S. Impacts of Zeolite Nanoparticles on Substrate Properties of Thin Film Nanocomposite Membranes for Engineered Osmosis. J. Nanopart. Res. 2018, 20, 113. [Google Scholar] [CrossRef]

- Munshi, F. Forward Osmosis for Algae Dewatering and Electric Field-driven Membrane Fouling Mitigation. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, 2019. [Google Scholar]

- Munshi, F.M.; Church, J.; McLean, R.; Maier, N.; Sadmani, A.H.M.A.; Duranceau, S.J.; Lee, W.H. Dewatering Algae Using an Aquaporin-based Polyethersulfone Forward Osmosis Membrane. Sep. Purif. Technol. 2018, 204, 154–161. [Google Scholar] [CrossRef]

- Xu, W.; Chen, Q.; Ge, Q. Recent Advances in Forward Osmosis (FO) Membrane: Chemical Modifications on Membranes for FO Processes. Desalination 2017, 419, 101–116. [Google Scholar] [CrossRef]

- Choi, B.G.; Zhan, M.; Shin, K.; Lee, S.; Hong, S. Pilot-scale Evaluation of FO-RO Osmotic Dilution Process for Treating Wastewater from Coal-fired Power Plant Integrated with Seawater Desalination. J. Membr. Sci. 2017, 540, 78–87. [Google Scholar] [CrossRef]

- Akther, N.; Lin, Y.; Wang, S.; Phuntsho, S.; Fu, Q.; Ghaffour, N.; Matsuyama, H.; Shon, H.K. In Situ Ultrathin Silica Layer Formation on Polyamide Thin-film Composite Membrane Surface for Enhanced Forward Osmosis Performances. J. Membr. Sci. 2021, 620, 118876. [Google Scholar] [CrossRef]

- Huang, R.; Liu, Z.; Yan, B.; Li, Y.; Li, H.; Liu, D.; Wang, P.; Cui, F.; Shi, W. Layer-by-layer Assembly of High Negatively Carged Polycarbonate Membranes with Robust Antifouling Property for Microalgae Harvesting. J. Membr. Sci. 2020, 595, 117488. [Google Scholar] [CrossRef]

- Li, M.; Karanikola, V.; Zhang, X.; Wang, L.; Elimelech, M. A Self-Standing, Support-Free Membrane for Forward Osmosis with No Internal Concentration Polarization. Environ. Sci. Technol. Lett. 2018, 5, 266–271. [Google Scholar] [CrossRef]

- Liang, S.; Wu, J.; Wang, C.; Zhao, X.; Wang, C.; Yang, X.; Huo, H.; Wang, T.; Geng, Z.; Wang, X. Ultra-high Selectivity Self-supporting Symmetric Membrane for Forward Osmosis Separation. Desalination 2022, 534, 115796. [Google Scholar] [CrossRef]

- Zou, S.; Gu, Y.; Xiao, D.; Tang, C.Y. The Role of Physical and Chemical Parameters on Forward Osmosis Membrane Fouling During Algae Separation. J. Membr. Sci. 2011, 366, 356–362. [Google Scholar] [CrossRef]

- Kim, S.-B.; Paudel, S.; Seo, G.T. Forward Osmosis Membrane Filtration for Microalgae Harvesting Cultivated in Sewage Effluent. Environ. Eng. Res. 2015, 20, 99–104. [Google Scholar] [CrossRef]

- Volpin, F.; Yu, H.; Cho, J.; Lee, C.; Phuntsho, S.; Ghaffour, N.; Vrouwenvelder, J.S.; Shon, H.K. Human Urine as a Forward Osmosis Draw Solution for the Application of Microalgae Dewatering. J. Hazard. Mater. 2019, 378, 120724. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.; Law, Y.-M.; Das, S.; Ting, Y.-P. Direct and Complete Phosphorus Recovery from Municipal Wastewater Using a Hybrid Microfiltration-Forward Osmosis Membrane Bioreactor Process with Seawater Brine as Draw Solution. Environ. Sci. Technol. 2015, 49, 6156–6163. [Google Scholar] [CrossRef] [PubMed]

