Abstract

Agro-industrial activities generate a great amount of bioproducts as biomass residues containing energy and with potentially useful applications in the thermochemical conversion process. The management of this feedstock as uncontrolled combustion (“open burning”) can often be a problem within the supply chain for disposal practices, both in environmental and economic aspects. The residual matrices from agroforestry biomass processing can be treated to increase their energy levels and economic value. A widespread practice for sustainable disposal is the production of pellets from residual biomass, such as pruning. The aim of this study is to explore the combustion of pellets obtained from olive and citrus pruning, and their emissions into the atmosphere. This study confirms the possibility of using waste biomass to obtain a high-energy biofuel that is usable in a controlled combustion system and to monitor the process and its related emissions (CO, CO2, NOx, SO2, PM). Three different pellets (olive pellet, citrus pellet and a pellet obtained from a mix of olive and citrus) were characterized to determine their physicochemical properties and burned in an 80 kWth boiler equipped with multicyclone filter bags as an abatement system to evaluate relative emission. The characterization results show that citrus pellet has a higher ash content, moisture content and lower energy value than mixtures of olive pellet. The emission results suggest that, during combustion, higher emissions of CO and SO2 were monitored from mixtures of citrus pellet compared to burning only olive pellet.

1. Introduction

In recent years, the threat of climate change has led European institutions to issue new environmental policies, establishing new bioenergy objectives on the reduction in pollutant emissions, increasing the use of renewable sources, and producing green energy as strategies for safeguarding human health and the environment [1,2].

In the bioenergy sector, the use of woody biomass as an energy source has already been extensively studied and proven to mitigate greenhouse gas (GHG) emissions [3,4,5].

Lignocellulosic biomass, derived from agroforestry practices, has widespread applications in thermochemical transformation processes due to its chemical–physical characteristics (low moisture, ash, sulfur and high energy value), that make it ideal for producing electricity, steam and heat, like fossil fuels, but advantageous in terms of environmental, human and socio-economic impacts [6].

Increasing the share of renewable energy to at least 42.5% of consumption represents one of the objectives that the EU energy strategy plans to reach by 2030, and this new objective is contained in the new European directive on renewable energies, also known as RED (RED III).

The European Green Deal establishes important targets to be achieved by 2030 with a view to greater environmental sustainability. In particular, the Green Deal will transform the EU into a modern, resource-efficient and competitive economy by ensuring the following: (1) In 2050, there will no longer be any net emissions of greenhouse gases; (2) economic growth will be decoupled from resource use; (3) let no person and no place be overlooked. In addition, the Fit for 55 package sets out the EU’s goal to reduce net greenhouse gas emissions by at least 55% by 2030.

To achieve these objectives, biomass, agriculture and forestry, as well as all waste from agroforestry products will play a fundamental role. These types of products, if properly treated, can be reused to produce energy and, in some cases, new products relevant to a green and circular economy.

On the one hand, there are both European and national interests in finding new sources of clean energy, such as agroforestry biomass. On the other hand, there is a need to control the amount of emissions into the atmosphere, which are produced by biomass itself.

To contain and limit emissions, the European Commission issued the first “Clean Air” package in 2013, which includes measures that aim to reduce air pollution and derives from the use of biomass for energy purposes.

At a European legislative level, the most significant reference for reducing emissions is Directive 2003/87/EC, also called the Emission Trading Directive, which introduces an internal EU system for substituting certain emissions in the atmosphere, with the aim of minimizing emissions. The new RED III on bioenergy and biomass strengthens the sustainability criteria for the use of biomass for energy purposes, reducing the risk of unsustainable bioenergy production. It ensures the application of the cascading principle, with particular attention paid to supporting schemes and considering national specificities.

In Italy, European legislation has been implemented in the Consolidated Environmental Act, which regulates the methods and limits of emissions in the atmosphere of major industrial and civil plants, including biomass plants. The normative system, defined as two-track, ensures the control of atmospheric emissions and guarantees, if correctly applied, the protection of the environment and human health. In the Mediterranean area, several tree crops are extensively pruned, and olive and citrus trees are widespread all over Italy. The most common practice for the disposal of these pruning residues is open burning, with a consequent loss of resources and uncontrolled emission of pollutants in the atmosphere. While forestry biomass availability for energy in Italy has been widely studied and quantified with the development of consolidated management models, residual biomass from agricultural crops, despite its widespread availability, is not sufficient for use in energy models and economic development. In fact, in rural areas, agroforestry is widely recognized for increasing and diversifying farm productivity, while releasing pressure on existing forests. Therefore, agroforestry (or agriculture forestry) causes major energy exploitation by using up local wood resources in rural areas, for which wood harvesting is commonly based on a semi-mechanized harvesting system [7].

