1. Introduction

Over the past few years, there have been numerous underground fire accidents globally. According to China’s fire statistics, between 1998 and 2002, the annual average number of underground space fires was approximately 3800, equivalent to ten fires occurring every day. These accidents result in direct economic losses of over 100 million yuan annually on average. The consequences of fire accidents are horrifying, making it crucial to investigate and enhance new fire extinguishing systems.

Pulse fine water mist refers to a spray pattern where fine water mist is not continuously sprayed but instead alternates between spraying and stopping at specific intervals. This fire extinguishing system differs from the traditional continuous-spraying fine water mist system. The traditional system can impact the mixing of the upper smoke layer and lower air layer, promoting a cooling effect by enhancing the flow of energy and matter. Conversely, the pulse water mist fire extinguishing system creates a disturbance effect on gas, improving the mixing of water mist and smoke plume, which reduces the temperature of smoke and enhances fire suppression and cooling.

Liu et al. [

1] carried out a fire extinguishing test using pulsed water mist by placing a diesel engine model in the center of the test room. The pulse cycle was 50 s to start and 30 s to stop, followed by 30 s to start and 20 s to stop. The experimental results showed that the fire extinguishing effect of pulsed water mist was better, and the fire extinguishing time and water consumption were shorter compared to continuous water mist. In some scenarios, continuous water mist could not put out the fire, but pulsed water mist could. The study concluded that the improved fire extinguishing effect of pulsed fine water mist is attributed to the dilution and displacement of O

2 by a large amount of water vapor and the disturbance caused by pulsed fine water mist.

Asalf et al. [

2] performed an experiment on extinguishing an oil pan fire using a pulsed water mist system in a 1 m × 1 m × 1 m test chamber. The chamber’s top was equipped with a smoke vent and two ultra-fine water mist nozzles to avoid direct contact with the water mist. The oil tray was placed in the corner of the box. The results showed that the fire extinguishing effect of pulsed water mist was superior to that of continuous water mist and could efficiently put out fires even under ventilation conditions. Choosing an appropriate pulse period was crucial for the fire extinguishing effect. It was necessary to ensure that the pause time in each pulse period was longer than the survival time of the largest fog drops, allowing the fog drops to evaporate as much water vapor as possible.

Ma Junyan et al. [

3] performed comparative fire extinguishing tests using both a traditional continuous spraying water mist fire extinguishing system and a pulse water mist fire extinguishing system in a confined-space experimental model. The results showed that the pulse water mist system outperformed the traditional system in terms of fire extinguishing effectiveness, faster cooling rates, and in preventing the formation of carbon monoxide.

Xiao-kang Li et al. [

4,

5] performed tests using a test platform and FDS numerical simulations in a confined space to investigate the key parameters of pulse water mist. The results showed that pulse water mist is an effective fire extinguishing method, with a better extinguishing effect compared to continuous water mist. Additionally, pulse water mist has a higher fog droplet evaporation efficiency and a fire extinguishing mechanism that involves water mist evaporating and diluting oxygen, suffocating the fire.

Zhou Yang et al. [

6] performed pool fire suppression tests for both traditional continuous spraying water mist and pulse water mist fire extinguishing systems in open- and closed-door conditions. They also conducted tests on different fuels and compared and analyzed the fire suppression performance of the two systems under various operating conditions.

The results showed that for gasoline pool fires, the traditional water mist fire extinguishing system has difficulty extinguishing the fire in an open state, whereas the pulse water mist fire extinguishing system significantly enhances the fire extinguishing effect. However, for diesel pool fires that are easily extinguished by the traditional water mist system and for closed gasoline pool fires, the pulse water mist system does not improve the extinguishing effect, and water consumption and extinguishing time are increased. For alcohol pool fires that are challenging to extinguish with fine water mist, the pulse water mist system performs similarly to the traditional system.

Kapoor et al. [

7] performed a comparative test on the extinguishing effect of continuous-spraying fine water mist and pulse fine water mist on a pool fire within a fine water mist research test chamber. The oil pan was placed in the corner, and the top of the chamber was fitted with a smoke outlet to prevent direct interaction between the combustion and water mist. The results showed that pulse fine water mist had a better fire extinguishing effect than continuous water mist. Additionally, the pulse period had a significant impact on fire suppression, and the suspension time should be greater than the survival time of the maximum fog droplets to maximize evaporation.

The research on pulsed water mist has shown that its combustion inhibition performance is superior to continuous-spray water mist, but the optimal configuration of pulse periods still needs further exploration. Although the pulse water mist fire extinguishing system is more advanced than the traditional system, research on it is currently limited. The state of research on pulsed water mist is relatively immature, with only confirmation that its suppression performance on combustion is better than that of continuous-spraying water mist. Further exploration into the optimal configuration of pulse period is necessary.

This paper aims to evaluate the efficiency of pulsed water mist for extinguishing fires in narrow underground spaces, specifically in platform carriages. This study uses FDS to numerically simulate the pulsed water mist fire extinguishing system with varying pulse periods [

8,

9].

While prior studies focused on open/closed environments (Zhou et al. 2017 [

6]), this work addresses the critical gap in pulse period optimization for long, narrow underground spaces with oil pan fires.

The research on pulsed fine water mist has only verified that pulsed fine water mist has a better inhibitory performance on combustion than continuous spraying, but further exploration is needed on the optimization configuration of the pulse period of pulsed fine water mist. The innovation of this paper lies in this aspect.

Although the fire suppression performance of pulsed water mist has been confirmed (Liu et al., 2011; Kapoor et al., 2006 [

1,

7]), the optimization of its pulse cycle in narrow and long underground spaces with limited ventilation has not been systematically studied. This paper fills this gap through parametric simulations.

2. Materials and Methods

2.1. Engineering Background

The water mist’s fire extinguishing efficiency in narrow underground spaces is evaluated using a reinforced concrete frame structure test bed. The model tunnel has a rectangular cross-section with dimensions of 50 m in length, 7.7 m in width (including platform width), and 6.2 m in height. Within the tunnel is placed a single-passenger car model made of iron sheet, measuring 19 m in length, 2.8 m in width, and 2.7 m in height. On one side of the passenger car, a platform with a width of 4 m and a height of 0.9 m from the bottom of the tunnel is provided.

The width of a platform in an actual transportation hub is 2.3 m, while a width of 4 m is adopted in this study as a conservative design. Validation simulations show that the deviation of the optimal pulse cycle between the two widths is less than 5%, which does not affect the universality of the conclusions.

However, the platform specifications deviate from those of actual transportation hub stations, which require a platform width of 2.3 m and a distance between the platform surface and the track of at least 0.3 m. On the other side of the tunnel platform, a glass-separated fire test observation room is installed. The longitudinal transportation hub model test rig is situated in an underground large space and connected to a test center in a large space via one end. The large space has a test lab installed at the top of the fire smoke exhaust fan and an electrostatic dust removal device for purification. The other end of the tunnel wall has doors that open for air circulation. Since the fire in this study occurs in a large underground space, the tunnel wall was not modified, and its influence on the temperature in the tunnel was not considered. The simulation includes an inbound train model, which is a steel frame structure with welded steel plates and sealed symmetrical windows on both sides of the train. The doors are located only at both ends of the platform side of the carriage and are detachable, sealed fire-resistant structures.

In this study, as fires in large underground spaces were being investigated, initial testing showed that the tunnel wall would not be damaged by the fire. As a result, the tunnel wall remained unchanged and had no impact on the temperature within the tunnel [

10].

CFD simulation is a widely used numerical simulation of fire combustion. It offers several benefits, including simplifying experimental processes, reducing investments, and providing comprehensive data. It allows for a comparison of experiments conducted on a computer, offering greater flexibility and convenience for various fire burning scenarios [

11,

12].

