Abstract

Biopolymers obtained from renewable resources are an interesting alternative to conventional polymers obtained from fossil resources, as they are sustainable and environmentally friendly. Poly(lactic acid) (PLA) is a biodegradable aliphatic polyester produced from 100% renewable plant resources and plays a key role in the biopolymer market, and is experiencing ever-increasing use worldwide. Unfortunately, this biopolymer has some usage limitations when compared with traditional polymers; therefore, blending it with other biopolymers, such as poly(butylene succinate) (PBS), poly(butylene succinate-co-butylene adipate) (PBSA), poly(butylene adipate-co-butylene terephthalate) (PBAT) and different poly(hydroxyalkanoates) (PHA), is considered an interesting method to improve it significantly, customize its properties and extend the range of its applications. The following review highlights, in its first part, the physico-chemical and mechanical properties of PLA in comparison to the other biopolymers listed above, highlighting the various drawbacks of PLA. The second part of the review deals with recent developments, results, and perspectives in the field of PLA-based blends.

1. Introduction

The exponential growth in global plastic manufacturing in recent years is a result of the rising world population, and is having a detrimental effect on the natural world and biodiversity [1]. As of 2020, there were 370 million tons of plastic items produced, up from a total of 1.5 million tons in 1950, and predictions show that by 2050, this percentage will have quadrupled [2,3].

Moreover, during the last 150 years, the industrial system has been based on a linear economic model involving the production of manufactured goods from fossil-based raw materials, their commercialization, utilization, and finally disposal as waste through incineration or landfill. As a result of the reduction in natural resources and the arising negative environmental impacts, this model is considered no longer sustainable for the future.

Nowadays, the production of most consumable items occurs using non-biodegradable traditional oil-based polymers, mainly polyolefins (polyethylene (PE), polypropylene (PP), polystyrene (PS)) and terephthalic-based polyesters (polyethylene terephthalate (PET)), leading to their accumulation in landfills or the Earth’s environment [4].

Back in 1970, the concept of the circular economy (CE) was introduced for the first time, as a useful industrial and political tool, for the reevaluation of global growth sustainability, changing the paradigm from a linear model, in which thinking is “produce-use-dispose”, to a new circular logic of “produce-use-reuse-recycle-value-reintegrate” [5].

This CE model involved two different types of recycling: biological and technical. Regarding biological recycling, a material of biological origin is used for anaerobic digestion, leading to benefits for the natural ecosystem. Hence, this organic material is considered a renewable resource to support the economy because this type of recycling leads to the regeneration of natural habitat characteristics of, for example, soil or marine environments. Instead, technical recycling allows the recovery of the material or product by exploiting strategies of reuse or repair until recycling is achieved [6]. The goal of this recycling type is to decrease the amount of plastic waste using destructive thermal treatment, such as combustion or pyrolysis [7].

The increasing use of polymeric materials in a wide range of industries makes it reasonable to develop an assessment to the life cycle of plastic products. Life cycle assessment (LCA) is one of the widely recognized and currently commercially available tools for assessing environmental impacts associated with all the stages of the life cycle of a commercial product [8,9]. It is based on a methodology governed by international standard 14040 and 14044 [10,11] and allows for quantifying and qualifying the relevant environmental impacts associated with the life cycle of a manufactured product, starting from preparing resources to obtain raw materials to the disposal of the manufactured product itself, through its processing, transportation, manufacturing, and end use. This review [12] reports on the large body of work analyzed to demonstrate that LCA is an important tool for evaluating how a preventive activity can reduce the environmental impact of such materials, and looks at the multiple perspectives that LCA can offer to different sectors (food packaging, agriculture, construction sector, and the automotive sector).

Also, from the perspective of sustainability, it is essential to conduct a life cycle cost analysis (LCC) with a life cycle impact assessment (LCIA). This is essential for building a techno-eco-efficient framework for comparing technical properties, environmental impacts and costs and making sure to maximize the utility and value of waste plastics in industrial applications. In the work of Jayawardane et al. [13], an LCIA and LCC evaluation was performed by comparing an artifact made by 3D printing from a PLA filament from virgin raw material and a filament derived from 100% recycled PLA. It was seen that the mechanical properties, density and hardness decreased dramatically with the content of fully recycled material compared to the virgin material. However, the manufactured product obtained from the fully recycled PLA was more eco-efficient. In this study, the evaluation of techno-eco-efficiency was limited to the PLA biopolymer, but this evaluation can be performed on all polymers and blend in future research and applications.

In this context, bioplastic materials have gained great interest in the plastic industry, with the resulting increment in the use of bioplastics derived from renewable sources leading to the reduction in plastic wasted in landfills, and promoting the use of renewable resources derived from agri-food scraps, which contributes to reducing the depletion of fossil resources to obtain plastic materials [14,15,16,17].

To clarify the meaning of biopolymer, the European Bioplastic Associations definition considers [18] as biopolymers both macromolecules synthesized starting from at least one monomer originating from sustainable resources and polymers that are biodegradable regardless of the origin of its raw materials [19].

In recent decades, biodegradable polymers, which can be based on either petroleum or renewable resources, are gaining attention as interesting alternatives, since through microbial degradation it is possible to reduce them into simple molecules, such as carbon dioxide (CO2), methane (CH4), water (H2O), biomass, and minerals [20]. The implementation of these new materials means that the CE model, if carefully applied, can be efficient at increasing resource efficiency, decreasing depletable or fossil raw materials, and minimizing the release of harmful substances into the environment [21].

Based on socio-economic pathways, it is necessary to formulate reduction strategies and implement policies to raise global awareness of greenhouse gas (GHG) emissions, as they are detrimental to air quality and ozone layer depletion. The Intergovernmental Panel on Climate Change in 2018 published a report proposing to limit global warming to 1.5 °C in order to avoid a range of global climate change impacts [22]. Unfortunately, GHG emissions occur at every stage of the life of plastics, including the extraction and transport of raw materials, plastic production, waste treatment and release into the environment [23]. Currently, recycling, incineration and landfill are used to manage most fossil-derived plastic waste. Data shown by Plastic Europe [24] state that the largest emissions from the incineration of plastic packaging waste were estimated at 16 million tons in 2015 and that this continued production of plastics will lead to an increase of 84 and 309 million tons by 2030 and 2050, respectively. According to the Intergovernmental Panel on Climate Change (IPCC) Working Group I [25], concentrations of CO2, CH4 and N2O have increased by 41%, 160% and 20%, respectively, since the Great Industrial Revolution, causing serious environmental imbalance problems. The GHGs released can have a negative impact on “carbon fixation” as they adversely affect the photosynthesis process carried out by “phytoplankton”, adversely affecting the natural habitat [26]. For this reason, the introduction of biobased and bio-degradable polymers, mostly of natural origin (deriving from agri-food or bacterial production waste) is essential, as they can reduce the impact of the global carbon footprint, reduce the transport of raw materials, and cancel the extraction process, as well as having a much shorter biodegradation time than conventional polymers and therefore lower GHG emissions. Indeed, if we think of the agricultural field, mulch films are frequently used for cultivation in the soil. According to a review by Somanathan et al. [27], several studies have shown that use of biodegradable polymers to make mulch films lead to rapid decomposition of the film, protection of the agricultural soil from both biotic and abiotic factors, increased yields, increased nutritional values to the soil, and maintenance of the bacterial population in the soil without polluting it.

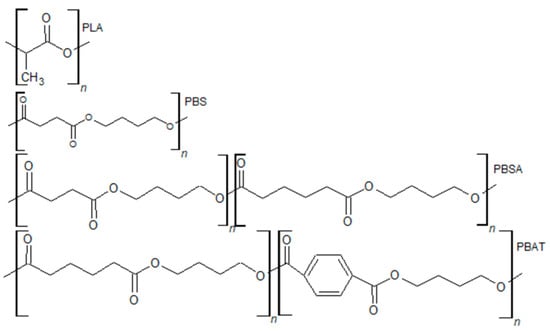

Regarding biodegradable polymers, one of the most studied classes is aliphatic polyesters, due to their wide variety of properties and synthetic versatility. In this class, poly(lactic acid) (PLA), poly(butylene-succinate) (PBS), poly(butylene-succinate-co-adipate) (PBSA), and poly(butylene adipate-co-terephthalate) (PBAT) are included (Figure 1). Lately, an emerging class of biopolymers of great interest is bacterial-origin polymers such as the poly(hydroxy alkanoates) (PHAs) (Figure 2).

Figure 1.

Biodegradable aliphatic polyesters structures.

