Abstract

In small and medium-sized chemical plants, explosions constantly occur owing to runaway reactions because of equipment defects or human errors and so on. Accordingly, in this study, based on a case study of an explosion accident in a polystyrene reactor in South Korea, the dis-charge capacity of hazardous substances during a runaway reaction is reviewed and a method for safely disposing of hazardous substances is proposed. Using an acceleration rate calorimeter, the maximum temperature rise rate during the polystyrene reaction was determined, and it was determined that 355,643 kg/h can flow during a runaway reaction. A 30-inch header size was then selected to consider maximum flow rate, and two 81.4 heat exchangers were selected to completely condense the hazardous substances. As a result, the facilities at the workplace were configured to condense all hazardous substances and discharge them into the atmosphere. If this method is used, it is believed that the lives of workers can be protected by preventing fires and explosions in small and medium-sized chemical plants in which runaway reactions may occur.

1. Introduction

Small and medium-sized chemical plants handle hazardous materials, such as flammable liquids. There is a high probability of fire, explosion, or leakage if problems occur because of operator errors, aging equipment, or equipment failures []. Additionally, if reaction heat is not controlled owing to a failure of the cooling system, or if impurities are introduced during the reaction process, a runaway reaction may occur, so special care must be taken during the operation [,]. When atoms or molecules combine, heat is released, generating reaction heat, and when atoms or molecules break, energy is absorbed and heat is removed. Therefore, in the case of a batch reactor that produces polymers, such as urethane resin, acrylic resin, and styrene resin, the heat of the reaction is relatively high because the chains continue to combine during the reaction, and the possibility of fire or explosion is high because the batch reactor contains a large amount of flammable and reactive substances [,]. In such exothermic reactions, the phenomenon in which the reaction rate rapidly increases because of changes in the flow rate, concentration, inflow, or other parameters is called a runaway reaction [,]. This phenomenon is the cause of major industrial accidents, and it is the representative and main industrial accident that occurs in chemical reaction processes [,]. Serious industrial accidents caused by leaking of hazardous substances and fires and explosions in chemical plants have become a major issue worldwide, and studies and research to prevent them are being actively performed. In South Korea, the Process Safety Management System was introduced in the Safety and Health Act, and it has been in effect since 1996 []. Nevertheless, in the case of small and medium-sized South Korean chemical plants built in the 1970s and 1980s, the risk of major accidents is gradually increasing owing to workers’ carelessness, facility and equipment defects, and lack of awareness of the dangers of chemicals []. In South Korea chemical plants, when hazardous substances that can cause fire or explosion are discharged through a pressure safety valve or rupture disk, they are disposed of by combustion through a flare stack. For small and medium-sized chemical plants, the cost of installing flare stacks is high and the space is limited, so hazardous substances are dealt with by being discharged into the atmosphere at a certain height or connecting the reactor to a small-capacity scrubber or activated carbon tower. This method creates an explosive atmosphere on the ground, which may cause additional fires or explosions. Article 267 of the South Korea Occupational Safety and Health Standards Rules stipulates that hazardous substances emitted from process safety valves or rupture disks must be properly treated and discharged into the atmosphere [,]. In small and medium-sized chemical plants in South Korea, most hazardous substances are treated using scrubbers, activated carbon towers, or thermal storage incinerators depending on the physical and chemical characteristics of the materials. Unlike in other industries, large amounts of hazardous substances are generated. However, owing to space constraints or cost issues, treatment facilities are only constructed according to normal discharge characteristics, and their capacity is not calculated according to the occurrence of adverse reactions, making it impossible to completely treat dangerous substances. The design of the scrubbers or activated carbon towers used in these plants is not in accordance with the Occupational Safety and Health Act and engineering specifications. To solve this problem, the capacity must be calculated based on the total amount of hazardous substances emitted during an adverse reaction, but the size of the equipment (scrubber, activated carbon tower, or thermal storage incinerator) designed in this way makes it difficult to install it in local industrial complexes in South Korea, and governmental permission is impossible because of public complaints [].

As industrialization progresses in South Korea, fire and explosion accidents, such as runaway reactions or open pool fires, frequently occur in reactors handling hazardous materials, and several studies have been performed to prevent these accidents. By conducting and analyzing experiments using thermal risk assessment tests, Lee demonstrated that a runaway reaction can occur, but they did not suggest preventive measures in the event of a runaway reaction [,]. Han analyzed the maximum temperature increase rate to identify the risk of a runaway reaction and proposed a measure to automatically inject a polymerization inhibitor to prevent a runaway reaction. However, in the case where a runaway reaction occurs despite various measures, no countermeasures were established []. Fujita reported that during acrylic reactions, not only monomers but also addition dimers generate water and explosions owing to heat. In each accident scenario, the reaction progress was subdivided into each reaction step to investigate the energy release and identify the chemical species. However, in the case where a reaction occurs, no specific treatment measures were provided []. Schmidt presented three modules to control runaway reactions. The first module consisted of a runaway reaction detection method, the second module was a potential risk assessment method, and the third module consisted of a countermeasure evaluation method after the runaway reaction began. However, no plan was provided on how to design the rear end after a runaway reaction occurred and the rupture disk ruptured []. Previous studies identified the risks during reactions, but they did not provide treatment methods, such as standards for installing safety devices.