The utilisation of agricultural by-products fully aligns with the concept of circular economy; in fact, circular economy is concerned with how resources are used, as opposed to bioeconomy, a concept focused on which resources are used. Bioeconomy does not exclude eco-efficiency, but it does not actively search for it. It does not refer to circularity neither. In fact, using bio-renewables instead of non-renewables is not an assurance of sustainability since, if overused, they can be depleted in the long run too. This is what happened when the boom in first-generation biofuels cannibalised crop reserves and skyrocketed the prices. However, scholars have recently brought up an effort to connect the two models into a new one called “Circular Bioeconomy”, which applies the circular economy waste hierarchy to biomass resources, prioritising material recovery before energy production.

However, even if biomass is considered a sustainable carbon-neutral feedstock, during biomass burning, some pollutants are generated depending on the process conditions [8].

Among woody biomass, pellet has optimal parameters not only for its energy use, but also its higher density and low management costs [9], thus it plays a significant role in the biomass market, generating a decrease in the availability of the biomass in recent years [10,11,12,13].

Because of the rising use of pellets in household stoves and heating systems, the pellet business has grown significantly. [11,14]; in fact, the transformation of woody biomass materials into pellets, briquettes, or chips reduces costs and problems with handling, transportation, storage, disposal and utilisation of low bulk-density biomass materials. Among the various transformation methods tried, pelletizing has achieved a good compromise in terms of expenditure of energy, economic and time resources [7,11]. On the other hand, the recommended raw materials for producing wood pellets, such as cutting chips and sawdust, are used to the greatest extent possible. This strategy results in a highly competitive dedicated biomass energy market between pellet production and power generation. The competitive commodity market has driven up raw material prices, particularly during the COVID era. In recent years, various biomass materials have been used to make pellets, such as tea waste, bamboo, wastepaper, wheat straw blends, cotton stalk, rapeseed cake, olive cake, palm kernel cake, corn stew, peanut shells and poultry waste. This scenario has involved researchers and employers in the sector to study new pellet production systems obtained from agroforestry and agro-industrial waste matrices to not subtract raw materials such as dedicated biomasses, but above all to improve the quality of combustion and reduce emissions.

Also, among the advantages of using pellets is the ability to vary and optimise the composition, selecting optimal biomass mixtures during production phases when considering energy plants (Miscanthus, reed cannula, semolina, timothy grass, rape, sunflower, hemp) and/or food industry wastes (cereals, potatoes, beets, corn, flax, olive pips), adding additives and natural compounds in order to improve the energy qualities, to increase the calorific value and have positive effects on the process conditions (combustion) [15,16,17,18].

In this regard recent study reported research about characterization and the use of agro-pellets for combustion in small boilers to evaluate the production of particulate matter (PM), gaseous emissions, efficiencies, ash and related problems such as the corrosion and fouling of plants, compared with forest pellet [10,19,20,21].

These studies found that agricultural and industrial waste residues, such as wheat straw, grass and peat pellets, have relatively low emissions during gasification and combustion [15,22,23], with a 90% reduction in CO2 emissions and a positive energy balance; thus, they intended to compare emissions from pellets of innovative raw materials to coal and other fuels [24,25].

Even with good results in energy conversion systems, these raw materials must be characterised in order to evaluate their useful potential and avoid damages that might jeopardise the operating condition process and boiler maintenance. Furthermore, significant levels of pollutant emissions such as PM, CO, NOx [26,27] and unburned hydrocarbons are associated with incomplete combustion due to boiler configuration [28,29], inconstant process conditions, the nature of biomass and fuel physical and chemical properties [26,30,31,32,33,34,35].

Indeed, several studies have highlighted that the use of lower-quality matrices for pellet production (e.g., high ash and metals content) strongly affects the emission [9,34].

The feasibility of employing pellets produced from two distinct agroforestry waste materials (citrus and olive pruning) and their mixing for combustion in a small boiler was investigated in this study. The purpose of this work is to assess the emission of gas and particulate matter (PM) from the combustion of the above-mentioned tree type of pellet.

2. Materials and Methods

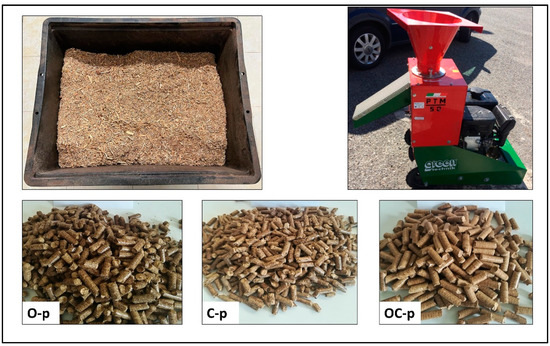

As a first step for the innovative biofuel energy valorisation, the characterization of three types of pellet was carried out. The mixes included 100% olive pruning (O-p), 100% citrus pruning (C-p) and a combination of 50% citrus and 50% olive pruning (OC-p). The biomass used (olive pruning, citrus pruning) to form the mixtures came from typical pruning operations on several private agroforestry farms in the Italian province of Reggio Calabria. Following the physicochemical characterization, each pellet mixture was burned separately, and emissions were monitored during combustion experiments to highlight the differences, criticalities and benefits of the three different pellets tested, in terms of pollutant generation.