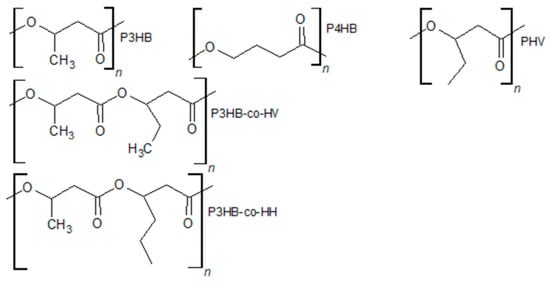

Figure 2.

Different PHA structures.

In this case, the polymers are prepared directly from biomass exploitation, for example, genetically modified microorganisms. PHAs are produced directly through fermentation of the carbon-containing substrate within the microorganism cells. The type of biomass used as an energy source depends on the microorganisms employed. For instance, it is well established in the literature that for E. coli, lipids and polysaccharides are generally used, while for R. eutropha, glucose is used as a carbon source [28]. PHA accumulates in granule form within the cell cytoplasm, acting as an energy reserve for the cell.

The issue with these biopolymers is that, when used alone as structural materials, they fail to meet the requirements of traditional polymers such as PP, PE, or PET.

Polymer blends are widely used in industry since they allow combining the properties of its components into a new material, without the need to design and develop a new polymer, which would be much more expensive and time consuming. Thus, by modifying the composition of blends, materials with properties suitable for various applications can be obtained [29,30].

As the preparation of sustainable PLA blends has been achieved in the last decade with significant results, detailed information on PLA blends with other biopolymers has been specifically summarized and analyzed. Therefore, this review is focused on the current developments in PLA blends produced by polymer blending methods. Different biopolymers commercially available today used in PLA blending are also discussed and systematically organized: PBS, PBAT, PBSA, PHA, Bio-PE and EVA. The aim is to provide as up-to-date a picture as possible of the different PLA-based blends currently accessible in the agri-food industrial packaging sector, highlighting their strengths and main critical issues.

2. Packaging Application of PLA and Its Blends

Most of the plastic packaging and containers are made with polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), polyamides (PA) and polyvinyl chloride (PVC), derived from non-renewable and non-biodegradable petrochemical sources. In recent years, global plastic production has reached about 400 million tons per year and this represents an important source of waste [31]. More than 50% of this plastic packaging is used only one time before disposal [32]. Moreover, many traditional polymers are used to make multilayer, laminated, and mixed packaging in which aluminum foil or silica is inserted in the middle layer to improve barrier properties. At their end of life, only a small fraction of this waste is recycled as the multilayer separation process is expensive and a large part of plastic waste, especially from the food packaging sector, is disposed of in landfills. Furthermore, foodstuffs often contaminate the plastic containers, making their reuse or recycling process even less economically convenient and creating large quantities of waste at the end of its life, without energy and material recovery [33,34,35].

Currently, many biobased but non-biodegradable polymers are used in flexible and rigid packaging (e.g., bags and bottles) and are synthesized from renewable resources, such as Bio-PE, biopropylene (Bio-PP) or biopolyethylene terephthalate (Bio-PET) [36,37,38]. They have a greater application in the food industry than biodegradable and compostable biopolymers as they have the same properties and processing methods as conventional polymers and are therefore well known to the industry [39]. The problem with these bioplastics is that, even if they are derived from renewable resources, they are not biodegradable and therefore do not best meet the requirements of a sustainable circular economy. When considering the applications of short-life packaging (fruit, vegetables, and salad containers), disposable packaging for fresh food and ready meals and hygiene products, which do not require high barriers, these biobased but non-biodegradable bioplastics (Bio-PE, Bio-PP and Bio-PET) pose a major problem of management and disposal as they are used in large quantities in everyday life. One solution regarding the production of single-use and short-life packaging that is also eco-friendly are biodegradable and compostable bioplastics, which can play a crucial role in and have great potential for production from flexible films to rigid plastics, as they combine a renewable origin and the prerequisite of biodegradable end-of-life due to their susceptibility to microbial attack [40,41]. In food and non-food packaging applications, the most widely used biopolymers are PLA, PBS, PBSA, and PBAT, as well as the newly emerging class of PHAs.

The function of food packaging is not only to contain the food but also to protect it throughout its supply chain (from the place of production to the table) from external abiotic and biotic agents by preventing chemical or microbiological contamination that can cause adulteration, as well as to increase shelf life [42,43,44]. This has generated the need in the food industry to develop new packaging systems to maintain both the safety and quality of packaged food [45].

The essential prerogatives that packaging needs vary according to different applications and uses. Among the most common properties are barriers to gases (CO2, N2, O2, or volatile compounds) and moisture, useful mechanical properties (flexible or rigid), sealing and thermo-perforation, processability and heat stability, transparency or opacity depending on the application, anti-fog, printability, and resistance to light, acids and grease, and, as the last but not the least important factor, the cost [46,47]. The changes in mechanical properties will be covered in the review, so we will also mention the other prerogatives to emphasize the importance they have for an application.

As is well known, PLA has several benefits for these applications, as it is easy to process, transparent, has a high disintegration rate in compost, is nontoxic, and inexpensive, and has therefore been approved as a direct food contact material, and is currently being used to produce packaging for short-term applications. In addition, this biopolymer is in demand for a wide range of industries such as agricultural, medical, and pharmaceutical (e.g., drug delivery).

Studies have reported that currently PLA and the rest of the biopolymers are used more for packaging short-life products that do not require a high barrier to gases and water vapor. PLA has a low heat deflection temperature, which is an excellent prerequisite for making food packages stored in freezers under refrigerated conditions [48]. Due to this property of PLA, there is no deformation of the packaging, which is why currently PLA is also used to produce thermoformed trays and to transport fruits and organic products in a refrigerated condition.

However, this represents a limitation if one wants to broaden the range of applications in food packaging because, as explained, PLA has several problems compared to conventional polymers derived from oil resources that make it non-performing in several applications. As previously described, this biopolymer is characterized by low thermal, mechanical and gas barrier properties that are essential for food packaging to ensure its safety and preservation [49].

Therefore, an efficient and cost-effective solution to achieve desirable properties for films and packaging materials is blending with other biodegradable polymers, as it represents a valid strategy to increase and modulate their desired properties. More complex multilayer systems are still used on the market today, but they are largely made of conventional polymers, which pose a recycling and disposal problem [50]. The realization of a multilayer material consisting of only biodegradable or compostable biopolymers by means of an eco-friendly processing technology can lead to significant improvements not only in the final properties but also of the disposal benefits if the domestic compostability prerequisite is achieved, contributing to solve the problem of waste accumulation in landfills [51].

When considering barrier properties, an essential prerequisite for a food packaging material, it is known that most biodegradable biopolymers have lower moisture barrier properties than conventional plastics due to their chemical structure, but unlike them they exhibit similar oxygen barrier properties [52]. Therefore, the first applications to which this class of biopolymers is referred are food and short-life products. PLA exhibits low crystallinity and thus poor gas barrier properties [53], except for a lower oxygen transmission rate (OTR) than PET and PS [54]. If we think of moisture-sensitive products such as biscuits and bakery products, it is impossible to apply PLA-only packaging in this case [55]. Various methods are exploited in industry to improve the barrier properties of PLA, such as lamination with barrier materials, such as PP, PE and EVOH [55,56], or coating with silica dioxide (SiOx) and aluminum dioxide (AlOx) [56,57].

NatureWorks in collaboration with Metalvuoto have produced the first flexible, high-barrier PLA-based material that can be used for long-life foodstuffs. As a result, much academic and industrial effort has been put into increasing the crystallinity of PLA and making the material as eco-friendly as possible. Among the PHAs, PHB and PHBV have high crystallinity and thus good barrier properties towards O2, CO2 and moisture, similar to PE or PP [58,59,60]. Therefore, fusion with the PLA matrix can provide good gas barrier performance as well as adjusting its physical properties [61,62,63,64]. Furthermore, the production of PHAs is very expensive due to the fermentation and purification processes, so blending them with PLA can also lead to cost benefits [65,66]. From the point of view of barrier properties, Luzi et al. [67] formulated different mixtures of PLA/PBS (10, 20 and 30 wt%) to which cellulose nanocrystals (CNC) were added. The combination of both with PLA resulted in improved oxygen barrier properties, and the formulation with 77PLA/20PBS/3CNC was the best formulation, as it exhibited a 47% decrease in oxygen permeability. Furthermore, the migration levels of all composites produced were below European legislative limits and, therefore, they are useful as food packaging materials.

Still in the area of food packaging for active packaging in direct contact with food, Songtipya et al. [68] studied different PLA/PBAT formulations for packaging and containers in direct contact with ground coffee and tea leaves. The study showed that the total migration values were below the maximum migration limit (10 mg/dm2) imposed by European Union (EU) regulations. Therefore, these PLA- and PBAT-based materials may have a positive effect on food safety.