In this study, we investigated methods to resolve the risks when discharging hazardous substances directly into the atmosphere or connecting the reactor to a scrubber or activated carbon tower in case of emergency discharge of hazardous substances owing to runaway reaction or open pool fire in small and medium-sized chemical plant. These methods include the following:

- Determination of the emission capacity during runaway reactions and open pool fires in the polystyrene polymerization process (styrene monomer).

- Selection of a discharge header size with a Mach number of ≤0.5 and calculation of the amount of condensation for each climate using a process simulation program (the Aspen flare system analyzer).

- Assuming that the smallest amount of condensation for each climate is condensed in the knockout drum and that uncondensed steam flows into the heat exchanger, a process simulation program was used to design the steam to be condensed.

Considering the results, we proposed a three-step design plan to completely remove hazardous substances not only in normal operations but also in abnormal operations.

2. Problem Description and Selection of the Chemical Plant

2.1. Runaway Reaction

Most polymerization processes are exothermic, so care must be taken with polymerization reactions. In particular, the polystyrene polymerization process is dangerous because it is highly likely to proceed to a runaway reaction if temperature control or the initiator input amount is not appropriate during the additional polymerization reaction of the styrene monomer []. The polystyrene reaction is shown in Figure 1.

Figure 1.

Polystyrene reaction equation.

2.2. Accident Overview and Previous Research

In South Korea, during test operations after regular maintenance at a polystyrene production plant, a rupture disk ruptured owing to an increase in the pressure owing to a runaway reaction in the reactor, and a large amount of styrene monomer vapor was ejected. The cause of the problem was presumed to be a runaway reaction caused by failure in the temperature control of the reactor owing to the cooling water inside the condenser not flowing smoothly []. In this polymerization process, the heat transfer of the material is slow. Therefore, if the reaction heat generated during polymerization is not properly dissipated, local overheating may finally occur. Loss of temperature control is one of the main reasons why runaway reactions occur [,]. Polystyrene is manufactured by the addition polymerization of the styrene monomer. Polystyrene is essential in our daily lives. It is a hard plastic widely used in packaging materials, insulation materials, disposable cups, and kitchen utensils [,].

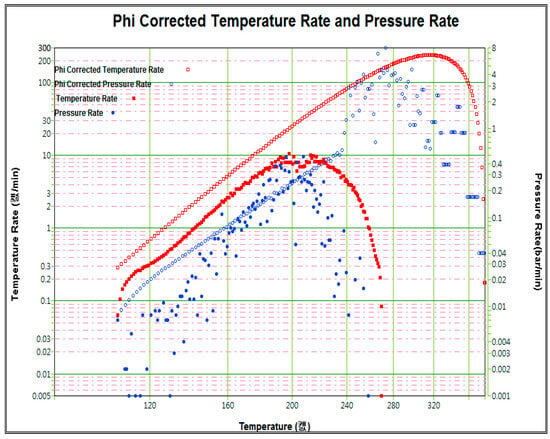

The experimental results of accelerating rate calorimetry of the runaway reaction of the styrene monomer performed by the Occupational Safety and Health Research Institute are shown in Figure 2 []. An accelerating rate calorimeter is a device that measures the thermal stability of materials under adiabatic conditions.

Figure 2.

Experimental results of accelerated rate calorimetry of the runaway reaction of the styrene monomer.

Some of the key factors in this process are heat generation, onset temperature, and changes in temperature and pressure over time. You can measure TMR (time to maximum rate), etc.

The capacity of the bottle into which the sample was introduced is 10 mL. In case of an actual accident, proper temperature control was not achieved. Assuming the worst case, 5.5 mL of styrene monomer was put into the bottle, and the experiment was conducted by setting the experimental conditions for each temperature as follows: temperature range of 30 to 450 °C, heat detection sensitivity of 0.02 °C/min, and heat step of 5 °C.

Based on the experimental results, the maximum temperature rise rate of the styrene monomer required for the calculation of the runaway reaction is given in Table 1.

Table 1.

Maximum temperature rise rate.

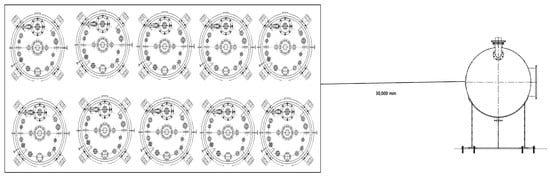

2.3. Selection of the Polystyrene Production Plant

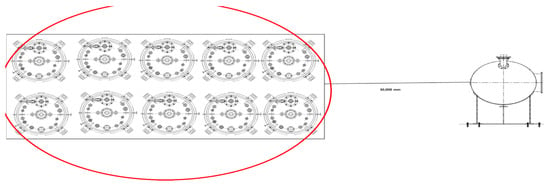

To review the safety design criteria, the process conditions must be selected. For the calculation of the emission capacity, there are cases where the entire factory is affected, such as an open pool fire, and cases where a single piece of equipment is affected, such as a runaway reaction. In this study, we applied similar process conditions to those of the polystyrene-producing South Korean company where the accident had occurred. The specifications of the chemical plant and the process conditions are given in Table 2, and the layout of the factory is shown in Figure 3. Five reactors with an inner diameter of 2000 mm were installed in the same direction, and the separation distance between the reactors was 300 mm. Five reactors with an inner diameter of 2000 mm were installed in the same direction, spaced 1000 mm apart, for a total of 10 reactors in operation.