2.1. Pellet Processing

Pellets were made at the Department of Agraria’s laboratory in Reggio Calabria, using a rotating roller pelletizer (Green Technik, 11 kW gasoline engine—Figure 1) installed on a die with 6 mm-diameter holes. The pelletizer used also included a H-24 rotating flat die with 24 mm-long channels; the channels had a pre-compression chamber owing to a 60°-angle countersink present at the channel intake. The chipped biomass was sieved and placed in a hopper. Then, the biomass mixtures (O-p, C-p, and OC-p) were generated and the moisture measurement was carried out, which proved to be suitable for the pelletizing stage of the wood chips, as it was about 14%. Upon exiting the pelletizer, the pellets were allowed to cool, and measurements of average pellet length and diameter and an average durability value for each mixture were made (Table 1).

Figure 1.

Pellet processing with Greentechnik PTM50 Pellet Machine.

Table 1.

Physical characteristics of the pellet divided into mixtures.

2.2. Physicochemical Pellet Characterization

The physical and chemical properties of the various types of pellets studied were investigated at the LASER-B (Laboratory of Experi-mental Renewable Energies from Biomass) of CREA-IT of Monterotondo (Rome). The moisture content was determined using a Memmert UFP800 oven in accordance with UNI EN ISO 18134-1: 2015. Pellets were dried at 105 ± 2 °C and the humidity was determined considering the weight loss of the sample after 24 h. The ash content was determined using a Lenton EF11/8B muffle furnace according to the UNI EN ISO 18122: 2016. About 1 g of each pellet sample was placed in the ceramic crucible at thermal ramp (6 °C/min up to 250 °C and then 10 °C/min from 250 °C to 550 °C) into the furnace. The higher heating value (HHV) was determined by means of a Parr 6400 calorimeter, according to the UNI EN ISO 18125: 2018, and the lower heating value (LHV) was calculated from the HHV considering the hydrogen content. The elemental composition was evaluated by using a Costech ECS 4010 CHNS-O elemental analyser according to the UNI EN ISO 16948: 2015 to determine the C, H and N content. For biomass metal content determination, pellet samples were mineralized with a microwave oven (Start D, Milestone), then the mineralized solution was filtered, diluted and analysed by ICP-MS (Agilent 7700, Agilent, Santa Clara, CA United States).

2.3. Combustion and Emission Monitoring

Biomass burning was carried out at CREA-IT by using the boiler GSA-80 (D’Alessandro Termomeccanica Series GSA 80 kWth), simulating the open burning without any abatement system for particulate matter (PM). Only for the last burning trial conducted on citrus pellet, a multicyclonic filter was installed as an abatement system, and its effective yield was monitored with an electrical low-pressure impactor (ELPI) able to give real-time PM detection. The constant operative parameters were shown in Table 2.

Table 2.

Combustion test operative conditions.

For the flue gas sampling, a multigas portable analyser was used for measurements of NOx, SO2, CO, CO2 and O2. The multigas portable analyser was Horiba Model PG-250, specifically designed for compliance with 40 CFR 60.

The total suspended particles (TSP) were sampled with an isokinetic probe (DADOLAB HP5 + ST5), bringing a filter holder for glass microfiber filters (⌀ 47 mm, 0.3 µm, MK-360 Munktell). Filters were pre-conditioned at 400 °C before being brought to measure a constant weight. They were weighed after sampling to determine the TSP. Only during citrus burning was it possible to measure the PM fractions with an electrical low-pressure impactor (ELPI) able to give real-time detection of particles by combining electrical detection of charged particles with a low-pressure cascade impactor. Using the ELPI, the real time concentration (mg/m3) of three PM fractions (10 μm, 2.5 μm and 1 μm), the number size and the mass size distributions were measured to understand the real efficiency of the multicyclonic filters that was installed in the boiler during the citrus pellet burning test.

2.4. Statistical Analysis

The statistical analysis was entirely conducted in R ver. 3.6.1. Since different data nature and structure were obtained from the experimental design, many statistical tests and analyses turned out to be useful for their comprehension.

For emissions variables (CO, NOx, SO2, O2, CO2 and PM), a one-way ANOVA was used to examine the differences between biomasses. The individuation of such differences was then determined using the post hoc Tukey HSD test, able to compare group means. To assess the normality and homoscedasticity of biomass characterisation variables, the Shapiro–Wilk and F-tests were used.

The multivariate data analysis was conducted via principal component analysis (PCA) to evaluate the correlations between biomass and combustion emission parameters. PCA is used as an exploratory data analysis to reduce dimensionality by projecting each data point onto only the first two principal components to obtain lower-dimensional data, while maintaining data variation.

