Abstract

This paper investigates the reliability of a dual-axis solar tracking system using Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Reliability Block Diagrams (RBD). The system’s control and data transfer subsystems are evaluated under indoor and outdoor conditions using failure rate data. Key vulnerabilities—particularly sensor degradation—are modeled through probabilistic analysis. Results show a significant drop in reliability (to 15.02%) in harsh environments, primarily due to light sensor failures. However, mitigation strategies such as Built-In Self-Test (BIST) architectures improve test coverage, thereby increasing the chance of fault detection. The findings highlight the need for reliability-focused design in solar trackers to ensure long-term energy efficiency and fault resilience.

1. Introduction

The ongoing demand for alternative energy options has pushed humanity to embrace sustainable energy sources. Solar energy is the most abundant renewable energy source, and it may be gathered successfully using Photovoltaic (PV) devices. Home customers choose static placed PV panels due to their inexpensive installation costs and easier maintenance processes. However, because of their fixed position, home PV panels can only generate power during the afternoon, when the sun rays are perpendicular to the payload’s surface. This lack of optimal orientation has generated interest in constructing mobile variations, known as dual-axis solar trackers, that are capable of optimizing the azimuth and elevation angles, hence increasing energy generation by 30–45% [1,2]. However, these performance advantages come with trade-offs—namely increased system complexity, cost, and vulnerability to environmental and mechanical stressors.

The reliability of solar tracking systems is a central concern in both commercial and research contexts [3]. Maximum energy generation is generally affected by two crucial aspects: unfavorable weather conditions and PV panel misalignment. In the second case, several factors can lead to sub-optimal angle positioning, such as sensor degradation and inactivity, mechanical damage, or complete control system shutdown [4], all of which can alter the financial Return on Investment (ROI). More frequently, sensors that are directly exposed to outdoor conditions may suffer additional risks of failure [5,6], due to humidity, UV radiation, dust, and temperature fluctuations, to name only a few. Consequently. evaluating and improving the reliability of solar tracking systems is vital not only for technical reasons, but also for their long-term economic capacity and safety.

Under these circumstances, FMEA [7] and FTA [8] represent valuable assessment tools in reliability engineering. These structured methodologies enable a systematic exploration of potential failure pathways, root causes, and their impacts on overall system performance. Specifically, this research focuses on applying these techniques to a dual-axis solar tracking prototype, with an emphasis on modeling component failures, quantifying system reliability, and identifying critical vulnerabilities in both control and data transmission subsystems [9].

The novelty of this research is predicated upon the integration of quantitative reliability analysis, graph-based fault propagation, and explicit intervention modeling, notably the incorporation of BIST architectures, to effectively simulate and enhance fault tolerance. This hybrid methodological approach affords the capability not only to delineate high-risk failure modes (e.g., sensor drift, power outages) but also to quantify the efficacy of diverse mitigation strategies, such as the application of BIST architectures specifically designed for Electronic Control Units [10], and System-On-Chip (SoC) devices [11].

Ultimately, the research contributes to the development of more resilient and self-aware solar tracking systems capable of maintaining high efficiency even under adverse operating conditions. By addressing the interplay between hardware failures, environmental exposure, and diagnostic mechanisms, this study aims to establish a foundational reliability framework for future solar energy applications where uptime, safety, and ROI are non-negotiable factors.

The remainder of the paper is organized as follows. Section 2 explores the growing market demand for reliable solar tracking systems by presenting supporting arguments, and it establishes a clear connection between energy production efficiency and system reliability. Section 3 describes the research methodology consisting of RBDs, FTAs, and FMEA for assessing the reliability of solar trackers. Section 4 presents the experimental platform and results, beginning with the analysis of failure modes and their occurrence probabilities, followed by a detailed discussion of the effects and their implications. Section 5 introduces the mathematical framework, including the energy production computation formula and a novel method based on intervention nodes within Bayesian networks. Finally, Section 6 concludes this paper and presents the future work.

2. Literature Review

2.1. Reliability and Power Generation in Modern PV Systems

Modern literature emphasizes PV system reliability as an important factor for establishing their long-term power generation and efficiency. Several studies explore this detail by investigating the performance of individual components as well as to more advanced system-level grid structures.

The authors in [12] present a reliability evaluation approach that incorporates the thermal characteristics of inverters into the overall PV system model. Their analysis demonstrates that sustained heat stress can reduce inverter reliability by approximately 30%, which in turn leads to an overall reduction of nearly 20% in PV plant reliability. Similarly, the study in [13] applies Reliability, Availability, and Maintainability (RAM) analysis to PV plants of different scales over 20 years, revealing that inverter reliability declines sharply over time, especially in larger systems, eventually reaching zero in multi-megawatt configurations. The research presented in [14] employs the FTA approach to systematically identify the most critical PV component failures, highlighting issues such as solder bond failures, broken cells and interconnects, delamination, shading-related faults, and material discoloration as primary contributors to performance decline.

The review in [15] synthesizes findings from long-term outdoor testing and concludes that PV module degradation under field conditions tends to follow a near-linear pattern over decades, leading to a steady decline in power output over the 25–30 year expected lifespan. The authors in [16] focus on optical degradation mechanisms, demonstrating that soiling, discoloration, and delamination negatively affect the module’s spectral response and significantly reduce its short-circuit current. According to the data compiled in [17], soiling alone can result in average annual energy losses of 3–4%, with the associated economic impact reaching billions of euros globally. Potential-Induced Degradation (PID) is discussed extensively in [18], where the authors describe its primary causes—namely high operating voltage, elevated temperature, and high humidity—and note that it can lead to power losses of up to 30%. The study further outlines preventive measures such as effective grounding strategies and careful inverter configuration.

The article in [19] outlines a set of widely used techniques for assessing the reliability of grid-connected PV systems, including RAM analysis, Weibull statistical modeling, Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and FMEA. Expanding on this, the authors in [20] review methodological advancements in reliability modeling, emphasizing statistical and simulation-based approaches that improve performance prediction accuracy. More recent developments are highlighted in [21], where the authors present predictive modeling techniques using artificial neural networks (ANN), Adaptive Neuro-Fuzzy Inference Systems (ANFIS), and Hardware-In-the-Loop (HIL) simulations to forecast reliability trends. In [22], the discussion shifts toward accelerated reliability testing, linking laboratory-based stress tests to field performance data to shorten evaluation timeframes and improve predictive accuracy.

The study in [23] examines the broader impact of high PV penetration on power systems, noting that the use of power electronic interfaces decouples PV generation from the grid’s rotational inertia. This reduction in inertia can impair frequency stability, prompting the development of control strategies that introduce “synthetic inertia” into PV inverters. A more comprehensive review is presented in [24], where the authors discuss how large-scale PV integration affects multiple aspects of grid operation, including voltage stability, frequency regulation, protection coordination, harmonic distortion, rotor-angle stability, and overall grid flexibility.

2.2. The Demand for Reliable Solar Tracking Systems

The performance of solar energy systems is fundamentally tied not only to solar irradiance [25] and panel efficiency [26] but also to the operational reliability of the entire system. In particular, dual-axis solar tracking systems, while capable of maximizing incident sunlight capture, introduce additional mechanical and electronic components—such as motors, sensors, controllers, and communication interfaces—that increase the likelihood of failure over time. Any malfunction or degraded performance within these components can result in significant misalignment or downtime, directly reducing energy production and, by extension, economic viability.

Assessing the reliability of solar tracking devices is important for several reasons, as these systems play an essential role in the efficiency and profitability of solar energy installations [27]. A few years ago, a significant concern was that solar tracking systems were considered less cost-effective than fixed PV installations, primarily due to their relatively modest energy gain, ranging from +15% to a maximum of +30%. However, recent technological advancements have significantly improved the appeal of solar trackers in the renewable energy market. A recent study [28] supports this shift, indicating a promising future for solar tracking technology. Comparative data reveal a 5.95–57.4% efficiency range across 14 solar tracker groups, with encoder-based control systems offering enhanced reliability and superior Sun-tracking performance. According to [28], solar trackers can increase energy efficiency by 15% to 67.65% compared to stationary PV systems.