Table 2.

Chemical plant and process conditions.

Figure 3.

Layout of the polystyrene-producing Korean company where the accident occurred.

3. Results and Discussion

3.1. Determination of Rupture Disk Size When the Runaway Reaction Occurs

A runaway reaction is a typical abnormal reaction in which the temperature and pressure become abnormally large. When hazardous substances are discharged through a rupture disk, the two phases are mixed, so the bubbles generated at this time act as an obstacle to the discharge of the discharged material, resulting in a rupture disk that is larger than the calculated value for a single-phase gas. The design of this two-phase flow is based on selecting a larger rupture disk than the typical rupture disk so that the discharge is smoothly discharged at the set pressure of the rupture disk [,,]. The mass of the styrene monomer introduced during the runaway reaction was 5600 kg. From the results of testing using an acceleration rate calorimeter, the maximum temperature rise rate at the saturation temperature (476.62 K) of the reactor design pressure ( was approximately 45 K/min (0.75 K/s) (Table 1). Additionally, the maximum temperature rise rate at the saturation temperature (501.36 K) of the maximum allowable working pressure was approximately 48.7 K/min (0.81 K/s). This shows that if the coolant is not properly supplied, a runaway reaction may occur. Because instantaneous overpressure occurs during a runaway reaction, the Occupational Safety and Health Act stipulates that a rupture disk should be installed among the pressure relief devices.

When the runaway reaction occurs and the set pressure is reached, the rupture disk opens and the pressure momentarily decreases. The pressure of the styrene monomer in the reactor is instantly reduced and flashing occurs, reaching the saturation temperature of the reduced pressure. At this time, the styrene monomer instantaneously evaporates. The mass flux () can be calculated from the amount of the flashing liquid and the Clausius–Clapeyron equation.

The definitions of the variables are given in Table 3.

Table 3.

Variables for the mass flux calculation.

The physicochemical properties for the calculation were identified by process simulation using Aspen plus V12. The mass flux () was calculated to be 3528.2 kg/· s.

The exothermic heat release rate is expressed as

The definitions of the variables required to calculate the exothermic heat release are given in Table 4.

Table 4.

Variables required to calculate the exothermic heat release rate.

The exothermic heat release rate calculated using Equation (2) was 1.504 kJ/kg·s.

Based on the mass flux () and heat release rate results, the size of the rupture disk required during a runaway reaction can be calculated by

The definitions of the variables are given in Table 5.

Table 5.

Variables required for the rupture disk calculation.

Applying the physical properties and process conditions presented above, the size of the rupture disk was calculated to be 0.028 . Thus, the required diameter of the rupture disk is 0.18 m. The variables required for the calculation are given in Table 5.

Additionally, by multiplying the rupture disk area by the mass flux ( = 3528.2 kg/· s) and converting the time, the mass of the styrene monomer flowing per hour was determined to be 355,643 kg/h.

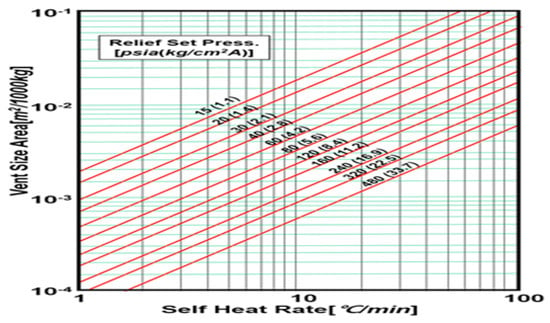

3.2. Determination of Rupture Disk Size When the Runaway Reaction Occurs (Diagrammatic Method)

The mass of the styrene monomer during the reaction was 5600 kg, and the maximum temperature rise rate measured by an acceleration calorimeter at the set rupture disk pressure was 45 K/min. Based on these values, from the nomograph for sizing the two-phase rupture disk area (Figure 4), the required rupture disk area was approximately 0.018 /1000 kg. The mass of the reactant was 5600 kg, so the required rupture disk area was 0.101 . Because the rupture disk area calculated by the diagrammatic method generally represents a conservative value, the rupture disk area was multiplied by the correction coefficient of 0.5 [,,]. Therefore, the rupture disk area was 0.051 (diameter of 0.253 m).

Figure 4.

Nomograph for sizing the two−phase rupture disk area.

