Experimental Study on the Impact of Smoke Exhaust Rate and Exhaust Vent Opening Mode on the Smoke Control Effect of the Point Smoke Exhaust System in an Asymmetric V-Shaped Tunnel

Abstract

1. Introduction

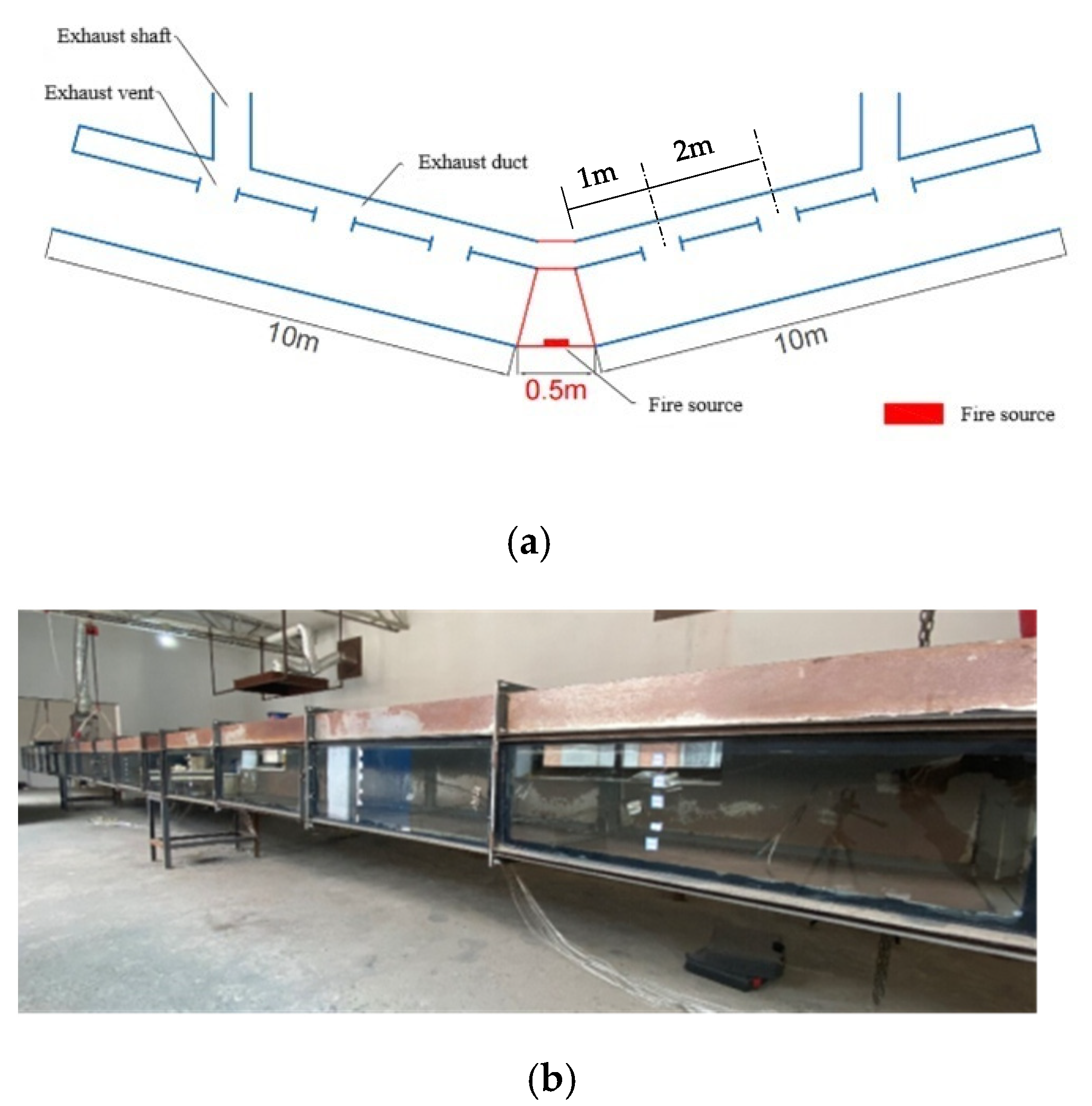

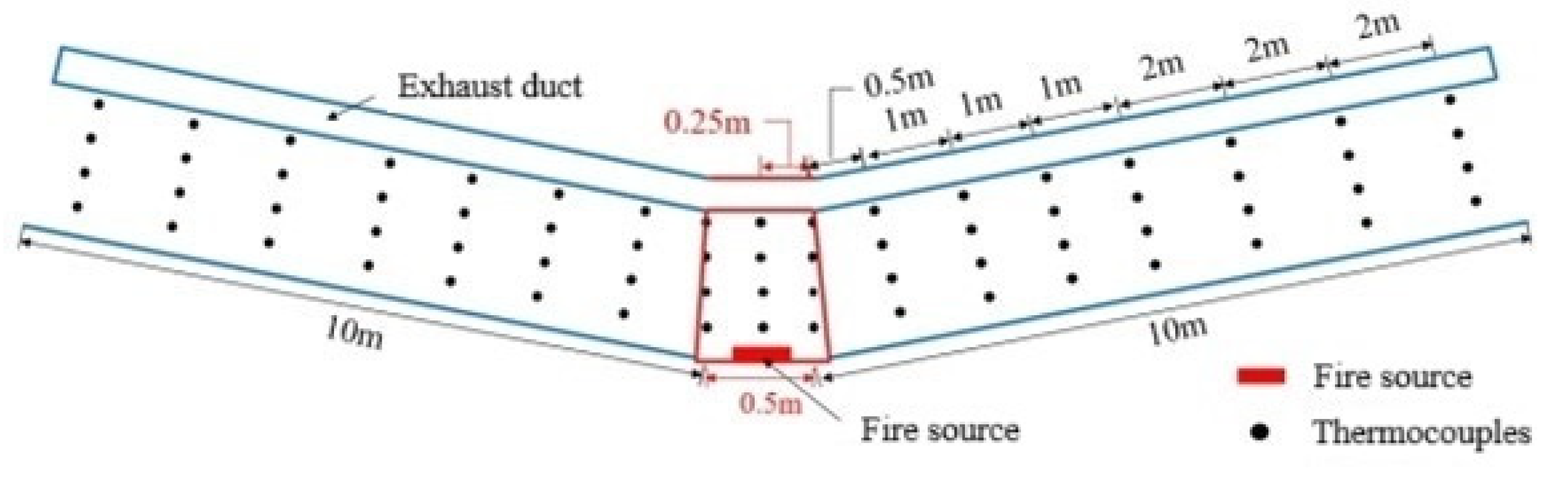

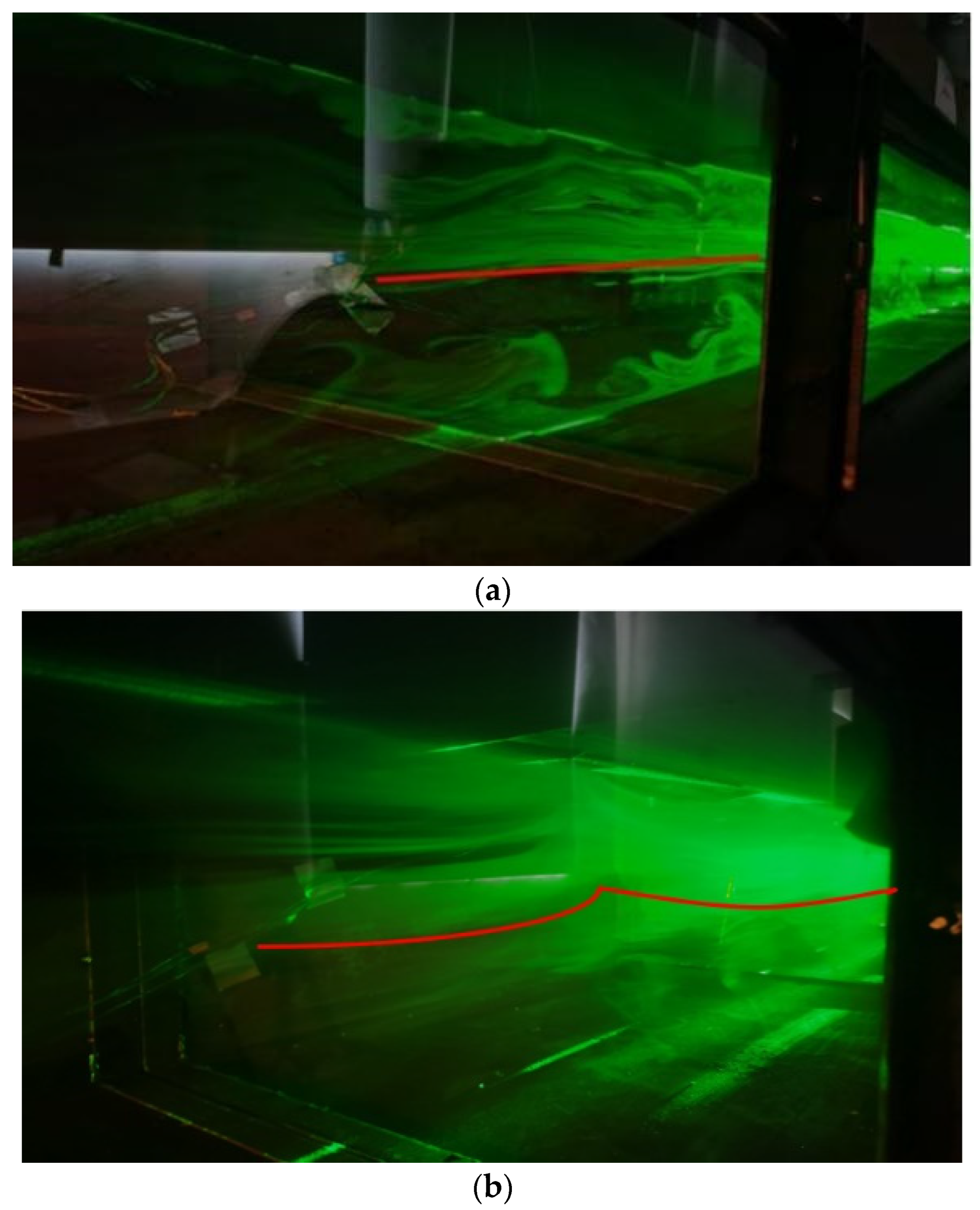

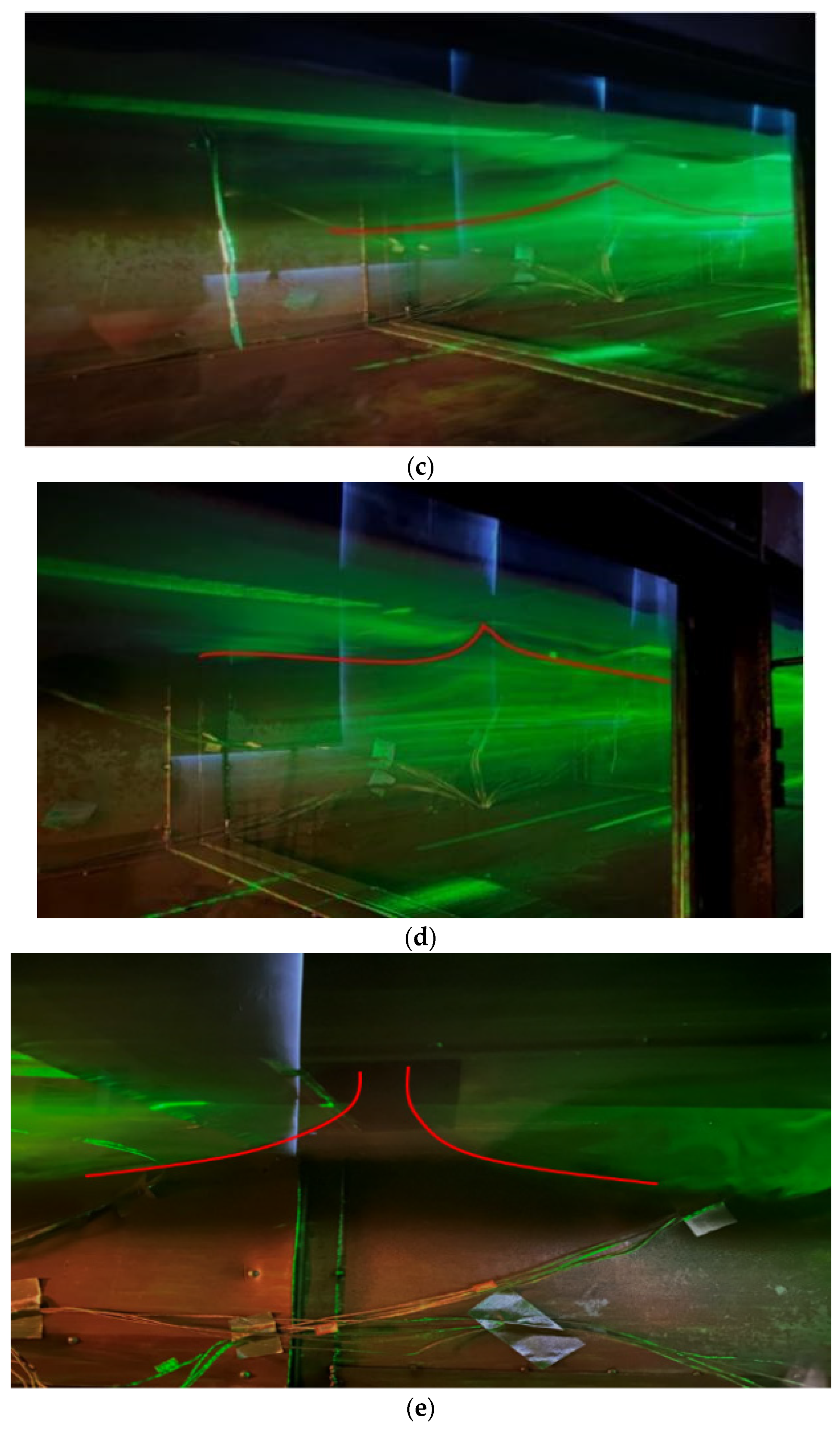