Hongsriphan and Sanga [69], after producing a PLA/PBS blend (90/10 wt%), developed an antibacterial food packaging towards E. coli and S. aureus by coating the PLA/PBS film with chitosan. It was observed that as the concentration of chitosan on the surface increased, from 0.25 to 2% w/v, bacterial growth decreased. The chitosan coating also decreased water vapor transmission rates compared to normal mixtures. This favorable phenomenon is due to the formation of intermolecular interactions between the chitosan and the polymer matrix.

The literature shows that biopolymers belonging to the PHA family were initially used for applications in cosmetics and articles for everyday use (such as vials, bottles, and containers) [70,71]. Today, they are also proposed for applications in short-term food packaging [59,72,73,74], medical devices and tissue regeneration, household goods, hygiene products and compostable bags due to their mechanical properties, biocompatibility, and biodegradability [75,76,77].

Food manufacturers such as Nestlé (Vevey, Switzerland) and PepsiCo (New York, NY, USA), in collaboration with Danimer Scientific (Bainbridge, NY, USA) and Kaneca (Tokyo, Japan) (leading manufacturers of biodegradable plastics), have developed PHA-based water bottles and flexible packaging for their snacks [78,79]. Concerning PepsiCo, the goal was to make the final artefact home-compostable by adding PHA to PLA and to improve certain properties, such as the sound of a bag of chips when opened. The Taghleef Industries company (Dubai, United Arab Emirates) is involved in the production of PLA-based films: for example the NATIVIA portfolio of PLA films is in the market for different packaging applications, like bread bags, coffee capsules, frozen food, labels, fashion and luxury products, and so on. But in recent years it has been collaborating with leading biopolymer manufacturers to make PLA-based films mixed with different biopolymers, and thus make the film home compostable rather than industrially compostable [80]. Also, in 2019 Danimer Scientific collaborated with UrthPact (Leominster, MA, USA) to produce edible straws using the biopolymer NodaxTM. In addition, PHAs are also used to produce waste bags in which PHA film is laminated with paper and other polymers such as PVC [77].

The company Rivoira (a fruit producer and distributor, Verzuolo, Italy) in cooperation with Bio-On (Bologna, Italy) have created the company Zeropack (Bologna, Italy) to produce 100% natural and biodegradable PHA-based films, containers, and holders for fruit and labels [81].

As reported by the authors of [51,82], mixing PLA with PHB at 25 wt% resulted in an improvement in the oxygen and water barrier properties of a film, while at the same time reducing the transparency of the final film (an intrinsic property of PLA).

The appearance and quality of the final packaging is a second essential prerequisite that can influence the buyer of a product during purchase, as it is essential to see through the packaging [47,49]. Since PLA is transparent, it is used as a single-layer packaging film, as biaxially oriented PLA (BOPLA) or in laminated films (barrier films) [55].

Another essential prerequisite is the cost of the final product. Regarding rigid packaging, PLA and PHA are stiffer than PS and therefore less plastic material would be required to produce the final manufactured product with the same stiffness, thus resulting in a lower final price [83].

In the agricultural sector, mulching is a widely used practice worldwide to maximize plant growth, allow water retention, regulate soil temperature, and protect agricultural soil from weeds. Normally, mulching films are made of PE and this has caused serious environmental problems as they are difficult to recycle and dispose of. This is why farmers prefer to leave the films in the fields and then burn them [84]. This procedure leads to negative effects that affect both crop growth, the environment and soil, as the accumulation of these films leads to a reduction in soil porosity as well as groundwater pollution [85]. Since biopolymers are non-toxic, biodegradable, and compostable, they are promising materials for mulching films as they can be degraded [86,87] and catabolized by the soil microbiota at their end of life [88]. Therefore, mulching films based on PHBH (NodaxTM) and PHB (MirelTM) have been produced [89,90]. In the work of Gao et al. [91], they produced mulching films based on PLA mixed with PBAT and directly field-tested these films on potato growth over a two-year period. They evaluated the effects on soil temperature dynamics and water retention and saw that crop yields did not change compared to the use of a PE-based film. They also evaluated the effects of the films during degradation in agricultural soils and the authors are very confident on the application of these films because in addition to improved crop yields, porosity and soil health also improved. BASF is promoting a PLA/PBAT blend, called Ecovio, for agricultural films [48].

In the work of Jandas et al. [92], they obtained mulching films by blending PLA with PHB and using maleic anhydride as a compatibilizer to improve polymer interaction. The addition of PHB to PLA not only improved the flexibility and impact strength of PLA, but also decreased the degradation time of PLA. Therefore, applied tests suggested that this type of film can be applied for short-term harvests (100–150 days).

Furthermore, PHA is biodegradable in water, which is why Havens et al. [93] patented a fishing gear made partly of PHA that can biodegrade in a marine environment.

In the biomedical field, these biopolymers and their blends have been extensively studied in various applications such as bone scaffolds and implants [94], sutures, drug delivery systems [95,96,97,98] and in tissue engineering [99,100,101]. This is due to their excellent properties such as biocompatibility, bioresorbability, biodegradability and non-toxicity. For example, polymer scaffolds provide sites for regeneration and functional restoration of tissues and for drug delivery. They require specific characteristics depending on the application and the tissue of interest. The key point of these biopolymer scaffolds is that once they have performed their restorative or structural function they biodegrade, eliminating the need for patient surgery [102]. By means of FDM printing and electrospinning, it is possible to produce different types of porous scaffolds useful for tissue regeneration due to the presence of pores that allow the transport of nutrients, oxygen and growth factors [103,104,105,106]. PLA has been blended with PHB to enhance its bioactivity and cell proliferation for medical use such as artificial muscles, wound dressings or drug delivery systems.

An important field of application for PLA-based blends is that of intelligent materials capable of responding to different stimuli. With PLA/PHB blends, a system called ‘non-woven fabric’, that showed a controllable, thermally induced shape memory effect, is realized [107]. He et al. [108] formulated various PLA/PHBH and PLA/PHBV blends for the fabrication of medical sutures. Their results showed that these blends can be used as medical sutures as they had high tensile strength, good elasticity, and biocompatibility.

3. PLA

In this regard, PLA or polylactide, a thermoplastic aliphatic polyester, is the most widespread and used among biopolymers, mainly made using the same bacterial fermentation that exploits sugar beet, corn, potatoes and other agricultural production wastes as a nutrient supply for lactic acid bacteria [109,110]. The phylum Firmicutes contains roughly twenty genera of lactic acid-producing bacteria, according to Reddy et al. [111]. Among them, the most important genus of lactic acid-producing bacteria is Lactobacillus, which has about 80 species and includes Lactobacillus casie, Lactobacillus bavaricus, Lactobacillus maltoromicus, and Lactobacillus salivarius [112]. At the same time, D-lactic acid and a combination of the two stereoisomers are produced by strains of Lactobacillus delbrueckii, Lactobacillus jensenii, and Lactobacillus acidophilus [113].

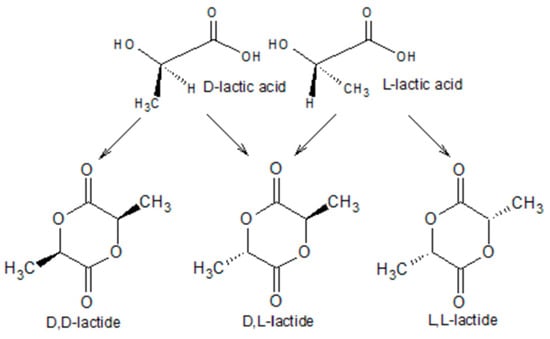

PLA can be obtained industrially by the polycondensation of D- or L-lactic acid (2-hydroxypropionic acid) or by the polymerization of lactide (the cyclic dimer of lactic acid) upon the ring-opening reaction [113,114,115]. Lactic acid, presenting a chiral center, comes in the form of two enantiomers, L-lactic acid (LLA) and D-lactic acid (DLA) (Figure 3). From the latter, it is possible to obtain two optically active cyclic stereoisomers (D,D-lactide and L,L-lactide) or two optically inactive stereoisomers (meso-lactide and the racemic mixture of LLA and DLA called rac-lactide).

Figure 3.

The enantiomers L-lactic acid and D-lactic acid, from which to obtain the two optically active stereoisomers (D,D-lactide ad L,L-lactide) or two optically inactive stereoisomers (D,L-lactide).

The presence of chiral centers within the PLA biopolymer is of considerable importance, as it determines distinct polymer properties. Indeed, PLA biopolymers containing more than 90% of LLA tend to be semi-crystalline. On the other hand, increasing the concentration of the DLA stereoisomer tends to result in more amorphous PLA biopolymers. In addition, the increase in the DLA content results in a decrease in the melting (Tm) and glass transition (Tg) temperatures of PLA, and this is critical when a low activation temperature is required, as in the case of heat-sealable layers that make use of amorphous polymers [113].