Figure 4 shows a graph produced based on the following assumptions: 20% overpressure generation; low viscosity; choke flow; and turbulent flow. In addition, there is the possibility of human error when checking the graph, and it is written conservatively. Therefore, from the perspective of rupture disk size optimization, it is considered to be more reasonable to use the method involving calculation through Equation (3) rather than the method involving calculation through Figure 4.

3.3. Determination of Emission Capacity during an Open Pool Fire

Reactions like polystyrene polymerization reactions handle flammable substances, so the effects of fire should be considered regardless of whether the batch reactor is indoors or outdoors, and the design should reflect this in the event of an open pool fire. For the amount of heat generated during a fire, the following equation is applied if appropriate exhaust equipment is available and if the fire-extinguishing equipment can be maintained for more than 2 h.

where F is the environmental factor that blocks heat conduction in the event of an open pool fire, which is a value between 0 and 1, and is the total wetted surface area (). If the fire-extinguishing equipment cannot be maintained for more than 2 h, the following equation is applied:

Appropriate drainage equipment can be determined from a subjective rather than an objective perspective, and, above all, it should be designed to move dangerous substances to a safe area. According to South Korean law, appropriate fire-extinguishing equipment only needs to contain sufficient fire-extinguishing water to ensure fire safety for up to 30 min, except in cases where large-scale petrochemical plants or semiconductor companies operate in a large area and have large fire-extinguishing water-storage tanks. Therefore, most small and medium-sized chemical plants apply Equation (5).

Owing to the rapid reaction during the runaway reaction, foam-shaped emissions are discharged through the rupture disk. Therefore, because smooth discharge becomes difficult, it is recommended to select a rupture disk that is larger than that calculated for the single-phase gas. When handling flammable substances, the largest emission capacity is generally an open pool fire. In the case of small and medium-sized chemical plants, Equation (5) is only used because they have fire-extinguishing water that meets the fire safety standard (NFSC) for 30 min, which is the minimum standard. Because the reactor was installed in a confined space (Table 2), according to API Standard 521, the power factor was calculated to be 1 and the environmental factor (F) was assumed to be 1 considering the worst conditions. The total wetted surface area () was calculated using the reactor area and 10% piping area (25.52 ) in Table 2. By dividing the calculated result (1,809,368 kcal/h) by the latent heat required for evaporation in the case of an open pool fire (76 kcal/kg), the required ejection amount of an open pool fire was calculated to be 23,807.5 kg/h. As a result, Equation (5) is modified to

Once the emission capacity is calculated, the rupture disk area can be calculated by

From the physical and chemical properties calculated using Aspen plus V12, the required area of the rupture disk is 0.007232 , which indicates a diameter of 0.096 m. The coefficient (α) according to the rupture disk type varies depending on how the rupture disk is installed, but 0.68 was applied to provide the most conservative calculation. The variables required for the calculation are given in Table 6.

Table 6.

Variables required for the mass flux calculation.

In the event of an open pool fire, the discharge capacity is determined based on the scope of the influence of the fire. In API 521, the calculation is performed based on a height of ≤ 7.6 m from the center of the ignition source and an area between 230 and 460 . There are a total of 10 reactors in the polystyrene process where the accident occurred. The inner diameter is 2000 mm and the height is 3000 mm, and the separation distance between reaction periods is 300 mm horizontally and 1000 mm vertically. Thus, based on a diameter of 12.2 m of the 460 circle area and a height of 7.6 m, all of the reactors in the chemical plant are subject to open pool fire [,]. Based on this standard, 10 reactors in the chemical plant are included within the scope of the fire, as shown in Figure 5. Ultimately, if an open pool fire occurs, the styrene monomer emission capacity is 238,075 kg/h.

Figure 5.

Fire range when an open pool fire occurs.

3.4. Selection of the Discharge Header

To safely handle the hazardous substances discharged through a process safety valve or rupture disk, it is important to select an appropriate discharge header. The amounts of hazardous substances discharged through the tail pipe and header were selected based on Table 7.

Table 7.

Design criteria for the treatment system headers of the pressure relief devices.

The material of the header must be selected so that it has no effect on the fluid characteristics and so that it is resistant to the temperature changes in summer and winter. When high-pressure discharge is momentarily discharged to the header through a pressure release device, noise is generated owing to the turbulent flow resulting from a high pressure drop. At this time, high-frequency circumferential vibration is generated on the outer wall, which can cause rapid fatigue failure. To minimize this phenomenon, the Mach number is designed to be within a certain standard. New factories set the Mach number to ≤ 0.5. The tail pipe should be connected to the header at an angle of 45°, if possible, rather than at an angle of 90°, to reduce the repulsion force []. Even if an appropriate length of the header size is calculated, there are many variables that depend on the Mach number, such as the pipe diameter. The calculation process is very complicated and difficult, so the size is selected by a header simulation. Since this program has several equations of state, you must understand the handling process and select an appropriate one. Since the raw material for producing polystyrene resin is a hydrocarbon material, the Soave–Redlich–Kwong (SRK) equation of state is applied. It follows the Redlich–Kwong equation of state, which is a previously announced formula, and it is an improved equation of state because it adds several improvements and options. Thus, it is suitable for styrene monomers composed of hydrocarbons due to it improving the volume transformation concept and improving the phase equilibrium calculation through the selection of the Kabadi–Danner mixing law. In the case of header piping, there is no problem using regular steel pipes, but as the discharge header and knockout drum are installed outdoors, there is a risk of corrosion, and since their soundness must be maintained under any circumstances, the material should be stainless steel (STS304), which is resistant to corrosion, rather than steel pipe.

