Modeling of Wood Surface Ignition by Wildland Firebrands

Abstract

1. Introduction

2. Materials and Methods

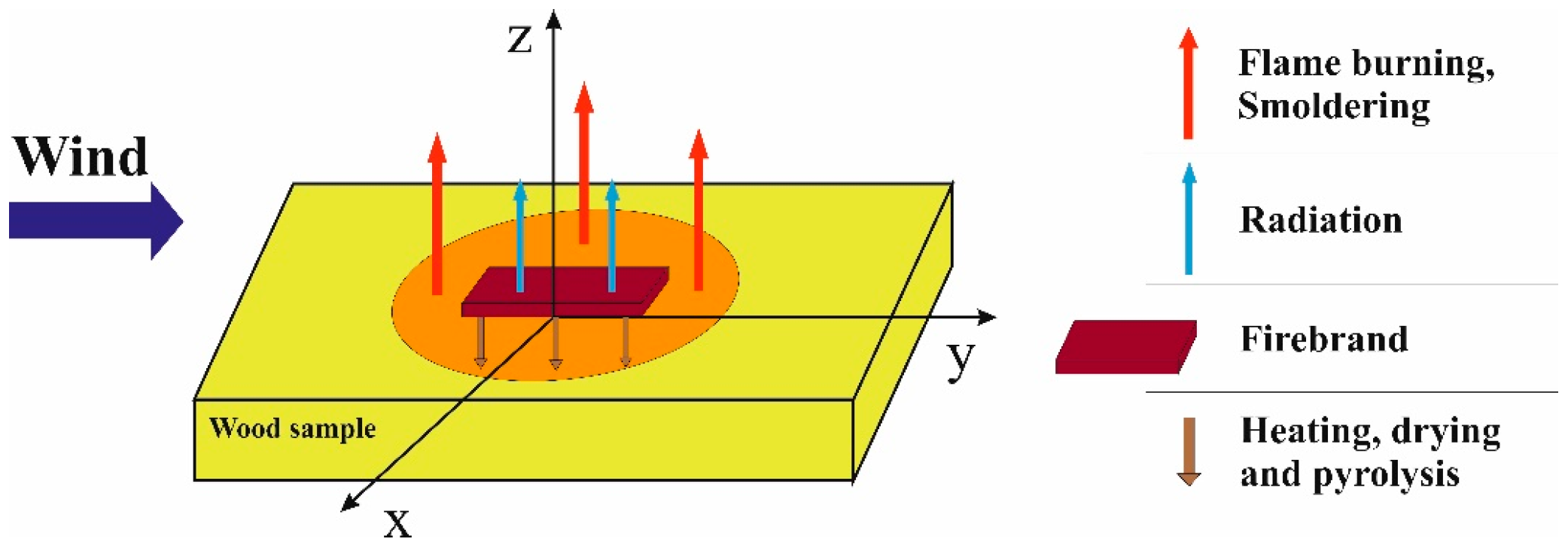

2.1. Mathematical Model

2.2. Method of Solving the Problem

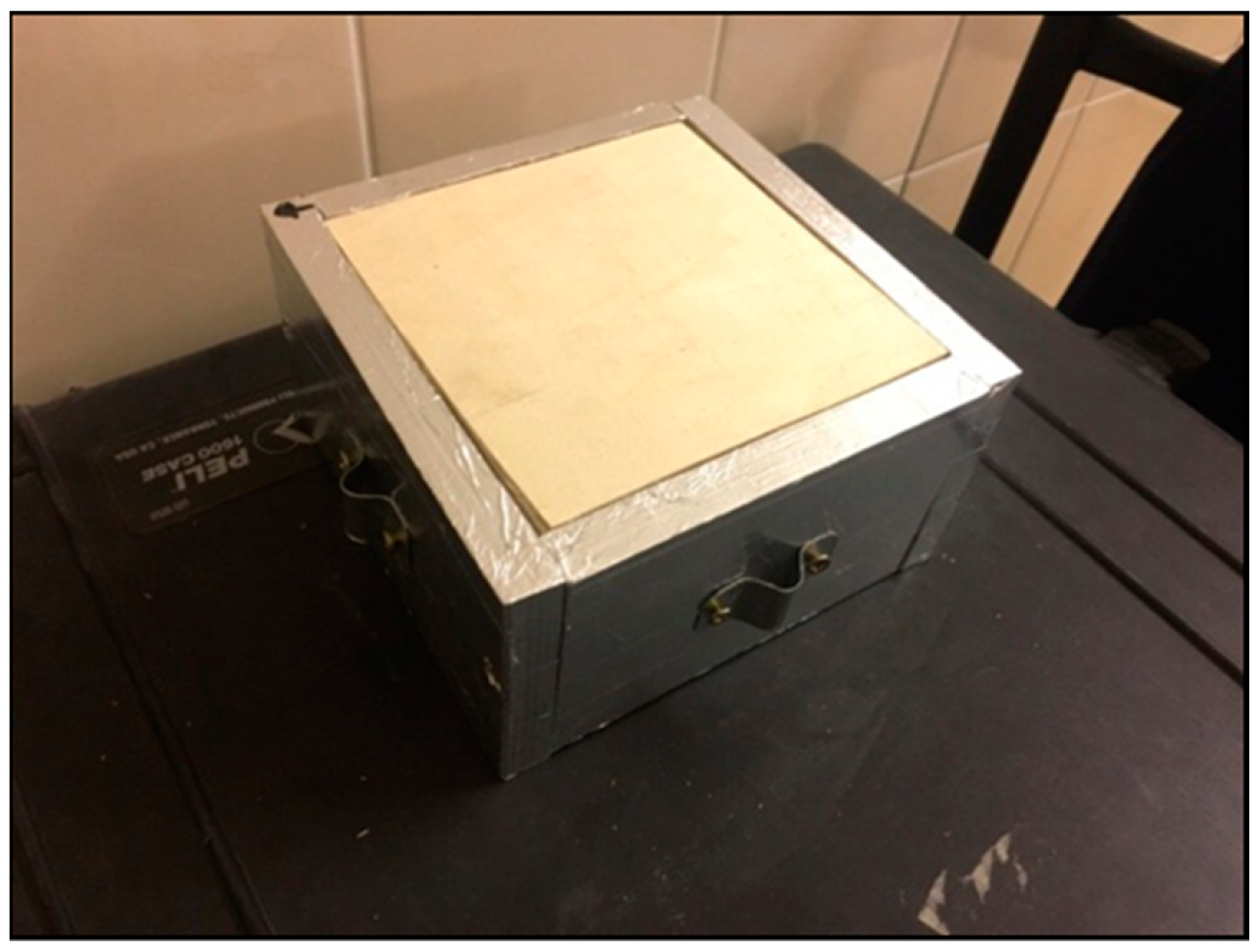

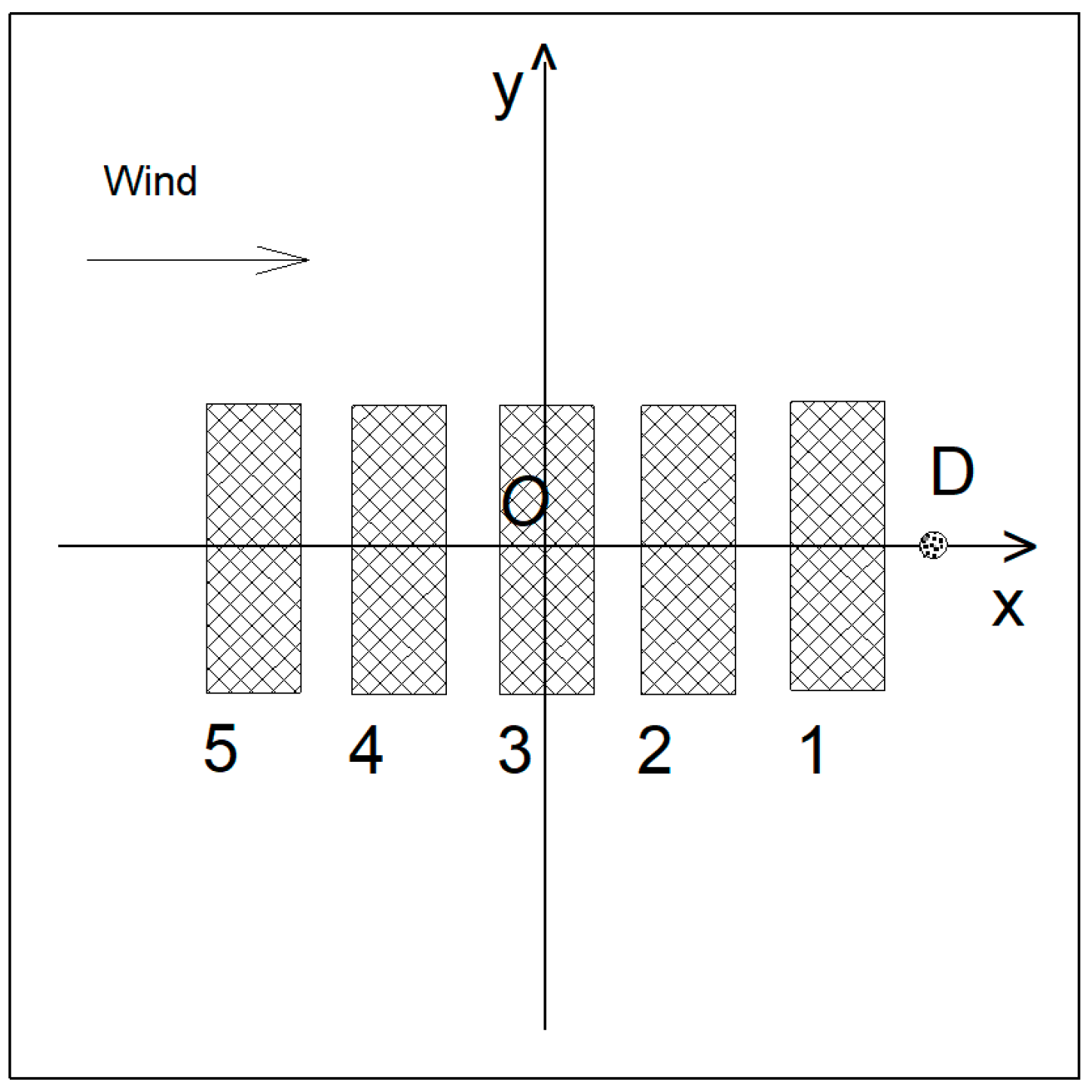

2.3. Experimantal Procedure

3. Results

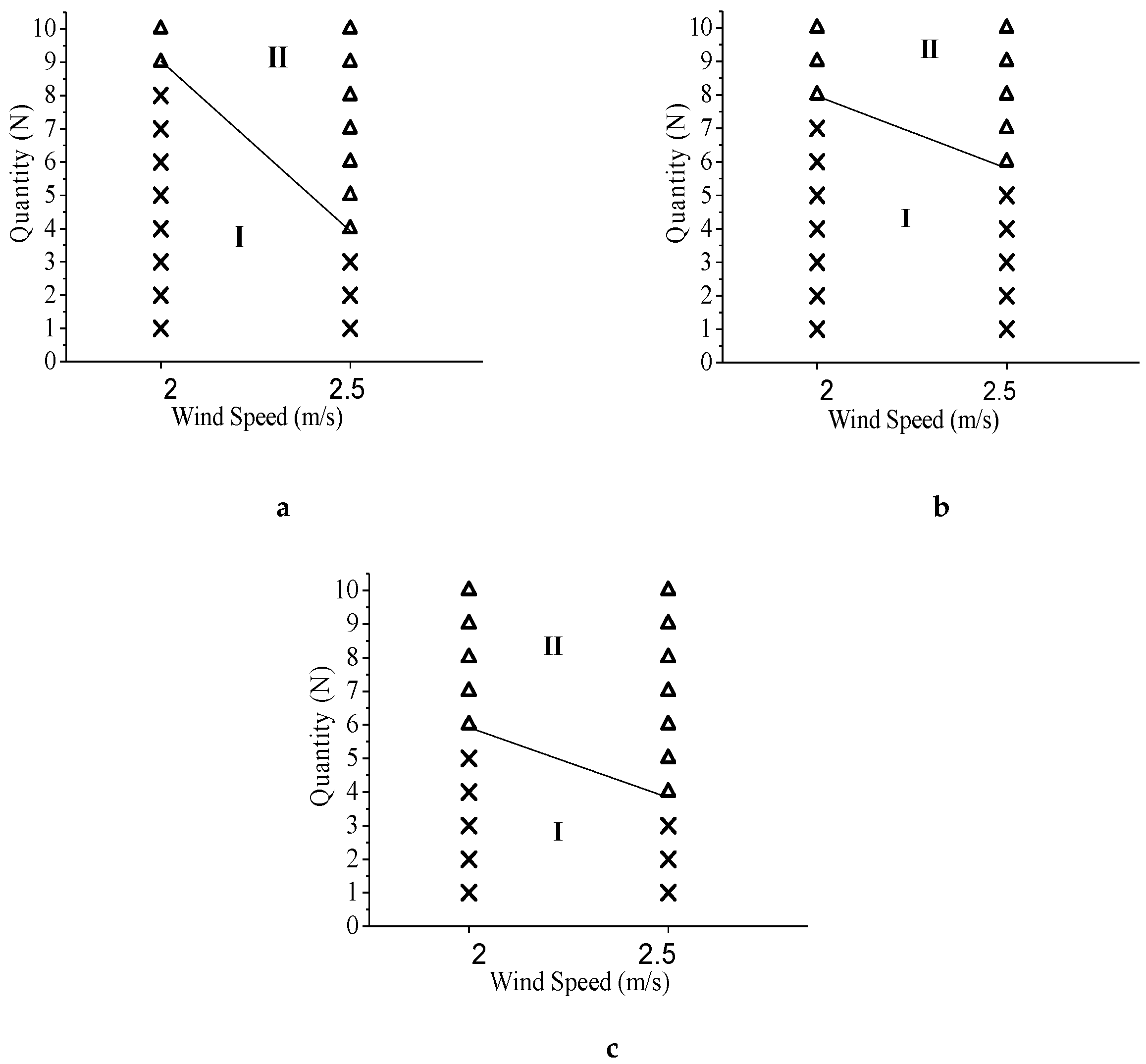

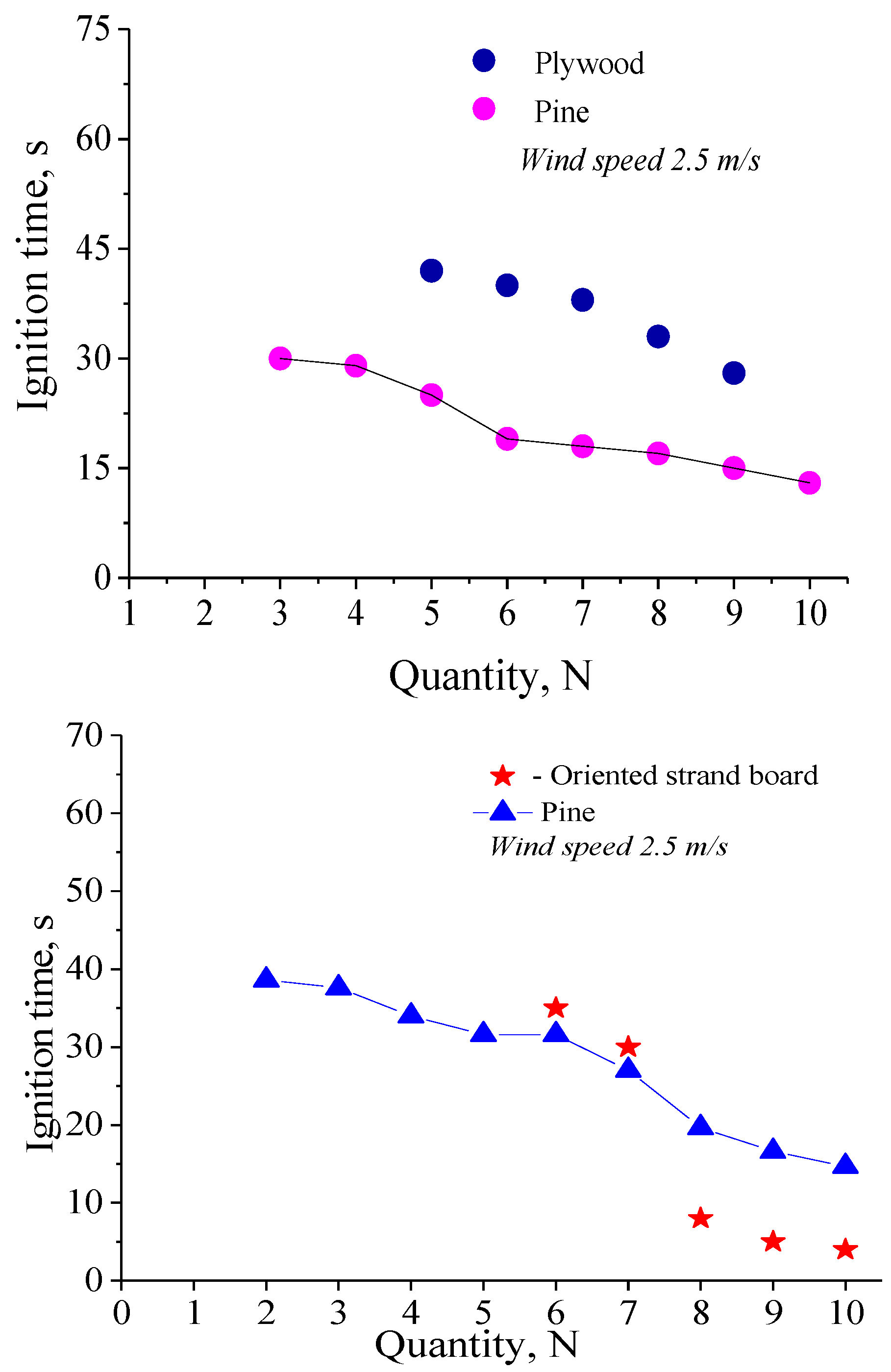

3.1. Experiment

3.2. Mathematical Modeling

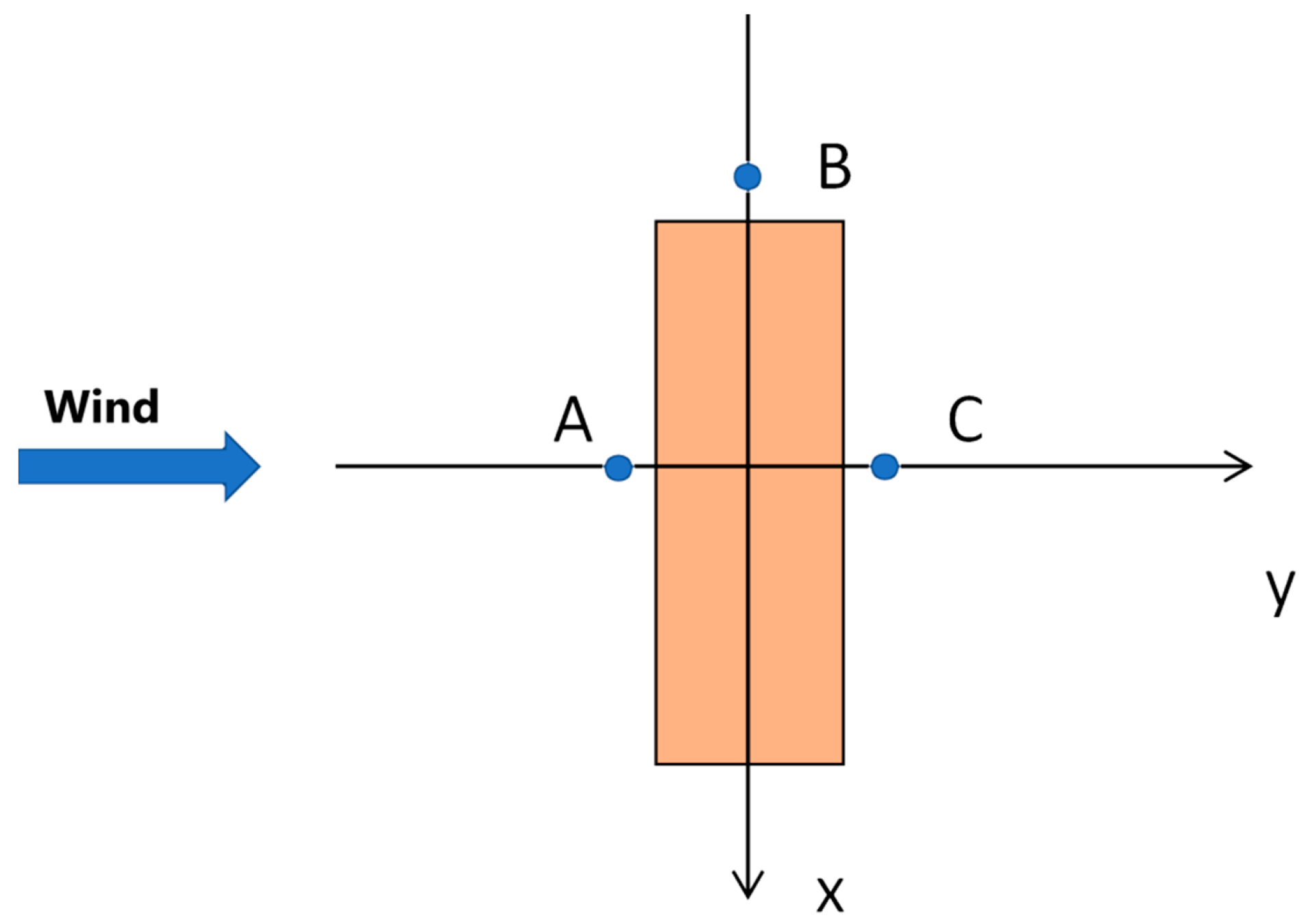

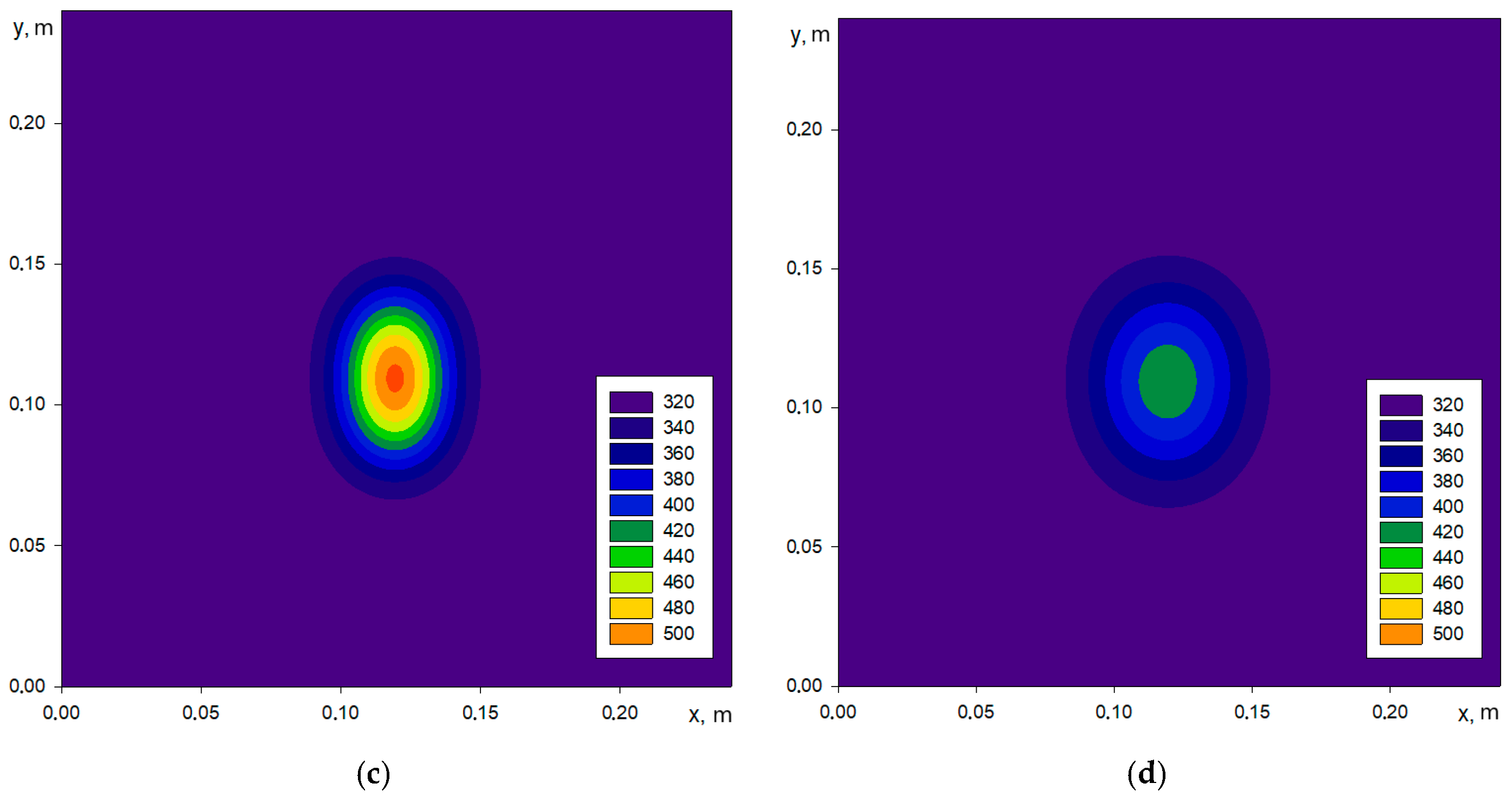

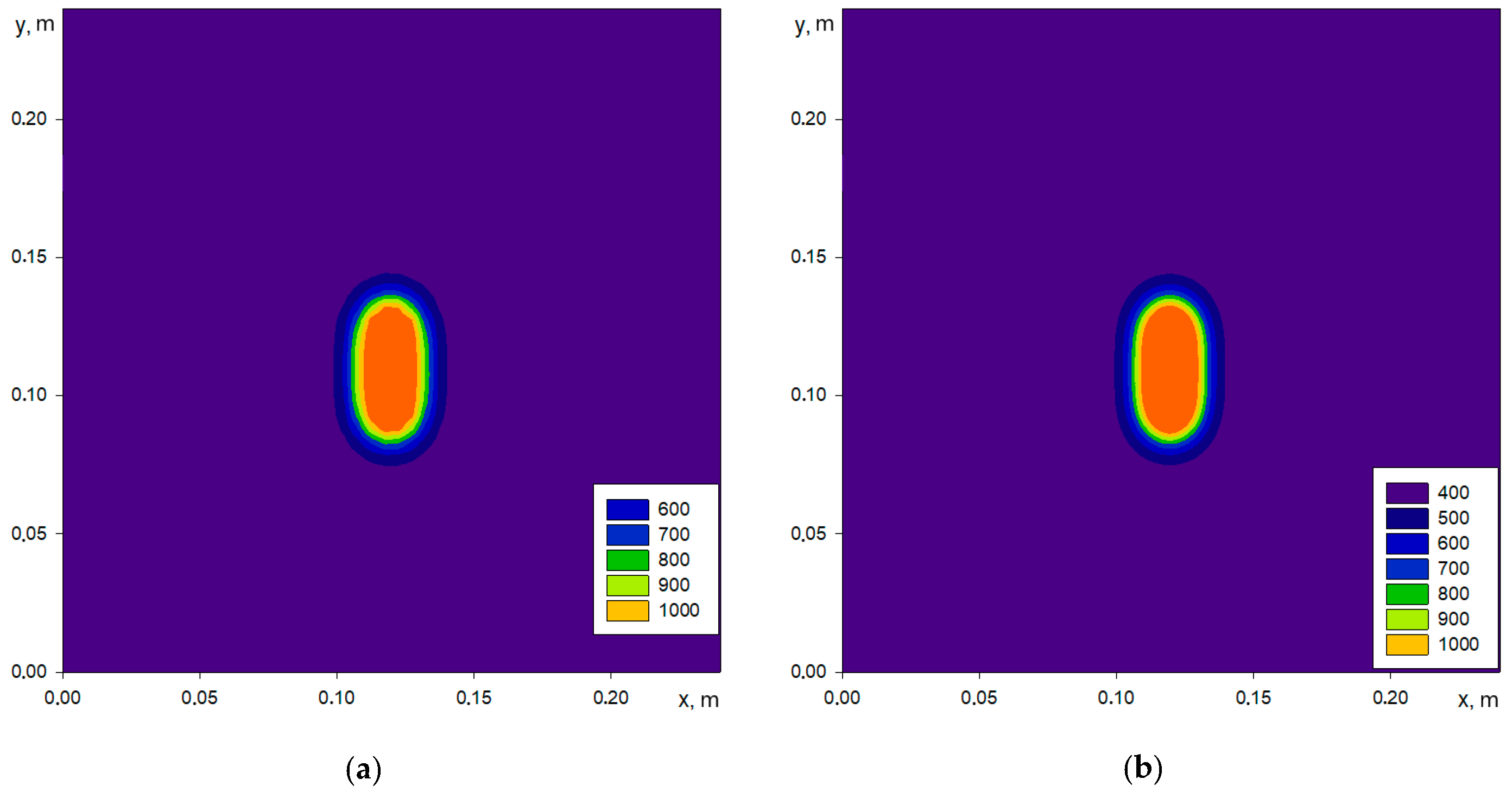

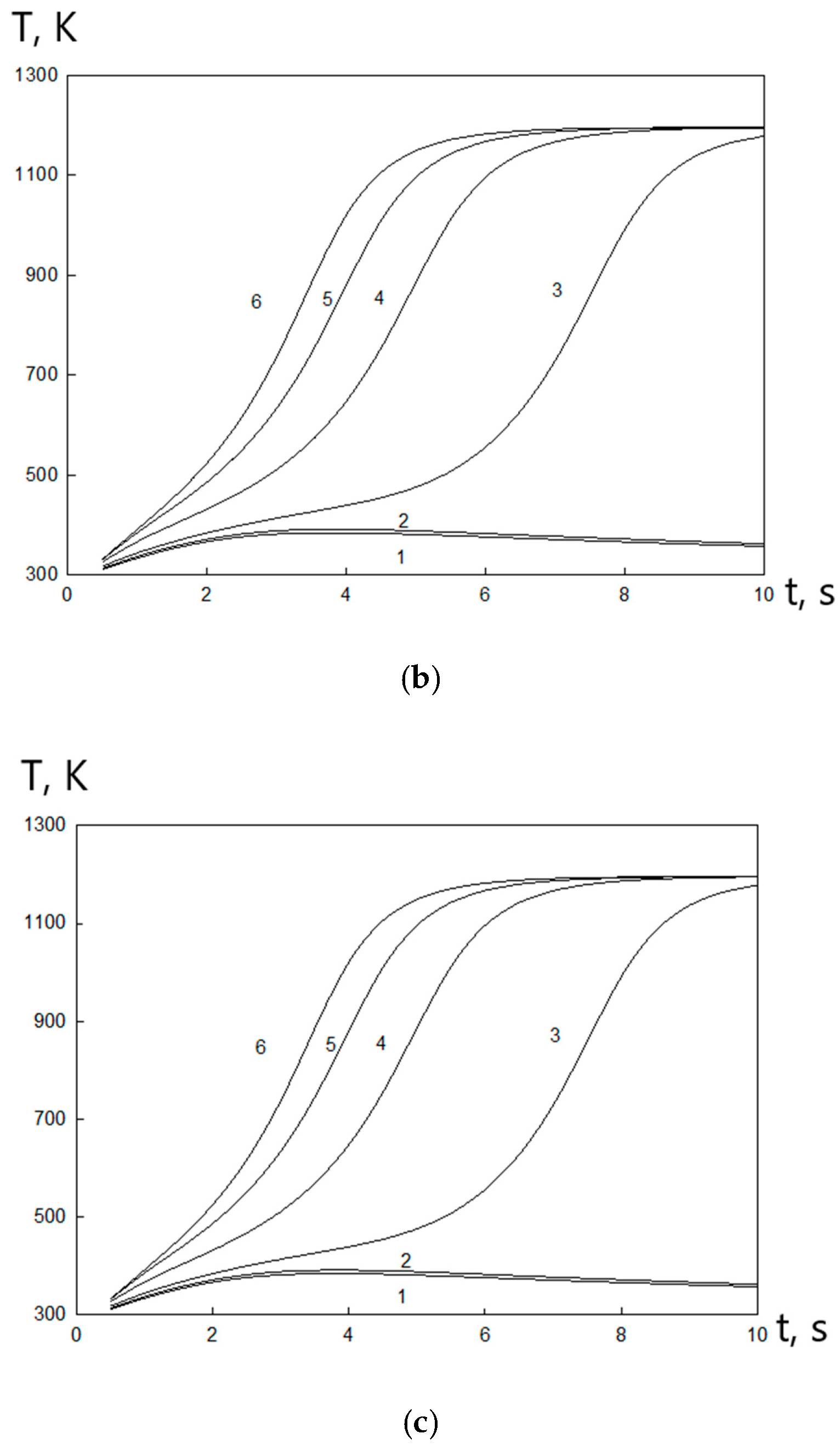

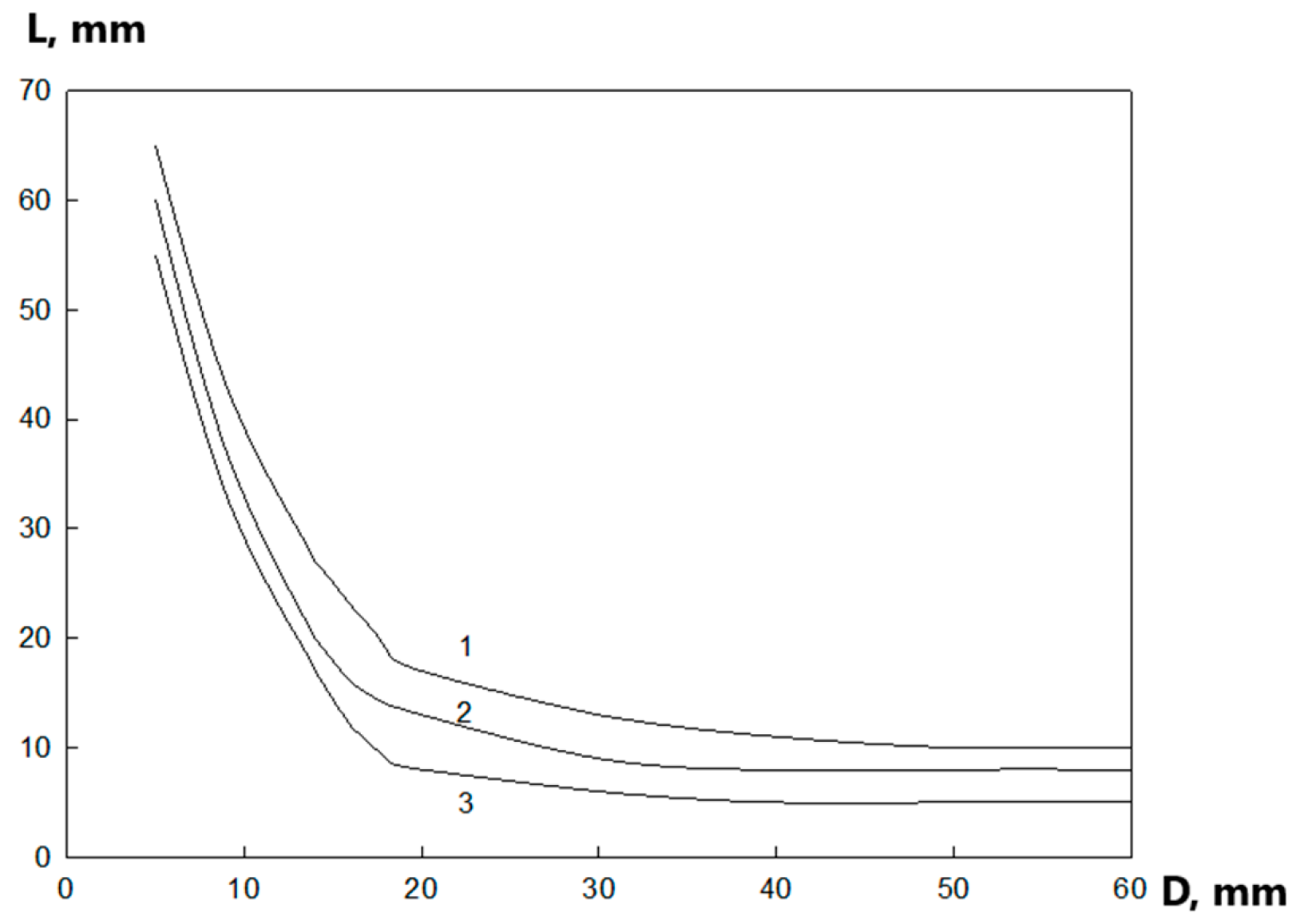

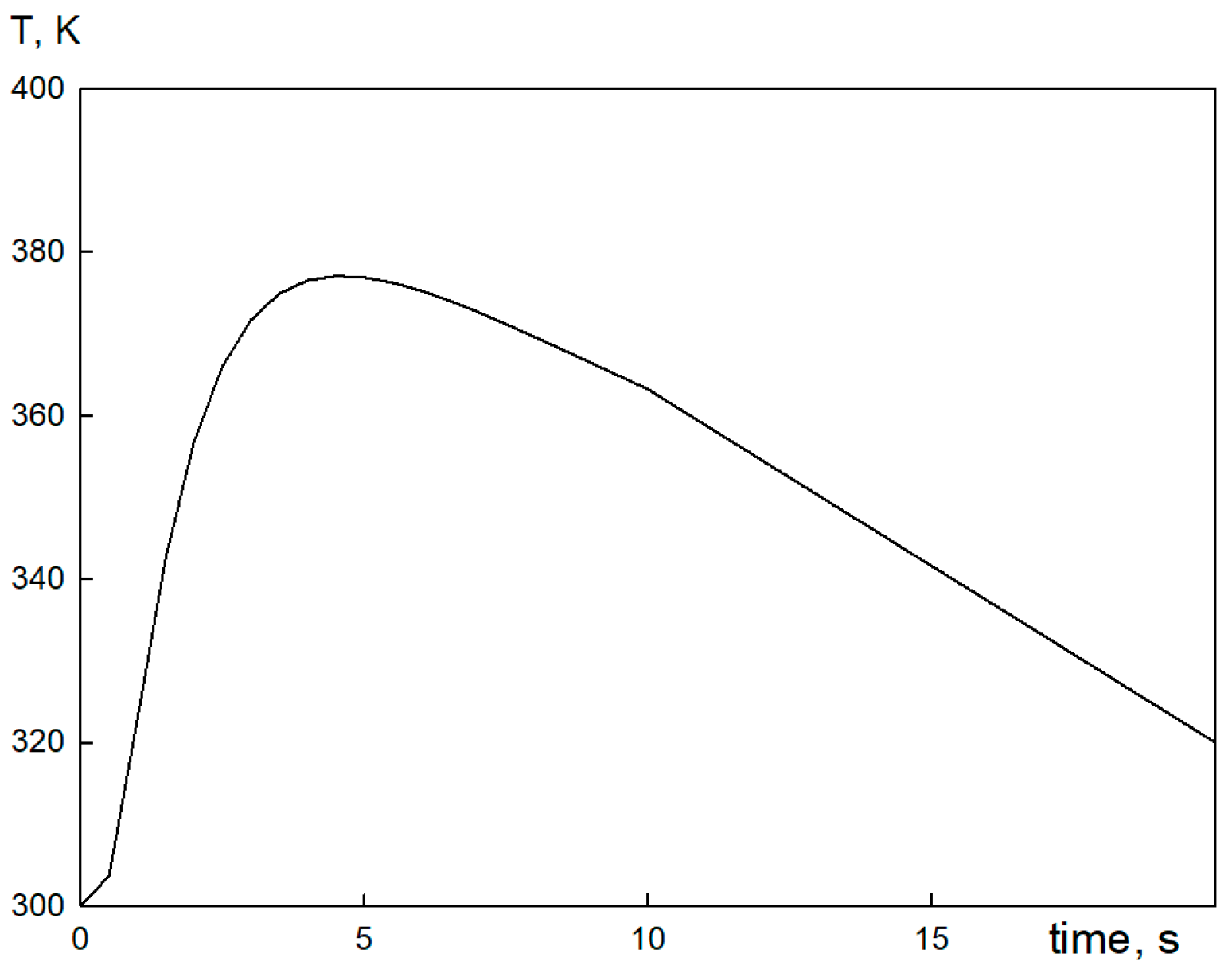

3.2.1. Single Firebrand Modeling

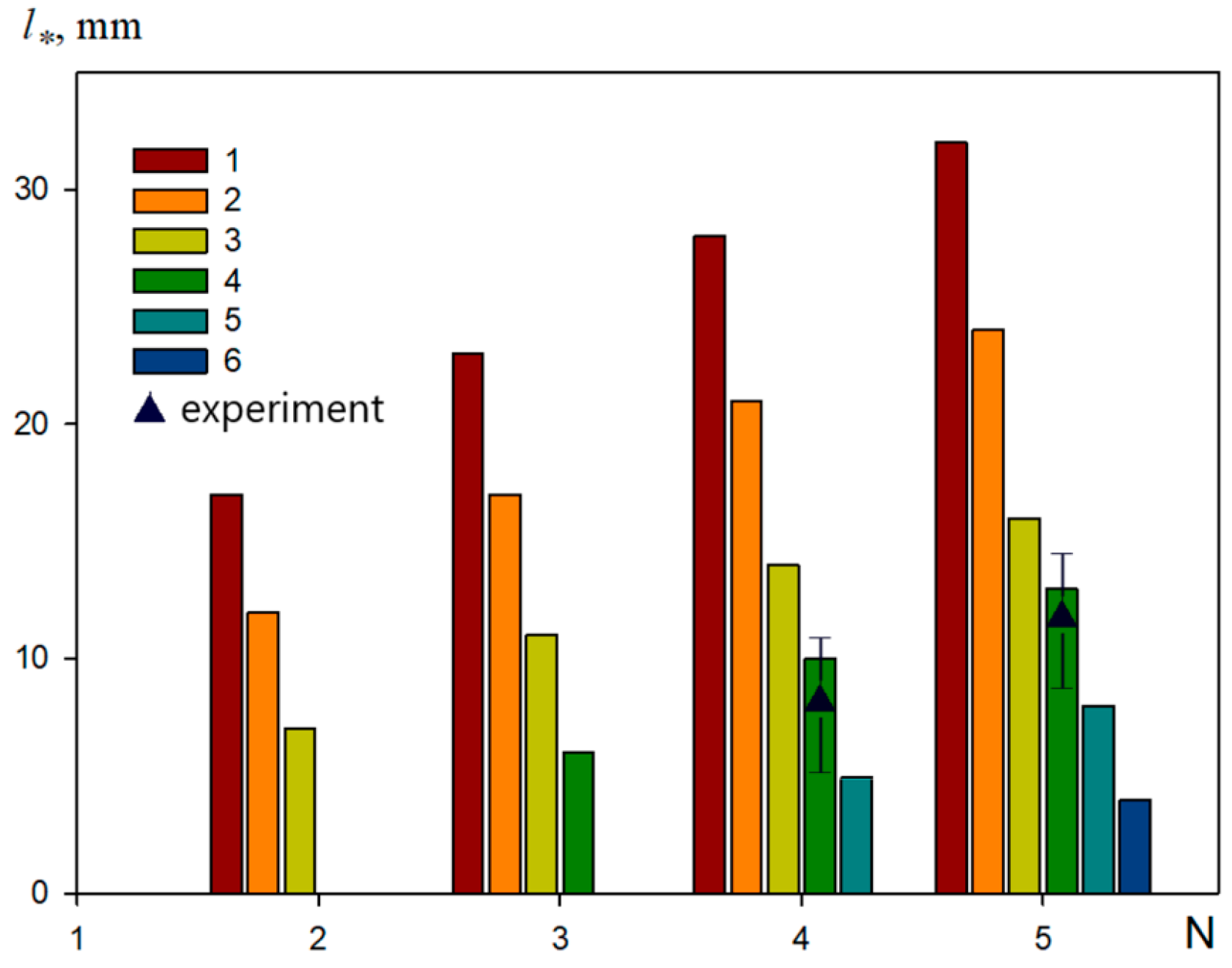