This variety of structures highlights the importance of the choice of the PLA biopolymer matrix as it is reflected in the performance of the blends and its properties.

At present, PLA shows attractive mechanical properties that can be even superior to those of PET, PP and PE, with renewability, biodegradability, biocompatibility, a relatively low cost, and transparency [116]. Furthermore, a pure PLA polymer has a lower glass transition temperature (55–65 °C) than other fossil-based polymers, resulting in less energy (and subsequently processing costs) to transform and mold PLA. For this reason, PLA is one of the most abundant biopolymers on the market. Transparent bottles, food containers and wrappers can be produced using PLA, which is at the same time transparent, biodegradable and compostable. Furthermore, PLA is widely used for food service items, grocery bags and food waste, and coatings for paper and cardboard. In the biomedical field, it is used for sutures, prostheses, dialysis media and drug delivery devices [117]. This is due to its biocompatibility and safe degradation process. Once in contact with biological media, the polymer triggers an immune response as it is recognized as a “foreign body” [118,119]. The cells of the immune system (macrophages, neutrophils, and fibroblasts), by the secretion of enzymes, (such as acid phosphatase and lactate dehydrogenase) degrade the polymer matrix into lactic acid (LA) (a naturally occurring product and metabolic precursor of pyruvate in the Cori cycle) [120] or into carbon dioxide and water [121,122,123]. These products are subsequently metabolized intracellularly or excreted in the urine and airways.

These numerous applications are available because PLA can be processed using traditional and innovative transformation technologies used for processing plastic materials, respectively, extrusion (conventional, cast and blow film), injection molding, thermoforming, and additive manufacturing, such as fused deposition modeling [124,125,126,127].

Despite this, PLA suffer from major drawbacks. In fact, commercially available PLA has many inherent weaknesses, notably its brittleness, poor toughness, and low heat and impact resistance, which prevent its use for durable applications [128,129,130]. More importantly, PLA has a narrow processing window and a very slow crystallization rate that results in poor processability in the molten state [19,131,132,133]. Furthermore, another critical issue of bioplastics, which also affects PLA although to a lesser extent, is the higher cost of bioplastics compared to standard polymers, which limits the expansion of their market. Polymers of biological origin have a production cost that in many circumstances is 20% to 100% higher than conventional polymers. This is mainly due to the high costs of polymerization of polymers of biological origin, attributable to the fact that most technologies are still in the early stages of development and therefore have not yet achieved fully industrial production.

PLA is primarily degraded by hydrolysis through a two-step process. First, random chain cleavage of PLA’s ester groups reduces its molecular weight. The rate of chain cleavage depends on the pH value, temperature, and humidity levels of the environment [134]. Polymer embrittlement occurs as the molecular weight decreases. Secondly, microorganisms metabolize low-molecular-weight PLA, producing CO2, H2O, and humus [135]. Typically, a high rate and degree of crystallization is an important parameter because it enables applications where high mechanical performance is required. The degree of crystallization and thermal properties of PLA are influenced by its molecular weight (Mw), polymerization parameters and circumstances, as well as by its purity. In addition, the different lactide isomers can significantly influence Mw, Tg, Tm, the crystallization temperature (Tc) and the enthalpy of crystallization. In addition, PLA also has in general a relatively low Tg (55–65 °C), which can be a disadvantage for hot packing applications in which PS and PMMA are usually used. Moreover, it is essential to control the PLA degradation rate, mechanical and thermal properties as well as gas barrier properties, considering that for PLA, a lower permeability coefficient is reported if compared to PET.

To overcome these shortcomings regarding PLA, it is interesting to consider binary and ternary blends with other biodegradable polymers, including PBS, PBSA, and polymers of the PHA family, such as polyhydroxy butyrate (PHB), polyhydroxy valerate (PHV) and their co-polymers, which will be discussed later.

4. PBS

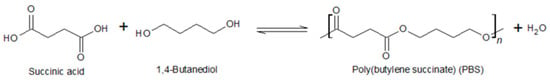

A biobased, biodegradable, and compostable material could be obtained by mixing PLA and PBS. This biopolymer has similar properties to PE and PP. PBS is a biodegradable aliphatic polyester that can be composted in accordance with ISO EN13432 [136] and is made through the polymerization of 1,4 butanediol (BDO) and succinic acid (SA) in a step-by-step process (Figure 4).

Figure 4.

Condensation reaction to obtain PBS.

The monomers are usually obtained from fossil-based raw materials (mainly maleic anhydride) as well as various biological sources [137,138,139], the latter providing improved sustainability. SA can be obtained using microbial fermentation or genetically modified yeasts that take advantage of different carbon sources, such as different carbohydrates (starch, cellulose, sucrose, etc.) [140,141,142,143,144,145]. These carbon sources can be obtained from potatoes, sugar beets, corn, wheat, lignin–cellulose [146,147]. In addition, glycerol has been seen to be an alternative route as a carbon source [148]. As far as BDO is concerned, since it is not present in nature, a green method has been developed by engineering Escherichia coli, using carbon sources derived from biomass [149,150].

PBS exhibits high flexibility, good thermal resistance, and chemical and physical stability, resulting in high compatibility with conventional processing techniques [117,151,152,153,154]. Its physical properties and biodegradation rate are strongly influenced by its molecular weight [155]. Details about the physical, chemical, and mechanical properties, as well as biodegradability of PBS have been the subject of several reviews [156,157,158].

PBS exhibits a Tm of around 100–115 °C, lower than PLA, estimated between 170–180 °C. The low Tm of PBS suggests that less energy is required for processing the melt. Furthermore, PBS has a high heat deflection temperature (HDT = 90–95 °C) compared to PLA, which has an HDT of 50–55 °C, and, therefore, PBS can be used in addition to contact with food (e.g., packaging material), and with hot liquid and solid aliments. The combination of its low melting temperature and its high thermal stability, greater than 300 °C, leads to the excellent processing properties of this biopolymer [151,153]. Tc of PBS ranges between 70 and 90 °C, while its Tg can be observed between −40 and −10 °C, depending on the supplier and the methods of fabrication [117,152].

Regarding the mechanical properties for PBS, an elastic modulus (E) of 300–350 MPa and elongation at break (ε) as a percentage, which can reach up to 650%, are observed. Its flexural modulus values have been measured around 650 MPa and its flexural strength about 40 MPa, although lower values have also been reported in the literature [159,160]. Its impact strength values have been recorded between 5 and 20 kJ/m2 [161], compared to the 1.5–2.5 kJ/m2 of PLA. These properties of PBS can go a long way in improving the poor brittleness, toughness, and ductility of PLA. Moreover, PBS is significantly more ductile than PLA, PHA, PHB, and PHV when the Mw is above 1.8 × 105 g/mol [158]. In fact, an Mw below 105 g/mol results in a polymer that is brittle and would not improve the properties of PLA. A higher molecular weight leads to a PBS with excellent properties, which can be easily processed through injection and extrusion techniques [158].

Some alternatives to improve the performance of PBS involves the use of bio-sourced plant fibers. Non-lignified fibers (flax and hemp) have been shown to exhibit higher interfacial forces with the PBS matrix [162], highlighting that the use of natural plant fibers can significantly not only improve the properties of PBS, but that this concept can be extended to other biopolymers such as PLA. The properties of fillers, such as polarity, particle size and water content, influence the final properties of the biocomposite material, as well as the quality of the interface between the matrix and filler and its processing. Therefore, in this same context, the use of plant fibers can affect the extrusion process depending on the polarity of the biopolymer matrix. Therefore, there is a trade-off between the improvement in the performance of the polymer’s properties and its subsequent processing using conventional techniques when bio-sourced plant fibers are embedded into the polymer matrix [163].

PLA/PBS Blends

Before describing the effects of different biopolymers mixed with PLA, it might be pertinent to remember that depending on how compatible the components are, polymer blends can be divided into either miscible or immiscible systems [164]. The compatibility between the components of the blend prevents the phase separation and, therefore, improves the performances of the resulting blend. The molecular interactions between the components of the blend are influenced by the Mw of the polymer chains, which in turn impacts their miscibility. When components in a miscible binary mixture are completely dissolved in each other, this results in a homogenous morphology at the nanoscale, which results in obtaining a mixture with improved properties compared to pure components [165,166,167]. On the other hand, if immiscible mixtures are produced, they exhibit a coarse morphology that is unevenly dispersed throughout the polymer matrix, commonly known as “droplet morphology”, and have weak interfacial adhesion. In this instance, the dispersed polymer phase often consists of spherical droplets with holes or spaces between them and the surrounding matrix. Therefore, in these situations, it is crucial to alter the interfacial characteristics of these mixes in order to have a reduction in interfacial tension and lower degrees of coalescence in order to have good final qualities.