If hazardous substances flow inside the header, there is a possibility that condensation may occur over time and become two-phase due to the influence of external air from pipes installed outdoors. Therefore, Beggs and Brill equations were applied.

The atmosphere needs to be considered because hazardous substances discharged through the rupture disk and process safety valve are affected by the atmosphere as they flow through the header to the treatment facility. Because the temperature difference between summer and winter in South Korea is large, the size of the pipe header must be selected taking this into consideration. The highest temperature in summer in the area where the accident occurred was 37.8 °C, the lowest temperature in winter was −21.8 °C, the maximum wind speed was 26.8 m/s, and the average wind speed was 2 m/s. For an open pool fire, the flow rate was calculated to be 238,075 kg/h. For a runaway reaction, the flow rate was calculated to be 355,643 kg/h. When determining the size of the main header, the larger flow rate is considered, which is that of the runaway reaction.

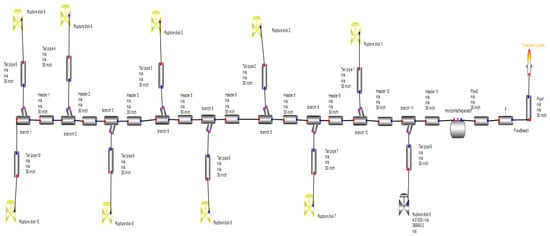

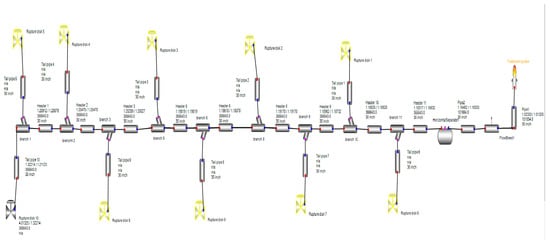

To confirm the degree of condensation, the locations of the reactors where the runaway reaction occurred were determined to be reactor number 10, the farthest reactor from the knockout drum, and reactor number 6, the closest reactor to the knockout drum Additionally, the pressure drop of the heat exchanger to be installed for condensation was determined to be 0.14 bar. Figure 6 shows that in four cases—(37.8 °C, 26.8 m/s), (37.8 °C, 2 m/s), (−21.8 °C, 26.8 m/s), (−21.8 °C, 2 m/s)—hazardous substances are released through the rupture disk closest to the exhaust facility. This is a simulation to determine the amount of condensation when discharged.

Figure 6.

Header simulation for reactor closest to exhaust facility in four cases [(37.8 °C, 26.8 m/s), (37.8 °C, 2 m/s), (−21.8 °C, 26.8 m/s), (−21.8 °C, 2 m/s)].

Figure 7 is a simulation to determine the amount of condensation when hazardous substances are discharged through the rupture disk farthest from the exhaust facility under the same climatic conditions. As a result, the simulation was performed a total of eight times, and the results are presented in Table 8.

Figure 7.

Header simulation for reactor farthest from exhaust facility in four cases [(37.8 °C, 26.8 m/s), (37.8 °C, 2 m/s), (−21.8 °C, 26.8 m/s), (−21.8 °C, 2 m/s)].

Table 8.

Simulation results.

As a result, the maximum condensation behind the header can be calculated based on the maximum wind speed in the winter. Of the total amount of 355,643 kg/h discharged during the runaway reaction, 254,070.3 kg/h was condensed.

3.5. Selection of the Knockout Drum and Heat Exchanger

While hazardous materials are passing through the header to the treatment facility, condensation may occur owing to the influence of the atmosphere. If the header is connected to the treatment facility in this state, not only will droplets flow into the treatment facility and will absorption, cleaning, and collection not be able to properly occur, but in the case of activated carbon towers, large amounts of dangerous substances, such as flammable liquids, will be adsorbed, which poses the risk of fire or explosion. Therefore, these substances must be removed [].

A heat exchanger refers to a device that exchanges the heat of a fluid by bringing it into contact with two fluids with different temperatures [,]. If dangerous substances resulting from a runaway reaction pass through the knockout drum and flow into the facility with insufficient processing capacity, a fire or an explosion may occur, so it is desirable to ensure 100% condensation.

From the knockout drum size based on the results of the header simulation program, it was calculated that the amount of liquid accumulated was the greatest at the lowest temperature and maximum wind speed in winter. In general, when hazardous substances are discharged from a petrochemical plant, the drop constant is calculated based on API 521, and the knockout drum size is calculated accordingly, assuming separation of the gas and liquid. For a holding time of 5 min, the knockout drum size is 31.8 according to API 521. In reality, a knockout drum of this size cannot be installed in small and medium-sized factories in South Korea owing to site size issues. Even if large knockout drums are installed, their size is approximately 10 . In this case, the holding time is approximately 1 min and 30 s, so an automatic starting device for the drain pump must be installed according to the knockout drum level. Additionally, in the event that hazardous substances are released owing to adverse reactions, it is deemed to be necessary to implement a rapid response to ensure workplace safety.