3.2.2. Modeling of the Interaction between a Group of Firebrands and a Wood Sample

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Term | Meaning (Units) |

| Nomenclature | |

| heat capacity () | |

| density () | |

| temperature () | |

| thermal conductivity () | |

| radiation intensity (W ) | |

| the characteristic particle size () | |

| reaction heat of pyrolysis, drying and combustion of coke () | |

| the rate of pyrolysis, drying and combustion (coke) | |

| is the degree of blackness of the wood layer | |

| integral radiation absorption coefficient () | |

| integral radiation attenuation coefficient () | |

| is the black body radiation constant | |

| pre-exponential factor | |

| relative moisture content of wood sample | |

| mass fraction of dry organic matter | |

| mass fraction of condensed pyrolysis products | |

| mass fraction | |

| rate of the enthalpy change () | |

| activation energy, () | |

| wind speed ( | |

| gravity factor ( | |

| coefficient of diffusion ( | |

| molecular mass, () | |

| pressure, | |

| viscosity, | |

| universal gas constant () | |

| heat capacity of gas at constant pressure, | |

| t | time (s) |

| x, y, z | coordinates (m) |

| Subscripts | |

| firebrand | |

| solid phase (wood, firebrand) | |

| thermal degradation | |

| pyrolysis | |

| drying | |

| wood layer | |

| gas | |

| 1 | dry organic substance |

| 2 | water in the liquid-drop condition |

| 3 | condensed pyrolysis products |

| oxygen | |

| carbon monoxide | |

| carbon dioxide | |

| nitrogen | |

| water | |

| О | ambient |

References