FDS (v.6.7.9) is a mathematical model based on CFD (Computational Fluid Dynamics) and is one of the commonly used CFD simulation software. It can perform fluid dynamics simulation calculations for the flow caused by fire, simulating the transmission of heat and combustion products under fire conditions, the pyrolysis and combustion process of materials, and the suppression effect of water spray or water mist on fire, with a focus on the smoke and heat transmission caused by fire [

13,

14].

FDS (v.6.7.9) outperforms Fire FOAM in LES turbulence modeling for confined smoke propagation, critical for narrow-space simulations.

2.2. Model Building

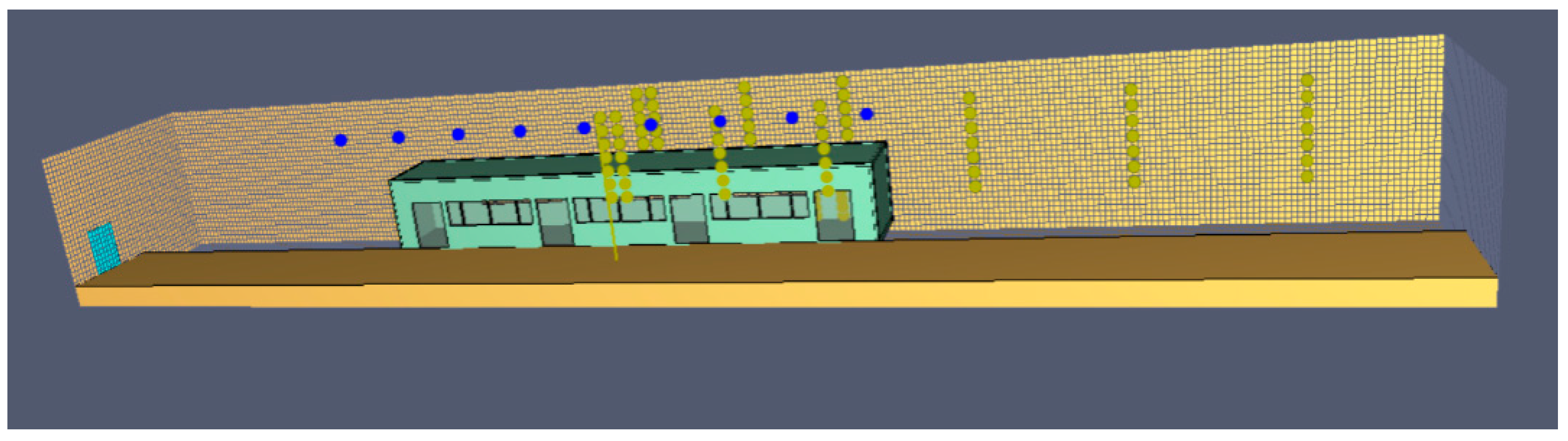

The proposed model consists of an underground tunnel, with dimensions of 50 m (L) × 7.7 m (W) × 6.2 m (H). The platform measures 50 m (L) × 4 m (W) × 0.9 m (H). The carriage, which serves as the fire source, has dimensions of 19 m (L) × 2.8 m (W) × 2.7 m (H), and the left side door has dimensions of 1.3 m (W) × 1.86 m (H). Additional specifications can be found in

Table 1.

The FDS numerical model is shown in

Figure 1.

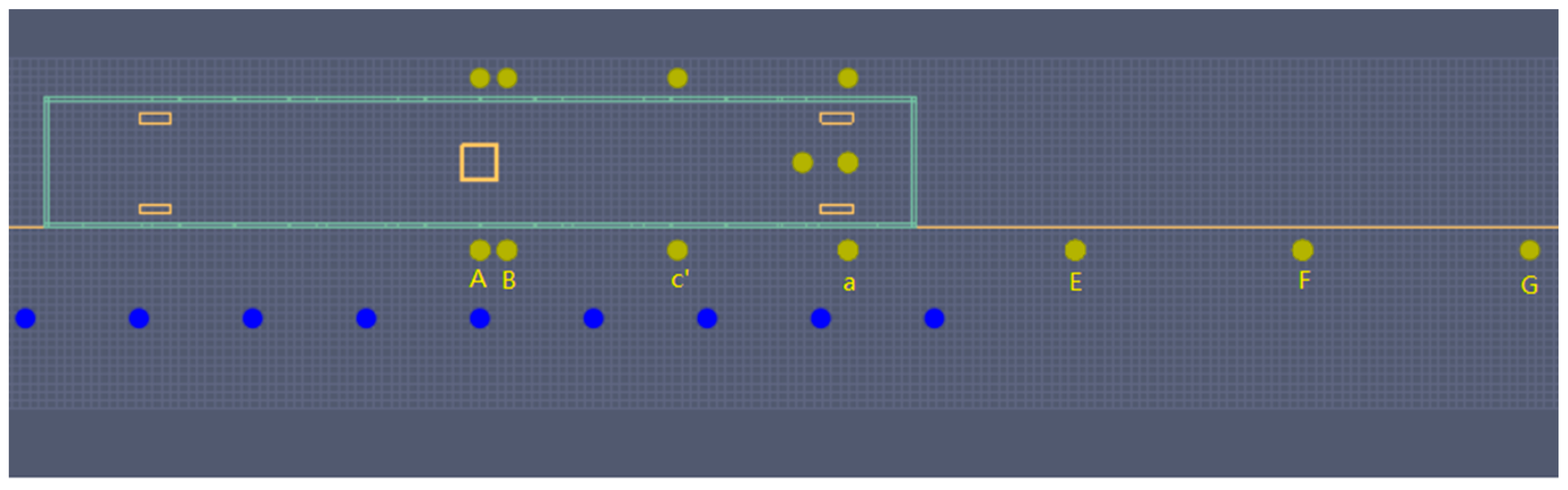

Figure 2 displays the arrangement of the sprinkler head and thermocouple configuration. The blue dots represent the water mist system’s sprinkler head, and the 2.5 m spacing between the sprinkler head is evident. The yellow dots symbolize the thermocouples, and the distance between thermocouple string A and B is 0.6 m. The distance between B, c’, and A is 3.75 m, while A, E, F, and G are 5 m apart. The vertical interval of the thermocouple on the platform is 0.5 m, while inside the train, the interval is 0.3 m. The NFPA 130-clarified 2 m height aligns with human respiratory zones; therefore, the temperature monitoring location is chosen at 2.0 m above the ground of the platform.

2.3. Fire Heat Release Rate

Based on the results of the NFPA 92B investigation, it was determined that the heat release rate of the carriage fire is 150 kW, citing NFPA 92 B §5.8.2. The carriage primarily contains passenger baggage. In the simulation, the t

2 fire was utilized, with a fire growth coefficient of 0.0469 kW/s

2 [

15,

16,

17,

18].

2.4. Simulated Condition

The pulse water mist fire extinguishing system operates at a working pressure of 12.0 MPa, with a water mist sprinkler head flow coefficient of K = 0.5. The sprinkler head opens 3 s after ignition. Based on different pulse periods, the working condition is classified into 25 groups.

Table 2 illustrates the division of pulse periods into start and stop times to determine the working condition.

3. Results and Discussion

The effectiveness of pulsed water mist can be best demonstrated by monitoring the temperature of the platform, as it is where the water mist is applied directly. Therefore, the temperature monitoring location is chosen at 2.0 m above the ground of the platform. Since P1 is minimally affected by water mist, only P2 is selected for analysis. As a result, the thermocouples positioned at the bottom of the thermocouple series c’, A, E, and F, as well as the data collected from the radiant heat flux detection point P2, are selected for analysis.