Solar tracking systems are designed to adjust the position of solar panels based on the sun’s movement across the sky to maximize sunlight capture and, by implication, energy production. If a solar tracking system is not reliable, it can work incorrectly, leading to a suboptimal orientation of the panels and therefore a significant reduction in the energy generated [29]. Malfunctions or errors in system operation can lead to costly outages and negatively affect the long-term profitability of the solar installation. Although two-axis PV systems could be economically non-profitable [30], reliable solar tracking systems reduce the need for frequent interventions for repairs or adjustments, which contributes to lower operating and maintenance costs [31]. Additionally, a proper assessment of the reliability of tracking systems helps to identify potential problems and to implement preventive solutions that extend the life of the system [32,33]. This ensures that the systems perform to the manufacturer’s specifications and are not subject to premature wear or damage from malfunction.

Another valid argument for improving the reliability of solar tracking systems is linked to the ROI key factor. Investments in solar tracking technology are significant, and system dependability directly impacts the return on this investment. If the tracking system is not reliable, the ROI decreases due to energy losses and additional costs. By rigorously assessing dependability, steps can be taken to minimize risks and ensure ROI is met or even exceeded [34]. For manufacturers, careful testing and documentation of results help to improve product quality and establish a positive reputation in the market. Customers will have greater confidence in products that have undergone rigorous testing and are known for their high performance and reliability [35].

Solar tracking systems involve moving mechanical components and electrical equipment, which must comply with applicable safety standards and regulations. Dependability is essential to prevent accidents, mechanical failures, and other risks that could affect the safety of personnel or the environment. A relevant article supporting the idea of safety concerns about solar trackers mounted on stations built for space missions. These stations are highly dependent on the energy generated by the solar tracker; therefore, optimizing the dependability of these systems is critical [36].

Furthermore, solar tracking systems must work correctly in various weather conditions (wind, rain, extreme temperatures). Their dependability determines their ability to withstand these conditions without deteriorating or losing their effectiveness. Reliability assessment ensures that systems are designed and built to perform optimally in all possible scenarios [37].

3. Research Methodology

3.1. Reliability Block Diagrams

In the field of reliability engineering, the configuration of components within a system significantly influences the overall system reliability. One of the most fundamental configurations is the series connection, where components are arranged such that the failure of any single component results in the failure of the entire system. This configuration is commonly encountered in many engineering systems, particularly in power transmission, aerospace systems, and manufacturing processes [38].

In a series system, the reliability of the entire system is the product of the reliabilities of its individual components. The series model assumes statistical independence between component failures and no repair during operation. While simplistic, this assumption provides a foundational understanding of system behavior and is widely used in early-stage design and risk assessments [39].

However, the inherent vulnerability of series systems—where a single point of failure leads to total system failure—has prompted the development of more robust configurations and the inclusion of redundancy in practical applications [40]. Despite this, series models remain critically important for understanding baseline system reliability and for evaluating the impact of component quality on overall performance.

Parallel system configurations are a key strategy in reliability engineering for enhancing system robustness and minimizing the risk of total system failure. In contrast to series systems, parallel systems are designed so that the failure of one or more components does not necessarily lead to overall system failure, as long as at least one component remains functional. This architectural approach is widely applied in critical systems where uninterrupted operation is essential, such as in aerospace, nuclear power plants, and data centers [38,39].

In a parallel configuration, system reliability increases with the number of redundant components. As a result, parallel arrangements are often used to introduce fault tolerance and ensure high availability, especially in mission-critical applications [40].

Parallel systems may be implemented as active redundancy—where all units operate simultaneously—or as standby redundancy, where backup units are activated only upon failure of the primary ones. Each approach has distinct implications for system reliability and maintenance strategy [41]. Moreover, advanced reliability modeling often incorporates non-identical component reliabilities, dependencies, and repair policies, allowing for more accurate assessments of system performance in real-world environments [42].

To construct the RBD of the dual-axis solar tracking prototype, the system components must first be categorized based on their role within the overall architecture. Based on its functionality, the solar tracking system can be divided into two primary subsystems: the control subsystem and the data transfer subsystem, as depicted in Figure 1. The control subsystem is responsible for executing key operations such as the homing function, the flat position function, and the optimal sunlight positioning function. In contrast, the data transfer subsystem handles the acquisition of sensor data and its transmission to the virtual IoT platform for remote monitoring and analysis. This classification, presented in Table 1, allows for a structured representation of how each component contributes to the system’s functionality and reliability. The failure rates of each element are expressed in Failure Per Million Hours (FPMH) according to the international standard presented in [43].

Figure 1.

Dual-Axis Solar Tracker Architecture comprising the Control Subsystem (green), Actuators/Gear (red), Photovoltaic System (light orange), Power Supply (orange), Data Transfer Subsystem (blue), and Cloud layer (purple).

Table 1.

Solar Tracker Components with their respective Failure Rates.

The Arduino Mega 2560 MCU (Arduino S.r.l., Monza, Italy) is commonly housed in a plastic enclosure when installed indoors, but can be exposed in outdoor setups as well. Failure modes primarily include corrosion of contacts and degraded solder joints due to humidity and condensation. In outdoor use, UV radiation and temperature cycling can cause plastic warping and micro-cracking in solder joints, significantly increasing their failure rate. The TB6560 Motor Driver, packaged typically in a heatsinked PCB mount, handles stepper motor control. Its primary vulnerability is overheating, especially when ventilation is poor. Outdoor conditions like rain ingress and high humidity can lead to short circuits or corrosion of exposed terminals, drastically reducing reliability.

The Tongling 5 V module, enclosed in a semi-sealed plastic case, is an electromechanical relay that can suffer from arcing, contact pitting, and coil degradation. High outdoor failure rates are due to moisture penetration, which leads to corrosion or even coil failure.

The Weidmuller 24 V Relay is an industrial-grade relay with relatively better sealing. Nonetheless, oxidation of contacts and thermal fatigue due to outdoor temperature fluctuations can cause operational failure over time, especially in less-protected outdoor installations.

The Astrosyn Stepper Motor is usually mounted without full environmental sealing. Dust ingress and water exposure can lead to bearing failure or internal corrosion. Over time, these stressors result in increased resistance or stalling. The Superior Electric Slo-Syn represents another stepper motor variant, vulnerable to similar issues as the Astrosyn motor. Wind-blown particles, thermal cycling, and humidity can reduce the insulation resistance, potentially causing shorts or excessive wear in the gear mechanism.

Regarding the sensor components, we can identify the TEMT6000 module. This light sensor module is exposed to ambient light and UV radiation. In outdoor conditions, degradation of the lens material and solder fatigue are common. Moisture ingress can cause measurement drift or total failure.

Another sensor component, the ACS172, is an analog current sensor in a plastic DIP or SOIC package. While relatively robust, long-term outdoor use may cause epoxy encapsulant degradation, leading to pin corrosion or erratic readings due to electromagnetic interference amplified by weather changes. The ML8511 is an UV sensor sensitive to environmental damage. Outdoor use exposes it to actual UV radiation, which can paradoxically degrade the sensor itself. PCB corrosion and encapsulation failure are also concerns under high humidity and rain.

The BH1750, packaged in a small IC form, is a digital light sensor that can degrade in performance due to condensation, lens fogging, or PCB corrosion. Even indoors, fluctuating humidity can cause internal oxidation over time. The DHT22 is a digital temperature and humidity sensor that is notoriously sensitive to condensation. In outdoor setups, if not well-sealed, it suffers from accuracy drift, rust on pins, and eventual sensor failure due to exposure to rain or frost.

Mechanical encoders are vulnerable to dust and moisture. Outdoor conditions may lead to rusting of mechanical parts and misreading due to signal bounce or degradation of optical elements in some variants. On the other hand, limit switches are typically mechanical and enclosed in plastic or metal housings. However, they can still fail from moisture ingress, leading to contact corrosion or mechanical jamming due to dirt buildup.