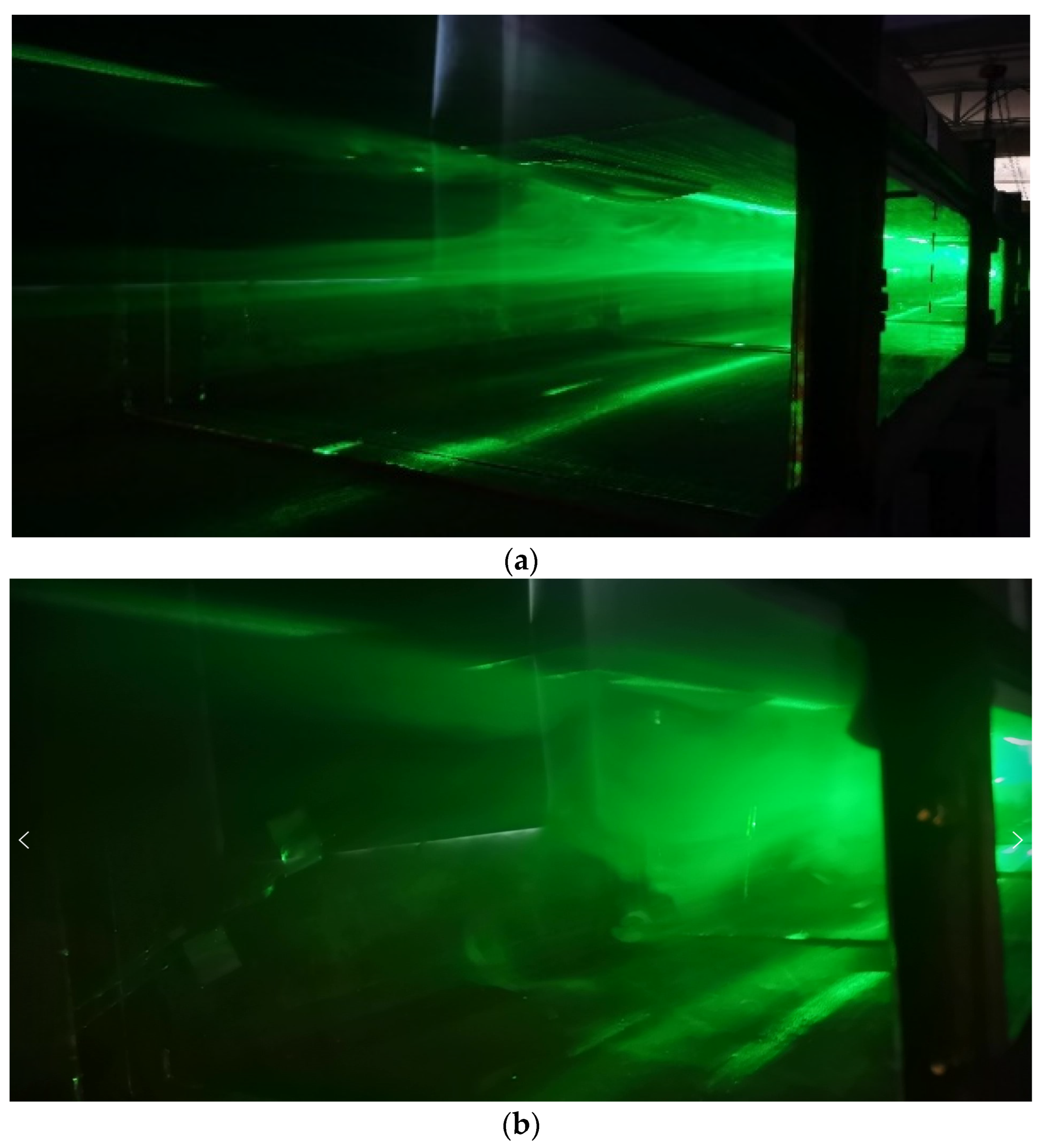

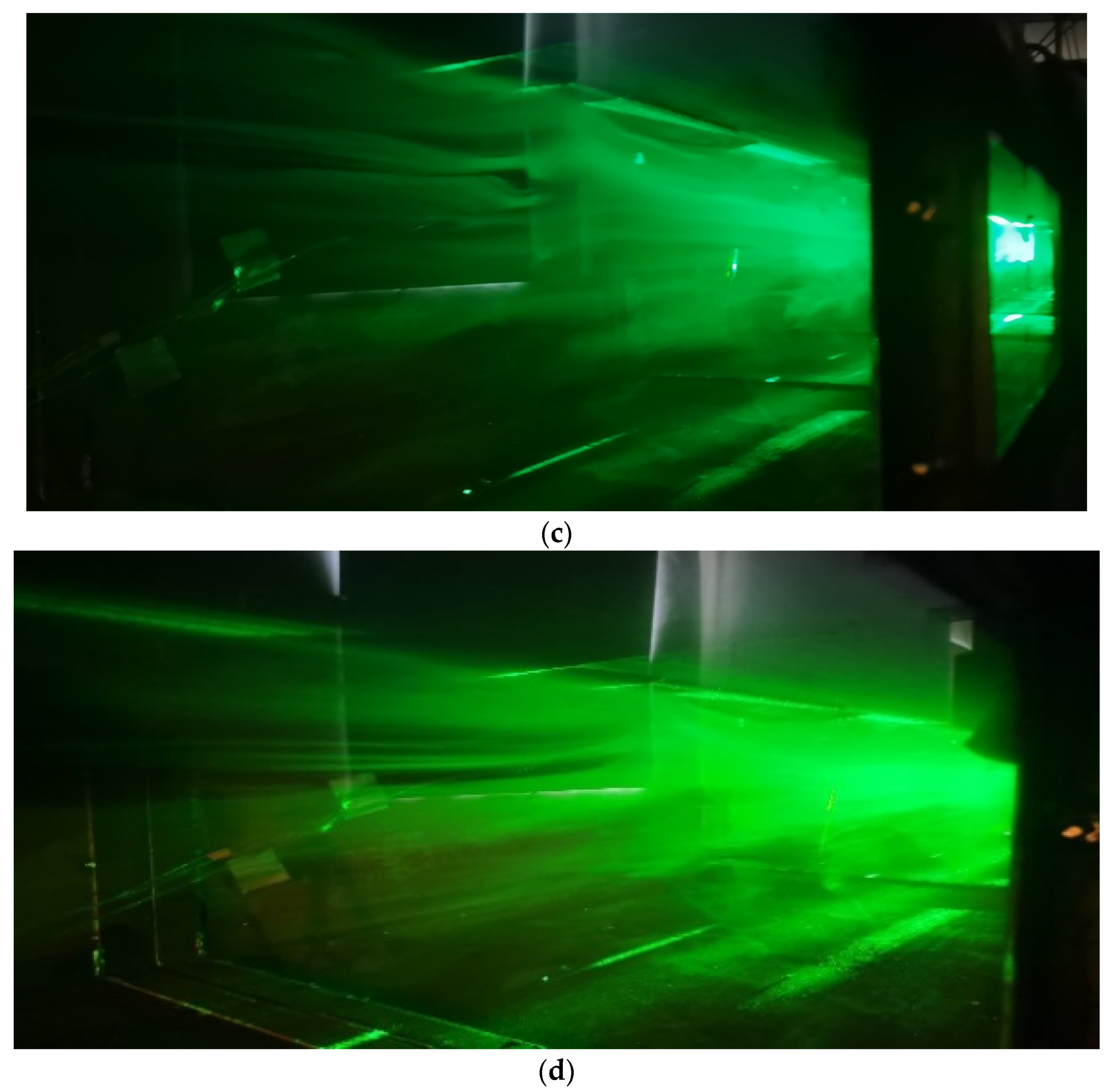

2. Experimental Setup

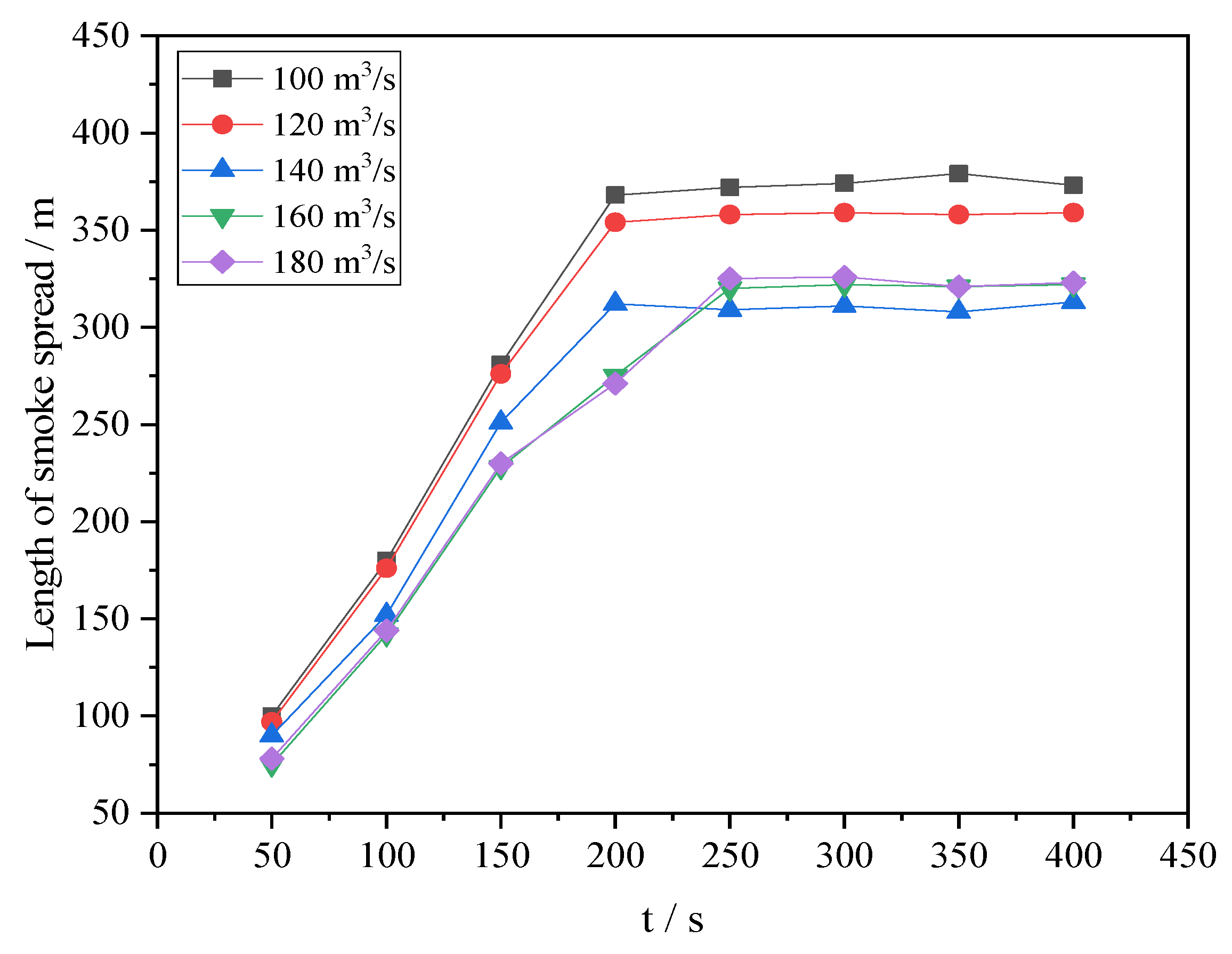

3. Study on Smoke Exhaust Rate of Point Exhaust System in Straight Tunnel

3.1. Experimental Scenarios

3.2. Results and Discussion

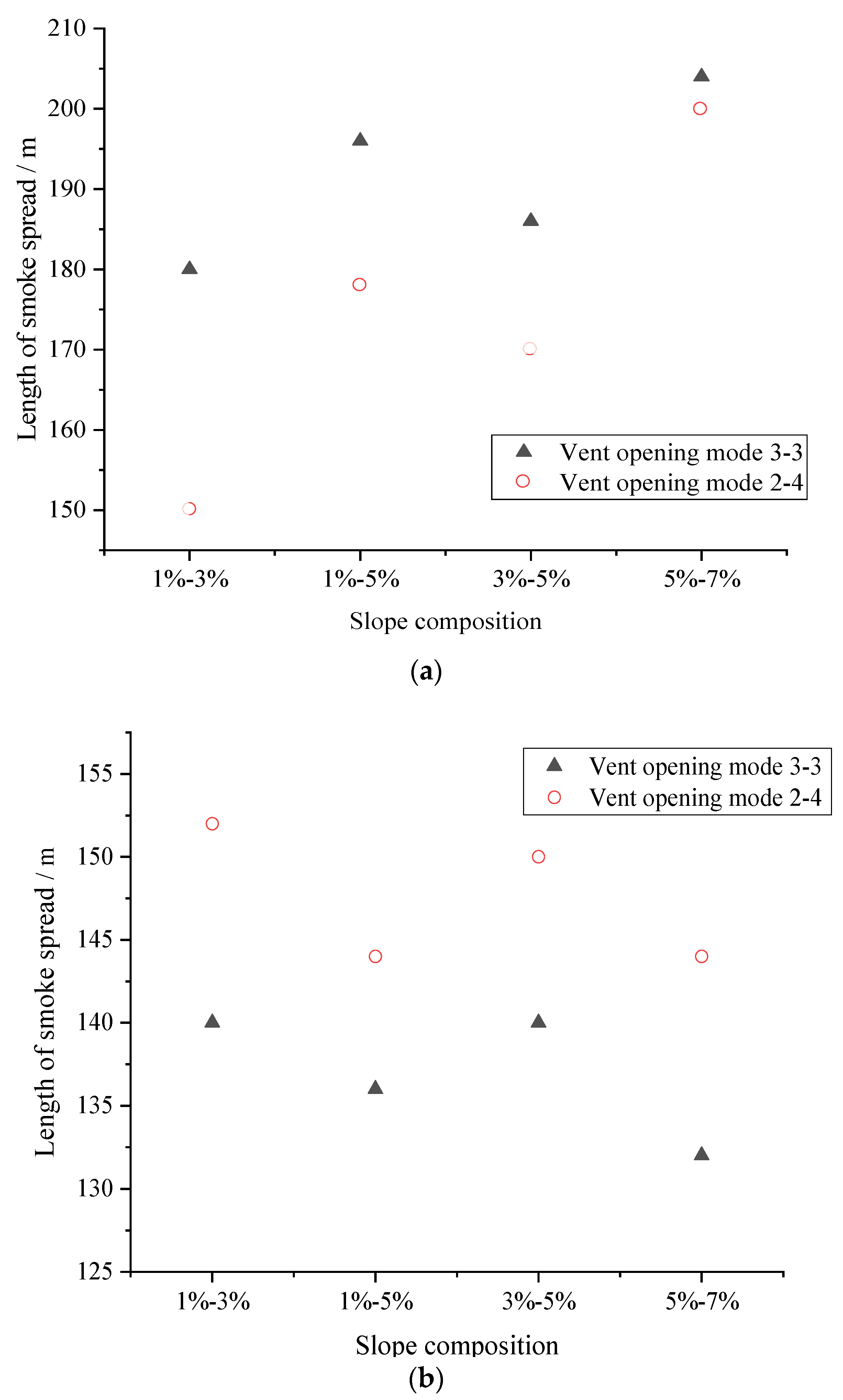

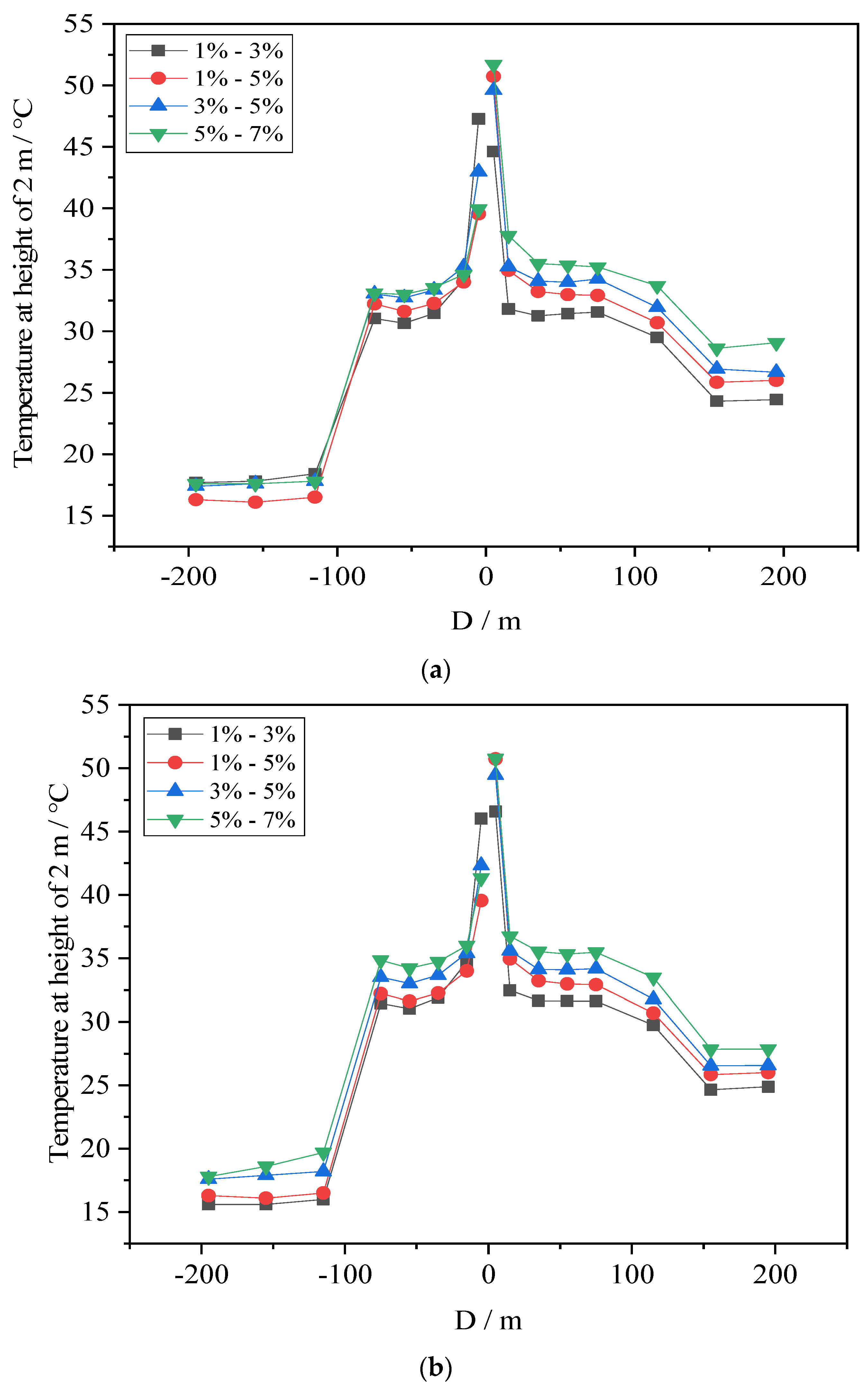