For example, PBS with PLA can be miscible and/or partially miscible when used at low concentrations (5–20%), and in this case, PBS can assume the role of the plasticizing agent within the PLA polymer matrix [168,169,170,171]. Meanwhile, if PBS is used at high concentrations (20–40%), phase separation is observed and, thus, the blend performance drops compared to the pristine polymers [165].

There is some confusion in the literature regarding miscibility between the two polymers. PBS and PLA polymers were shown to be immiscible when PBS was over 20 wt% in the work of Bathia et al. [172], and when increasing the amount of PBS, phase separation took place. In addition, the average diameter of PBS domains was seen to increase when increasing the amount of PBS. Above the 50/50 wt% (PLA/PBS) mixture, the morphology reverses: when the concentration of PLA is below 50 wt%, PLA becomes the dispersed phase in PBS. The same immiscible behavior has been observed for PLA blends with PBSA by Lee and Lee [173].

According to the findings of Hassan et al. [168], PBS and PLA are only partially miscible when the PBS content is ≤10 wt%. This conclusion was supported by Jompang et al. [169], who used a SEM to examine the surface morphology of PBS/PLA blends. There are studies that, however, presume the immiscibility of PBS and PLA independent of the weight ratio, such as that of Yokohara and Yamaguchi [174].

To study PLA/PBS blends, Deng and Thomas [170] varied the PBS content between 0 and 100 wt%. According to reports, the degree of crystallinity in two different phases has increased as a result of a larger PBS concentration, but PLA has remained completely amorphous. Additionally, a continuous phase PLA-PBS with PBS contents between 10 and 40 wt% was disclosed [170]. This structure improved the elongation at break, increasing it in the range 270–340%.

PLA-PBS mixtures frequently show different mechanical properties. Ostrowska et al. [175] studied PLA/PBS blends with different concentrations. The mechanical properties of the blends were an average compared with the properties of pure polymers in the different phases.

In some cases, the reported results were higher for the mixture than for both individual components. In addition, previous studies indicate that PBS allows improvement of the thermal, mechanical, and biodegradation properties of PLA; in particular, the resulting blends appear to show a faster biodegradability [166,176].

Hassan et al. [168] confirmed that PBS/PLA blends were significantly more flexible than PLA, with the elongation at break reaching the value of 30% with a 40 wt% PBS content. However, Bhatia et al. [172] did not measure any increase in the ductility until reaching an amount of PBS up to 90%.

It is well recognized in the literature that stress may be transmitted from one component to another through the formation of “bridges” between polymer chains as a result of chemical or physical interactions, which can improve the properties of a polymer blend. This is possible through the use of a co-polymer (e.g., PLA-PBS) [177,178] and/or some compatibilizing agents such as fatty acids (lauric, palmitic and stearic acid) [179], maleic anhydride (MAH), acetyl tri-n-butyl citrate (ATBC) [180], isosorbide diester (IDE) [181], lysine tri-isocyanate (LTI), polyaryl-polymethylen-isocyanate (PAPI) [182], or triphenyl phosphite (TPP) [183]. The use of isocyanate as a reactive processing agent allowed the fabrication of a 10/90 wt% PBS/PLA blend with an up-to-four-fold improvement in impact strength over pure PLA [171]. In particular, reactive processing is a widely used compatibility strategy for the economic production of new polymer blends. During the processing of these polymeric materials, the high extrusion temperatures allow the reaction between the hydroxyl moieties of polymer and the isocyanate groups of the compatibilizer. The formation of more urethane bonds creates new cross-linking in the final blend.

Dicumyl peroxide (DCP), which was used by Ji et al. to study the compatibility of PLA/PBS blends, enabled the creation of PLA-co-PBS copolymers in the melt phase between the different polymer chains [184,185].

Bifunctional chemicals can, therefore, be used to improve interactions between blended polymers containing hydroxyl, carboxyl or amine functional groups, generating block copolymer structures at the interface of the two immiscible polymer chains. These chemicals include diacids, dibases hydroxy-acids or amino-acids.

As an example, applying two different types of compatibilizers such as the toluene di-isocyanate (TDI) and maleic anhydride-functionalized polylactide (MA-g-PLA), and two plasticizers such as the triethyl citrate (TEC) and tricresyl phosphate (TRP), Phetwarotai et al. [186] compatibilized PLA-PBS blends.

Some compatibilizers, such as ATBC and polyester adipate (PEA), can also be used as plasticizers. For example, introducing ATBC and IDE to PLA/PBS blends (PBS 20 wt%) allowed Fortunati et al. to study the plasticization of the mixtures [181]. It was demonstrated that ATBC is effective at plasticizing PLA (due to extremely comparable solubility parameters), but it is incompatible with PBS to the point ATBC levels of 30 wt% render PBS processing impossible. Despite having a different solubility parameter, IDE is also more effective on PLA, as shown by the decrease in the glass transition temperature (about 30 °C), cold crystallization temperature (around 35–45 °C), and melting temperature (up to 10 °C) of the PLA phase. With PBS, neither plasticizer works well.

Somsunan et al. [187] investigated the application of PEA to plasticize PLA/PBS mixtures by reducing intramolecular interactions and enhancing the mobility of the PLA and PBS chains. Due to the limited miscibility of the plasticizers in PBS, PEA does not have a plasticizing impact on PBS, deteriorating many of its mechanical properties. With 15% by weight of PEA in the mixture, PEA also causes a decrease in tensile strength and stiffness (76 and 38%, respectively), while increasing the elongation at break (up to 266%). Finally, PEA promotes the crystallization of pure PLA, barely changing its transparency.

However, high plasticizer concentrations excessively reduce the viscosity of the blend for flat die extrusion, requiring the addition of a copolymer (e.g., PLA-PBS) to increase the melt flow rate (MFR).

5. PBSA

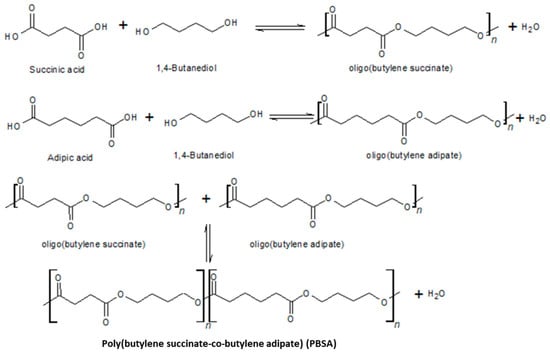

PBSA is a biodegradable aliphatic polyester resulting, respectively, from the polycondensation of BDO with SA and adipic acid (AA) [188,189,190] (Figure 5).

Figure 5.

Condensation reaction to obtain PBSA.

The nature of the oligomers used, butylene-succinate and butylene-adipate, influences the final properties of PBSA [191] as well as its biodegradation rates [192]. PBSA, compared to PBS, degrades much more rapidly, and shows a lower Tm and Tc [193]. Since the crystal fraction created is unstable and experience a melt–recrystallization–melt process during heating, PBSA exhibits two melting peaks between 80 °C and 100 °C. It exhibits a Tg that can be as low as −50 °C [194]. PBSA is highly flexible, processable, and highly resistant to impact, high temperatures and chemicals [173,195]. Its physical and mechanical properties, including density, tensile strength, and stiffness, are comparable with those of some flexible traditional fossil-based polymers [192], with a strength of around 20 MPa and a modulus of under 400 MPa, and with an elongation at break greater than 300% [196]. In addition to being somewhat less expensive than PBS [197], PBSA has been suggested for use in the production of films, notably for packaging and agricultural applications [133,198]. In addition, it is readily available thanks to the 100,000 tons/year amount produced. The tensile strength of this biopolymer declines as the amount of the AA component increases, and the same behavior is also found for its other physical properties [193].

PLA/PBSA Blends

According to the PBSA characteristics, the use of PBSA is very suitable for fabricating blends with PLA, since it increases its toughness and elongation at break [199,200,201]. Through blending PBSA with PLA, the resulting mixture’s ductility and toughness can be boosted while also enhancing its crystallization rate, transparency, workability, mechanical and barrier properties, and viscoelasticity [202]. Furthermore, the work of Gui et al. [203] showed that PLA/PBSA blends biodegrade faster than pure components because of the larger space in the microstructure, which facilitates their early degradation by microorganisms.

As a result, several research teams have lately emphasized the prospect of mixing PBSA with PLA to lessen PLA’s brittleness [204,205,206,207,208].

Nevertheless, PLA has been reported to be immiscible with PBSA due to unfavorable enthalpy mixing [209], thus obtaining a coarse morphology with poor compatibilization [210,211,212].