The SIM800L V2 module, with a compact module design, is usually sensitive to temperature extremes and condensation. Failures can result from corrosion on antenna connectors, solder fatigue on small pins, and Electrostatic Discharge (ESD) events during storms. The Solar Charge Controller is critical for battery health and is often mounted near panels. Outdoor usage may see degradation of connectors, internal MOSFET failure due to heat, or board-level corrosion, especially if the housing is not IP-rated. The LM2596 is a buck converter exposed to outdoor elements may fail due to overheating or corrosion of its inductor or capacitors. Electrolytic capacitors are particularly prone to drying out in heat or swelling due to moisture. Finally, the Varta 12 V·44 Ah battery is a sealed lead-acid battery that performs well under moderate conditions but suffers under high temperatures, which accelerate electrolyte evaporation and plate degradation. Cold temperatures can reduce capacity and cause internal pressure buildup, leading to case rupture in extreme cases.

Based on the above-mentioned system components and their respective failure rates, the RBD of the dual-axis solar tracker is illustrated in Figure 2.

Figure 2.

Dual-Axis Solar Tracker Reliability Block Diagram depicting a mixture of Series and Parallel Connections.

The first step for computing the reliability of the entire system is to convert the failure rates from FPMH to failures per hour (λ in 1/h). The lambda subsystem indoor and outdoor values will be calculated for comparison purposes only. It is essential to determine if the solar tracker’s subsystem components manage to withstand stress factors and weather conditions. As depicted in Figure 2, the reliability values will be independently calculated for the control circuits, motors, sensors, and power supply components. For this calculation, only the midpoint value of each failure rate interval will be considered.

For the control circuits, which encompass the first four components, the associated failure rate exhibits a significant difference based on the operating environment. Specifically, the indoor failure rate is λcontrol, indoor = 2.35 × 10−6 failures/h, whereas the outdoor rate is substantially higher at λcontrol, outdoor = 8 × 10−6 failures/h. The reliability of the control subsystem, denoted as R(t), was subsequently computed using the exponential reliability function for a time interval of t = 1000 h. The resulting values are R(1000)control, indoor ≈ 0.9977 for indoor usage, and R(1000)control, outdoor ≈ 0.9920 for outdoor usage.

The automation circuits, encompassing the following four components, exhibit distinct failure rates based on the operational environment: λautomation, indoor = 1.975 × 10−7 failures/h and λautomation, outdoor = 5.965 × 10−6 failures/h. Consequently, the reliability of the automation and gear subsystem after t = 1000 h is R(1000)automation, indoor ≈ 0.9998, and R(1000)automation, outdoor ≈ 0.9941 for indoor and outdoor usage, respectively.

The RBD for the data transfer subsystem is structured as a combination of series (GSM module) and parallel configurations (sensors). This reflects the system’s dependency on multiple components for successful data transmission. Specifically, sensor data will fail to be transmitted if: (a) all sensors simultaneously fail to capture environmental data; (b) the GSM/GPRS module becomes faulty, preventing communication with the Things Speak server. This configuration, illustrated in Figure 2, highlights critical points of failure that must be addressed to ensure the reliability of the data transfer process. Therefore, the reliability of the following five components (9 through 13) when connected in a parallel configuration under indoor and outdoor conditions for a time interval of t = 1000 h is extremely high, computed as approximately R(1000)data transfer, indoor, outdoor ≈ 1.0 (specifically, 1 − 5.46 × 10−20). In reliability engineering, a value this close to unity (1.0) is indicative of a system where the probability of all components failing simultaneously is negligible.

Regarding the GSM/GPRS module, comprising the next two components in a series connection, the computed lambda values are λdatatransfer, indoor = 6.25 × 10−7 failures/h (for outdoor usage) and λdatatransfer, outdoor = 2.10 × 10−6 failures/h. Substituting the values for t = 1000 h will result in a reliability value of R(1000)datatransfer, indoor ≈ 0.999375 (for indoor usage), and R(1000)datatransfer, outdoor ≈ 0.9979 (for outdoor usage).

Concerning the last three components, which are responsible for the power supply unit, the corresponding lambda values are λpowersupply, indoor = 7.7 × 10−7 failures/h and λpowersupply, outdoor = 1.8 × 10−6 failures/h. The associated reliability values are computed for t = 1000, as follows: R(1000)powersupply, indoor ≈ 0.99923 and R(1000) powersupply, outdoor ≈ 0.9982.

Finally, the reliability of the entire system (components 1 through 18) for indoor usage over a time interval of t = 1000 h is approximately R(1000)system, indoor ≈ 0.9961 and R(1000)system, outdoor ≈ 0.9823 for outdoor usage.

The reliability of the entire system is highly sensitive to the environmental transition from indoor to outdoor conditions. While the total system reliability only decreased by approximately 1.38% over 1000 h, this small change is underpinned by a 351.1% increase in the system’s equivalent failure rate. This difference is largely driven by the extreme sensitivity of electromechanical components (such as the Anemometer) and the cumulative, additive effect of increased failure rates within the system’s series architecture. Consequently, long-term operational success for the outdoor application is critically dependent on focused design efforts, such as isolating the most sensitive components (e.g., through robust enclosures) or implementing redundancy, as demonstrated by the resilient parallel subsystem.

3.2. Fault Tree Analysis

FTA is a systematic, deductive methodology employed to evaluate the reliability and safety of complex systems. Originally developed in 1962 by H.A. Watson at Bell Laboratories for the U.S. Air Force’s Minuteman ICBM program, FTA has since become a cornerstone in reliability engineering across various high-risk industries, including aerospace, nuclear energy, and chemical processing [44].

The essence of FTA lies in constructing a graphical representation—a fault tree—that maps the logical relationships between system failures and their root causes. This tree begins with a “top event,” representing the undesired system failure, and branches downward through intermediate events to basic events, which are the fundamental causes of failure. Logical gates such as AND and OR are used to depict how these events combine to lead to the top event [45,46].

FTA serves both qualitative and quantitative purposes. Qualitatively, it helps identify minimal cut sets—the smallest combinations of basic events that can cause the top event—thereby highlighting critical vulnerabilities within the system. Quantitatively, it allows for the calculation of the probability of the top event occurring, based on the probabilities of the basic events and the logical structure of the fault tree [20].

The versatility of FTA makes it applicable in various domains. For instance, in the energy sector, it aids in assessing the reliability of power systems and identifying potential points of failure. In the context of control automation, FTA is instrumental in analyzing complex systems like nuclear plants and water distribution networks, where it helps in designing robust systems by identifying and mitigating potential faults during the design phase [47].

FTA can also be utilized to classify system failures based on their severity. In the context of the solar tracking system, three distinct levels of failure criticality can be identified: (a) critical—failures that cause complete system shutdown or pose safety risks, (b) less critical (malfunction)—faults that impair performance but do not halt operation entirely, and (c) non-critical—minor faults with negligible impact on system functionality. To illustrate each level of severity, an individual FTA will be constructed for each corresponding failure scenario.

A critical failure in the solar tracking system typically results from an unexpected power supply outage occurring during execution cycles. This type of failure can lead to a complete system shutdown, interrupting all ongoing operations. The corresponding FTA illustrating this scenario is presented in Figure 3. The FTA diagram systematically depicts the sequence of failures that can lead to a power supply outage within the solar tracking system. At the top of the tree, the undesired event—power supply outage—is broken down into two main contributory paths: battery failure and power conversion failure. The battery failure branch includes internal faults in the Varta 12 V 44 Ah battery as well as malfunctions in the solar charge controller, both of which are influenced by underlying stressors such as long-term usage, thermal cycling, and moisture ingress. On the other hand, the power conversion failure branch considers the malfunction of the LM2596 converter and the overloading of downstream components, including the SIM800L GSM module and relay circuitry.

Figure 3.

Critical Scenario involving a Complete Power Supply Outage in the Solar Tracking System.

These failures may arise independently or in combination, as represented by OR logic gates. The analysis emphasizes how environmental and operational stress factors at the component level can propagate upward through the system architecture, ultimately resulting in a complete power disruption.