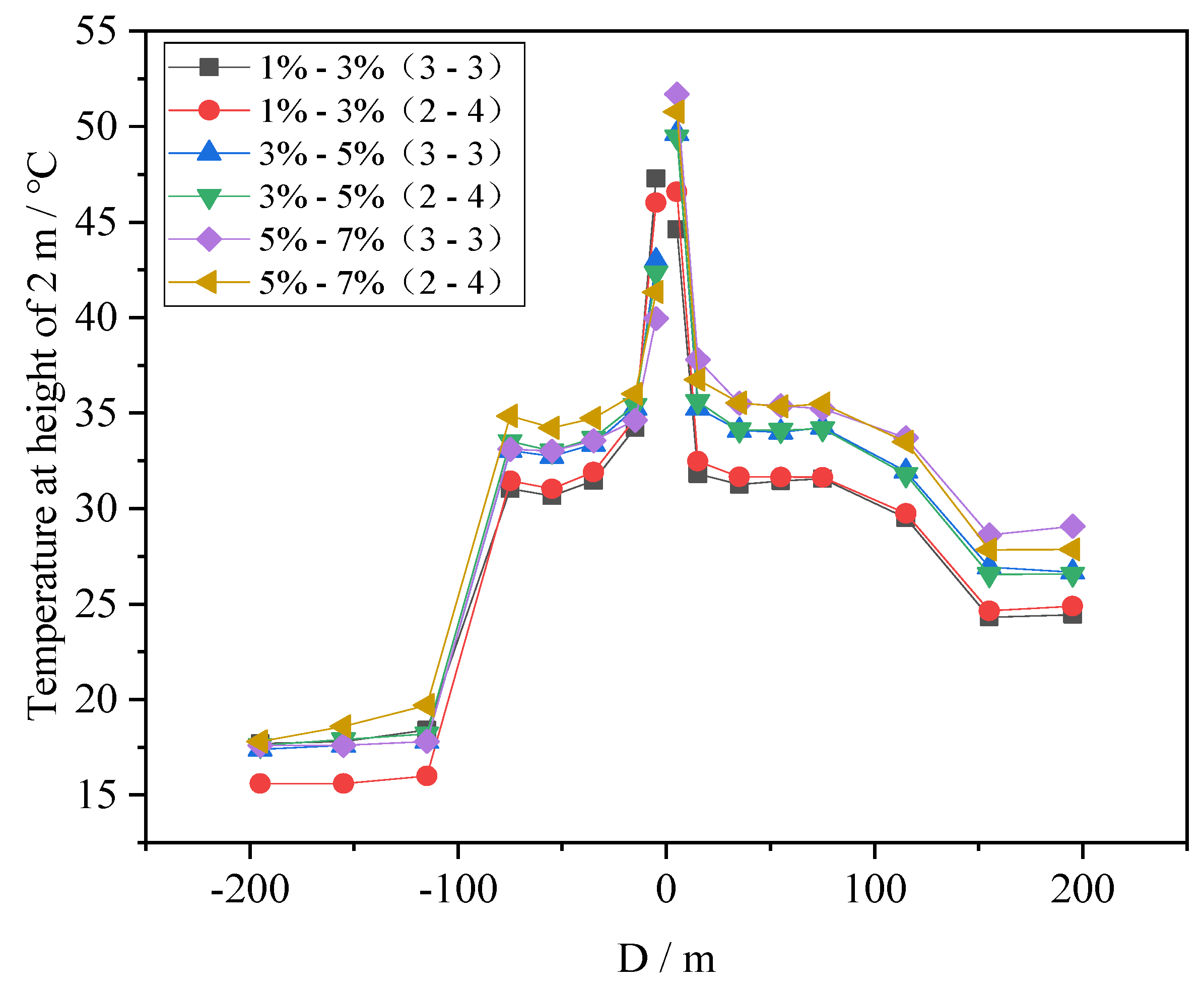

4. The Effect of the Vent Opening Mode on the Smoke Control Effect of the Point Exhaust System in an Asymmetric V-Shaped Tunnel

4.1. Experimental Scenarios

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- JTG/T D70/2-02-2014; Guidelines for Design of Ventilation of Highway Tunnels. People’s Communications Publishing House Co., Ltd.: Beijing, China, 2014. (In Chinese)