From the header simulation program, the most conservative condition for the installation of the heat exchanger at the rear of the knockout drum is the situation where reactor number 6 is close to the knockout drum. The maximum temperature in summer is higher than the maximum temperature in winter, and the external wind speed of 2 m/s cannot smoothly condense the fluid inside the header, so the heat exchanger installed at the rear of the knockout drum must take on more load. If the header is directly connected to the treatment facility without installing a cooling device, such as a heat exchanger, additional damage may occur owing to fire and air emissions owing to heat accumulation because of the insufficient capacity of the air purification device, such as an activated carbon tower. In addition, the South Korea Occupational Safety and Health Standards stipulate that the hazardous substances emitted from process safety valves must be disposed of by methods such as combustion, absorption, cleaning, collection, or recovery; and laws, such as the Chemical Substances Control Act, specify that hazardous substances must be treated and discharged.

At the highest temperature and average flow rate, the flow entering the heat exchanger without condensation in the header was 114,757.4 kg/h. This was implemented using Aspen exchanger design and rating, a heat exchanger simulation program, to determine the size of the heat exchanger capable of complete condensation. A BEM-type heat exchanger is frequently used, as the front-end stationary head type corresponding to the head is a cover type and the shell type E corresponding to the body has an effective structure, has a large heat transfer effect, and is economical. This is the most widely used heat exchanger form.

The input parameters of the heat exchanger are given in Table 9.

Table 9.

Heat exchanger input parameters.

In the simulation, two 81.4 heat exchangers were connected in parallel to minimize vibration issues and the pressure drop to fully condense the flow of the styrene monomer through the header. If the rate of runaway reactions in the workplace is not high and emergency situations do not frequently occur, the vibration problem can be ignored. The heat exchanger can then be made more compact.

It is desirable to design the heat exchanger so that it can completely condense hazardous substances. Another consideration when constructing a heat exchanger is the constant operation of the cooling water pump. The line speed within the header is over 20 m/s (Table 10), which means that the time it takes to reach the treatment facility after discharging the hazardous materials is less than 2 s. Therefore, in the case of general small and medium-sized businesses, not large-scale chemical plants, the cooling water pump must be operated at all times and connected to an emergency generator or Uninterruptible Power Supply (UPS) to ensure the cooling performance of the heat exchanger at all times, and a spare pump must be installed to prepare for all mechanical and electrical failures.

Table 10.

Heat exchanger simulation result.

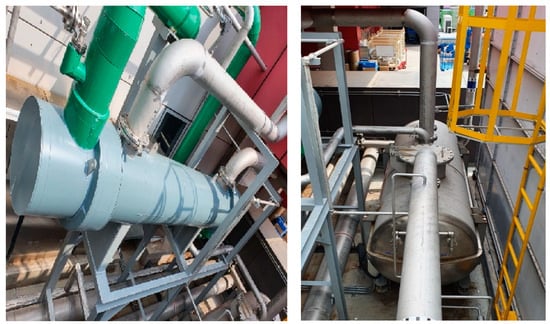

3.6. Case Study of the Application in a Small–Medium-Sized Chemical Plant in South Korea

After the occurrence of the polystyrene runaway reaction accident, government agencies, such as the South Korea Occupational Safety and Health Agency, studied various methods to solve the problem in reactors where exothermic reactions occur. However, it is not possible to place a flare stack in an area where air purification devices, such as scrubbers and activated carbon, are installed in advance and space is limited. After several trials and errors, a heat exchanger was installed at the end of the header, leading to the establishment of a rapid emergency action plan in the case of the discharge of hazardous substances. Although this method may not be legally appropriate, it is currently judged to be the best method applicable to small and medium-sized businesses in South Korea. An example of a chemical plant where this is applied is shown in Figure 8.

Figure 8.

Knockout drum and heat exchanger installed in the same manner as in this study.

4. Conclusions

Hazardous substances generated during the operation of a chemical plant must be safely disposed of, but in the case of small and medium-sized chemical plants, hazardous substances are not completely treated and are discharged into the atmosphere. From this perspective, this study studied safety design standards for safe handling in case of the emergency release of hazardous substances. Based on the case of an accident in the polystyrene polymerization batch reactor process, the maximum amount of hazardous substances in a runaway reaction was calculated through experiments, and the size of the header that could smoothly condense them was determined. Afterwards, overall safety design standards were presented to completely condense hazardous substances that were not condensed through the knockout drum through a heat exchanger and discharge them into the atmosphere. Currently, in small and medium-sized chemical plants in Korea, when hazardous substances are discharged through process safety valves or rupture disks, the discharge capacity is not accurately calculated, but it is installed to be the same as the header of the existing factory or is installed to be the same as the largest size of the individual process safety valve or rupture disk. Moreover, the reality is that it is simply connected to an environmental treatment facility such as an activated carbon tower or scrubber and is discharged into the atmosphere without treatment. Applying this method is expected to be of great help in preventing fires and explosions and improving safety in Korea. Lastly, the simulation program to set the safety design standards after the experiment can be properly implemented only when appropriate physical properties are selected according to the hazardous substance, so it is important to understand the physicochemical characteristics of the substance.