A less critical failure scenario in the solar tracking system is the tracking misalignment. This event occurs when the solar panel is no longer accurately oriented toward the sun, resulting in reduced energy harvest. It does not completely disable the system but significantly lowers performance. The corresponding FTA is illustrated in Figure 4.

Figure 4.

Less Critical Scenario involving a Tracking Misalignment in the Solar Tracking System.

This FTA illustrates a secondary-level failure scenario in the solar tracking system, focusing on tracking misalignment as the top event. The misalignment may arise from one of three primary causes: sensor failure, actuator malfunction, or control signal error. Sensor failure is further traced to faults in components such as the TEMT6000 and ML8511 modules, influenced by environmental aging and UV-induced degradation. Actuator malfunction is attributed to the failure of the stepper motor, often caused by wind-blown dust or corrosion. Control signal errors originate from faults in the rotary encoder and misreadings by the Arduino, with mechanical debris and noise acting as the triggering factors. The hierarchical structure captures how less-critical, yet impactful, faults can reduce system efficiency without leading to a total power outage.

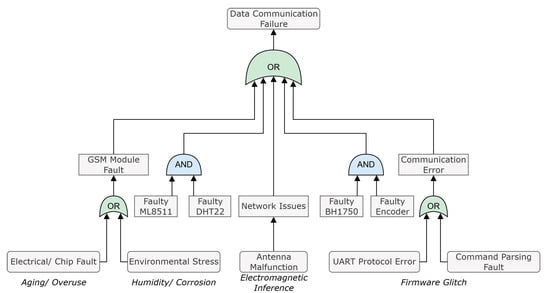

The FTA in Figure 5 models a non-critical failure scenario in the solar tracking system, namely a data communication failure, which impacts remote monitoring and data logging functionalities. The top-level event is decomposed into three main contributing branches: GSM module fault, signal loss or network issues, and microcontroller communication error. The GSM module fault centers on the SIM800L V2, which may fail due to electrical defects or environmental stressors such as humidity and corrosion. Signal loss arises from weak cellular reception, electromagnetic interference, or antenna malfunction, all of which can interrupt data transmission. Microcontroller-related errors are linked to the Arduino Mega 2560, including UART protocol issues and command parsing faults, often caused by firmware glitches or transient electrical noise. These contributing factors are modeled using OR gates, highlighting that the failure of any single component or condition can lead to communication loss without affecting energy generation.

Figure 5.

Non-Critical Scenario involving Data Communication Failure in the Solar Tracking System.

Additionally, the FTA incorporates AND gates to emphasize that a data communication failure arises also when all sensor modules fail simultaneously. In such a case, the system is unable to collect any environmental data, making it impossible to transmit information to the Things Speak server.

In summary, FTA is a vital tool in reliability engineering, offering a structured approach to identifying and mitigating potential system failures. Its ability to provide both a visual representation of failure pathways and quantitative risk assessments makes it indispensable in the design and analysis of complex, safety-critical systems.

3.3. Failure Mode and Effects Analysis

FMEA is a structured, inductive methodology utilized in reliability engineering to proactively identify and mitigate potential failure modes within systems, products, or processes. The FMEA process involves a systematic examination of components and subsystems to determine how they might fail (failure modes), the causes of these failures, and the potential effects on system performance. Each identified failure mode is assessed based on three criteria: Severity (S), which measures the impact of the failure; Occurrence (O), which estimates the likelihood of the failure; and Detection (D), which evaluates the probability of detecting the failure before it occurs. These factors are combined to calculate a Risk Priority Number (RPN), guiding engineers in prioritizing corrective actions [48]. A FMEA is conducted on the solar tracking prototype, as presented in Figure 6. This analysis provides a detailed overview of the most common potential failure modes within the system, their root causes, and the corresponding impact on system performance and overall operation.

Figure 6.

Failure Mode Analysis performed on the Solar Tracking System’s Light Dependent Resistors and Anemometer.

Most of the solar tracker’s electrical components, listed in Table 1, are housed within a metallic enclosure that offers additional protection against environmental stressors. However, several sensors essential for automating the control subsystem and enabling remote monitoring within the data transfer subsystem are mounted externally, leaving them directly exposed to varying environmental conditions.

As shown in Figure 6, one such component is the Light Dependent Resistor (LDR), which is used to measure light distribution across different corners of the PV panel. According to the first layer, if an LDR in a solar tracking system is directly exposed to environmental stressors like sunlight, moisture, dust, and temperature swings, several potential failure root causes arise. For instance, prolonged exposure to UV rays can chemically degrade the plastic encapsulation and even the sensing material itself (typically cadmium sulfide in many LDRs). The result will be shifted sensitivity or permanent loss of responsiveness to light over time. A second root cause for failure is moisture that can oxidize the metallic contacts and the sensitive material inside the LDR. The result will be increased resistance, intermittent operation, or complete failure. A third root cause is constant heating (from the sun) and cooling (at night) over the entire summer days, which creates thermal expansion and contraction. This leads to microcracks in the internal structure, leading to fatigue or delamination of internal layers. A fourth root cause is contamination due to dust and pollution, which results in wrong readings, delayed or inaccurate tracking. A fifth root cause is mechanical damage due to rain, hail, and wind-borne particles. This usually leads to physical destruction or altered optical properties.

The second layer (bottom-up approach) in Figure 6 represents the failure mode, which most commonly involves the malfunction or complete failure of an LDR. Given that four LDRs are utilized to orient the solar panel toward the Sun, four individual points of potential failure can be identified. Two of these failure points are associated with the West–East rotation along the horizontal axis, while the other two are linked to the North–South rotation along the vertical axis.

For the azimuth rotation, if the West LDR, shown in layer 3, becomes faulty, the Microcontroller Unit (MCU) will behave as described in layer 4. A malfunctioning LDR typically leads to a sudden decrease in resistance, causing the Arduino Mega MCU to continuously register a low voltage value on the A0 analog input. Typically, a damaged photoresistor is interpreted as shading on one side of the PV panel, prompting the solar tracking system to rotate the payload until the West–East sensors read equal values. However, with the West LDR malfunctioning, the system continuously detects an imbalance, causing the solar tracker to keep moving the PV panel until it reaches the sunset position, marked by the maximum horizontal limit switch, where it ultimately becomes stuck, as depicted in layer 5 of Figure 6. Similarly, if the East LDR malfunctions, the MCU will continuously receive a low voltage reading on input A1. This will cause the solar tracking system to rotate in the opposite direction, ultimately becoming stuck at the homing (sunrise) position, triggered by the activation of the lower horizontal limit switch.

For the elevation rotation, the MCU’s behavior mirrors the previous scenarios. If the North LDR malfunctions, the Arduino Mega board will consistently detect a low voltage value on input A2, prompting the solar tracking system to search for the optimal position by moving the PV panel upward. As a result, the solar tracker will eventually become stuck in the flat position, triggered by the activation of the maximum vertical limit switch. If the South LDR malfunctions, the MCU will continuously read a low voltage value on pin A3. This will cause the solar tracking system to remain stuck at the initial homing position, marked by the activation of the lower vertical limit switch, as shown in layer 5.

The FTA diagram for the previously described failure scenario involving all four LDRs is presented in Figure 7. The FTA highlights critical failure pathways that lead to the system becoming immobilized in specific operational states—sunset, homing, or flat. Immobilization at the sunset position occurs when a low voltage is detected at sensor A0 concurrently with a failure of the West Light Dependent Resistor (LDR). Similarly, the system may remain stuck in the homing position due to either a combination of low voltage at A1 and a faulty East LDR, or low voltage at A3 paired with a malfunctioning South LDR. In the case of the flat position, the system becomes fixed when low voltage at A2 is accompanied by failure of the North LDR. These individual fault conditions collectively define a broader category of LDR malfunction, which can be traced to either environmental stressors or degradation from age and usage. Environmental stress is further broken down into contributing factors such as ultraviolet radiation, high humidity, thermal cycling, dust and pollution, and mechanical damage—any of which can independently impose detrimental effects on the LDR sensors.