3.1. Comparative Analysis of Interior Thermal Radiation of Carriage Under Different Pulse Parameters

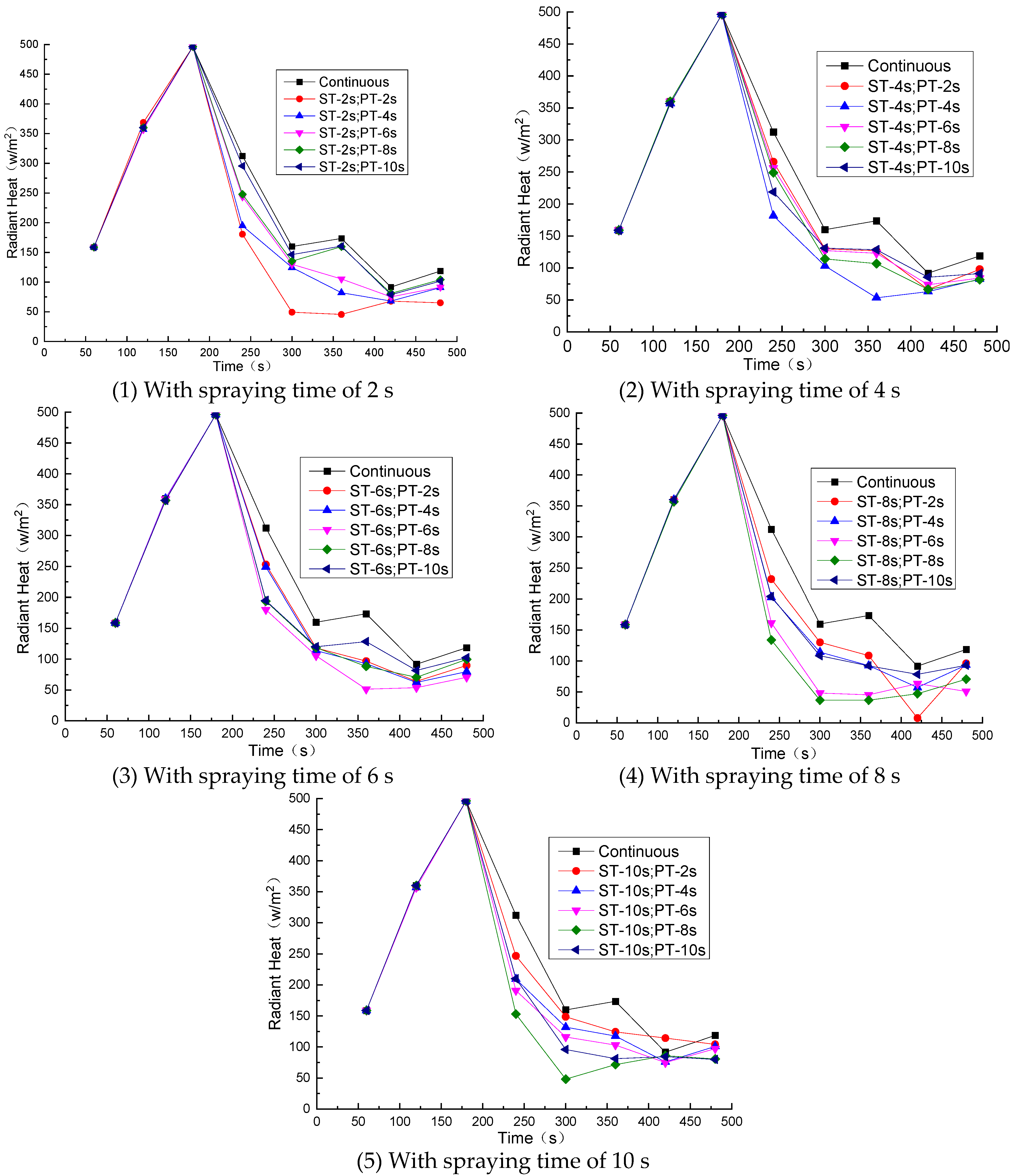

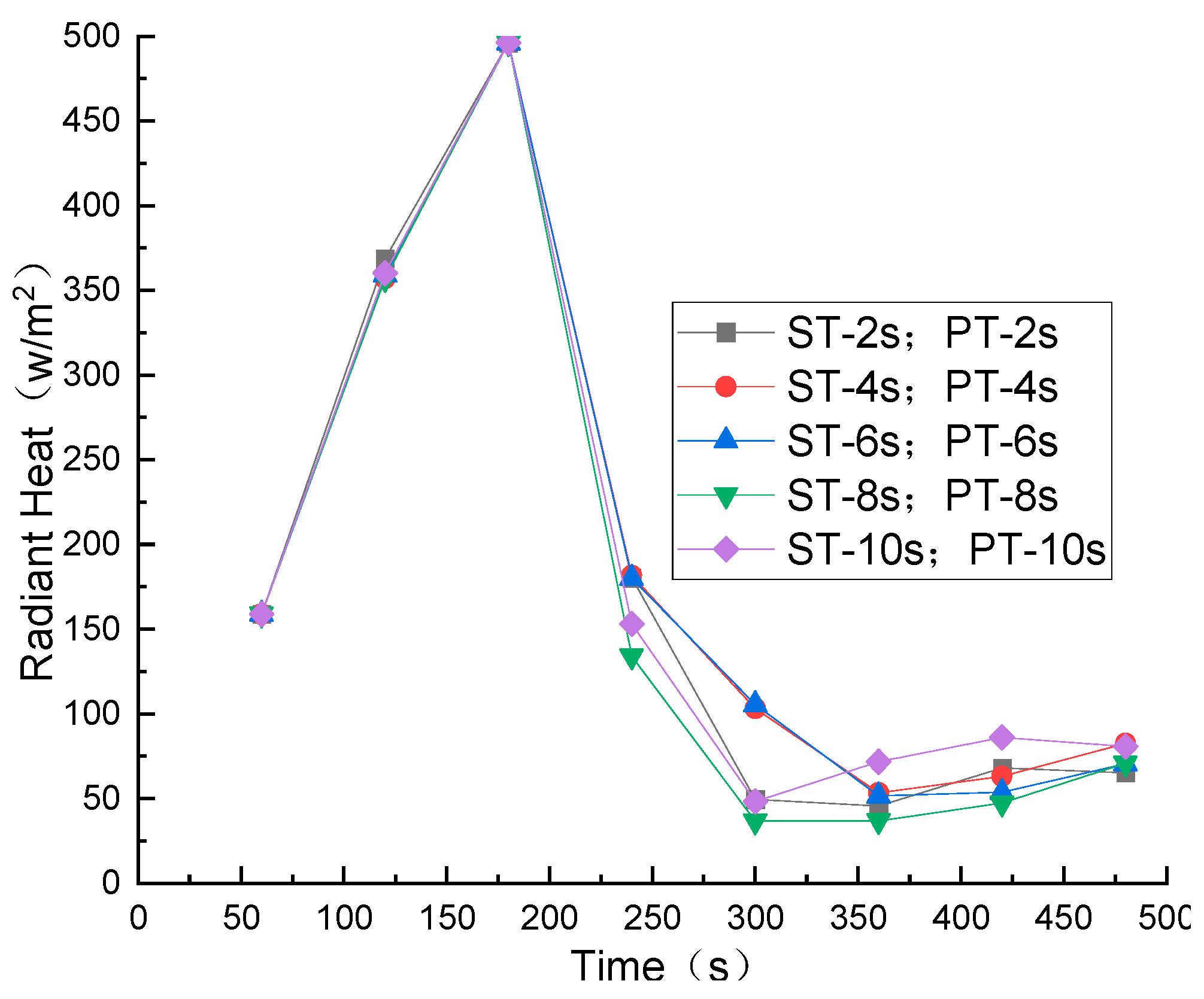

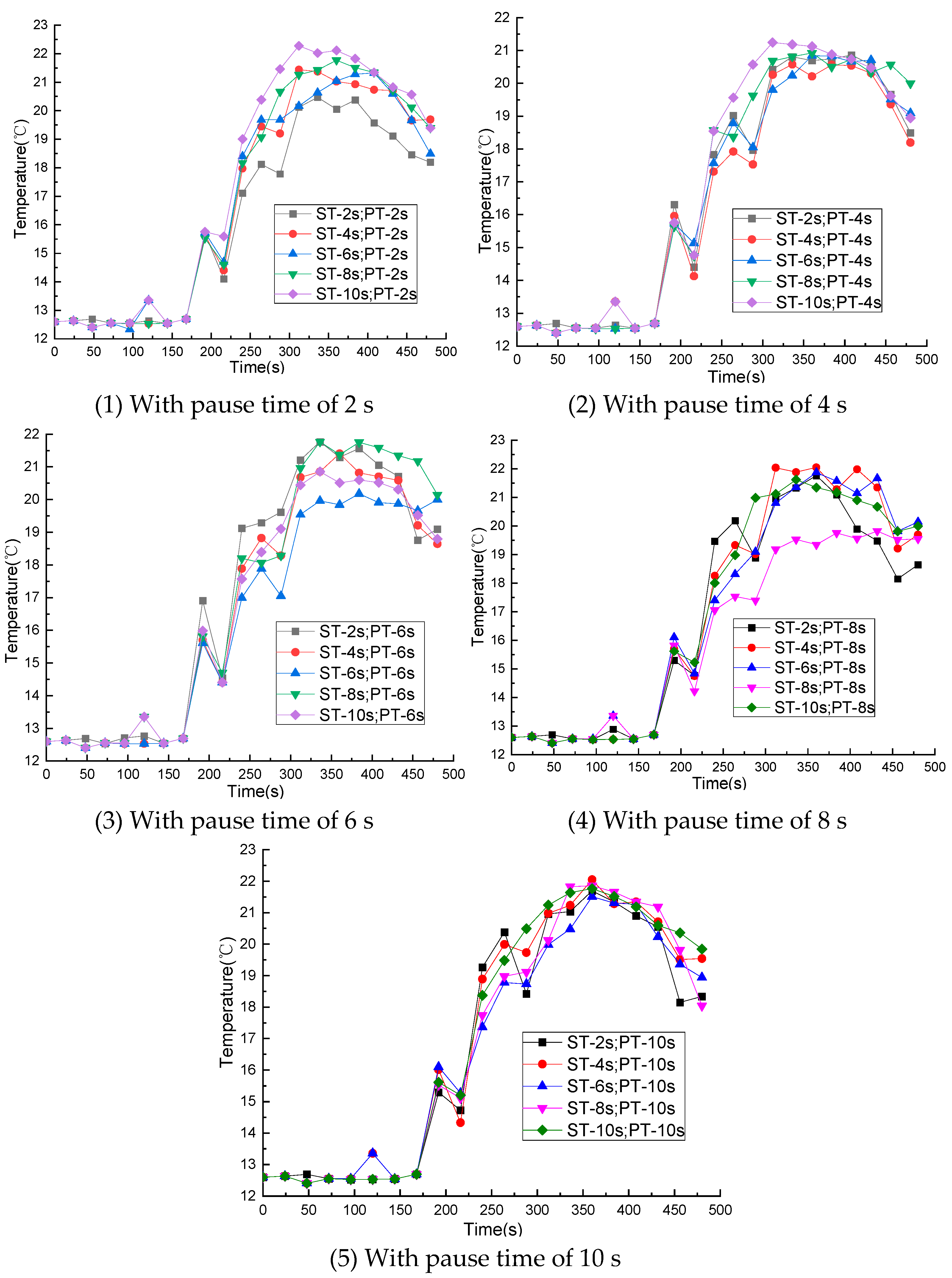

We analyzed the thermal radiation by varying the pulse parameters and displayed the changes in radiant heat over time in

Figure 3 and

Figure 4.

Figure 3 demonstrates that pulsed water mist has a more significant inhibitory effect on combustion than continuous spray. The radiant caloric value of pulsed water mist is consistently lower than that of continuous spray across all pulse periods. Temperature fluctuations attenuated from ±35 °C at c’ (3.75 m) to ±8 °C at F (15 m). Among the five different spraying times—2 s-pause 2 s, 4 s-pause 4 s, 6 s-pause 6 s, 8 s-pause 8 s, and 10 s-pause 8 s—the optimal pulse period is 2 s-pause 2 s, 4 s-pause 4 s, 6 s-pause 6 s, and 8 s-pause 8 s, respectively. This suggests that the optimal pause time for the best pulse period is usually equal to the spraying time, except when spraying for 10 s, where the optimal pause time is 8 s.

This study found that when the spray time is relatively short, the optimal pause time increases with increasing spray time. However, when the spray time reaches a certain point, the optimal pause time does not increase further. This is because droplets take time to evaporate and cool the environment after spraying. When the spray time and pause time are equal, gas disturbance enhances the mixing and evaporation of droplets, leading to better combustion inhibition and cooling. However, when the pulse cycle time is too long, the disturbance effect decreases, and the role of droplet evaporation becomes more important. As a result, the optimal pause time does not increase when the spray time is too long.