- Manzello, S.L.; Cleary, T.G.; Shields, J.R.; Maranghides, A.; Mell, W.; Yang, J.C. Experimental investigation of firebrands: Generation and ignition of fuel beds. Fire Saf. J. 2008, 43, 226–233. [Google Scholar] [CrossRef]

- Hassan, Q.K.; Rahaman, K.R.; Ahmed, M.R.; Hossain, S.M. Examining Post-Fire Perceptions of Selected Mitigation Strategies after the 2016 Horse River Wildland Fire in Alberta, Canada. Appl. Sci. 2021, 11, 10155. [Google Scholar] [CrossRef]

- Brewer, M.J.; Clements, C.B. The 2018 Camp Fire: Meteorological Analysis Using In Situ Observations and Numerical Simulations. Atmosphere 2020, 11, 47. [Google Scholar] [CrossRef]

- Brown, T.; Leach, S.; Wachter, B.; Gardunio, B. The Extreme 2018 Northern California Fire Season. Bull. Am. Meteorol. Soc. 2020, 101, S1–S4. [Google Scholar] [CrossRef]

- Cohen, J.D. Preventing disaster: Home ignitability in the wildland-urban interface. J. For. 2020, 98, 15–21. [Google Scholar]

- Mell, W.; Manzello, S.; Maranghides, A.; Butry, D.; Rehm, R. The wildland-urban interface problem—current approaches and research needs. Int. J. Wildland Fire 2010, 19, 238–251. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Ignition Vulnerabilities of Combustibles around Houses to Firebrand Showers: Further Comparison of Experiments. Sustainability 2021, 13, 2136. [Google Scholar] [CrossRef]

- Koo, E.; Pagni, P.J.; Weise, D.R.; Woycheese, J.P. Firebrands and spotting ignition in large-scale fires. Int. J. Wildland Fire 2010, 19, 818–843. [Google Scholar] [CrossRef]

- Pokswinski, S.; Gallagher, M.R.; Skowronski, N.S.; Loudermilk, E.L.; O’Brien, J.J.; Hiers, J.K. Diurnal Pine Bark Structure Dynamics Affect Properties Relevant to Firebrand Generation. Fire 2020, 3, 55. [Google Scholar] [CrossRef]

- Houssami, М.; Mueller, E.; Filkov, A.; Thomas, J.C.; Skowronski, N.; Gallagher, M.R.; Clark, K.; Kremens, R.; Simeoni, A. Experimental Procedures Characterising Firebrand Generation in Wildland Fires. Fire Technol. 2015, 52, 731–751. [Google Scholar] [CrossRef]

- Filkov, A.; Prohanov, S.; Mueller, E.; Kasymov, D.; Martynov, P.; El Houssami, M.; Thomas, J.; Skowronski, N.; Butler, B.; Gallagher, M.; et al. Investigation of firebrand production during prescribed fires conducted in a pine forest. Proc. Combust. Inst. 2017, 36, 3263–3270. [Google Scholar] [CrossRef]

- Hudson, T.R.; Bray, R.B.; Blunck, D.L.; Page, W.; Butler, B. Effects of fuel morphology on ember generation characteristics at the tree scale. Int. J. Wildland Fire 2020, 29, 1042–1051. [Google Scholar] [CrossRef]