3. Results and Discussion

3.1. Biomass Characterization

Results from the physical and chemical characterization show that the pellet moisture content is on average lower than that of wood chip and other lignocellulosic biomass, depending on the nature of the biomass and pretreatments. Pelletization, in fact, represents a transformation process responsible for the matrix water loss [36,37]. The ash content is higher for C-p and decreases adding olive to the mixture, with the lowest value reached in O-p (Table 3). In terms of elemental composition, the C, H and N content shown in Table 3 are similar for C and N and lowest for H with respect to that of lignocellulosic biomass suitable for energy uses in thermochemical conversion plants. Generally, for lignocellulosic biomasses dedicated to thermochemical processes (e.g., poplar, elm), the content of C, H and N is on average 40%, 6% and 2%, respectively. Specifically, the carbon content is reflected in a high lower-calorific value that appears comparable to the energy biomasses in all three pellet samples. Comparing C-p with citrus wood chips [38], it is possible to observe a higher ash content in C-p, that could be reflected in a lower LHV in C-p with respect to that of citrus wood chip. On the other hand, both O-p and olive wood chips show significantly lower ash content than citrus ones, and the slight ash increase in pellets does not seem to affect O-p LHV, which in turn increases. When the ash percentage is low, the most influencing factor for LHV shifting remains the composition, in particular, the carbon and hydrogen content [39]. Ash is the only variable that slightly exceeds the values defined for best-quality commercial pellets.

Table 3.

Physical and chemical characterization of olive and citrus pellet, and their mixture.

Table 4 shows the results of the metal content obtained from pellet mixture analysis. The results indicate that all the samples have a greater content of macro-elements such as K, Na, Ca, Mg and Fe, typical of woody biomass and related to the conditions of plant growth, soil characteristics and the use of plant protection products. A high content of these metals may represent a mechanical problem for the boiler during the combustion process, causing phenomena like bed agglomeration, slagging, fouling and corrosion, that can occur and limit the boiler’s functioning [40,41,42]. The other metals, including heavy metals, have regular values and non-significant changes, except for Cu which is significantly lower in C-p. Such a variation may suggest difference in crop management in terms of fertilisation, pesticide use and irrigation, or it may indicate closeness to contamination material emission sources.

Table 4.

Metal content in pellet mixtures.

3.2. Emissions

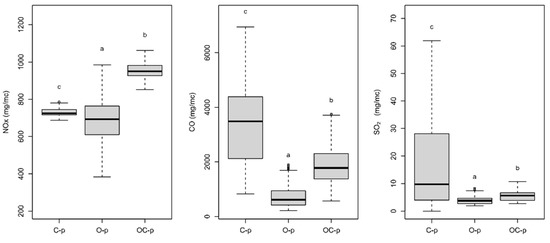

The best combustion conditions recorded during O-p burning laed to thermal NOx production. In fact, nitrogen oxides, collectively referred to as NOx, are formed in essentially all combustion processes, mostly as nitric oxide (NO), with smaller amounts of nitrogen dioxide (NO2) and nitrous oxide (N2O). Nitric oxide is subsequently oxidised to NO2 in the atmosphere. NO is formed as a result of the fixation of N2 in the combustion air at elevated temperatures [43,44]. Despite this, the reduced N content in the biomass makes olive a less significant emitter of NOx. Because of this dual behaviour, there is considerable fluctuation in NOx emissions when O-p is burned (Figure 2, left). Furthermore, we found the largest O2% variability in flue gas (3.57) during O-p combustion, compared to C-p (1.2) and OC-p (0.75). Since NOx generation is likewise highly linked to comburent, larger variability in surplus air inevitably leads to higher variability in NOx emission.

Figure 2.

Boxplots of NOx, CO and SO2 emissions. Boxes not accompanied by the same letter are significantly different (p < 0.05) according to the one-way ANOVA and the post hoc Tukey HSD tests.

Such variability is mainly lost when CO and SO2 are examined, confirming more stable and better combustion conditions than the other mixes. Despite the worst combustion conditions, with a lower CO2% in the gaseous effluents than O-p, C-p shows less variability, but a higher average in NOx generation, suggesting that the production of nitrogen oxides in citrus is mostly attributable to matrix composition. When olive and citrus pellets are combined, the combustion conditions improve compared to 100% citrus pellet, and the N content is higher than 100% olive pellet, resulting in a significant increase in both thermal and compositional nitrogen oxide generation.

Focusing on carbon monoxide emissions (Figure 2, centre), an improvement in combustion conditions can be seen when olive dominates the blend, with a lower CO concentration in flue gas. Regarding the SO2 emissions (Figure 2 right), they are strictly correlated to CO and the worst combustion conditions with higher CO variability laed to higher and more variable SO2 emissions. Through the correlation test in R using the non-parametric Kendall method since SO2 and CO were not normally distributed, strong correlations were found between these two variables for all three blends, with p-values rejecting the null hypothesis of covariance equalling to 0. The higher variability of CO and SO2 observed for C-p is likewise associated to the worst biomass characteristics, with higher humidity, ash and lower LHV. High fluctuation in emissions linked to combustion quality, such as CO, favours unstable combustion circumstances.