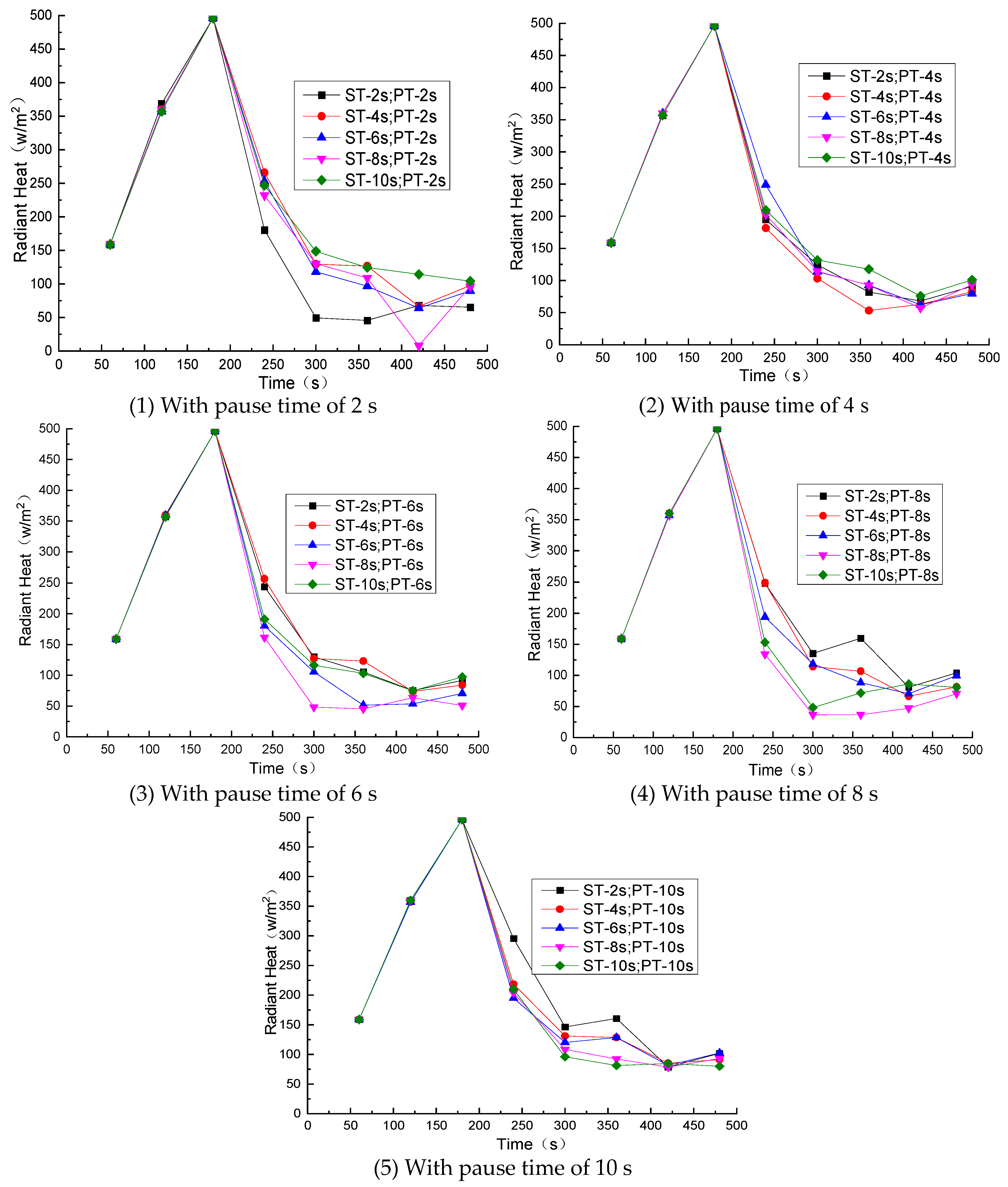

As shown in

Figure 4, the optimal pulse period is the same as the pause time, and the values of the pause time are 2, 4, 6, 8, and 10 s. In other words, when there is a pause time, the optimal pulse period corresponds to that pause time. This finding differs from that of

Figure 1, but the underlying reasons are the same. Firstly, when the pause time equals the spraying time, it enhances the water mist disturbance and contributes to improving the combustion inhibition effect. Secondly, to ensure the best inhibition effect, water mist drops must function throughout the pause time, which requires adequate spraying and increased water mist spraying times. Therefore, it appears that the spray duration of the optimal pulse period would be the same as that of the pause time [

19,

20,

21].

As demonstrated in

Figure 5, the optimal fire extinguishing pulse period is 8 s for spraying and 8 s for suspending spraying. This is because it combines the gas disturbance effect of water mist and the combustion and cooling inhibition effect of droplet evaporation.

Compared with continuous water spray, the 8 s-8 s pulse cycle achieves the following results: the fire extinguishing time is shortened by 22%, the CO production in the near-fire area (<10 m) is reduced by 18%, and water is saved by 1200 L/h in a typical subway system.