- Thomas, J.; Mueller, E.V.; Santamaria, S.; Gallagher, M.; Houssami, M.; Filkov, A.; Clark, K.; Skowronski, N.; Hadden, R.M.; Mell, W.; et al. Investigation of firebrand generation from an experimental fire: Development of a reliable data collection methodology. Fire Saf. J. 2017, 91, 864–871. [Google Scholar] [CrossRef]

- Hajilou, M.; Hu, S.; Roche, T.; Garg, P.; Gollner, M.J. A Methodology for Experimental Quantification of Firebrand Generation from WUI Fuels. Fire Technol. 2021, 57, 2367–2385. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Characteristics of firebrands collected from actual urban fires. Fire Technol. 2018, 54, 1533–1546. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Initial study on thatched roofing assembly ignition vulnerabilities to firebrand showers. Fire Saf. J. 2019, 103, 34–37. [Google Scholar] [CrossRef]

- Santamaria, S.; Kempna, K.; Thomas, J.; El Houssami, M.; Mueller, E.; Kasimov, D.; Filkov, A.; Gallagher, R.M.; Skowronski, N. Investigation of structural wood ignition by firebrand accumulation. In Proceedings of the First International Conference on Structures Safety Under Fire Blast, Glasgow, UK, 2–4 September 2015; pp. 1–13. [Google Scholar]

- Manzello, S.; Park, S.; Cleary, T. Investigation on the ability of glowing firebrands deposited within crevices to ignite common building materials. Fire Saf. J. 2009, 44, 894–900. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L.; Lage, M.; Laing, G. Firebrand generation data obtained from a full scale structure burn. Int. J. Wildland Fire. 2012, 21, 961–968. [Google Scholar] [CrossRef]

- Zhou, A.; Quarles, S.L.; Weise, D.R. Final Report: Fire Ember Production from Wildland and Structural Fuels; JFSP Project ID: 15-1-04-4; North Carolina Agricultural and Technical State University: Greensboro, NC, USA, 2019; pp. 1–66. [Google Scholar]

- Quarles, S.L. Vulnerability of Vents to Wind-blown Embers; IBHS: Richburg, SC, USA, 2017. [Google Scholar]

- Kasymov, D.P.; Paletsky, A.A. Effect of a fire retardant on the ignition of pine wood exposed to smoldering particles of pine bark. In Proceedings of the EPJ Web of Conferences, Crete, Greece, 17–29 August 2017; Volume 159, pp. 1–6. [Google Scholar] [CrossRef][Green Version]

- Suzuki, S.; Manzello, S.L. Firebrand production from building components fitted with siding treatments. Fire Saf. J. 2016, 80, 64–70. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, S.; Manzello, S.L. Garnering understanding into complex firebrand generation processes from large outdoor fires using simplistic laboratory-scale experimental methodologies. Fuel 2020, 267, 117–154. [Google Scholar] [CrossRef]

- Kasymov, D.P.; Agafontsev, M.V.; Perminov, V.V.; Martynov, P.S. Estimation of pine wood fire-resistance exposed to the heat emission using thermography. In Proceedings of the 25th International Symposium on Atmospheric and Ocean Optics: Atmospheric Physics, Tomsk, Russian, 30 June 2019–5 July 2019; Volume 11208. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L.; Hayashi, Y. The size and mass distribution of firebrands collected from ignited building components exposed to wind. Proc. Combust. Inst. 2013, 34, 2479–2485. [Google Scholar] [CrossRef]

- Kasymov, D.P.; Tarakanova, V.A.; Martynov, P.S.; Agafontsev, M.V. Studying firebrands interaction with flat surface of various wood construction materials in laboratory conditions. J. Phys. Conf. Ser. 2019, 1359, 012092. [Google Scholar] [CrossRef]

- Salehizadeh, H.; Hakes, R.S.P.; Gollner, M.J. Critical Ignition Conditions of Wood by Cylindrical Firebrands. Front. Mech. Eng. 2021, 7, 630324. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S.; Naruse, T. Quantifying wind-driven firebrand production from roofing assembly combustion. Fire Mater. 2019, 43, 3–7. [Google Scholar] [CrossRef] [PubMed]

- Manzello, S.L.; Maranghide, A.; Mell, W.E. Firebrand generation from burning vegetation. Int. J. Wildland Fire 2007, 16, 458–462. [Google Scholar] [CrossRef]

- Mell, W.; Maranghides, A.; McDermott, R.; Manzello, S.L. Numerical simulation and experiments of burning douglas fir trees. Combust. Flame 2009, 15, 2023–2041. [Google Scholar] [CrossRef]

- Yin, N.; Liu, H.; Chen, J.S.; Lozano, Y. Shan New correlation between ignition time and moisture content for pine needles attacked by firebrands. Fire Technol. 2012, 50, 79–91. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Chen, H.; Liu, N. Interaction between flaming and smouldering in hot-particle ignition of forest fuels and effects of moisture and wind. Int. J. Wildland Fire 2016, 26, 71–81. [Google Scholar] [CrossRef]

- Wessies, S.S.; Chang, M.K.; Marr, K.C. Experimental and Analytical Characterization of Firebrand Ignition of Home Insulation Materials. Fire Technol. 2019, 55, 1027–1056. [Google Scholar] [CrossRef]

- Bearinger, E.; Lattimer, B.Y.; Hodges, J.L.; Rippe, C.; Kapahi, A. Statistical Assessment of Parameters Affecting Firebrand Pile Heat Transfer to Surfaces. Front. Mech. Eng. 2021, 7, 702181. [Google Scholar] [CrossRef]

- Wickramasinghe, N.K.; Khalid, M. Potential of Modelling Firebrand Load on Structure in Wildland Urban Interface; Bushfire and Natural Hazard CRC: Melbourne, Australia, 2019. [Google Scholar]

- Koo, E.; Rodman, R.; Linn, P.J.; Pagni, C.B. Edminster Modelling firebrand transport in wildfires using HIGRAD/FIRETEC. Int. J. Wildland Fire 2012, 21, 396–417. [Google Scholar] [CrossRef]

- Caton, S.E.; Hakes, R.S.P.; Gorham, D.J. Review of Pathways for Building Fire Spread in the Wildland Urban Interface Part I: Exposure Conditions. Fire Technol. 2017, 53, 429–473. [Google Scholar] [CrossRef]

- Muraszew, A.; Fedele, J.B.; Kuby, W.C. Trajectory of firebrands in and out of fire whirls. Combust. Flame 1977, 30, 321–324. [Google Scholar] [CrossRef]

- Tse, S.D.; Fernandez-Pello, A.C. On the flight paths of metal particles and embers generated by power lines in high winds—A potential source of wildland fires. Fire Saf. J. 1998, 30, 333–356. [Google Scholar] [CrossRef]

- Baum, H.R.; Atreya, A. A model for combustion of firebrands of various shapes. Fire Saf. Sci. 2014, 11, 1353–1367. [Google Scholar] [CrossRef][Green Version]

- Manzello, S.L.; Suzuki, S.; Gollner, M.; Carlos Fernandez-Pello, A. Role of Firebrand Combustion in Large Outdoor Fire Spread. Prog. Energy Combust. Sci. 2020, 76, 100801. [Google Scholar] [CrossRef]

- Zvyagils’kaya, A.I.; Subbotin, A.N. Influence of moisture content and heat and mass exchange with the surrounding medium on the critical conditions of initiation of surface fire. Combust. Explos. Shock Waves 1996, 32, 558–564. [Google Scholar] [CrossRef]

- Grishin, A.M.; Dolgov, A.A.; Zima, V.P.; Kryuchkov, D.A.; Reino, V.V.; Subbottin, A.N.; Tsvyk, R.S. Ignition of a layer of combustible forest materials. Combust. Explos. Shock Waves 1998, 34, 613–620. [Google Scholar] [CrossRef]

- Thomas, P.H. A comparison of some hot spot theories. Combust. Flame 1964, 9, 369–372. [Google Scholar] [CrossRef]

- Lautenberger, C.; Fernandez-Pello, A.C. Generalized pyrolysis model for combustible solids. Fire Saf. J. 2009, 44, 819–839. [Google Scholar] [CrossRef]

- Lautenberger, C.; Fernandez-Pello, A.C. Spotting ignition of fuel beds by firebrands. WIT Trans. Model. Simul. 2009, 48, 603–612. [Google Scholar] [CrossRef]

- Fernandez-Pello, A.C. Wildland fire spot ignition by sparks and firebrands. Fire Saf. J. 2017, 91, 2–10. [Google Scholar] [CrossRef]