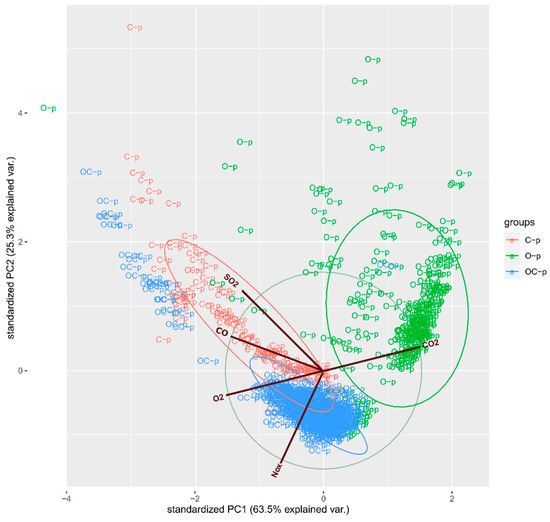

The PCA analysis was performed using the SO2, NOx, O2 and CO2 emission variables, permitting a clear classification of the three mixture emissions into different groups, as shown in Figure 3. The principal components 1 and 2 explain 88.8% of the variability; component 1 depends mostly on oxygen, carbon monoxide and carbon dioxide percentages, which are negatively correlated with each other. These two parameters can explain the combustion quality and the biomass oxidation that occurred during combustion; in fact, the higher the CO2 percentage, the higher the oxidation of the organic matter, indicating a more complete combustion. Component 2 is mainly related to NOx and SO2, which are also negatively correlated. Increasing the combustion quality usually causes NOx to increase due to thermal mechanisms, while SO2 decreases.

Figure 3.

Biplot obtained via principal component analysis applied to the emission data.

Olive pellet emissions (in green) are driven by a high CO2 percentage in flue gas, indicating the best burning condition and lower SO2 and NOx emissions. C-p burning brings higher CO and SO2 emissions with the worst combustion conditions, while OC-p emissions lead to high NOx concentrations due to the thermal and compositional production of nitrogen oxides [43,44]. In Figure 3, it is possible to see that the blue cloud, indicating OC-p emissions, is in the middle of the orange and green clouds, indicating C-p and O-p emissions, respectively. Except for NOx, which definitely drives the OC-p emission cloud in the lower part of the graph, for all the other variables used in the PCA analysis, it is possible to see that the mixture, OC-p, has emissions on average within the boundaries of the pure material emissions. This indicates that if olive is added to the citrus blend, it is possible to mostly improve combustion quality, with some concern regarding the NOx emissions.

Due to the long duration of emission monitoring, many outliers are recorded due to transient variations in combustion conditions, increasing emission variability and the records spread on the PCA biplot.

Between the three pellet blends, there are no significant differences in TSP emissions with 169.42 mg/Nm3, 172.35 mg/Nm3 and 176.91 mg/Nm3, respectively, for O-p, OC-p and C-p.

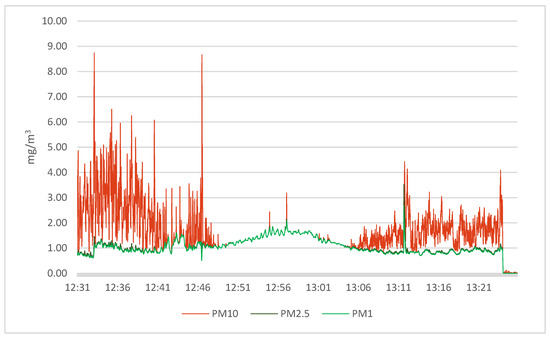

The PM fraction trend (Figure 4) obtained with the ELPI during C-p combustion reveals a significant particle abatement only for PM10 (in red) when the multicyclone filter was functioning (from 12:48 to 13:05). The other two fractions (PM2.5 and PM1, in black and green, respectively) are unaffected; in fact, while the PM10 concentration decreases during filtered conditions, the relative concentration per volume of the smallest particles (PM2.5 and PM1) slightly rises. When the filter is activated, the dimensional distributions of the various PM fractions vary considerably. When we evaluate the amount of particles detected with the filter switched on, we found that a mean of 8.00 × 107 particles were emitted per cm3 only for the particle size of 0.01 μm. When the multicyclone was switched off, the number of particles with smaller diameters slightly decreases, but all the other size classes (PM10 and PM2.5) rose, with a total average of 3.4 × 108 particles released per cm3.

Figure 4.

PM fraction trends during the citrus combustion emission sampling. The multicyclonic filter was activated between 12:48 and 13:05.