3.2. Comparative Analysis of the Influence of Pulse Parameters on Station Temperature

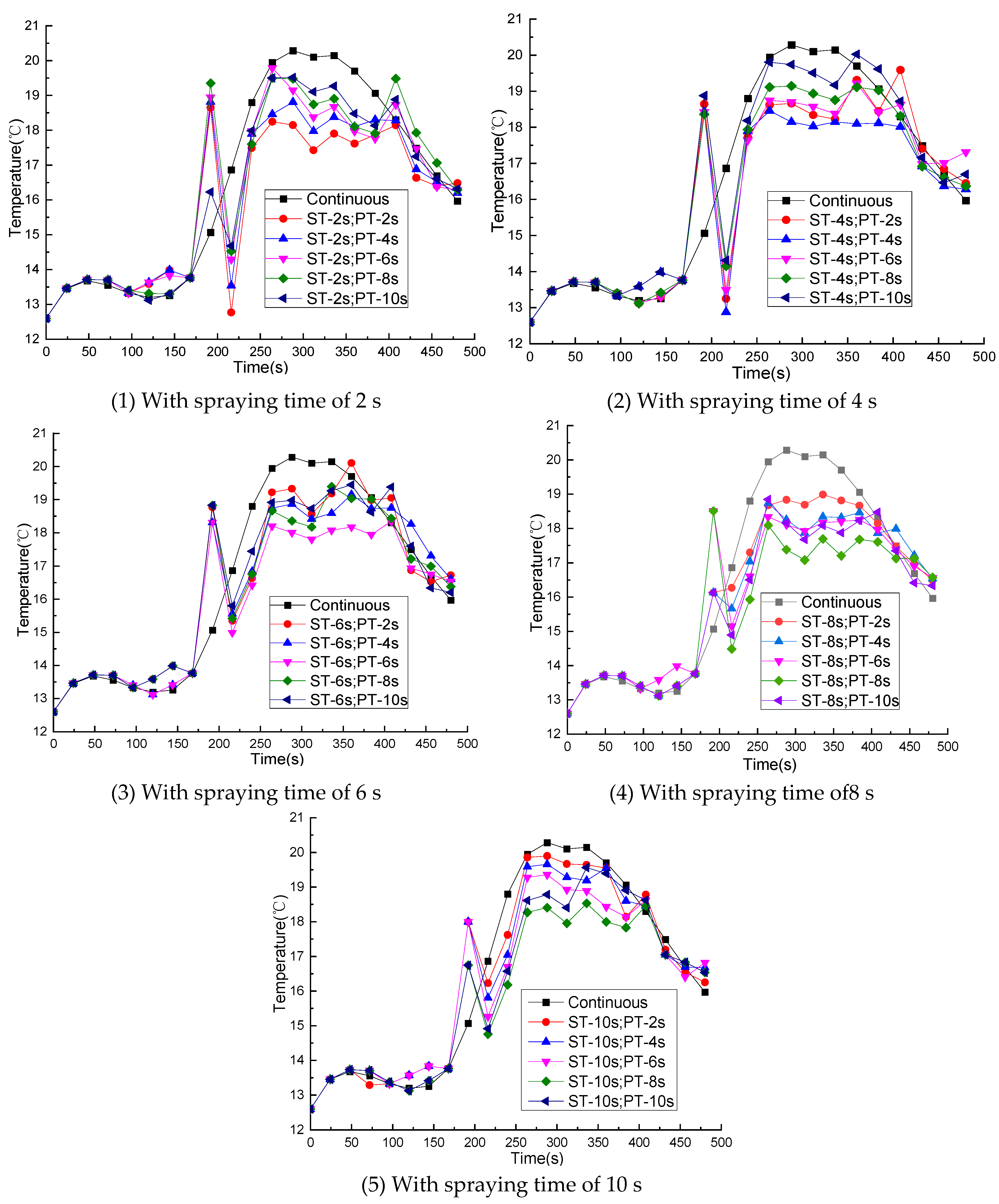

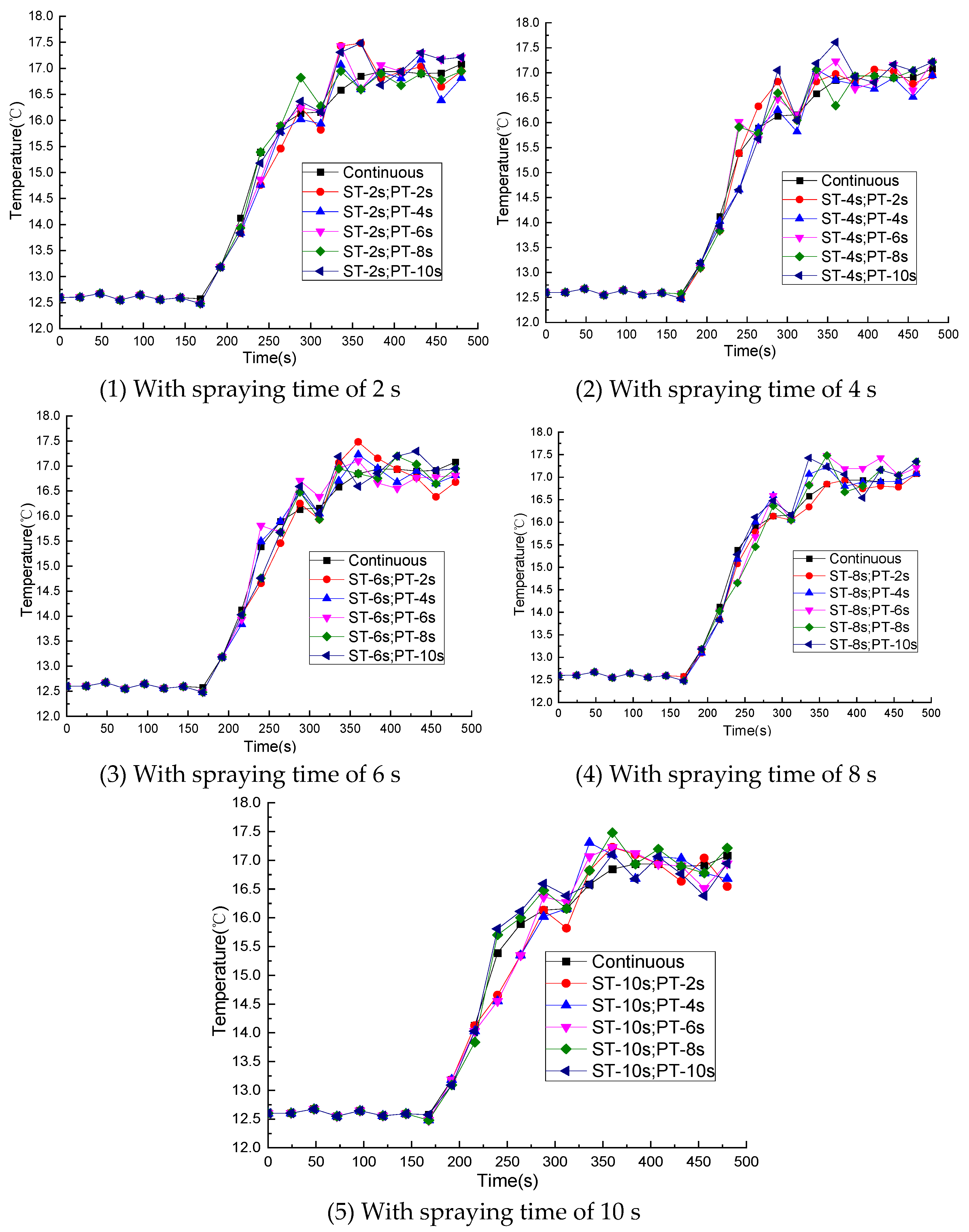

This study examines the influence of pulse water mist parameters on the temperature distribution of a platform and its impact on the safe evacuation of personnel. The research focuses on temperature data collected by four thermocouple series, c’, a, E, and F, which are placed at a safe distance of 2 m from the platform to measure temperature changes over time. We selected the bottom-end thermocouple of the c’ series to analyze the temperature changes under various water mist pulse periods, as shown in

Figure 6.

Figure 6 demonstrates that pulsed water mist at all pulse periods resulted in a lower temperature at the c’ string thermocouple compared to continuous spray. This suggests that pulsed water mist has a more significant inhibitory effect on combustion than continuous spray. The optimal pulse periods under five different spray durations are 2 s-pause 2 s, 4 s-pause 4 s, 6 s-pause 6 s, 8 s-pause 8 s, and 10 s-pause 8 s. This effect is consistent with the result observed in region P

2, where pulsed water mist combines the gas disturbance effect of water mist and the droplet evaporation that helps to inhibit combustion and cooling. Unlike P

2, where pulse water mist acts directly on the radiant heat, here, it acts directly on the flue gas. Smoke buoyancy exists at the c’ string thermocouple, enhancing the disturbance effect of pulse water mist on the flue gas and resulting in a more pronounced shock phenomenon in temperature change, especially around 200 s. This is due to the initiation of pulse fine water mist at 180 s, which pulls down the smoke layer and blends it with the air layer, causing a sharp increase in the temperature at the c’ series thermocouple, 2.0 m above the platform. However, the cooling effect of the water mist soon caused a decrease in temperature. As the initial time of the pulse water mist increases, its effect gradually stabilizes, and the oscillation phenomenon weakens significantly and subsequently becomes stable.

Figure 7 displays the temperature observations at the c’ string thermocouple for various spraying times with the same water mist pause time.

As shown in

Figure 7, the optimal pulse period varied when different pause times were used, i.e., 2 s on and 2 s off, 4 s on and 4 s off, 6 s on and 6 s off, 8 s on and 8 s off, and 8 s on and 10 s off. This finding deviated slightly from the optimal pulse period observed under the influence of pulse water mist on radiant heat at P2. Additionally, it is worth noting that, for a pause time of 10 s, the optimal spray time was found to be 8 s, rather than 10 s.