- DG/TJ08-2033-2017; Road Tunnel Design Code. Tongji University Press: Shanghai, China, 2017.

- PIARC Technical Committee on Road Tunnels. Fire and Smoke Control in Road Tunnels; World Road Association: Paris, France, 1999. [Google Scholar]

- Ingason, H.; Li, Y. Model scale tunnel fire tests with point extraction ventilation. J. Fire Prot. Eng. 2011, 21, 5–36. [Google Scholar] [CrossRef]

- Vauquelin, O.; Megret, O. Smoke extraction experiments in case of fire in a tunnel. Fire Saf. J. 2002, 37, 525–533. [Google Scholar] [CrossRef]

- Mei, F.; Tang, F.; Ling, X.; Yu, J. Evolution characteristics of fire smoke layer thickness in a mechanical ventilation tunnel with multiple point extraction. Appl. Therm. Eng. 2017, 111, 248–256. [Google Scholar] [CrossRef]

- He, L.; Xu, Z.; Chen, H.; Liu, Q.; Wang, Y.; Zhou, Y. Analysis of entrainment phenomenon near mechanical exhaust vent and a prediction model for smoke temperature in tunnel fire. Tunn. Undergr. Space Technol. 2018, 80, 143–150. [Google Scholar] [CrossRef]

- Lin, P.; Lo, S.M.; Li, T. Numerical study on the impact of gradient on semi-transverse smoke control system in tunnel. Tunn. Undergr. Space Technol. 2014, 44, 68–79. [Google Scholar] [CrossRef]

- Ying, H.; Jiao, W.; Xu, Z.; Zhao, J.; Yu, Z. Study on smoke spreading behavior under multi-point centralized smoke extraction in tunnel fires. Case Stud. Therm. Eng. 2025, 66, 105731. [Google Scholar] [CrossRef]