The blend’s composition, processing circumstances, rheological properties, and interfacial tension of the two elements all affect how a two-phase system evolves morphologically [213,214,215,216]. By adjusting the ratio of PLA to the rubbery polymer, several morphologies (droplet, co-continuous or double emulsion) may be produced, allowing the mechanical performance of the finished product to be managed [217,218,219]. In the work of Ojijo et al. [194] different blends of PLA/PBSA (100/0, 90/10, 70/30, 60/40, 50/50, 40/60, 30/70, 10/90, 0/100) were prepared and Fourier-transform infrared (FTIR) spectroscopy allowed them to assess the phase separation resulting from the absence of any significant interaction between the two components.

Since the mechanical properties of PLA/PBSA blends are poorer than those resulting from pure polymers alone, various attempts have been undertaken to increase their compatibility and give better interfacial adhesion [169,174,220,221].

Interestingly, chain extenders can be employed to reconnect the cleaved chains, resulting in an increase in the molecular weight [222,223,224]. Multifunctional epoxides [225], diisocyanate compounds [226], dianhydride [227], bis-oxazolines, tris(nonyl-phenyl) and phosphate (TNPP) [172] are a few examples of chain extenders that are also commercially available and have been the subject of in-depth research. Polymer degradation can also be better controlled and reduced thanks to the use of chain extenders during processing [222,223,228,229] while simultaneously favoring extrusion and injection molding [229,230]. In addition, chain extenders can react with both polymers to generate block copolymers, which are especially effective in the interfacial areas and boost the adhesion between the two phases of the polymer blend. In their study of PLA-PBSA blends (10-30 wt%) compatible with a chain extender, namely a styrene-acrylic oligomer with epoxy functionality (ESA) (0.5 phr), Lascano et al. [231] observed that compatibilization had an impact on the blend’s elongation at break. The researchers additionally detected a large improvement in impact strength (approximately 30%) and an order-of-magnitude increase in ductility. Similar results were obtained by Palai et al. [232] who showed that PLA/PBSA blends (5–20 wt%) using the identical chain extender ESA (added up to 3 wt%) could effectively make flexible films. In this work, morphological studies revealed positive polymer interaction thanks to the action of chain extenders, thus resulting in an enhancement of the mechanical properties of the blown film extruded. When compared to the PLA film, the blend’s rates of oxygen transmission (OTR) and water-vapor transmission (WVTR) were found to be 60% and 14% lower, respectively.

Ojijo and Ray [233] also prepared a PLA/PBSA blend using ESA through melt mixing. The chain extender was demonstrated to improve resilience, ductility, thermal stability, and crystallization. The same researcher demonstrated a similar effect when using triphenyl phosphate (TPP) in some blends containing, respectively, 30 and 10 wt% of PBSA [196]. Aliotta et al. [209] presented a study on PLA/PBSA blends (15–40 wt%) produced using twin-screw extrusion. The biggest increases in toughness (elongation at break and increase in impact strength) came from the 80-20 and 60-40 blends. The compatibilizer effect of an epoxy oligomer (EO) added up to 2% by weight was also investigated. Micromechanical analysis was performed on these mixtures, capable of going to record both axial and transverse elongation during tensile testing. The outcomes demonstrated that EO functions well as a compatibilizer, enhancing the compatibility of PBSA in a PLA matrix. The two blends vary morphologically in that the PBSA particles in the 80-20 blend are scattered throughout the PLA matrix, whereas the 60-40 blend exhibits a co-continuous microstructure. Although the reaction of the 60-40 blend is unaffected by the addition of EO, the response of the 80-20 blend is significantly altered, switching to deviatoric behavior as opposed to the basic blend, which displays cavitational behavior. Under cavitational behavior, the material, when tensile stressed, undergoes a volume increase in the area of interest as well as a change in shape while the deviatoric behavior results only in a change in shape and not volume [234]. This suggests that this response is likely due to a change in the morphology of the dispersed PBSA phase due to the addition of EO.

Eslami and Kamal [235] used a multifunctional epoxy-based chain extender to increase the melt strength of biodegradable polymer blends based on PLA and PBSA. The findings demonstrated that while the chain extender had no discernible impact on elastic modulus and strain at break of the blends, PBSA significantly improved the ductility of PLA/PBSA blends. They confirmed that such an approach results in a system with increased performance and processability since the combination of blending PLA with PBSA and including the chain extender gave the system both ductility and melt strength.

In the work of Yang et al. [236], a study was carried out involving both PLA-PBSA blends and blends in which PLA was functionalized with a fully biobased compatibilizer, namely crotonic acid (CA), subsequently coupled with PBSA (PLA-CA-PBSA) with a plasticizer function. Both blends were compared with pure PLA. The CA compatibilizer derives from the PHB recycling was coupled to PLA using a radical grafting reaction [237]. The analysis of differential scanning calorimetry (DSC) was used to assess its thermal properties. Tg dropped at around room temperature for PLA-CA-PBSA and PLA-PBSA. Tg for pure PLA was 44.3 °C, while it was 18.3 °C for the mixture with 20 wt% PBSA. Contrarily, PLA-CA-PBSA showed a Tg of 24.4 °C, which was greater than the Tg of PLA-PBSA but still 20 °C lower than the Tg of pure PLA. This reduction shows that adding PBSA to PLA, either by mixing or coupling, increased PLA’s chain mobility in each circumstance. This finding is of considerable significance when compared to a study in which PLA was mixed with PBS at different weight ratios and the mixture showed a reduction in Tg of only 4 °C [165,237]. Increases in the elongation at break of PLA from 14% to 165% and 460%, respectively, were found for PLA-CA-PBSA and PLA-PBSA.

Regarding the packaging application, gas permeability is an important property. Studies in the literature report that from simple PLA/PBSA binary blends, oxygen permeability increases slightly, in contrast to what is observed for blends in which a compatibilizer is used where oxygen permeability decreases [236].

6. PBAT

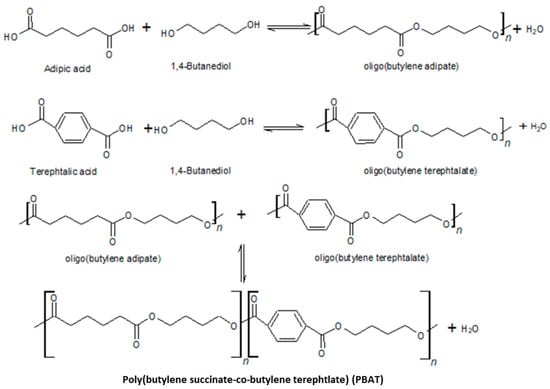

PBAT is an aliphatic–aromatic copolyester, produced currently from fossil resources, and consists of two types of comonomers, a rigid butylene terephthalate segment (BT) consisting of BDO and terephthalic acid (TPA) monomers, while the second butylene adipate segment (BA), is flexible and the section consists of BDO and AA [18] (Figure 6).

Figure 6.

Condensation reaction to obtain PBAT.

Although being so far completely fossil-based, biobased monomers are planned to be gradually introduced, as announced by manufacturers [238].

PBAT shows interesting properties at relatively low costs, which makes it suitable for various applications. To date, PBAT is applied for products such as shopping or rubbish bags, packaging materials, mulch films, cutlery, hygiene products, biomedical fields, and industrial composting [239,240].

It has good mechanical and physical properties, including high toughness, high ductility, resistance to moisture and water and is biodegradable and compostable [241]. The chemical composition and environmental conditions affecting degradation determine the speed at which PBAT biodegrades [19,242,243]. Witt et al. [191,244] published a study in 1996 that demonstrated how the amount of TPA in a polymer affects how quickly PBAT degrades: the chemical hydrolysis allows biodegrading even long aromatic oligomers in compost at high temperatures, while oligomers containing one or two terephthalates are easily and rapidly degraded.

The mechanical behavior of PBAT is similar to that of a thermoplastic elastomer due to its high elongation at break and low modulus of elasticity. As other biopolymers, the structural composition and molecular weight influences the mechanical properties of PBAT. In studies by Lee et al. and Herrera et al. it was reported that stiffness increases with an increasing BT unit content, while ductility decreases [245,246]. At the same time, tensile strength increases as the molecular weight increases in contrast to the elongation at break, which decreases. Considering these outcomes, the mechanical properties of PBAT can be changed by varying the reaction pressure and temperature, as both variables cause a reaction shift toward products and influence the molecular weight of PBAT.

According to the literature, low-density polyethylene (LDPE) and PBAT both have similar mechanical properties [247,248]. PBAT is a flexible material with flexural strength greater than 7 MPa and flexural modulus of about 130 MPa, as well as Young’s modulus of about 50 MPa, tensile strength between 20 and 35 MPa, and an elongation at break that can reach 700% [249,250].

PBAT shows a Tm that depends on the ratio of BA and BT units: as BT units increase, the melting temperature varies from 42 °C (10% mol BT) to 190 °C (80% mol BT) [251].