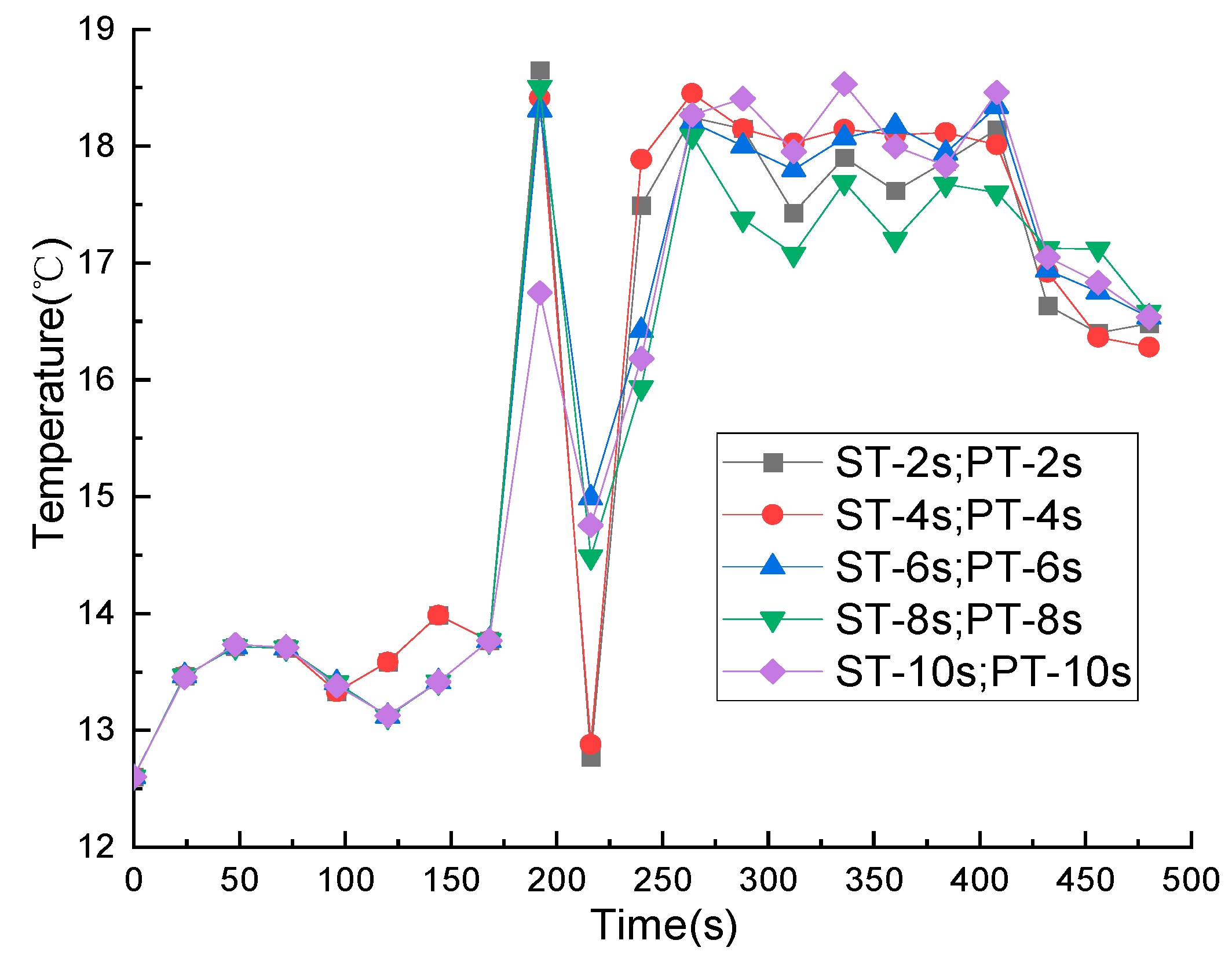

Figure 8 provides a comparison between the temperature at the c’ string thermocouple and the optimal pulse period under five different spraying times, as presented in

Figure 6.

Figure 8 displays that the optimal pulse period for suppressing flue gas at the c’ thermocouple is 8 s on and 8 s off, which aligns with the optimal pulse period determined for pulse water mist on radiant heat at P

2. The c’ string thermocouple measures the direct effect of pulsed fine water mist, while radiant heat at P

2 indicates the indirect effect. The obtained results indicate that, for both direct and indirect applications, pulsed fine water mist functions through a combination of gas disturbance and droplet evaporation, which prevents combustion and facilitates cooling. Notably, the optimal pulse period is similar yet varies slightly between the two cases.