4. Conclusions

The results attempted to define and concretely improve a new ecological macroeconomy that takes into account both energy and environmental factors, and seeks to reconcile human activities with the Earth’s constrained resources.

The use of waste biomass and the treatments that it undergoes before energetic transformation are generally factors that influence the conversion processes and, as a result, the generation of emissions into the atmosphere. The results show that pellets made from residual materials (citrus and olive tree pruning mixes) had a different effect on the production of pollutants during combustion. Starting with the characterization of the biomass, it emerged that in general, the pellets investigated have a lower average humidity value than other dedicated lignocellulosic biomass applied for energy use; this factor is relevant to predict a good combustion and could determine a lower production of pollutants, in contrast to the content in ash, which changes as the function of pellet composition, in particular, decreases when a higher content of olive tree pruning is used in the mixture. Metals in the initial matrix are within permissible limits; therefore, their presence does not cause any issues with polluting emissions. Metal values are higher for macro-elements, which might harm plants in any circumstance. In terms of macro-pollutant emissions, O-p has more variability in NOx emissions and better combustion conditions are detected. CO and CO2 have a more constant trend, with greater CO2 levels and lower CO values when compared to any other blend. Such findings imply that olive biomasses have a greater potential and may be blended with other biomasses with poor combustion performances to improve the latter’s energy potential. Another remarkable issue concerns the PM abatement. In fact, biomass burning is naturally a source of PM, but when abatement systems are used, this risk notably decreases. Therefore, as a result of the multicyclone filter use, a considerable reduction in PM10 was achieved, suggesting the application of systems such as efficient filters that are easy to install both technically and economically, as well as on the smallest boilers, which could be useful for small farms’ energy balance. The incentive of such technologies in the agricultural sector is also a strategy to contrast today’s energy crisis, promoting European independence from Russian fossil fuel. The results published in this paper can help expand the potential candidate materials for the future production of renewable densified solid biofuel, particularly using orchard residues as the primary source of biomass raw material [45].

Author Contributions

Conceptualization; methodology, F.G. and A.R.P.; validation, E.P. and F.G.; formal analysis, M.C., B.V., A.P., E.P. and S.P.; investigation, V.D.S. and M.S.; resources; data curation, E.P., A.P., B.V., M.C. and S.P.; writing original draft preparation, M.C., E.P., A.P., B.V., S.P. and A.R.P.; writing review and editing, E.P., A.P., V.D.S., B.V., M.C., S.P. and A.R.P.; visualization, M.S.; supervision, F.G. and A.R.P.; project administration, F.G. and A.R.P.; funding acquisition F.G. and A.R.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Italian Ministry of Agriculture, Food Sovereignty and Forests (MASAF) as part of grant AGROENER project (D.D. n. 26329, 1 April 2016), FAESI project (D.M. 4056, 24/07/08) and the sub-project “Tecnologie digitali integrate per il rafforzamento sostenibile di produzioni e trasformazioni agroalimentari (AgroFiliere)” (AgriDigit programme), (DM 36503.7305.2018 of 20 December 2018), and by the European Agricultural Fund for Rural Development (EAFRD) with the PSR Calabria 2014–2020 Misura 16.01.01—3 Action Oil.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank Franco Bernardini, Marco Scalambrino, Gino Brannetti, Luciano Serafini and Cesare Cervellini for their participation during the technical and practical activities of the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Luque, R.; Herrero-Davila, L.; Campelo, J.M.; Clark, J.H.; Hidalgo, J.M.; Luna, D.; Marinas, J.M.; Romero, A.A. Biofuels: A Technological Perspective. Energy Environ. Sci. 2008, 1, 542–564. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; De Ruyck, J. Small Scale Biomass Heating Systems: Standards, Quality Labelling and Market Driving Factors—An EU Outlook. Biomass Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Labbé, R.; Paczkowski, S.; Knappe, V.; Russ, M.; Wöhler, M.; Pelz, S. Effect of Feedstock Particle Size Distribution and Feedstock Moisture Content on Pellet Production Efficiency, Pellet Quality, Transport and Combustion Emissions. Fuel 2020, 263, 116662. [Google Scholar] [CrossRef]

- Thrän, D.; Peetz, D.; Schaubach, K.; Trømborg, E.; Pellini, A.; Lamers, P.; Richard Hess, J.; Schipfer, F.; Hektor, B.; Olsson, O.; et al. Global Wood Pellet Industry and Trade Study 2017. Available online: https://www.researchgate.net/profile/Kay-Schaubach/publication/322505965_Global_Wood_Pellet_Industry_and_Trade_Study_2017/links/5a5cc10ea6fdcc68fa96df32/Global-Wood-Pellet-Industry-and-Trade-Study-2017.pdf (accessed on 6 July 2023).