Owing to the high cost of manufacture and poor mechanical qualities of pure PBAT polymer products as compared to conventional plastics, the market has not yet accepted these materials for commercial products. In the future either the cost shall be reduced or the performance increased to allow for the development of a wide market for this type of polymer.

PLA/PBAT Blends

As seen for PBS, the properties of PLA may be considerably improved by combining PBAT with it, allowing for a greater range of applications in finished goods without compromising its biodegradability.

In the work of Jang et al. [132] PLA was blended with PBAT (5, 10, 14 and 20% by weight) in the molten state. This greatly improved the processability of PLA. During extrusion, pure PLA pellets led to high melt flow resistance, and this led to high screw torque and pressure during processing. PBAT has a lower melting point than PLA. Mixing it with PLA resulted in the reduction in screw torque and extrusion pressure as PBAT behaves as a lubricant at low extrusion/processing temperature. It was found that introducing PBAT accelerates the formation of crystals in the PLA but has no discernible impact on the final degree of crystallinity. The combination shows decreased tensile strength and Young’s modulus with increasing PBAT concentration (5–20% by weight), but enhanced elongation at break and toughness. Additionally, when the PBAT concentration increased, the specimen’s failure mode during the tensile test switched from brittle fracture to ductile fracture. Jiang et al. [132] showed that small amounts of PBAT added to the PLA matrix results in a significant and gradual increase in ductility, without significantly reducing its mechanical strength and stiffness.

Moreover, the addition of PBAT to PLA increases its toughness, as shown by the increase in the impact strength values from 21 J/m in pristine PLA to 50 J/m for a 75/25 PLA/PBAT blend [252].

Also, in the work of Gigante et al. [199] PLA/PBAT blends were prepared with an amount of 10 to 25% of PBAT, which results as dispersed phase within the PLA matrix. This is because it is known from the literature that, with an amount of 30–40% and over, PBAT would appear as a co-continuous morphology [253]. Additionally, it was noted how the quantity of PBAT affects the mechanical response of PLA. Data from further investigations [254,255,256] demonstrate that the elongation at break increases for mixes containing 20 and 25% PBAT up to 300 and 350%, respectively.

All the blends showed two distinct Tg values corresponding to the PLA and PBAT phases. This is evidence that the blends formed are thermodynamically immiscible. Signori et al. [257] observed similar findings for PLA/PBAT mixes having 75 wt% PLA. The addition of PBAT to PLA resulted in 20 °C drop in Tc, demonstrating the impact of PBAT on the rate of PLA crystallization in the combination, as previously described [132].

A review by Krishnan et al. [167] confirmed that the blending allows obtaining good toughness and flexibility, while maintaining biodegradability. Regarding processing, Quero et al. [258] reported a decrease in the final torque value since there are scattered PBAT domains in PLA matrix, while in an article by Gu et al. [259] it was noted that the linear viscoelastic limits of the molten PLA/PBAT blend were lower unlike those of pure PLA.

The immiscibility between PLA and PBAT remains a problem for optimizing the properties of blends based on these two polymers. It was shown by Ma et al. [260] that DCP functions as a free radical initiator for the in-situ compatibility of PLA/PBAT blends, reducing the domain size of the PBAT dispersion phase and increasing the toughness of the blend.

Chain extenders, which boost melt-state strength and thermal stability of polymer blends while also increasing polymer molecular weight, were recently developed [229,261]. Polyesters have made extensive use of multipurpose chain extenders with epoxy groups [229]. The hydroxyl and carboxyl groups in the polyester chain ends might react with the epoxy groups in the chain extender. This occurs as a result of a mechanism that also produces covalent bonds with the creation of hydroxyl and opens the epoxy group ring [224]. Thus, when compounding in the molten state, the production of copolymers is encouraged [262,263].

In their study, Arruda et al. [223] described the addition of various concentrations of Joncryl ADR4368 (BASF), a multifunctional epoxy chain extender utilized as a compatibilizer, to the PLA/PBAT blend. The compatibilizer-containing mixes exhibit an increase in viscosity. The correlation between the rise in complex viscosity and the increase in polymer molecular weight is brought on by the epoxy group of the chain extender interacting with both ends of the polymer chain [226]. Al-Itry et al. [256,264] also showed that the BASF product improved the stiffness, strain at break (up to 135%), and melt strength of PLA/PBAT blends. The addition of Joncryl and 1,6-hexanediol diglycidyl ether improved the compatibility of PLA and PBAT and increased the strain at break by up to 500% without noticeably reducing the strength, according to Dong et al. [265].

Another compatibilizer, glycidyl methacrylate (GMA), was employed by Kumar et al. [252] to enhance the interface regions of PLA-PBAT blends. The toughness and stiffness of the PLA matrix were seen to increase with increasing the amount of PBAT. In the presence of GMA and nano-clay, morphological images by SEM show increased interfacial adhesion between the PLA-PBAT blend. Compared to virgin PLA, DSC and TGA thermograms demonstrated superior thermal properties. Additionally, in the study of Zhang et al. [266], the introduction of GMA confirms the improvement in phase compatibility and, therefore, rheological properties due to the increased surface adhesion between the PLA and PBAT phases. Furthermore, the tensile strength was improved by up to 180% without compromising the strain at break.

Pan et al. [267] found that methylene diphenyl diisocyanate (MDI), as a responsive chain extender, can enhance the compatibility of PLA/PBAT. The strength of PLA/PBAT blends is increased by the formation of urethane bond between the chains of PLA and PBAT. However, due to the toxicity and volatility of diisocyanate compounds, which are reportedly gravely dangerous to humans according to the literature, the use of these blends is restricted.

Coltelli et al. [222] showed that including a radical initiator in PLA/PBAT blends during polymer mixing in the molten state improved compatibility while maintaining the Mw at similar values. In another work by Coltelli et al. [255], adding the plasticizer ATBC up to 30 wt% increased the elongation at break of the PLA/PBAT blend up to 300%. In another study, Dong et al. added phthalic anhydride (PA) and bioxazoline (BOZ) as compatibilizers to PLA/PBAT blends [268]. Due to the smaller domain size of PBAT, modest concentrations of PA or BOZ enhanced the elongation at break up to 515% without influencing the tensile strength. According to Nishida et al. [269], the application of 2,5-dimethyl 2,5-di(tert-butylperoxy) hexane (DMBPH) as a reactive compatibilizer decreased the domain size and therefore enhanced the elongation at break up to 30%, but more significantly, it enhanced the impact strength up to 30 times. Additionally, according to Coltelli et al. [222], the DMBPH affects the increase in mixture viscosity and the enhancement of elongation at break by up to 60%.

7. PHAs

Polymers of the PHA family have attracted growing interest since they are biocompatible, biodegradable, easy to process and show good mechanical properties [270]. PHAs are thermoplastic biopolymers produced directly by numerous microorganisms through the bacterial metabolism of carbohydrates or fatty acids. PHA macromolecules are accumulated by these bacteria as a water-insoluble inclusion that serve as carbon and energy storage components in their bodies [271,272]. Furthermore, it has been claimed that the variation in the amount and type of carbon sources fed to the bacteria affects the content and properties of the resulting polymer [100,273]. The most interesting feature of the PHA family is its complete biodegradability in compost, soil, and seawater, which makes it a suitable candidate for the development of environmentally friendly packaging. Additionally, the biocompatibility of PHAs is yet another crucial attribute that makes them appropriate for use in medical applications since they are not rejected by the body and their absorption generates nontoxic residues.

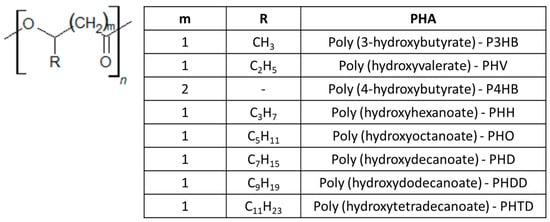

Regarding the chemical structure, PHAs are composed of aliphatic polyesters presenting a variable number of carbon atoms in the monomer unit. Depending on the number of monomers, they can be classified as “short-chain length PHA” (SCL-PHA) when obtained from C3-C5 units, or “medium-chain length PHA” (MCL-PHA) when made of C6-C14 monomers [274] (Figure 7). Monomeric units of SCL-PHA consist of 3-hydroxybutyric acid (3HB), 4-hydroxybutyric acid (4HB) or 3-hydroxyvaleric acid (HV), whereas those composing MCL-PHA are constituted by of 3-hydroxyhexanoic acid (HH), 3-hydroxyoctanoic acid (HO), 3-hydroxydecanoic acid (HD), 3-hydroxydodecanoic acid (HDD), 3-hydroxytetradecanoic acid (HTD) or even longer-chain co-monomeric units [275]. The physical properties of the resulting polymer, such as crystallinity, mechanical and processing properties, depend on the length of the side groups of the monomer units.