- Li, J.; Zeng, Y.; Tao, L.; Liu, Z.; Li, B. Experimental study on temperature decay and smoke control in tunnel fires with combination of multi-point smoke exhaust and longitudinal ventilation. Int. J. Therm. Sci. 2023, 183, 107847. [Google Scholar] [CrossRef]

- Tang, F.; He, Q.; Mei, F.; Wang, Q.; Zhang, H. Effect of ceiling centralized mechanical smoke exhaust on the critical velocity that inhibits the reverse flow of thermal plume in a longitudinal ventilated tunnel. Tunn. Undergr. Space Technol. 2018, 82, 191–198. [Google Scholar] [CrossRef]

- Zhao, P.; Yuan, Z.; Yu, N.; Liang, C. Effect of heat release rate and exhaust vent settings on the occurrence of plug-holing during tunnel fires with two-point extraction ventilation. Tunn. Undergr. Space Technol. 2020, 106, 103617. [Google Scholar] [CrossRef]

- Tao, L.; Zeng, Y. Effect of different smoke vent layouts on smoke and temperature distribution in single-side multi-point exhaust tunnel fires: A case study. Fire 2022, 5, 28. [Google Scholar] [CrossRef]

- Jin, J.; Jiang, X. A study of the characteristics of smoke stratification in lateral point smoke exhaust tunnel. Fire Saf. J. 2023, 140, 103833. [Google Scholar] [CrossRef]

- Ura, F.; Kawabata, N.; Tanaka, F. Characteristics of smoke extraction by natural ventilation during a fire in a shallow urban road tunnel with roof openings. Fire Saf. J. 2014, 67, 96–106. [Google Scholar] [CrossRef]

- Tanaka, F.; Kawabata, N.; Ura, F. Smoke spreading characteristics during a fire in a shallow urban road tunnel with roof openings under a longitudinal external wind blowing. Fire Saf. J. 2017, 90, 156–168. [Google Scholar] [CrossRef]

- Ingason, H.; Anders, L.; Li, Y. Model of ventilation flows during large tunnel fires. Tunn. Undergr. Space Technol. 2012, 30, 64–73. [Google Scholar] [CrossRef]

- Ho, Y.T.; Kawabata, N.; Seike, M.; Hasegawa, M.; Chien, S.W.; Shen, T.S. Scale model experiments and simulations to investigate the effect of vehicular blockage on backlayering length in tunnel fire. Buildings 2022, 12, 1006. [Google Scholar] [CrossRef]

- NFPA 92; Standard for Smoke Control System. National Fire Protection Association: Quincy, MA, USA, 2018.

- CJJ 221-2015; Code for design of urban underground road engineering. China Architecture & Building Press: Beijing, China, 2015.

| Characteristic Relationship | Expression |

|---|---|

| Position or length | |

| Temperature | |

| Velocity | |

| Total heat release rate | |

| Volumetric flow rate |

| Number of Scenarios | Spacing Between Vents/m | Vent Area/m2 | Number of Vent Openings | Smoke Exhaust Rate/m3/s |

|---|---|---|---|---|

| 1 | 40 | 6 | 6 | 100 |

| 2 | 120 | |||

| 3 | 140 | |||

| 4 | 160 | |||

| 5 | 180 |

| Number of Scenarios | Exhaust Rate /m3/s | Exhaust Vent Area/m2 | Exhaust Vent Opening Mode | Slope Composition |

|---|---|---|---|---|

| 1 | 140 | 6 | 3-3 | 1%-3% |

| 2 | 2-4 | 1%-3% | ||

| 3 | 3-3 | 1%-5% | ||

| 4 | 2-4 | 1%-5% | ||

| 5 | 3-3 | 3%-5% | ||

| 6 | 2-4 | 3%-5% | ||

| 7 | 3-3 | 5%-7% | ||

| 8 | 2-4 | 5%-7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qie, Y.; Li, J.; Li, Y.; Zhao, H.; Lin, X.; Li, D.; Hou, S.; Wang, Z. Experimental Study on the Impact of Smoke Exhaust Rate and Exhaust Vent Opening Mode on the Smoke Control Effect of the Point Smoke Exhaust System in an Asymmetric V-Shaped Tunnel. Fire 2025, 8, 162. https://doi.org/10.3390/fire8040162

Qie Y, Li J, Li Y, Zhao H, Lin X, Li D, Hou S, Wang Z. Experimental Study on the Impact of Smoke Exhaust Rate and Exhaust Vent Opening Mode on the Smoke Control Effect of the Point Smoke Exhaust System in an Asymmetric V-Shaped Tunnel. Fire. 2025; 8(4):162. https://doi.org/10.3390/fire8040162

Chicago/Turabian StyleQie, Yuzhou, Junmei Li, Yanfeng Li, Hengxuan Zhao, Xiushan Lin, Dongxue Li, Shiran Hou, and Zheng Wang. 2025. "Experimental Study on the Impact of Smoke Exhaust Rate and Exhaust Vent Opening Mode on the Smoke Control Effect of the Point Smoke Exhaust System in an Asymmetric V-Shaped Tunnel" Fire 8, no. 4: 162. https://doi.org/10.3390/fire8040162

APA StyleQie, Y., Li, J., Li, Y., Zhao, H., Lin, X., Li, D., Hou, S., & Wang, Z. (2025). Experimental Study on the Impact of Smoke Exhaust Rate and Exhaust Vent Opening Mode on the Smoke Control Effect of the Point Smoke Exhaust System in an Asymmetric V-Shaped Tunnel. Fire, 8(4), 162. https://doi.org/10.3390/fire8040162