Figure 7.

Solar Tracking Optimal Position Failure due to Environmental Stressors and Aging affecting the Light Dependent Resistors.

4. Experimental Setup and Results

A summarized view of the dual-axis solar tracking prototype, as well as of the electrical equipment contained in the control panel box can be seen in Figure 8. While the prototype hardware is small-scale, the entire reliability methodology is component-dependent and fully scalable. For a large-scale PV farm, the component list (Table 1) and failure rates (λ) would be updated for industrial-grade actuators and controllers, but the fundamental RBD, FTA, FMA approaches remain directly applicable. Additionally, our study is restrained only to the investigation of electrical/electronic components failure modes, instead of studying the effects of mechanical component failure.

Figure 8.

Summarized View of the Physical Solar Tracking Prototype (Left), and Electronic Circuits installed in the Control Panel Box (Right).

The current experimental evaluation utilized a focused dataset derived from in-field solar tracker prototype testing located in Arad, Romania (46°11′30.4″ N 21°20′41.6″ E) using a 100 W·PV panel from Bruma brand. The experimental trials were carried out between 26 June 2025 and 2 July 2025. We acknowledge that the scope of this dataset is deliberately circumscribed. This approach is primarily justified by the foundational objective of this study, which is the analytical assessment of system reliability through established engineering methodologies, namely FMEA, FTA, and RBDs.

The principal contribution of this work lies not in the exhaustive empirical validation across all operational conditions, but in the systematic development and proposal of the BIST architecture as a critical mechanism for proactive reliability enhancement. More precisely, the experimental data presented is derived from a fault-injection study, specifically designed to quantify the immediate energy yield degradation caused by the system being stuck in critical positions. This short-term scope allowed for a robust, quantitative FMEA output rather than a general long-term reliability assessment.

4.1. Failure Mode and Occurrence Probability

As mentioned earlier, both the FTA and FMEA are bottom-up approaches in which root causes are evaluated and rated based on their probabilities of occurrence. These methods help identify and prioritize potential failure modes by assessing their likelihood and impact on system performance, as shown in Figure 9.

Figure 9.

Failure Analysis Diagram of a Dual-Axis Solar Tracker, illustrating Mechanical and Electrical Root Causes.

Hence, the failure analysis of the dual-axis solar tracker can be broadly divided into two domains: mechanical root causes and electrical root causes. Both categories stem from the overall system-level design and trace down to the component level, where the failures ultimately manifest. The diagram illustrates how environmental conditions, lifespan limitations, and electrical disturbances affect the various subsystems of the tracker, leading to either mechanical or electrical failure.

On the mechanical side, two key origins of failure are identified: environmental stressors and lifespan degradation. Environmental stressors such as wind, hail, and gusts exert continuous physical loads on the structural components, particularly the worm gear and stepper mechanisms. These elements are essential for positioning and rotation, yet they are highly susceptible to fatigue and damage under extreme weather conditions. Additionally, lifespan-related factors, including usage over time and natural aging, contribute to mechanical wear, reducing efficiency and reliability. Together, these mechanical challenges compromise the stability and precision of the tracking system, often leading to gear misalignment or actuator breakdowns.

In contrast, the electrical root causes are driven by both environmental stressors and inherent electrical vulnerabilities. Environmental factors such as moisture, temperature fluctuations, dust, and prolonged exposure to ultraviolet radiation directly affect sensitive components, including the microcontroller unit, stepper motor, power supply, and control circuits. These stressors can result in corrosion, insulation breakdown, or overheating, thereby degrading performance. Meanwhile, purely electrical causes such as short circuits, overvoltage, and voltage drops pose additional risks to motor drivers, cables, and connectors. These disruptions may trigger sudden failures, data communication issues, or permanent damage to electronic circuitry, undermining the control and responsiveness of the tracking system.

At the component level, the analysis shows a clear mapping between root causes and the specific parts most vulnerable to them. Mechanical components like worm gears and steppers primarily fail due to external stress and wear, whereas electrical components—from microcontrollers to connectors—are compromised by environmental exposure and unstable power conditions. The cumulative effect of these vulnerabilities results in either mechanical failure or electrical failure, both of which reduce the operational lifespan and efficiency of the solar tracker.

Assigning occurrence probabilities for each of the listed environmental factors affecting LDRs in a solar tracking system (Figure 7) involves estimating how likely each factor is to occur in a given operational environment, as depicted in Table 2.

Table 2.

Estimated Occurrence Probability Distribution for Environmental Factors Affecting the Solar Tracker.

To compute the likelihood of at least one environmental stressor affecting the LDRs, we will assign the average probabilities to each of the items from Table 2, as follows: PMoisture = 0.55; PHeating = 0.75; PUV = 0.90; PDust; PMechanical = 0.20. The final answer, P(environmental stressors) ≈ 0.9997, shows a very high probability (~99.97%) that at least one environmental stressor will affect the LDR system.

Regarding the next OR operation from Figure 7, let us assume an average use case of a solar tracking system over time. The probability of failure due to age or usage can vary, but for estimation, we will consider the following values from Table 3.

Table 3.

Estimated Occurrence Probability Distribution for Aging affecting the Solar Tracking System [53,54,55].

Let us further suppose that the system is around 3 years old with moderate to high daily usage—a reasonable average. So, we can assign P(Age/Usage) = 0.4. Then, by solving the second OR gate, we can write P(LDR Malfunction) = 1 − (1 − 0.9997)(1 − 0.40). The final result, P(LDR Malfunction) ≈ 0.9998, indicates that there is a 99.98% chance of malfunction when both environmental stressors and aging are considered with an OR gate.

The upper layer, which incorporates the AND gates, can be interpreted as a series connection between the previously determined malfunction condition and the probability that the corresponding analog pin on the Arduino module registers a low voltage reading. This configuration emphasizes that both conditions must occur simultaneously to trigger the associated system failure. In practical scenarios, residual voltage levels often persist on the analog inputs of the board. As a result, the probability that a malfunctioning LDR will lead to a low voltage reading on the corresponding analog pin is estimated at p = 85%. Therefore, for any direction—West, East, South, or North—the estimated probability that the system becomes stuck in a specific position is P(stuck) = 0.9998 × 0.85 = 0.84983. This calculation assumes that the probability of LDR malfunction is 0.9998 and the probability of the analog pin registering a low voltage due to that malfunction is 0.85. Hence, there is approximately an 84.98% chance the system will lock in a given position under these fault conditions.

Since the FTA quantifies the system’s failure probability, the reliability R of the solar tracking device under the given fault scenario can be calculated as R = 1 − F = 1 − 0.8498 = 0.1502. In other words, when considering the likelihood of the system becoming stuck in one of its operational positions due to LDR failures and corresponding low voltage readings, the overall reliability of the solar tracker drops to 15.02%. This highlights a significant vulnerability that must be addressed to ensure dependable operation.

4.2. Effects Analysis and Discussion

Recent progress in solar tracker reliability research highlights a stronger emphasis on environmental stressors impacting the mechanical components of these devices (left-hand side of Figure 9), while comparatively less attention has been given to analyzing the effects of electronic component failures on overall system performance (right-hand side of Figure 9).

Failure mode identification is crucial for reliability analysis, as demonstrated in the investigation of solar tracker collapse under wind loads. According to [56], solar trackers are vulnerable to structural failure or collapse due to aerodynamic loads. Fatigue is a major concern, defined as failure due to repeated stress cycles, making it critical to analyze cyclic wind effects rather than only static loads. Failure is most likely at connection joints (between the main beam and supporting post), which were identified as critical regions in the study. Therefore, identifying where maximum stresses and strains occur allows engineers to design safer and more reliable structures. The study found the factor of safety = 2.16, meaning the design is safe under expected loads, but stresses concentrate in specific regions, highlighting potential weak spots. Fatigue analysis predicted the system could withstand >21,700 load cycles before failure, showing how life expectancy estimates support reliability claims. Finite element modeling was applied with static and cyclic wind load scenarios to simulate realistic operating conditions. A stress-life (S–N) fatigue approach was used, directly linking load-induced stresses to structural life expectancy. Validation with earlier studies gave confidence in the setup, as results were within an acceptable deviation range.