- Mazzuca Sobczuk, T.; Ibanez Gonzalez, M.J.; Molina Grima, E.; Chisti, Y. Forward Osmosis with Waste Glycerol for Concentrating Microalgae Slurries. Algal Res. Biomass Biofuels Bioprod. 2015, 8, 168–173. [Google Scholar] [CrossRef]

- Cui, H.; Zhang, H.; Yu, M.; Yang, F. Performance Evaluation of Electric-responsive Hydrogels as Draw Agent in Forward Osmosis Desalination. Desalination 2018, 426, 118–126. [Google Scholar] [CrossRef]

- Hau Thi, N.; Nguyen Cong, N.; Chen, S.-S.; Wu, S.-Y. Concentrate of Surfactant-based Draw Solutions in Forward Osmosis by Ultrafiltration and Nanofiltration. Water Sci. Technol. Water Supply 2015, 15, 1133–1139. [Google Scholar] [CrossRef]

- Xu, Z.; Song, X.; Xie, M.; Wang, Y.; Huda, N.; Li, G.; Luo, W. Effects of Surfactant Addition to Draw Solution on the Performance of Osmotic Membrane Bioreactor. J. Membr. Sci. 2021, 618, 118634. [Google Scholar] [CrossRef]

- Ma, C.; Yu, H.; Gao, Y.; Xu, W.; Xu, T.; Wang, L.; Zhao, B.; Zhang, Z.; Xu, J. Operation Parameters Optimization of a Hybrid Dead-end/Cross-flow Forward Osmosis System for Microalgae Dewatering by Response Surface Methodology. Process Saf. Environ. Prot. 2020, 143, 14–24. [Google Scholar] [CrossRef]

- Liyanaarachchi, S.; Jegatheesan, V.; Shu, L.; Muthukumaran, S.; Baskaran, K. A Preliminary Study on the Volume Reduction of Pre-treatment Sludge in Seawater Desalination by Forward Osmosis. Desalin. Water Treat. 2014, 52, 556–563. [Google Scholar] [CrossRef]

- Blandin, G.; Rodriguez-Roda, I.; Comas, J. Submerged Osmotic Processes: Design and Operation to Mitigate Mass Transfer Limitations. Membranes 2018, 8, 72. [Google Scholar] [CrossRef] [PubMed]

- Onyshchenko, E.; Blandin, G.; Comas, J.; Dvoretsky, A. Influence of Microalgae Wastewater Treatment Culturing Conditions on Forward Osmosis Concentration Process. Environ. Sci. Pollut. Res. 2020, 27, 1234–1245. [Google Scholar] [CrossRef] [PubMed]

- Manickam, S.S.; Ramon, G.Z.; McCutcheon, J.R. Modeling the Effect of Film-pore Coupled Transport on Composite Forward Osmosis Membrane Performance. J. Membr. Sci. 2017, 523, 533–541. [Google Scholar] [CrossRef]

- Itliong, J.N.; Villagracia, A.R.C.; Moreno, J.L.V.; Rojas, K.I.M.; Bernardo, G.P.O.; David, M.Y.; Manrique, R.B.; Ubando, A.T.; Culaba, A.B.; Padama, A.A.B.; et al. Investigation of Reverse Ionic Diffusion in Forward-osmosis-aided Dewatering of Microalgae: A molecular dynamics study. Bioresour. Technol. 2019, 279, 181–188. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Wang, J.; Ngo, H.H.; Zhang, H.; Bai, R.; Jia, H.; Zhang, X. Numerical and Experimental Investigation on the Forward Osmosis (FO) Process for the Operational Conditions and Spacer Configuration Optimization in Microalgae Dewatering. J. Water Process Eng. 2021, 40, 101922. [Google Scholar] [CrossRef]

- Ryu, H.; Cho, H.; Park, E.; Han, J.-I. Modeling of Forward Osmosis for Microalgae Harvesting. J. Membr. Sci. 2022, 642, 119910. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).