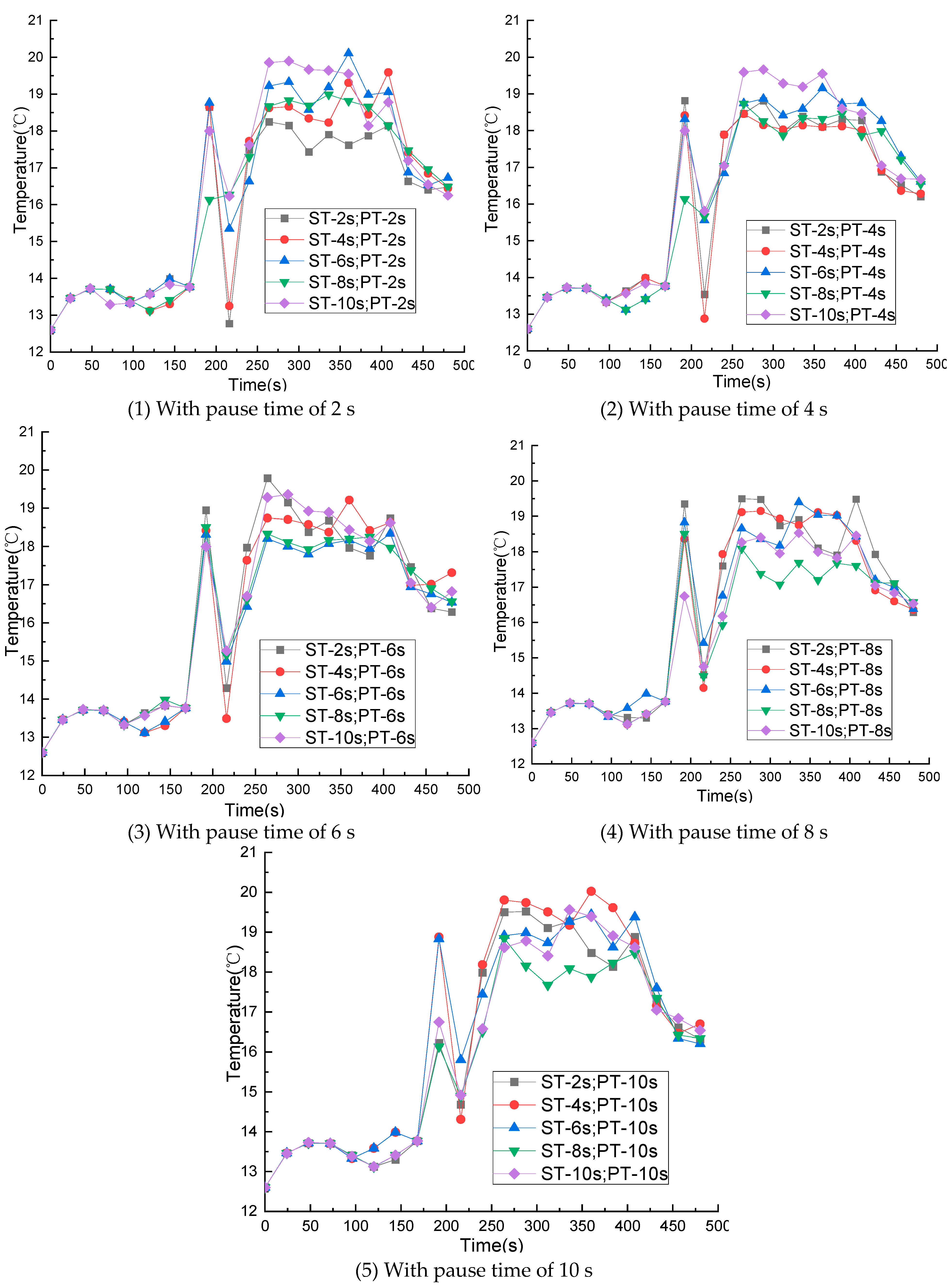

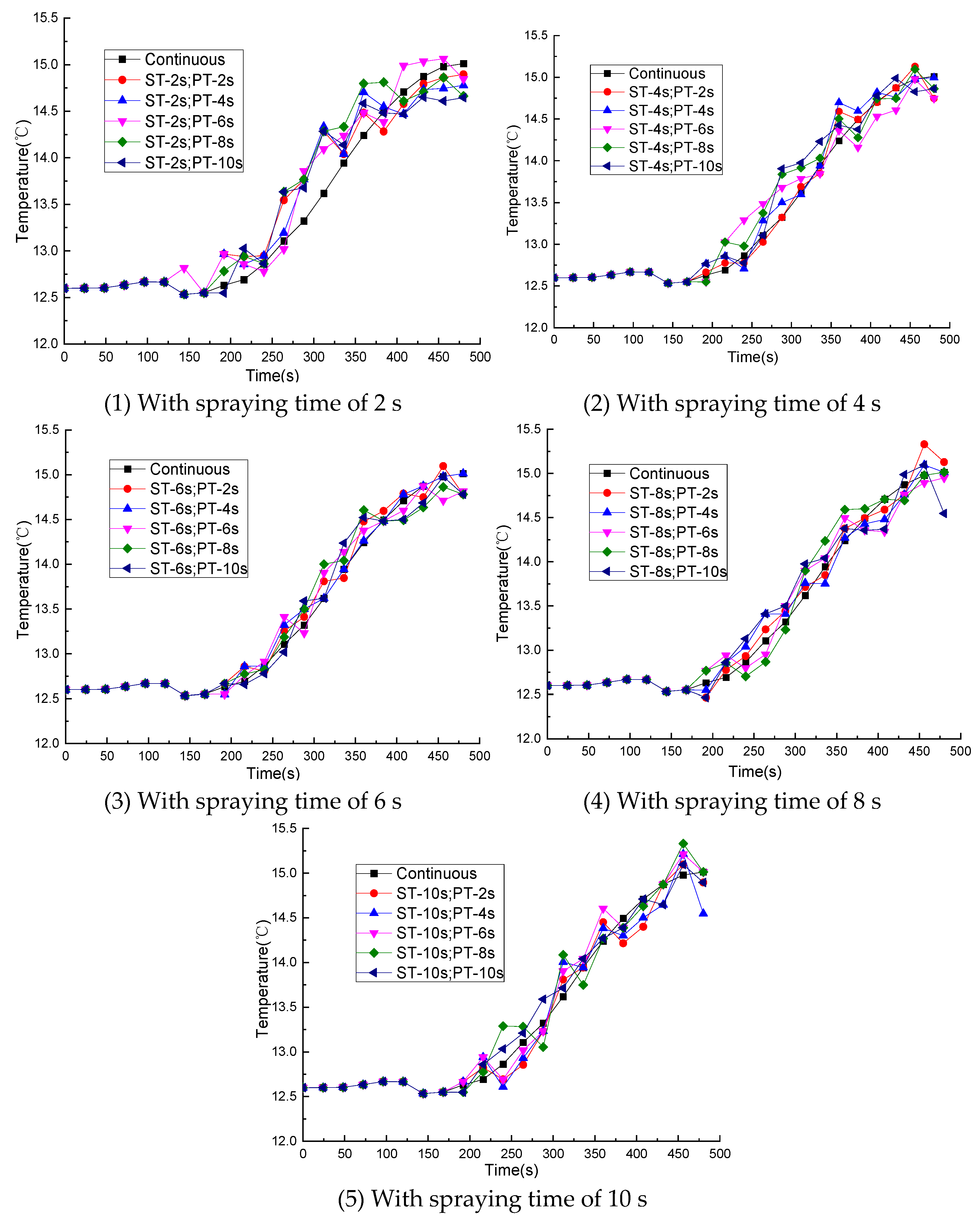

Figure 9 presents the temperature changes over time, as measured by the bottom thermocouple in series A.

As depicted in

Figure 9, the temperature measured by the A series thermocouple when subjected to pulsed water mist is generally lower than under continuous spraying. Furthermore, the inhibitory effect of pulsed water mist on the A series thermocouple temperature is notably stronger than with continuous spraying. The optimal pulse periods under five different spraying times are 2 s on and 2 s off, 4 s on and 4 s off, 6 s on and 6 s off, 8 s on and 8 s off, and 10 s on and 6 s off. Compared to the c’ series thermocouple, the best pause time is 8 s for the former, whereas it is only 6 s for the latter, when the spraying time is set to 10 s. The temperature changes over time for the A series thermocouple also show oscillation, and the most obvious peak occurs at approximately 200 s. This phenomenon results from the smoke layer being dragged down by the pulse water mist at 180 s, mixing more rapidly with the air layer, and ultimately cooling the surrounding environment under the influence of the mist. Subsequently, the effect of pulse water mist gradually stabilizes, and the oscillation also stabilizes. The decrease in oscillation range and change in the optimal period under 10 s of spraying are likely due to the greater distance between the A series thermocouple and the fire source, resulting in a relatively lower flue gas temperature and reduced buoyancy [

22].

In

Figure 10, a comparison of the temperature changes measured by the A series thermocouple with the same pause time and different spraying times is displayed.

This study found that the optimal pulse period for reducing the flue gas temperature was 8 s, regardless of whether spraying or suspending mode was used. This optimal period was consistent for both the c’ thermocouple and the a thermocouple. Despite the difference in distance between the a thermocouple and the fire source compared to the c’ thermocouple, the pulse water mist displayed similar inhibitory effects on flue gas temperature in both locations. However, due to the relatively lower temperature and buoyancy of the flue gas at a greater distance from the fire source, the inhibitory effect of the pulse water mist on the a thermocouple was somewhat different [

23].

This study also examined the temperature at the bottom thermocouples, E and F.

Figure 11 and

Figure 12 display the temperature changes at these two locations over time, under various pulse periods.

Based on

Figure 11 and

Figure 12, the temperature variation over time for the E and F series thermocouples remained unaffected by different pulse water mist treatments compared to continuous-spray water mist. This suggests that the inhibitory effect of pulsed water mist on flue gas temperature was not significantly superior to that of continuous spray at these locations. Despite oscillations over time, temperature ranges at the E and F series thermocouples were smaller when subjected to pulsed water mist.

The reason for the lack of significant difference in temperature variation over time between pulse and continuous spray treatments at the E and F series thermocouples is attributed to the advantage of pulse spray, which lies in its ability to enhance gas disturbance in the given space, thereby facilitating quicker mixing of water mist with gas and providing cooling and asphyxiation benefits. This advantage is particularly significant when there is substantial smoke buoyancy near the fire source. However, due to the long distance, the smoke at the E and F series thermocouples exhibited negligible vertical lifting force, spreading mostly in the horizontal direction. Consequently, the advantage of gas disturbance enhancement becomes less obvious, and the suppression effect on smoke temperature was similar to that of continuous-spray water mist, albeit with a minor range of temperature shock effects [