Author Contributions

Conceptualization, S.-R.K.; methodology, S.-R.K.; validation, S.-G.K.; writing—original draft preparation, S.-R.K. and S.-G.K.; writing review, S.-G.K.; editing, S.-R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Byun, Y.S. A Study on the Improvement of Preventive Measures for Improving the Safety of Chemical Reactor. J. Korean Inst. Gas 2020, 24, 32–38. [Google Scholar] [CrossRef]

- Kim, Y.H.; Song, S.G.; Park, H.A. Chemical Accident Case Study; Report No.: 2020-Professional Engineering Bureau-338; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2020; pp. 2–7.

- Kim, S.R. The Appropriateness Review of the Pressure Safety Device in Polyurethane Polymerization Process; Korea National University of Transportation: Chungju, Republic of Korea, 2018; pp. 1–10. [Google Scholar]

- Kim, S.R. A Study on the Improvement of Treatment Methods in the Discharge of Hazardous Substances from the Phenolic foam Reaction Process; Korea National University of Transportation: Chungju, Republic of Korea, 2021; pp. 42–45. [Google Scholar]

- Lee, K.H.; Kim, W.S.; Jun, J.W.; Joo, Y.J.; Park, K.S. The Risk Assessment of Runway Reaction in the Process of Fridel-Crafts Acylation for Synthesis Reaction. J. Korean Soc. Saf. 2021, 36, 24–30. [Google Scholar] [CrossRef]

- Han, W.S. Technical Guidelines for Fire and Explosion Prevention in Mixing Processes in Chemical Plants; Report No P-132-2013; KOSHA: Ulsan, Republic of Korea, 2013; p. 1.

- Kim, W.S.; Lee, K.W. Hazard Evaluation of Runaway Reaction in Deboronation Process Using H2O2 in DIET Synthesis of Pharmaceutical Raw Material. J. Korean Inst. Gas 2018, 22, 49–54. [Google Scholar] [CrossRef]

- Park, K.M.; Lee, D.K.; Lee, J.M.; Ahn, W.S. Qualitative Hazard Analysis for a Batch Radical Reaction Process using HAZOP Method. J. Korea AICS 2019, 20, 385–393. [Google Scholar] [CrossRef]

- Kang, M.J. The Accident Analysis and Risk Reduction Plan during Runaway Reaction in Batch Polymerization Process; Inha University: Inchon, Republic of Korea, 2018; pp. 2–7. [Google Scholar]

- Shin, I.J. Comparative Study on the Institution Framework of Risk Assessment between German UK and Korea, Japan in Asian Countries. J. Korean Soc. Saf. 2013, 28, 151–157. [Google Scholar] [CrossRef][Green Version]

- Lee, H.S.; Yun, H.C. A Study on the Rupture Disk Design and Application at the Two Phase Flow by Runaway Reaction at Batch Reactor. J. Korean Inst. Gas 2017, 21, 1–8. [Google Scholar] [CrossRef]

- Korea Ministry of Government Legislation. Occupational Safety and Health Act and Enforcement Regulations of the Act. Korea Ministry of Employment and Labor (Sejong). 2020. Available online: https://www.law.go.kr/LSW/lsInfoP.do?lsId=007364&ancYnChk=0#0000 (accessed on 1 January 2024).

- Korea Ministry of Government Legislation. Rules on Occupational Safety and Health Act Standards. Korea Ministry of Employment and Labor (Sejong). 2020. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%82%B0%EC%97%85%EC%95%88%EC%A0%84%EB%B3%B4%EA%B1%B4%EA%B8%B0%EC%A4%80%EC%97%90%EA%B4%80%ED%95%9C%EA%B7%9C%EC%B9%99 (accessed on 1 January 2024).

- Kim, S.R.; Yang, W.B.; Rhim, J.K. The Appropriateness Review of the Pressure Release Device in Small-scale Polyurethane Polymerization Reaction Process. J. Korean Hazard. Mater. 2019, 7, 108–116. [Google Scholar] [CrossRef]

- Lee, K.W.; Lee, J.S.; Choi, I.R.; Han, I.S. An Evaluation of Thermal Stability on Esterification Process in Manufacture of Concrete Mixture Agents. J. Korean Soc. Saf. 2009, 24, 40–46. [Google Scholar]

- Lee, K.W.; Han, I.S. Hazard Evaluation of Runaway Reaction in the Vinyl Acetate Polymerization Process. J. Korean Soc. Saf. 2011, 26, 46–53. [Google Scholar]

- Han, I.S.; Lee, J.S.; Lee, K.W. Thermal Hazards of Polystyrene Polymerization Process by Bulk Polymerization. J. Korean Inst. Gas 2013, 17, 1–8. [Google Scholar] [CrossRef][Green Version]