Furthermore, Valentín et al. showed in [57] that static wind forces alone could not explain solar tracker failure; instead, the root cause was torsional galloping, a dynamic aeroelastic instability producing large torsional deformations. Identifying this failure mode was essential to reveal the weakest structural elements (shaft joints, PV supports, and module frames) and to explain how local damage triggered a chain of progressive failures, ultimately leading to catastrophic collapse. The study further highlighted that only by correctly identifying the governing failure mechanism could targeted mitigation measures—such as increasing torsional stiffness or implementing real-time monitoring and tilt control—be developed. This underscores the role of failure mode identification in ensuring realistic reliability assessments and effective preventive strategies, such as Artificial Intelligence (AI) algorithms [58,59].

To the best of our knowledge, this work represents the first attempt to investigate the effects of failure modes in light sensors that are directly exposed to environmental factors. Therefore, the failure mode scenarios discussed in Section 3.3 are illustrated in Figure 10. These include: the stuck-on-sunrise position, resulting from failures in the East and South LDRs (Figure 10a), which drives the PV panel to the homing position when both the lower horizontal and vertical limit switches are active HIGH; the stuck-on-sunset position, caused by a malfunction of the West LDR (Figure 10b), which forces the solar panel to rotate 180 degrees until it reaches the maximum horizontal limit switch; and the stuck-on-safe position (Figure 10c), triggered by a North LDR failure, which drives the solar panel into a flat orientation when the payload activates the maximum vertical limit switch.

Figure 10.

Dual-Axis Solar Tracker Stuck on (a) sunrise position, (b) sunset position, and (c) safe-flat position due to Light Dependent Resistor Failure.

For this purpose, a series of experiments was carried out over a 4-day trial conducted at the end of June and the beginning of July 2025. Test samples were recorded every hour, from 08:00 AM to 08:00 PM. The experiments primarily focused on key parameters, including ambient temperature, solar panel temperature, PV panel voltage and current output, and the overall power generation of the system, as can be seen in Table 4.

Table 4.

Solar Tracking Normal Operation Experimental Results.

The first set of results was obtained on 26 June 2025. The ambient temperature ranged from a minimum of 26 °C in the morning to a maximum of 37 °C in the afternoon, with a daily average of 34.32 °C. The PV panel temperature showed higher fluctuations, with a minimum of 34.6 °C in the morning, a peak of 63.1 °C in the afternoon, and an average of 53.56 °C over the day.

For the electrical parameters, the PV panel output voltage varied between a maximum of 21.14 V in the early morning and a minimum of 19.19 V in the afternoon, averaging 19.64 V across the full cycle. The PV panel current output recorded a maximum of 5 A in the afternoon and a minimum of 1.16 A in the late evening, with a daily mean of 4 A. Finally, the power generation ranged from a minimum of 22.85 W in the late evening to a maximum of 95.9 W in the afternoon, yielding an average of 78.29 W throughout the day. The results collected from the following trial day are presented in Table 5.

Table 5.

Solar Tracker Stuck-on-Sunrise Position Experimental Results.

The second set of results was recorded on 29 June 2025. The ambient temperature started at a minimum of 21 °C in the morning, rose to a maximum of 32 °C in the afternoon, and averaged 28.38 °C over the course of the day. The PV panel temperature followed this trend, with a minimum of 34.2 °C in the morning, a peak of 44.5 °C in the afternoon, and a daily average of 40.49 °C.

For the electrical performance, the PV output voltage reached a maximum of 20.80 V in the early morning, dropped to a minimum of 18.56 V in the evening, and had an average of 19.6 V. The current output ranged between a maximum of 3.25 A in the afternoon and a minimum of 0.14 A in the late evening, with an average of 1.11 A. Finally, the power generation values showed a minimum of 2.6 W in the late evening, a maximum of 65.81 W in the morning, and an average of 22.23 W throughout the day. These results will then be further analyzed with the next set of results, as depicted in Table 6.

Table 6.

Solar Tracker Stuck-on-Sunset Position Experimental Results.

The third set of measurements was collected on 30 June 2025. The ambient temperature ranged from a minimum of 23 °C in the morning to a maximum of 34 °C in the late afternoon, with a daily average of 30.69 °C. Correspondingly, the PV panel temperature recorded a minimum of 29.2 °C in the early morning, peaked at 48.6 °C in the evening, and averaged 42.25 °C across the day.

From the electrical perspective, the PV panel output voltage fluctuated between a minimum of 18.51 V in the afternoon and a maximum of 20.41 V in the evening, with an average of 19.48 V. The current output showed a minimum of 2.65 A in the late evening, a maximum of 3.4 A in the evening, and an average of 1.5 A. Finally, the power generation values indicated a minimum of 7.46 W in the morning, a maximum of 69.39 W in the morning, and an average of 29.97 W for the full-day cycle. These values will then be further examined side-by-side with the final results from Table 7.

Table 7.

Solar Tracker Stuck-on-Flat Position Experimental Results.

The final set of measurements was obtained on 2 July 2025. The ambient temperature varied between a minimum of 18 °C in the morning and a maximum of 32 °C in the late afternoon, resulting in a daily average of 28.46 °C. The PV panel temperature ranged from a minimum of 23.9 °C in the early morning to a peak of 59.1 °C in the afternoon, with an average of 43.66 °C throughout the day.

In terms of electrical performance, the PV panel output voltage recorded a minimum of 19.57 V in the evening and a maximum of 20.84 V in the morning, yielding a daily average of 20.01 V. The current output varied between a minimum of 1.62 A in the morning and a maximum of 5 A in the afternoon, with an average of 3.44 A. Finally, the power generation values showed a minimum of 14.26 W in the late evening, a maximum of 98.65 W in the morning, and a daily average of 68.8 W.

5. Energy Production Computation and Mitigation Strategies

5.1. Energy Production Graphical Charts

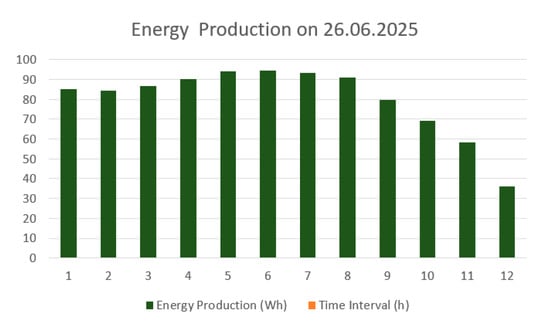

Since instantaneous power was recorded at hourly timestamps according to Table 5, Table 6, Table 7 and Table 8, we can construct the energy production graphical charts for each experimental day. The graphical chart corresponding to the normal operation of the solar tracking device is depicted in Figure 11.

Table 8.

Side-by-Side Comparison of Current, Voltage, and Power Parameters.

Figure 11.

Dual-Axis Solar Tracker Energy Production (green label) computed between hourly intervals (under normal operation conditions).

As shown in Figure 11, the energy production reached a peak value of 94.6 Wh between 01:00 PM and 02:00 PM, followed by a sharp decline in the evening, reaching 36.07 Wh between 07:00 PM and 08:00 PM. The average energy production over the course of the day was 80.25 Wh. The next chart, shown in Figure 12, depicts the most severe test scenario, in which energy production experiences a significant drop compared to normal operating conditions.

Figure 12.

Dual-Axis Solar Tracker Energy Production (dark red label) computed between hourly intervals (when the system is stuck on the sunrise position).

According to Figure 12, the energy production reached a maximum value of 58.49 Wh between 11:00 AM and 12:00 PM, followed by a sudden drop to 6.68 Wh between 07:00 PM and 08:00 PM. The average recorded value here was 23.23 Wh during the entire experimental day. A less critical scenario is illustrated in Figure 13, depicting the stuck-on-sunset position. As shown in Figure 13, energy production peaked at 68.33 Wh between 05:00 and 06:00 PM, while the minimum of 6.69 Wh occurred between 12:00 and 01:00 PM. The average output was 29.67 Wh, slightly higher than in the previously described scenario.