- Palma, A.; Paris, E.; Carnevale, M.; Vincenti, B.; Perilli, M.; Guerriero, E.; Cerasa, M.; Proto, A.R.; Papandrea, S.F.; Bonofiglio, R.; et al. Biomass combustion: Evaluation of pops emissions (VOC, PAH, PCB, PCDD/F) from three different biomass prunings (olive, citrus and grapevine). Atmosphere 2022, 13, 1665. [Google Scholar] [CrossRef]

- Uddin, S.N.; Barreto, L. Biomass-Fired Cogeneration Systems with CO2 Capture and Storage. Renew Energy 2007, 32, 1006–1019. [Google Scholar] [CrossRef]

- Thomas, M.; Van Zuilichem, D.J.; Van Der Poel, A.F.B. Physical Quality of Pelleted Animal Feed. 2. Contribution of Processes and Its Conditions. Anim. Feed Sci. Technol. 1997, 64, 173–192. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A Study of Bonding and Failure Mechanisms in Fuel Pellets from Different Biomass Resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Kristensen, E.F.; Kristensen, J.K. Development and Test of Small-Scale Batch-Fired Straw Boilers in Denmark. Biomass Bioenergy 2004, 26, 561–569. [Google Scholar] [CrossRef]

- Dias, J.; Costa, M.; Azevedo, J.L.T. Test of a Small Domestic Boiler Using Different Pellets. Biomass Bioenergy 2004, 27, 531–539. [Google Scholar] [CrossRef]

- Vicente, E.D.; Vicente, A.M.; Evtyugina, M.; Tarelho, L.A.C.; Almeida, S.M.; Alves, C. Emissions from Residential Combustion of Certified and Uncertified Pellets. Renew Energy 2020, 161, 1059–1071. [Google Scholar] [CrossRef]

- González, J.; González-García, C.; Ramiro, A.; González, J.; Sabio, E.; Gañán, J.; Rodríguez, M. Combustion optimisation of biomass residue pellets for domestic heating with a mural boiler. Biomass Bioenergy 2004, 27, 145–154. [Google Scholar] [CrossRef]

- Proto, A.R.; Benalia, S.; Papandrea, S.; Bernardi, B.; Bonofiglio, R.; Leuzzi, A.; Zimbalatti, G.; Tonolo, A.; Pari, L.; Gallucci, F. Harvesting citrus and olive pruning residues for energy use in Southern Italy. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Lisbon, Portugal, 27–30 May 2019; pp. 393–396. [Google Scholar]

- Kallis, K.X.; Pellegrini Susini, G.A.; Oakey, J.E. A Comparison between Miscanthus and Bioethanol Waste Pellets and Their Performance in a Downdraft Gasifier. Appl. Energy 2013, 101, 333–340. [Google Scholar] [CrossRef]

- Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.; Pessina, D.; Facchinetti, D. Pellet production from miscanthus: Energy and environmental assessment. Energies 2021, 14, 73. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef]

- Miranda, T.; Román, S.; Montero, I.; Nogales-Delgado, S.; Arranz, J.I.; Rojas, C.V.; González, J.F. Study of the emissions and kinetic parameters during combustion of grape pomace: Dilution as an effective way to reduce pollution. Fuel Process. Technol. 2012, 103, 160–165. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; Delattin, F.; Laha, P.; Vandendael, I.; Hubin, A.; De Ruyck, J. Agro-Pellets for Domestic Heating Boilers: Standard Laboratory and Real Life Performance. Appl. Energy 2012, 90, 17–23. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M.; Hartge, E.U.; Ogada, T.; Siagi, Z. Combustion of Agricultural Residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Öhman, M.; Boman, C.; Hedman, H.; Nordin, A.; Boström, D. Slagging Tendencies of Wood Pellet Ash during Combustion in Residential Pellet Burners. Biomass Bioenergy 2004, 27, 585–596. [Google Scholar] [CrossRef]

- Andreasen, P.; Larsen, M.G. Straw Pellets as Fuel in Biomass Combustion Units. In Proceedings of the 9th European Bioenergy Conference, Copenhagen, Denmark, 24–27 June 1996. [Google Scholar]

- Burvall, J. Influence of Harvest Time and Soil Type on Fuel Quality in Reed Canary Grass (Phalaris arundinacea L.). Biomass Bioenergy 1997, 12, 149–154. [Google Scholar] [CrossRef]

- Paulrud, S.; Nilsson, C. Briquetting and Combustion of Spring-Harvested Reed Canary-Grass: Effect of Fuel Composition. Biomass Bioenergy 2001, 20, 25–35. [Google Scholar] [CrossRef]

- Winter, F.; Wartha, C.; Hofbauer, H. NO and N2O Formation during the Combustion of Wood, Straw, Malt Waste and Peat. Bioresour. Technol. 1999, 70, 39–49. [Google Scholar] [CrossRef]

- Thomson, H.; Liddell, C. The Suitability of Wood Pellet Heating for Domestic Households: A Review of Literature. Renew. Sustain. Energy Rev. 2015, 42, 1362–1369. [Google Scholar] [CrossRef]