- Filkov, A.; Kasymov, D.; Zima, V.; Matvienko, O. Experimental investigation of surface litter ignition by bark firebrands. AIP Conf. Proc. 2016, 1698, 060004. [Google Scholar] [CrossRef]

- Matvienko, O.V.; Filkov, A.I.; Grishin, A.M. Computational Investigation of the Transport of Burning Particles. J. Eng. Phys. Thermophys. 2016, 89, 1315–1324. [Google Scholar] [CrossRef]

- Matvienko, O.V.; Kasymov, D.P.; Filkov, A.I.; Daneyko, O.I.; Gorbatov, D.A. Simulation of fuel bed ignition by wildland firebrands. Int. J. Wildland Fire 2018, 27, 550–561. [Google Scholar] [CrossRef]

- Ozicik, M.N. Radiative Transfer and Interactions with Conduction and Convection; Wiley: New York, NY, USA, 1973. [Google Scholar]

- Grishin, A.M. Mathematical Modeling of Forest Fires and New Methods of Fighting Them; Albini, F.A., Ed.; Tomsk State University: Tomsk, Russia, 1997. [Google Scholar]

- Grishin, A.M.; Matvienko, O.V. Numerical Investigation of the Formation of a Convective Column and a Fire Tornado by Forest Fires. J. Eng. Phys. Thermophys. 2014, 87, 1080–1093. [Google Scholar] [CrossRef]

- Arkhipov, V.A.; Matvienko, O.V.; Trofimov, V.F. Combustion of sprayed liquid fuel in a swirling flow. Combust. Explos. Shock Waves 2005, 41, 140–150. [Google Scholar] [CrossRef]

- Ushakov, V.M.; Matvienko, O.V. Numerical investigation of the heat exchange and firing of reactive channel walls by a high-temperature swirling-gas glow. Eng Phys. Thermophys. 2005, 78, 541–547. [Google Scholar] [CrossRef]

- Arkhipov, V.A.; Egorov, A.G.; Ivanin, S.V.; Maslov, E.A.; Matvienko, O.V. Numerical simulation of aerodynamics and combustion of a gas mixture in a channel with sudden expansion. Combust. Explos. Shock. Waves 2010, 46, 647–655. [Google Scholar] [CrossRef]

- Matvienko, O.V. Mathematical Modeling of the Heat Transfer and Conditions of Ignition of a Turbulent Flow of a Reactive Gas. J. Eng. Phys. Thermophys. 2016, 89, 212–220. [Google Scholar] [CrossRef]

- Egorov, A.G.; Tizilov, A.S.; Niyazov, V.Y.; Arkhipov, V.A.; Matvienko, O.V. Effect of the swirl of cocurrent high-velocity wind speed on the geometry of an aluminum-air flame. Russ. J. Phys. Chem. 2014, 8, 712–715. [Google Scholar] [CrossRef]

- Westbrook, C.K.; Dryer, F.L. Chemical Kinetic Modeling of Hydrocarbon Combustion. Prog. Energy Combust. Sci. 1984, 10, 1–57. [Google Scholar] [CrossRef]

- Loboda, E.L.; Matvienko, O.V.; Vavilov, V.P.; Reyno, V.V. Infrared thermographic evaluation of flame turbulence scale. Infrared Phys. Technol. 2015, 72, 1–7. [Google Scholar] [CrossRef]

- Matvienko, O.V.; Baigulova, A.I.; Bubenchikov, A.M. Mathematical Modeling of Catalytic Oxidation of Methane in a Channel with a Porous Insert. J. Eng. Phys. Thermophys. 2014, 87, 1298–1312. [Google Scholar] [CrossRef]

- Grishin, A.M.; Matvienko, O.V.; Rudi, Y.A. Mathematical modeling of gas combustion in a twisted jet and of the formation of a fiery whirlwind. J. Eng. Phys. Thermophys. 2009, 82, 906–913. [Google Scholar] [CrossRef]

- Loitsyanskii, L.G. Mekhanika Zhidkosti I Gaza [Fluid and Gas Mechanics]; Nauka Publish: Moskow, Russia, 1987; 840p. [Google Scholar]

- Gebhart, B.; Jaluria, Y.; Mahajan, R.L.; Sammakia, B. Free-Convective Flows, Heat and Mass Transfer; MIR: Moscow, Russia, 1991; Volume 1, 678p. [Google Scholar]

- Patankar, S. Numerical Methods of Solving Problems on Heat and Mass Exchange and Fluid Dynamics; Énergoatomizdat: Moscow, Russia, 1983. [Google Scholar]

- Van Doormal, J.P.; Raithby, G.D. Enhancements of the SIMPLE method for predicting incompressible fluid flows. Numer. Heat Transf. 1984, 7, 147–163. [Google Scholar] [CrossRef]

- Sardoy, N.; Consalvi, J.-L.; Poterie, B.; Loraud, J.-C.; Fernandez-Pello, C.A. Modeling transport and combustion of firebrands from burning trees. Combust. Flame 2007, 150, 151–169. [Google Scholar] [CrossRef]

- Anthenien, R.A.; Tse, S.D.; Fernandez-Pello, C. On the trajectories of embers initially elevated or lofted by small scale ground fire plumes in high winds. Fire Saf. J. 2006, 41, 349–363. [Google Scholar] [CrossRef]

- Woycheese, J.P.; Pagni, P.J.; Liepmann, D. Brand Lofting Above Large-Scale Fires. In Proceedings of the Second International Conference of Fire Research and Engineering, Gaithersburg, MD, USA, 10–15 August 1997; pp. 137–150. [Google Scholar]

- Kasymov, D.P.; Agafontsev, M.V.; Perminov, V.V.; Tarakanova, V.A. Studying the resistance to fire of wood under the different type of thermal impact while forest fires. In Proceedings of the 24th International Symposium on Atmospheric and Ocean Optics: Atmospheric Physics, Tomsk, Russian, 2–5 July 2018; Volume 10833. [Google Scholar] [CrossRef]

- Fateev, V.; Agafontsev, M.; Volkov, S.; Filkov, A. Determination of smoldering time and thermal characteristics of firebrands under laboratory conditions. Fire Saf. J. 2017, 91, 791–799. [Google Scholar] [CrossRef]

- Kasymov, D.P.; Agafontsev, M.V.; Tarakanova, V.A.; Loboda, E.L.; Martynov, P.S.; Orlov, K.E.; Reyno, V.V. Effect of wood structure geometry during firebrand generation in laboratory scale and semi-field experiments. J. Phys. Conf. Ser. 2020, 1867, 12–20. [Google Scholar] [CrossRef]

| Plywood | Chipboard | OSB | |

|---|---|---|---|

| Type | broadleaf (birch) | coniferous | coniferous |

| Type of glue | urea | phenolic | phenolic |

| Size, m: | 0.100 × 0.100 | 0.100 × 0.100 | 0.100 × 0.100 |

| Thickness, m: | 0.021 | 0.018 | 0.018 |

| Density, kg/m3: | 705–725 | 700–720 | 570–590 |

| Moisture content, %: | 4.2 | 5.7 | 4.7 |

| Thermal conductivity, (Wm−1 K−1) | 0.14 | urea glue | urea glue |

| Pine twigs | Length, [mm] | Exposure time, [s] |

| 20 | 15 | |

| 40 | 20 | |

| 60 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matvienko, O.; Kasymov, D.; Loboda, E.; Lutsenko, A.; Daneyko, O. Modeling of Wood Surface Ignition by Wildland Firebrands. Fire 2022, 5, 38. https://doi.org/10.3390/fire5020038

Matvienko O, Kasymov D, Loboda E, Lutsenko A, Daneyko O. Modeling of Wood Surface Ignition by Wildland Firebrands. Fire. 2022; 5(2):38. https://doi.org/10.3390/fire5020038

Chicago/Turabian StyleMatvienko, Oleg, Denis Kasymov, Egor Loboda, Anastasia Lutsenko, and Olga Daneyko. 2022. "Modeling of Wood Surface Ignition by Wildland Firebrands" Fire 5, no. 2: 38. https://doi.org/10.3390/fire5020038

APA StyleMatvienko, O., Kasymov, D., Loboda, E., Lutsenko, A., & Daneyko, O. (2022). Modeling of Wood Surface Ignition by Wildland Firebrands. Fire, 5(2), 38. https://doi.org/10.3390/fire5020038