Figure 13.

Dual-Axis Solar Tracker Energy Production (red label) computed between hourly intervals (when the system is stuck on the sunset position).

The final graphical representation illustrates the least severe scenario, in which the PV panel remains in a flat orientation while facing the sun. As illustrated in Figure 14, energy production peaked at 98.45 Wh, then declined sharply in the evening to 24.55 Wh, with a daily average of 72.55 Wh.

Figure 14.

Dual-Axis Solar Tracker Energy Production (light green label) computed between hourly intervals (when the system is stuck in the flat position).

Based on these findings, it becomes evident that power generation plays a crucial role in conducting the FMEA procedure for the dual-axis solar tracking prototype. A side-by-side comparison is provided in Table 5, highlighting the daily energy yield. The daily average power was used as a reference metric, under the assumption that the measurement window remained consistent across all test days, with computed losses expressed relative to Day 1 (representing the fully healthy system). To complement the FMEA analysis, additional indicators such as peak power, average current, and average voltage were also taken into consideration.

According to Table 8, variations in average voltage are negligible (<2%), whereas average current exhibits significant reductions on faulty days. This indicates that the observed performance degradation is primarily caused by reduced incident irradiance on the module (i.e., tracking/orientation losses), rather than by temperature-induced effects or electrical operating point changes within the system. On day 2, average power decreased by 71.6% compared to the healthy baseline, while peak power was reduced by approximately 31%. This behavior is consistent with the system capturing solar irradiance only during the early hours and missing most of the afternoon, leading to substantial energy yield losses. On Day 3, average power decreased by 61.7% relative to the healthy case. The overall behavior was similar to Day 2, though slightly improved—likely attributable to differences in morning cloud coverage or seasonal/site-related variations in morning irradiance.

On Day 4, average power decreased by only 12.1% compared to the healthy case, while peak power was actually ≈2.9% higher than on Day 1. This suggests that under the tested conditions (late June–early July, at the given site latitude), a flat orientation was still able to capture most of the midday irradiance. Consequently, the incremental benefit of dual-axis tracking was limited on these days—though this effect is strongly dependent on latitude, season, and solar path geometry. Panel temperatures varied across the measurement days, with Day 1 showing the highest peak value of 63.1 °C. While elevated cell temperatures are typically associated with reduced voltage and increased efficiency losses, the observed voltage variations across days were minimal (<2%). Instead, the main performance driver was the change in output current, indicating that temperature played only a secondary role in the measured energy losses.

Finally, for this subsection, a sensitivity analysis will be performed on the energy production computation in order to compare the energy harvesting with the solar irradiance registered during the trial days. More precisely, based on the analyzed data, the total energy production under normal operation reached a maximum of 963 Wh, whereas the maximum solar irradiance level on Day 1 was 1211.3457 Wh/m2. In comparison, the most severe day recorded only 279 Wh at maximum, while the maximum solar irradiance on Day 2 was 1209.765 Wh/m2. For the moderately severe day, the energy production reached a maximum of 356 Wh, whereas the maximum solar irradiance was rated at 1209.1378 Wh/m2. Regarding the least severe day, the solar tracker achieved up to 870 Wh at maximum peak value, while the maximum solar irradiance level was observed to be 1207.7322 Wh/m2. Thus, the most severe day registered losses of 71%, the moderately severe day showed losses of 63%, while the least severe day recorded a reduction of only 9.7%

5.2. Built-In Self-Test Architecture

When referring strictly to Figure 6, the mitigation strategies previously mentioned serve to address the LDR-related vulnerabilities and enhance system reliability. These include: (i) BIST architectures [60,61], which allow autonomous hardware verification during runtime; (ii) Reconfigurable features [62], providing adaptive fault isolation and improved fault coverage; (iii) Maintenance-oriented metric systems [63], which track wear, aging, and stress exposure to predict failures and schedule preventive interventions. These layered methods form a comprehensive fault tolerance framework to significantly reduce the system’s failure risk depicted in the fault tree. Since it is out of scope to detail all previously mentioned test methodologies, this work will exclusively focus on the BIST architecture.

The first step in designing the BIST architecture is referred to as Test Pattern Generation. At this stage, a Pseudo-Random Pattern Generator (PRPG) is constructed to provide test patterns that will eventually be connected as stimulus signals to the Device Under Test (DUT) input. Because the Arduino Mega 2560’s ADC module instantly translates analog data to digital format, we can effectively replicate these sensor values using an Linear Feedback Shift Register (LFSR)-based device and a reduced number of test vectors, as illustrated in Figure 15.

Figure 15.

Proposed PRPG Architecture for Test Vector Generation using Set and Reset Lines.

The hardware design of the 5-bit LFSR is implemented according to the non-primitive polynomial P(x) = x5 + x4 + x3 + x2 + x + 1 and requires only 5 clock cycles to generate distinct test patterns to its outputs. Moreover, since one memory component can output two boolean values (one binary digit and its complement), we can generate the required test vector length using only five DFF units. However, since it is necessary to inject test patterns on two 10-bit digital channels (West and East photoresistors for the horizontal rotation and North and South photoresistors for the vertical rotation), only one 5-bit LFSR component may not suffice. Therefore, our complete PRPG architecture is composed of a pair of 5-bit LFSRs, whose outputs will be tethered, in turn, to each of the digital channels.

Regarding the seed value of the LFSR device, we included two command lines: reset (highlighted with blue wire) and set (highlighted with red wire). When the asynchronous reset line is active low, the 5-bit shift register will output the seed value ‘1010101010’ on the first positive edge of the clock signal, representing a random digital value (682). On the other hand, a second 5-bit LFSR with the same characteristics could be employed with a distinct seed value ‘1001010101’ (597) generated by the asynchronous set line on the same clock edge. Thus, we can simulate the horizontal and vertical movement of the solar tracking system by generating higher values on the first TPG unit and lower values on the second TPG unit, in a parallel manner. Based on the digital values’ concurrent generation, the horizontal and vertical modules of the solar tracking device will output a binary sequence equal to the axis rotation step.

The second step for constructing the BIST design is more complex and encompasses three sub-steps: signature generation, compression, and analysis. The aforementioned binary sequences provided by the DUT will be further processed through a Signature Analyzer, known as an ORA unit. The RBIST architecture, shown in Figure 16, can function as both a TPG and an ORA unit, depending on the control signal configuration. Table 5 summarizes the operational modes of the proposed Reconfigurable Built-in Self-Test (RBIST) design.

Figure 16.

Proposed RBIST Architecture for Test Vector Generation and Signature Compression.

The RBIST architecture, such as the PRPG design shown in Figure 15, adds a set and reset signal to each of the five DFF units to establish the initial seed value of the shift register. According to Table 9, when the set signal is active and reset inactive, the entire content of the register will be set to a non-zero value, indicating that the architecture can now operate as an LFSR. On the other hand, when set is disabled and reset is active, the register’s content will be cleared, thus preparing the architecture to operate as a Multiple Input Signature Register (MISR). As depicted in Figure 16, the RBIST architecture makes use of a minimum number of digital components, (8 × AND gates, 6 × OR gates, and 6 additional EXOR gate) in addition to the structure of a PRPG, to construct the reconfigurable mechanism. A third command line denoted with C allows the switching between the PRPG and MISR modes of the shift register, according to the input values depicted in Table 9. An expanded RBIST mode of operation can be employed by inserting three additional input lines denoted with G1, G2, and G3, representing the generator polynomial functions (G1(x), G2(x), and G3(x)) on the feedback paths of the proposed architecture. The expanded RBIST functions describe our proposed solution for the aliasing issue which usually occurs when two signals (signatures) are identical, thus hindering the Signature Analyzer to diagnose the system correctly. The actual cost-performance evaluation will be presented as future work for our further investigations toward incorporating these devices into the solar tracking system design.

Table 9.

Operational Modes for the Proposed RBIST Architecture.