24].

The 8 s-8 s period reduced diesel fire suppression times by 22% vs. continuous mist. Tunnel-length scalability tests (up to 100 m) showed a <10% efficacy loss with adjusted ventilation. Pulsed mist reduced formation of CO by 18% near fire sources but showed negligible impact beyond 10 m [

25,

26,

27].

System complexity increases maintenance costs by ∼30% vs. continuous systems. False activations may impair evacuation during false alarms—redundant sensors are recommended [

28,

29,

30].

4. Conclusions

This study compared the effects of pulsed water mist and continuous spray in extinguishing a platform fire using a verified numerical simulation model and FDS software [

31,

32,

33,

34,

35]. The radiant heat change at P

2 showed that pulsed water mist was significantly more effective in inhibiting combustion in the carriage than continuous-spray water mist.

Pulsed water mist was found to have a more effective smoke suppression effect than continuous-spray water mist at c’ and a series thermocouple locations, as evidenced by the lower temperature readings in these areas. However, no significant advantage was found for pulsed water mist at E and F series thermocouple locations.

Analysis of the radiant heat at P2 and temperature data from c’ and a thermocouple indicated that the optimal pulse period for the greatest inhibition of combustion inside the carriage, along with an effective cooling effect on the smoke temperature at these two locations on the platform, was 8 s-8 s.

The effect of pulsed water mist on enhancing gas disturbance is relatively close to the fire source. Due to the larger buoyancy of the smoke, its disturbance effect is more pronounced. As a result, pulsed water mist is notably superior to continuous-spray water mist near the fire source. However, far away from the fire source, the smoke exhibits almost no vertical buoyancy, primarily spreading horizontally. Consequently, the benefit of enhancing gas disturbance is not significant, and the effect of pulsed water mist is comparable to that of continuous spray, with no perceptible advantage.

The use of pulsed water mist leads to temperature oscillations that increase the closer it is to the fire source. The range of the oscillations decreases when the mist is farther away from the fire source.

Deploying 8 s-8 s pulsed mist near ignition zones reduces water usage by 40% while maintaining safe radiant heat (<2.5 kW/m2 at P2). For horizontal smoke zones (>10 m from fire), hybrid systems with continuous mist are advised.

Pulsed operations cut water consumption by 1200 L/hr for typical subway systems.

In conclusion, pulsed water mist offers significant advantages in terms of combustion suppression and cooling when used near a fire source. In contrast, its effect on the inhibition of smoke spread is similar to that of continuous water mist, displaying no apparent advantages.

It is recommended that the 8 s-8 s pulsed water spray be adopted in the near-fire area (<10 m), while a continuous water spray hybrid system be used in the horizontal-spread area (>10 m), so as to balance fire suppression efficiency and economic feasibility.