- Michiya, F.; Yuichiro, I.; Yoshiaki, I.; Atsumi, M. Thermal hazard evaluation of runaway polymerization of acrylic acid. J. Loss Prev. Process Ind. 2019, 80, 339–347. [Google Scholar] [CrossRef]

- Carsten, S.; Johannes, B.; Jurgen, S.; Jens, D. Protection of Chemical Reactors Against Exothermal Runaway Reactions with Smart Overpressure Protection Devices. Chem. Eng. Trans. 2022, 90, 493–498. [Google Scholar] [CrossRef]

- Lin, Z.; Wen, Z.; Maria, I.P.; Sammannam, M.; Mustafa, A. Probing into Styrene Polymerization Runaway Hazards: Effects of the Monomer Mass Fraction. ACS Omega 2019, 4, 8136–8145. [Google Scholar] [CrossRef]

- Korea Occupational Safety and Health Agency (Ulsan). Ulsan Area Chemical Accident Case/Analysis. 2016. Available online: https://www.kosha.or.kr/kosha/intro/ulsanBranch_A.do?mode=download&articleNo=339877&attachNo=186796 (accessed on 1 January 2024).

- Ni, L.; Cui, J.; Jiang, J.; Pan, Y.; Wu, H.; Shu, C.-M.; Wang, Z.; Mou, S.; Shi, N. Runaway inhibition of styrene polymerization: A simulation study by chaos divergence theory. Process Saf. Environ. Prot. 2020, 135, 294–300. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, J.; Jiang, J.; Pan, Y.; Yu, Y.; Zhou, D. Numerical simulation of thermal runaway and inhibition process on the thermal polymerization of styrene. Process Saf. Environ. Prot. 2016, 44, 465–473. [Google Scholar] [CrossRef]

- Hari, P.; Angan, S. A Case Study on Online Estimation of Polystyrene Formation Runaway Reaction Process Parameters. J. Loss Prev. Process Ind. 2022, 80, 104873. [Google Scholar] [CrossRef]

- Yao, H.; Michael, A.; Caroline, D.; John, J.; Snape, C.; Charles, A. Cross-linking of polystyrene by Friedel–Crafts chemistry: Reaction of p-hydroxymethylbenzyl chloride with polystyrene. Polym. Degrad. Stab. 2001, 72, 399–405. [Google Scholar] [CrossRef][Green Version]

- OSHIRI. Polystyrene Polymerization Process Thermal Risk Assessment; Report No 2013-OSHRI-24; KOSHA: Ulsan, Republic of Korea, 2013; pp. 1–8.

- Stoessel, F. Thermal Safety of Chemical Processes Risk Assessment and Process Design, 2nd ed.; Wiley VCH: Basel, Switzerland, 2020; pp. 42–57. [Google Scholar]

- Stoessel, F. Planning protection measure against runaway reactions using criticality classes. Process Saf. Environ. Prot. 2009, 87, 105–112. [Google Scholar] [CrossRef]

- Health and Safety Executive (Bootle). Chemical Reaction Hazards and the Risk of Thermal Runaway. 2014. Available online: https://www.hse.gov.uk/pubns/indg254.pdf (accessed on 1 January 2024).

- Fauske, H.K. Generalized Vent Sizing Nomogram for Runaway Chemical Reactions. Plant/Oper. Prog. 1984, 3, 213–215. [Google Scholar] [CrossRef]

- Fisher, H.G.; Forrest, H.S.; Grossel, S.S.; Huff, J.E.; Muller, A.R.; Noronha, J.A.; Shaw, D.A.; Tilley, B.J. Emergency Relief System Design Using DIERS Technology: The Design Institute for Emergency Relief Systems (DIERS) Project Manual, 4th ed.; AlChE: New York, NY, USA, 1992; pp. 399–400. [Google Scholar]

- KOSHA. KOSHA GUIDE P-65 Technical Guide for Design of Rupture Disk Size against Runaway Reaction; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2012.

- American Petroleum Institute. API STANDARD 521 Pressure-Relieving and Depressuring Systems, 6th ed.; American Petroleum Institute Publishing Services: Washington, DC, USA, 2014; p. 67. [Google Scholar]

- KOSHA. KOSHA GUIDE D-18 Technical Guidelines for Calculating and Installing the Discharge Capacity of Safety Valves, etc.; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2020.

- Jo, P.R.; Lee, H.J. Technical Guidelines for the Design of Safety Valve Discharge Piping; Report No D-60-2018; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2017; pp. 8–12.

- Jung, C.B.; Ma, B.C. Technical Guidelines for Flare System Knock out Drum Design and Installation; Report No D-63-2017; Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2018; pp. 1–12.

- Min, E.D. Heat Exchanger Theory and Design Ch.2; Chemical Industry Research Council: Seoul, Republic of Korea, 1994; pp. 1–9. [Google Scholar]

- Sadik, K.; Hongtan, L.; Anchasa, P. Heat Exchanger Selection, Rating, and Thermal Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 9–11. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).