The BIST architecture models a diagnostic routine that constantly monitors the four LDR analog inputs for values falling outside a predefined operational window (e.g., Vmin < VLDR < Vmax). This runtime monitoring allows the system to detect sensor degradation before it causes a complete system lock-up.

The experimental cases are divided into three main batches encompassing single stuck-at-faults, double stuck-at-faults, and triple stuck-at-faults. Several test scenarios were considered for each of these batches via a testbench module which was written and executed in the Altera Modelsim environment. Single stuck-at-faults generally affect the functionality of only one digital pin of the MCU while operating.

Initially, valid signatures for each axis movement (horizontal anticlockwise and clockwise, correspondingly vertical anticlockwise and clockwise) have been generated using the polynomial function G1(x) associated with the hardware layout shown in Figure 15.

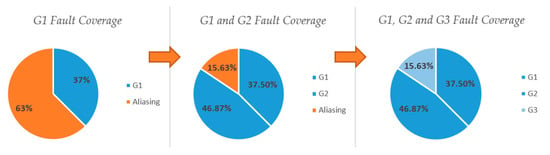

In the first batch of stuck-at-faults, the diagnosis system recognized only 12 Stuck-at-0 and Stuck-at-1 faults out of 32 test scenarios using a single polynomial function (G1), yielding an initial fault coverage of 37.5%. During the second simulation, when the polynomial function of the proposed RBIST design changed to G2, 27 samples were detected as Stuck-at-0 and Stuck-at-1 faults, increasing fault coverage by 46.87%. Finally, during the third trial, the fault diagnosis system was able to identify all Stuck-at-0 and Stuck-at-1 faults with the help of the G3 polynomial function, further enhancing fault coverage by 15.62%. As can be seen in the left graphical chart of Figure 17, the low fault coverage is the result of aliasing. In the context of computer systems and digital communication, aliasing refers to the phenomenon where two different signals produce the same output when sampled or quantized by a digital system. Due to the limitations of the polynomial function G1 in identifying more stuck-at faults, reconfigurability is a significant advantage for fault coverage improvement. While aliasing was rated at 63% after the first simulation trial, the implementation of the G2 polynomial function reduces the aliasing characteristic to 15.63%, as observed in the middle portion of Figure 17. Moreover, by employing the G3 polynomial function, aliasing is completely removed from the right graphical chart of Figure 17. As a result, the final fault coverage for all 96 test cases, regarding single Stuck-at-0 and Stuck-at-1 faults, after applying reconfigurability is 100%, which is consistent with a case study conducted in [61]. However, our previous OBIST design used a 16-bit MISR architecture, that required additional 1-bit registers in the DFF chain, increasing power consumption and delay times.

Figure 17.

Fault Coverage and Aliasing Evaluation for Single Stuck-at-Faults using Reconfigurability.

In the second batch of stuck-at-faults, the fault diagnostic approach identified 12 Stuck-at-0 and Stuck-at-1 out of 24 test instances, utilizing the G1 polynomial function, resulting in an initial fault coverage of 50%, as shown in the left chart of Figure 18. After using the second set of test vectors and modifying the polynomial to G2, the initial fault coverage increased to 79.16%, lowering aliasing by 29%, as seen in the middle chart of Figure 18. Furthermore, by performing an additional set of 24 test vectors with the G3 polynomial function, we were able to increase fault coverage by 20.8% while decreasing aliasing to 0%, as seen in the right portion of Figure 18. After completing all 72 test cases with double Stuck-at-0 and Stuck-at-1 faults, the final result reveals that fault coverage can be maintained at 100%, identical to the single stuck-at-fault scenario.

Figure 18.

Fault Coverage and Aliasing Evaluation for Double Stuck-at-Faults using Reconfigurability.

In the third batch of stuck-at-faults, the RBIST approach was able to detect 15 Stuck-at-0 and Stuck-at-1 faults out of 32 test scenarios, representing an initial fault coverage of 46.87% with only the G1 polynomial function. Using an additional set of 32 test vectors and switching to the G2 polynomial results in an increased fault coverage of 81.24%, with 26 successful detections. However, during the third simulation run, using the G3 polynomial function, the fault coverage increases by only 12.51%, leaving 6.25% aliasing as a leftover, as shown in Figure 19. Therefore, the overall fault coverage for all 96 test cases was rated at 93.75%, representing 30 successful identifications out of 32 possible Stuck-at-0 and Stuck-at-1 fault scenarios.

Figure 19.

Fault Coverage and Aliasing Evaluation for Triple Stuck-at-Faults using Reconfigurability.

Conclusively, the global fault coverage for all 264 experimental trials was rated at an average value of 98%, with only 2% aliasing occurrence during the simulation period. The experimental results show that the proposed RBIST architecture improves the initial fault coverage by an average value of 53%, highlighting its potential as a low-cost and flexible design for an efficient fault diagnosis implementation.

5.3. Comparison with Other Related Works

The quantitative comparison between the FMEA of polycrystalline PV panels derived from the manuscript in [4] and the FMEA/FTA of the dual-axis solar tracking system, in this work, reveals a distinction in the nature, location, and quantification of the most critical system vulnerabilities. More exactly, the work in [4] performs a system analysis on the PV generation unit itself, focusing on material and component degradation (e.g., cells, glass, encapsulant), whereas our research efforts are driven toward the electronic and mechanical control system responsible for panel movement, including the microcontroller, sensors, and actuators. Whereas the author’s primary methodology in [4] is the traditional FMEA utilizing the Risk Priority Number (RPN) metric, this work employs a combination of FMEA, FTA, and RBDs, emphasizing system reliability (R) calculation and performance loss.

The quantitative results of the two studies demonstrate that risk concentrations occur in fundamentally different subsystems. Patil et al. in [4] utilize the RPN as the primary metric, identifying the most severe risks associated with the physical degradation of the PV module. The encapsulant material was determined to be the most critical component, contributing 40.30% to the total system RPN. According to the authors study, critical failure modes are primarily physical and environmental: (i) delamination (maximum RPN: 224); (ii) soiling (maximum RPN: 140).

Our research, on the other hand, which focuses on the control system, quantifies risk by the resultant loss in system reliability (R) and energy generation, directly linking component failure to operational downtime. The most critical component was determined to be the LDR (TEMT6000) within the control subsystem. It was established that the sensor malfunction generally leads to a “stuck” position. The system reliability (R) was calculated to drop to a mere 15.02% in the presence of this single critical fault scenario. Experimental results show a substantial reduction in average power output when the tracker is stuck in a suboptimal position, namely 71.61% for stuck-at-sunrise position and 61.72% for the stuck-at-sunset position.

In summary, while the PV panel itself is highly susceptible to material degradation quantified by a high RPN, the dual-axis tracking system possesses a potential point of failure, found in the LDR sensor array that, when compromised, results in a far more immediate and quantifiable catastrophic loss of energy yield, nearly three-quarters of the optimal generation.

6. Conclusions and Future Work

This study investigated the reliability of a microcontroller-based dual-axis solar tracking system through a combined application of FMEA, FTA, and RBDs. The analysis demonstrated that environmental stressors—particularly light sensor degradation—represent the most significant source of vulnerability, leading to a sharp reliability decline of up to 15.02% under harsh outdoor conditions.

The originality of this work lies in its integration of probabilistic reliability modeling with experimental validation. The proposed mathematical framework, based on probabilistic occurrence modeling and energy production computations, enabled a rigorous quantification of fault impact and recovery strategies. Experimental trials confirmed the theoretical findings, showing that system malfunctions such as LDR failures can significantly reduce daily power generation, while the implementation of diagnostic and fault-tolerant mechanisms restores stable and efficient operation. More precisely, based on the analyzed data, the total energy production under normal operation reached a maximum of 963 Wh. In comparison, the most severe day recorded only 279 Wh, the moderately severe day reached 356 Wh, while the least severe day achieved up to 870 Wh. Thus, the most severe day registered losses of 71%, the moderately severe day showed losses of 63%, while the least severe day recorded a reduction of only 9.7%.