Figure 7.

Short-chain- and medium-chain-length PHA classification. In the table, the column “m” indicates the number of -CH2-(methylene group) repeats in the monomer unit, “R” indicates the side chain, and “PHA” stands for the type of polymer created by the monomer unit.

From the literature, it has been seen that SCL-PHAs exhibit a high degree of crystallinity and behave as rigid and brittle materials, while MCL-PHAs show a smaller elastic modulus thanks to lower crystallinity. The repeating units’ pendant group dimensions have a sizable impact on the physical properties of the resulting polymer [270].

Poly(3-hydroxybutyrate) (PHB), along with its copolymers poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH), represents the most commercially available and industrially produced microbial polyester thanks to its interesting mechanical properties, its thermoplastic behavior, and the various synthesis routes [276,277].

7.1. PHB

PHB can be obtained by various bacteria, as well as by cyanobacteria and/or microalgae. These species store PHB intracellularly as a source of reserve energy [278]. In addition to being a biopolymer, PHB is associated with the property of being biocompatible as low-molecular-weight oligomers of this biopolymer can be found in the bloodstream of humans. In addition, the biocompatibility of PHB is also related to its degradation product (3-hydroxybutyric acid), which is a common metabolite in living matter [279]. Therefore, due to its outstanding biodegradability and biocompatibility characteristics, PHB can find applications in various fields, such as packaging, agriculture, biomedicine, and cosmetics.

PHB (P3HB) has as its alkyl group -R a methyl group. It displays Tg between 0 and 5 °C, Tm between 170 and 180 °C, a degree of crystallization in the range of 60–80%, and a degradation temperature (Tdeg) of about 220 °C. The narrow window between Tm and Tdeg is critical since polymer decomposition may likely occur during processing. Thus, plasticizers are required to process PHB as well as to improve the strength and elasticity of the melt [280,281].

In particular, the elastic modulus and tensile strength of PHB are like PP values [282]. On the contrary, its ductility is much lower, making PHB an intrinsically brittle material, thus limiting its applications. Therefore, the addition of different monomeric hydroxyalkanoate co-units, such as hydroxyvalerate or hydroxyhexanoate, into PHB chains through microbial synthesis leads to an improvement in the mechanical properties of PHB [283]. All this leads to an expansion of the potential applications of these biopolymers.

Regarding homopolymer P4HB, it is more processable, flexible, and ductile than P3HB, thanks to its lower degree of crystallinity. This polymer has then found interesting applications in medicine to fabricate biomedical devices for repairing soft tissues [281].

7.2. PLA/PHB Blends

The research of PLA-PHB blends has been the subject of several studies [284,285,286,287,288,289]. These investigations showed that the molecular weight and fluidity index of the polymers affect the miscibility of PLA-PHB blends. The literature showed that PHB is only miscible with low-molecular-weight PLA, and the presence of PLLA affects PHB’s crystallization kinetics [286,290]. Likewise, in a melt containing up to 50 wt% of PHB, the PLA is also miscible with low-molecular-weight PHB but is not miscible with high-molecular-weight and commercial-grade PHB [287,288]. According to Ohkoshi et al. [288], PLA is only miscible with low molecular weight atactic PHB, combining PLLA with different molecular weights of atactic PHB. Moreover, the addition of PHB to PLA matrices could increase its crystallinity [291]. Given that crystallinity directly affects gas penetration, it is well recognized that raising the amount of crystallinity might enhance the usage of PLA as a packaging material [198]. In general, the barrier properties of PLA/PHB blends are generally better than PLA’s [51,292], but the strain at break values are still relatively low since improvements of less than 1% were found [82,293]. In agreement with this, Ni et al. [291] observed that introducing 3-hydroxybutyrate (HB) oligomers, at an amount less than 40 %, within the PLA biopolymer led to improved crystallinity. It is known from several studies that the PLA/PHB 75/25 blend shows significantly better mechanical properties than pure PLA: PHB crystals act as a filler and nucleating agent in PLA. Mixing PLA and PHB also leads to an improvement in PLA biodegradability as the PHB content increases, due to ester bonding, that can be broken [272] when exposed to biologically active conditions (soils, seawater or freshwater, aerobic and anaerobic composts, activated sludge, landfills). PHB also sinks in water, which speeds up the process of biodegradation in sediments [294].

Both PLA and PHB are semicrystalline polymers that, when exposed to room temperature, show excellent strength and stiffness but low fracture toughness and brittle behavior. The lack of ductility and flexibility limits their applications, such as film production. The brittleness results from the high Tg of PLA [295] and the high crystallinity degree and relatively large spherulites of PHB [296].

Tensile strength and elongation, fracture toughness, and impact strength are unquestionably the mechanical properties that packaging applications are most interested in [297,298]. As a result, PLA and PHB require the addition of plasticizers to increase their ductile properties and obtain the flexibility needed for film production. This is because PLA and PHB are naturally brittle.

The values of elongation at break reported for PLA/PHB (75:25 w/w) mixed with different plasticizers increase and are between 6% and 15% for poly(ethylene glycol) (PEG) [51,299], D-limonene [82] and Lapol 108 [293], and up to 90% for ATBC [34,35,43,300]. Furthermore, it has been demonstrated that ATBC works well to quicken the decomposition process while composting [43]. The application of PEG [301] and ATBC [302] does not create safety issues for food contact materials, according to the European Food Safety Authority (EFSA).

7.3. PHB Copolymers

The usefulness of PHB is limited due to its brittleness [303]. However, the addition of poly-3-hydroxyvalerate (PHV) to the PHB polymer chain can improve the ductility and processability of the polymer [304]. Regarding PHBV, the resulting copolymer structure consists of 3-hydroxybutyrate and 3-hydroxyvalerate repeating units randomly distributed in the polymer chain [305,306], adapting the polymer properties to specific applications as for conventional thermoplastics [307]. For biological applications, PHBV has been the topic of in-depth and ongoing study using different molar ratios of PHV units [308,309]. When the molar percentage of HV in the copolymers is increased, the processing temperature window can be widened and the processability of the melt is improved by lowering the Tm to 95 °C and the crystallinity to 25% without appreciably affecting the Tg and Tdeg [310,311]. Impact strength increases and tensile strength decreases with increasing HV units [312]. The degradation rate of PHBV is faster than PHB one. The degradation kinetics depends on the structure (copolymer or homopolymer) and crystallinity and, consequently, on the processing conditions [305].

These properties make PHBV a good candidate to substitute oil-based polyolefins in many areas [313], being able to process it by conventional techniques such as extrusion, injection, or compression molding [303]. The European Plastics Regulation (EU) No. 10/2011 authorizes the use of PHBV materials in food contact applications, and global migration tests have already been conducted to assess their inertness in liquid food simulants [314,315]. However, due to its high manufacturing costs [316,317], the broad application of PHBV is also constrained.

In the case of PHBH, the possibility of customizing its composition by combining highly crystalline (3HB) and elastomeric (3HH) units allows obtaining higher thermal stability, and better mechanical properties if compared to PHB and PHBV [318].

By raising the molar proportion of HH, the processing window may be opened up while minimizing thermal degradation, lowering the Tm for PHBH to 54 °C and reducing the crystallinity to 15% [319]. The Young’s modulus and elongation at break values for PHBV (0.5–3.5 GPa, 5–50%) and PHBH (0.1–0.5 GPa, 5–850%) given in the literature are typically lower than those recorded for PHBH (0.9–4.0 GPa, 5–20%).

This makes PHBH distinct from other PHAs and allows its usage in applications that require both flexibility and room-temperature compostability [320,321,322]. In this context, PHBH can be used for manufacturing processes such as injection molding [323,324], extrusion [325,326], thermoforming [327,328], foaming [329], non-woven fabrics and fiber production [330,331], 3D printing [332,333], as well as paper and fertilizer coating [334].

However, PHAs are currently too expensive to utilize on their own; thus, they are frequently combined with other, less expensive polymers that have complimentary features [19].

7.4. PLA/PHB Copolymer Blends

Studies have been performed regarding blends of PLA, the miscibility of two polymers, and the potential improvement in their physical properties [286,290,335].

Iannace and Huanc [336] studied the thermal and mechanical properties of a PLA/PHBV blend by means of a solvent melting process and reported a miscibility problem between the two polymer matrices, as also found in the work of Ferreira et al. [337].

Some authors also demonstrated that the addition of PHBV to the PLA polymer matrix caused a reduction in the crystallinity of PLA and its degradation rate [273,336].

On the other hand, it was also demonstrated that the dispersed phase of PHBV might serve as crystal nucleation sites, improving the crystallinity of PLA [338,339]. Partial miscibility with high compatibility or immiscibility has also been confirmed by other authors [271,340,341,342].