- Venturini, E.; Vassura, I.; Agostini, F.; Pizzi, A.; Toscano, G.; Passarini, F. Effect of Fuel Quality Classes on the Emissions of a Residential Wood Pellet Stove. Fuel 2018, 211, 269–277. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R. Critical Parameters for Particle Emissions in Small-Scale Fixed-Bed Combustion of Wood Pellets. Energy Fuels 2004, 18, 897–907. [Google Scholar] [CrossRef]

- Klason, T.; Bai, X.S. Computational Study of the Combustion Process and NO Formation in a Small-Scale Wood Pellet Furnace. Fuel 2007, 86, 1465–1474. [Google Scholar] [CrossRef]

- Lamberg, H.; Tissari, J.; Jokiniemi, J.; Sippula, O. Fine Particle and Gaseous Emissions from a Small-Scale Boiler Fueled by Pellets of Various Raw Materials. Energy Fuels 2013, 27, 7044–7053. [Google Scholar] [CrossRef]

- Nižetić, S.; Papadopoulos, A.; Radica, G.; Zanki, V.; Arıcı, M. Using Pellet Fuels for Residential Heating: A Field Study on Its Efficiency and the Users’ Satisfaction. Energy Build 2019, 184, 193–204. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; Vandendael, I.; Laha, P.; Hubin, A.; De Ruyck, J. Residential Pellet Boilers in Belgium: Standard Laboratory and Real Life Performance with Respect to European Standard and Quality Labels. Appl. Energy 2011, 88, 2628–2634. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R.; Boman, C.; Boström, D.; Öhman, M. Influence of Fuel Ash Composition on High Temperature Aerosol Formation in Fixed Bed Combustion of Woody Biomass Pellets. Fuel 2007, 86, 181–193. [Google Scholar] [CrossRef]

- Win, K.M.; Persson, T. Emissions from Residential Wood Pellet Boilers and Stove Characterized into Start-up, Steady Operation, and Stop Emissions. Energy Fuels 2014, 28, 2496–2505. [Google Scholar] [CrossRef]

- Wöhler, M.; Jaeger, D.; Reichert, G.; Schmidl, C.; Pelz, S.K. Influence of Pellet Length on Performance of Pellet Room Heaters under Real Life Operation Conditions. Renew Energy 2017, 105, 66–75. [Google Scholar] [CrossRef]

- Samuelsson, R.; Larsson, S.H.; Thyrel, M.; Lestander, T.A. Moisture Content and Storage Time Influence the Binding Mechanisms in Biofuel Wood Pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Castellano, J.M.; Gómez, M.; Fernández, M.; Esteban, L.S.; Carrasco, J.E. Study on the Effects of Raw Materials Composition and Pelletization Conditions on the Quality and Properties of Pellets Obtained from Different Woody and Non Woody Biomasses. Fuel 2015, 139, 629–636. [Google Scholar] [CrossRef]

- Proto, A.R.; Palma, A.; Paris, E.; Papandrea, S.F.; Vincenti, B.; Carnevale, M.; Guerriero, E.; Bonofiglio, R.; Gallucci, F. Assessment of Wood Chip Combustion and Emission Behavior of Different Agricultural Biomasses. Fuel 2021, 289, 119758. [Google Scholar] [CrossRef]

- Adamovics, A.; Platace, R.; Gulbe, I.; Ivanovs, S. The content of carbon and hydrogen in grass biomass and its influence on heating value. Eng. Rural. Dev. 2018, 17, 1277–1281. [Google Scholar] [CrossRef]

- Arvelakis, S.; Vourliotis, P.; Kakaras, E.; Koukios, E.G. Effect of Leaching on the Ash Behavior of Wheat Straw and Olive Residue during Fluidized Bed Combustion. Biomass Bioenergy 2001, 20, 459–470. [Google Scholar] [CrossRef]

- Quaak, P.; Knoef, H.; Sfassen, H. Energy from Biomass. A Review of Combustion and Gasification Technologies; World Bank Technical Papers; World Bank Publications: Washington, DC, USA, 1999. [Google Scholar]

- Spliethoff, H.; Scheurer, W.; Hein, K.R.G. Effect of Co-Combustion of Sewage Sludge and Biomass on Emissions and Heavy Metals Behaviour. Process Saf. Environ. Prot. 2000, 78, 33–39. [Google Scholar] [CrossRef]

- Glarborg, P.; Jensen, A.D.; Johnsson, J.E. Fuel Nitrogen Conversion in Solid Fuel Fired Systems. Prog. Energy Combust. Sci. 2003, 29, 89–113. [Google Scholar] [CrossRef]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling Nitrogen Chemistry in Combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Cataldo, M.F.; Marcu, V.M.; Iordache, E.; Zimbalatti, G.; Proto, A.R.; Borz, S.A. Performance of forwarding operations in biomass recovery from dismantled apple orchards. Small-Scale For. 2022, 21, 349–367. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).